Page 1

Series 67 and 767

Low Water Cut-Offs

For Steam Boilers

INSTRUCTION MANUAL

MM-201H

Page 2

A

D

2

INST

ALLATION –

T

OOLS NEEDED:

One (1) tube cutter, one (1) pencil, one (1) flathead

screwdriver, one (1) adjustable wrench and two (2)

pipe wrenches.

The Series 67 and Series 767 low water cut-offs are

float-type boiler controls designed to interrupt current

to the burner whenever the water drops to the cut-off

level.

The Series 767 is identical to Series 67 in all

respects except one. The Series 767 is equipped with

a 2-1/2" (63.5mm) pipe tap opening in the body, and

does not require the quick hook-up fittings supplied

with the Series 67. The pipe tapping allows for a

direct connection to the side of the boiler.

Electrical Ratings

Pump Circuit Rating (Amperes)

V

oltage Full Load Locked Rotor Pilot Duty

125 VA at

120 or 240 VAC

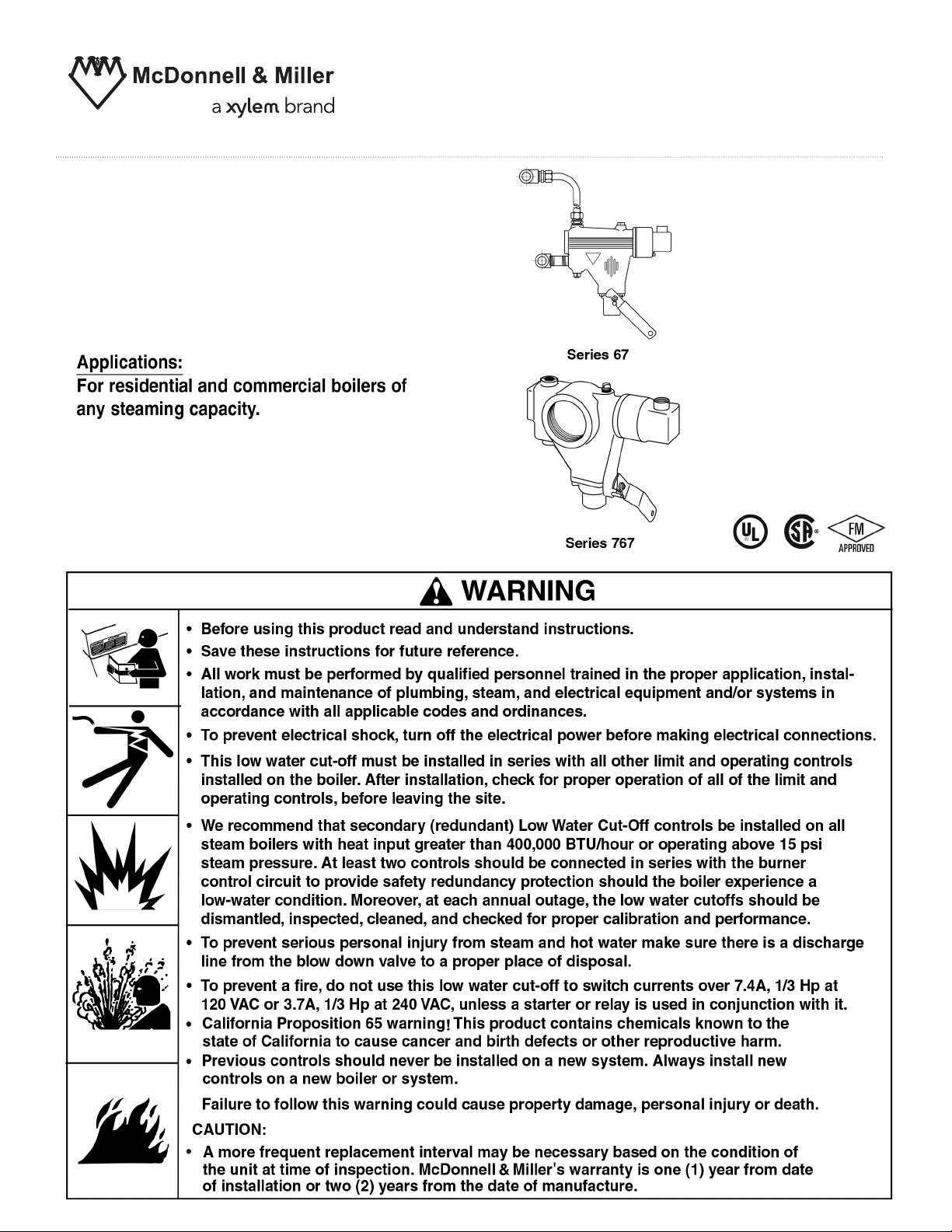

For Series 67 - The elevation of the control (A)

is already determined by the location of the

gauge glass tappings (B,C) on the boiler. The

horizontal cast line (D) should be located at or

above the boiler manufacturer's minimum safe

water level (E).

For Series 767 - The elevation of the control (A)

is already determined by the location of the 21/2 (63.5mm) pipe tapping on the boiler. The

horizontal cast line (D) of the body (A) should

be located at or above the boiler manufacturer's

minimum safe water level.

STEP 1 - Determine the Ele

vation at Which the

Low Water Cut-Off Controller Must be Installed

C

A

E

B

D

IMPOR

TANT: Follow the boiler manufacturer's

instructions along with all applicable codes and

ordinances for piping, blow down valve and water

gauge glass installation.

OPERA

TION

Maxim

um Steam Pressure: 20 psi (1.4 kg/cm

2

)

Series 67

Series 767

Note: 11 MV is rated at 24 V

A @ 24 VAC to 120 VAC

120 VAC

240 VAC

7.4

3.7

44.4

22.2

Page 3

3

a. Turn the boiler off.

b. Drain the water in the boiler to a level which

is below the lower gauge glass tapping (B)

of the control body (A). Allow the boiler to

cool to 80˚F (27˚C) and allow the pressure

to release to 0 psi (0 bar).

STEP 2 - Preparation

OFF

ON

AA

B

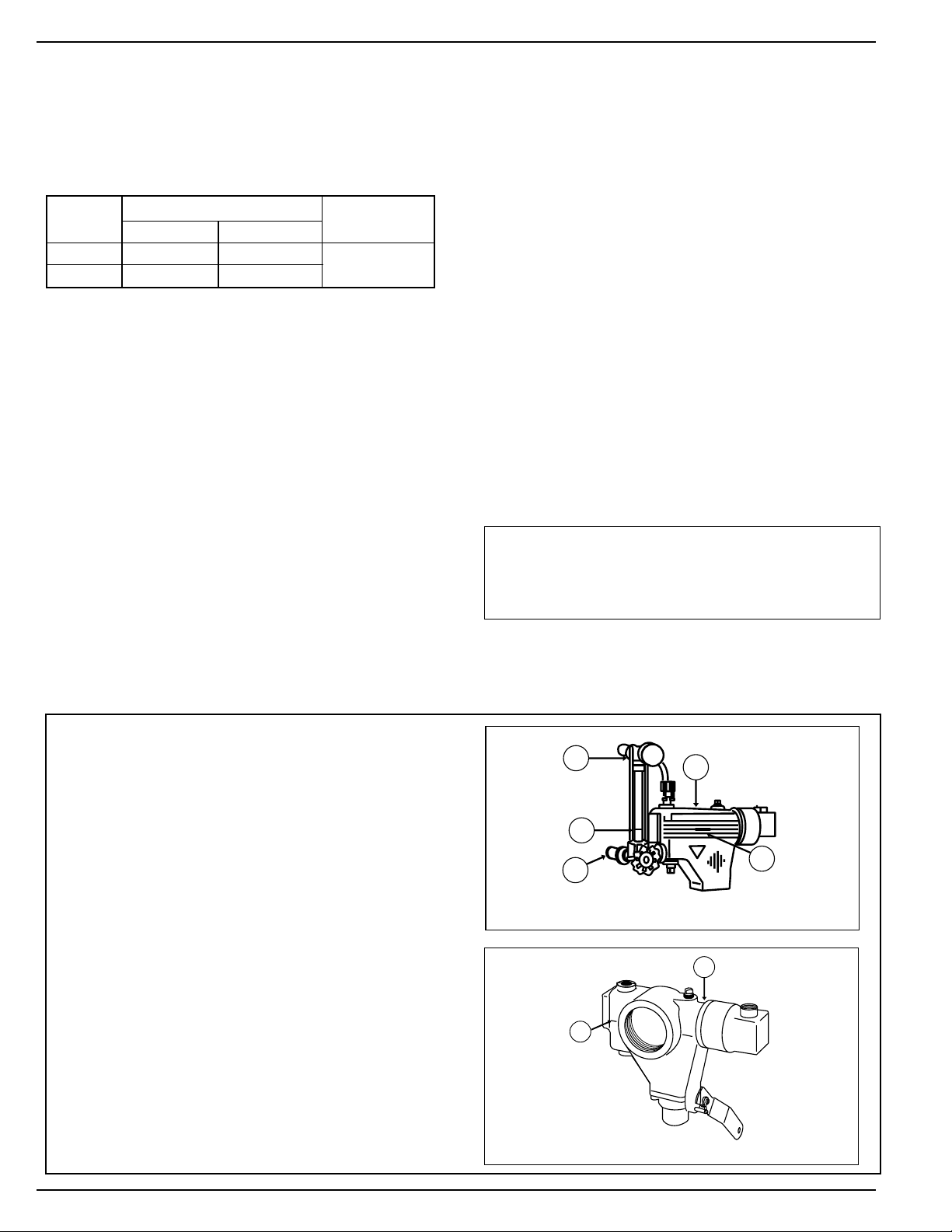

a. Using a pipe wrench, remove the float blocking

tube (F) from the new control and tighten a 2"

(13mm) NPT pipe plug (G) (provided) into the

tapping on the bottom of the control body (A).

Tighten the pipe plug to 31 ft•lb (42 N•m).

A

F

G

When using the tape sealant on the external threads of pipes or fittings, follow the manufacturers instructions. Use

sparingly and do not place on the first thread.

!

CAUTION

STEP 3 - Installing the New Low Water Cut-Off

b. Using a pipe wrench, install a 2" (13mm)

nipple (H) into the lower gauge glass tapping

(B) and pipe tee assembly (J). Tighten both

connections to 31 ft•lb (42 N•m).

J

B

H

Page 4

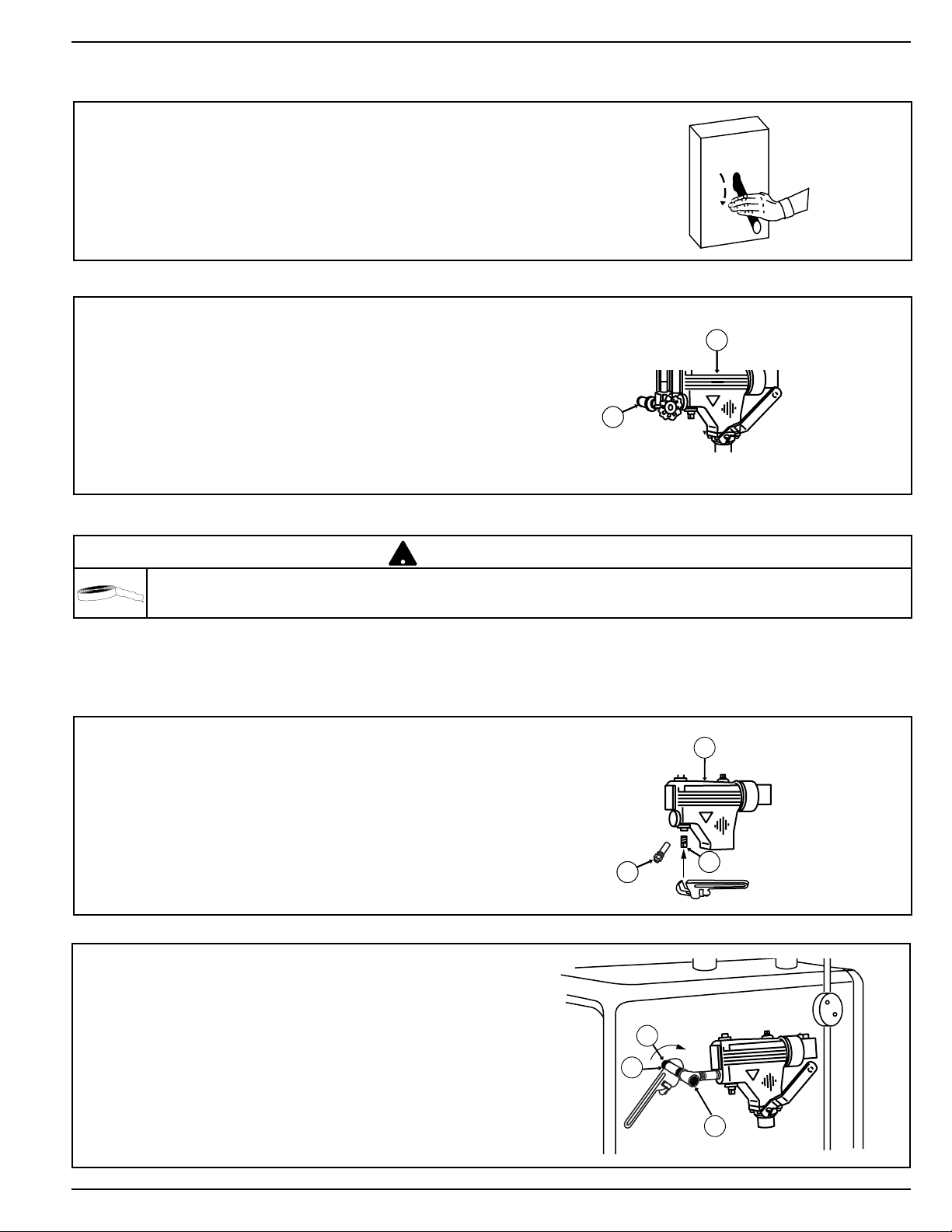

c. Using an adjustable wrench, install a a"

(9.5mm) NPT compression fitting base (K)

to the upper tapping (L) in the control (A).

Tighten to 31 ft•lb (42 N•m).

A

L

K

N

M

d. Using a pipe wrench, install a 2" (13mm)

nipple (M) into the upper tapping (N).

Tighten to 31 ft•lb (42 N•m).

e. Using a pipe wrench, install the pipe tee (P)

(provided) onto the nipple (M) in the upper

tapping (N). Tighten to 31 ft•lb (42 N•m).

N

M

P

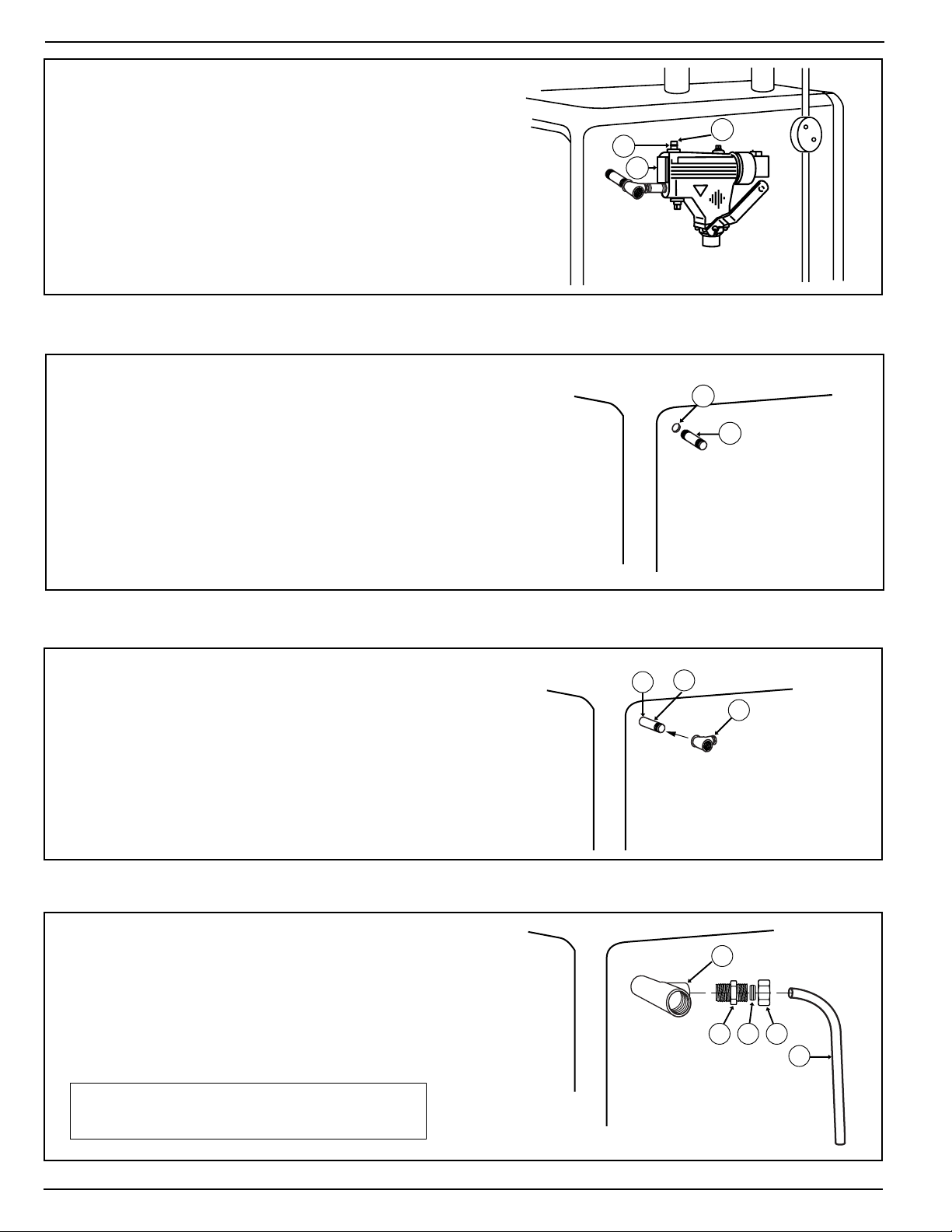

f. Using an adjustable wrench, install 1/2 (13mm) NPT

compression fitting base (U) into the upper tee (P).

Tighten to 31 ft•lb (42 N•m). Place the compression nut

(R) and compression ring (S) over the top of tubing (Q).

Insert tubing (Q) into compression base (U). Turn

compression nut (R) hand tight. DO NOT TIGHTEN.

IMPORTANT: Do not use tape or pipe

sealant on the compression fittings.

Q

U S R

P

4

Page 5

h. Insert the tubing (Q) into the upper compres-

sion fitting (U) and tighten the fitting to 31 ft•lb

(42 N•m).

U

Q

g. Position the tubing (Q) next to the compression

fitting (K) and, using a pencil, mark the tubing

(Q) for proper insertion into the compression

fitting (K).

Remove the tubing (Q), and, using the tube

cutter, cut the tubing to its proper length.

Q

K

5

i. Using two (2) pipe wrenches, rotate the upper

tee (P) counterclockwise and the lower tee (J)

clockwise.

j. Place the compression nut (R) and the compres-

sion ring (S) over the bottom of the tubing (Q).

P

J

Q

S

R

Page 6

k. Using two (2) pipe wrenches, rotate the upper

tee (P) clockwise and the lower tee (J) counterclockwise so that the end of the tube can be

inserted into the lower compression fitting (K).

NOTE: Make sure that the control is in a horizontal position. Using an adjustable wrench,

tighten the lower compression fitting (K) to

31 ft•lb (42 N•m).

K

J

P

6

T

U

V

l. Using a pipe wrench, install a w" (19mm) NPT

pipe (T) into the opening of the blow down

valve (U) and tighten to 47 ft•lb (64 N•m).

A

W

m. Hang the blow down card (W) (enclosed) as

close to the control (A) as possible, or

remove the protective backing and affix the

card on the boiler jacket close to the control.

X

a. Using a pipe wrench, install a 22" (63.5mm)

nipple (X) into the side of the boiler. Tighten

to 109 ft•lb (148 N•m).

For Series 767

To prevent burning or scalding, pipe blow-off

discharge from blow-down valve to floor –

allowing enough height for a pail under discharge pipe to collect blow down discharge.

This pipe must be same 3/4” size as blowdown connection; do not reduce. Do not

thread end of pipe.

!

CAUTION

Page 7

7

T

U

A

W

c. Using a pipe wrench, install a w" (19mm) NPT

pipe (T) into the opening of the blow down

valve (U) and tighten to 47 ft•lb (64 N•m).

A

b. Install the control (A) by rotating it onto the 22"

(63.5mm) nipple (X, as shown in Step a on

previous page). Tighten to 109 ft•lb (148 N•m).

d. Hang a blow down card (W) (enclosed) as

close to the control (A) as possible, or remove

the protective backing and affix the card on

the boiler jacket close to the control.

To prevent burning or scalding, pipe blow-off

discharge from blow-down valve to floor –

allowing enough height for a pail under discharge pipe to collect blow down discharge.

This pipe must be same 3/4” size as blowdown connection; do not reduce. Do not

thread end of pipe.

!

CAUTION

Page 8

STEP 4 - Electrical Wiring

Directory: 67 Low Water Cut-Off and Uni-Match Water Feeder page 8 - 9

67 Low Water Cut-Off and 101 Water Feeder page 10 - 11

For 67 Low Water Cut-Off Installed with McDonnell & Miller Uni-Match Water-Feeder

WARNING

!

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls installed on the

boiler. After installation, check for proper operation of all of the limit and operating controls, before leaving

the site.

Failure to follow this warning could cause electrical shock, an explosion and/or a fire, which could result in

property damage, personal injury or death.

a. Using a flathead screwdriver, remove the one

(1) screw that secures the low water cut-off

switch cover (Y).

b. Using a flathead screwdriver, loosen the two

(2) screws and remove the feeder cover (Z).

Y

Z

c. Position the slide switch selector (AA) in the

position.

8

AA

Page 9

Page 10

NOTE: To connect wires to the terminals

on the burner, or low water cut-off, place

the bare end of the wire under the terminal

screw and tighten the screw with a flathead screwdriver. On the 101-A water

feeder use wire nuts.

Y

a. Using a flathead screwdriver, remove the one

(1) screw that secures the low water cut-offs

switch housing (Y).

BB

b. Using a flathead screwdriver, remove the

two

(2) screws that secure the feeder cover

(BB).

For 67 Low Water Cut-Off Installed with McDonnell & Miller Series 101-A Water-Feeder

For the 120V Burner/120V Feeder setups.

BURNER

120 VAC

SUPPLY

12

34

N

H

101A

69

c. Using a wire nut, connect a wire from the

neutral side of the power supply to one of

the wires inside the feeders junction box.

(Does not make a difference which one).

Connect a wire from the "hot" side of the

power supply to terminal #2 of the Series 67

junction box. Connect the neutral side of the

power supply to the burner.

BURNER

120 VAC

SUPPLY

12

34

N

H

101A

d. Connect the wire from the burner to terminal

#1 of the low water cut-off. Connect a

"jumper" from terminal #2 to terminal #3 of the

low water cut-off. Connect a wire from terminal #4 of the low water cut-off to the remaining wire in the 101A water feeder.

10

Page 11

For the 24V Burner/24V Feeder setups.

BURNER

101A-24

120 VAC

SUPPLY

24V TRANSFORMER

(101-24V-48)

12

34

N

H

24V

69

c. Connect the "hot" wire from the boiler trans-

former to terminal #2 of the low water cut-off.

Connect the "hot" side of the water feeder

transformer to terminal #3 of the low water

cut-off. Connect the neutral side of the boiler

transformer to the burner. Using a wire nut,

connect the neutral side of the water feeder

transformer to the water feeder.

BURNER

101A-24

120 VAC

SUPPLY

24V TRANSFORMER

(101-24V-48)

12

34

N

H

24V

d. Connect the wire from the burner to terminal

#1 of the low water cut-off. Connect a wire

from terminal #4 of the low water cut-off to the

remaining wire in the water feeder. Wire nut

together.

BURNER

101A

120 VAC

SUPPLY

N

H

24V

12

34

69

Wiring Alternative

For the 120V Burner/24V Feeder setups. For the 24V Burner/120V Feeder setups.

BURNER

101A-24

120 VAC

SUPPLY

24V TRANSFORMER

(101-24V-48)

TO AVOID DAMAGE TO 101A

SOLENOID COIL, TRANSFORMER

101-24V-48 MUST BE USED.

N

H

12

34

69

11

IMPORTANT: It is very important that you use the transformer supplied with the 101-A-24. The boiler

transformer in most cases is not big enough to handle the current draw of the 101-A-24.

Use the supplied transformer (101-24-48). In most cases it will handle both the boiler

and feeder. Do not try to use two transformers in the same circuit.

Page 12

For All Installations

The BX outlet (GG) on the control is mov

able

into any of the four positions by simply

removing the two black-headed screws and

rotating the housing.

BOTTOM TOP LEFT RIGHT

ALLA

INST

MAINTENANCE

SCHEDULE:

• Blo

w down weekly (at least once) when the

boiler is in operation.

• Disassemble and inspect annually. Replace

the low water cut-off if it is worn, corroded,

or if components no longer operate properly.

• Inspect the float chamber and equalizing

piping annually. Remove all sediment

and debris.

• Replace every 10 years. More frequent replace-

ment may be required when severe conditions

exist such as rapid switch cycling, surging water

levels, and use of water treatment chemicals.

TION COMPLETE

PROCEDURE:

To

prevent serious personal injury from steam and hot

water, make sure there is a discharge line from the

blow down valve to a proper place of disposal.

Failure to follow this caution could cause

personal injury.

1. Blo

w down the low water cut-off when the

water level is at its normal level and the

burner is on. Fully open the blow down

valve and observe the water level fall in the

gauge glass. Close the valve after verifying

that the feeder contacts have closed and

the burner shuts off. If this does not happen,

immediately shut off the boiler and correct

the problem.

CAUTION

!

Xylem Inc.

8200 N.

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.mcdonnellmiller.com

McDonnell & Miller is a trademark of

© 2014 Xylem Inc. MM-201H March 2014 Part No. 246752

Austin Avenue

Xylem Inc. or one of its subsidiaries.

Loading...

Loading...