Page 1

INSTRUCTION MANUAL

P2000516

Marlow Series

Impeller Static Balancing

INSTRUCTIONS

Page 2

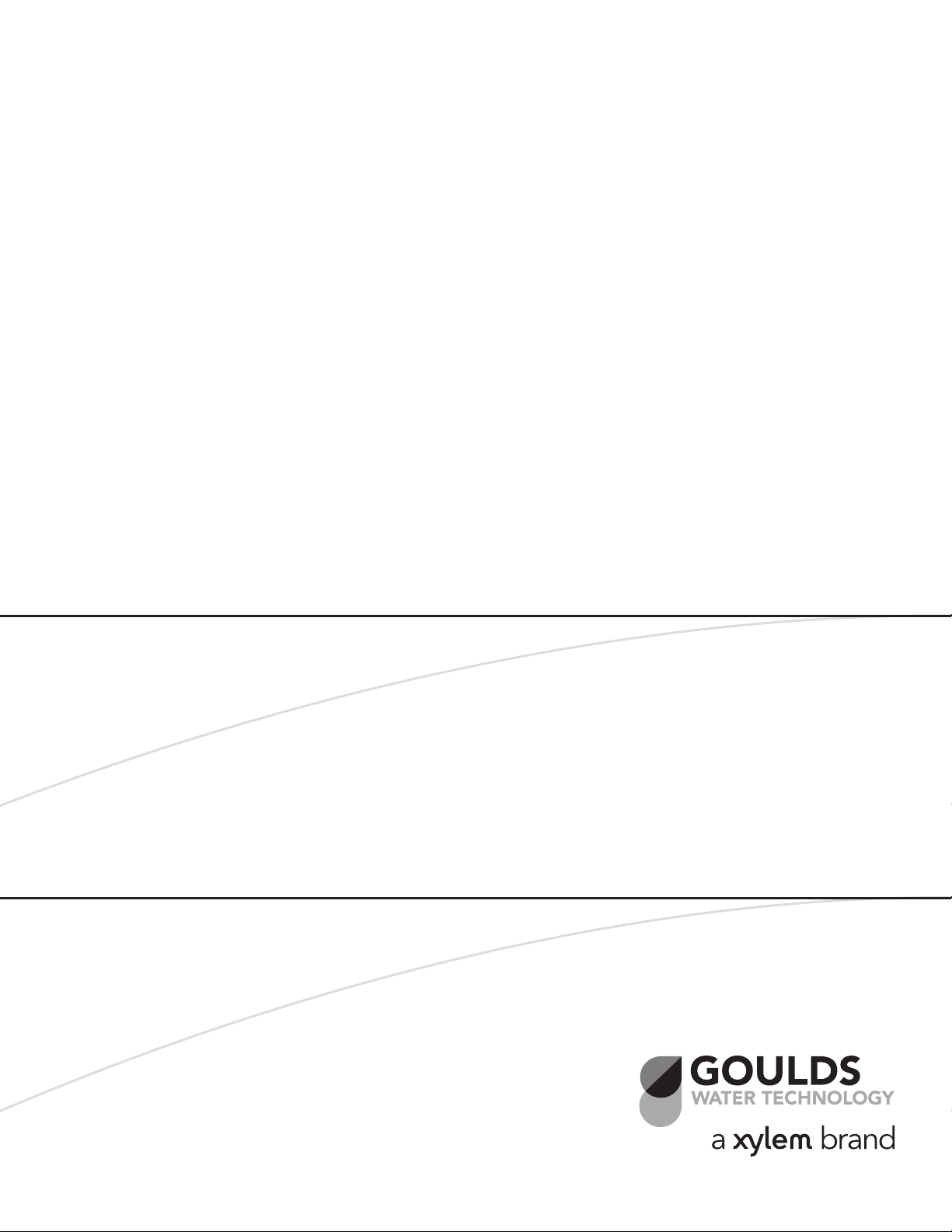

FIGURE 1

FIGURE 2

STEP 1 — When cutting the impeller O.D. it is

suggested that the tail stock of the lathe be utilized

and act as a stablizer.

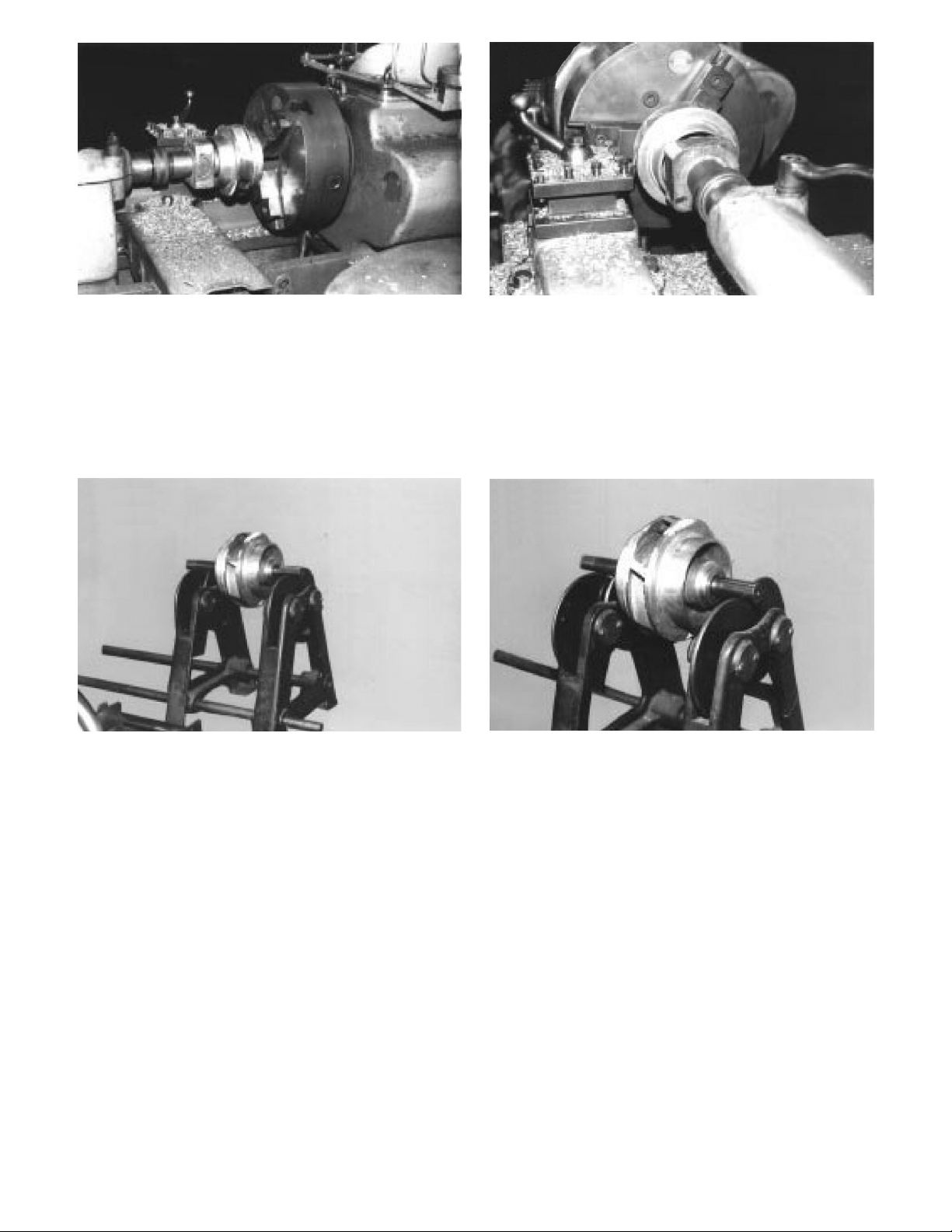

FIGURE 3

STEP 2 — After impeller has been cut to size, make

certain that all burrs are removed. Insert mandril

into impeller and place on balancing ways. Spin the

impeller lightly and allow to turn until it stops rocking.

For holding the impeller in the chuck. Note the use of

a at block of wood between impeller and blunt tail

stock.

FIGURE 4

Make a chalk mark at the bottom center of the

impeller. This is the unbalanced point.

2

Page 3

FIGURE 5

STEP 3 — Place impeller in chunk on drill table. Align

at mill cutting tool at center of imbalance point on

the impeller wall. If the unbalanced condition is quite

pronounced make the rst cut about 1/64" deep and

2" to the left and right of the center point.

FIGURE 6

This is done by moving the handle attached to drill

table back and forth. A continuous balance check

should be made during this operation. The impeller is

properly balanced when it remains stationary on the

balance ways on any point of its 360º periphery.

3

Page 4

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.gouldswatertechnology.com

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2013 Xylem Inc. P2000516 March 1979

Loading...

Loading...