Yaskawa P1000 Product Flyer

P1000 Industrial Fan and Pump Drive

240V Class: ¾ to 175 HP

480V Class: 1 to 1000 HP

600V Class: 2 to 250 HP

The P1000 is the next generation in Industrial Fan and Pump control,

designed specifically for variable torque applications. Simple to use,

intuitive, and user friendly are key features in the P1000 design. The

P1000 supports a wide range of network and control options providing

for the most flexible and cost-effective solution.

Specifi cations

Overload Capacity

• 120% for 60 seconds

LCD Operator with Real Time Clock

5-line, 16-character alpha-numeric display with time and date stamping for

events, along with timer controls for starting, stopping, and speed changes

without the need for external controls.

Application Macros

Choose from pre-confi gured fan and pump setup macros to match the

application for quick and easy set up.

Selectable and Custom Engineering Units

Allows for easy confi guration of keypad display to match process and

feedback devices such as PSI, GPM, Feet.

Underload Detection

Monitors load and will shut system down in the event of a fan belt or

pump shaft breakdown.

Parameter Storage and Removable Terminal Board

Allows for easy replacement of control card without removing control

wires, and stores all drive settings without the need for a copy device.

PI Process Control

Maintains a set point for closed loop control of fans and pumps for

pressure, fl ow, or temperature regulation, and eliminates the need for a

closed loop output signal from a process controller. Independent PI to

control an external device in the system.

Power Quality

Built-in DC reactors (30 HP and larger) provide input harmonics benefi t,

and protection from input disturbances. Integrated 12 Pulse version (480V,

40 HP and larger) provides a cost-effective solution for low harmonics.

Dynamic Noise Control

Monitors the load at all times and reduces the output voltage

automatically, reducing motor audible noise.

Networking Options

Industrial Communication

• Modbus RTU (built-in)

• DeviceNet

• EtherNet/IP

• Modbus TCP/IP

• PROFIBUS-DP

• PROFINET

Note: All communication protocols are by option card mounted within drive.

Building Automation Networks (BAS)

• BACnet

• Lonworks

• Metasys (N2)

• Apogee (P1)

Output Frequency

• 0.01 to 400 Hz

Control Methods

• V/Hz Control

Enclosure Solutions

• Open Type / IP00

• NEMA Type 1 (kit required for some

models)

• Flange Type (front = Open/IP00,

back = NEMA Type 12)

Power Solutions

• Six Pulse (Standard)

240V: 3/4 to 175 HP

480V: 1 to 1000 HP

600V: 2 to 250 HP

• Twelve Pulse (Low Harmonic)

480V: 40 to 1000 HP

Ambient Operating Temperature

• -10°C to 40°C (14°F to 104°F)

Global Certifi cation

• UL, CSA, CE, RoHS, C-Tick

Standard I/O

• (8) multi-function digital inputs (24Vdc)

• (3) multi-function analog inputs

(0-10Vdc, 4-20 mA)

• (1) multi-function pulse input

• (1) fault relay output (form C)

• (1) multi-function relay (form C)

• (2) multi-function relay outputs (form A)

• (2) multi-function analog outputs

(0 +/- 10Vdc, 4-20 mA)

• Sensor feedback power supply

(+24Vdc @ 150 mA supply)

• 120V converter for 8 standard digital

inputs (option)

Yaskawa America, Inc.

Drives & Motion Division

| 1-800-YASKAWA (927-5292) • Local: 847-887-7000 | www.yaskawa.com

P1000 Industrial Fan and Pump Drive

240V Class: ¾ to 175 HP

480V Class: 1 to 1000 HP

600V Class: 2 to 250 HP

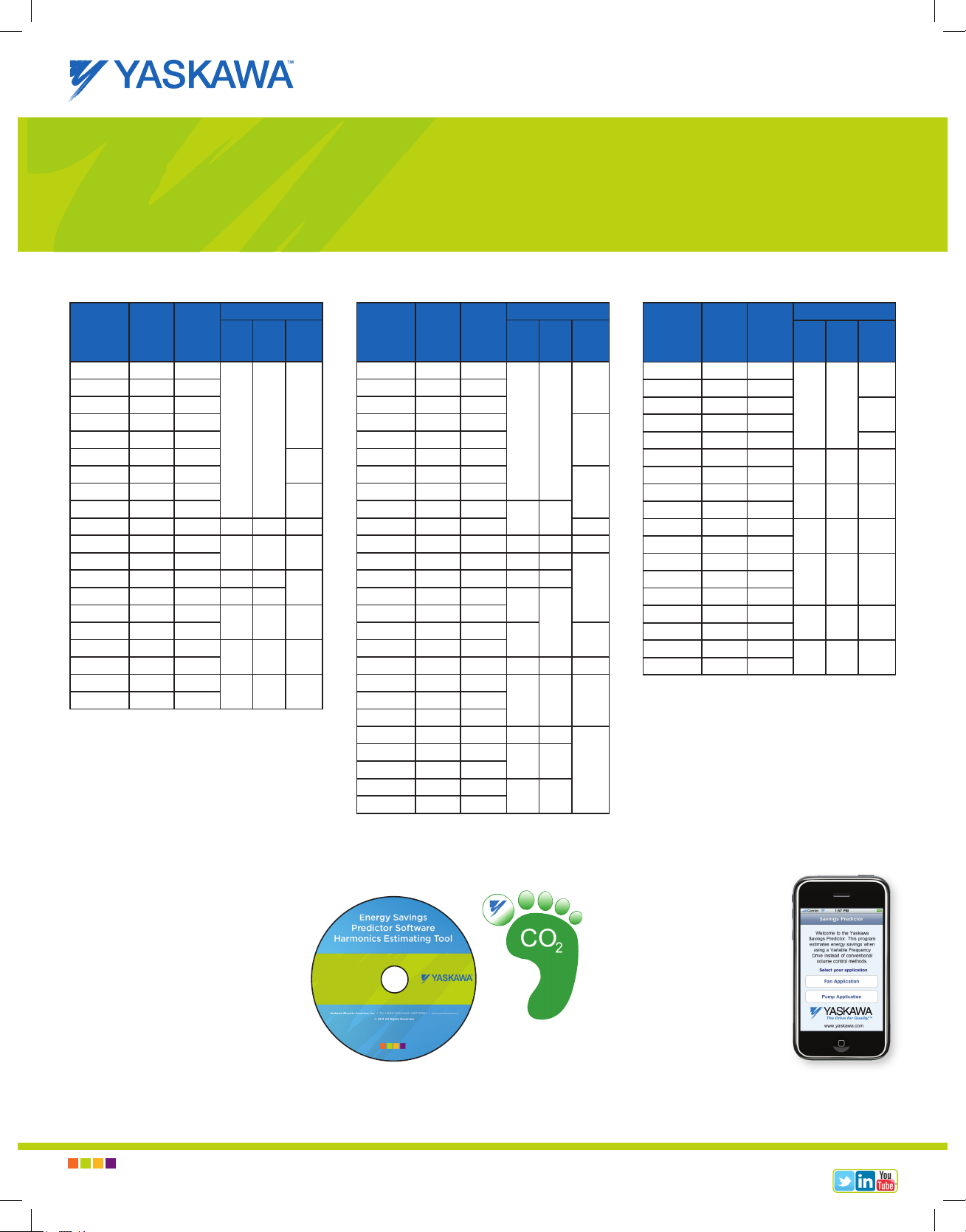

200-240V / 3-Phase

Model

Number

CIMR-PU

2A0004FAA 3.5 3/4

2A0006FAA 6.0 1

2A0008FAA 8.0 2

2A0010FAA 9.6 3

2A0012FAA 12.0 3

2A0018FAA 17.5 5

2A0021FAA 21.0 7.5

2A0030FAA 30.0 10

2A0040FAA 40.0 15

2A0056FAA 56.0 20 13.39 7.09 7.36

2A0069FAA 69.0 25

2A0081FAA 81.0 30

2A0110FAA 110 40 21.02 10.00

2A0138FAA 138 50 24.17 10.98

2A0169FAA 169 60

2A0211FAA 211 75

2A0250AAA 250 100

2A0312AAA 312 125

2A0360AAA 360 150

2A0415AAA 415 175

Rated

Output

Current

(Amps)

HP

Dimensions (in.)

H W D

11.81 5.51

15.75 8.66 7.76

28.74 12.95 11.14

27.76 17.72 12.99

31.50 19.69 13.78

5.79

6.46

6.57

10.16

380-480V / 3-Phase

Model

Number

CIMR-PU

4A0002FAA 2.1 1

4A0005FAA 5.4 3

4A0007FAA 6.9 4

4A0011FAA 11.1 7.5

4A0018FAA 17.5 10

4A0031FAA 31.0 20

4A0038FAA 38.0 25 7.36

4A0044FAA 44.0 30 15.75 8.66 7.76

4A0058FAA 58.0 40 18.31 10.00

4A0072FAA 72.0 50 20.28 10.98

4A0088FAA 88.0 60

4A0103FAA 103 75

4A0139FAA 139 100

4A0165FAA 165 125

4A0208AAA 208 150 27.76 17.95 12.99

4A0250AAA 250 200

4A0362AAA 362 300

4A0414AAA 414 350 37.40 19.69

4A0515AAA 515 400 - 450

4A0675AAA 675 500 - 550

4A0930AAA 930 600 - 800

4A1200AAA 1200 1000

Rated

Output

Current

(Amps)

HP

Dimensions (in.)

H W D

11.81 5.51

13.39 7.09

24.80

12.95

28.74 11.14

31.50 19.84 13.784A0296AAA 296 250

44.88 26.38

54.33 49.21

5.794A0004FAA 4.1 2

6.464A0009FAA 8.8 5

6.574A0023FAA 23.0 15

10.16

14.57

500-600V / 3-Phase

Model

Number

CIMR-PU

5A0003FAA 2.7 1 - 2

5A0004FAA 3.9 3

5A0006FAA 6.1 5

5A0009FAA 9.0 7.5

5A0011FAA 11.0 10 6.57

5A0017FAA 17.5 15

5A0022FAA 22.0 20

5A0027FAA 27.0 25

5A0032FAA 32.0 30

5A0041FAA 41.0 40

5A0052FAA 52.0 50

5A0062FAA 62.0 60

5A0099FAA 99.0 100

5A0125AAA 125 125

5A0144AAA 144 150

5A0192AAA 192 200

5A0242AAA 242 250

Rated

Output

Current

(Amps)

HP

Dimensions (in.)

H W D

11.81 5.51

13.39 7.09 7.36

15.75 8.66 7.76

20.28 10.98 10.16

28.74 12.95 11.145A0077FAA 77.0 75

37.8 17.95 12.99

45.98 19.84 13.78

5.79

6.46

FREE Estimating Tools via

www.yaskawa.com

• Energy Savings Predictor

• Harmonics Estimator

• Carbon Footprint Calculator

Yaskawa America, Inc. | 1-800-YASKAWA (927-5292) • Local: 847-887-7000 | www.yaskawa.com

Drives & Motion Division

iTunes App

Energy savings app

for the iPhone

and the iPod touch

is available at

iTunes.com –

search for Yaskawa.

Document Number: FL.P1000.01 • 05-01-2012 • © 2012

Loading...

Loading...