Page 1

Series 63

Low Water Cut-Off

Typical Applications:

- Primary or secondary low water cut-off

for hot water and steam boilers.

- Low water cut-off

- High water cut-off

- Alarm actuator

OPERATION

Maximum Boiler Pressure: 50 psi (3.5 kg/cm2)

Electrical Ratings

Motor Switch Rating (Amperes)

Voltage

120 VAC 10.2

240 VAC 5.1 30.6

Full Load Locked Rotor

61.2 125 VA at

Pilot Duty

120 or 240 VAC

INSTRUCTION MANUAL

MM-206F

CUT OFF

LEVEL

Model 63

WARNING

!

CAUTION

WARNING

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be

0 psi (0 bar) before servicing.

To prevent electrical shock, turn off the electrical power before making electrical connections.

•

• This low water cut-off must be installed in series with all other limit and operating controls

installed on the boiler. After installation, check for proper operation of all of the limit and

operating controls, before leaving the site.

• We recommend that secondary (redundant) Low Water Cut-Off controls be installed on all

steam boilers with heat input greater than 400,000 BTU/hour or operating above 15 psi of

steam pressure. At least two controls should be connected in series with the burner control

circuit to provide safety redundancy protection should the boiler experience a low water

condition. Moreover, at each annual outage, the low water cut-offs should be dismantled,

inspected, cleaned, and checked for proper calibration and performance.

• To prevent serious personal injury from steam blow down, connect a drain pipe to the control

opening to avoid exposure to steam discharge.

• To prevent a fire, do not use this low water cut-off to switch currents over 10.2A, 1/2 Hp at

120 VAC or 5.1A, 1/2 Hp at 240 VAC, unless a starter or relay is used in conjunction with it.

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell Miller s warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

!

&

'

Page 2

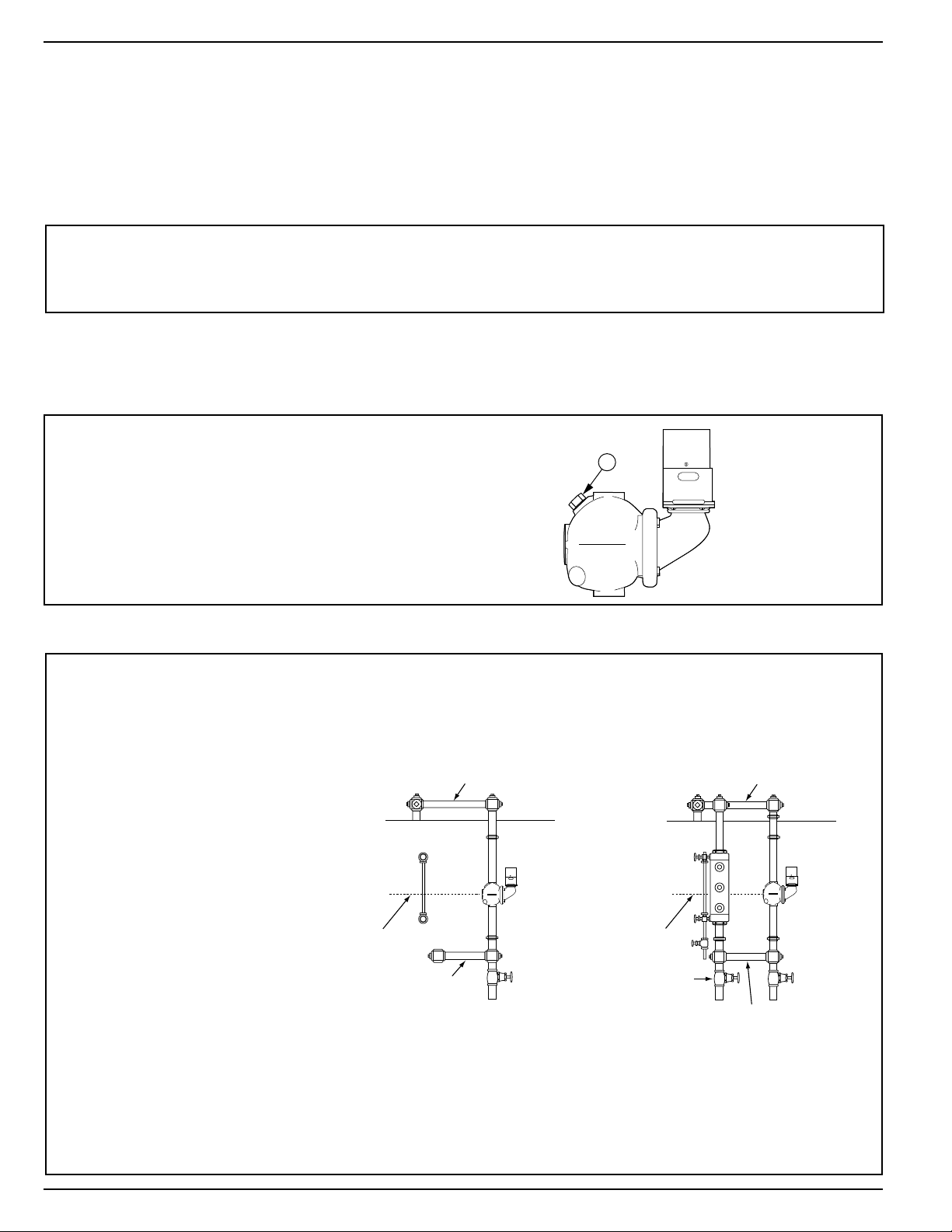

Gauge Glass Mounted

Directly into Boiler

CUT-OFF

LEVEL

1" BLOW DOWN

VALVE

For Boilers with

Independent Water Columns

1" STEAM

EQUALIZING PIPE

MODEL 63

LOW WATER

CUT-OFF

1" WATER

EQUALIZING PIPE

1" WATER

EQUALIZING PIPE

1" WATER

EQUALIZING PIPE

CUT-OFF

LEVEL

MODEL 63

LOW WATER

CUT-OFF

2

a. Whether the gauge glass is mounted directly into the boiler or on an independent water column, the

cut-off line on the 63 body casting should be mounted 1/2” (15mm) above the lowest visible point of the

gauge glass.

a. Locate the gauge glass and

determine the level that the 63

has to be mounted at in order

to achieve the criteria in Step 1.

b. Pipe the 63 following the

diagrams shown to the right.

Follow the diagram that

represents your boiler.

c. Crosses should be used at

each right angle connection for

inspection and cleaning.

d. Make sure the blow-down

valves are full port.

e. While the burner is operating,

open the blow-down valve,

causing the water level to drop in

the float chamber while burner is

operating. As the float drops the

alarm circuit (if used) closes first;

then on further drop the cut-off

circuit will open, shutting the

burner off.

f. Test the Model 63 before leaving

the site.

STEP 2 - Installation of the Model 63

Model 63 – For Steam Boilers with 1” (25mm) Equalizing Lines

INSTALLATION –

TOOLS NEEDED:

One (1) flathead screwdriver and two (2) pipe wrenches.

STEP 1 - Determine the Location of the Low Water Cut-Off

For 63 models with float block

CUT OFF

LEVEL

A

Using pipe wrench

• Remove float blocking plug (A) from low

water cut-off body tapping.

• Screw 3/4” NPT steel plug (provided) in

tapping.

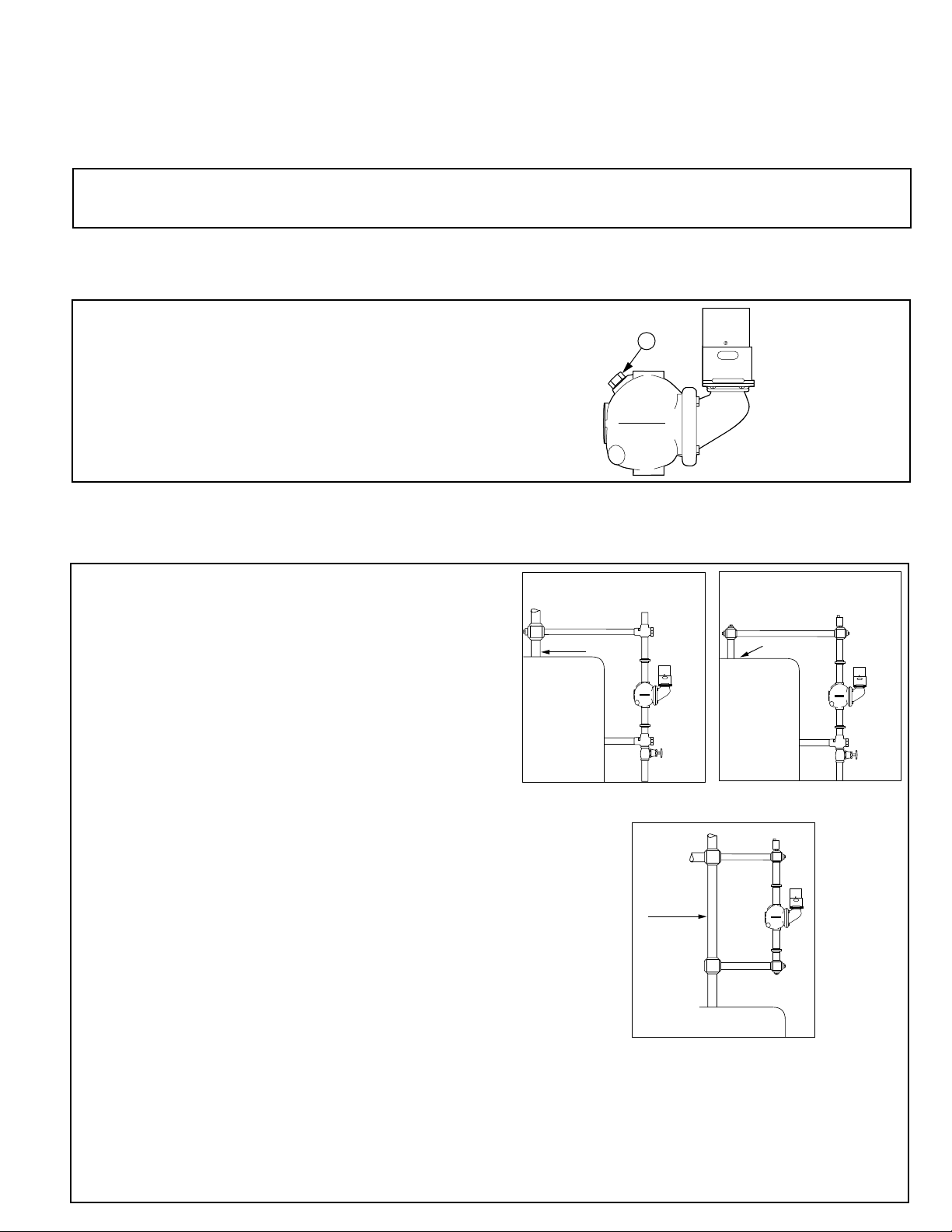

Page 3

3

a. The line on the casting of the model 63 must be installed above the lowest permissible water level

determined by the boiler manufacturer.

a. Study the figures to the right and determine which

figure shows how the 63 control will be attached to

the boiler.

Figure 1. Connect the upper equalizing pipe to

the riser going to the radiation or to the compression

tank. Connect the lower equalizing pipe to any

available opening in the side of the boiler. NOTE: If

no opening is available in the side of the boiler,

connect the lower equalizing pipe into the drain

connection.

Figure 2. If there is a tapping available on the

top of the boiler, connect the upper equalizing pipe to

it. NOTE: During initial filling or after blow-down the

upper equalizing pipe and possibly the 63 control will

have an air pocket. Connect a vent or bleed valve on

the top of the vertical equalizing pipe. If the Test-NCheck (TC-4) valve is used the vacuum breaker can

be used to bleed the air pocket.

CAUTION: When bleeding an air pocket manually,

protect yourself from being burned with hot water.

Figure 3. If there is no tapping available on the boiler,

connect both the upper and lower equalizing pipe

into the vertical riser going to the radiation or to the

compression tank. IMPORTANT: The horizontal equalizing

pipe should be below the horizontal run going to the

radiation. If it is not, an air pocket will be created and

a vent or bleed will have to be installed.

b.

While the burner is operating open the blow-down

valve, causing the water level to drop in the float

chamber. As the float drops the alarm circuit (if used)

closes first; then on further drop the cut-off circuit will

open, shutting the burner off.

c. Test the Model 63 before leaving the site.

STEP 2 - Installation of the Model 63

Model 63 – For Hot Water Boilers with 1” (25mm) Equalizing Lines

INSTALLATION –

TOOLS NEEDED: One (1) flathead screwdriver and two (2) pipe wrenches.

For float type controls it is recommended that Test-N-Check

®

(TC-4) valves be used in the upper and

lower equalizing lines. They offer a functional means for testing the 63 control, and conform to the

ASME CSD-1 code.

STEP 1 - Determine the Location of the Low Water Cut-Off

VERTICAL RISER

TO RADIATION

HOT WATER

BOILER

MODEL

63

Figure 1

Figure 2

Figure 3

For 63 models with float block

CUT OFF

LEVEL

A

Using pipe wrench

• Remove float blocking plug (A) from low

water cut-off body tapping.

• Screw 3/4” NPT steel plug (provided) in

tapping (A).

VERTICAL RISER TO RADIATION

OR COMPRESSION TANK

TC-4

AVAILABLE OPENING

IN TOP BOILER

AIR

VENT

HOT WATER

BOILER

MODEL

63

HOT WATER

BOILER

MODEL

TC-4

63

Page 4

4

1. Assemble the TC-U (the upper Test-N-Check

valves, with the vacuum breaker) into the upper

equalizing line in place of the cross described

in the low water cut-off installation instructions.

NOTE: The vacuum breaker must be on the top

and the long leg must face the boiler. NOTE:

Make sure low water cut-off position is located

in accordance with the boiler manufacturer’s

recommended cut-off level.

2. Assemble the TC-L (the lower Test-N-Check

valve, without the vacuum breaker) into the

lower equalizing line in place of the cross

described in the low water cut-off installation

instructions. NOTE: The brass cap must be

located above the center of the lower equalizing

line, and the long leg must face the boiler.

3. Assemble the blow-off valve into the bottom

port of the TC-L.

4. Assemble 1” NPT pipe plugs into the remaining

open port in both the TC-U and TC-L.

5. Complete the installation as described in the

low water cut-off installation instructions.

6. After all piping assembly has been completed,

refill the system with water, turn on all electrical

supply and bring system to operating

conditions. After system reaches operating

pressure, inspect to make sure no leaks exist at

the threaded connections. Test valves by

opening blow-off valve while burner is on, to

make sure valves operate correctly and low

water cut-off shuts burner off.

Simplify Testing of Low Water Cut-offs on Hot Water Boilers

TEST-N-CHECK®VALVES

Installation of the TC-4 Test-N-Check valves with a New Low Water Cut-off

IMPORTANT:

• Installation should be performed by qualified personnel only, in accordance with all applicable codes.

• If vacuum breaker stem is accidentally depressed, hot water could be discharged causing burns.

• Blow-off valve drain piping should be piped to a suitable drain to handle hot water and steam discharge,

and should be the same size as the equalizing pipe.

REMOVE CROSS

TC-U in Place

LWCO

LWCO

TC-L

in Place

Brass

Cap

Blow-off Valve

Page 5

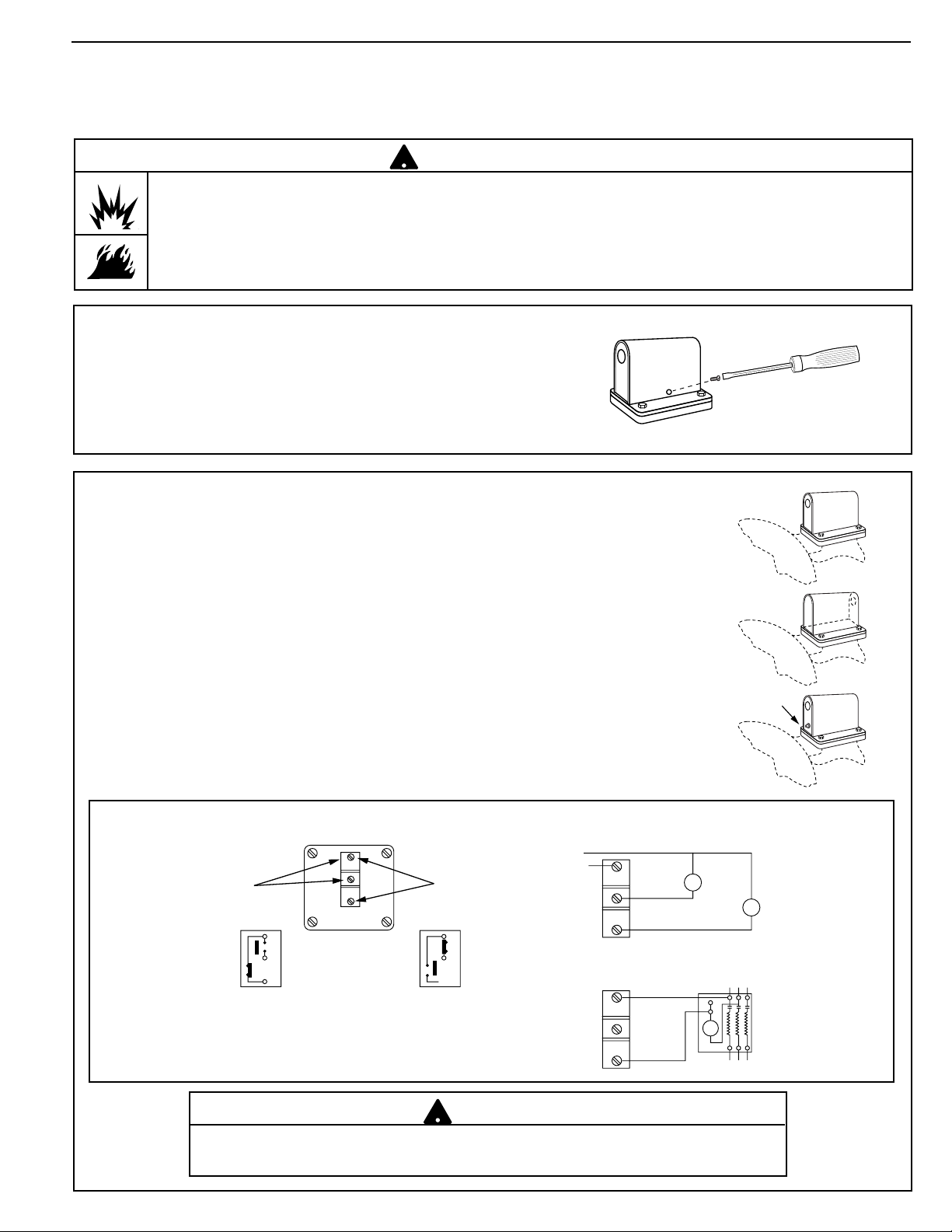

5

ELECTRICAL WIRING

TOOLS NEEDED:

One (1) flathead screwdriver.

Conduit opening facing

toward float chamber

Conduit opening facing

away from float chamber

Manual reset button

on No. 2m Switch

a. The No. 2 switch can be positioned with the conduit opening

facing toward or away from the float chamber. These are the

only positions in which the switch will function properly.

See drawing at right.

b. On initial fill-up, push the 2M manual reset button after the

proper water level is reached to energize the burner. If a

low water condition occurs and the water level has been

restored, push the reset button to energize the burner.

c. Follow the wiring diagrams below to wire the No. 2 Switch.

Terminals C and NC are the low water cut-off switch.

Terminals C and NO are alarm switch. If the electrical load

exceeds the rating of the switch, use an auxiliary relay or

motor starter.

USED AS A MAIN LINE SWITCH

AND/OR LOW WATER ALARM

USED AS A PILOT SWITCH TO COIL

OF RELAY OR MOTOR STARTER

N.

O.

N.C.

C.

N. O.

N.C.

C.

Neutral

120 V.A.C.

Supply Hot

Low

Water

Alarm

Burner

Circuit

Line

Load

SCHEMATIC OF SWITCH OPERATION

Water Level Normal

Burner On

Alarm Off

Low

Water

Alarm

Terminals

Low Water

Cut-Off

Terminals

C.

N.O.

N.C.

Water Level Low

Burner Off

Alarm On

C.

N.O.

N.C.

N.

O.

N.C.

C.

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls installed on the

boiler. After installation, check for proper operation of all of the limit and operating controls, before leaving

the site.

Failure to follow this warning could cause electrical shock, an explosion and/or a fire, which could result in

property damage, personal injury or death.

!

WARNING

Cover Removal and Installation Procedure

• Using a flathead screwdriver, remove the one

(1) screw that secures the switch cover.

• Place the cover on the switch housing and,

using a flathead screwdriver, tighten the one

(1) screw to approximately 2 ft•lb (2.6 N•m).

Do not use automatic water feeders with manual reset LWCO’s.

Failure to follow this warning could cause flooding, property damage, personal injury or death.

!

WARNING

Page 6

6

TROUBLESHOOTING

TESTING

Problem:

1. Burner does not shut off on low water.

a. Cause: Float chamber is loaded with mud or

sediment.

Test: With water level below the control

check if terminals C and N.C. are open.

If not, remove switch and manually test

if terminals C and N.C. can be opened.

Solution: Open float chamber and clean. At this

time, check for a build-up of scale or

sediment between corrugations of the

bellows.

b. Cause: Contacts are fused together.

Test: Remove switch and operate manually to

verify proper switch operation.

Solution: Replace switch. Check electrical load

and make sure it is within the ratings

of the switch.

CUT OFF

LEVEL

TEST

OPENING

• Control can be tested on a hot water

boiler by gently inserting a screwdriver

or similar tool in the test opening below

the switch (see drawing) and lifting linkage

to cause float to drop, thereby simulating a

low water condition.

Page 7

7

MAINTENANCE

SCHEDULE:

• Blow down control as follows when boiler is in

operation:

Steam:

– Daily if operating pressure is above 15 psi.

– Weekly if operating pressure is below 15 psi.

Hot Water:

– Quarterly

• Disassemble and inspect annually. Replace the

low water cut-off if it is worn, corroded, or if

components no longer operate properly.

• Inspect the float chamber and equalizing piping

annually. Remove all sediment and debris.

• Replace head mechanism every 5 years.

More frequent replacement may be required when

severe conditions exist such as rapid switch cycling,

surging water levels, and use of water treatment

chemicals.

• We recommend head mechanism replacement

when the switch(es) no longer operate properly.

If you choose to replace the switch(es), order the

proper McDonnell & Miller replacement switch or

switch assembly and follow the Repair Procedure

provided.

More frequent blow-down may be necessary due to dirty

water and/or local codes.

NOTE

PROCEDURE:

1. Blow down the low water cut-off when the water

level is at its normal level and the burner is on.

Slowly open the blow down valve until it is fully

open and observe the water level fall in the gauge

glass. Close the valve after verifying that the pump

contacts have closed and the burner shuts off.

If this does not happen, immediately shut off

the boiler and correct the problem.

To prevent serious personal injury from steam

pipe blow down, connect a drain pipe to the

control opening to avoid exposure to steam

discharge.

Failure to follow this caution could cause

personal injury.

!

CAUTION

Page 8

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-206F July 2013 Part No. 246746

Loading...

Loading...