Global Water Instrumentation

1

SIT65 Users Manual

Internet Accessible Satellite Telemetry Solutions

Global Water

International : (979) 690-5560, Fax : (979) 690-0440

Publication Number 39200712

01-850

Instrumentation, Inc.

151 Graham Road

P.O. Box 9010

College Station, TX 77842-9010

Telephone : 800-876-1172

e-mail : globalw@globalw.com

Global Water Instrumentation

2

Introduction ...................................................................... 3

Controller Layout ............................................................. 4

Analog Inputs .................................................................... 5

Digital Inputs .................................................................... 6

Digital Control Outputs ................................................... 7

Time Stamps and Latency Time ...................................... 8

Real-Time Time Stamp .................................................... 9

Power Consumption ......................................................... 9

Battery Voltage Monitor ................................................ 10

Solar Power Systems ...................................................... 10

Station ID and Sensor Offsets ........................................ 12

Sensor Data Format ........................................................ 13

Calibration Numbers ...................................................... 13

Alarms ............................................................................. 14

Installation ...................................................................... 14

Troubleshooting .............................................................. 16

Technical Support: ......................................................... 18

Appendix A: Spec i f ications ........................................... 19

Appendix B: Adder and Multiplier Numbers ............. 20

Global Water Instrumentation

3

Introduction

Thank you for the purchase of a Global Water SIT65 Satellite Telemetry Station.

This instrument has been quality test ed to provide you with accurate and reliable

operation for your remote monitoring needs. We are confident that you will find this

product to be a valuable asset to your applications . Should you require any

assistance, our technical staff will be happy to help.

The SIT65 Field Station is a cost effect iv e and complet ely self-contained system for

relaying analog and digital sensor data from the most remote locations around the

world to any computer connected to the internet. Up to 8 analog inputs are available

in a number of configurations and up to 5 digital I/O channels that can be

programmed as input counters, s tatus inputs or control outputs. A separate battery

voltage monitor is provided which can be very us eful when monitoring system

performance, especially when using solar power. A VHF radio modem and antenna

is included for accessing the satellit e network and two different databases are

provided for viewing your data. No complicated setup or antenna alignment is

required, just an unobstructed view of the sky.

The satellite network that the SIT65 communicates with is owned and operated by

Orbcomm. With over 30 low-earth orbiting satellites, they provide a constantly

rotating and complete coverage of the entire Earth. Ground stations spaced all

around the world receive the data f r om t hese satellites and relay it via the internet to

each of two separate databases. These databases hav e different appearances and

features so accounts are provided to our c us tomers for both. They are also located

in separate geographical locations and have different IP addresses; which provides a

higher level of redundant internet ac c es s and data storage.

The system is programmed at the factory to transmit at regular intervals from every

few minutes to several hours apart dependin g on the application. The controller is

also able to send additional alarm transm is s ions w hen any of the digital inputs

change state. The databases allow the set ting of threshold levels that will provide

email and text message notificat ion w hen these thresholds are exceeded. Alarms

levels can be set for any of the analog or digital sens or s .

The Orbcomm network charges fees based on the amount of data transmitted.

There are many input channel options availab le and when combined with different

transmission intervals, alarm trans missions and control commands; a wide range of

data charges can occur. There is always a balance bet ween the number of sensor

channels enabled, the transmission int er v al, and the subscription fees. These fees

Global Water Instrumentation

4

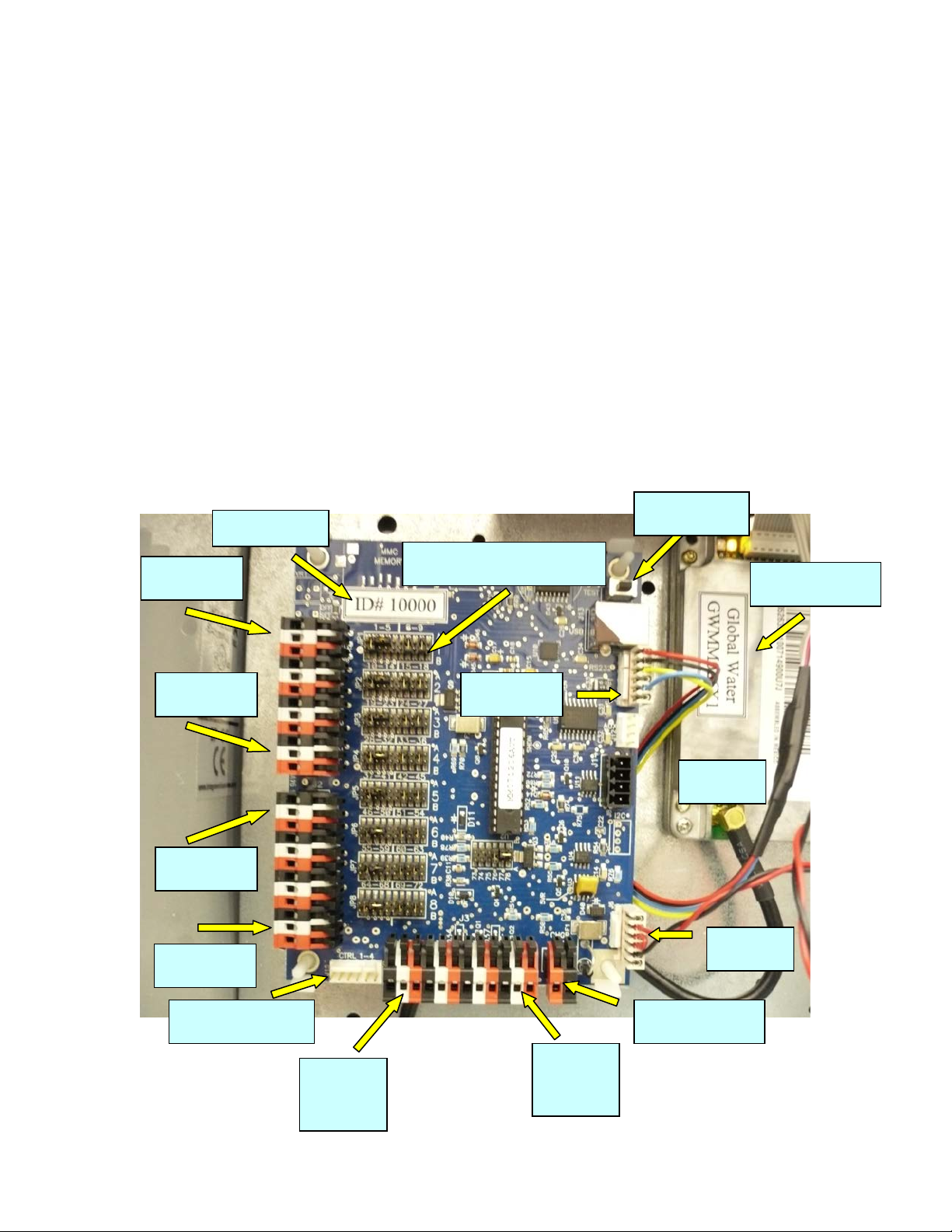

Analog 1

Analog 4

Analog 5

Data Port

Antenna

Configuration Jumpers

Analog 8

Battery

Control Outputs

Charger Input

Digital

1

Digital

4

Station ID#

Radio Name

Test Button

are rarely more than the cost of recovering dat a from even slightly remote locations,

but they should be considered. For mor e infor m ation on applications and

subscription fees, please consult Global Wat er .

Each station is identified by a unique Radio Na m e and S tation ID# which are used by

the satellites for communicating with t he field station. These numbers can be found

on the documentation provided with the sy s tem, or on labels placed on the radio

modem and controller board. Have these num bers available when contacting Global

Water for technical support.

The SIT65 hardware is provided in a NEMA 4 rated hinged and lockable instrument

enclosure with a microprocessor based c ontroller, radio modem, 5Ahr battery,

antenna with 16 feet of cable, and mounting ha r dw ar e.

Controller Layout

Input

Input

Global Water Instrumentation

5

Analog Inputs

There are provisions for up to 8 analog inputs . The number of enabled inputs is

factory programmable but the inputs can be configured by the user as 0-20mA, 01mA, 0-500uA, 0-5VDC or 0-10VDC. To conserve power, the sens or s connect ed to

these inputs are usually switched on only when r eadings ar e being taken, the sensor

warm-up time. This warm-up time is a factory programmed setting but the voltage

powering the sensors during this time is user configurable for 5V, 12V or 18V

switched; or 12 volts continuous. The sens or warm-up time setting applies to all

analog channels. Setting the configuration jumpers for 12 volt continuous operation

defeats the sensor power switch and warm-up time and pow er s the sensor

connected to that analog channel at 12 volt s all the time.

The quick-connect input connectors ar e c olor c oded for eas y wiring. The ground

terminals are black, sensor power is red, and t he sensor input is white. Insert the

wire into the connector and push the locking lev er down. To release the wire, lift the

lever up until it locks it place.

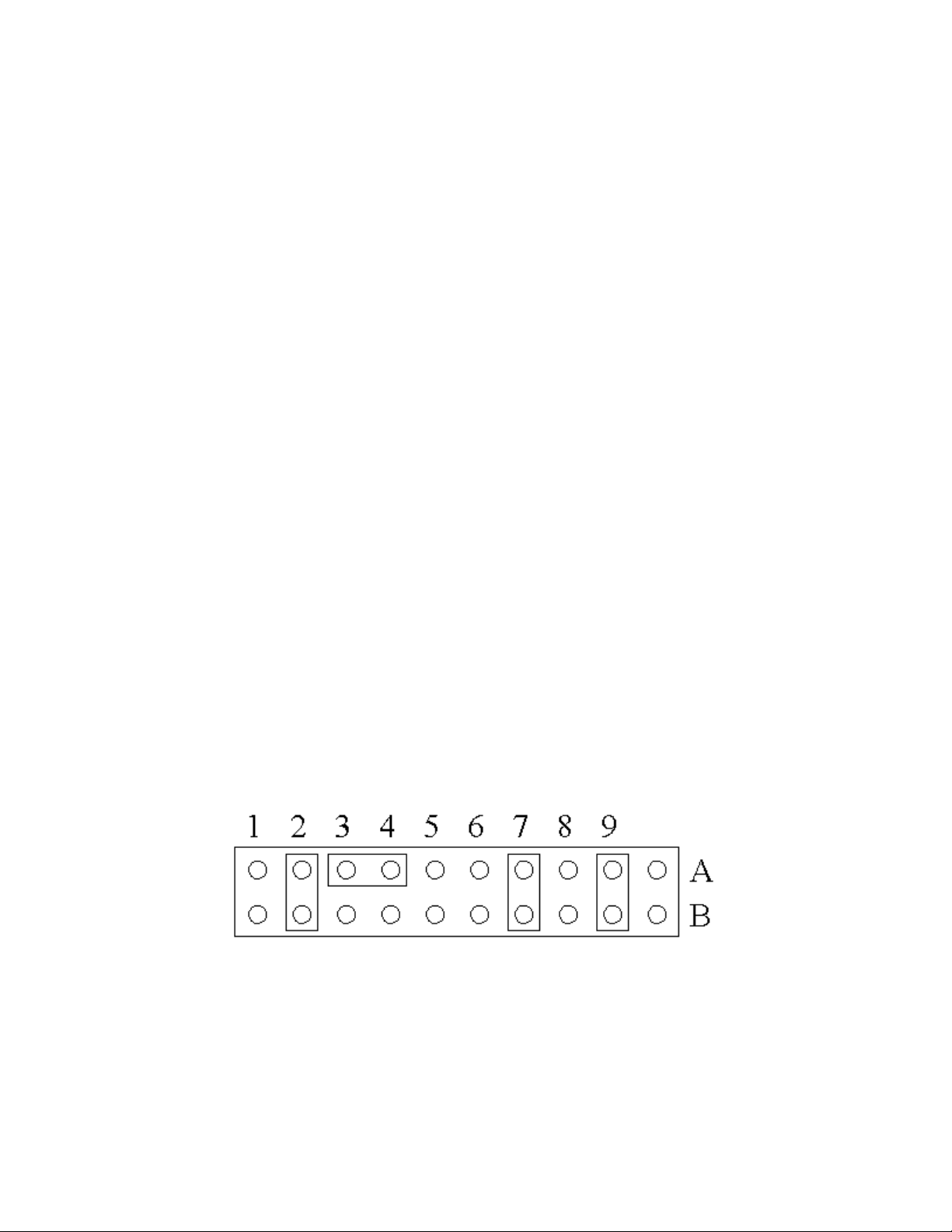

Each channel can be configured separately usin g jumpers on the controller board.

Two jumpers are used for the input type and t wo are used to select the sensor

voltage. The jumper settings are the s am e for each channel. The diagram below

illustrates a 0-20mA (4-20mA) input with 12V DC swit c hed s ens or power. Disconnect

the battery when connecting sensors or c hanging the jumper settings.

Global Water Instrumentation

6

The jumper settings for the analog input configurations are as follows:

Input Type Jumper 1 Jumper 2

0-20mA 2a-2b 3a-4a

0-1mA 1a-2a 3a-3b

0-500uA 1a-2a 4a-4b

0-10VDC 1a-2a 4b-5b

0-5VDC 1a-2a 3a-4a

Sensor Power Jumper 3 Jumper 4

18V Switched 7a-8a 9a-9b

12V Switched 7a-7b 9a-9b

5V Switched 6a-7a 9a-9b

12V Continuous 7a-8a 8b-9b

Digital Inputs

Up to 3 digital inputs are available that can be c onfigured in any combination of

accumulators (rain gauges, flow sens or s ) or status inputs (doors swit ches, power

failure). These inputs can also be program m ed to initiate a transmission on any

change of state (event), a door opening or a pum p turning on for example. All input

configurations are factory programmable only.

The quick-connect input connectors ar e c olor c oded for eas y wir ing. Black terminals

are connected to ground, red terminals ar e c onnected to 12VDC continuously, and

the digital inputs are colored white. I ns er t t he wire int o the connector and push the

locking lever down. To release the wire, lift the lever up until it locks it place.

The digital inputs have 20Kohm pull-up resist or s to the +5volt internal power supply

of the circuit board. This input is intended t o be s witched to ground only, either by a

switch contact closure or by a switching transistor. Driving these inputs with a

positive voltage other than 5volts c an r es ult in excess current drain and improper

circuit operation.

Global Water Instrumentation

7

Digital Control Outputs

There are up to two control outputs available that can be used to remotely control

pumps, valves, lights, etc. These are open-c ollec tor outputs that source current to

ground with a maximum of 100mA per channel. Driving lar ger loads r equires a relay

or some other type of switching device. T he output s ar e pr otected from driving

inductive loads. Enabling the use of these output channels is a factory

programmable option only.

Access to the control outputs is through a 6-pin polarized connector on the controller

board. If the system is ordered with any control out puts enabled, a matching

connector is provided. This connector has three wires, red is connected to the

12VDC power supply continuously, purple is t he output for channel one and white is

the output for channel two. If any high curr ent 12 volt power supply connections are

required, they should be tied directly to the battery terminals or some other low

impedance power or ground source. High s witching currents should not be sent

through the controller board.

The control outputs can be turned on and off v ia comm ands s ent through one of the

databases and the current status of the outputs is shown in all transmitted data.

The radio modem must be turned on to receive the control c om m ands from the

satellite. In cases of low battery v oltage, the radio may be shut off by the power

management system to conserve power and will not receive any transmissions.

More about the power consumption is discuss ed in another section of this manual.

In solar powered systems, care must be taken to ensur e that the system will have

sufficient power at the time access to control outputs is needed. With AC powered

systems, power failure must also be considered, although the battery may provide

backup power for several hours or more depending on configuration.

There is a variable time delay between the contr ol c ommand being sent and the time

that action is taken; this is called t he latency time. Global Water has no over latency

time, the operation of the Orbcomm sat ellite network or any of the servers involved in

relaying data to or from our database. While the transmission of sensor data and

commands is reliable, it’s possible t hat gaps in transmissions could occur and cause

commands to be delayed or missed entirely. It is strongly recommended that th e

control outputs not be used in cases where life or property could be

threatened by the failure of the outputs to operate. Global Water is not

responsible for damage caused by failur es when us ing this feature.

Global Water Instrumentation

8

Time Stamps and Latency Time

Latency time is the total time between t he SIT65 transmitting data and the data

appearing on the hosting web site. The data is held in the radio module until one of

the satellites is within range, and then sent . The information is further held at the

satellite until its data buffers ar e full before relaying it to one of several ground

stations where it is transferred to the Internet. These two factors contribute m os t of

the latency time but additional time delays c an be added by the transfer of data

through servers. This latency time also applies to contr ol and interrogation

commands being sent to the SIT65. Total delay t ime is not predictable but areas

with good satellite coverage and an unobstructed view of the sky can expect a total

delay of 2 to 5 minutes. Some international locat ions may not be as well covered

and could experience longer delays; as c an ins tallat ions in c any ons , mountainous

areas and places surrounded by tall buildings w her e the view of the open sky is

partially obstructed.

The latency time will delay alarm event transmissions sent, and control commands

received, by the field station. T his will r es ult in unpredictable delays between alarm

event transmissions and the email and t ex t message notifications sent by the

database. These delays also apply to t he time between control commands being

sent and the digital outputs acting on them.

The time stamp for data readings is applied by the database at the time the data

arrives. This time stamp includes the latency time and does not indicate the actual

time the data was taken. Because the latency time varies from one transmission to

another, the interval between data readings also varies. This variation can be

several minutes. If the SIT65 is program m ed to transmit once each hour, a typical

time stamp may vary from 55 minutes to 65 minutes between transmissions, which

does not create a significant err or in m ost cases. However, the variation in time

stamps remains the same regardless of the transmission interval. For systems

transmitting at faster intervals , the variation in time stamps can produce a much

greater percentage of error. This puts a practical limit on how often the SIT65 can

transmit and still produce useful data. It is generally not recommended that the

system be programmed to transmit mor e than once ev er y 15 minutes.

Global Water Instrumentation

9

Real-Time Time Stamp

In cases where the time stamp is more critical, a real-time time stamp feature can be

enabled. This is a factory programmable feature that allows the field station to

transmit the actual time the data r eadings wer e taken along with the sensor data.

Because the time stamp is transmitted t hr ough the satellite network, the amount of

data being sent increases, along with the subscription fees charged by Orbcomm .

Depending on the transmission inter v al and the number of enabled sensor channels,

this feature can noticeably increase t hese fees.

Power Consumption

The SIT65 draws different amounts of power depending on what mode it is in.

Typically, the controller draws 5mA all the time. When the radio is turned on, an

additional 75mA is used in standby and 2 amps are used f or br ief periods when

transmitting. The analog s ens or current, including 4-20mA output cur r ents, is drawn

during the sensor warm-up time when readings ar e being taken. Active digital

sensors generally are powered up all the tim e and dr aw some current. Additional

current is drawn when control outputs ar e power i ng ex ternal devices from the SIT65

power supply. Other sources my also apply . All these together form an average

current that must be handled by the power supply if the system is to operate reliably.

The controller uses a variable power managem ent scheme that provides a balance

between current draw and available feat ur es . This process relies on the fact that the

controller has the ability to swit c h the modem off when not transmitting, reducing

standby power consumption from 80mA to 5mA. However, the SIT65 can also be

remotely interrogated by comm ands r elay ed through the satellite network. In order

for the request to be received, the modem m us t be turned on. The modem must

also be turned on if commands are sent to turn the cont r ol outputs on and off.

Two methods can be used for enabling remote interrogation of the SIT65 and

controlling the outputs. One method is to leave the modem powered on all the time.

This is a factory programmable setting only and is not recommended. The second

method is to communicate with the station at times when it is most likely to have

enough available power to keep t he modem turned on. With AC power, it is likely

that the modem will be powered up all of the time. With solar powered systems,

sufficient voltage to keep the modem turned on may only be available during daylight

Global Water Instrumentation

10

hours. Systems that require access to interrogation and control should have power

systems designed according to the r equir em ents of the system. The voltage

thresholds for the different power m odes ar e as follows:

Battery Voltage >= 12.8 volts; Battery Charging. The battery has sufficient charge

and the radio remains on all of the time to receive commands.

12.0 volts < Battery Voltage < 12.8 volts; Low battery. Radio remains on only

when data is being transmitted.

11.3 volts < Battery Voltag e < 12.0 volts; Very Low Battery. Radio remains on

only when data is being transmitted. The SV LED blinks every 5 seconds

Battery Voltage <= 11.3 volts; Dead battery. All operations st op and the radio

remains shut off until the battery recharges again.

Battery Voltage Monitor

The SIT65 offers a full time battery v oltage monitor that reports system voltage

automatically with every tr ans m is s ion. This is a very important tool for checking the

installation, system c omponents , solar panels and battery. It should be watched

carefully when the system is first ins talled and periodically from then on. Downward

trends that seem abnormal may be an indicator that something is wrong. Sudden

changes in operation may be caused by envir onmental changes, an electrical

problem that is drawing excessive curr ent, or a problem with the charging system. A

slowly dropping voltage may indicate t hat the battery is losing its capacity and needs

to be replaced. Other signs of this are that the problem will likely occur when going

into fall or winter, and that the size of t he v oltage fluctuations from day to night will be

larger than normal.

Solar Power Systems

The SIT65 systems are especially suited for v er y r em ote locations where solar

power is the only option. Solar powered system s r equir e a very good understanding

of the application and system requirem ents. Some systems need to be powered

reliably all of the time and some can be shut down during t he entire winter.

Availability of interrogation and contr ol, transmission intervals, alarm tr ansmiss ions ,

the number of sensors connected, and many other factors must be evaluated. Most

importantly; seasonal changes and geographical factors like cloud c over,

temperature, snow, dust and how high the sun is in the sky can change solar system

efficiency. No attempt is made here t o dis c us s all of t he factors in solar system

design.

Global Water Instrumentation

11

Typically, a system is designed to make s ufficient power available during the wor s t

times of the year. In these cases, solar panels should be oriented to gather the most

light when the sun is lowest in the sky. In areas with snow, they may even be

pointed lower to allow the snow to slide off . This reduc es the efficiency but overall,

will probably produce more tot al c ur r ent. Clouds can reduce the output current of a

panel by 90% or more, even a small cloud will reduce the output to almost nothing as

it goes by. Shade is a very big factor and clouds create shade, even if it seems very

bright out.

Solar systems designed to provide enough power in the winter will produce far too

much in the summer. The result is the battery will become overcharged, reducing

the capacity to hold stored energy. When the following winter arrives, the battery

may not provide enough storage capacity to keep the system operating as it was

designed. For this reason, a charge contr oller s hould alw ay s be us ed. This device

senses the battery voltage and adjusts the charging current to match the demand.

The charger is selected based on the amount of solar capac ity that is connected to it.

High ambient temperatures may make it neces sary to over-rate the charger.

Many other factors affect the ability of a battery to maintain a charge. A solar system

that is under-rated will cause the batt er y to make large voltage fluctuations. Typical

batteries used in these applications are the sealed lead acid type, which slowly lose

capacity when charged and discharged by large amounts over long periods of time.

The larger the typical voltage fluctuations are, the more the effect. If the batter y is

allowed to become severely overcharged or discharged, the capacity can be

significantly reduced. Low ambient t emperatures also reduce available power

capacity but this capacity retur ns w hen the temperatures rise again.

The solar power output and battery capacit y ar e the key des ign features. When

simplified; the capacity of the bat teries is chosen based on the amount of time the

system needs to be running in the absence of s unlight, while the size of the solar

panels is chosen for their ability to r ec har ge the batteries at the end of that time with

whatever sunlight may be available. What the worst case scenario is depends on

the application, but designing the system for that possibility is the ultimate goal.

There are too many applications to make est imates of what is typical. The total

power drain depends on transmission inter v al and s y s tem configuration; while

recharging limitations depend mostly on the environment. Two things to consider

are that an extra solar panel is usually cheaper than lost data, and the cost of a fresh

replacement battery is much less when someone is already in the field.

Global Water Instrumentation

12

Station ID and Sensor Offsets

Each field station has a unique Station ID number . This number is shown on the

configuration report provided with t he s y s tem, and on a label placed at the top of the

controller board. The databases identify the sensor data for each of the input

channels using this station ID along with a sensor offset number. The offset is

added to the station ID to calculate the unique sens or num ber . These sensor

numbers are used to identify each of the input c hannels for any particular station.

The offsets are as follows:

Offset Channel Type

+0 Digital Control Output Register

+1 Analog Input Channel #1

+2 Analog Input Channel #2

+3 Analog Input Channel #3

+4 Analog Input Channel #4

+5 Analog Input Channel #5

+6 Analog Input Channel #6

+7 Analog Input Channel #7

+8 Analog Input Channel #8

+9 Battery Voltage Monitor

+10 Digital Status Input Register

+11 Digital Accumulator Input Channel #1

+12 Digital Accumulator Input Channel #2

+13 Digital Accumulator Input Channel #3

+14 Digital Accumulator Input Channel #4

For Example: For a SIT65 with a Station ID# of 14200, the Sensor ID# for analog

channel one is 14201, analog channel two is 14202, battery monitor is 14209, digital

input accumulator for channel one is 14211, etc.

Global Water Instrumentation

13

Sensor Data Format

Analog sensor data is transmitt ed as a 10-bit number in the range of 0-1023. A

calibration equation is applied to the r aw data number at the database to scale the

sensor reading in the appropriate range and engineering units. Digital input

accumulators count input events from things like tipping bucket rain gauges and flow

monitors. The ac c umulator is transmitted as a 11-bit number in the range of 0-2047

and calibration factors are also used t o s c ale the data. Once reaching 2047, the

accumulator counter rolls back t o zero wit h the next count. Digital status inputs

transmit all channel data in a single st atus register with 1-bit for each channel, one or

zero, true/false, on/off, open/clos ed, etc. Digital control outputs also have t heir

status transmitted in a single register with 1-bit for each output channel.

Because digital status inputs and control out puts only need one data bit to transmit

their state, these channels c an be c om bined into one data value. The state of up to

4 status inputs are combined into one status regis ter in binary format, channel one

shown by bit one, channel two with bit two, etc. In the same manner, the current

state of the control outputs is transmitted in a single status register. Register

contents returned as 0011 (binary) shows channels 1 and 2 High (ON), and channels

3 and 4 Low (OFF). Features in the databases allow the mapping of these bits t o

text labels.

Calibration Numbers

Data values are transmitted to the hosting databases as raw data numbers. This

number is scaled to the desired engineering units (EU) by first multiplying it wit h a

scaling factor (Multiplier), then adding an offset (Adder). These numbers are the

coefficients in a straight line equation: EU = Adder + (Multiplier * RawData). These

calibration numbers are entered int o the databases and the scaling takes place as

the data comes in. Thus, all the calibration is done at the database, independent of

the field station. There is an Excel spreadsheet calculator for finding these

calibration factors that can be downloa ded from our website at globalw.com/support.

Some examples are also given in Appendix B.

Another important feature is available f or c alc ulating data. When the raw data has

been adjusted to the proper engineering units us ing the straight line equation

discussed above, the database calibrat ions allows for additional mathematical

operations. For example; these equat ions c an be flume or weir equations for

Global Water Instrumentation

14

converting water level to flow, or c an be us ed as best-fit polynomial approximations

for almost any non-linear sensor or f unction. These features are available in both

databases, but they work differently and the format won’t be detailed here.

Alarms

Alarm notifications can be sent via email or text messaging when incoming data

exceeds thresholds defined in the alarms s ec tion of the databases. Both high and

low threshold settings are available for all analog inputs to alert the user based on

water level, wind speed or any other analog parameter. Digital inputs can generate

alarm messages based on the state of thes e inputs, a door being opened or a power

failure for example.

Besides transmitting data at regular intervals, the SIT65 can be programmed to

transmit upon any change of stat e on any of the digit al s tatus or accumulator inputs.

These alarm transmissions occur wit h all c hanges of state. A door switch for

example will cause an event transmis s ion ev er y t im e the door opens and closes.

The alarm thresholds can be configured to send em ail and text message notification

on just a single state, like the door being opened, but the transmission will occur

every time the door is both opened and closed. In cases where the state changes

often, many extra transmissions will be s ent. In some cases, this can be enough

data to affect the subscription fees.

Installation

The antenna is a 1 meter whip antenna with no alignment required; however, an

open view of the sky is. Anything block ing the view of the sky can limit or totally

prevent communication with the s atellite network. Trees, buildings, overhangs, and

canyon walls are some examples of obstruc tions that will limit performance. If only a

partial view of the open sky is available, latency times may increase but

communication can still be pos s ible. Satellites are constantly passing overhead and

eventually one will come into view in even a small open space. However, this can

dramatically increase the latency time and if the satellite goes by too quickly, t her e

may not always be enough time to transmit the data, resulting in gaps in data. The

widest possible view of the sky will always produce the best results.

The SIT65 is provided with the necessary har dw ar e for mounting the enclosure and

antenna to a wall or on a 2” pipe. For best performanc e, the antenna should be

Global Water Instrumentation

15

installed so that there is nothing alongside of it all the way down to its base for at

least 4-6 feet in all directions, the further the better. This includes the mast it is

mounted on, solar panels, walls, t ower s , et c. Locations near s our c es of electrical

noise may also limit the performance, es pec ially r adio frequencies in the VHF band.

The antenna is provided with 16 feet of cable. If the ant enna needs to be located

further away, additional cable can be added up to 50 feet or more. Another

important installation consideration is providing enough solar power to keep the

system operational which also requires an open and unobstructed view of the sky.

The output from the charging system can be c onnected dir ec tly to the battery

terminals, or to the Charger input t er m inals at the lower right corner of the controller

board. This charger input is protec ted from high current surges by a self-resetting

fuse. Slightly more power is delivered to t he batt er y w hen the charger is connected

directly to the battery, but any protection is assumed to be provided by the charge

controller. If no charge controller is used, the charger input will limit high charging

currents, but may also reduce the curr ent available for charging the battery.

Make all necessary connections, including the antenna, before connect ing the

battery. The antenna connects to the N-Type connect or on the bottom of the

instrumentation enclosure. Make the battery connection last by plugging the battery

cable into the controller board. Check that the red wire connects to the positive side

of the battery and the black wire is connec ted to the negative terminal. While the

connector is protected from rever s e c onnec tion, check that it is aligned correctly

before plugging it into the controller.

A test button is provided at the top right corner of the controller for initiating a

transmission on demand. Once all connections ar e m ade, press the test button for

one second and the unit will become operational. This is indicated by the activity of

several LED’s on the controller and radio modem. The operation of these LED’s is

described in the section on Troubleshooting. If possible, being in contact with

someone who can check that valid data is being t r ans mitted is recommended.

Transmit several times, paying attention to the sensor data and battery voltage.

Global Water Instrumentation

16

Signal

Buffer

Troubleshooting

The biggest source of trouble is due to insuffic ient battery voltage. If the unit is

transmitting erratically or has stopped, look at the trend in battery voltage going back

a week or more. The battery voltage monitor can be a very good indic ator of what

the problem may be. Sudden changes in system voltage m ay be c aused by sudden

changes in the local environmental, an elec trical problem that is drawing excessive

current, or a problem with the charging sys tem. A slowly dropping voltage may

indicate that the battery is losing its capac ity and needs to be replaced. Other signs

of this are that the problem will likely occur when going int o fall or winter, and that the

size of the voltage fluctuations f r om day to night will be larger than normal.

Besides checking the battery v oltage monitor at the database, there is another tool

for troubleshooting the syst em . LED ’s on the controller and r adio modem show the

system operation, battery level, whether data is waiting to be transmitted, and if a

satellite is being received with sufficient signal strength.

SV: Sensor Voltage. This LED is red and has different functions depending on what

mode the system is in. During the time that the analog sensors are powered up, the

sensor warm-up time, it is lit continuously . When the system is in a standby mode

the LED blinks briefly every 15 seconds when the bat tery voltage is above 12.0 volts,

and every 5 seconds when the voltage is below 12.0 volts,

RV: Radio Voltage. The LED is yellow and is lit while the radio modem is turned on.

The radio is on continuously when the batter y voltage is abov e 12.8 volts. Below this

voltage, the radio is kept on only when attempting to transmit.

TX: Transmit. This LED is green and is on when t r ans m itting data to the radio

modem. It also blinks briefly every 15 seconds when in standby mode and the

battery is above 12.8 volts.

Signal: Signal Strength. This is a dual-color LED that is on only when power is

applied to the modem. The LED is green continuously when in st andby mode and

receiving good signal strength. It blink s gr een every s ec ond when c om municating

Global Water Instrumentation

17

and also has sufficient signal strength. It blinks orange once each second when the

received signal is too weak to communicate.

Buffer: Data Buffer. This yellow LED is lit when ther e is data in the data buffer

waiting to be transmitted, and off w hen the data buffer is empty.

Some typical problems indicated by the operation of these LED’s are:

• The SV LED blinks every 5 seconds and the modem LED’s are off. The

battery voltage is too low and the modem has been turned off. Unplug the

battery cable from the controller board and rec harge or replace the battery.

• The Signal LED is green and the Buffer LED is yellow and never goes out.

There is good signal strength but dat a is not being transmitted, possibly due

to satellites not being in view long enough to tr ans m it or because the

transmission is not being accepted due t o inc or r ec t Orbcomm account or

modem configurations. Contact Global Water to have the satellite activity

checked.

• The Signal LED is always red. This indicates a weak or absent signal. Check

the antenna position, coax cable and connect or s . Another possibility is that

the modem has been damaged due to an electrical sur ge.

Data is being transmitted but one or more sensor readings ar e inc or r ec t:

• Check the wiring between the sensors and the contr oller boar d.

• For analog sensors, check that the configur ation jumpers are set correctly for

the sensor type and supply voltage.

• If all the sensor readings are wr ong, press the test button and use a voltmeter

to measure the voltage applied to the sens or s while the SV LE D is lit. It

should be within 0.5 volts of the battery v oltage.

• If a sensor does not appear in the database, check that it is defined correctly

in the sensor configuration window.

• The sensor appears to work but the values in the databas e ar e wr ong, check

the Adder and Multiplier calibration num ber s in the sensor configurations.

• Confirm with Global Water that the sens or c hannel was enable d w hen the

SIT65 was programmed at the factory. To reduce data c har ges , only sensor

channels that are enabled will transmit. Enabling new channels requires that

the unit be returned to the factory , t his w ill als o aff ec t subscription fees.

Global Water Instrumentation

18

Technical Support:

Call Global Water for technical support or s ales information:

Phone: (800) 876-1172

(979) 690-5560

Fax: (979) 690-0440

Email:

When calling for technical support , have as much of the following information ready

as possible:

Station ID# from the documentation or the label on the controller board

Radio Name from the documentation or the label on the radio modem

Model Number of the product experiencing prob lem s

Serial Number of that product and for the SIT65 field station

Purchase order number that the equipment was purchased on

The Global Water sales order number or invoice number

Repair instructions and/or specific problems relating to the product

Be prepared to describe the problem you are experienc ing including specific details

of the application, installation, and any additional other pertinent information.

In the event that the equipment needs to be returned t o the factory for any reason,

please call to obtain a RMA# (Return Material Authorization). Do not return items

without a RMA# displayed on the outside of the package. Include a written

statement describing the problems.

Send the package with shipping prepaid to our factory address. Insure your

shipment; Global Water’s warrant y does not cover damage incurred during transit.

globalw@globalw.com.

Global Water Instrumentation

19

Appendix A: Specifications

Analog Inputs: Up to 8 inputs available

10-bit resolution

Type: 0-20mA, 0-1mA, 0-500uA, 0-5VDC, 0-10VDC

Sensor Power: 5Vsw, 12Vsw, 18Vsw or 12V Continuous

Digital Inputs: Up to 3 inputs available, counters or status

Contact closure or open collector to ground

Inputs have 20K pull-up resistor to 5VDC

Maximum accumulator count: 2047 ( 11-bit)

Control Outputs: Up to 2 outputs available

Open collector output to ground

100mA each output maximum

Inductive load protected

Radio Modem: Frequency: Transmit-150MHz, Receive-138MHz

Communication speed: 9600 Baud

Transmit power: 5 Watt

Antenna: 1 meter whip, 16 foot cable standard

Power Supply: 12VDC, 5Ahr Battery standard

Current draw: 80mA in receive mode @12VDC

5mA in power save mode

2A briefly when transmitting

Environment: -40° to +60° Celsius, -40° to 140° Fahrenheit

100% Humidity, Non-condensing

Global Water Instrumentation

20

Appendix B: Adder and Multiplier Numbers

1) Define the Engineering Units (EU) and span (0 to 100 MPH, -50°C to +50°C, etc).

EU(min) = Minimum EU corresponding to minimum sensor output

EU(max) = Maximum EU corresponding to maximum sensor output

EU(span) = EU(max) – EU(min), observe polarity

2) Calculate the Raw Data (RD) span.

For 4-20mA Current Output Sensors:

I(min) = Sensor output current @ EU(min)

I(max) = sensor output current @ EU(max)

RD(min) = I(min) / 4 x Raw(4mA), round down to nearest integer

RD(max) = I(max) / 19 x Raw(19mA), round up to nearest integer

RD(span) = RD(max) – RD(min)

Raw(4mA) and Raw(19mA) are provided on the Configuration Report

For 0-5VDC Voltage Output Sensors:

V(min) = Output voltage @ EU(min)

V(max) = Output voltage @ EU(max)

RD(min) = V (min) / 5 x 1023

RD(max) = V(max) / 5 x1023

RD(span) = RD(max) – RD(min), Round Off

3) Calculate the Multiplier for Sensor Calibration Settings. EU=Adder+(Multiplier*RawData)

Multiplier = EU(span) / RD(span)

4) Calculate the Adder for Sensor Calibration Settings.

Adder = - (Multiplier x RD(min)) + EU(min), obse r ve polarity

Example 1: 4-20mA, 0-100 MPH Wind Speed sensor. Raw(4mA)=205, Raw(19mA)=972

EU(min) = 0 MPH EU(max) = 100 MPH

EU(span) = EU(min) – EU(max) = 100 – 0 = 100 MPH

I(min) = 4.004mA @ 0MPH I(max) = 19.884mA @ 100MPH

RD(min) = 4.004 / 4 x 205 = 205.2 ≅ 205

RD(max) = 19.884 / 19 x 972 = 1017.2 ≅ 1017

RD(span) = RD(max) - RD(min) = 1023 – 204 = 812

Multiplier = EU(span) / RD(span) = 100 / 812 = 0.123153

Adder = - (Multiplier x RD(min)) + EU(min) = - (0.123153 x 205) + 0 = - 25.2463

Example 2: 4-19mA, -50°C - +50°C Temperature sensor, °F. Raw(4mA)=204, Ra w( 19m A) =971

EU(min) = -50°C = -58°F, EU(max) = +50°C = 122°F, [°F = (°C x 9 / 5) + 32]

EU(span) = 122°F – (-58°F) = 1 80°F

I(min) = 3.846mA @ -58°F, I(max) = 18.988mA @ 122°F

RD(min) = 3.846 / 4 x 204 = 196.1 ≅ 196

RD(max) = 18.988 / 19 x 971 = 970.4 ≅ 970

RD(span) = EU(max) – EU(min) = 972 – 196 = 774

Multiplier = EU(span) / RD(span) = 180 / 774 = 0.232558

Adder = - (Multiplier x RD(min)) + E U (min) = - (0.232558 x 196) + (-58) = -103.5814

Loading...

Loading...