Page 1

Global Water

800-876-1172 • globalw.com

Global Water

Instrumentation, Inc.

151 Graham Road

P.O. Box 9010

College Station, TX 77842-9010

T: 800-876-1172

Int’l: (979) 690-5560, Fax: (979) 690-0440

E-mail : globalw@globalw.com

PC320 Process Controller

02-107

Publication Number 39370712

- 1 -

Page 2

Global Water

800-876-1172 • globalw.com

Congratulations on your purchase of the Global Water PC320 Process

Controller. This instrument has been quality tested and approved for

providing accurate and reliable measurements. We are confident that you

will find the monitor to be a valuable asset for your application. Should you

require assistance, our technical staff will be happy to help.

Table of Contents

I. PC320 Process Controller Description • • Page 3

II. PC320 Specifications • • • • 5

III. Display Modes • • • • • 6

IV. Switch Settings • • • • • 7

V. Sensor Input • • • • • 8

VI. 4-20mA Output • • • • • 8

VII. Relay Operation • • • • • 8

VIII. Power Saving Mode • • • • • 11

IX. Scientific Notation • • • • • 11

X. Programming Setup Parameters • • • 11

XI. Data Logger Option • • • • • 17

XII. Technical Support • • • • • 17

XIII. Appendix A: Terminal Strip Diagram • • • 19

* Copyright Global Water Instrumentatio n, Inc. 2012

- 2 -

Page 3

Global Water

800-876-1172 • globalw.com

I. PC320 Process Controller Description

The PC320 Process Controller is reliab le, accurate and suitable for measuring

any type of 2 and 3 wire sensors with 4-20 mA, 0-1 volt and 0-5 vo lt o ut put s.

The controller comes pre-programmed for use with 12 different common

sensor types and appropriate selectable engineering units. In addition, the

PC320 can be programmed by the user to monitor any type of custom sensor

in any user defi ne d u ni ts. Custom user defined engineering units are also

programmable for all standa rd sensor types. Both 2-poi nt and 3-point

calibration methods are supported and an additional 3

equation can be applied t o the sensor data to correct for non-linearities in

sensor output. The polynomial mode is useful for calculating other

parameters ba se d on a sensor reading such as calculating water flow rate

from water level.

The PC320 controller is enclosed in a NEMA 4 enclos ure and is easily

programmed and calibrated in the field using the water resistant 8 button

keypad and 2-line LCD display, by going through a series of simple menu

options.

The LCD display shows what type of sensor is being monit ored, the data

reading aver aged over a user programmable time period, and the engineering

units selected. The display also shows the current On or Off state for each of

the 4 relays. Two other display modes are available. One shows the

maximum and minimum se nsor readings since last rese t. Another m ode

displays the current sta te of any of the 4 relays in real time, the s ensor

reading tha t caused the last triggerin g event, and the On or Off time

remaining in the control cycle. The LCD display can be backlit for easy

viewing at all times and offers a power saving m ode for limiting curre nt

drain in battery powered applica ti ons.

Four relays are pr ovided for controlling external devices including samplers,

alarms, mixers, pumps, control valves, floodgates and telemetry systems.

Each relay is independe ntly program mable to trig ger on maximum and/or

minimum threshold le ve ls in one of five different control modes.

Relay opera tion is defined by setting upper and low e r sens or thr e sh old levels

and turning relays on when sensor readings exceed a normally defined range.

rd

order polynomial

- 3 -

Page 4

Global Water

800-876-1172 • globalw.com

Both normally open and normally closed relay contacts are provided. Relay

modes include a One Time tr igger that will engage a relay one time only for

a programmed on time period when a sensor reading falls outside of a

defined normal range. The Steady state mode will turn on a rela y as long as

the sensor readin g is ou t of the normal ran ge. The Cyclic mode will

continually turn a relay on and off for user definable on and off times while

the sensor readin g is outside of normal range. Additionally, High Control

and Low Control Modes are provided. These modes are used for maintaining

a sensor rea ding within a specific range; for example keeping the water level

in a tank between tw o predefined levels. A sixth mode allows a relay to be

deactivated regardles s of sett in g s. There are also programmable Delay

Times and Hysteresis. Setting a Delay Time will delay a relay from turning

on for that amount of tim e when a sensor reading falls outside of normal

range. This is used to limit the effect of rapidly changing sensor reading s

and keeping the relays from reacting q uickly to very small changes near a

threshold setting. The Hysteresis function allows the relay to r emain on until

the sensor readin g fa l ls int o the normal range again, plus a defined hy ste re si s

percentage . This also prevents the relays from overreacting to rapidly

changing events near a threshold level. A test mode is provided for manually

testing rela y operation.

A fully scala ble 4-20mA output i s available for recording sensor data

readings by devices like data loggers, PLC’s, telemetry systems and chart

recorders. There is a factory installed USB data logger option available that

can record these data readings to memory at regular intervals, as well as the

exact times of all changes in relay states and the current sensor reading at t hat

time. Contact a Sales or Technical Support representative for m ore

informatio n. To easily interpret this sensor and relay data, a free sof tw ar e

package is available. A separate manual titled “ FC220-PC320 Data Logger

Option” describes this i n more detail and is available for free download at

globalw.com/support.

- 4 -

Page 5

Global Water

800-876-1172 • globalw.com

II. PC320 Specifications:

Power Requirements: 12VDC or 18-24VDC Input, +/-10%

Supply Curr ent: 13mA + Sensor Current + B acklight + 4-2 0mA Output

150mA M aximum Total Cur rent

Backlight C urrent: 23mA when on

Internal Fuse: 315mA

Power Adap tor: 18VDC Universal Power Supply, 90-220VAC Input

AC Version only

Sensor Types/Units: Level (Feet, Inches, Meters, Centimeters, C ustom)

Temperature (ºF, ºC, Custom)

pH (ph, Custom)

Conducti vity (uS, mS, C ustom)

Dissolved Oxygen (%, mbar, ppm, mg/L, Custom)

ORP (mV, Custom)

Turbidity (NTU, Custom)

Wind Speed (MPH, KPH, Ft/Sec, M/Sec, Custom)

Wind Direction (º, Cus tom)

Humidity (%, Custom )

Solar Radiation (W/M², Custom)

Pressure ( mbar, hPa, inHg, PSI, Pa, Custom)

Custom (Custom)

Output Relays: 4 Independent S PDT Relays

Contact Rating: 8A @ 250VAC, 5A @ 30VDC Resistive

Level Sensor Input: 2-Wire or 3-wire, 4-20mA, 0-5VDC, 0-1VDC

Output: 4-20mA Scalable

Display/Keypad: 16 Character x 2 Line Backlit LCD, 8-Button Tactile Keypad

Sensor Resolution: 7 Digit Maximum, Auto-Floating point

Accuracy: Sensor Accuracy + 0.1% + 1 Digit

Dimensions: 7.1”W x 5.1”H x 1.4D (180mm x 130mm x 35mm)

Weight: 1 lb

- 5 -

Page 6

Global Water

800-876-1172 • globalw.com

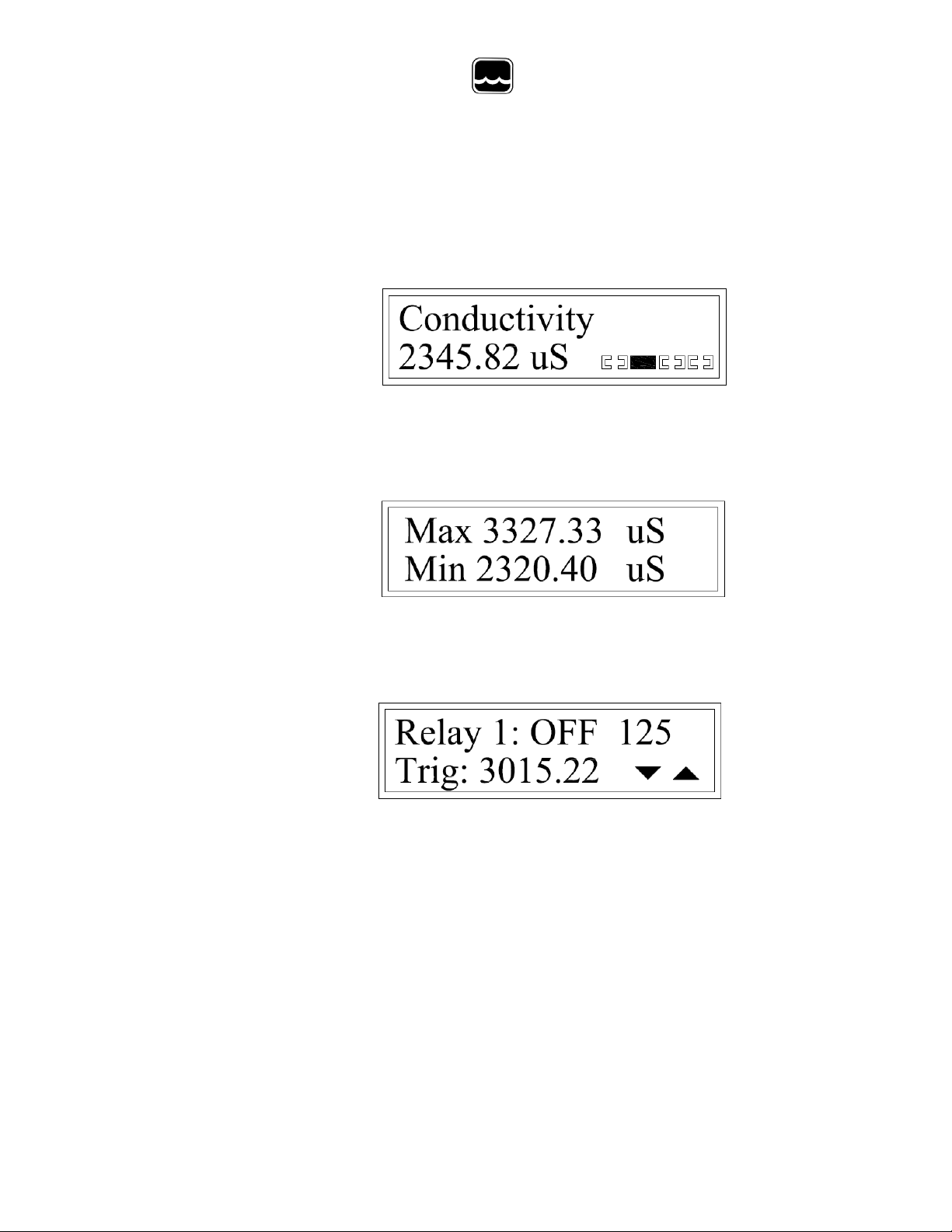

III. Display Modes

The PC320 has three display mode s, pressing the DISPLAY button on the fron t pane l

cycles through them: Sensor Reading > Max/Min > Relay Status > Sensor Reading ...

Sensor Reading

The top line shows the sensor type. The second line shows the current sensor reading

and units updated once eac h second. The brackets to the right of the sensor read ing

indicate the current on or off status of each of the 4 relays, relay 1 to the left and relay

4 to the right. When the brackets are fil led the relay is on. In the above example, relay

2 is on and the others are off.

Max/Min

This display mode shows t he minimum and maximum re adings since la st reset. To

reset the display, press SAVE for 2 sec onds. Pressing SAVE also turns off all 4 relays.

Once reset, the relays will not trigger again for 15 seconds.

Relay Status

This display mode shows t he current status for each of the relays. Use the UP and

DOWN arrow buttons to scroll through relays 1-4. The top line shows the relay

number, whether it is currently on or off, and how many seconds remain in the on or

off cycle, if applicable . Depending on the relay mode selected, the on and off times

may not apply and would not be displaye d. The bottom line shows if that relay has

been trigge red since last reset. If the relay has been triggered, the sensor reading at the

time of triggering is shown. If the relay has not been triggered, “None” will be

displayed. The relays are turned off and the status reset when the SAVE button is

pressed for 2 seconds. Once reset, the relays will not trigger for 15 seconds. In the

above example, relay 1 is currently off with 125 seconds remaining before it is turned

on again. The relay was last triggered by a sensor reading of 3015.22 uS.

- 6 -

Page 7

Global Water

800-876-1172 • globalw.com

IV. Switch Settings

Inside the PC320 is a bank of 8 swi tches which are used to select the sensor type and

power input. Select the switches as follows:

Select only one of SW1 and SW2, leave the other switch off

SW1: ON, Sensor power is 12 vol ts

SW2: ON, Sensor power is 18-24 volts depending on the voltage input to the

Note this feature is not available when running from a 12 volt battery

SW3: ON, Sensor power is continuous

SW3: OFF, S ensor power is switched on and off by the microprocess or in power

saving mode. If not using power saving mode, set SW3 to ON.

SW4: ON, Sensor type is 4-20mA

SW4: OFF, S ensor type is 0-5 VDC or 0-1 VDC

SW5: ON, Sensor type is 4-20mA or 0-5 VDC

SW5: OFF, S ensor type is 0-1 VDC

SW6: This switch is unused

Select only one of SW7 and SW8, leave the other switch off

SW7: ON, Power input to the PC320 is 18-24 VDC

SW8: ON, Power input to the PC320 is 12 VDC

- 7 -

Page 8

Global Water

800-876-1172 • globalw.com

V. Sensor Input

The PC320 accepts any analog sensor with a 4-20mA, 0-5VDC or 0-1VDC output.

Available power for the sensor depends on the power input to the PC320. When

powering the PC320 from 12 volts, the sensor pow er is also 12 volts. If you are

running from a power supply of 18-24 volts, the sensor power can be se lected from

either a regulat ed 12 vo lt s upply, or directly from the 18-24 volt input. The power can

also be conne cted continuously or it can be set to be tur ned on and off by the PC320

when using a powe r saving mode . In this mode the sensor is t urned on at user defined

intervals f or a programmable warm-up time, then turned off again to conserve powe r.

VI. 4-20mA Output

A 4-20mA output is prov ide d tha t is pro p ort i ona l to any defined sensor range. This

allows the data history to be re corded by an external data logger or PLC, or by the

internal da ta logger option, or both. The output is fully scalable and allows the user to

select the sensor ranges that are proportional to the 4mA and 20mA output currents.

VII. Relay Operation

Several settings independently control the operat ion of the 4 relays. These settings are

Upper Threshold, Lower Threshold, Hysteresis, Delay Time, Relay Mode, On Time

and Off Time. Not all of these settings m ay apply depending on which relay mode is

selected.

The Upper and Lower Threshold settings establish a normal band whic h the sensor

reading should remain in. If a sensor reading rises above the Upper Threshold, the

relay will trigger. Likewise; if the sensor reading f alls below the Lower Threshold, the

relay will a lso trigger. If either the U pper or Lower Thresholds are not needed, they

should be set to a value outside of the sensor output.

Example: A water level sensor has a range of zero to 15 feet and is install ed in a wat er

tank to control a pump. Relay 1 has an Upper Thre shold of 10 f eet and a Lower

Threshold of 5 feet. The relay may trigger (depending on mode) when the water leve l

rises above 10 feet or falls below 5 feet. I f it is desired for the relay to turn on only

when the level is above 10 fe et, but not below 5 feet; change the Low er Threshold t o a

value outside of the normal range of the sensor, li ke a negative number (-10 feet).

- 8 -

Page 9

Global Water

800-876-1172 • globalw.com

Since in norm al use the water level will never fall below zero, the Lowe r Threshold

will have no effec t an d not tr ig ger th e rel ay .

Hysteresis is a percentage change of the full span of the sensor required to turn a relay

off again once it has been triggered. This is used to keep the relays from turning on

and off too often whe n a se nsor reading is very near a t hreshold level. Note that the

percentage is of the span the sensor is ca librated for, not necessarily the full range of

the sensor. If there is a pH sensor capa ble of measuring from 0-14, but is calibrated at

a pH of 4 and 10, the span is considered 10-4 or 6 pH units. If the Hysteresis is set to

10%, that is equivalent to 10% of 6 or 0.6 pH units. The maximum hysteresis is 25%.

Example: A water level sensor monitors the level in a tank and the PC320 is

connected to a pump; which will pump water out of the tank. The Upper Threshold is

set to 10 feet and the Hyste resis is set to z ero. When the level rises a bove 10 feet, the

pump will turn on. When the level falls t o 9.999 feet, the pump will turn off. Thus;

the pump will turn on and off re peatedly trying to maintain the level at exactly 10 feet.

The level se nsor has a total calibrated span of 15 feet and 10% of that is 1.5 feet. If the

Hysteresis is set to 10%; the relay will trigger when the level rises to 10 feet, pumping

water from the tank. The pump will not t urn off again until the leve l falls to 10 feet

minus 10% or 8.5 feet. The level in the tank will be m aintained between 8.5 and 10

feet, saving the pump fr om turning on and off so often and wearing it out.

Example: A te mperature sensor has a span of -50ºC to +50ºC, or 100 degrees

centigrade. The controlle r is set to turn on a heater when the temperature falls below

25ºC (Lower Threshold). The Hysteresis is set to 5% or 5ºC (5% of 100º span). The

heater will turn on just below 25ºC but not turn off until the temperature rises to 25C +

5% or 30C. The normal tempera ture range in the tank will be 25ºC to 30ºC.

The Delay Time is the amount of time require d for a sensor reading to be above or

below a threshold level before a rel ay is turned on. This can be used to prevent a relay

from triggering when a sensor reading briefly falls outside of a nor mal range.

Maximum delay time is 99 seconds.

- 9 -

Page 10

Global Water

800-876-1172 • globalw.com

Relay Modes:

Off: In Off mode, relays will not turn on regardless of settings

One Time: In One Time mode, a relay will turn on one time only when a sensor

reading is a bove or below a threshold level. The relay will turn on for the programmed

On Time, then turn off regardless of sensor reading. If during the On Time the sensor

reading returns to a normal range, the relay will turn off even if the On Time has not

elapsed. Once the On Time has elapsed, t he relay will remain off un til the sensor

reading returns to a normal level (between thresholds), and then crosses past a

threshold level again. The Off Time does not apply in this mode an d has no effect on

relay opera tion, the Delay Time and Hysteresis set tings do apply.

Steady: In Steady (Steady State) mode the relay will turn on when a sensor reading is

outside of the normal range, and stay on. The relay will remain on as long until the

sensor reading is outside of the th re sh ol d poi nts. The Delay Time and Hysteresis

settings are used in this mode. Programmed ON and Off times do not apply.

Cyclic: In cyclic mode the relay will trigger when a sensor reading falls outside of the

threshold settings. The relay will tur n on for the On Time, then off for the Off Time.

The cycle of on and off wil l continue until the sensor reading falls w ithin a normal

range again. The De lay Time and Hysteresis set ting apply in this mode.

High Control: In High Control mode, the relay will turn on when the sensor reading

rises above the Upper Threshold. The relay will remain on until the sensor reading

falls below the Lower Threshold. This mode could be used to turn on a pump when a

water level rises above 10 feet and continue to pum p until the level falls below 5 feet.

Delay Time does apply. On Time, Off Time and Hysteresis do not apply and have no

effect on relay operation.

Low Control: This mode is the opposite of High Control mode. The relay will turn

on when a sensor reading falls below the Lower Threshold and remain on until the

sensor reading rises abo ve the Upper Threshold. This might be used to pump water

into a tank when the level falls below 5 feet and continue t o pump until the level rise s

above 10 feet. Delay Time does apply. On Time, Off Time and Hysteresis do not

apply and have no effect on relay operation.

- 10 -

Page 11

Global Water

800-876-1172 • globalw.com

VIII. Power Saving Mode

A power saving mode is provided that allows the operating current to be reduce d in

remote monitoring applications. One w ay this is acc omplished is to turn off the L CD

display backlight, this saves about 20mA of current. Three modes allow the user to

turn the backli ght on a ll the time, off all the time, or turn it on for one minute only. In

this last mode, the backl ight will come on for one minute when any of the buttons on

the keypad are pressed, then turn off again after one minute of in ac tiv ity . The sensor

can also be t urned on and off periodically to reduce power consumption. The user can

program a sample rate of 0-60 minutes, an d can set the sensor warm-up time of 0-60

seconds. Example: The sample rate is 3 0 minutes and the warm-up time is 3 seconds.

The sensor will be turned on for 3 secon ds every 30 m inutes then shut off again.

During the time the sensor is off the LCD display and 4-20mA output will indicate the

last sensor reading. The relays will continue to oper ate, based on that last reading.

After 30 m inutes more, a new reading will be taken and the display and 4-20mA

output updated again. Note that usin g the 4-20mA output will incr ease the current

draw by an am ount e qu al to the out p ut cur r en t. It is also possible to fail to react to

rapidly changing events.

IX. Scientific Notation

Scientific no tat i on is used in the PC320 for enterin g parameters for the Polynomial

mode and is generally used for di splaying very large or very small numbers. It

represents a number as being multiplied by 10 raised to a power, such as 5.67*10^2

being equal to 567 since 10^2 equals 100 (10^2 = 10²). The n otation E2 is a lso

equivalent to “shift the decimal point to the right two times”. This makes the di splay

of large and small num bers easi er to rea d; 5.6 7E 3 is 5.6 7 th ousand or 5670, 5.67E6 is

5.67 million, etc. In the s ame way, small numbers less that one can be shown as 10

raised to a negative power, or “shift the decimal point that m any times to the left”;

such as 5.67E-3 = 0.00567 or 5.67 thousandths, 5.67E-6 = .00000567 or 5.67

millionths.

X. Programming Setup Parameters

Press the MENU button for 2 seconds to enter the setup menu. Pressing the MENU

button again cycles through the differ ent setup options. Pressi ng the BACK button

moves backw ard to the previous display. Pressing the DISPLAY button from any

menu exits se tu p and r et urn s to t he normal display mode. Press the RIGHT arrow

- 11 -

Page 12

Global Water

800-876-1172 • globalw.com

button to enter any of the setup sub-menus. These sub-menus are Set Sensor Type,

Calibrate Sensor, Polynomial Mode, 4-20mA Output Calibration, Decimal Places,

Averaging Time, Power Saving, Relay Settings, and Relay Test Mode. Note that while

in the setup menus, all normal operations will stop. After one minut e of in act i vit y,

the PC320 will automat ically return t o the main disp lay and operat ion mode.

Set Sensor Type:

Press the RIGHT arrow button to enter this or any other su b-menu. To change the

sensor type, use the UP and DOWN arrow buttons to scr oll through the different preprogrammed sensor types, or to select the “Custom” sensor option. Select the sen sor

type and press SAVE. Pre ss MENU to m ove forward to the units menu. Each sensor

type has pre-defined engineering units to c hoose from, a s well as a “Custom” setting

that allows the units to be set to any 4 character symbol. Select the desired units and

press SAVE. For the case of custom sensor or custom units, press the LEFT and

RIGHT arrows to select a character to change, then use the UP and DOWN arrow

buttons to scro ll thr oug h up per an d lowe r ca se let te r s, numbers, and a list of spec ia l

characters. When all characters in the custom senso r name or units menus have be en

changed, pre ss SAV E to stor e them to memory. A list of standard sensors and units is

shown in the Specifications Section of this manual. Custom Sensor names are limited

to 16 characters an d Cus t om Units are limited to 4.

Calibrate Sensor:

To change or check the sensor calibra tion press the RIGHT arrow button. To skip the

calibration option press the MENU ke y to move to the next programming option.

- 12 -

Page 13

Global Water

800-876-1172 • globalw.com

First select whether the sensor will be calibrated using a 2 or 3 po int method.

Generally ; sensors are calibrated at 2 points as close to the ends of the sensor’s

measurement range as possible. For example: A 15 foot water level sensor wou ld be

calibrated us in g a 2-point method and be set at zero feet and as close to 15 fee t as

practically possible. However; a pH sensor with a range of 0-14 m ay be typically

calibrated at a pH of 4 and 10 due to the hazards of using very strong acids and bases.

Calibrating a sensor at points other than the full range of the sensor wi ll no t st op the

PC320 from measuring the full sensor range, but may slightly decrease the overall

accuracy . A ph sensor migh t also be calib rated using a 3-point method at pH values of

4, 7 and 10. U sing a 3-point calibration will increase the accuracy of sensors that have

small amounts of nonlinea rity.

After selecting the number of calibration points, press SAVE and MENU. Using the

arrow buttons, set the High Value to the upper calibration point, first setting the +/sign, then separately each digit. If you are calibrating a 15 foot water level sensor but

only have an 8.5 foot column of water, set the High Value to +8.500 00. If you are

using a pH 10 buffer solut ion to calibrate a 0-14 pH sensor, set it to +10.0000. Use the

UP and Down b uttons to cha nge the sign t o + or -. Use LEFT and RIGHT to select

each digit, then UP and Down to change it in the range of 0-9 or decimal point. Press

SAVE when d one and then MENU to move forward. Next place the sensor in a

condition that corresponds to the Hi gh Value previously set, or use a loop or process

calibrator. Press SAVE to store the High Raw data number, then MENU. For 3-point

calibration, the next menu will allow you to set the middle calibr ation point; then the

Low point. A 2-point calibration will skip the middle point and jump to the L ow point.

Set each of these Middle and Low calibration points in the same wa y as the High.

Polynomial Mode:

The calibration process previously discussed can be further modified. This is best

described w ith an example that will use a water level sensor and from this level da ta,

calculate the water flow rate in a flume.

Calibrate a w ater level sensor as previously described. When selecting the sensor type,

you can use the Custom Se nsor and Units selection; the sensor name and units

displayed don’t actually have anything to do with calculations, they are just used as

- 13 -

Page 14

Global Water

800-876-1172 • globalw.com

identifier s for the user on the LCD displa y. Calibrate the sensor nor mally. You can

set the sensor ty pe to Water Flow and the units to CFS (Cubic Feet per Second) .

A flume or w eir equation u sually has the form of Q = A * B ^ C; where Q is flow in

CFS, A is a multiplier, B is water level in feet and C is an exponent applied to B.

However; in many cases a 3

rd

order polynomial can give a close appr oximation of

flow. Example: The flow equation for a 3” Parshall Flume is:

Water Flow (C FS) = 0.994 * [(Water Level in Feet) ^ 1.55]

rd

A 3

order polynomial can approximate this with:

CFS = -1.499E-2 + [3.746E-1 * Level] + [7.164E-1 * Level^ 2] – [8.771E-2 * Level^3]

The accuracy of the equation will vary depending o n the application but the

polynomial function can usually calculate non-linear par ameters accurately and can

correct for some sensor non-linearities. This mode will only calculate positive

numbers from positive data, any negat ive results or data will be c onsidered zero.

Press the RIG HT Arrow, the n use UP or DOWN to select the polynomial mode to On,

press SAVE. Press MENU and program the numbers for each coefficient A - D.

Unused para meters should be set to zero.

4-20mA Output Calibration:

To scale and calibrate the 4-20mA output press the RIGHT arrow key. The 4mA Set

Point defines the sensor reading that results in an output current of 4mA . Use the

arrow buttons to change the sign to + or - a nd set the value, then press SAVE. The

20mA Set Point is th e sensor value that results in a 20m A output current. As before,

use the arrows to change the 20mA Set Point. Press SAV E to store this setting. Any

sensor reading between these two points will be scaled to the corresponding output

current. The next three menus are set at the factory and should no t normally need to be

changed. The 4mA Output Cal menu allows the 4-20mA output to be set to exactly

4.000mA, or very close. Connect a DC curr ent meter between the 4-20mA output and

ground. Use the UP and DOWN arrows to raise and lower the raw data number (and

output current) until t he current meter reads as close to 4.000mA as possible. Press

- 14 -

Page 15

Global Water

800-876-1172 • globalw.com

SAVE and MENU. A sensor does not ne ed to be connected during this process. The

20mA Output C al menu sets the 20mA output in the same way. Use UP and DOWN

to adjust the output until the current meter reads e xactly 20.000mA. The Calibrate

Logger me nu is used to recalibrate the PC320 data logger option only and will be

discussed in the section titled Data Logger Option and in the Data Logger Option

software manual.

Decimal Places:

Use this menu option to set the maximum number of dec imal places for the sensor

readings in the display. Press RIGHT arrow to select, then UP and DOWN to change

the display resolution, Then SAVE to store. If the disp lay overflow s, the decimal point

will automatically be shifted to the right to provide the most accurate data. The

maximum number of decimal pla ces is 5.

Averaging T ime:

The PC320 Process Controller can average the sensor reading over a programm able

period of time. A one second time setting defeats the averaging f eature, since the

display is normally updated every second anyway . Press the RIGHT arrow button to

change the setting. use the UP and DOWN arrows to set the averaging time and then

press SAVE. The maximum averaging time is 30 seconds.

Power Saving Mode:

The power sa ving mode allows the average power consumption to be reduced by

controllin g the time the s ensor and LCD backlight are turned on. To set the power

saving parameters, press the RIGHT arrow button. The LCD Backlight has 3 setti ngs,

ON turns the backlight on all the time, OFF forces the backlight to be off, and 1

Minute mode will turn the backlight on when any button on the keypad is pressed, then

it will turn off again a fte r one m inute of ina c tiv ity . Use the UP and DO WN arrows

and SAVE to change and save the se ttin g. The Sample Rate is the interval between

sensor readings (and how often the dis pl ay and 4-20mA output will be updated). Use

LEFT and RIG HT to select a digit and use UP and DOWN to scroll through 0-9, press

- 15 -

Page 16

Global Water

800-876-1172 • globalw.com

SAVE to store the setting. The Sensor Warmup time is how long the sensor will be

powered on befor e a rea din g is tak en, consult the sensor manual. Set this parameter in

the same manner as the sample rate. In this example the backlight is in 1 minute mode .

The sensor will be turned on for 3 seconds every 60 minutes. The display and 4-20mA

output will remain on but will continue to indicate the flow that corr e spo n ds to the last

sensor measurement. Dur ing the tim e the sensor is off , the display will show the la st

reading and the relays will continue to operate bas ed that.

Relay Settings:

To change Relay Settings, press the RIGHT arrow button. F or m ore information on

relay modes please consult the secti on of this manu al titled Relay Operation.

Each relay is independe nt of the others and can be programmed separately. Use the

UP and DOW N arrows to select which relay is to be changed, press MENU to move to

the next sub-me nu.

Each relay must have upper and lower threshold defined. Depending on the relay

mode, the relays will trigger when the sensor reading rises above the upper threshold

or below the lower threshold. If only one threshold is needed, set the other thres hold

outside of any normal sensor reading. B y default the se settings are stored as +/9000000 so fa lse triggering should be pr evented.

Once a relay number is selected, press Menu. Use the arrow buttons to se t the +/- sign,

each digit, and decimal poin t for each threshold number . Press SAVE. Do this for

both the uppe r and lower thresholds as needed. The next menu defines a hysteresi s

percentage. Use the arrow buttons to set hysteresis and SAVE, then press MENU. Set

a delay time as needed and SAVE. The last two sections set the On an d Off times for

the relays. Use the arrows and SAVE to change these. Note that not all of these

settings make any changes to relay operation, what effect they have depend s on the

relay mode selected for e ach relay and the sensor reading.

- 16 -

Page 17

Global Water

800-876-1172 • globalw.com

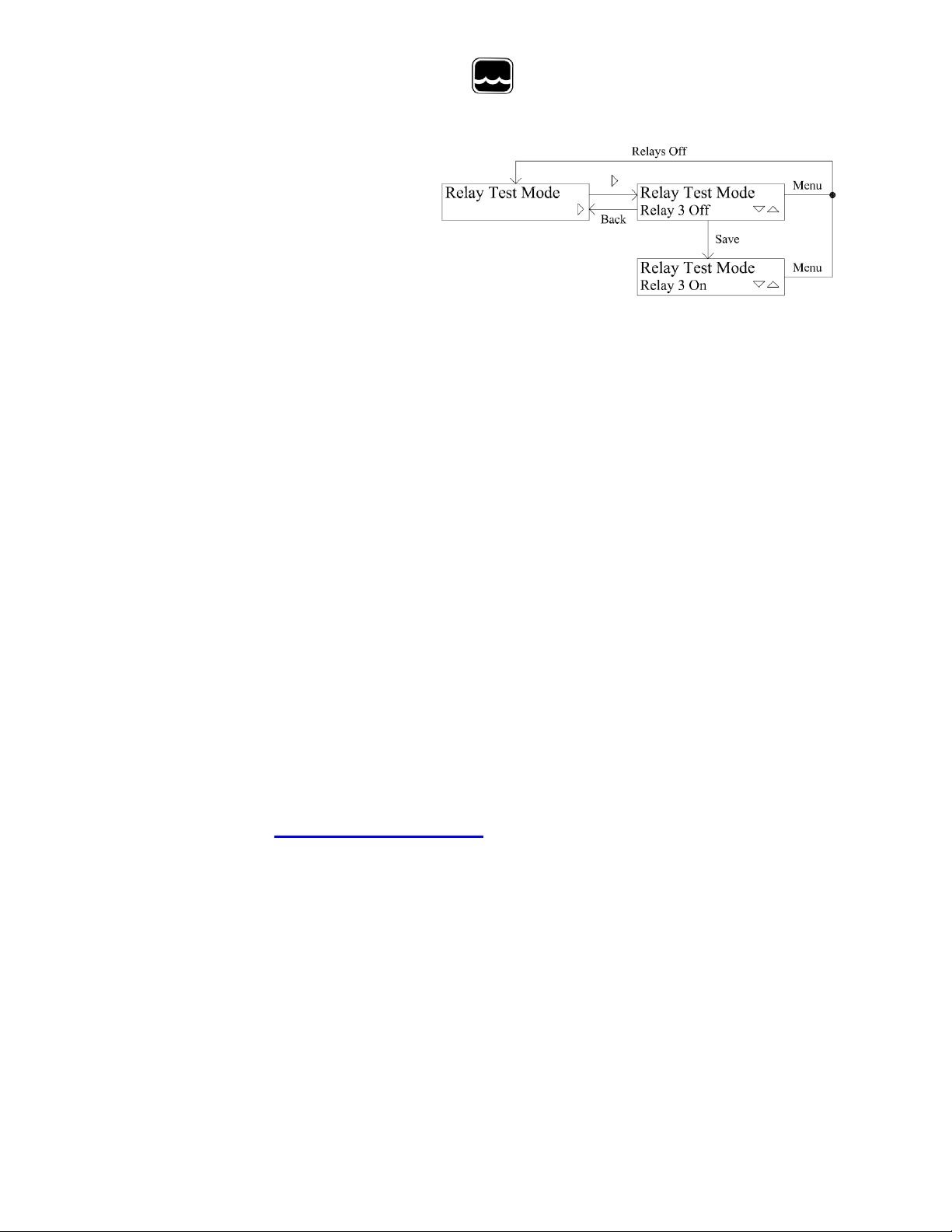

Relay Test M ode:

To manually test relay ope ration, press the RIGHT arrow.

Use UP and DOWN to select t he relay number to test.

When a relay is selected, press SAVE t o toggle the re lay between On and Off. Press

Display or Ba ck to exit test mode, the relays will tur n off upon exit.

XI. Data Logger Option

A factory option for the PC320 is an intern al data logger which records a historical

record of wa ter flow, and r ecords the exact time of each relay pulse. C ha nne l o ne of

the data logger records f low and channel two records relay events. A special sof tware

package allows the programming of the logger and the download of recorded flow and

relay data. This softwar e differs from other Global Water data logger software in the

way it proce sses the relay data. Softwar e such as Global Logger II will work with the

PC320 data logger option but som e relay information will no t be seen. The da ta lo gge r

is factory calibrated a nd should not need to be recalibrated again. Should you need to

recalibrate the logger, consult the Data Logger Option manual.

XII. Technical Support

a. Call Global Water for tec h support: 800-876-1172 or 979-690-5560

(many problems can be solved over the phone). Fax: 979-690-0440 or Email:

When calling for tech support, please have the following information

ready;

globalw@globalw.com.

1. Model #.

2. Unit serial number.

3. P.O.# the equipment w as pur c ha sed o n.

4. Our sales numbe r or the invoice number.

5. Repair instructions and/or specific probl ems relating to the

product.

- 17 -

Page 18

b. In the event that the equipm ent needs to be returned to the f actory for any

Warranty

a. Global Water Instrumentation, Inc. warrants that its products a re free

b. The warranty begins on the date of your invoice.

Global Water

800-876-1172 • globalw.com

Be prepared to describe the problem you are experiencing including

specific deta ils of the appl ica ti on, ins tal la ti on, an d any a dditional

pertinent inf ormation.

reason, ple ase call to ob tain an RMA# (Return Material Authori zation).

Do not return items without an RMA# displayed on the outside of the

package.

Clean and decontaminate the PC320 if necessary.

Include a written statement describing the problems.

Send the package with shipping prepaid to our factory address. Insur e

your shipment, Global Water’s warranty does not cover damage incurred

during transi t.

from defects in material and workmanship under nor mal use and

service for a period of one year from date of shipm ent from factory.

Global Water’ s ob lig ati o ns under this warranty are limited to, at

Global Water ’s option: (I) replacing or (II) repairing; any products

determined to be defective. In no case shall Global Water’s liab ility

exceed the prod uc ts or igi na l pur c has e pr ice . This warra nty does not

apply to any equipment that has been repa i re d or alte re d, exce pt by

Global Water Instrumentation, Inc., or which has been subject to

misuse, negligence or a ccident. It is e xpressly agreed that this

warranty will be in lieu of a ll warranties of fitness and in lieu of the

warranty of merchantability.

- 18 -

Page 19

Global Water

800-876-1172 • globalw.com

XIII. Appendix A: Terminal Strip Diagram

POWER IN:

V+ 12VDC or 18-24VDC Input

V+ 12VDC or 18-24VDC Input

12VDC Input: SW7 OFF, SW8 ON

18-24VDC Input: SW7 ON, SW8 OFF

GND Power Supply and System Ground

GND Power Supply and System Ground

SENSOR IN:

V+ Sensor Power

12VDC Sensor Power: SW1 ON, SW2 OFF

18-24VDC Sensor Power: SW1 OFF, SW2 ON

(18VDC Power Input Only)

IN Sensor Input

Sensor Power Cont inuous: SW3 ON

Sensor Power Switched: SW3 OFF (Power Saving Mode)

4-20mA Sensors: SW4 ON, SW5 ON

0-5VDC Sensors: SW4 OFF, SW5 ON

0-1VDC Sensors: SW4 OFF, SW5 OFF

4-20mA:

OUT 4-20mA Output

GND Power Supply and System Ground, 4-20mA return Path

RELAY 1-4:

- 19 -

Loading...

Loading...