Page 1

Oxi 3210

15.11.2008

08:37

Menu

O

2

7.92

25.0

mg/l

[S

a

l]

Operating manual

ba75795e02 03/2009

Dissolved oxygen (D.O.) meter

Page 2

Oxi 3210

Accuracy when

going to press

The use of advanced technology and the high quality standard of our

instruments are the result of a continuous development. This may result in

differences between this operating manual and your meter. Also, we cannot

guarantee that there are absolutely no errors in this manual. Therefore, we

are sure you will understand that we cannot accept any legal claims resulting

from the data, figures or descriptions.

Copyright

© Weilheim 2009, WTW GmbH

Reproduction in whole - or even in part - is prohibited without the express

written permission of WTW GmbH, Weilheim.

Printed in Germany.

ba75795e02 03/2009

Page 3

Oxi 3210 Contents

Oxi 3210 - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Socket field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 10

3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Inserting the batteries. . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Switching on the meter. . . . . . . . . . . . . . . . . . . . 14

3.2.3 Setting the date and time . . . . . . . . . . . . . . . . . . 14

4 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Switching on the meter . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 General operating principles . . . . . . . . . . . . . . . . . . . . . . 16

4.2.1 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.3 Example 1 on navigation: Setting the language. 19

4.2.4 Example 2 on navigation: Setting the date and

time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 Sensor-independent settings . . . . . . . . . . . . . . . . . . . . . 24

4.3.1 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.2 Data storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3.3 Automatic Stability control . . . . . . . . . . . . . . . . . 25

4.4 Dissolved oxygen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4.1 General information . . . . . . . . . . . . . . . . . . . . . . 26

4.4.2 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4.3 Settings for D.O. sensors

(menu or measurement and calibration settings) 29

4.4.4 D.O. calibration . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.4.5 Displaying calibration records . . . . . . . . . . . . . . 33

4.5 Data storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.5.1 Manual storage . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.5.2 Displaying and editing the measurement data

storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.3 Erasing the measurement data storage . . . . . . . 37

ba75795d02 03/2009

3

Page 4

Contents Oxi 3210

4.6 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.6.1 Resetting the measurement settings . . . . . . . . . 37

4.6.2 Resetting the system settings. . . . . . . . . . . . . . . 38

5 Maintenance, cleaning, disposal . . . . . . . . . . . . . . . . . 39

5.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.1 Replacing the batteries. . . . . . . . . . . . . . . . . . . . 39

5.2 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3 Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2 Measuring ranges, resolution, accuracy . . . . . . . . . . . . . 44

8 Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4

ba75795d02 03/2009

Page 5

Oxi 3210 Overview

15.11.2008

08:37

Menu

O

2

7.92

25.0

mg/l

1

2

3

[S

a

l]

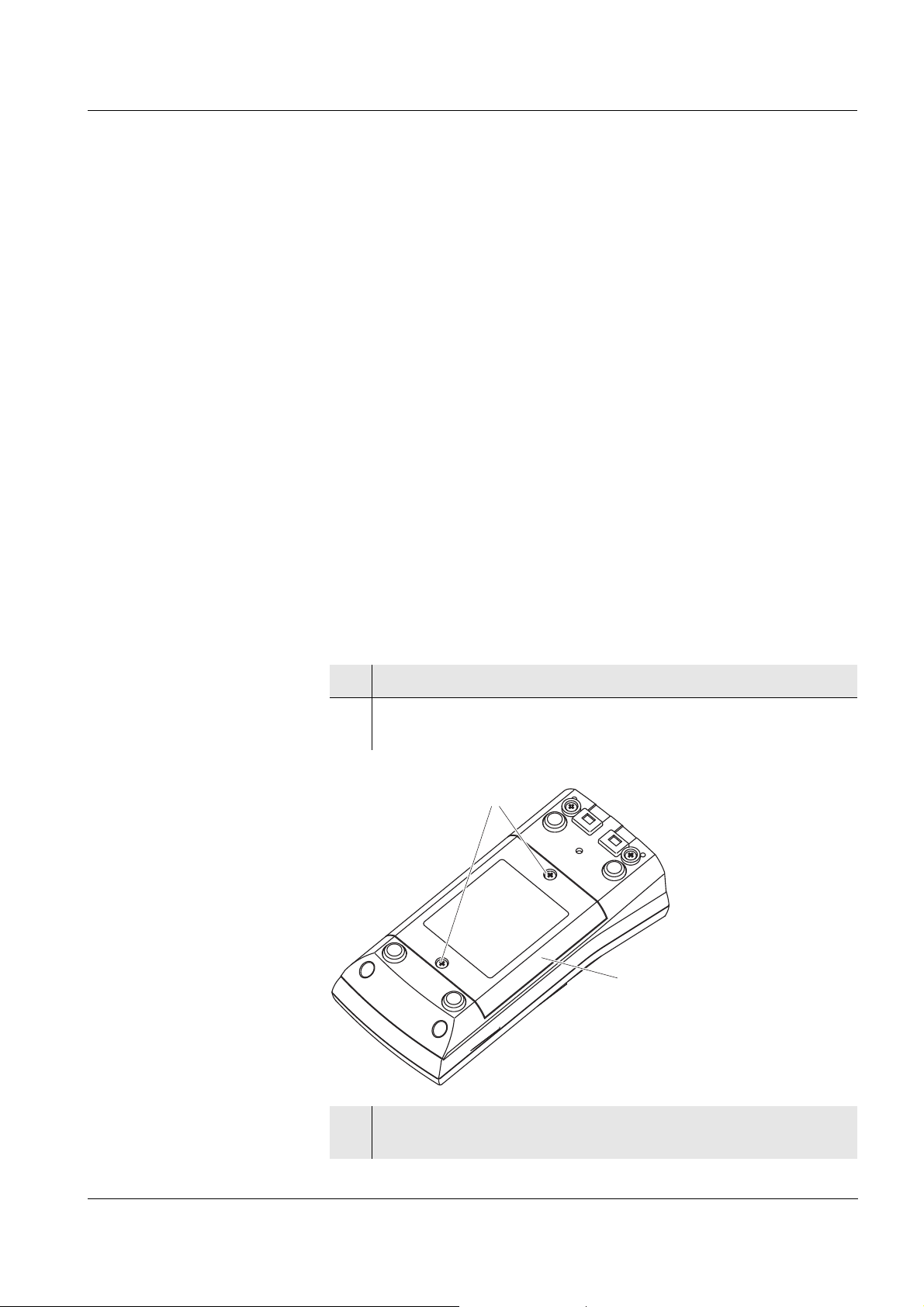

1Overview

The Oxi 3210 compact precision dissolved oxygen (D.O.) meter

enables you to perform D.O. measurements quickly and reliably.

The Oxi 3210 provides the maximum degree of operating comfort,

reliability and measuring certainty for all applications.

The proven OxiCal calibration procedure supports you in your work

with the D.O. meter.

ba75795e02 03/2009

1 Keypad

2 Display

3 Socket field

5

Page 6

Overview Oxi 3210

ENTER

M

Oxi 3210

F1

F2

AR

CAL

STO

RCL

F1

CAL

STO

RCL

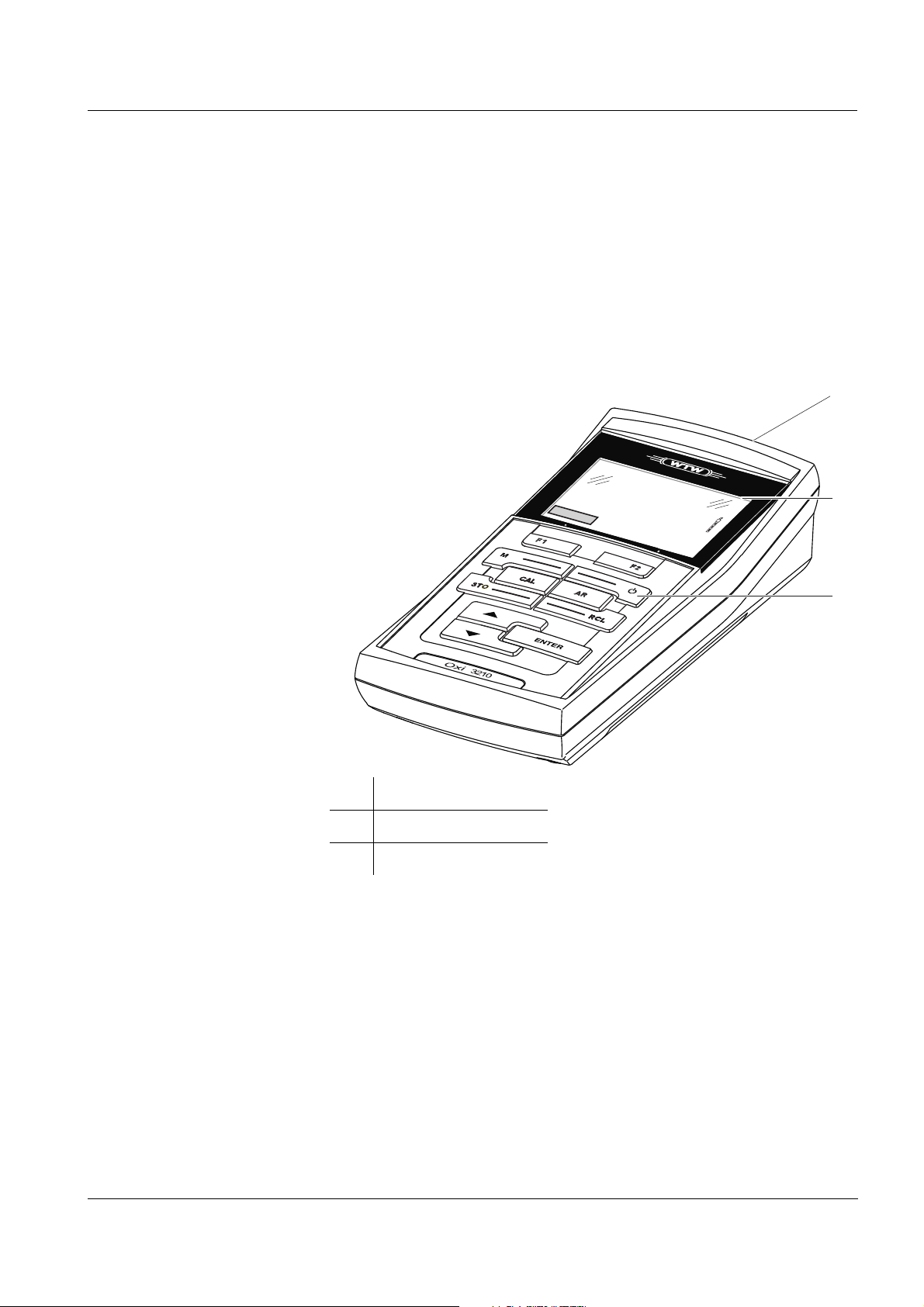

1.1 Keypad

In this operating manual, keys are indicated by brackets <..> .

The key symbol (e.g. <ENTER>) generally indicates a short keystroke

(under 2 sec) in this operating manual. A long keystroke (approx.

2 sec) is indicated by the underscore behind the key symbol (e.g.

<F1>:

<F1

_>:

<ENTER

_>).

Softkey providing situation dependent functions, e.g.:

<F1>/[Menü]: Opens the menu for measurement settings

<F1

_>/[Menü]: Opens the menu for system settings

<On/Off>: Switches the meter on or off

<M>: Selects the measured parameter

<CAL>:

<CAL

_>:

<STO>:

Calls up the calibration procedure

Displays the calibration data

Saves a measured value manually

<STO_>

<RCL>:

Displays the manually stored measured values

<RCL_>

<▲>: Increments values, scrolls

6

<▼>: Decrements values, scrolls

ba75795e02 03/2009

Page 7

Oxi 3210 Overview

ENTER

AR

HOLD AR

25.0

7.92

°C

3

2

4

5

6

7

1

O

2

mg/l

Menü

22.09.2008

08:00

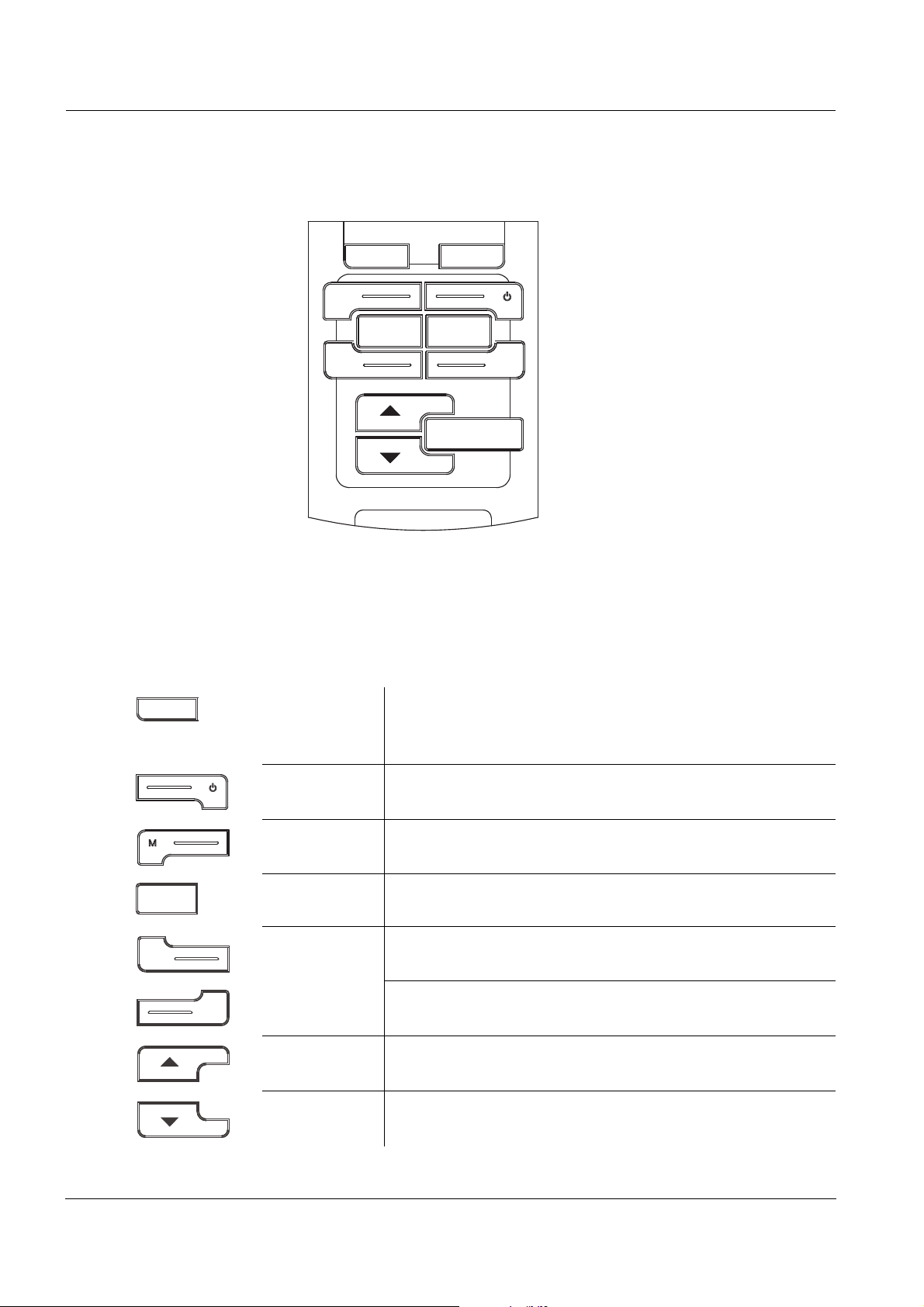

<ENTER>:

<ENTER

<AR> Freezes the measured value (HOLD function)

_>:

Opens the menu for measurement settings / confirms

entries

Opens the menu for system settings

Switches the AutoRead measurement on or off

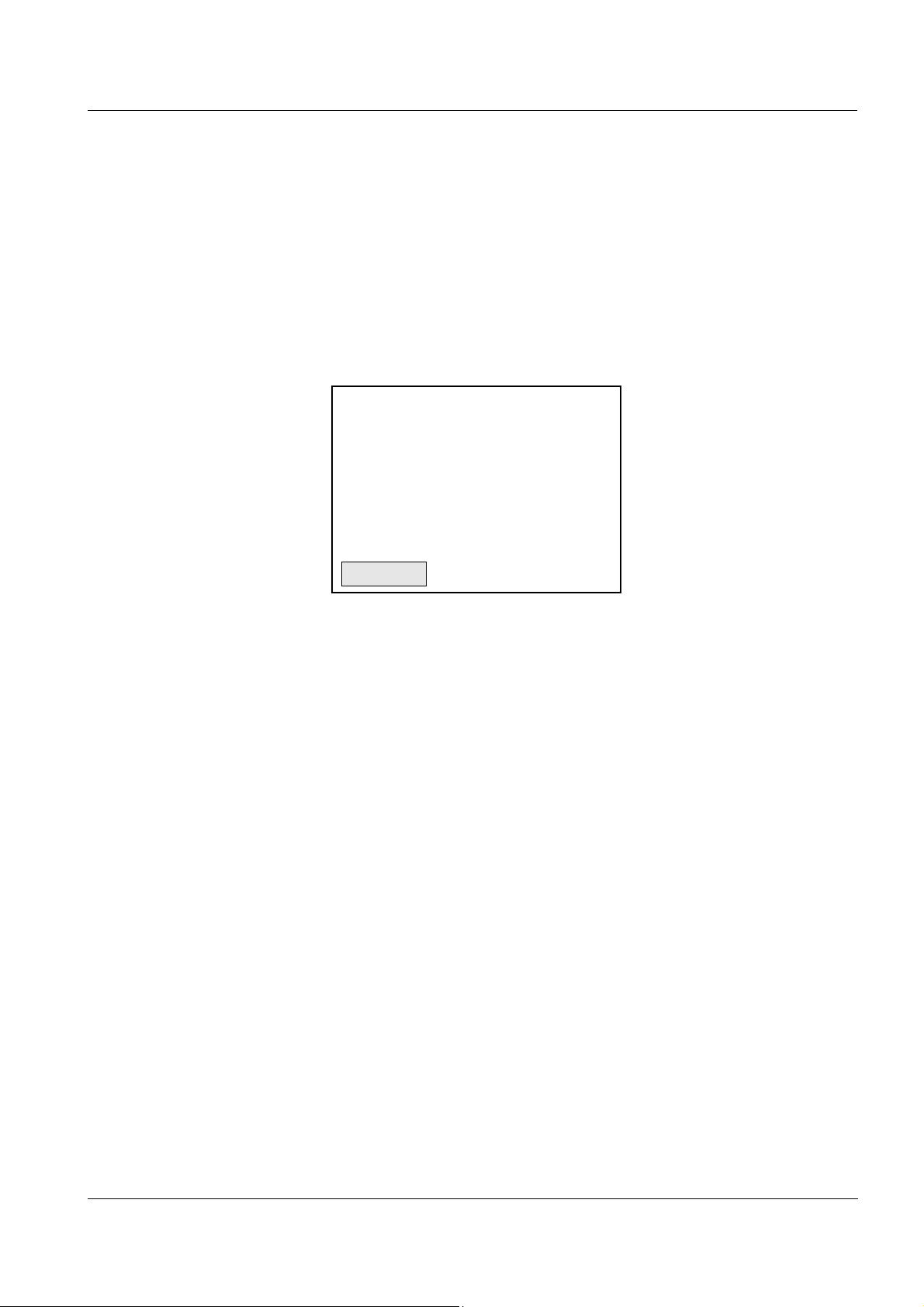

1.2 Display

1 Status information

2 Measured value (with unit)

3 Measured parameter

4 Sensor symbol (calibration evaluation, calibration

interval)

5 Measured temperature (with unit)

6 Status line

7 Softkeys and date + time

Function display

indicators

Error An error occurred during calibration

AR Stability control (AutoRead) is active

HOLD Measured value is frozen (<AR> key)

7

ba75795e02 03/2009

Page 8

Overview Oxi 3210

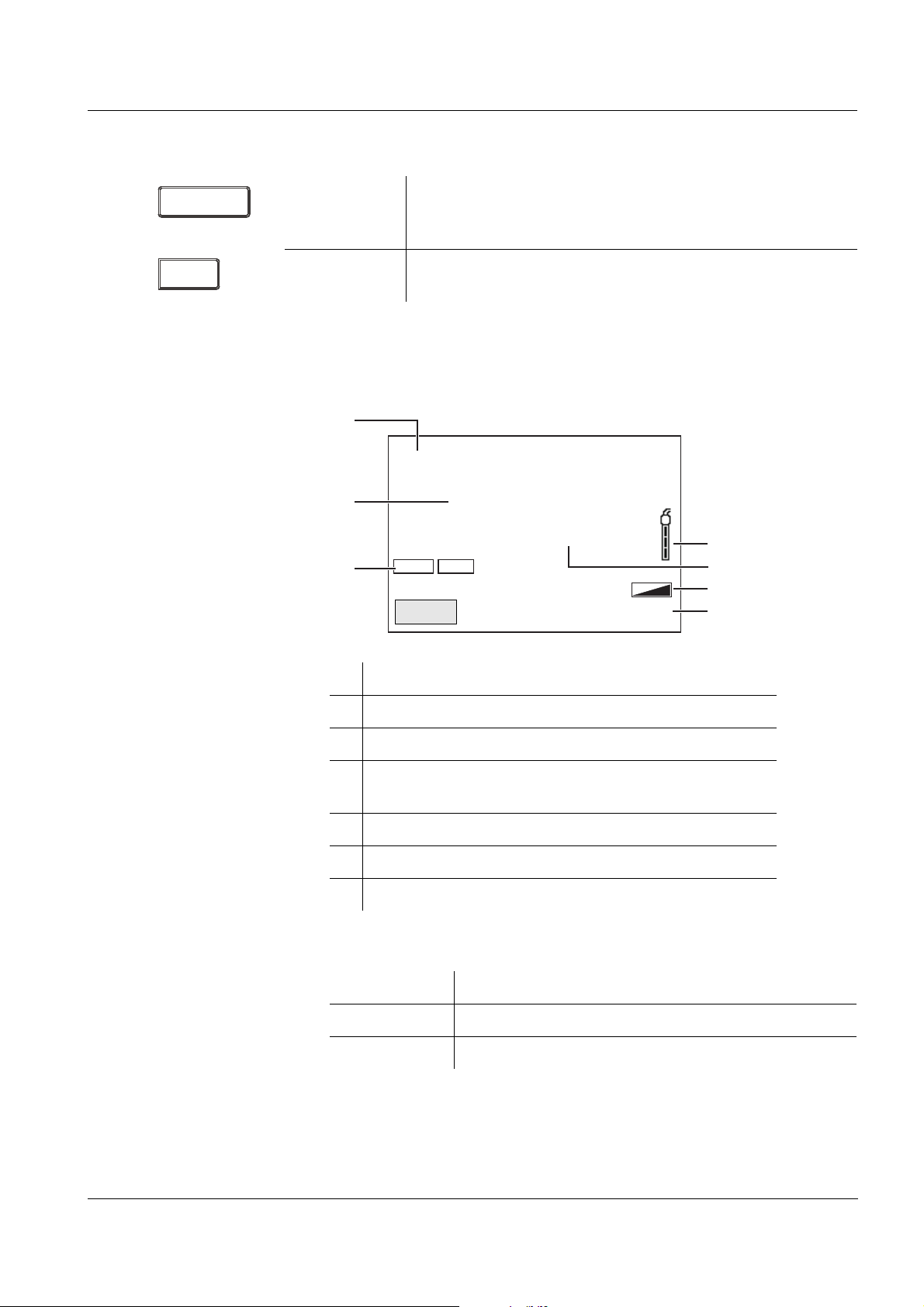

2

1

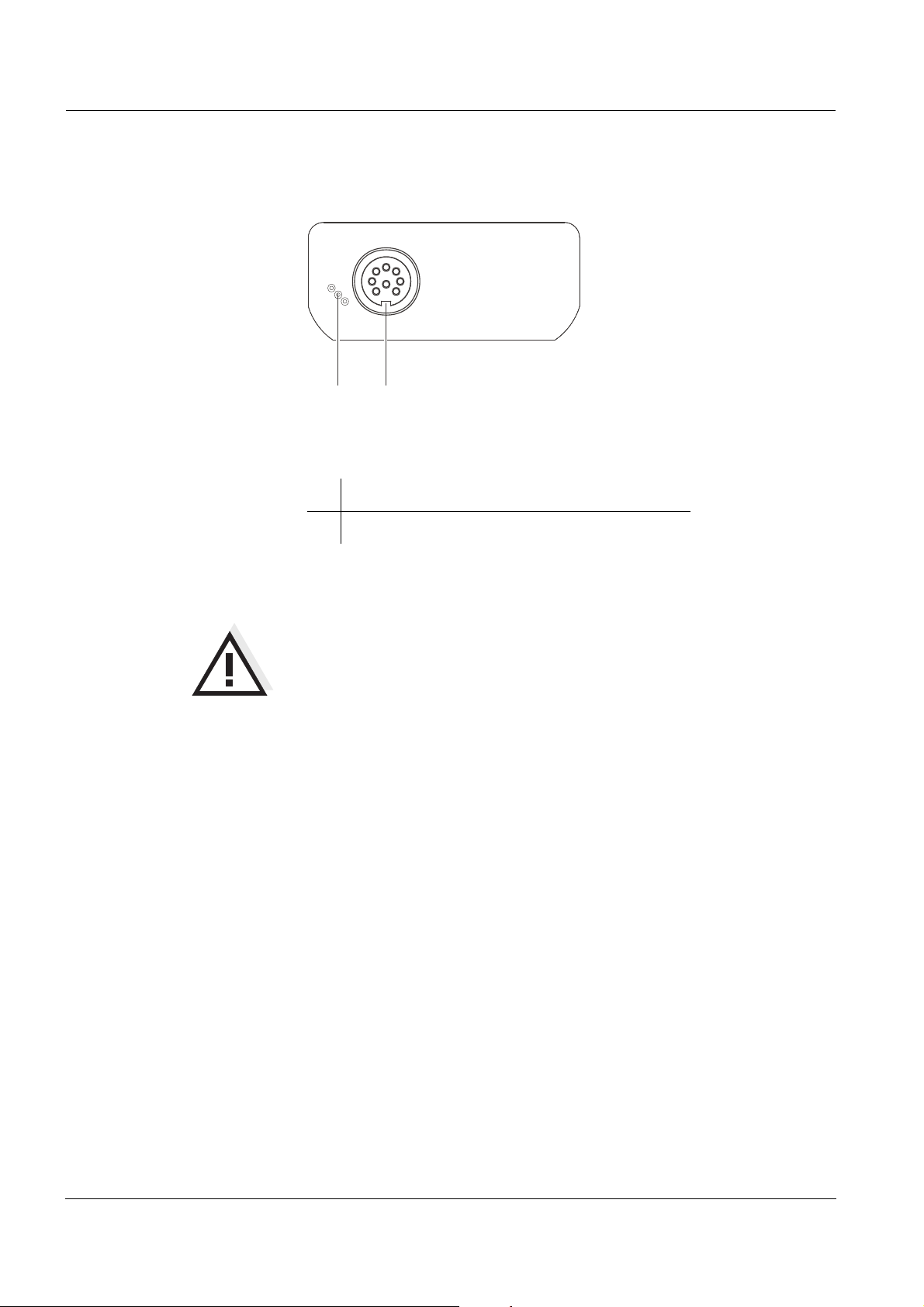

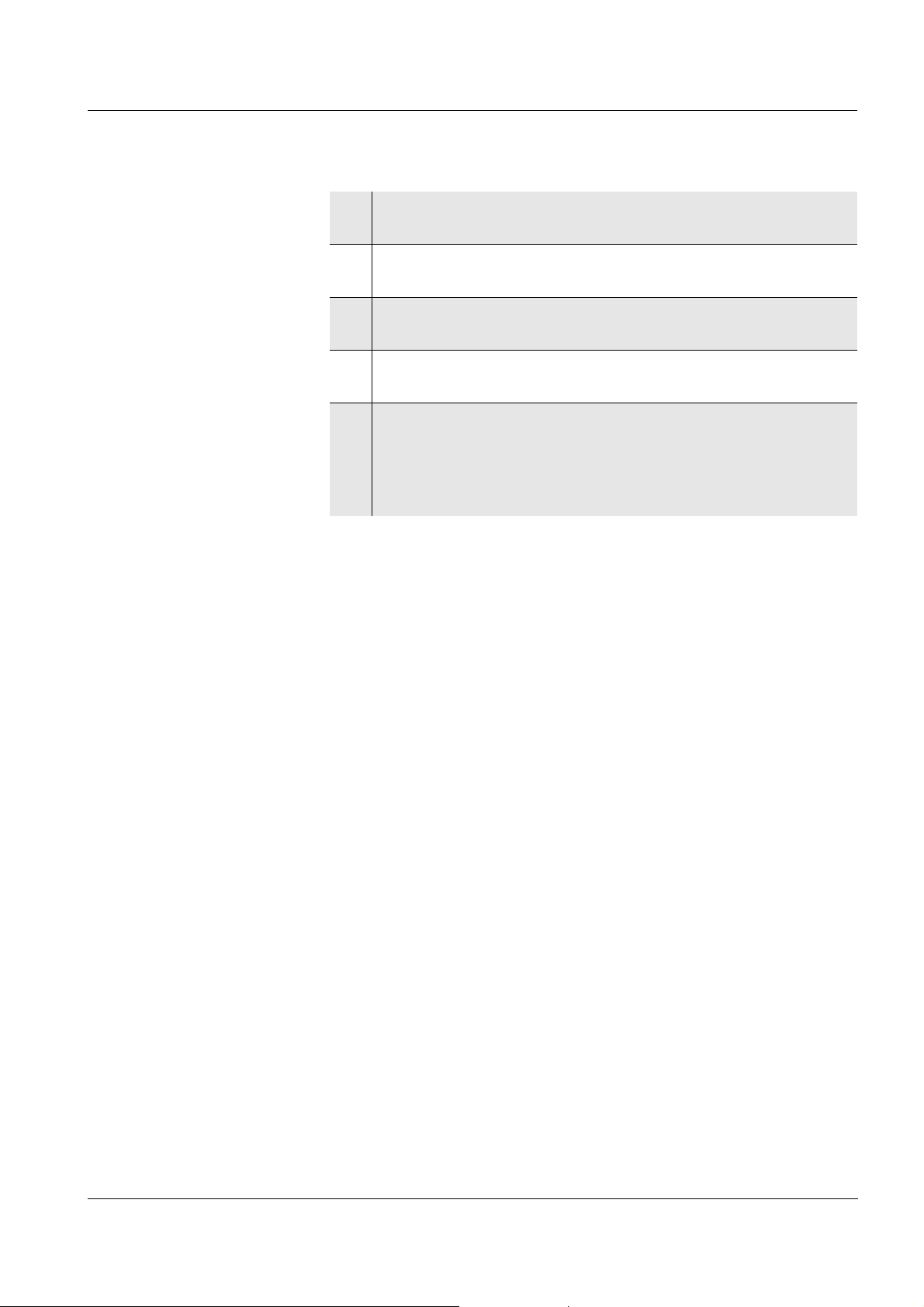

1.3 Socket field

Connectors:

1 D.O. sensor

2 Service interface

Caution

Only connect D.O. sensors to the meter that cannot return any

voltages or currents that are not allowed (> SELV and > current

circuit with current limiting).

Almost all customary D.O. sensors fulfill these conditions.

8

ba75795e02 03/2009

Page 9

Oxi 3210 Safety

2 Safety

This operating manual contains basic instructions that you must follow

during the commissioning, operation and maintenance of the meter.

Consequently, all responsible personnel must read this operating

manual before working with the meter.

The operating manual must always be available within the

vicinity of the meter.

Target group The meter was developed for work in the field and in the laboratory.

Thus, we assume that, as a result of their professional training and

experience, the operators will know the necessary safety precautions

to take when handling chemicals.

Safety instructions Safety instructions in this operating manual are indicated by the

warning symbol (triangle) in the left column. The signal word (e.g.

"Caution") indicates the level of danger:

Further notes

Warning

indicates instructions that must be followed precisely in order to

avoid possibly great dangers to personnel.

Caution

indicates instructions that must be followed precisely in order to

avoid the possibility of slight injuries or damage to the meter or

the environment.

Note

indicates notes that draw your attention to special features.

Note

indicates cross-references to other documents, e.g. operating

manuals.

ba75795e02 03/2009

9

Page 10

Safety Oxi 3210

2.1 Authorized use

The authorized use of the meter consists exclusively of the

measurement of dissolved oxygen and temperature of liquid media in

a field and laboratory environment.

The technical specifications as given in chapter 7 T

ECHNICAL DATA must

be observed. Only the operation and running of the meter according to

the instructions given in this operating manual is authorized.

Any other use is considered unauthorized.

2.2 General safety instructions

This meter is constructed and tested in compliance with the IEC 1010

safety regulations for electronic measuring instruments.

It left the factory in a safe and secure technical condition.

Function and

operational safety

The smooth functioning and operational safety of the meter can only be

guaranteed if the generally applicable safety measures and the specific

safety instructions in this operating manual are followed during

operation.

The smooth functioning and operational safety of the meter can only be

guaranteed under the environmental conditions that are specified in

chapter 7 T

ECHNICAL DATA.

If the meter was transported from a cold environment to a warm

environment, the formation of condensate can lead to the faulty

functioning of the meter. In this event, wait until the temperature of the

meter reaches room temperature before putting the meter back into

operation.

Caution

The meter is only allowed to be opened by authorized personnel.

10

ba75795e02 03/2009

Page 11

Oxi 3210 Safety

Safe operation If safe operation is no longer possible, the meter must be taken out of

service and secured against inadvertent operation!

Safe operation is no longer possible if the meter:

z has been damaged in transport

z has been stored under adverse conditions for a lengthy period of

time

z is visibly damaged

z no longer operates as described in this manual.

If you are in any doubt, please contact the supplier of the meter.

Obligations of the

purchaser

The purchaser of this meter must ensure that the following laws and

guidelines are observed when using dangerous substances:

z EEC directives for protective labor legislation

z National protective labor legislation

z Safety regulations

z Safety datasheets of the chemical manufacturers.

Caution

In addition to the safety instructions mentioned here, also follow

the safety instructions of the sensors used.

The operating manuals of the sensors are available on the

supplied CD and on the Internet under www.WTW.com.

ba75795e02 03/2009

11

Page 12

Safety Oxi 3210

12

ba75795e02 03/2009

Page 13

Oxi 3210 Commissioning

2

1

3 Commissioning

3.1 Scope of delivery

z D.O. meter Oxi 3210

z 4 batteries 1.5 V Mignon type AA

z Short instructions

z CD-ROM with detailed operating manual

3.2 Initial commissioning

Perform the following activities:

z Insert the supplied batteries

z Switch on the meter

z Set the date and time

3.2.1 Inserting the batteries

1 Unscrew the two screws (1) on the underside of the meter.

2 Open the battery compartment (2) on the underside of the

meter.

ba75795e02 03/2009

3 Place four batteries (type Mignon AA) in the battery

compartment.

13

Page 14

Commissioning Oxi 3210

Note

Alternatively, you can also use Ni-MH rechargeable batteries (type

Mignon AA). In order to charge the batteries, an external charging

device is required.

Caution

Make sure that the poles of the batteries are positioned correctly.

The

± signs on the batteries must correspond to the ± signs in the

battery compartment.

4 Close the battery compartment (2) and tighten the screws (1).

3.2.2 Switching on the meter

1 Press the <On/Off> key.

The meter performs a self-test.

The display shows the manufacturer's logo while the self-test

is being performed.

Subsequently, the meter switches to the measuring mode

(measured value display).

Note

The meter has an energy saving feature to avoid unnecessary battery

depletion.

The energy saving feature switches off the measuring instrument if no

key is pressed during the adjusted interval. (How to set the switch-off

interval, see section 4.3.1).

3.2.3 Setting the date and time

2 See section 4.2.4

14

ba75795e02 03/2009

Page 15

Oxi 3210 Operation

O

2

7.92

mg/l

25.1

°C

22.09.2008

08:00

Menu

4 Operation

4.1 Switching on the meter

Switching on Press the <On/Off> key.

The meter performs a self-test.

The display shows the manufacturer's logo while the self-test is being

performed.

The measured value display appears.

Switching off Press the <On/Off> key.

Automatic switch-off

function

Display illumination The meter automatically switches off the display illumination if no key

The instrument has an automatic switch-off function in order to save the

batteries (see section 4.3.1). The automatic switch-off function

switches off the measuring instrument if no key is pressed for an

adjustable period.

is pressed for 30 seconds. The illumination is switched on with the next

keystroke again.

You can also generally switch the display illumination on or off (see

section 4.3.1).

ba75795e02 03/2009

15

Page 16

Operation Oxi 3210

4.2 General operating principles

This section contains basic information on the operation of the

Oxi 3210.

Operating elements,

display

Operating modes,

navigation

An overview of the operating elements and the display is given in

section 1.1 and section 1.2.

An overview of the operating modes and navigation of the Oxi 3210 is

given in section 4.2.1 and section 4.2.2.

4.2.1 Operating modes

The meter has the following operating modes:

z Measuring

The measurement data of the connected sensor is shown in the

measured value display

z Calibration

The course of a calibration with calibration information, functions

and settings is displayed

z Data storage

The meter stores measurement data manually

z Setting

The system menu or a sensor menu with submenus, settings and

functions is displayed

16

ba75795e02 03/2009

Page 17

Oxi 3210 Operation

General

Clock

Service information

Reset

System

22.09.2008

08:00

Back

Language: English

Illumination

: On

Contrast: 48 %

Switchoff time: 30 min

General

22.09.2008

08:00

Back

4.2.2 Navigation

Measured value display In the measured value display, you can

z Open the menu for calibration and measurement settings with <F1>

(short

keystroke)

z Open the Storage & config menu with the sensor-independent

settings with <F1

_> (long keystroke (approx. 2 s).

z Change the display in the measurement window by pressing <M>

(e.g. D.O. concentration −> D.O. saturation index −> D.O. partial

pressure −>).

Menus and dialogs The menus for settings and dialogs in procedures contain further

submenus. The selection is made with the <▲><▼> keys. The current

selection is displayed with a frame.

z Submenus

The name of the submenu is displayed at the upper edge of the

frame. Submenus are opened by confirming with <ENTER>.

Example:

ba75795e02 03/2009

z Settings

Settings are indicated by a colon. The current setting is displayed on

the right-hand side. The setting mode is opened with <ENTER>.

Subsequently, the setting can be changed with <▲><▼> and

<ENTER>. Example:

17

Page 18

Operation Oxi 3210

Calibration record

Calibration interval

: 150 d

O

2

22.09.2008

08:00

Back

Calibration

Temperature unit °C

Sal correction On

Salinity 21.7

Stability control On

Reset

i

Air pressure = 941 mbar

O

2

22.09.2008

08:00

Back

z Functions

Functions are designated by the name of the function. They are

immediately carried out by confirming with <ENTER>.

Example: Display the Calibration record function.

i

Messages Information is marked by the

symbol. It cannot be selected. Example:

18

Note

The principles of navigation are explained in the two following sections

by reference of examples:

z Setting the language (section 4.2.3)

z Setting the date and time (see section 4.2.4).

ba75795e02 03/2009

Page 19

Oxi 3210 Operation

O

2

7.92

mg/l

25.1

°C

22.09.2008

08:00

Menu

System

Data storage

Storage & config

22.09.2008

08:00

Back

4.2.3 Example 1 on navigation: Setting the language

1 Press the <On/Off> key.

The measured value display appears.

The instrument is in the measuring mode.

2 Using <F1_>/[Menu] open the Storage & config menu.

The instrument is in the setting mode.

3 Select the System submenu with <▲><▼>.

The current selection is displayed with a frame.

4 Open the System submenu with <ENTER>.

ba75795e02 03/2009

19

Page 20

Operation Oxi 3210

General

Clock

Service information

Reset

System

22.09.2008

08:00

Back

Language: English

Beep: Off

Illumination: On

Contrast

: 48 %

Switchoff time: 30 min

General

22.09.2008

08:00

Back

Language: English

Beep: Off

Illumination: On

Contrast

: 48 %

Switchoff time: 30 min

General

22.09.2008

08:00

Back

5 Select the General submenu with <▲><▼>.

The current selection is displayed with a frame.

6 Open the General

submenu with <ENTER>.

7 Open the setting mode for the Language with <ENTER>.

20

8 Select the required language with <▲><▼>.

ba75795e02 03/2009

Page 21

Oxi 3210 Operation

9 Confirm the setting with <ENTER>.

The meter switches to the measuring mode.

The selected language is active.

ba75795e02 03/2009

21

Page 22

Operation Oxi 3210

Date format: dd.mm.yyyy

Date: 30.10.2008

Time

: 14:53:40

Clock

22.09.2008

08:00

Back

4.2.4 Example 2 on navigation: Setting the date and time

The measuring instrument has a clock with a date function. The date

and time are indicated in the status line of the measured value display.

When storing measured values and calibrating, the current date and

time are automatically stored as well.

The correct setting of the date and time and date format is important for

the following functions and displays:

z Current date and time

z Calibration date

z Identification of stored measured values.

Therefore, check the time at regular intervals.

Note

After a fall of the supply voltage (empty batteries), the date and time are

reset to 01.01.2008, 00:00 hours.

Setting the date, time

and date format

The date format can be switched from the display of day, month, year

(dd.mm.yyyy) to the display of month, day, year (mm/dd/yyyy or

mm.dd.yyyy).

1 In the measured value display:

Using <F1

_>/[Menu], open the Storage & config menu.

The instrument is in the setting mode.

2 Select and confirm the System / Clock menu with <▲><▼> and

<ENTER>.

The setting menu for the date and time opens up.

3 Select and confirm the Time menu with <▲><▼> and

<ENTER>.

The hours are highlighted.

22

ba75795e02 03/2009

Page 23

Oxi 3210 Operation

4 Change and confirm the setting with <▲><▼> and <ENTER>.

The minutes are highlighted.

5 Change and confirm the setting with <▲><▼> and <ENTER>.

The seconds are highlighted.

6 Change and confirm the setting with <▲><▼> and <ENTER>.

The time is set.

7 If necessary, set the Date and Date format. The setting is made

similarly to that of the time.

8 To make further settings, switch to the next higher menu level

with [Back]<F1>.

or

Switch to the measured value display with <M>.

The instrument is in the measuring mode.

ba75795e02 03/2009

23

Page 24

Operation Oxi 3210

4.3 Sensor-independent settings

The Storage & config menu comprises the following settings:

z System (see section 4.3.1).

z Data storage (see section 4.3.2)

4.3.1 System

Overview The following sensor-independent meter characteristics can be

adjusted in the Storage & config/System menu:

z Menu language

z Illumination

z Display contrast

z Interval of the automatic switch-off function

z Clock and date function

z Reset of all sensor-independent system settings to the default

condition

Settings To open the Storage & config menu, press the <F1

the measured value display. After completing the settings, switch to the

measured value display with <M>.

Menu item Setting Description

System / General /

Language

System / General /

Illumination

System / General /

Contrast

System / General /

Switchoff time

System /Clock Time

Deutsch

English

(further)

Auto

On

Off

0 ... 100 % Changing the display contrast

10 min ... 24 h Adjust the switch-off time

Date

Date format

Select the menu language

Switching the display

illumination on/off

Settings of time and date.

For details, see section 4.2.4

_>[Menu] key in

24

System /Service

information

Hardware version and software

version of the meter are

displayed.

ba75795e02 03/2009

Page 25

Oxi 3210 Operation

Menu item Setting Description

System /Reset - Resets the system settings to

the default values.

For details, see section 4.6.2

4.3.2 Data storage

This menu contains all functions to display, edit and erase stored

measured values.

Note

Detailed information on the storage functions of the Oxi 3210 is given

in section 4.5.

4.3.3 Automatic Stability control

The function, automatic Stability control (AutoRead) continually checks

the stability of the measurement signal. The stability has a considerable

impact on the reproducibility of measured values.

You can activate or switch off the automatic Stability control function

(see section 4.4.3).

The measured parameter flashes on the display

z as soon as the measured value is outside the stability range

z if you switch over between the measured parameters with <M>.

z if the automatic Stability control is switched off.

ba75795e02 03/2009

25

Page 26

Operation Oxi 3210

4.4 Dissolved oxygen

4.4.1 General information

You can measure the following parameters:

z D.O. concentration

z D.O. saturation index ("D.O. saturation")

z D.O. partial pressure

D.O. measurements with the Oxi 3210 can be carried out with the

CellOx 325 or DurOx 325 D.O. sensor.

The measuring instrument automatically recognizes the type of the

connected D.O. sensor.

Temperature

measurement

The CellOx 325 and DurOx 325 D.O. sensors have an integrated

temperature sensor.

Preparatory activities Perform the following preparatory activities when you want to measure:

1 Connect the D.O. sensor to the meter.

The D.O. measuring window is displayed.

2 Calibrate or check the meter with the sensor.

Note

Incorrect calibration of D.O. sensors will result in incorrect measured

values. Calibrate at regular intervals.

26

ba75795e02 03/2009

Page 27

Oxi 3210 Operation

O

2

7.92

mg/l

25.1

°C

22.09.2008

08:00

Menu

4.4.2 Measuring

You can carry out D.O. measurements as follows:

1 Perform the preparatory activities according to section 4.4.1.

2 Immerse the D.O. sensor in the test sample.

Selecting the

displayed

measured parameter

Salinity correction When measuring the concentration of solutions with a salt content of

Freezing the measured

value (HOLD function)

You can switch between the following displays with <M>:

z D.O. concentration [mg/l]

z D.O. saturation [%]

z D.O. partial pressure [mbar].

more than 1 g/l, a salinity correction is required. For this, you have to

measure and input the salinity of the measured medium first. When the

salinity correction is switched on, the [Sal] indicator is displayed in the

measuring window.

Note

You can switch the salinity correction on or off and enter the salinity in

the menu for calibration and measurement settings (see section 4.4.3).

With the HOLD function, you can freeze the current measured value.

The displayed measured value stops changing until you switch the

HOLD function off.

1 Freeze the measured value with <AR>.

The [HOLD] status indicator is displayed.

ba75795e02 03/2009

Note

If the HOLD function is active, you can, e.g. start a manual

measurement with stability control.

27

Page 28

Operation Oxi 3210

2 Release the frozen measured value again with <AR>.

The HOLD function is switched off.

The [HOLD] status display disappears.

Stability control

(AutoRead )

The stability control function (AutoRead) continually checks the stability

of the measurement signal. The stability has a considerable impact on

the reproducibility of measured values. The display of the measured

parameter flashes until a stable measured value is available.

You can start the Stability control function manually at any time,

irrespective of the setting for automatic Stability control (see page 25)

in the Measurement menu.

1 Freeze the measured value with <AR>.

The [HOLD] status indicator is displayed.

2Using <ENTER>, activate the Stability control function

manually.

The [AR] status indicator appears while the measured value is

assessed as not stable. The [HOLD][AR] status indicator

appears as soon as a stable measured value is recognized.

Note

You can prematurely terminate the Stability control function manually

with <ENTER> at any time.

Criteria for a stable

measured value

3 Using <ENTER>, start a further measurement with Stability

control.

or

Release the frozen measured value again with <AR>.

The display switches to the measured value display.

The [AR][HOLD] status display disappears.

The Stability control function checks whether the measured values are

stable within the monitored time interval.

Measured parameter Time interval Stability in the time interval

D.O. concentration 10 seconds

D.O. saturation 10 seconds

D.O. partial pressure 10 seconds

Δ : better than 0.05 mg/l

Δ : better than 0.6 %

Δ : Better than 1.2 mbar

The minimum duration until a measured value is assessed as stable is

the monitored time interval. The actual duration is mostly longer.

28

ba75795e02 03/2009

Page 29

Oxi 3210 Operation

4.4.3 Settings for D.O. sensors (menu or measurement and calibration settings)

Overview The following settings are possible for D.O. sensors:

z Salinity correction

z Salinity (salinity equivalent)

z Calibration interval

z Automatic Stability control

Settings The settings are available in the menu for measurement and calibration

settings. To open the settings, display the required parameter in the

measured value display and press the <F1>/[menu] or <ENTER> key.

After completing the settings, switch to the measured value display with

<M>.

Menu item Possible

Description

setting

Calibration /

Calibration record

Calibration /

Calibration interval

- Displays the calibration

record of the last calibration.

1 ... 999 d Calibration interval for the

D.O. sensor (in days).

The meter reminds you to

calibrate regularly by the

flashing sensor symbol in

the measuring window.

Sal correction On

Off

Manual salt content

correction for concentration

measurements.

Salinity 0.0 ... 70.0 Salinity or salinity equivalent

for the salt content

correction.

This function is only

available for concentration

measurements if the

manual salt content

correction is switched on.

ba75795e02 03/2009

Stability control On /Off Switches on or off the

automatic stability control

during measurement (see

section 4.3.3)

29

Page 30

Operation Oxi 3210

Menu item Possible

Description

setting

Temperature unit °C

°F

Temperature unit,

degrees Celsius or degrees

Fahrenheit.

All temperatures are

displayed with the selected

unit.

Reset - Resets all sensor settings to

the delivery condition (see

section 4.6.1).

30

ba75795e02 03/2009

Page 31

Oxi 3210 Operation

4.4.4 D.O. calibration

Why calibrate? D.O. sensors age. This changes the slope of the D.O. sensor.

Calibration determines the current slope of the sensor and stores this

value in the instrument.

When to calibrate? z After connecting another D.O. sensor

z When the sensor symbol flashes (after the calibration interval has

expired).

Calibration datasets The Oxi 3210 administrates two sets of calibration data:

z Set 1 for the type, "CellOx": – CellOx 325

z Set 2 for the type, "DurOx": – DurOx 325

Sensors of different types can be calibrated separately from each other.

When one sensor type is calibrated, the calibration data of the other

type remains stored. The Oxi 3210 recognizes the type of the

connected sensor and automatically uses the correct calibration data.

Calibration procedures With the Oxi 3210, the following calibration procedure is available:

Calibration in water vapor-saturated air.

®

air calibration vessel for calibration.

Stability control

(AutoRead)

Use an OxiCal

In calibration, the Stability control function (AutoRead) is automatically

activated.

Display calibration data You can have the data of the last calibration displayed (see section

4.4.5).

ba75795e02 03/2009

31

Page 32

Operation Oxi 3210

Calibration evaluation After the calibration, the measuring instrument automatically evaluates

the current status of the calibration. The evaluation appears on the

display and in the calibration record.

Display Calibration record Relative slope

+++ S = 0.8 ... 1.25

++ S = 0.7 ... 0.8

+ S = 0.6 ... 0.7

Calibration in

water vapor

saturated air

(air calibration vessel)

Error Error

S < 0.6 or S > 1.25

Eliminate the error according to

chapter 6 W

HAT TO DO IF...

Proceed as follows to calibrate the instrument:

1 Connect the D.O. sensor to the meter.

2 Put the D.O. sensor into the air calibration vessel.

Note

The sponge in the air calibration vessel must be moist (not wet). Leave

the sensor in the air calibration vessel for a time long enough to adjust.

3 Start the calibration with <CAL>.

The last calibration data (relative slope) is displayed.

32

ba75795e02 03/2009

Page 33

Oxi 3210 Operation

O

2

0.88

25.1

°C

OxiCal

22.09.2008

08:00

4 Start the measurement with <ENTER>.

The measured value is checked for stability (stability control).

The [AR] status indicator is displayed. The measured

parameter flashes.

5 Wait for the end of the AutoRead measurement or accept the

calibration value with <ENTER>.

The calibration record is displayed.

Displaying the

calibration record

6 Using <F1>/[Continue] or <ENTER>, switch to the measured

value display.

4.4.5 Displaying calibration records

The calibration record of the last calibration is to be found under the

menu item, Calibration / Calibration record. To open it in the measured

value display, press the <CAL

_> key.

ba75795e02 03/2009

33

Page 34

Operation Oxi 3210

4.5 Data storage

You can transmit measured values (datasets) to the data storage:

z Manual storage (see section 4.5.1)

Measurement dataset A complete dataset consists of:

z ID number

z Date/time

z Measured value of the connected sensor

z Measured temperature value of the connected sensor

z AutoRead info: AR appears with the measured value if the

AutoRead criterion was met while storing (stable measured value).

Otherwise, the AR display is missing.

z Calibration evaluation: +++, ++, +, -, or no evaluation

Storage locations The Oxi 3210 meter has a measurement data memory.

Storage Maximum number of datasets

Manual data storage 200

34

ba75795e02 03/2009

Page 35

Oxi 3210 Operation

Data record: 4 of 200

30.10.2008 11:24:16

O2 = 7.92 mg/l 25.1 °C AR +++

Sal = 6.5

ID number: 1

Continue

Manual data storage

22.09.2008

08:00

Back

Data storage full. Erase?

Yes

No

Warning

22.09.2008

08:00

Back

4.5.1 Manual storage

You can transmit a measurement dataset to the data storage as

follows.

1 Press the <STO> key shortly.

The menu for manual storage appears.

2 If necessary, change and confirm the ID number (1 ... 10000)

with <▲><▼> and <ENTER>.

The dataset is stored. The meter switches to the measured

value display.

If the storage is full The following window appears if all 200 storage locations are occupied:

You have the following options:

z To erase the entire storage, confirm Yes.

ba75795e02 03/2009

z To cancel the storage process and switch to the measured value

display, confirm No.

35

Page 36

Operation Oxi 3210

Manual data storage (200)

Data record 3 of 64

30.10.2008 11:24:16

ID number:1

O2 = 7.92 mg/l 25.1 °C AR +++

Sal = 6.5

22.09.2008

08:00

Back

4.5.2 Displaying and editing the measurement data storage

The contents of the manual measurement data storage can be shown

on the display.

The measurement data storage has a function to erase the entire

contents.

Editing the data storage The storage is edited in the menu, Storage & config/ Data storage. To

open the Storage & config menu, press the <F1

_>[Menu] key in the

measured value display. Open the manual storage directly with the

<RCL> key.

Settings

Display presentation

of a dataset

Menu item Setting/

function

Data storage /

- Displays all measurement

Manual data storage /

Display

Data storage /

- Erases the entire manual

Manual data storage /

Erase

Description

datasets page by page.

Further options:

z Scroll through the

datasets with <▲><▼>.

z Quit the display with

<F1>/[Back].

measurement data storage.

Note:

All calibration data remains

stored when this action is

performed.

Quitting the display To quit the display of stored measurement datasets, you have the

36

following options:

ba75795e02 03/2009

Page 37

Oxi 3210 Operation

z Switch directly to the measured value display with <M>.

z Quit the display and move to the next higher menu level with <F1>/

[Back].

4.5.3 Erasing the measurement data storage

How to erase the measurement data storage is described in section

4.5.2 D

ISPLAYING AND EDITING THE MEASUREMENT DATA STORAGE.

4.6 Reset

You can reset (initialize) all sensor settings and sensor-independent

settings separately from each other.

4.6.1 Resetting the measurement settings

Note

The calibration data are reset to the default settings together with the

measuring parameters. Recalibrate after performing a reset.

The following settings for D.O. measurements are reset to the default

settings with the Reset function:

Setting Default settings

Cal. interval 14 d

Comparison meas. Off

Measured parameter D.O. concentration

Relative slope (S

)1.00

Rel

Salinity (value) 0.0

Salinity (function) Off

Stability control On

Temperature unit °C

ba75795e02 03/2009

The sensor settings are reset under theReset menu item in the menu

for calibration and measurement settings. To open the settings, display

the required parameter in the measured value display and press the

<F1>/[menu] or <ENTER> key.

37

Page 38

Operation Oxi 3210

4.6.2 Resetting the system settings

The following system settings can be reset to the delivery status:

Setting Default settings

Language English

Contrast 50 %

Illumination Auto

Switchoff time 1 h

The system settings are reset in the menu, Storage & config / System

/ Reset. To open the Storage & config menu, press the <F1

key in the measured value display.

_>[Menu]

38

ba75795e02 03/2009

Page 39

Oxi 3210 Maintenance, cleaning, disposal

2

1

5 Maintenance, cleaning, disposal

5.1 Maintenance

The only maintenance activity required is replacing the batteries.

Note

See the relevant operating manuals of the D.O. sensors for instructions

on maintenance.

5.1.1 Replacing the batteries

1 Unscrew the two screws (1) on the underside of the meter.

2 Open the battery compartment (2) on the underside of the

meter.

ba75795e02 03/2009

3 Remove the four batteries from the battery compartment.

4 Place four new batteries (type Mignon AA) in the battery

compartment.

Note

Alternatively, you can also use Ni-MH rechargeable batteries (type

Mignon AA). In order to charge the batteries, an external charging

device is required.

Caution

Make sure that the poles of the batteries are positioned correctly.

The

± signs on the batteries must correspond to the ± signs in the

battery compartment.

39

Page 40

Maintenance, cleaning, disposal Oxi 3210

5 Close the battery compartment (2) and tighten the screws (1).

5.2 Cleaning

Occasionally wipe the outside of the measuring instrument with a

damp, lint-free cloth. Disinfect the housing with isopropanol as

required.

Caution

The housing is made of synthetic material (ABS). Thus, avoid

contact with acetone or similar detergents that contain solvents.

Remove any splashes immediately.

5.3 Packing

This meter is sent out in a protective transport packing.

We recommend: Keep the packing material. The original packing

protects the meter against damage during transport.

5.4 Disposal

Note

This meter contains batteries. Batteries that have been removed must

only be disposed of at a recycling facility set up for this purpose or via

the retail outlet.

It is illegal to dispose of it in household refuse.

40

ba75795e02 03/2009

Page 41

Oxi 3210 What to do if...

6 What to do if...

Error message,

OFL

Error message,

Error

Sensor symbol flashes

Display

Cause Remedy

– Measured value outside the

measuring range

Cause Remedy

– D.O. sensor contaminated – Clean D.O. sensor and

Cause Remedy

– Cleaning interval expired – Recalibrate the measuring

Cause Remedy

– Batteries almost empty – Replace the batteries (see

– Use a suitable D.O. sensor

replace it if necessary

system

section 5.1 M

AINTENANCE)

Meter does not react to

keystroke

You want to know which

software

version is in the meter

Cause Remedy

– Operating condition undefined

or EMC load unallowed

Cause Remedy

– E. g., a question by the service

department

– Processor reset:

Press the <ENTER> and

<On/Off> key

simultaneously

– Switch on the meter.

Open the menu, <F1

[Menü] / Speicher & Konfig. /

System / Service

Information. The instrument

data is displayed.

_>/

ba75795e02 03/2009

41

Page 42

What to do if... Oxi 3210

42

ba75795e02 03/2009

Page 43

Oxi 3210 Technical data

7 Technical data

7.1 General data

Dimensions approx. 180 x 80 x 55 mm

Weight approx. 0.4 kg

Mechanical structure Type of protection IP 67

Electrical safety Protective class III

Test certificates CE

Ambient

conditions

Power

supply

Guidelines

and norms used

Storage - 25 °C ... + 65 °C

Operation -10 °C ... + 55 °C

Climatic class 2

Batteries 4 x 1.5 V alkali-manganese batteries, type

AA

Rechargeable

batteries

Operational life up to 800 h without / 100 h with illumination

EMC EC directive 2004/108/EC

Meter safety EC directive 2006/95/EC

Climatic class VDI/VDE 3540

IP protection class EN 60529

4 x 1,2 V NiMH rechargeable batteries,

type AA (no charging function)

EN 61326-1

EN 61000-3-2

EN 61000-3-3

FCC Class A

EN 61010-1

ba75795e02 03/2009

43

Page 44

Technical data Oxi 3210

7.2 Measuring ranges, resolution, accuracy

Measuring ranges,

resolution

The values quoted in brackets apply especially for the

Note:

DurOx 325 sensor.

Parameter Measuring range Resolution

D.O. concentration

[mg/l]

0 ... 20.00 (0 ... 20.0)

0 ... 90.0 (0 ... 90)

Saturation [%] 0 ... 200.0 (0 ... 200)

0 ... 600

D.O. partial pressure

[mbar]

0 ... 200.0 (0 ... 200)

0 ... 1250

T [°C] 0 ... 50.0 0.1

Accuracy (± 1 digit) Parameter Accuracy

D.O. concentration

[mg/l]

± 0.5 % of measured value

at ambient temperature + 5 °C ... + 30 °C

Saturation [%] ± 0.5% of measured value

when measuring in the range of ± 10 K

around the calibration temperature

D.O. partial pressure

[mbar]

± 0.5 % of measured value

at ambient temperature + 5 °C ... + 30 °C

0.01 (0.1)

0.1 (1)

0.1 (1)

1

0.1 (1)

1

T [°C] / temperature sensor

NTC 30 ± 0,1

PT 1000 ± 0,1

Correction functions Temperature

compensation

Salinity correction 0 ... 70.0 SAL

Air pressure

correction

Note

The accuracy values specified here apply exclusively to the meter. The

accuracy of the D.O. sensors has also to be taken into account.

Accuracy better than 2 % at 0 ... + 40 °C

Automatic through integrated pressure

sensor in the range of 500 ... 1100 mbar

44

ba75795e02 03/2009

Page 45

Oxi 3210 Technical data

FCC Class A Equipment Statement

Note: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to

correct the interference at his own expense.

Changes or modifications not expressly approved by the

manufacturer could void the user‘s authority to operate the

equipment.

ba75795e02 03/2009

45

Page 46

Technical data Oxi 3210

46

ba75795e02 03/2009

Page 47

Oxi 3210 Lists

8Lists

This chapter provides additional information and orientation aids.

Specialist terms The glossary briefly explains the meaning of the specialist terms.

However, terms that should already be familiar to the target group are

not described here.

Index The index will help you to find the topics that you are looking for.

Glossary

Adjusting To manipulate a measuring system so that the relevant value (e. g. the

displayed value) differs as little as possible from the correct value or

a value that is regarded as correct, or that the difference remains

within the tolerance.

AutoRange Name of the automatic selection of the measuring range.

Calibration Comparing the value from a measuring system (e. g. the displayed

value) to the correct value or a value that is regarded as correct.

Often, this expression is also used when the measuring system is

adjusted at the same time (see adjusting).

D.O. partial pressure Pressure caused by the oxygen in a gas mixture or liquid.

D.O. saturation Short name for the relative D.O. saturation.

Measured parameter The measured parameter is the physical dimension determined by

measuring, e. g. pH, conductivity or D.O. concentration.

Measured value The measured value is the special value of a measured parameter to

be determined. It is given as a combination of the numerical value and

unit (e. g. 3 m; 0.5 s; 5.2 A; 373.15 K).

OxiCal

®

WTW name for a procedure to calibrate D.O. measuring systems in

water vapor saturated air.

Reset Restoring the original condition of all settings of a measuring system.

Resolution Smallest difference between two measured values that can be

displayed by a meter.

ba75795e02 03/2009

47

Page 48

Lists Oxi 3210

Salinity The absolute salinity SA of seawater corresponds to the relationship

of the mass of dissolved salts to the mass of the solution (in g/Kg). In

practice, this dimension cannot be measured directly. Therefore, the

practical salinity according to IOT is used for oceanographic

monitoring. It is determined by measuring the electrical conductivity.

Salt content General designation for the quantity of salt dissolved in water.

Slope (relative) Designation used by WTW in the D.O. measuring technique. It

expresses the relation of the slope value to the value of a theoretical

reference sensor of the same construction type.

Stability control Function to control the measured value stability.

Test sample Designation of the test sample ready to be measured. Normally, a test

sample is made by processing the original sample. The test sample

and original sample are identical if the test sample was not processed.

48

ba75795e02 03/2009

Page 49

Oxi 3210 Lists

Index

A

Air calibration beaker . . . . . . . . . . . . . . . . . 31

Authorized use . . . . . . . . . . . . . . . . . . . . . . 10

Automatic switch-off . . . . . . . . . . . . . . . . . . 15

AutoRead . . . . . . . . . . . . . . . . . . . . . . . . . . 28

B

Battery compartment . . . . . . . . . . . . . . 13, 39

C

Calibration evaluation . . . . . . . . . . . . . . . . 32

D

Dataset . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Date and time . . . . . . . . . . . . . . . . . . . . . . . 22

Default settings

Measured parameter . . . . . . . . . . . . . . 37

System settings . . . . . . . . . . . . . . . . . . 38

E

Energy saving feature . . . . . . . . . . . . . . . . 14

P

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . 9

R

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

S

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sample display . . . . . . . . . . . . . . . . . . . . . . 7

Saving . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Scope of delivery . . . . . . . . . . . . . . . . . . . . 13

Setting the date . . . . . . . . . . . . . . . . . . . . . 14

Setting the time . . . . . . . . . . . . . . . . . . . . . 14

Slope relative . . . . . . . . . . . . . . . . . . . . . . . 31

Socket field . . . . . . . . . . . . . . . . . . . . . . . . . 8

Stability control

Automatic . . . . . . . . . . . . . . . . . . . . . . . 25

T

Temperature measurement . . . . . . . . . . . . 26

I

Initial commissioning . . . . . . . . . . . . . . 13, 14

Initialize . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

K

Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

M

Measured value display . . . . . . . . . . . . . . . 17

Measurement data storage

Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Erase . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Storage locations . . . . . . . . . . . . . . . . . 34

Measurement dataset . . . . . . . . . . . . . . . . 34

Measuring . . . . . . . . . . . . . . . . . . . . . . . . . 27

Menu for calibration and measurement

settings . . . . . . . . . . . . . . . . . . . . . . . 29

Menus (navigation) . . . . . . . . . . . . . . . . . . 17

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 18

O

Operational safety . . . . . . . . . . . . . . . . . . . 10

ba75795d02 03/2009

49

Page 50

Lists Oxi 3210

50

ba75795d02 03/2009

Page 51

Page 52

Wissenschaftlich-Technische Werkstätten GmbH

Dr.-Karl-Slevogt-Straße 1

D-82362 Weilheim

Germany

Tel: +49 (0) 881 183-0

+49 (0) 881 183-100

Fax: +49 (0) 881 183-420

E-Mail: Info@WTW.com

Internet: http://www.WTW.com

Loading...

Loading...