Whirlpool WGD5790V, WGD5700V, WGD5100V, WGD5000V, WGD5200V User Manual

®

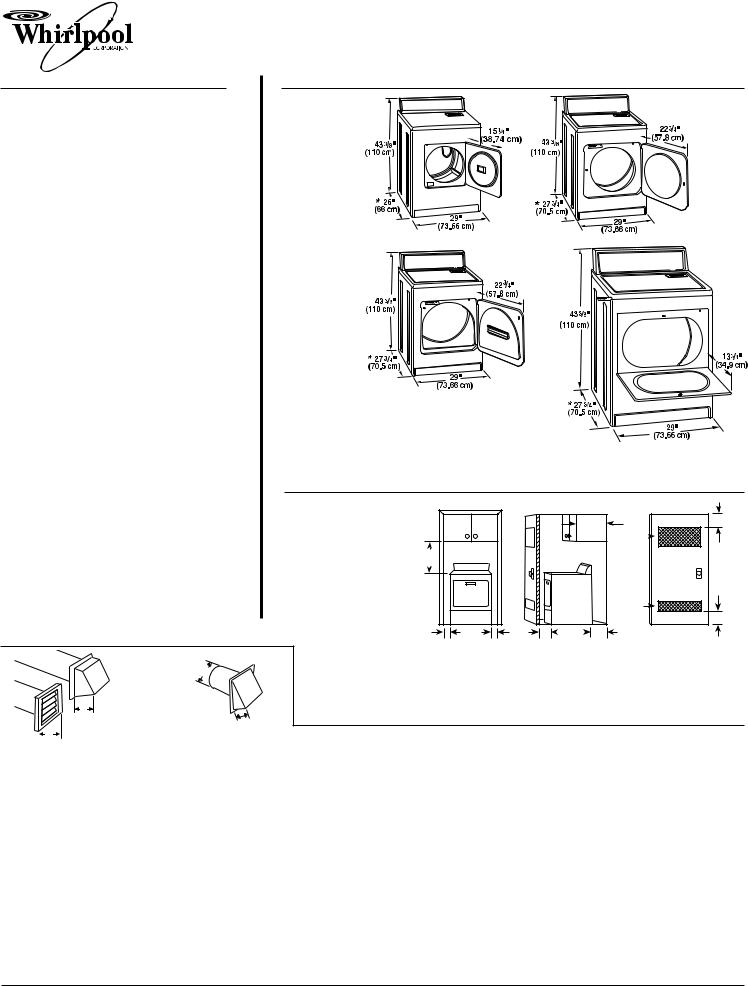

29" (73.7 cm) Gas Dryer

PRODUCT MODEL NUMBERS |

PRODUCT DIMENSIONS |

|

||

WGD5000V |

WGD5700V |

|

|

|

WGD5100V |

WGD5790V |

|

|

|

WGD5200V |

|

|

|

|

Gas supply: Dryer is equipped for use with |

|

|

||

Natural gas. Dryer can be converted to L.P. gas. |

A |

B |

||

When rigid pipe is used it should be 1/2" IPS. When |

A. Small Opening |

|

||

acceptable to the gas supplier and local codes, 3/8" |

|

|||

Side-Swing Door |

|

|||

approved aluminum or copper tubing may be used |

|

|||

B. Large Opening |

|

|||

for lengths under 20 ft (6.1 m). For lengths more |

|

|||

than 20 ft (6.1 m), larger tubing and a different size |

Side-Swing Door |

|

||

adapter fitting should be used. Pipe-joint compounds |

|

|

||

resistant to the action of L.P. gas must be used. Do |

|

|

||

not use TEFLON®† tape. If local codes permit, it is |

|

|

||

recommended that new flexible metal tubing, design- |

|

|

||

certified by CSA, be used for connecting the |

|

|

||

appliance to the rigid gas supply line. (The gas pipe |

C |

|

||

which extends through the lower rear of the |

|

|||

appliance has 3/8" male pipe thread.) An individual |

|

D |

||

manual shutoff valve must be installed within 6 ft |

C. Wide Opening |

|||

(1.8 m) of the dryer in accordance with the National |

|

|||

Fuel Gas Code ANSI Z223.1. |

Side-Swing Door |

|

||

Electrical: A 120-volt, 60-Hz, AC-only, 15or |

D. Wide Opening |

|

||

20-amp, fused electrical supply is required. A time- |

Hamper Door |

|

||

delay fuse or circuit breaker is recommended. It is |

*Most installations require a minimum 5" (12.7 cm) clearance |

|||

recommended that a separate circuit serving only |

||||

behind the dryer for the exhaust vent with elbow. |

|

|||

this dryer be provided. |

|

|

||

|

|

|

||

Exhaust venting: Exhaust your dryer to the outside. |

RECESSED AREA AND CLOSET INSTALLATION |

|

|

|

|||||||

4" (10.2 cm) diameter heavy metal exhaust vent and |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

clamps must be used. DURASAFE™ venting products |

|

|

For closet installation |

|

|

|

|

|

|

|

3"* |

are recommended. For best drying performance, rigid |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

14"max.* |

|

(7.6cm) |

||||

metal vents are recommended. Flexible metal vents are |

|

with a door, minimum |

|

|

|

|

48in.2 * |

|

|||

|

|

|

|

|

(35.6cm) |

|

|||||

acceptable only if accessible for cleaning. Do NOT use |

|

ventilation openings in |

18"* |

|

|

|

|

|

(310cm2 ) |

|

|

plastic or metal foil vent. Exhaust outlet hood must be |

|

the top and bottom of |

|

|

|

|

|

|

|

||

|

(45.7 cm) |

|

|

|

|

|

|

|

|||

at least 12" (30.4 cm) from the ground or any object |

|

|

the door are required. |

|

|

|

|

|

|

|

|

that may be in the path of the exhaust. |

|

|

Louvered doors with |

|

|

|

|

|

|

|

|

†®TEFLON is a registered trademark of E.I. Du Pont De |

|

|

equivalent ventilation |

|

|

|

|

|

|

24in.2* |

|

|

|

openings are acceptable. |

|

|

|

|

|

|

3"* |

||

Nemours and Company. |

|

|

|

|

|

|

|

|

(155cm2 ) |

(7.6cm) |

|

EXHAUST VENTING |

|

|

|

1" |

29" |

1" |

1"* |

27¾" |

5"* |

|

|

|

|

|

|

(2.5cm) |

(73.66 cm) |

(2.5 cm) |

(2.5 cm) |

(70.5 cm) |

(12.7 cm) |

|

|

4" |

|

|

|

|

A |

|

|

B |

|

|

C |

2 cm) |

|

|

|

|

A. Recessed area |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

Box hood style |

|

|

|

|

B. Side view - closet or confined area |

*Required spacing |

|||||

|

|

|

|

C. Closet door with vents |

|

|

|||||

|

|

|

|

|

|

|

|||||

4" |

|

2.5" |

|

|

|

|

|

|

|

|

|

(10.2 cm) |

|

|

|

|

|

|

|

|

|

|

|

(6.4 cm) |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

4" |

|

Angled hood style |

|

||||

|

(10.2 cm) |

|

|

|

|

1. Select the route that will provide the straightest and most direct path outdoors. Plan |

|||

NOTE: Side and bottom exhaust installations have a |

|||||||||

the installation to use the fewest number of elbows and turns. When using elbows or |

|||||||||

90º turn inside the dryer. To determine maximum |

making turns, allow as much room as possible. Bend vent gradually to avoid kinking. |

||||||||

exhaust length, add one 90º turn to the chart. |

Avoid 90° turns. |

||||||||

|

Vent Length Chart |

|

|

|

2. Determine vent length. |

||||

|

Number of |

Type of |

Box or |

Angled |

The maximum length of the exhaust system depends upon: |

||||

|

90° turns |

vent |

Louvered |

hoods |

• The type of vent (rigid metal or flexible metal). |

||||

|

or elbows |

|

hoods |

|

|

||||

|

|

|

|

|

|

|

|

||

0 |

Rigid metal |

64 ft (20 m) |

58 ft (17.7 m) |

• The number of elbows used. |

|||||

|

|

|

|

Flexible metal |

36 ft (11 m) |

28 ft (8.5 m) |

• Type of hood. |

||

|

|

|

|

|

|

|

|

||

1 |

Rigid metal |

54 ft (16.5 m) |

48 ft (14.6 m) |

See the exhaust vent length chart that matches your hood type for the maximum vent |

|||||

|

|

|

|

Flexible metal |

31 ft (9.4 m) |

23 ft (7 m) |

|||

|

|

|

|

|

|

|

|

lengths you can use. |

|

2 |

Rigid metal |

44 ft (13.4 m) |

38 ft (11.6 m) |

||||||

3. Determine the number of elbows you will need. |

|||||||||

|

|

|

|

Flexible metal |

27 ft (8.2 m) |

19 ft (5.8 m) |

|||

|

|

|

|

|

|

|

|

IMPORTANT: Do not use vent runs longer than specified in the Vent Length Chart. |

|

3 |

Rigid metal |

35 ft (10.7 m) |

29 ft (8.8 m) |

||||||

|

|

|

|

Flexible metal |

25 ft (7.6 m) |

17 ft (5.2 m) |

In the column listing the type of metal vent you are using (rigid metal or flexible metal), |

||

|

|

|

|

|

|

|

|

||

4 |

Rigid metal |

27 ft (8.2 m) |

21 ft (6.4 m) |

||||||

find the maximum length of metal vent on the same line as the number of elbows. |

|||||||||

|

|

|

|

Flexible metal |

23 ft (7 m) |

15 ft (4.6 m) |

|||

Because Whirlpool Corporation policy includes a continuous commitment to improve our products, we reserve the right to change materials and specifications without notice.

Dimensions are for planning purposes only. For complete details, see Installation |

Ref. W10150630 |

Instructions packed with product. Specifications subject to change without notice. |

09-19-08 |

Loading...

Loading...