Page 1

INSTRUCTION MANUAL

IM253 R0

AquaStart

COMBINATION SOFT STARTERS

START-UP MANUAL

™

Page 2

INDEX

Power Connections ................................................................................................................................................................ 3

Basic Wiring ............................................................................................................................................................................ 4

Start-Up By Voltage Ramp ....................................................................................................................................................5

Local / Remote Modes ..........................................................................................................................................................6

Control and Signal Connections ..........................................................................................................................................6

Control Wiring Terminals ......................................................................................................................................................7

Connections for Remote Start/Stop ....................................................................................................................................8

Control via 2-Wire Start / Stop (Remote Mode) .................................................................................................................9

Control via 3-Wire Start / Stop (Remote Mode) ...............................................................................................................10

Programming via DIP Switches and Trim Pots ..................................................................................................................10

Parameters Example ............................................................................................................................................................11

Minimum Trim Pots and DIP Switches to Set ....................................................................................................................12

Current Limiting for Loads with High or Constant Starting Torque ...............................................................................13

Soft Starter Operation .........................................................................................................................................................14

Fault Codes ...........................................................................................................................................................................14

Limited Warranty ..................................................................................................................................................................16

2

Page 3

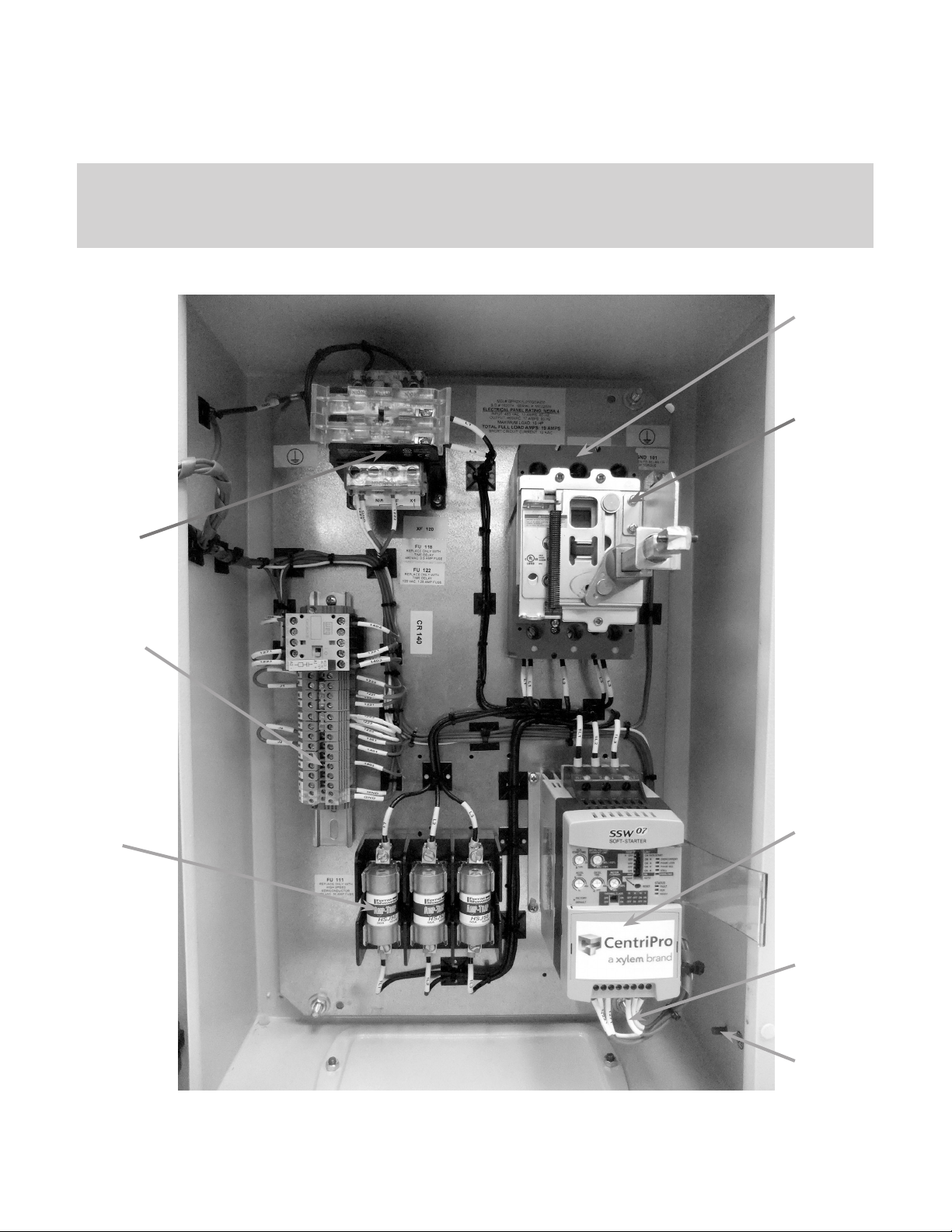

POWER CONNECTIONS

The AquaStart Start-up Manual is a supplement to help get the AquaStart commissioned quickly using the

most common installation and conguration options. This manual is not meant to replace the SSW07 User’s

Manual. For detailed safety precautions, mounting, installation, conguration, or operation instructions, please

refer to the SSW07 User’s Guide.

WARNING: Only qualied personnel should plan or implement the installation, start-up, operation and

maintenance of this equipment. Personnel must read the entire SSW07 User’s Guide before attempting to

install, operate or troubleshoot the AquaStart Panel.

Input

Supply

Power

Fusible

Disconnect

Control

Power

Transformer

Control

Wiring

Terminals

Fuse

Block

SSW-07

Soft

Starter

Output

FIGURE 1 – Panel Internal Layout

Power

to Motor

Ground

(M6

thread)

3

Page 4

BASIC WIRING

1. Mount the AquaStart panel to a at vertical surface.

2. Connect the three-phase incoming power leads to the R, S, and T connections on the power terminal (refer

to Figure 1). Connect the motor leads to the U, V, and W connections on the power terminal and connect

the GROUND lead to PE on the chassis (refer to Figure 1). Note: Only three-phase AC motors can be

used.

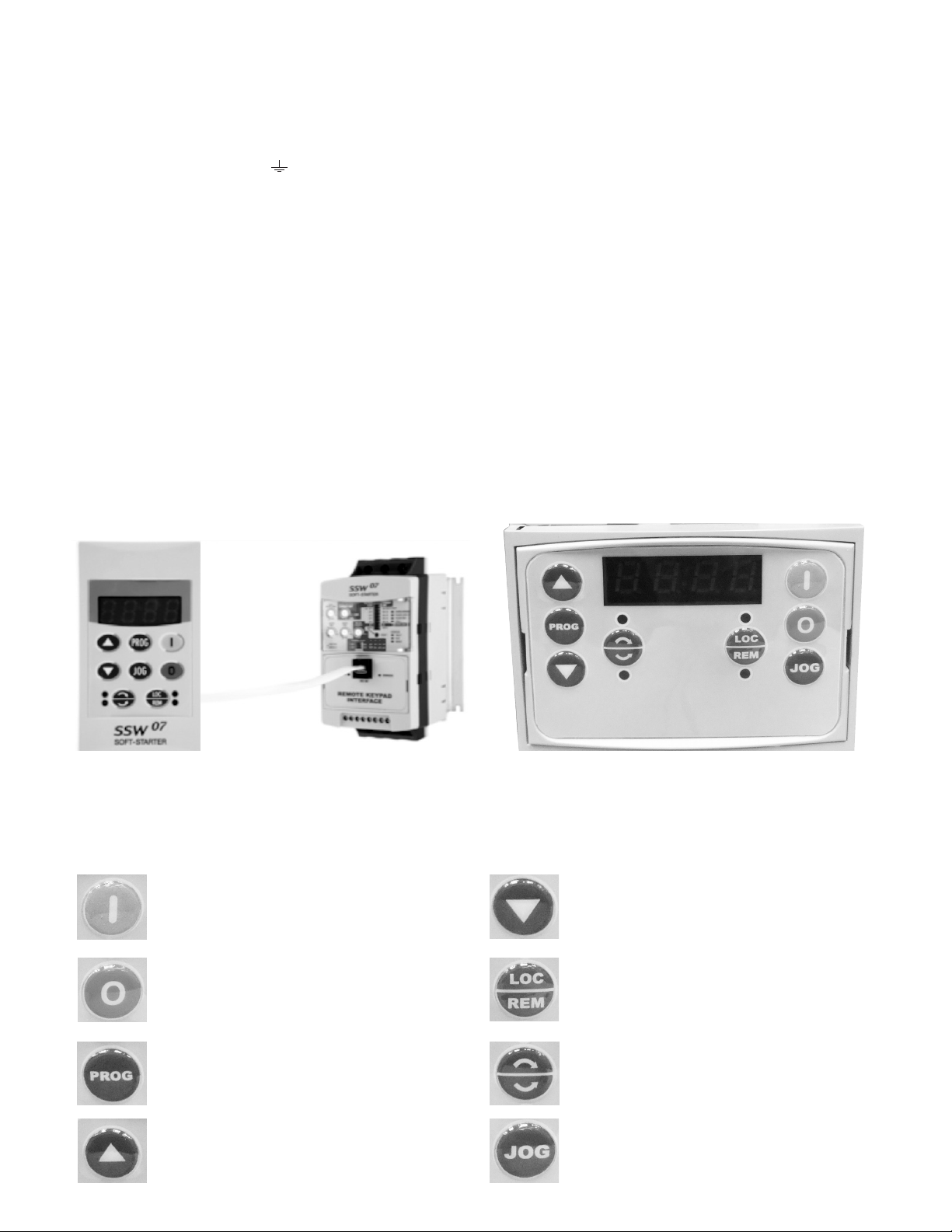

USING THE KEYPAD (OPTIONAL)

The keypad can be used in the following arrangements:

• Keypad on controller:

o Local keypad is attached to the SSW07 controller for commanding, programming, and/or visualizing

parameters.

• Keypad on door:

o Remote keypad is mounted “through door” attached to the SSW07 controller with a cable for

commanding, programming, and/or visualizing parameters.

The SSW-07 local or remote keypads present a 7-segment 4-digit LED display, 4 status LEDs, and 8 keys. The

gures below show a front view of the remote keypad and the local keypad.

REMOTE KEYPAD LOCAL KEYPAD FRONT VIEW

FIGURE 2 – Keypads

BASIC FUNCTIONS OF THE KEYS:

Enables the motor (start);

Disables the motor (stop), Resets the

Soft-Starter after the occurrence of

errors;

Selects (toggles) the display between

the parameter number and its value

(position/content);

Increments the parameter number or

parameter value;

4

Decrements the parameter number or

parameter value;

Selects the origin of the commands

between Local or Remote;

No Function on SSW-07

No Function on SSW-07

Page 5

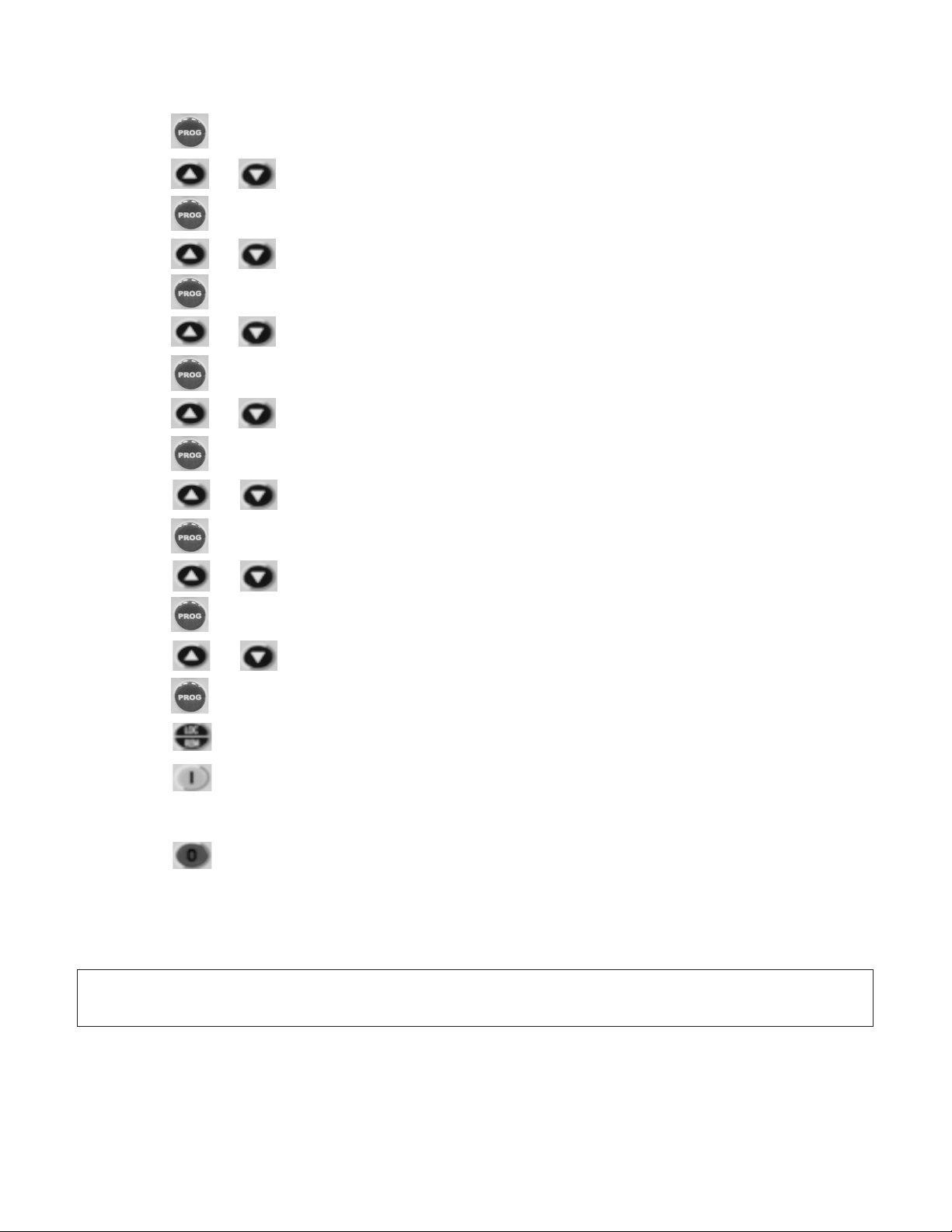

START-UP BY VOLTAGE RAMP USING THE KEYPAD: (most common conguration)

1. The soft starter should be powered up with a display of “RDY”.

2. Press the key to enter the programming mode.

3. Press the or key to select P000 (Access to parameters).

4. Press the key to change value of parameter.

5. Press the or key to set to “5” to allow access to parameters.

6. Press the key to save the selected option.

7. Press the or key to select P219 (Parameterization via keypad).

8. Press the key to change value of parameter.

9. Press the or key to set to “0” for keypad programming.

10. Press the to save the selected option.

11. Press the or key to select P202 (the Password is).

12. Press the key to change value of parameter.

13. Press the or key to set to “0” for Voltage Ramp.

14. Press the key to save the selected option and exit the programming mode.

15. Press the or key to select P003 (Motor Current).

16. Press the key to read the Motor Current value (This is a read parameter).

17. Press the key to operate soft-start via HMI.

18. Press the start key. The motor accelerates to full voltage and the bypass contact engages.

Note: If the direction of rotation is not correct, turn the input disconnect to the off position and swap any

two wires at the motor output.

19. Press the stop key. The motor decelerates until stopping by coast to rest. Time to stop depends on

load inertia and friction.

Note: For a complete description of Parameters and Error codes refer to Chapters 6 and 7 in the SSW07

Programming Manual.

NOTE: FOR SUBMERSIBLE MOTORS, SET THE INITIAL VOLTAGE P101 TO 70% AND THE MOTOR

PROTECTION THERMAL CLASS P640 TO 2 (CLASS 10).

5

Page 6

LOCAL/REMOTE MODES (Optional Keypad):

In the previous section the soft starter was operated from the keypad (Local Mode). Note the green local

indicator LED on the bottom right of the keypad. For the factory default programming, the selection of the

operation mode (Local/Remote) is made via the “Local/Remote” key (default is Remote). Pressing of the “Local/

Remote” will alternate operation between local & remote. Notice the indicator switches from the green to

the red indicator LED when “Local/Remote” is pressed. If you wish to use an external Local/Remote switch set

P220=4, connect the switch to one of the Digital Inputs (DI1-DI3), and set the corresponding parameter (P263

to 265=2).

To always run in Local mode set P220=0.

To always run in Remote mode set P220=1.

CONTROL AND SIGNAL CONNECTIONS:

Control and signal connections (digital inputs and relay outputs) are made through the terminals (see Figure 3).

Terminal Description Specications

A1

Electronics Supply

A2

Terminal Factory Default Specications

DI1 Starts/Stops Motor

DI2 Fault reset

DI3 Fault reset

13 Relay 1 output - Operation

14 / 23 Relay common point

24 Relay 2 output - Full voltage

FIGURE 3 – SSW-07 Control and Signal Connections

6

Voltage: 110 to 240 Vac (-15% a +10%)

Current: 140mA Maximum

(factory connections)

3 isolated digital inputs

Voltage: 110 to 240 Vac (-15% a +10%)

Current: 2 mA Maximum

Contact capacity:

Voltage: 250Vac

Current: 1A

Torque Nm

(in lb)

0.5 (4.5)

Page 7

CONTROL WIRING TERMINALS

CONTROL WIRING TERMINAL STRIP

Control Relay

ES1

ES2

1221

1221

1223

1223

1301

1401

1441

1403

SP

SP

GND

GND

FIGURE 4 – Control Wiring Terminals

SSW 07

Terminals

A1 1221

A2 1223

13 1301

Control

Terminal

Label

ES1

ES2

1221

1223

1401

1441

1403

SP

SP

Control Terminal

Description

Safety/Emergency Stop*

Connected by J1. To enable an

emergency stop function, re-

move J1 and install the control

device between ES1 and ES2

110Vac Control Voltage

Neutral for Control Voltage

Connected to 1401 by J2.

J2 Enables Start and Stop

Buttons on enclosure cover.

To disable buttons on the cover,

remove J2. To add a remote

Start/Stop, connect a jumper

from 1301 to 1441 and wire the

control device between 1441

and 1403.

Connection to Start and Stop

Buttons on enclosure cover.

Remote Start/Stop**

Spares

CONNECTIONS FOR REMOTE START/STOP

* Emergency Stop

A Safety or Emergency Stop function can be implemented

by removing the J1 jumper connecting terminals ES1

and ES2. The emergency stop device will then be wired

between ES1 and ES2. When an emergency situation

(high pressure, high temperature, …) is encountered the

device must open to disconnect control power to the

circuitry enabling the soft starter. This will then stop the

pump/motor. This control device must be sized to operate

at 2.5A at 115Vac.

CAUTION! THE EMERGENCY STOP DEVICE DOES

NOT DISCONNECT LINE POWER TO THE SOFT

STARTER.

GND

Ground

GND

7

Page 8

CONNECTIONS FOR REMOTE START/STOP

** Remote Start/Stop

A Remote Start/Stop function can be implemented to

allow control of the soft starter by an external control

device (pressure switch, ow switch, …). To implement

a remote start/stop, remove the J2 jumper connecting

terminals 1301 and 1401. Then connect a jumper wire

from 1301 to 1441. The control device will then be

connected between 1441 and 1403. When the control

device is open, the soft starter will stop the pump/

motor. When the control device is closed, the soft

starter will start the pump/motor. This control device

must be sized to operate at 2.5A at 115Vac.

CAUTION! WHEN J2 IS REMOVED, THE START AND

STOP BUTTONS ON THE FRONT OF THE PANEL ARE

DISABLED.

8

Page 9

CONNECTIONS FOR REMOTE CONTROL OF THE SSW07 WHEN PURCHASED SEPARATELY

CONTROL VIA 2-WIRE START/STOP

(Remote Mode):

FIGURE 5 – Control via 2-wire Start/Stop

Control Wiring: Start/Stop switch is N.O.

(Normally Open) and is wired as shown in Figure 4.

Parameters (Optional Keypad):

1. Set P220 = 1 Always Remote

2. Set P230 = 1 Digital Inputs

3. Set P263 = 1 DI1 Enable/Disable

CONTROL VIA 3-WIRE START/STOP

(Remote Mode):

FIGURE 6 – Control via 3-wire Start/Stop

Control Wiring: “Start” and “Stop” are momentary push button switches and are connected as shown in

Figure 4. “Start” is a N.O. (Normally Open) contact and “Stop” is a N.C. (Normally Closed) contact.

Parameters (Optional Keypad):

1. Set P220 = 1 Always Remote

2. Set P230 = 1 Digital Inputs

3. Set P263 = 1 DI1 Start (three wires)

4. Set P264 = 1 DI2 Stop (three wires)

9

Page 10

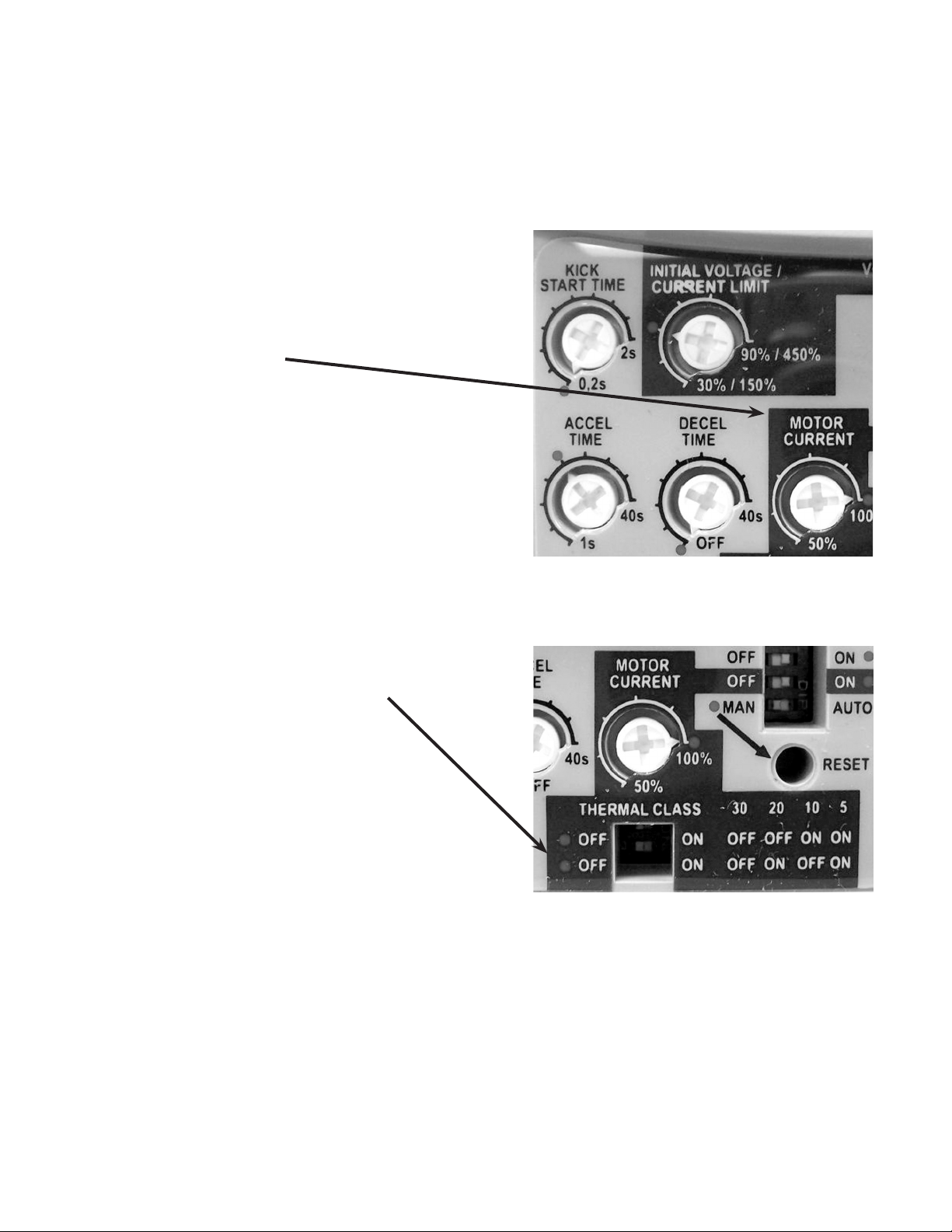

PROGRAMMING VIA DIP SWITCHES AND TRIM POTS:

To program DI2 for 3-wire control, refer to Figure 5 and perform the following:

1. Press and hold the reset button on the front of the SSW07 for 5 seconds to enter the programming mode.

Note: The reset button must remain pressed during programming.

2. When the programming mode is entered, two LED’s will illuminate (over-current and phase loss), indicating

that DI2 is programmed for fault reset.

3. To re-program for 3-wire control, switch the over-current dip-switch and return to the previous position.

Three LED’s will illuminate (over-current, phase loss, and phase sequence), indicating that DI2 is now

programmed for 3-wire control.

4. To change DI2 programming back to fault reset, switch the kick start dip-switch and return to the previous

position. Two LED’s will illuminate (over-current and phase loss), indicating that the DI2 is programmed for

fault reset.

5. Release the reset button to complete the programming.

FIGURE 7 – Trim-Pots and Dip Switch Locations

10

Page 11

PARAMETERS EXAMPLE (Optional Keypad) (P219 = 1):

Soft Starter Data (Example):

Enclosure Model: AST40150

SSW-07 Model: SSW07XY0024T5SZ

Motor Data (Example):

Power: 15 HP

Rated Speed: 3450 RPM

Motor FLA Current: 21A

Service Factor Current: 24A

Rated Voltage: 460 V

Service Factor: 1.15

The following is a typical list of parameter changes needed using the Motor/Soft Starter data shown above.

P000=5 Parameter Access (5 = Password)

P219=1 Parameterization via keypad/ (trim pots and DIP switches) (1 = keypad)

P202=0 Type of Control (0 = Voltage Ramp)

P101=50 Initial Selected Voltage (50%)

P102=20 Voltage Ramp Time (20 seconds)

P400=460 Motor Rated Voltage (460 volts)

P401=87.5% Motor Rated Current (21 amps)

P406=1.15 Motor Service Factor (1.15)

P640=6 Thermal Motor Protection Class (Class 30)

Local/Remote parameters allow the soft starter to be set up to operate from Keypad, Remote Terminal, or a

programmed combination of keypad and terminal inputs.

P220 – Local/Remote Selection

P229 – Local Status Command

P230 – Remote Status Command

Read Only Parameters (P001 – P081) can be used for monitoring and troubleshooting. For a full list and

description please read the SSW07 Programming Manual. By monitoring certain read only parameters, the

status of inputs, outputs, and soft starter operational values can be determined without the use of any other

test equipment.

P003 - Motor Current

P006 - Soft Starter Status

P007 - Output Voltage

P012 - Digital Input Status

P013 - (Relay Output Status) – used to monitor relay outputs.

11

Page 12

TRIM-POT AND DIP SWITCH SETTINGS (P219 = 0):

Soft Starters are shipped with factory default values. If Trim-Pots and Dip Switches have been changed, it

is advisable to reset to factory default positions prior to a new installation by aligning all trim-pots and dip

switches with the red factory default dots. By default the control type is Voltage Ramp Starting. This control

type is very easy to setup and is the most commonly used starting method. Current Limit Starting is the

second control type and is described below.

Motor Current Trim-Pot Setting - Factory default position is

100% and is marked with a red dot. To protect the motor from

overload, obtain the full load amperage (FLA) off the motor

and soft-starter name plates. Using the following formula,

calculate the percentage of current that the motor will draw

from the soft-starter and set the Motor Current Trim-Pot

accordingly.

– Max A of the soft-starter = 170A

– Max A of the motor = 140A

– Max A of the motor / Max A of the switch

= 140A / 170A = 0.823

– Motor Current Trim-Pot = 82.3%

Thermal Class Dip Switch Setting – Set to factory default of

30 if not specied on the motor name plate. (Note: Factory

default positions are marked with red dots).

Note: If using a submersible motor, set the

thermal overload class to class 10.

Note: These are the minimum settings for a

perfect adaptation between soft starter and motor.

For a complete description of Trim-Pot and Dip Switch

settings refer to Chapter 4 in the SSW07 User’s Guide.

Figure 8 - Motor Amp Trim-Pot

Figure 9 - Thermal Class Dip Switch

Initial Voltage/Current Limit Setting - When operating in Voltage Ramp Starting mode, this setting

congures the initial voltage applied to the motor during start up. When using a submersible motor, set the

initial voltage to 70% to ensure the motor accelerates to half speed in 1 second. For other motor types, set the

voltage so that the motor begins to spin as soon as a start command is given to the soft starter.

Accel Time Setting - When operating in Voltage Ramp Starting mode, this setting controls the time of the

voltage ramp. This is the time from the start of the ramp (initial voltage) to soft starter bypass. This is not the

motor acceleration time. For a faster start, decrease this setting. For a slower start, increase this setting.

12

Page 13

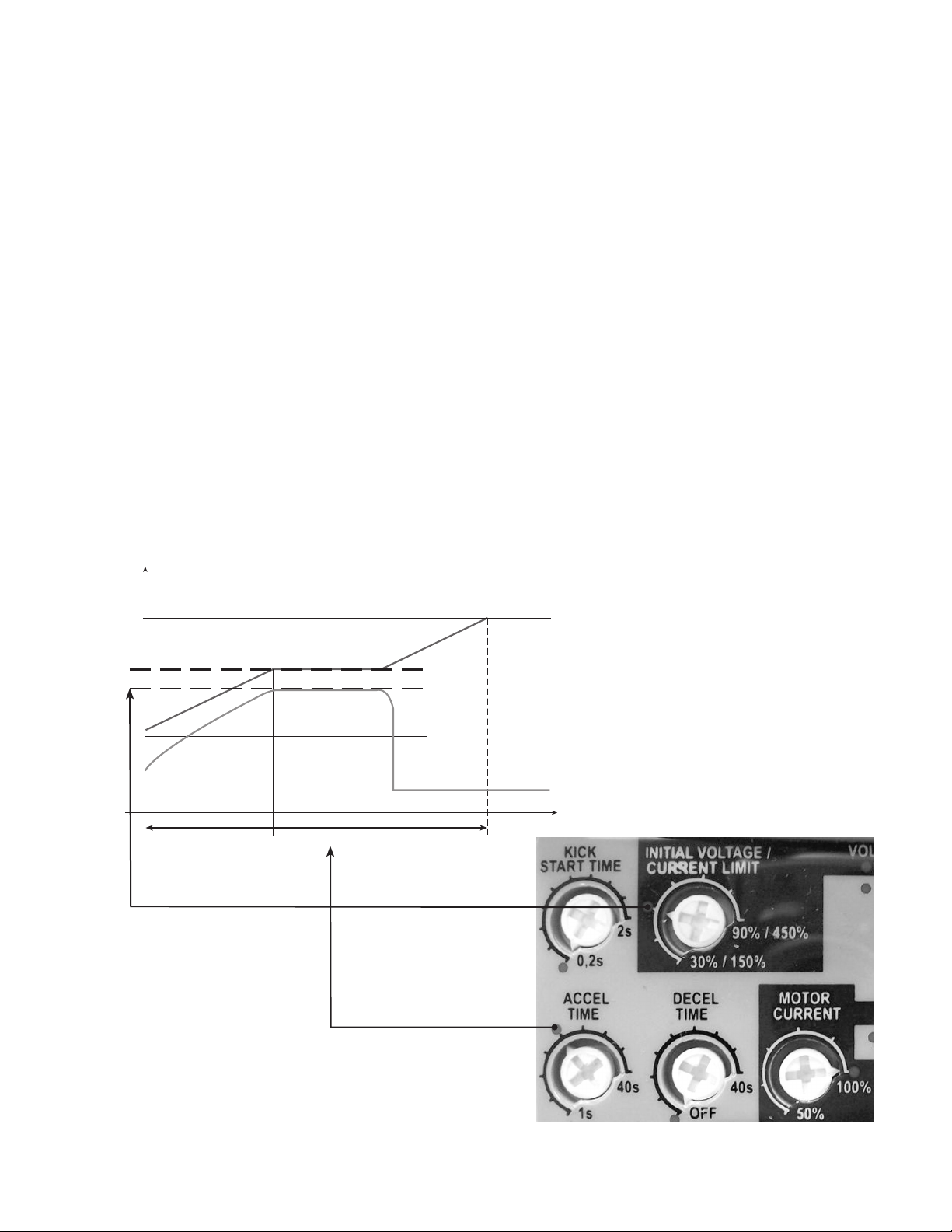

CURRENT LIMITING FOR LOADS WITH HIGH OR CONSTANT STARTING TORQUE:

Current limiting control is used to adapt the Soft Starter to the capacity limits of the power supply. It is often used

with power generators with limited output but may also be used to keep current draw to a minimum on loads

with high or constant starting torque.

Optional Keypad:

1. Set P202 = 1 Type of control = Current Limit

2. Set P110 to % of current you wish to limit using example below.

3. Set P102 to desired acceleration.

Trim-Pot and Dip Switch Settings (Figure 9):

1. Set the Voltage Ramp/Current Limit dip switch to the Current Limit position.

2. Set the Current Limit Trim-Pot using the following example.

Calculation example for limiting the current to 2.5 x IN of the motor:

– IN of the switch = 60A

– IN of the motor = 52A

– ILIM = 250% of the IN of the motor

– 2.5x 52A =130A

– 130A / IN of the switch = 130A / 60A = 2.17 x IN of the switch

– Current Limit = 217% of the IN of the switch = 2.5x IN of the motor

U

100 %

fixed voltage

Figure 10 - Current Limiting

current limit

Accel Time

reached set level

of current limit

Time

Notes: (1) The Current Limit must be set at a level that permits

the motor to accelerate otherwise the motor will not start. (2)

If the full voltage is not reached at the end of the acceleration

ramp time an E62 error will occur and the motor will be

disabled. For details on Fault Codes please refer to Chapter 6 in the SSW07 User’s Guide. (3) For details on

Current Limiting please refer to Chapter 5 in the SSW07 User’s Guide.

13

Page 14

SOFT STARTER OPERATION:

The Soft Starter is now ready to operate via the 2-Wire or 3-Wire Control that was set up in the previous steps.

To start the motor, press the “Start Button” and the Soft Starter will accelerate up to speed (default acceleration

time is 20sec). When full voltage is reached the internal bypass contactors will engage and switch the motor to

the supply line.

To stop the motor, press the “Stop Button” and the Soft Starter will decelerate to the stop position (default

deceleration time is “Off” so the motor will coast to rest). For details on setting deceleration time and other trim-

pots refer to Chapter 4 in the SSW07 User’s Guide.

FAULT CODES:

Optional Keypad:

When a fault is detected, the Soft Starter is disabled and the Fault Code is displayed (example E03). To restart

the Soft Starter after a fault has occurred, the Soft Starter must be reset. Resetting the Soft Starter can be done

by disconnecting and reapplying AC power (power-off reset), by pressing the “O/RESET” key (manual reset),

automatic reset, or via digital inputs. For details on Reset and a full list and description of Fault Codes, please

read Chapter 6 in the SSW07 User’s Guide.

Trim-pots and DIP switches:

When a fault is detected, the Soft Starter is disabled and the Fault Code is displayed by ashing LED’s. To restart

the Soft Starter after a fault has occurred, the Soft Starter must be reset. Resetting the Soft Starter can be done

by disconnecting and reapplying AC power (power-on reset), by pressing the “RESET” button on the front panel

(manual reset), automatic reset, or via digital inputs. For details on Reset and a full list and description of Fault

Codes please read Chapter 6 in the SSW07 User’s Guide.

14

Page 15

NOTES

15

Page 16

LIMITED WARRANTY

This warranty applies to this Xylem Inc. product.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall

exist for a period of thirty (30) months from date of installation or thirty-six (36) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Xylem Inc. distributor from whom the equipment was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Xylem Inc. Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these denitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Xylem Inc. and the dealer in purchases,

consignments or contracts for sale of the subject equipment.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing equipment to

customers.

(3) “Customer” means any entity who buys or leases the subject equipment from a dealer. The “customer” may mean an individual, partnership, corporation, limited

liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.centripro.com

CentriPro and AquaStart are trademarks of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. IM253 Rev. 0 September 2013

Loading...

Loading...