Xerox DOCUPRINT 65, DOCUPRINT 115, DOCUPRINT 75MX, DOCUPRINT 155MX, DOCUPRINT 115MX Manual

...

Generic MICR

Fundamentals Guide

701P22140 January 2003

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

©2002, 2003 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable material and information now allowed by statutory or judicial law or hereinafter granted, including without limitation, material generated from the software programs which are displayed on the screen, such as icons, screen displays, looks, etc.

Printed in the United States of America.

Publication number: 701P22140

Xerox® and all Xerox products mentioned in this publication are trademarks of Xerox Corporation. Other products and trademarks of other companies, including Dataglyph™, are also acknowledged.

Changes are periodically made to this document. Changes, technical inaccuracies, and typographic errors will be corrected in subsequent editions.

Table of contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

How to use this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

A brief history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 1-2 |

Why MICR? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

Check printing capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

Check processing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

Production cycle of a check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

Changes in check creation role . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-11 |

2. Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Types of MICR applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Manufacturing checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Issuing checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

Issuing turnaround documents . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

Printing financial forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-3 |

Xerox MICR printing systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-3 |

MICR printing technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-4 |

Printer technical optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-5 |

Typical MICR printing concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-5 |

3. Paper facts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Paper guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 MICR paper requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Basis weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 Sheffield smoothness scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 Grain direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 Moisture content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 Reflectance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5 Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6 Perforation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6 Metallic content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Stiffness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7 Cutting precision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8 Xerox paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Generic MICR Fundamentals Guide |

iii |

Table of contents

Paper maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Wrapping factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Storage factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9 Temperature and humidity conditions . . . . . . . . . . . . . . . . . . . 3-10

Paper runability criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Preprinted forms considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13 Inks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Security features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Duplication detection . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14 Alteration prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Application design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Numbered stocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15 Features to avoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

4. Document design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Check document content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Security features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Background printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 Fixed information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Date line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Amount lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 Payee line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Signature lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Name of financial institution . . . . . . . . . . . . . . . . . . . . . . . 4-4 Memo line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Account title . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Check serial number . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5 Fractional routing number . . . . . . . . . . . . . . . . . . . . . . . . 4-5

MICR line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

MICR line (clear band) format requirements . . . . . . . . . . . . . . . . . . . . . 4-5 Format specifications using E13B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

E13B character set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

E13B numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

E13B symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

On-Us symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Transit symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8 Amount symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Dash symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

E13B character design . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9 Field formats—E13B font . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Document Specifications form . . . . . . . . . . . . . . . . . . . . 4-11

Amount field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13 On-Us field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13 Transit field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

External processing code (EPC) field . . . . . . . . . . . . . . 4-14

Auxiliary On-Us field . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

iv |

Generic MICR Fundamentals Guide |

Table of contents

Field formats summary . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Character alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

CMC7 font . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16 CMC7 numbers and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Character design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

MICR character spacing requirements . . . . . . . . . . . . . . . . . . . . . . . . 4-19 Character spacing algorithm for 300 dpi . . . . . . . . . . . . . . . . . . 4-19

Fixed pitch and proportional font spacing . . . . . . . . . . . . . . . . . 4-19

Check size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23 Other application considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Two sided printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Perforations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25 Multiple-up printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Readability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

5. Document processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Proofing checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Amount determination errors . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 Proofing equipment errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Reader sorter function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Waveform generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4 Types of reader sorters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Waveform reader sorters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Matrix or AC reader sorters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5 Optical reader sorters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Dual read magnetic reader sorters . . . . . . . . . . . . . . . . . . . . . . . 5-6

Hybrid magnetic and optical reader sorters . . . . . . . . . . . . . . . . 5-7 Processing speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Paper handling by reader sorters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Hopper jogger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8 Separator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Aligner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Read/write heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Item numbering and endorsing stations . . . . . . . . . . . . . . . . . . . 5-9

Microfilm or image capture unit . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Sorter pockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10 Reject repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

6. Quality control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Print quality specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Optical tools used to check MICR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

MICR Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 Small Optical Comparator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 Magnetic testing equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 E13B calibration document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4 Testing sample documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Generic MICR Fundamentals Guide |

v |

Table of contents

Specifications for testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Horizontal position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Vertical position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7 Skew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Character-to-character spacing . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Voids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13 Extraneous ink spots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Signal strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Debossment and embossment . . . . . . . . . . . . . . . . . . . . . . . . . 6-20 Summary of ANSI standards . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Additional performance considerations . . . . . . . . . . . . . . . . . . 6-22

Dry ink slivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22 Damaged or ragged characters . . . . . . . . . . . . . . . . . . . 6-22

Crayoning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Operational maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Quality measurements: magnetic versus optical . . . . . . . . . . . . . . . . . 6-23

Magnetic testing equipment usage . . . . . . . . . . . . . . . . . . . . . . 6-23 Optical testing equipment usage . . . . . . . . . . . . . . . . . . . . . . . 6-25

Recommendation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

7. Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

When problem solving is required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

New accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Existing applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 Possible misinterpretations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Problem solving process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Determining the problem source . . . . . . . . . . . . . . . . . . . . . . . . 7-4 Reader sorter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Operator training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4 Application software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Unknown cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Reader sorter testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Interpreting test results . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Questions to consider . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Expected reject rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9 Reducing reject rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Inspecting documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Correct font placement or format . . . . . . . . . . . . . . . . . . 7-12 MICR character defects . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Document damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Excessive ink smears . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13 Paper size and characteristics . . . . . . . . . . . . . . . . . . . . 7-13 MICR line format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Job history or results . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Compare the documents with previous samples . . . . . . 7-14

vi |

Generic MICR Fundamentals Guide |

Table of contents

Analyzing reader sorter printout . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Test patterns: alternative to reader sorter testing . . . . . . . . . . . 7-15

Verifying problem resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

8. Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Xerox printing systems security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Physical security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2 Restricting physical access . . . . . . . . . . . . . . . . . . . . . . . 8-2

Securing paper stocks . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3 Responsible presence . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Software security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Logon levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

System commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Audit control processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Accounting information . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5 Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Tampering methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Chemical tampering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7 Mechanical tampering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Modifying printed checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Lithographic printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8 Impact printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Cold pressure fix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Xerography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9 Preventing tampering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Safety papers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Overprints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11 Textures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Amount limit statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Amount in Words fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Preventing check duplication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Microprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Watermarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13 Drop-out print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Dataglyph™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

VOID pantograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14 Avoiding counterfeit and stolen checks . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Alteration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Embezzlement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15 Stolen checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16 Counterfeits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Cost considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Generic MICR Fundamentals Guide |

vii |

Table of contents

A. References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Standards documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Instructions for ordering U. S. standards . . . . . . . . . . . . . . . . . . . . . . . . A-2 Ordering online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Ordering hardcopy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Standards development process information (U. S. only) . . . . . A-3

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glossary-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

viii |

Generic MICR Fundamentals Guide |

Introduction

About this guide

The purpose of the Generic MICR Fundamentals Guide is to provide a reference for the various facets of the MICR environment within the context of the Xerox MICR printing products. This document does not contain specific information on individual Xerox MICR printers.

Since the printing of MICR documents involves application and operational considerations not normally associated with any of the standard Xerox printing systems, this document provides principles and guidelines to ensure successful MICR printing.

This document has been developed with the assumption that readers have knowledge of standard Xerox printing systems products, and the skills to develop applications and job source libraries.

The Generic MICR Fundamentals Guide contains the following chapters and appendices:

Chapter 1: Overview. Describes MICR, its historical background, and the printing and processing procedures for the MICR document.

Chapter 2: Environment. Examines the types of applications that use MICR, trends within the industry, and typical MICR printing methods and concerns.

Chapter 3: Paper facts. Identifies paper grades and properties required for MICR printing, and describes paper maintenance procedures.

Chapter 4: Document design. Describes the standard format, features, and requirements of a check document.

Chapter 5: Document processing. Examines the common types of reader sorter technology and the way these systems function.

Generic MICR Fundamentals Guide |

ix |

Introduction

Chapter 6: Quality control. Describes MICR document print quality specifications, the tools available to determine if a document is within specifications, and general operator maintenance procedures.

Chapter 7: Problem solving. Provides information on identifying MICR printer related problems and using rejection rate information to isolate the problem source.

Chapter 8: Security. Provides an overview of the security procedures used to control and audit access to a Xerox MICR printing system and to check printing functions.

Appendix A: MICR references. Lists the domestic and international standards documents that apply to MICR publications. Also contains a list of Xerox documents containing MICR information.

Glossary: Lists terms and definitions related to MICR printing and banking environments.

How to use this guide

•First, become thoroughly familiar with the operation of your own MICR system.

•Read through this guide to acquaint yourself with all of the topics.

•As needed, refer to sections of this guide that are pertinent to your work.

x |

Generic MICR Fundamentals Guide |

1.Overview

MICR (Magnetic Ink Character Recognition) is a process by which documents are printed using magnetic ink and special fonts to create machine readable information for quick document processing.

Although traditionally MICR has been used to print accounting and routing information on bank checks and other negotiable documents, the magnetic encoding lends itself to any form of document processing.

The following figure shows a check with a MICR line. This line contains block-shaped numbers running along the bottom of the check, and non-numeric characters called “symbols.” This entire string of numbers and symbols is printed using magnetic ink.

Figure 1-1. MICR line on a check

Generic MICR Fundamentals Guide |

1-1 |

Overview

A brief history

Originally, checks were processed manually. However, by the mid-1940s the banking system became inundated with paper as society grew more mobile and affluent. Finding a means of handling the growing number of paper documents became vital to bankers. The banking and electronics industries searched for a standard process that could be used in all banks throughout the country.

In the mid-1950s, the first automated processing of checks was initiated. The system that is now known as MICR was developed by the Stanford Research Institute, using equipment designed by the General Electric Computer Laboratory. The E13B MICR font was also developed.

The specifications for producing the E13B font using magnetic ink were accepted as a standard by the American Bankers Association (ABA) in 1958. In April 1959, the ABA issued

Publication 147, The Common Machine Language for

Mechanized Check Handling.

Deluxe Check Printers had the task of translating the specifications into a working process. By the end of 1959, Deluxe successfully produced checks using magnetic ink.

In countries throughout the world there are groups that set standards and dictate the design specifications for document encoding, processing equipment, and quality criteria for MICR printing. Some of these are:

•American Banking Association (ABA)

•American National Standards Institute (ANSI)

•United Kingdom—Association for Payment Clearing Services (APACS)

•Canadian Payments Association (CPA)

•Australian Bankers Association (ABA)

•International Organization for Standardization (ISO)

•France—L'Association Francaise de Normalisation

1-2 |

Generic MICR Fundamentals Guide |

Overview

In 1963, the American National Standards Institute (ANSI) accepted the ABA specifications, with minor revisions, as the

American standard for MICR printing. The ANSI publication covering these standards is Print Specifications for Magnetic Ink

Character Recognition, first issued in 1969. Although compliance with the standards is voluntary in the U. S., the banking industry considers them to be the definitive basis for determining acceptable quality of a MICR document.

Another MICR font, called CMC7, was developed by the French computer company Machines Bull and has been the official French standard since September 1964. The CMC7 font is also used in other countries, including Italy, Spain, and Brazil. Like the E13B font, CMC7 is a magnetically readable font, but with a different character design and recognition criteria.

Some countries also use OCR-A or OCR-B, which are optically read check processing fonts. These fonts do not need to be printed with magnetic ink in order to be processed. The following table shows which countries use the four check printing fonts.

Generic MICR Fundamentals Guide |

1-3 |

Overview

Country |

E13B |

CMC7 |

OCR-A |

OCR-B |

|

|

|

|

|

North America: |

|

|

|

|

|

|

|

|

|

USA |

X |

|

|

|

|

|

|

|

|

Canada |

X |

|

|

|

|

|

|

|

|

Central America |

|

|

|

|

|

|

|

|

|

Bermuda |

X |

|

|

|

|

|

|

|

|

Mexico |

X |

|

|

|

|

|

|

|

|

Panama |

X |

|

|

|

|

|

|

|

|

South America: |

|

|

|

|

|

|

|

|

|

Argentina |

|

X |

|

|

|

|

|

|

|

Brazil |

|

X |

|

|

|

|

|

|

|

Chile |

|

X |

|

|

|

|

|

|

|

Columbia |

X |

|

|

|

|

|

|

|

|

Ecuador |

|

X |

|

|

|

|

|

|

|

Peru |

|

X |

|

|

|

|

|

|

|

Uruguay |

|

X |

|

|

|

|

|

|

|

Venezuela |

|

X |

|

|

|

|

|

|

|

Europe: |

|

|

|

|

|

|

|

|

|

Austria |

|

|

|

X |

|

|

|

|

|

Belgium |

|

X |

|

X |

|

|

|

|

|

Denmark |

|

X |

|

X |

|

|

|

|

|

Finland |

|

X |

|

X |

|

|

|

|

|

France |

|

X |

|

|

|

|

|

|

|

Germany |

|

|

X |

|

|

|

|

|

|

Holland |

|

X |

|

X |

|

|

|

|

|

Italy |

|

X |

|

X |

|

|

|

|

|

Norway |

|

X |

|

X |

|

|

|

|

|

Spain |

|

X |

|

|

|

|

|

|

|

Sweden |

|

X |

|

X |

|

|

|

|

|

United Kingdom |

X |

|

|

X |

|

|

|

|

|

Middle East and Africa: |

|

|

|

|

|

|

|

|

|

Israel |

|

X |

|

|

|

|

|

|

|

South Africa |

X |

|

|

|

|

|

|

|

|

Far East: |

|

|

|

|

|

|

|

|

|

Australia |

X |

|

|

|

|

|

|

|

|

Hong Kong |

X |

|

|

|

|

|

|

|

|

India |

X |

|

|

|

|

|

|

|

|

Japan |

X |

X |

|

|

|

|

|

|

|

Kuala Lumur |

X |

|

|

|

|

|

|

|

|

Malaysia |

X |

|

|

|

|

|

|

|

|

New Zealand |

X |

|

|

|

|

|

|

|

|

Philippines |

X |

|

|

|

|

|

|

|

|

Singapore |

X |

|

|

|

|

|

|

|

|

Taiwan |

X |

|

|

|

|

|

|

|

|

Thailand |

X |

|

|

|

|

|

|

|

|

1-4 |

Generic MICR Fundamentals Guide |

Overview

Recognizing significant market value in combining the advantages of electronic laser xerography with MICR technology,

Xerox initiated investigations in late 1979 and early 1980. Early efforts at the Xerox Webster Research Center concentrated on basic material physics. The objective was to provide a xerographic dry ink and developer that would produce high visual quality images that could be read using the standard banking reader sorter equipment.

Xerox’s MICR printing products combine the following:

•A modified xerographic engine

•A unique magnetic materials package

•The standard ANSI and ISO MICR character sets

The Xerox MICR systems meet ANSI, CPA, and ISO specifications for automatic check handling.

Why MICR?

MICR was chosen by the ABA because it can be read accurately by machine, it uses existing printing technology, and the printed documents are durable to withstand mutilation.

A MICR encoded document can be read through overstamping, pen and pencil marks, oils and greases, and carbon smudges.

However, MICR printing is one of the most quality-conscious application areas within the printing industry. It meets ABA security requirements for negotiable documents. MICR is the only system that produces reliable results at high processing speed.

Check printing capabilities

A Xerox MICR printing system with a magnetic material package and MICR fonts can print a character line at the bottom of a check form that is machine readable by standard banking reader sorter equipment. On blank security paper, the Xerox MICR printing system can produce the entire check image, including the form, all fixed and variable data, logos and signatures, and the MICR line, in a single pass.

Generic MICR Fundamentals Guide |

1-5 |

Overview

The printing process is one small part of the total processing procedure for a MICR printing system user. Quality and accuracy of the check documents must be closely controlled during printing to prevent problems from occurring when the document is processed off-site.

Check processing procedure

All checks impact at least three parties:

•The person who writes the check

•The person to whom the check is being paid

•The bank at which the check writer has an account

Depending on where and by whom the check is deposited, how the check is processed, and how the check is handled for funds clearance, many different parties can handle the same check.

Fraud can occur at any of the steps or access points in this process.

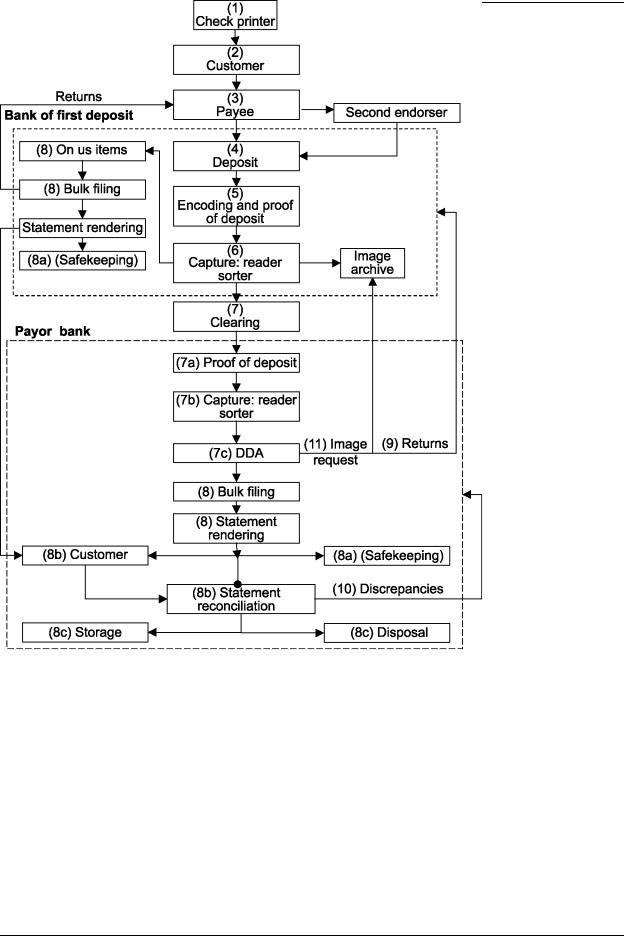

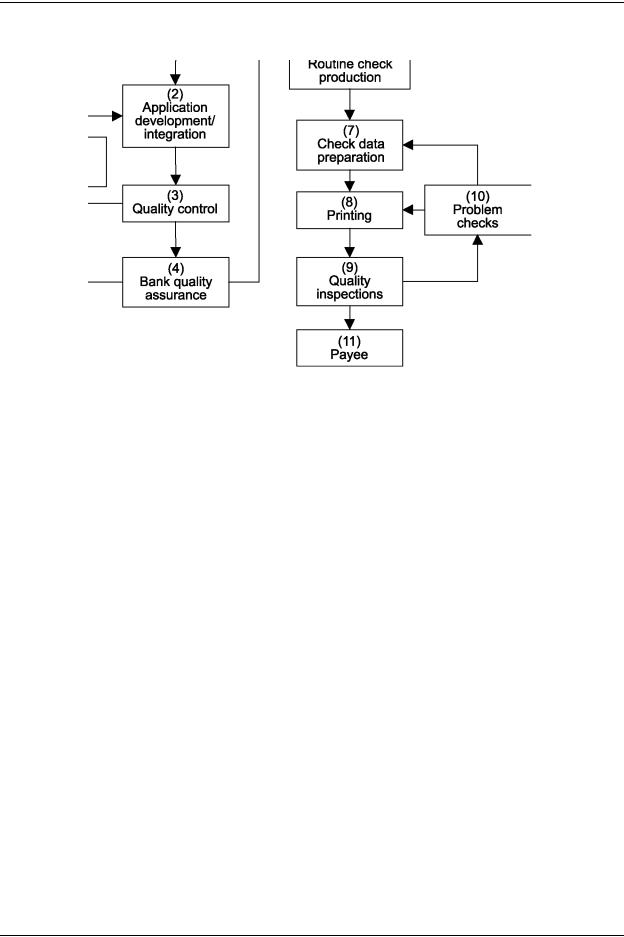

The following steps, illustrated in figure 1-2, trace a document through a series of corporate and banking system procedures typical of the MICR environment.

1-6 |

Generic MICR Fundamentals Guide |

Overview

Figure 1-2. Life cycle of a check

Generic MICR Fundamentals Guide |

1-7 |

Overview

1.The check printer (1) produces a blank check that will be completed later. This check includes the static data that is needed for a negotiable document:

•Financial institution name and address, issuer name and address, check form, company logo, etc.

•The MICR line, containing the account and routing information that is needed to process the check

•Other audit, account, and report information as required by the customer

2.The customer (2) adds the transaction information—payee, amount, and date—and authorizes the funds transfer with a signature.

NOTE: When using a MICR laser printer, steps 1 and 2 may happen simultaneously.

3.The completed check is transferred to the payee (3), who deposits it in the bank of first deposit (BOFD). The payee may receive the check in person, by mail, or through a third party.

A third party check may require a second endorsement.

4.Deposits (4) are made in several ways: through a teller, using an automated teller machine (ATM), using a drop box, or through a postal lock box. Deposited items are accompanied by a deposit ticket that lists and totals the items and identifies the payee account.

This is the entry point for the automated payment processing system.

5.The BOFD encodes the amount of the check in the MICR line

(5) and balances the check against the deposit ticket to verify that the correct amount is being credited to the payee account (proof of deposit).

6.MICR documents that are printed on a Xerox MICR printing system are usually corporate paychecks, stock dividend checks, etc. After printing, these type of documents require additional processing using a high-speed device called a “reader sorter.” The reader sorter identifies each magnetized character and symbol of the MICR line using logical analysis algorithms of the electronic wave patterns that the characters produce.

In the “capture pass,” checks are read in a reader sorter for the first time (6). At this time, they are sorted into checks drawn on the BOFD, known as “On-us items” (8), and checks drawn on other banks.

1-8 |

Generic MICR Fundamentals Guide |

Overview

7.Checks drawn on other banks are sent to the payor bank through a clearing (7) arrangement. The check may be cleared through the Federal Reserve, a correspondent bank, a clearing house, or directly by the issuing bank.

The payor bank also balances the check against the deposit ticket (proof of deposit) (7a) to verify the check amount, and performs its capture pass (7b) on the reader sorter in order to identify the issuer account (7c). (Refer to the “Proofing checks” section of chapter 5 for more information on this part of the process.)

8.In most cases, the check is debited from the issuer account and moved to bulk filing (8), where it is stored until time for monthly statement rendering.

From this point forward, an On-Us item is treated the same as one that was cleared to another bank.

Two exceptions may occur:

•If the payor bank does not honor the check, it is returned

(9) through the BOFD to the payee. The amount is then deducted from the payee account.

•During reconciliation, the account holder may discover a discrepancy (10) between its records and those of the bank. Their bank then researches any discrepancies.

NOTE: Account holders may contract with their banks to perform reconciliation before clearing the check.

Production cycle of a check

The check production process starts as soon as the need is identified. Design requirements should comprehend purchasing, distribution, warehousing, manufacturing, internal and external processing requirements, and the needs of the check issuer.

Banks frequently require new corporate accounts to submit checks for approval before the banks approve the account.

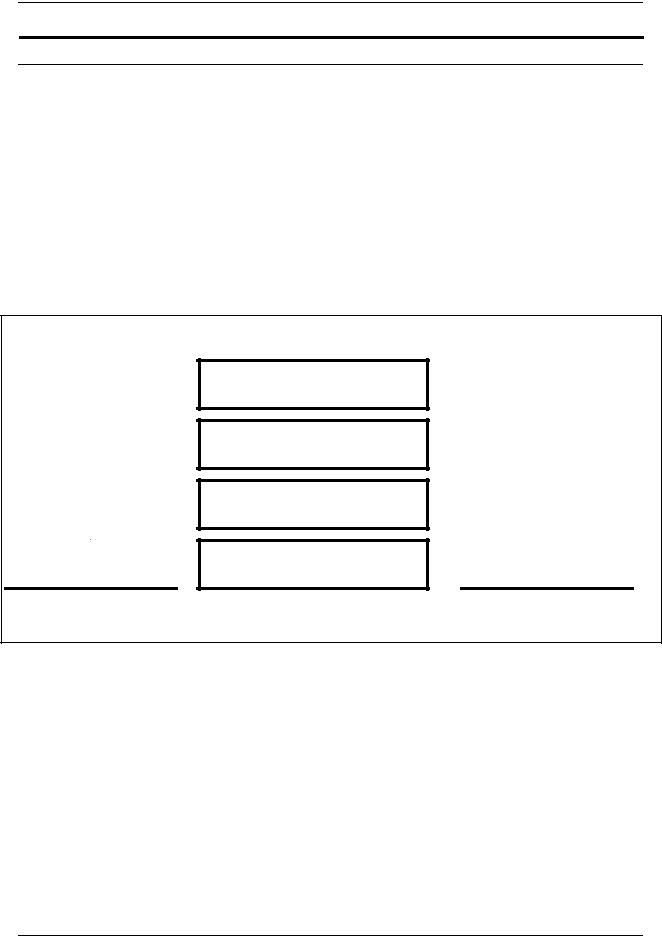

The following steps, illustrated in figure 1-4, describe the typical process that is required before the first negotiable checks are delivered to the payee.

Generic MICR Fundamentals Guide |

1-9 |

Overview

Figure 1-3. Check ordering and production cycle

1.Design requirements are defined for a new account.

2.Requirements are passed to application development.

3.Samples pass internal quality checks.

4.Samples are forwarded to the bank for approval.

5.Any problems are referred to application developers, who ensure that the problems cannot occur in production.

6.After approval by the bank, the check design becomes available for routine production.

7.Variable check data is prepared for incorporation.

8.The checks are printed.

9.The printed checks are inspected.

10.Any problems are reported to the source for correction and reprinting.

11.When they have passed bank validation and quality inspection by the issuer, the checks are issued to the payee.

1-10 |

Generic MICR Fundamentals Guide |

Overview

Changes in check creation role

In the past, the roles of manufacturer and check issuer were distinct. Because the technical requirements of doing MICR printing were fairly difficult, the manufacturer usually did all of the process steps that involved the generation of the check, except for entering the amount, date, and payee.

The introduction of MICR impact printers allowed the check issuer to sometimes take over printing the MICR line. With further technological advances, such as the Xerox MICR printing systems, the check issuer has assumed still more responsibilities that previously belonged to the manufacturer.

|

- - - - - Printing functions - - - - - |

|

|

Background |

|

Manufacturer |

Manufacturer |

|

|

Form and border |

|

|

MICR line and serial number |

|

Check |

Check |

|

issuer |

|

|

issuer |

|

|

Amount and payee |

|

|

|

|

|

Old areas of |

New areas |

of |

responsibility |

responsibility |

|

Figure 1-4. Changes in check creation roles

Because MICR documents are typically negotiable documents, every possible measure must be taken to ensure successful processing. With a less clear division between check manufacturer and check issuer responsibilities, the check issuer becomes more involved in the development of a new check issuance application.

Generic MICR Fundamentals Guide |

1-11 |

Overview

1-12 |

Generic MICR Fundamentals Guide |

2.Environment

Checks and other bank forms constitute the most frequent uses of MICR printing. All businesses issue checks to meet payroll and accounts payable obligations. In addition, all profitable publicly owned businesses make periodic stock dividend distributions by check.

Most medium and small companies buy check production services from a service bureau or a bank. Individuals who once obtained personal checks through their banks can now buy checks through the mail from check printers.

A major trend in the banking industry is check truncation.

Truncation refers to the ability of the bank of first deposit to process MICR documents, both theirs and those belonging to other banks, without further transfers of the paper document

(check). The check is processed electronically. This reduces cost and improves check clearance.

Types of MICR applications

A MICR system need not be dedicated to check printing or to any other MICR-specific application. A MICR system operates no differently from an identical system that does not have MICR.

MICR and non-MICR systems may be mixed at a site and do not impact scheduling of jobs that do not require MICR magnetic materials.

MICR printing is most frequently used for the following types of applications.

Manufacturing checks

Check manufacturing refers to the process of converting milled paper into finished check and deposit books, computer stationery, etc. This is usually done by a small group of specialty or security printers, mail order check printers, and others. MICR printing systems are becoming more popular in this market.

Generic MICR Fundamentals Guide |

2-1 |

Environment

Issuing checks

The most common use of MICR printing systems is the process of obtaining check stationery from the manufacturer and encoding it with MICR information. Most businesses regularly issue checks in at least two of the following categories.

•Payroll checks

•Accounts payable checks

•Dividend checks

•Benefit checks

•Drafts

•Warrants

•Negotiable orders of withdrawal

Issuing turnaround documents

Turnaround documents refer to any type of volume transaction, whether negotiable or not, that requires data capture. Familiar examples of turnaround documents are:

•Credit card invoices

•Insurance payment booklets

•Instant rebate coupons

Turnaround documents are also used in remittance processing, which is a procedure for handling items returned with a payment.

MICR encoded turnaround documents enable organizations to cut their resource and equipment costs. For example:

1.A bank card company MICR encodes an account number on the bill and remittance slip that is sent to the customer.

2.The payment is returned with the remittance slip. When the bank card company receives the check and payment slip, the two documents are visually checked to see that the amounts are the same on both.

3.The documents are processed by a MICR reader sorter, which reads magnetic ink characters.

2-2 |

Generic MICR Fundamentals Guide |

Environment

Printing financial forms

MICR is also used for printing a variety of financial forms.

Examples of MICR financial forms include:

•Personal checkbooks

•Limited transaction checks, such as money market checks

•Direct mail promotional coupons

•Credit remittance instruments

•Internal bank control documents, such as batch tickets

Xerox MICR printing systems

The Xerox MICR printing systems are a unique range of products that combine speed, intelligence, and high print quality. They also provide great flexibility in font selectivity, graphics capability, and dynamic page formatting.

An advantage to Xerox printing systems is their ability to print a document in a single pass, as shown in the following figure. The form design, variable data, logos, and signatures can all be printed together. With MICR enablement, the MICR line can be included.

Additional benefits include:

•The elimination of expensive production and inventory of preprinted forms

•The ability to produce multiple checks on one physical page

•Reduced handling steps by using cut sheet rather than fanfold paper

•The reduction of additional equipment, such as bursters, decollators, trimmers, and signature machines

•Reduced turnaround time

•Ability to print checks against multiple accounts

With the introduction of the latest MICR printing systems, Xerox has expanded its application base, using more paper sizes and multiple paper stocks.

Generic MICR Fundamentals Guide |

2-3 |

Environment

MICR printing technologies

The following basic printing techniques are capable of generating magnetic characters:

•Letterpress

Letterpress is based upon a raised typeface that sits above the plane of the image carrier. The typeface is inked with special magnetic ink and applied to the paper under pressure. Common forms of letterpress are: hot metal type, sequential number machines, and ribbon encoders.

•Offset lithography

Large offset devices are typically used to produce check stationery. The lithographic process uses magnetic ink and water to shape the image on a plate. The image is transferred to a rubber sheet called a blanket. The image is then “offset” to the paper.

•Impact ribbon encoding

Ribbon encoding, also called “direct printing,” is a letterpress technology with a different delivery method. Instead of the ink being applied to the typeface and then to the paper, the ink is suspended on a thin sheet of backing (usually a polymer base) called a ribbon.

The ribbon is held between the typeface medium (drum, daisy wheel, or hammer) and the paper, so that when the typeface is struck against the paper, the components on the ribbon are trapped and pressed onto the document to be printed.

•Non-impact (xerography and ionography)

Non-impact printing technologies have been growing in market penetration. They require highly sophisticated and consistent equipment utilizing magnetic materials.

•Thermal ribbon encoding

A non-impact, thermal transfer version of ribbon encoding combines some of the characteristics of the conventional ribbon encoding with those of non-impact technology.

2-4 |

Generic MICR Fundamentals Guide |

Environment

Printer technical optimization

The Xerox MICR systems use the same operating software as their standard configuration counterparts. In addition, the MICR systems have been enhanced to include the following features:

•Optimized print engine

•MICR materials package

•Optimized paper handling system

•Digitized MICR font

Optimization of the MICR print engines subsystem is required by the physical properties of the dry ink. As a result of these changes, dry ink and developer are not interchangeable between MICR and non-MICR printers, unless specifically designed to accept more than one type of materials.

The Xerox MICR systems have a paper handling system designed for the highly accurate registration. This is required for precise placement of the MICR line to maximize readability during check processing.

Typical MICR printing concerns

The following areas of MICR user concerns have made banks want to increase reliability of the MICR document generating process:

•Security: This can be addressed by providing high security within the document creation process. In addition, counterfeiting can be reduced by the use of various design and production techniques.

•Quality: Sensitive to the banking industry demands, printing businesses maintain tight quality control procedures.

•Production speed

•Cost

In addition to their need to adhere to required print quality standards, they have the following concerns about the printing operation:

•Traditional MICR printing devices are labor intensive.

Generic MICR Fundamentals Guide |

2-5 |

Environment

•High security measures are needed in any environment that uses check stationery. These measures affect physical access restrictions and staff supervision.

•Check printing usually requires frequent starting and stopping, which is time-consuming and degrades print speed.

•Storing hundreds of different preprinted check and deposit forms can be costly.

•Short print runs of continuous forms can waste materials.

•Check production requires short lead times.

Xerox MICR printing systems reduce many of these concerns.

There is no need to store different types of preprinted forms, and single pass printing eliminates many time constraints.

2-6 |

Generic MICR Fundamentals Guide |

3.Paper facts

MICR applications have special paper, print, and finishing requirements. Refer to your printer operator guide for a complete list of supplies and options.

Refer to Helpful Facts about Paper for information on solving printer problems relating to paper.

Paper guidelines

The paper that you use to print MICR documents must meet the criteria for the Xerox MICR laser printer and the specifications imposed by MICR industry standards. In addition, papers must resist alteration and prevent duplication of negotiable documents. They must support high print quality and feed through the printers properly.

NOTE: Some banking authorities specify the type and weight of paper that should be used for check printing in that country. It is essential that only the specified paper be used.

Follow these guidelines for best results:

•Understand check stock security requirements, and use security features that do not degrade printer performance.

•Do not accept delivery of paper or forms that are not reamwrapped in a moisture barrier.

•Do not open paper reams until you are ready to load the paper into the printer.

•Store paper in the printer room for at least 24 hours before using it. This allows the paper to stabilize to the temperature and relative humidity of the room.

•Do not allow the printer room to become excessively humid or dry. This can cause a difference in moisture content between the edges and center of each sheet of paper, and result in feeding, image permanence, or image deletion problems.

Generic MICR Fundamentals Guide |

3-1 |

Paper facts

•Do not use cut-sheet check paper that was converted from fanfold by the paper distributor. This conversion process can result in dimensional inaccuracy, poorly cut edges, and unacceptable paper curl.

MICR paper requirements

|

The following table summarizes Xerox’s recommendations for |

|

papers that are used for MICR printing. Papers with the following |

|

characteristics perform best in Xerox MICR printers. |

|

Table 3-1. Xerox paper recommendations |

|

|

Paper characteristics |

Recommended for optimal printer and reader/sorter performance |

|

|

Basis weight |

24-pound/90 gsm |

|

|

Sheffield smoothness |

80 to 150 |

|

|

Grain direction |

Parallel to the long edge of check or MICR document. Short grain direction |

|

may be acceptable for personal, 6 inch/152 mm checks. |

|

|

Moisture content |

3.9 to 5.e per cent |

|

|

Reflectance |

60 percent minimum |

|

|

Curl |

Refer to instructions in your MICR printing system operator guide |

|

|

Perforations |

60 to 80 ties per inch |

|

|

Metallic content |

No ferromagnetic materials can be present in the paper. |

|

|

Stiffness |

For recommendations, refer to “Paper stiffness,” later in this chapter. |

|

|

Cutting precision |

+/- 0.030 inch/0.762 mm length |

|

+/- 0.030 inch/0.762 mm width |

|

|

Coating |

Do not use paper containing clay or resin coatings. |

|

|

Lamination |

Do not use stock that is a combination of paper and plastic. |

|

|

Preprinting ink |

Must be heat resistant to approximately 400 degrees F/204 degrees C for laser |

|

printing. Heat resistance varies according to manufacturer. |

|

|

Size |

Refer to instructions in your MICR printing system operator guide |

|

|

Basis weight

Basis weight is an industry term for expressing the weight per unit area of paper. Paper weight is generally expressed as grams per square meter (gsm), a measure that makes it easy to compare any two pieces of paper, even if the papers are of different types, such as offset and index.

3-2 |

Generic MICR Fundamentals Guide |

Loading...

Loading...