Page 1

INSTRUCTION MANUAL

P81630

REVISION E

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Series VSC® and VSCS®

Base Mounted

Centrifugal Pumps

(TO BE USED IN CONJUNCTION WITH VSC PARTS LIST CONTAINING LINE DRAWINGS)

Page 2

DESCRIPTION

WARNING

ROTATING COMPONENTS

DISCONNECT AND LOCK OUT

POWER BEFORE SERVICING.

DO NOT OPERATE WITHOUT

ALL GUARDS IN PLACE.

CONSULT INSTALLATION

AND SERVICE INSTRUCTION

SHEET BEFORE OPERATING

OR SERVICING.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY

OR DEATH.

P70642

WARNING

EYEBOLTS OR LIFTING

LUGS IF PROVIDED ARE

FOR LIFTING ONLY THE

COMPONENTS TO WHICH

THEY ARE ATTACHED.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY

OR DEATH.

P70643

CAUTION

DO NOT RUN PUMP DRY,

SEAL DAMAGE MAY OCCUR.

INSPECT PUMP SEAL

REGULARLY FOR LEAKS,

REPLACE AS REQUIRED.

FOR LUBRICATION

REQUIREMENTS, CONSULT

SERVICE INSTRUCTIONS.

FAILURE TO FOLLOW

INSTRUCTIONS COULD

RESULT IN INJURY OR

PROPERTY DAMAGE.

P70644

CAUTION

COUPLER ALIGNMENT IS

REQUIRED! LEVEL AND GROUT

PUMP BEFORE USE!

CHECK ALIGNMENT BEFORE

GROUTING, AFTER SYSTEM IS

FILLED, AFTER SERVICING

PUMP, AND AS REQUIRED.

CONSULT THE SERVICE

INSTRUCTIONS FOR DETAILS.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD

RESULT IN INJURY OR

PROPERTY DAMAGE.

P70820

The VSC and VSCS Series centrifugal pumps are frame mounted

pumps which feature – high efficiency, rugged construction,

compact design, foot mounted volute, center drop out coupler,

and regreasable bearings. These features along with the vertically split case make installation, operation, and service easy to

perform.

OPERATIONAL LIMITS

Unless special provisions have been made for your pump by

Bell & Gossett, the operational limits for VSC/VSCS Series

Pumps are as follows:

Maximum Working Pressur

Listed on pump nameplate.

SEAL OPERATING LIMITS

Standard Seals

BUNA-PH Limitations 7-9; Temperature Range -40 to +225°F

EPT-PH Limitations 7-11; Temperature Range -40 to +250°F

For use on closed or open systems which are relatively free of

dirt and/or other abrasive particles.

Flushed Single Seals

PH Limitations 7-9; Temperature Range 0 to +250°F†

Note: On closed or open low pressure systems which may

contain a high concentration of abrasives an external flush is

required.

e

PUMP APPLICATION

The standard VSC and VSCS Series centrifugal pump’s br

fitted construction make it ideal for service with the following

liquids: unheated domestic and fresh water, boiler feed water

condensate, hydronic cooling or heating, pressure boosting,

general pumping and benign liquids.

For other applications contact your local B&G Representative.

Flushed Double Seals

PH Limitations 7-9; Temperature Range 0 to +250°F

Note: On closed or open low pressure systems which may

contain a high concentration of abrasives an external flush is

required.

Packing

PH Limitations 7-9; Temperatur

e Range 0 to +200°F

Note: On open or closed systems which require a large

amount of makeup water, as well as systems which are subjected to widely varying chemical conditions and solids buildup.

† For operating temperatures above 250°F a cooled flush is requir

and is recommended for temperatures above 225°F for optimum seal

life. On closed systems cooling is accomplished by inserting a small

heat exchanger in the flush line to cool the seal flushing fluid.

Flush-line Filters and Sediment Separators are available on special

request.

onze

ed

,

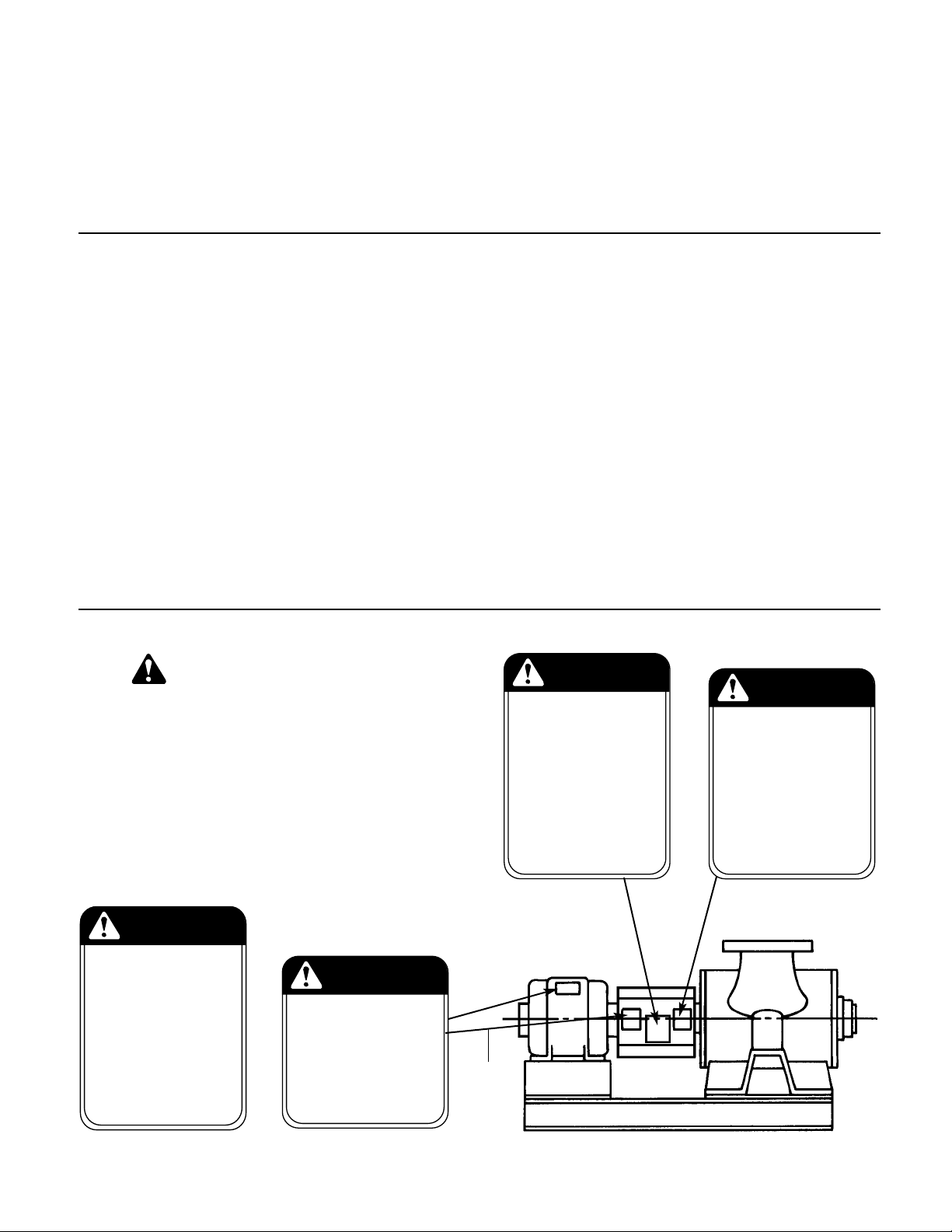

This safety alert symbol will be used in this manual and on the

pump safety Instruction decal to draw attention to safety related

instructions. When used, the safety alert symbol means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THE INSTRUCTIONS MAY RESULT IN

A SAFETY HAZARD.

Your VSC/VSCS Series Pump should have the following safety

instruction decals located approximately as shown. If the

decals are missing or illegible contact your local B&G representative for a replacement.

2

SAFETY

INSTRUCTION

ALTERNATE

LOCATION

(2) REQUIRED

(1 EACH SIDE)

Page 3

ADDITIONAL SAFETY REQUIREMENTS:

ELECTRICAL SAFETY:

MECHANICAL SAFETY:

WARNING: Electrical Shock Hazard

Electrical connections to be made by a qualified

electrician in accordance with all applicable codes, ordinances, and good practices. Failure to follow these instructions could result in serious personal injury or death,

or property damage.

WARNING: Electrical Overload Hazard

Three phase motors must have properly sized

heaters to provide overload and undervoltage protection.

Single phase motors have built-in overload protectors.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

THERMAL SAFETY:

WARNING: Extreme Temperature Hazard

If pump, motor, or piping are operating at extremely

high or low temperatures, guarding or insulation is required. Failure to follow these instructions could result in

serious personal injury or death, or pr

operty damage.

PUMP LOCATION

Locate the pump so there is sufficient room for inspection, maintenance and service. If the use of a hoist or tackle is needed,

allow ample head room.

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

W

ARNING: Excessive System Pressure Hazard

The maximum working pressure of the pump is listed

on the nameplate, do not exceed this pressure. Failure to

follow these instructions could r

esult in serious personal

injury or death, or property damage.

WARNING: Excessive Pr

essure Hazard

Volumetric Expansion

The heating of water and other fluids causes volumetric

expansion. The associated forces may cause failur

e of system components and release of high temperature fluids.

This will be prevented by installing properly sized and

located compression tanks and pressure relief valves.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

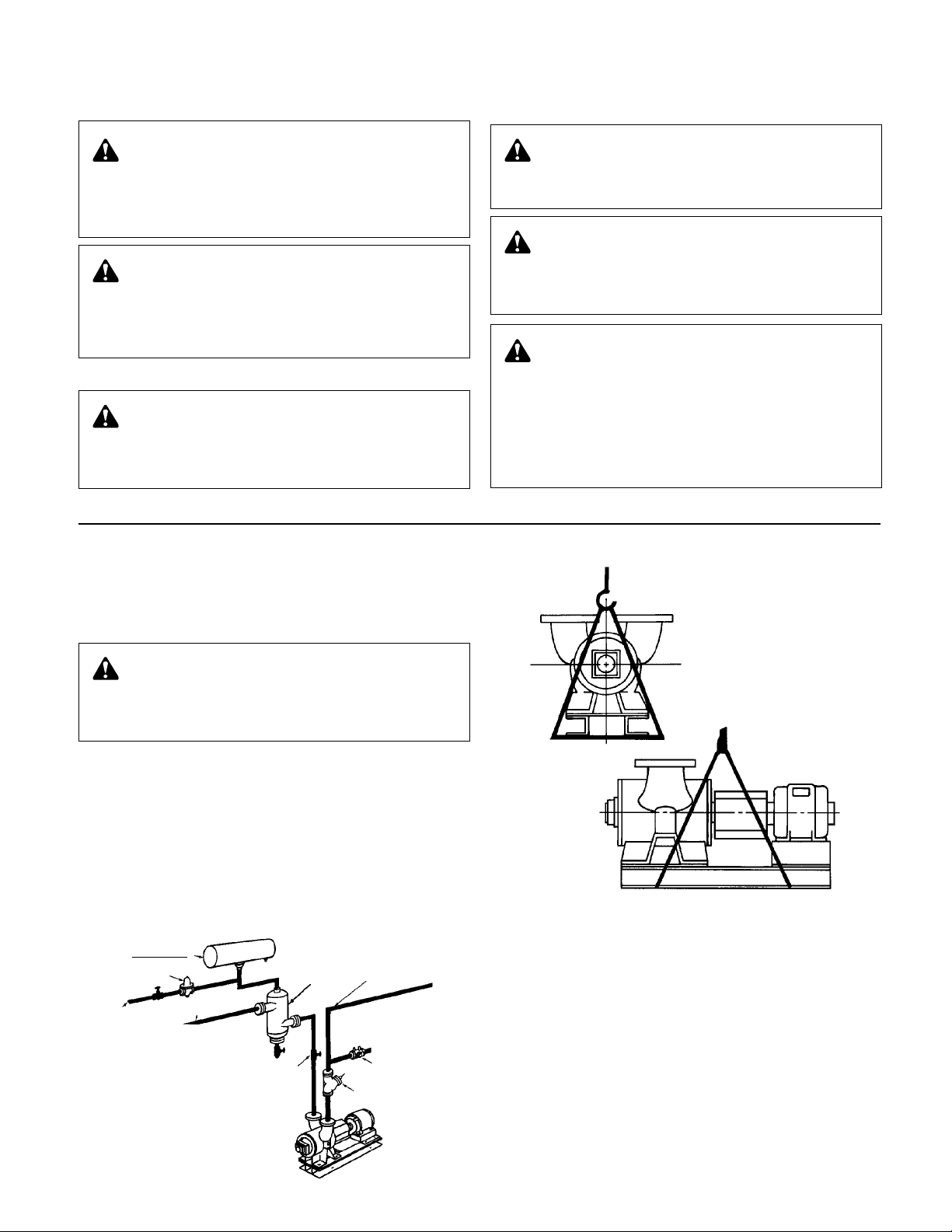

WARNING: Fall Objects Hazard

Eyebolts or lifting lugs, if provided, are for lifting only

the components to which they are attached. Failure to follow these instructions could result in serious personal

injury or death, or property damage.

If lifting of the entire pump is required, do so with slings placed

under the base rails as shown.

The best pump location for sound and vibration absorption is

on a concrete floor with subsoil underneath. If the pump location is overhead, special precautions should be undertaken to

reduce possible sound transmission, consult a sound specialist.

If the pump is not on a closed system, it should be placed as

near as possible to the source of the liquid supply, and located

to permit installation with the fewest number of bends or

elbows in the suction pipe.

COMPRESSION TANK

SHOULD BE LOCATED

ON THE SUCTION SIDE

OF THE PUMP

B&G REDUCING

VALVE

COLD

WATER

SUPPLY

FROM BOILER

CHILLER OR CONVER

TER

B&G ROLAIRTROL

AIR SEPARATOR

ISOLATION

VALVE

SUPPLY

TO SYSTEM

B&G CIRCUIT

SETTER

B&G TRIPLE DUTY

VALVE

The installation must be evaluated to determine that the Net

Positive Suction Head Available (NPSHA) meets or exceeds the

Net Positive Suction Head Required (NPSHR), as stated by the

pump performance curve.

IMPORTANT

Do not install and operate Bell & Gossett Pumps, 3D Valves,

Suction Diffusers, etc., in closed systems unless the system is

constructed with properly sized safety devices and control

devices. Such devices include the use of properly sized and

located pressure relief valves, compression tanks, pressure controls, temperature controls, and flow controls as appropriate. If

the system does not include these devices, consult the responsible engineer or architect before making pumps operational.

3

Page 4

INSTALLATION

This pump is built to provide years of service if installed properly

and attached to a suitable foundation. A base of concrete weighing 21/2 times the weight of the pump is r

the shipping ticket for pump weight.)

If possible, tie the concrete pad in with the finished floor. Use

foundation bolts and larger pipe-sleeves to give room for final

bolt location. (See Figure 6A.)

ecommended. (Check

PIPE

SLEEVE

FOUNDATION

BOLT

LEVELING

Place the pump on its concrete foundation supporting it with

steel wedges or shims totaling 1" in thickness. These wedges

or shims should be put on both sides of each anchor-bolt to

provide a means of leveling the base. (See Figure 6B.)

It is very important that the pump-base be set level to avoid any

mechanical difficulties with the motor or pump. This pump was

properly aligned (if furnished with a motor) at the factory

. However, since all pump bases are flexible they may spring and twist

during shipment. Don’t pipe the pump until it is realigned. After

piping is completed and after the pump is grouted-in and bolteddown, align it again. It may be necessary to re-adjust the alignment from time to time while the unit and foundation are new.

GROUTING

After the pump has been leveled, securely bolted to the floor,

and properly aligned, a good grade of non-shrinking grout

should be poured inside the pump base. To hold wedges or

shims in place, allow the grout to flow around them.

ROTATION

The VSC & VSCS pump is available in both right- and left-hand

rotation. An arrow cast into the pump body shows the direction

of rotation.

BUILT-UP

CONCRETE FOUNDATION

ALLOW 1" FOR SHIMS.

PLACE ON BOTH SIDES

OF ANCHOR BOLTS.

APPROX.

GAP

1"

LEVELING OF PUMP BASE

ON CONCRETE FOUNDATION.

WASHER

NOTE:

TO KEEP SHIMS IN

PLACE ALLOW GROUT

TO FLOW AROUND

HOLD DOWN LUGS.

GROUT

CONCRETE

FOUNDATION

FIGURE 6A

GROUT ONLY TO

TOP OF BASE RAIL.

PUMP

BASE RAIL

FIGURE 6B

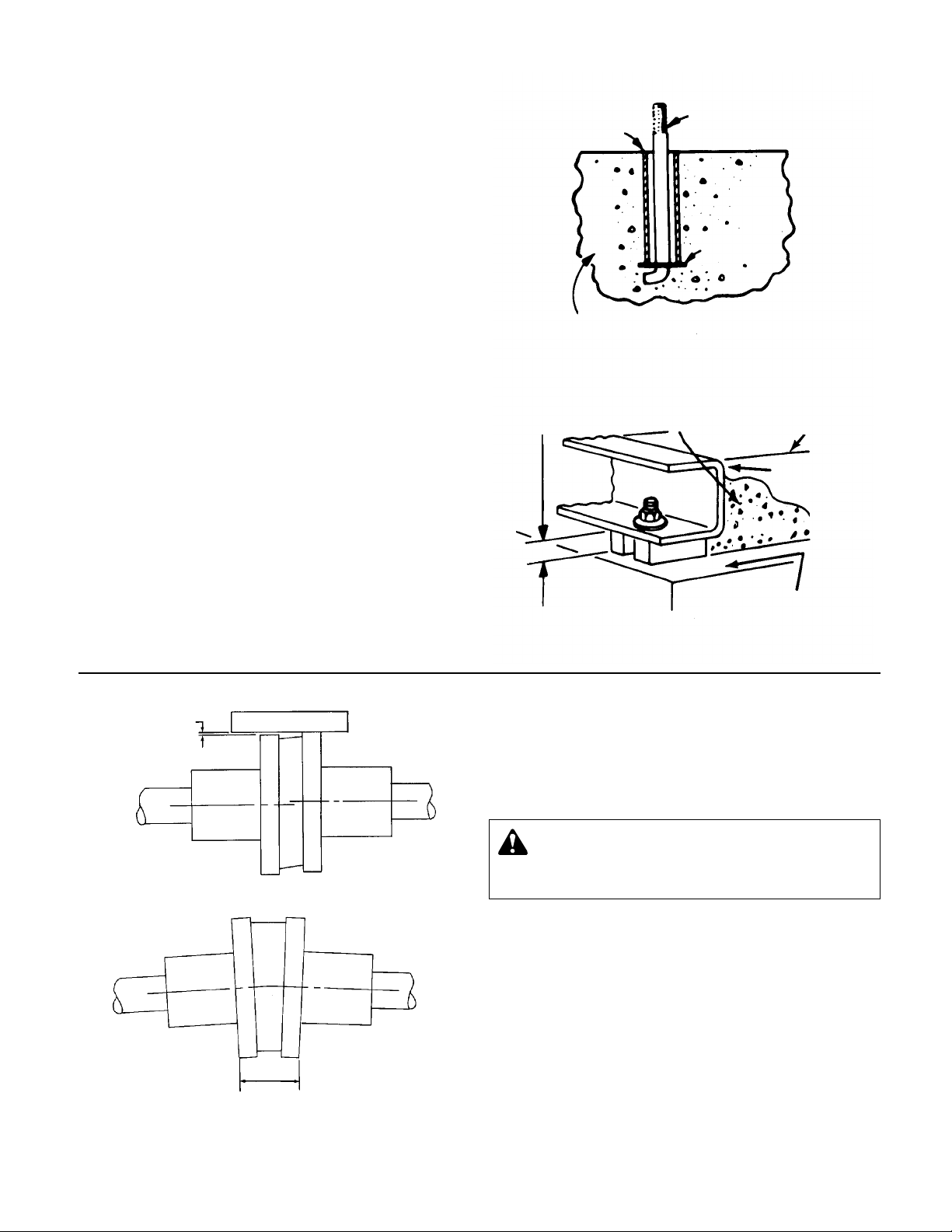

AMOUNT OF

PARALLEL

MISALIGNMENT

STRAIGHT EDGE

PARALLEL ALIGNMENT CHECK

DISTANCES ACROSS

COUPLER FLANGES

SHOULD BE EQUAL

(CHECK 4 PLACES)

ANGULAR ALIGNMENT CHECK

COUPLER ALIGNMENT

All alignment should be done by moving or shimming the motor

only. Adjustments in one direction may alter alignment in another.

Therefore, check alignment in all directions after a correction is

made. Black rubber inserts have different horsepower load

ratings than orange Hytrel sleeves. They should not be

interchanged.

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

STANDARD SLEEVE TYPE COUPLER

WITH BLACK RUBBER INSERT

Before aligning the coupler, make sure there is about 1/8" end

clearance between the sleeve and the two coupler halves.

1. Check angular misalignment using a micrometer or caliper.

Measure from the outside of one flange to the outside of the

opposite flange at four points 90° apart. DO NOT ROTATE

COUPLER. Misalignment up to 1/64" per inch of coupler

radius is permissible.

2. At four points 90° apart (DO NOT ROTATE COUPLER), measure the parallel coupler misalignment by laying a straight

edge across one coupler half and measuring the gap

between the straight edge and opposite coupler half. Up to a

1

/64" gap is permissible.

4

Page 5

FOR FINE ALIGNMENT, ORANGE HYTREL INSERTS,

3500 RPM OPERATION, OR ALL OTHER COUPLER TYPES

Use a dial indicator when greater alignment accuracy is required. Use the following alignment tolerances unless specified

otherwise by the coupler manufacturer. On sleeve type couplers

make sure there is about 1/8" end clearance between the sleeve

and the two coupler halves.

1. To check angular misalignment, mount the dial indicator

base to one coupler half, or shaft, and position the dial indicator button on the front or rear face of the opposite coupler

half. Set the dial to zero. Rotate both coupler halves together,

making sure the indicator button always indicates off the

same spot. Misalignment values within 0.004" TIR per inch of

coupler radius are permissible.

2. To check parallel misalignment, mount the dial indicator base

to one coupler half, of shaft, and position the dial indicator

button on the outside diameter of the opposite coupler half.

Set the dial to zero. Rotate both coupler halves together,

making sure the indicator button always indicates off the

same spot. Misalignment within 0.004" TIR is permissible.

PIPING

Always install a section of straight pipe between the suction

side of the pump and first elbow. This reduces turbulence of

the suction by straightening out the flow of liquid before it

enters the pump. The length should be equal to five times the

diameter of the suction pipe size.

Line up the piping so that the bolt-holes in the pump flanges

match the bolt-holes in the pipe flanges. DO NOT ATTEMPT

TO SPRING THE SUCTION OR DISCHARGE LINES INTO

POSITION. Coupling and bearing wear will result if suction or

discharge lines are forced into position. The code for Pressure

Piping (ANSI B.31.1) lists many types of supports available for

various applications.

When considerable temperature changes are anticipated,

equipment for absorbing expansion should be installed in the

system in such a way as to avoid strain on the pump.

When using an isolation base, flexible piping should also be

used on both suction and discharge sides of pump.

On an open-system with a suction-lift, use a foot-valve of equal

of greater area than the pump suction piping. Prevent clogging

by using a strainer at the suction inlet next to the foot-valve.

The strainer should have an area three times that of the suction

pipe with hole diameter of no less than 1/4".

The pipeline should have isolation valves around the pump and

have a drain valve in the suction pipe.

A Bell & Gossett Triple Duty Valve installed in the discharge line

will serve as a check valve to protect the pump from water

hammer, as a gate valve for servicing and for throttling.

PUMP INSULATION

When insulating a Series VSC/VSCS pump, ensure that the

grease fittings remain accessible and visible. Do not seal off the

drain holes in the bearing caps or bearing housings.

PRIMING AND STARTING

CAUTION: Seal Damage Hazard

Do not run pump dry, seal damage may occur.

Failure to follow these instructions could result in serious

property damage and/or moderate personal injury.

Before starting the pump, the pump body must be full of liquid.

Manual priming may be required if the system does not automatically fill the pump body with liquid. Vent plugs are provided

on the pump body to vent the air. While venting the air from the

pump body the pump shaft should be rotated a few times by

hand.

The pump should be started with the discharge valve closed

and the suction valve fully open. After the pump is up to operating speed the discharge valve should be opened slowly.

IMPORTANT: The pump should never be operated with the

suction valve closed or throttled. This could result in cavitation.

LUBRICATION

Lubricate pump bearings at least twice a year or flush bearings

whenever necessary with NLGI Grade No. 2 mineral base or

lithium base petroleum grease while the pump is running. On

chilled water applications it is important to keep the bearing

cavity full of grease to protect from condensation. Lubricate

motor bearings in accordance with the manufacturer’s instructions.

GENERAL INSTRUCTIONS

1. Keep this pump and motor properly lubricated.

2. Protect the motor against overload and low-voltage. Use a

motor-starter with proper size heater elements.

3. When there is danger of freezing, remove the plugs at the top

and bottom of the volute shell.

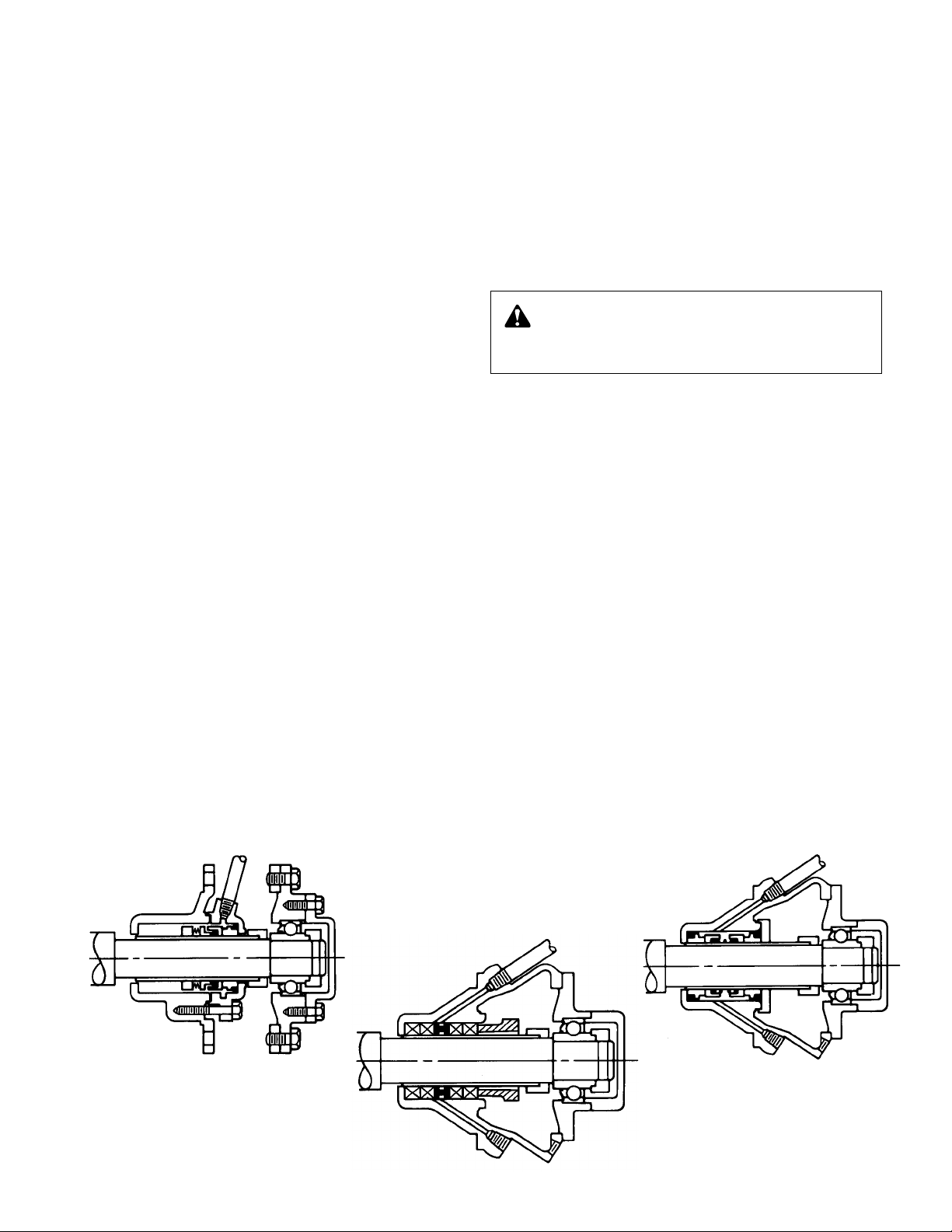

VSCS-S

VSCS-D

VSCS-PF

5

Page 6

COVERPLATE

CAPSCREWS

COVERPLATE

BEARING

HOUSING

CAPSCREW

BEARING

COVER

CAPSCREW

BEARING

COVER

BEARING

VOLUTE

IMPELLER

SEAL

SLINGER

SHAFT

STANDARD SEAL CONFIGURATION

COVERPLATE

CAPSCREW

COVERPLATE

BEARING

HOUSING

CAPSCREW

BEARING

COVER

BEARING

SHAFT

SLINGER

SEAL

IMPELLER

VOLUTE

SERVICE INSTRUCTIONS

(Follow these first three steps for all VSC(S) pumps, then proceed to the pump size and model that corresponds to the size

and model on the pump nameplate).

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

1. Close valves on suction and discharge sides of pump. If

no valves have been installed, it will be necessary to drain

the system.

2. Remove the coupler guard. Refer to section titled “Hex

Coupler Guard Removal/Installation.” 3. Loosen the capscrews which secure the coupler flanges to

6

CAUTION: Extreme Temperature Hazard

Allow pump temperatures to reach acceptable levels

before proceeding. Open drain valve, do not proceed until

liquid stops coming out of drain valve. If liquid does not

stop flowing from drain valve, isolation valves are not sealing and should be repaired before proceeding. After liquid

stops flowing from drain valve, leave valve open and continue. Remove the drain plug located on the bottom of the

pump housing. Do not reinstall plug or close drain valve

until reassembly is completed. Failure to follow these

instructions could result in property damage and/or moderate personal injury.

the coupler hubs. Remove the coupler flanges and sleeve

by compressing the flanges and pulling out from beneath

the hubs or by loosening the allen set screws and sliding

the hubs back on the shafts. Remove the coupler hub from

the pump shaft.

Page 7

INSTRUCTIONS FOR CHANGING DIRECTION OF ROTATION FOR VSC AND VSCS PUMPS

1. Remove coupler guard and coupler

.

2. Remove both bearing caps and bearing lock nuts.

3. Remove both bearing housings together with bearing.

4. Remove outboard cover plate.

5. Remove shaft and impeller assembly.

6. Remove impeller nut and pull (press fitted) impeller from

shaft. Observe direction that vane tips are pointing. Turn

impeller end for end (180°) and press back onto shaft.The

vane tips should be pointing in the opposite direction.

7. Remove volute from base. Remove inboard cover plate

from volute.*

8. Reassemble cover plate, which was removed from outboard side, by placing on same side of volute. Turn volute

end for end (180°) and mount back on base. The cover

plate that was located on the outboard side of the pump,

should now be on the inboard (motor) side of the pump.

9. Insert shaft assembly, with r

eversed impeller, back into

pump casing and reassemble second cover plate (now

outboard) to volute.

10. Reassemble seals, bearing housings, bearing and bearing

caps. (Bearings and housings are identical side to side.)

11. Reassemble coupler and reattach guard.

In summary, the impeller, volute and cover plates should all

have been reversed end for end. The orientation of the remaining parts should not have changed.

*It is important to remember that in the order to keep the water passages open, the cover plates must be reassembled to the same side

of the volute from which they were removed. In effect, they should be

rotated along with the volute. In fact, the inboard cover plate does not

need to be removed, if the complete pump end is reassembled before

being mounted on the base.

SERVICE INSTRUCTIONS FOR PUMPS WITH A STANDARD MECHANICAL SEAL (VSC-VSCS)

TO REPLACE THE SEALS:

4. Remove the bearing cover capscrews. To release the bearing cam lock, loosen the allen set screw and tap the cam

lock counter-clockwise with a drift pin.

5. Remove two capscrews and loosen the remaining capscrews that hold the bearing housing to the volute coverplate.

WARNING: Excessive Pressure Hazard

Make certain internal pressure is relieved before continuing. Failure to follow these instructions could result in

serious personal injury or death, or property damage.

Remove the bearing housing by placing two capscrews in

the jackscrew holes provided.

6. Remove the bearing from the bearing housing by gently

tapping the bearing’s inner race. NOTE: If the water slinger

has fallen into the bearing housing, be sure to remove and

replace with the one provided (see Figure 1). Take care to

avoid damage to the ceramic seal insert.

7. Remove the ceramic insert from housing by tapping from

the rear.

8. Using 2 screwdrivers, pull the rotating seal assembly from

the pump shaft (see Figure 2). Clean and inspect the shaft

and bearing housing for damage, replace if required.

IMPORTANT: When working on the seal on the noncoupler end, it is necessary to force the pump shaft back

from the coupler end as far as possible and to hold it in

this position while installing and locking the bearing to the

shaft. Also, when replacing both seals, the seal on the

non-coupler end of the pump should be installed first.

9. Lubricate the seal assemblies and insert cups with soapy

water, and then place the rotating seal assemblies on the

shaft and the ceramic inserts and cups into each of the

bearing housings, make certain inserts bottom against

bores. Install the bearing housing gaskets and the bearing

housings on the pump.

10. Slide the water slingers on the shaft and over the shoulder

so as not to interfere with the bearings. Clean and regrease bearings and insert into bearing housings. Push the

pump shaft back from the motor end as far as possible,

using a lever if necessary. Hold the shaft in this position.

Tap on the outboard bearing inner race until it is properly

positioned against the shaft shoulder. Install and lock the

cam lock into position. If the shaft and bearing are properly

positioned, the cam lock set screw will fall in the center of

the shaft undercut. Release the shaft. Install the outboard

bearing cap. Install the inboard bearing by tapping the

inner race until it contacts the shaft shoulder, lock the bearing in place with the cam lock. Install the inboard bearing cap.

11. Replace drain plug.

12. Install coupler and align, following the instructions located in

the “Coupler Alignment” section.

13. Install coupler guard. Refer to separate instructions titled

“Hex Coupler Guard Removal/Installation.”

14. Open isolation valves and check pump for leaks. If not

leaking, return pump to service.

FIGURE 1

FIGURE 2

7

Page 8

“O” RING*

SHAFT SLEEVE

SEAL COLLAR

SET SCREWS

ROTATING

SEAL MEMBERS

GASKET

SEAL CARBON

SEAL HOUSING

1

/16"

REF.

ASSEMBLY AID

DRIVE COLLAR

DRIVE COLLAR

SET SCREWS,

CUP POINT

PUMP SHAFT

COMPRESSION TO 1/4"

*NOTE: On earlier models this groove is cut into the shaft sleeve.

SHAFT SLEEVE

SET SCREWS,

DOG POINT

SERVICE INSTRUCTIONS FOR PUMPS WITH A SINGLE FLUSH MECHANICAL SEAL (VSC-S, VSCS-S)

(See special instructions for pumps 10 x 12 x 17, 12 x 14 x 121/2, 12 x 14 x 171/2 and 8 x 10 x 17)

TO REPLACE THE SEALS OR SHAFT SLEEVES:

4.

Remove bearing cover and release bearing cam lock.

5.

Remove bearing housing capscrews. Pull housing and

bearing from the pump shaft using capscrews in jackscrew holes.

WARNING: Excessive Pressure Hazard

Make certain internal pressure is relieved before con

tinuing. Failure to follow these instructions could result in

serious personal injury or death, or property damage.

6. Remove flushing tube and capscrews from seal housing.

7. Remove outer two set screws in shaft sleeve drive collar.

Loosen two inner set scr

8.

Remove the drive collar, seal housing, rotating seal assem-

ews one turn.

bly and sleeve.

9. To assemble the pump, clean shaft sleeve and pump shaft.

Replace shaft sleeve if pitted or scored. If replacing the

seal, remove shaft O-ring and replace (included in seal kit).

10. Lubricate O-ring on stationary seal seat (carbon) with silicone grease or soapy water. DO NOT USE PETROLEUM

LUBRICANT! Position in seal housing.

11. Place shaft sleeve in drive collar and tighten the two dog

point set screws in holes provided.

12. Set shaft sleeve and drive collar assembly on end and

place assembly aid spacer around the shaft sleeve.

Position against drive collar.

13. Place seal housing with carbon over the end of the sleeve

against assembly aid spacer.

14.

Lubricate O-ring in rotating seal assembly with silicone

grease or soapy water. DO NOT USE PETROLEUM

LUBRICANT! Slip rotating seal assembly on the end of the

sleeve and place against carbon.

15.

Compress rotating seal assembly to a

1

/

4" space between

the seal parts that house the compression springs. Tighten

set screws.

16. Apply anti-seize compound only to the area of the shaft

that will be under the sleeve. Place seal housing gasket in

position and slide complete assembly over pump shaft.

IMPORTANT! When working on the seal on the noncoupler end, it is necessary to force the pump shaft back

fr

om the coupler end as far as possible and to hold it in

this position while installing and locking the bearing to the

shaft. Also, when replacing both seals, the seal on the

non-coupler end of the pump should be installed first.

17.

Install the bearing housings. Clean and regrease the bearings and insert into bearing housings. Push the pump shaft

back from the motor end as far as possible, using a lever if

necessary. Hold the shaft in this position. On the outboard

bearing tap inner race until it is properly positioned against

the shaft shoulder. Install and lock the cam lock into position. If the shaft and bearing are properly positioned, the

cam lock set screw will fall in the center of the shaft undercut. Release the shaft. Install the outboard bearing cap.

Install the inboard bearing by tapping the inner race until it

contacts the shaft shoulder, lock the bearing in place with

the cam lock. Install the inboard bearing cap.

18. Push on the drive collar until the seal housing is against

the stuffing box bracket, bolt into place.

19. Tighten down collar set screws in undercut of shaft.

Remove assembly aid spacer and connect flush tubing to

seal housing.

20. Replace drain plug.

21. Install coupler and align, following the instructions located in

the section titled “Coupler Alignment.”

22. Install coupler guard. Refer to separate instructions titled

“Hex Coupler Guard Removal/Installation.”

23. Open isolation valves and check pump for leaks. If not

leaking, return pump to service.

SERVICE INSTRUCTIONS FOR PUMPS WITH A DOUBLE FLUSH MECHANICAL SEAL (VSC-D, VSCS-D)

(See special instructions for pumps 10 x 12 x 17, 12 x 14 x 121/2, 12 x 14 x 171/2 and 8 x 10 x 17)

TO REPLACE THE SEAL OR SHAFT SLEEVE:

4. Remove bearing cover and release bearing cam lock.

5. Remove bearing housing capscrews. Pull housing and

bearing from shaft using capscrews in jackscrew holes.

6. Remove flush tube and capscrews from seal housing.

7. Remove outer two screws in shaft sleeve drive collar.

WARNING: Excessive Pressure Hazard

Make certain internal pressure is relieved before continuing. Failure to follow these instructions could result in

serious personal injury or death, or property damage.

8

8. Remove stuffing box bracket capscrews and pull entire

stuffing box assembly from the volute coverplate.

9. Remove the seal cap and seal assembly from the stuffing

box.

10. If replacing the shaft sleeve, remove the sleeve and

replace. Inspect all parts to be re-used and replace if damaged.

11. Lubricate stationary O-ring with silicone grease or soapy

water. DO NOT USE PETROLEUM LUBRICANT! Insert

O-ring toward impeller. Place one seal carbon into the bottom of the stuffing box and carefully install in position.

12. Lubricate the O-rings of the rotating seal member and

position on sleeve against the seal carbon.

Page 9

13. Install the second seal carbon. Lubricate and insert

second stationary O-ring toward cap. Replace seal cap.

14. Apply anti-seize compound only to the shaft that will be

under the sleeve.

15. Place the stuffing box gasket onto the bracket and install

assembly into the coverplate. Position sleeve drive collar

outer holes over undercut in shaft and tighten set screws.

Install the bearing housings.

IMPORTANT! When working on the seal on the noncoupler end, it is necessary to force the pump shaft back

from the coupler end as far as possible and to hold it in

this position while installing and locking the bearing to the

shaft. Also, when replacing both seals, the seal on the

non-coupler end of the pump should be installed first.

16. Clean and regrease the bearings and insert into bearing

housings. Push the pump shaft back from the motor end as

far as possible, using a lever if necessary. Hold the shaft in

this position. On the outboard bearing tap inner race until it

is properly positioned against the shaft shoulder. Install

and lock the cam lock into position. If the shaft and bearing are properly positioned, the cam lock set scr

in the center of the shaft undercut. Release the shaft.

Install the outboard bearing cap. Install the inboard bearing by tapping the inner race until it contacts the shaft

shoulder, lock the bearing in place with the cam lock.

Install the inboard bearing cap.

17. Replace drain plug.

18. Install coupler and align per instructions located in the

section titled “Coupler Alignment.”

19. Install coupler guard. Refer to separate instructions titled

“Hex Coupler Guard Removal/Installation.”

20. Open isolation valves and check pumps for leaks. If not

leaking, return pump to service.

NOTE: Flushing pressure must be the suction pressure on

the pump plus 10 PSI.

SPECIAL INSTRUCTIONS FOR PUMPS (VSCS, VSC-S & VSCS-D)

10 x 12 x 17, 12 x 14 x 121/2 and 12 x 14 x 171/2

TO REPLACE THE SEAL OR SHAFT SLEEVE:

WARNING: Excessive Pressure Hazard

Make certain internal pressure is relieved before continuing. Failure to follow these instructions could result in

serious personal injury or death, or property damage.

ew will fall

4. Remove flush tube and tube fitting from seal housing

inside bearing bracket.

5. Remove bearing bracket capscrews and bearing cover

capscrews inside the bracket.

6. Remove bearing bracket using capscrews in jackscrew

holes. DO NOT PULL BEARING COVER.

7. Remove bearing locknut by straightening tab of lockwasher

from notch in locknut and turning locknut counterclockwise.

8. Remove lockwasher and pull bearing from shaft.

9. Remove retainer ring from shaft, except on 12 x 14 x 171/2.

10. Now remove bearing cover.

11. Remove capscrews from seal housing. Remove outer two

set screws from shaft sleeve drive collar and loosen two

inner set screws one turn.

12. Remove the sleeve and seal assembly from the shaft by

pulling on the seal housing.

13. To assemble the pump, clean shaft sleeve and pump shaft.

Replace shaft sleeve if pitted or scored. If replacing the

seal, remove shaft O-ring and replace (included in seal kit).

NOTE: If installing -D seals refer to steps 10-12 on -D

instructions then skip to 17.

14. Lubricate O-ring on stationary seal seat (carbon) with silicone grease or soapy water. DO NOT USE PETROLEUM

LUBRICANT! Position in seal housing. Place shaft sleeve

in drive collar and tighten the two dog point set screws in

holes provided. Set shaft sleeve and drive collar assembly

on end and place assembly aid spacer around shaft

sleeve. Position against drive collar.

15. Place seal housing with carbon over the end of the sleeve

against assembly aid spacer.

16. Lubricate O-ring in rotating seal assembly with silicone

grease or soapy water. DO NOT USE PETROLEUM

LUBRICANT! Slip rotating seal assembly on the end of the

sleeve and place against carbon.

17. Compress rotating seal assembly to a 1/4" space between

the seal parts that house the compression springs. Tighten

set screws.

18. Apply anti-seize compound only to the area of the shaft

that will be under the sleeve. Place seal housing gasket in

position and slide complete assembly over pump shaft.

19. Slide bearing cover on shaft. Replace snap rings (if used)

clean and regrease bearings. Place on shaft. Lock in place

with lockwasher and locknut. Install bearing bracket and

bearing cover.

20. Push on the drive collar until the seal housing is against

the coverplate. Bolt into place.

21. Tighten down collar set screws in undercut of shaft.

Remove assembly aid spacer and connect flush tubing to

seal housing.

22. Replace drain plug.

23. Install coupler and align, following the instructions located in

the section titled “Coupler Alignment.”

24. Install coupler guard. Refer to separate instructions

titled “Hex Coupler Guard Removal/Installation.”

25. Open isolation valves and check pump for leaks. If not

leaking, return pump to service.

9

Page 10

SPECIAL INSTRUCTIONS FOR PUMPS (VSCS-S & VSCS-D) 8 x 10 x 17

TO REPLACE THE SEAL OR SHAFT SLEEVE:

4. Remove bearing cover and release bearing cam lock.

5. Remove bearing housing capscrews. Pull housing and bearing from pump shaft using capscrews in jackscrew holes.

WARNING: Excessive Pressure Hazard

Make certain internal pressure is relieved before continuing. Failur

serious personal injury or death, or property damage.

6. Remove seal plate capscrews and flush tube.

7. Remove outer two screws in shaft sleeve drive collar and

loosen two inner set screws one turn.

8. Pull entire sleeve and seal assembly from shaft.

9. To assemble the pump, clean shaft sleeve and pump shaft.

Replacer shaft sleeve if pitted or scored. If replacing the

seal, remove shaft O-ring and replace (included in seal kit).

NOTE: If installing -D seals refer to steps 10-12 on -D

instructions, then skip to step 15.

10. Lubricate O-ring on stationary seal seat (carbon) with silicone grease or soapy water. DO NOT USE PETROLEUM

LUBRICANT! Position in seal housing.

11. Place shaft sleeve in drive collar and tighten the two dog

point set screws in holes provided.

12. Set shaft sleeve and drive collar assembly on end and

place assembly aid spacer around shaft sleeve. Position

against drive collar.

13. Place seal housing with carbon over the end of the sleeve

against assembly aid spacer.

14. Lubricate O-ring in rotating seal assembly with silicone

grease or soapy water. DO NOT USE PETROLEUM

LUBRICANT! Slip rotating seal assembly on the end of the

sleeve and place against carbon.

e to follow these instructions could result in

15. Compress rotating seal assembly to a 1/4" space between

the seal parts that house the compression springs. Tighten

set screws.

16. Apply anti-seize compound only to the area of the shaft

that will be under the sleeve. Place seal housing gasket in

position and slide complete assembly over pump shaft.

IMPORTANT! When working on the seal on the noncoupler end, it is necessary to force the pump shaft back

from the coupler end as far as possible and to hold it in

this position while installing and locking the bearing to the

shaft. Also, when replacing both seals, the seal on the

non-coupler end of the pump should be installed first.

17. Install the bearing housings. Clean and regrease the bearings and insert into bearing housings. Push the pump shaft

back from the motor end as far as possible, using a lever if

necessary. Hold the shaft in this position. On the outboard

bearing tap inner race until it is properly positioned against

the shaft shoulder. Install and lock the cam lock into position. If the shaft and bearing are properly positioned, the

cam lock set screw will fall in the center of the shaft undercut. Release the shaft. Install the outboard bearing cap.

Install the inboard bearing by tapping the inner race until it

contacts the shaft shoulder, lock the bearing in place with

the cam lock. Install the inboard bearing cap.

18. Push on the drive collar until the seal housing is against

the coverplate, bolt into place.

19. Tighten down collar set screws in undercut of shaft.

Remove assembly aid spacer and connect flush tubing to

seal housing.

20. Replace drain plug.

21. Install coupler and align, following the instructions located in

the section titled “Coupler Alignment.”

22. Install coupler guard. Refer to separate instructions titled

“Hex Coupler Guard Removal/Installation.”

23. Open isolation valves and check pump for leaks. If not

leaking, return pump to service.

SERVICE INSTRUCTIONS FOR PUMPS WITH FLUSH PACKING (VSC-PF, VSCS-PF)

(See special instructions for pumps 10 x 12 x 17, 12 x 14 x 121/2 and 8 x 10 x 17)

TO REPLACE THE P

4. Remove bearing cover and release cam lock.

5. Remove bearing housing capscrews. Pull housing and bearing from pump shaft using capscrews in jackscrew holes.

WARNING: Excessive Pressure Hazard

Make certain internal pressure is relieved before continuing. Failure to follow these instructions could result in

serious personal injury or death, or property damage.

6. Remove flush tube and capscrews from the stuffing box.

7. Remove packing gland and packing rings from stuffing box.

8. Loosen outer two set screws in shaft sleeve drive collar

and pull entire shaft sleeve with stuffing box from the

pump shaft.

9. To assemble, clean out stuffing box thoroughly and

assemble to volute coverplate.

10

ACKING OR SHAFT SLEEVE:

10.

Apply anti-seize compound only to the area of the shaft

that will be under the sleeve. Install shaft sleeve on shaft.

Position sleeve drive collar outer holes over undercut in

shaft and tighten set screws. If sleeve is pitted or scored,

the sleeve should be replaced.

11. Insert two packing rings into the stuffing box, staggering

the joints 90°.

12. Install the lantern ring and then the other two packing

rings, staggering them 90°.

13. Install, but do not tighten packing gland.

IMPORTANT! When working on the packing on the non-

coupler end, it is necessary to force the pump shaft back

from the coupler end as far as possible and to hold it in

this position while installing and locking the bearing to the

shaft. Also, when replacing both packings, the packing on

the non-coupler end of the pump should be installed first.

Page 11

14. Install the bearing housings. Clean and regr

ease the bearings and insert into bearing housings. Push the pump shaft

back from the motor end as far as possible, using a lever if

necessary. Hold the shaft in this position. On the outboard

bearing tap inner race until it is properly positioned against

the shaft shoulder. Install and lock the cam lock into position. If the shaft and bearing are properly positioned, the

cam lock set screw will fall in the center of the shaft undercut. Release the shaft. Install the outboard bearing cap.

Install the inboard bearing by tapping the inner race until it

contacts the shaft shoulder, lock the bearing in place with

the cam lock. Install the inboard bearing cap.

15. Connect flush tubing to seal housing.

16. Replace drain plug.

17. Install coupler and align, following instructions located in

the section titled “Coupler Alignment.”

18. Install coupler guard. Refer to separate instructions titled

“Hex Coupler Guard Removal/Installation.”

19. Open isolation valves and check pumps for leaks. If not

leaking, return pump to service using the -PF Start-up

Instructions.

SPECIAL INSTRUCTIONS FOR PUMPS (VSCS-PF) 10 x 12 x 17 and 12 x 14 x 12

TO REPLACE THE PACKING:

WARNING: Excessive Pressure Hazard

Make certain internal pressure is relieved before continuing. Failure to follow these instructions could result in

serious personal injury or death, or property damage.

4. Remove flush tube and tube fitting from inside bearing

bracket.

5. Remove bearing bracket capscrews and bearing cover

capscrews inside the bracket.

6. Remove bearing bracket using capscrews in jackscrew

holes. DO NOT PULL BEARING COVER.

7. Remove bearing locknut by straightening tab of lockwasher from notch in locknut and turning locknut counterclockwise.

8. Remove lockwasher and pull bearing from shaft.

9. Remove retainer ring from shaft.

10. Remove bearing cover.

11. Remove packing gland capscrews and packing gland.

12. Using a packing puller, remove packing rings and lantern

ring.

13. Remove and replace the shaft sleeve. Apply anti-seize

compound only to the area of the shaft that will be under

the sleeve. Install new sleeve on shaft. Position sleeve

drive collar outer holes over undercut in shaft and tighten

set screws.

14. Insert two packing rings, staggering the joints 90°.

15. Install the lantern ring and then the other two packing

rings, staggering them 90°.

16. Install, but do not tighten the packing gland.

17. Slide bearing cover on shaft. Replace snap rings (if used).

Clean and regrease bearings. Place on shaft, lock in place,

with lockwasher and locknut. Install bearing bracket and

bearing cover.

18. Replace drain plug.

19. Install coupler and align, following the instructions located in

the section titled “Coupler Alignment.”

20. Install coupler guard. Refer to separate instructions titled

“Hex Coupler Guard Removal/Installation.”

21. Open isolation valves and check pump for leaks. If not

leaking, return pump to service, using the -PF Start-up

Instructions.

1

/2

SPECIAL INSTRUCTIONS FOR PUMPS (VSCS-PF) 8 x 10 x 17

TO REPLACE THE PACKING:

WARNING: Excessive Pressure Hazard

Make certain internal pressure is relieved before continuing. Failure to follow these instructions could result in

serious personal injury or death, or property damage.

4. Remove flush tube and tube fitting from inside bearing

bracket.

5. Remove bearing cover and release bearing cam lock.

6. Remove capscrews that hold the bearing housing to the

volute coverplate and release, using capscrews in jackscrew holes.

7. Pull housing and bearing from shaft.

8. Remove packing gland capscrews and packing gland.

9. Using a packing puller, remove packing rings and lantern

ring.

10. Remove and replace the shaft sleeve. Apply anti-seize

11. Insert two packing rings, staggering the joints 90°.

12. Install the lantern ring and then the other two packing

13. Install, but do not tighten the packing gland.

compound only to the area of the shaft that will be under

the sleeve. Install new sleeve on shaft. Position sleeve

drive collar outer holes over undercut in shaft and tighten

set screws.

rings, staggering them 90°.

IMPORTANT! When working on the packing on the noncoupler end, it is necessary to force the pump shaft back

from the coupler end as far as possible and to hold it in

this position while installing and locking the bearing to the

shaft. Also, when replacing both packings, the packing on

the non-coupler end of the pump should be installed first.

11

Page 12

14. Install the bearing housings. Clean and regr

ings and insert into bearing housings. Push the pump shaft

back from the motor end as far as possible, using a lever if

necessary. Hold the shaft in this position. On the outboard

bearing tap inner race until it is properly positioned against

the shaft shoulder. Install and lock the cam lock into position. If the shaft and bearing are properly positioned, the

cam lock set screw will fall in the center of the shaft undercut. Release the shaft. Install the outboard bearing cap.

Install the inboard bearing by tapping the inner race until it

contacts the shaft shoulder, lock the bearing in place with

the cam lock. Install the inboard bearing cap.

ease the bear-

15. Connect flush tubing to seal housing.

16. Replace drain plug.

17. Install coupler and align, following the instructions located in

the section titled “Coupler Alignment.”

18. Install coupler guard. Refer to separate instructions titled

“Hex Coupler Guard Removal/Installation.”

19. Open isolation valves and check pump for leaks. If not

leaking, return pump to service, using the -PF Start-up

Instructions.

-PF START-UP INSTRUCTIONS

Prior to start-up, back off packing glands or screws until glands

are loose. Re-tighten with fingers until glands are just snug

against the first packing ring. WHEN PUMP IS STARTED,

WATER MAY RUN FREELY FROM PACKING. This is normal

and should be allowed to continue for a period of time before

further tightening the glands. Tighten the gland bolts uniformly,

one flat at a time.

An adequate leakage rate is NOT ONE SINGLE VALVE FOR

ALL pumps and installations, but is the amount required to provide adequate cooling and lubrication. The required leakage

will be largely influenced by operating pressures, fluid temperature, shaft speed, etc.

NOTE:

For fluid temperatures in the range of 32° to 190°F average

leakage rates of 60 to 80 drops per minute are recommended.

However, each individual pump and installation will have

unique operating conditions that will result in broadly variable

leakage rate requirements.

At fluid operating temperatures near the upper limit of 190°F,

the maximum temperature rise of the leakage is particularly

important. A packed pump should never operate with steam

forming at the gland. This necessarily limits the temperature

rise to a maximum of about 20°F. If the formation of steam persists at higher leakage rates, cooling water must be provided

by means of an external supply, or a heat exchanger used to

cool the by-pass flush.

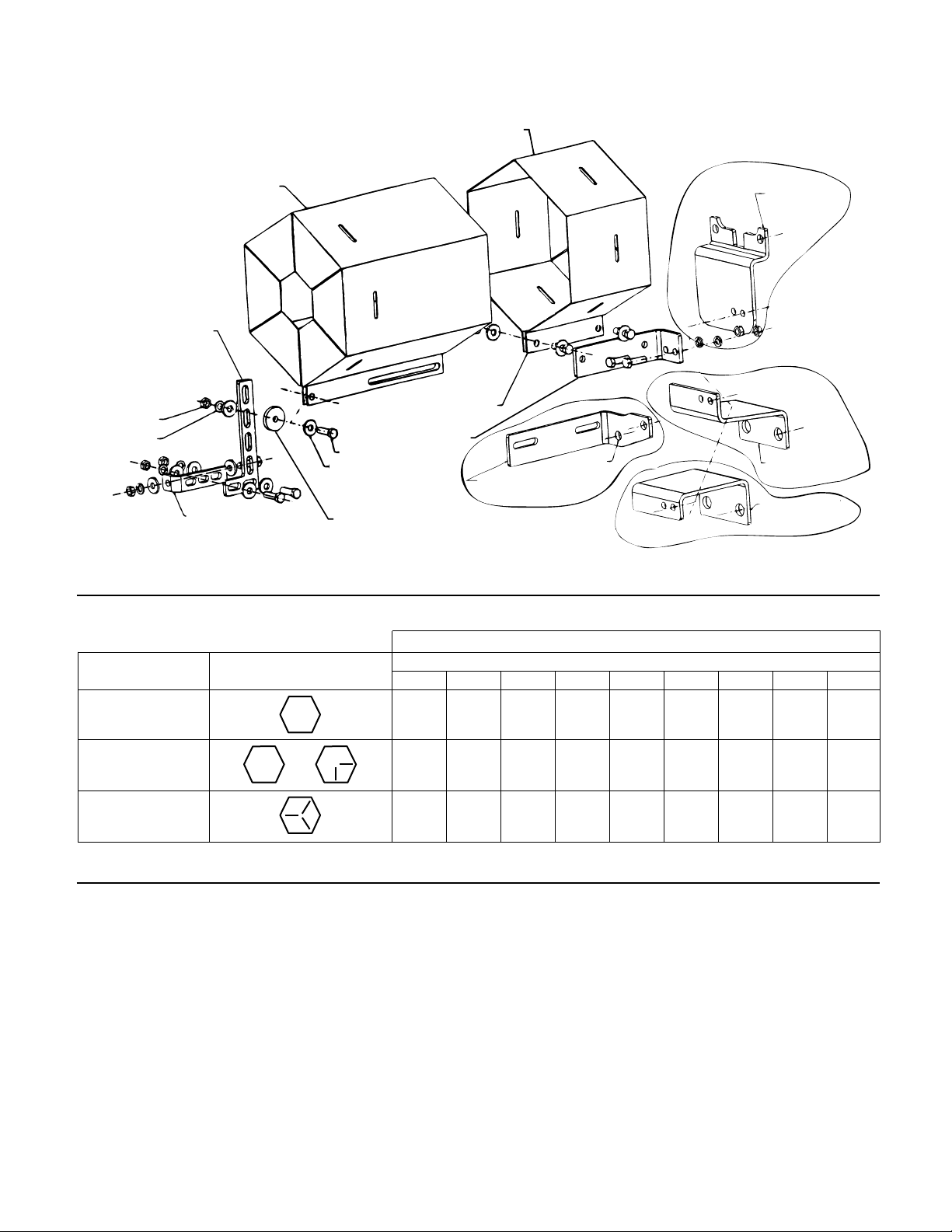

HEX COUPLER GUARD REMOVAL/INSTALLATION

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

NOTE: Do not spread the inner and outer guards more than

necessary for guard r

guards may alter their fit and appearance.

REMOVAL

1. Remove the two capscrews that hold the outer (motor side)

coupler guard to the support bracket(s).

2. Spread the outer guard and pull it off the inner guard.

3. Remove the capscrew that holds the inner guard to the support bracket.

4. Spread the inner guard and pull it over the coupler.

INSTALLATION

1. Check coupler alignment before proceeding. Correct if

necessary.

2. Spread the inner guard and place it over the coupler.

emoval or installation. Over spreading the

3. With the inner guard straddling the support bracket, install a

capscrew through the hole (or slot) in the support bracket

and guard located closest to the pump. Do not tighten the

capscrew.

4. Spread the outer guard and place it over the inner guard.

5. Install the outer guard capscrews by following the step stated

below which pertains to your particular pump:

a) For pumps with a motor saddle support bracket: Ensure

b) For pumps without a motor saddle support bracket: Insert

6. Position the outer guard so it is centered around the shaft,

and so that there is less than a 1/4" of the motor shaft

exposed. On guards that utilize a slotted support bracket,

the inner guard will have to be positioned so there is only a

1

/4" of the pump shaft exposed.

7. Holding the guard in this position, tighten the three

capscrews.

the outer guard is straddling the support arm, and install

but do not tighten the two remaining capscrews.

the spacer washer between the holes located closest to

the motor in the outer guard, and install but do not tighten

the two remaining capscrews.

12

Page 13

PUMP

BRACKET STYLE #2

ATTACH TO VSC/VSCS

COVERPLATE

ATTACH TO

VSC/VSCS

COVERPLATE

PUMP BRACKET STYLE #3

ATTACH TO

VSC/VSCS COVERPLATE

PUMP BRACKET STYLE #4

INNER GUARD

OUTER GUARD

SUPPORT ARM.

POSITION THE ARM BETWEEN

THE HOLES IN THE OUTER

GUARD AND HOLES IN THE

SADDLE BRACKET.

GUARD SUPPORT BRACKET

CAPSCREW

FLAT WASHER

THE GUARD SUPPORT

BRACKET ATTACHES INSIDE

HERE INLINE WITH CAPSCREWS

MOTOR SADDLE BRACKET

ATTACH TO MOTOR SADDLE

SPACER USED WITH COUPLER

GUARD KIT #2 IN PLACE OF

MOTOR SADDLE BRACKET AND

SUPPORT ARM

LOCKWASHER

NUT

PUMP BRACKET STYLE #1

BRACKET

SUPPORT ATTACH

TO BEARING

HOUSING

HEX GUARD EXPLODED VIEW FOR

TYPICAL VSC/VSCS PUMP INSTALLATION

CAPSCREW HEAD

TYPE MARKING

SAE Grade 2 6 13 25 38 60 120 190 210 300

Brass

Stainless Steel or 4 10 17 27 42 83 130 200 300

SAE Grade 5 10 20 35 60 90 180 325 525 800

DEALER SERVICING

If trouble occurs that cannot be rectified contact your local

B&G representative, He will need the following information in

order to give you assistance.

1. Complete nameplate data of pump and motor.

2. Suction and discharge pipe pressure gauge readings.

3. Ampere draw of the motor.

4. A sketch of the pump hook-up and piping.

1

/4

5

/16

CAPSCREW TORQUE (FOOT-POUND)

CAPSCREW DIAMETER

3

/8

7

/16

1

/2

5

/8

3

/4

7

/8 1

13

Page 14

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,000 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/bellgossett

Bell & Gossett is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. P81630E February 2012

Loading...

Loading...