Whirlpool WHD862CHC Installation Manual

HYBRIDCARE™ HEAT |

SÉCHEUSE À POMPE À |

PUMP DRYER |

CHALEUR HYBRIDCARE™ |

INSTALLATION |

INSTRUCTIONS |

INSTRUCTIONS |

D’INSTALLATION |

|

Table of Contents |

|

Table des matières |

|

|

|

DRYER SAFETY.......................................................................... |

2 |

SÉCURITÉ DE LA SÉCHEUSE................................................. |

|

21 |

|

|

INSTALLATION REQUIREMENTS............................................. |

3 |

EXIGENCES D’INSTALLATION................................................ |

|

22 |

|

|

|

Tools and Parts....................................................................... |

3 |

Outillage et pièces................................................................ |

|

22 |

|

LOCATION REQUIREMENTS.................................................... |

4 |

EXIGENCES D’EMPLACEMENT.............................................. |

|

23 |

|

|

DRAIN SYSTEM.......................................................................... |

5 |

SYSTÈME DE VIDANGE........................................................... |

|

24 |

|

|

ELECTRICAL REQUIREMENTS – U.S.A. ONLY........................ |

6 |

SÉCHEUSE ÉLECTRIQUE RACCORDEMENT |

|

|

||

ELECTRIC DRYER POWER HOOKUP – CANADA ONLY........ |

7 |

À L’ALIMENTATION ÉLECTRIQUE – |

|

|

|

|

INSTALL LEVELING LEGS......................................................... |

8 |

CANADA SEULEMENT............................................................. |

|

25 |

|

|

ELECTRICAL INSTALLATION – U.S.A. ONLY........................... |

8 |

INSTALLATION DES PIEDS DE NIVELLEMENT..................... |

26 |

|

||

|

Power Supply Cord Connection............................................ |

9 |

CONNEXION DU TUYAU DE SORTIE..................................... |

26 |

|

|

|

Direct Wire Connection........................................................ |

11 |

RÉGLAGE DE L’APLOMB DE LA SÉCHEUSE........................ |

27 |

|

|

CONNECT OUTLET HOSE....................................................... |

14 |

ACHEVER L’INSTALLATION LISTE DE VÉRIFICATION......... |

28 |

|

||

LEVEL DRYER.......................................................................... |

15 |

INVERSION DE LA PORTE (FACULTATIF).............................. |

28 |

|

||

COMPLETE INSTALLATION CHECKLIST............................... |

16 |

DÉPANNAGE....................................... |

COUVERTURE ARRIÈRE |

|||

DOOR REVERSAL (OPTIONAL)............................................... |

16 |

|

|

|

|

|

TROUBLESHOOTING............................................................... |

20 |

|

|

|

|

|

|

|

|

|

|||

|

Para una version de estas instrucciones en español, visite www.Whirlpool.com o www.maytag.com |

|

|

|||

|

|

|

|

|

|

|

INSTALLATION NOTES |

|

NOTES CONCERNANT L’INSTALLATION |

|

|

||

Date of purchase:_________________________________ |

Date d’achat :_____________________________________ |

|||||

Date of installation:_ _______________________________ |

Date d’installation :_ ________________________________ |

|||||

Installer:_________________________________________ |

Installateur :_______________________________________ |

|||||

Model number:____________________________________ |

Numéro de modèle :_________________________________ |

|||||

Serial number:____________________________________ |

Numéro de série :___________________________________ |

|||||

|

|

|

|

|

|

|

W11184511A W11184519A - SP

DRYER SAFETY

Certain internal parts are intentionally not grounded and may present a risk of electric shock only during servicing.

Service Personnel – Do not contact the thermostat bracket while the appliance is energized.

2

INSTALLATION REQUIREMENTS

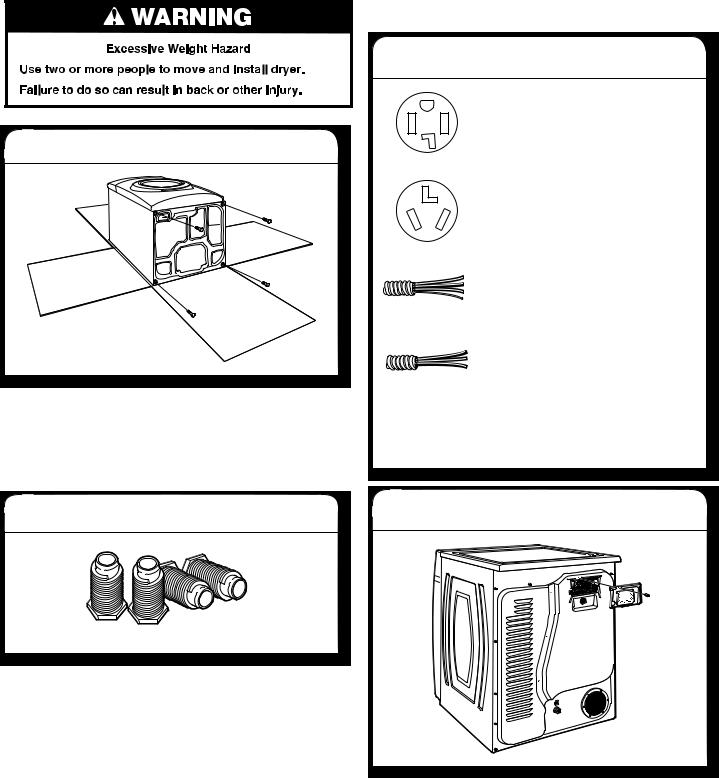

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Tools needed:

|

|

|

|

|

Flat-blade screwdriver |

|

#2 Phillips screwdriver |

|

|

|

|

|

|

|

|

Wire stripper (direct wire |

|

Channel locks |

installations) |

|

|

|

|

|

|

|

|

1/4" and 5/16" nut driver |

|

Adjustable wrench that |

||||

(recommended) |

|

opens to 1" (25 mm) or |

||||

|

|

hex-head socket wrench |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Utility knife |

|

Tape measure |

|

|

|

|

|

|

Level |

Pliers |

Parts supplied:

Leveling legs (4) |

6' (1.82 m) drain |

|

hose with couplers |

|

|

|

|

Cable ties (2)

Parts package is located in dryer drum. Check that all parts are included.

NOTE: Do not use leveling legs supplied with dryer if installing with a pedestal or a stack kit.

If using a power supply cord:

Use a UL Listed power supply cord kit marked for use with clothes dryers. The kit should contain:

■■A UL Listed 30 A power supply cord, rated 120/240 V minimum. The cord should be type SRD or SRDT and be at least 4 ft. (1.22 m) long. The wires that connect to the dryer must end in ring terminals or spade terminals with upturned ends.

■■A UL Listed strain relief.

Additional Accessories: (Not supplied with dryer)

Refer to your Use and Care Guide for information about accessories available for your dryer.

3

LOCATION REQUIREMENTS

Check codes requirements. Some codes limit, or do not permit, installing dryer in garages, closets, mobile homes, or sleeping quarters. Contact your local building inspector.

You will need:

■■A separate 30 A circuit.

■■If using a power supply cord, a grounded electrical outlet located within 2 ft. (610 mm) of either side of dryer. See “Electrical Requirements.”

■■Floor must support dryer weight of 200 lbs. (90.7 kg). Also consider weight of companion appliance.

■■Level floor with maximum slope of 1" (25 mm) under entire dryer. If forward slope is greater than 1" (25 mm), water could run out from front of filter. Install Extended Dryer Feet Kit, Part Number 279810. If not level, clothes may not tumble properly and automatic sensor cycles may not operate correctly.

■■For garage installation, place dryer at least 18" (460 mm) above floor. If using a pedestal, you will need 18" (460 mm) to bottom of dryer.

■■The dryer must not be installed or stored in an area where it will be exposed to water and/or weather.

IMPORTANT: Do not operate, install, or store dryer where

it will be exposed to water, weather, or at temperatures below 40°F (4°C). Lower temperatures may cause dryer to not

shut off at end of automatic sensor cycles, resulting in longer drying times.

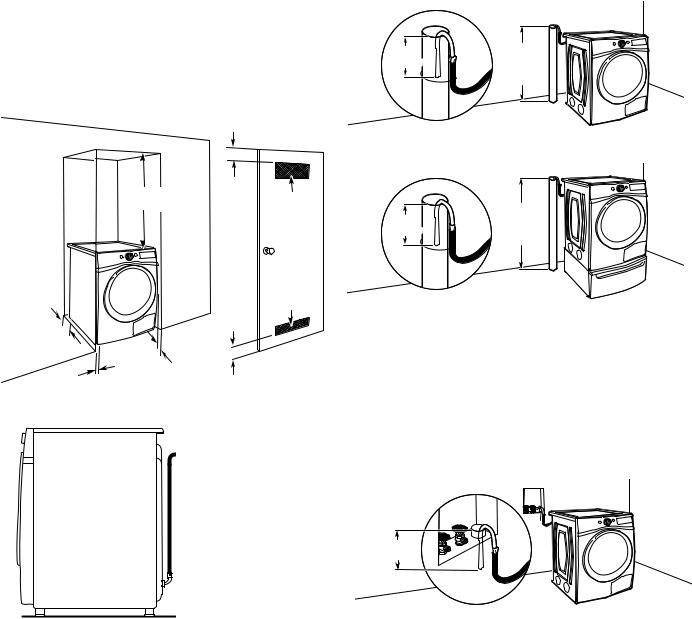

DRYER DIMENSIONS

Front view:

27" (686 mm)

Side view:

541/ "

51 " 2min.

" 2min.

(137814 mm)

31 31"min.

31"min.

(787806 mm))

53/4"

(146 mm)

(146 mm)

Back view:

NOTE: Allow clearance behind dryer for proper drain hose routing and cooling fan ventilation. Push dryer back as

far as possible and make sure drain hose is not crushed or kinked.

61/2" (165 mm)

61/2" (165 mm)

Power cord/ cable

297/8"*

Water Cooling (759 mm) drain fan

131/2" |

61/2" |

(343 mm) |

(165 mm) |

*Approx. measurement

IMPORTANT: Do not block cooling fan, as your dryer may not operate properly.

383/4" Min.

(984 mm)

39" Max. (990 mm)

4

Installation spacing for recessed area or closet installation:

All dimensions show recommended and minimum spacing allowed.

■■Additional spacing should be considered for ease of installation and servicing.

■■Additional clearances might be required for wall, door, floor, moldings, and drain system.

■■Additional spacing should be considered on all sides of the dryer to reduce noise transfer.

■■For closet installation, with a door, minimum ventilation openings in the top and bottom of the door are required. Louvered doors with equivalent ventilation openings are acceptable.

■■Companion appliance spacing should also be considered.

Recommended installation clearances (dryer only):

DRAIN SYSTEM

Drain system can be installed using a floor drain, wall standpipe, floor standpipe, or laundry tub. Select method you need.

IMPORTANT: To avoid siphoning, only 4.5" (114 mm) of drain hose should be inside standpipe. Always secure drain hose with cable tie.

Floor standpipe drain system

4.5" |

max. 54" |

|

(1372 mm) |

||

(114 mm) |

||

min. 30" |

||

|

||

|

(762 mm) |

Without pedestal

|

3" |

|

18" min. |

(76 mm) |

48 in.2 min. |

(457 mm) |

|

|

|

(310 cm2) |

0" – 5"* |

|

24 in.2 min. |

(0 mm – 127 mm) |

|

(155 cm2) |

5" |

|

3" |

(127 mm) |

|

|

|

(76 mm) |

|

|

|

|

|

1" |

1" |

|

(25 mm) |

|

|

(25 mm) |

|

|

|

*NOTE: 0" (0 mm) spacing is allowed behind dryer, providing drain hose is not kinked or pinched.

Mobile home – Additional installation requirements:

This dryer is suitable for mobile home installations. The installation must conform to the Manufactured Home Construction and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard for Mobile home construction and Safety, Title 24, HUD Part 280) or Standard CAN/CSA-Z240 MH.

|

max. 69" |

4.5" |

(1753 mm) |

(114 mm) |

min. 30" |

|

(762 mm) |

With 15" (381 mm) matching pedestal

Minimum diameter for a standpipe drain: 2" (51 mm). Minimum carry-away capacity: 17 gal. (64 L) per minute. A 1/4" (6 mm) diameter to 1" (25 mm) diameter Standpipe Adapter Kit is available. Top of standpipe must be at least 30" (762 mm) high; install no higher than 54" (1.37 m) from bottom of dryer.

IMPORTANT: Only 4.5" (114 mm) of drain hose should be inside standpipe; do not force excess hose into standpipe.

Wall standpipe drain system

4.5" (114 mm)

See requirements for floor standpipe drain system.

5

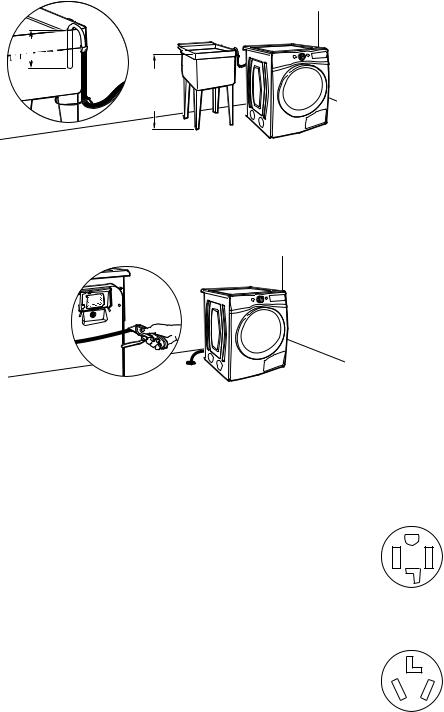

Laundry tub drain system

4.5"

(114 mm)

max. 54" (1372 mm) min. 30" (762 mm)

Minimum capacity: 20 gal. (76 L). Top of laundry tub must be at least 30" (762 mm) above floor; install no higher than 54" (1.37 m) from bottom of dryer.

IMPORTANT: Only 4.5" (114 mm) of drain hose should lay

on side of laundry tub. Do not lay the hose at the bottom of tub.

Floor drain system

Remove the U-bend at the end of the drain hose by cutting the hose at the end of the U-bend for the floor drain system as shown in the picture above.

NOTE: Cut hose so that no more than 4.5" (114 mm) of the hose is in the floor drain to avoid siphoning.

ELECTRICAL REQUIREMENTS – U.S.A. ONLY

It is your responsibility:

■■To contact a qualified electrical installer.

■■To be sure that the electrical connection is adequate and in conformance with the National Electrical Code, ANSI/

NFPA 70 – latest edition and all local codes and ordinances.

The National Electrical Code requires a 4-wire power supply connection for homes built after 1996, dryer circuits involved in remodeling after 1996, and all mobile home installations.

A copy of the above code standards can be obtained from: National Fire Protection Association, One Batterymarch Park, Quincy, MA 02269.

■■To supply the required 3- or 4-wire, single-phase, 120/240 V, 60 Hz, AC-only electrical supply (or 3- or 4-wire, 120/208 V electrical supply, if specified on the serial/rating plate) on a separate 30 A circuit, fused on both sides of the line. Connect to an individual branch circuit. Do not have a fuse in the neutral or grounding circuit.

■■Do not use an extension cord.

■■If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate.

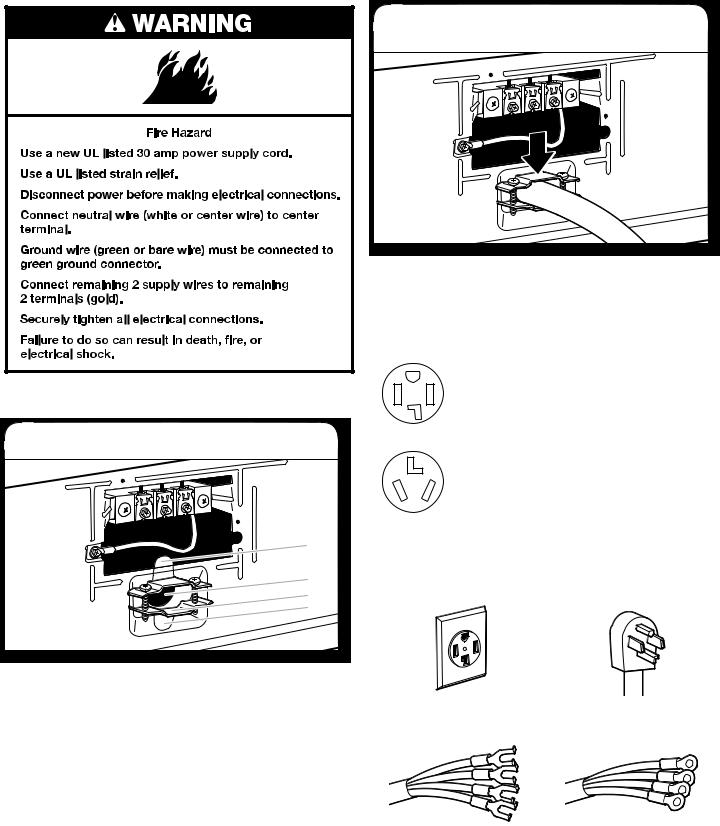

Electrical Connection

To properly install your dryer, you must determine the type of electrical connection you will be using and follow the instructions provided for it here.

■■This dryer is manufactured ready to install with a 3-wire electrical supply connection. The neutral ground conductor

is permanently connected to the neutral conductor (white wire) within the dryer. If the dryer is installed with a 4-wire electrical supply connection, the neutral ground conductor must be removed from the external ground connector (green screw), and secured under the neutral terminal (center or white wire) of the terminal block. When the neutral ground conductor is secured under the neutral terminal (center or white wire) of the terminal block, the dryer cabinet is isolated from the neutral conductor. The green ground wire of the 4-wire power cord must be secured to the dryer cabinet with the green

ground screw.

■■If local codes do not permit the connection of a neutral ground wire to the neutral wire, see the “Optional External Ground for 3-Wire Connection” section.

■■A 4-wire power supply connection must be used when the appliance is installed in a location where grounding through the neutral conductor is prohibited. Grounding through the neutral is prohibited for (1) new branch-circuit installations after 1996, (2) mobile homes, (3) recreational vehicles, and (4) areas where local codes prohibit grounding through the neutral conductors.

If using a power supply cord:

Use a UL Listed power supply cord kit marked for use with clothes dryers. The kit should contain:

■■A UL Listed 30 A power supply cord, rated 120/240 V minimum. The cord should be type SRD or SRDT and be at least 4 ft. (1.22 m) long. The wires that connect to the dryer must end in ring terminals or spade terminals with upturned ends.

■■A UL Listed strain relief.

If your outlet looks like this:

4-wire receptacle

(14-30R)

3-wire receptacle

(10-30R)

Then choose a 4-wire power supply cord with ring or spade terminals and UL Listed strain relief. The 4-wire power supply cord, at least 4 ft. (1.22 m) long, must have four 10-gauge copper wires and match a 4-wire receptacle of NEMA Type 14-30R. The ground wire (ground conductor) may be either green or bare. The

neutral conductor must be identified by a white cover.

Then choose a 3-wire power supply cord with ring or spade terminals and UL Listed strain relief. The 3-wire power supply cord, at least 4 ft. (1.22 m) long, must have three 10-gauge copper wires and match a 3-wire receptacle of NEMA Type 10-30R.

If connecting by direct wire:

Power supply cable must match power supply (4-wire or 3-wire) and be:

■■Flexible armored cable or nonmetallic sheathed copper cable (with ground wire), covered with flexible metallic conduit.

All current-carrying wires must be insulated.

■■10-gauge solid copper wire (do not use aluminum) at least 5 ft. (1.52 m) long.

6

ELECTRIC DRYER POWER HOOKUP – CANADA ONLY

ELECTRICAL REQUIREMENTS

It is your responsibility:

■■To contact a qualified electrical installer.

■■To be sure that the electrical connection is adequate and in conformance with the Canadian Electrical Code, C22.1-latest edition, and all local codes. A copy of the above codes standard may be obtained from: Canadian Standards Association, 178 Rexdale Blvd., Toronto, ON M9W 1R3 CANADA.

■■To supply the required 4-wire, single-phase, 120/240 V,

60 Hz., AC-only electrical supply on a separate 30 amp circuit, fused on both sides of the line. A time-delay fuse or circuit breaker is recommended. Connect to an individual branch circuit.

■■This dryer is equipped with a CSA International Certified Power Cord intended to be plugged into a standard 14-30R wall receptacle. The cord is 5 ft. (1.52 m) in length. Be sure wall receptacle is within reach of dryer’s final location.

4-wire receptacle (14-30R)

■■ Do not use an extension cord.

If using a replacement power supply cord, it is recommended that you use Power Supply Cord Replacement Part Number 8579325. For further information, please reference the “Assistance or Service” section of the Use and Care Guide.

GROUNDING INSTRUCTIONS

■ For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the equipmentgrounding conductor can result in a risk of electric shock. Check with a quali•ed electrician or service representative or personnel if you are in doubt as to whether the dryer is properly grounded. Do not modify the plug provided with the dryer: if it will not •t the outlet, have a proper outlet installed by a quali•ed electrician.

SAVE THESE INSTRUCTIONS

7

INSTALL LEVELING LEGS

1. Prepare dryer for leveling legs

To avoid damaging floor, use a large flat piece of cardboard from dryer carton; place under entire back edge of dryer. Firmly grasp dryer body (not console panel) and gently lay dryer down on cardboard.

NOTE: Residual water from factory testing may drain when dryer is laying on its side.

2. Screw in leveling legs

Using a wrench and tape measure, screw leveling legs into leg holes until bottom of foot is approximately 1/2" (13 mm) from bottom of dryer.

Now stand the dryer on its feet. Slide the dryer until it is close to its final location.

ELECTRICAL INSTALLATION – U.S.A. ONLY

Before you start, disconnect power.

1. Choose electrical connection type

Power supply cord 4-wire receptacle (NEMA Type 14-30R).

Go to “Power Supply Cord Connection.”

Power supply cord 3-wire receptacle (NEMA Type 10-30R).

Go to “Power Supply Cord Connection.”

4-wire direct connection:

Go to “Direct Wire Connection.”

3-wire direct connection:

Go to “Direct Wire Connection.”

NOTE: If local codes do not permit connection of a cabinet-ground conductor to neutral wire, go to “Optional External Ground for 3-Wire Connection.” This connection may be used with either a power supply cord or a direct wire connection.

2. Remove terminal block cover

Remove hold-down screw and terminal block cover.

8

Power Supply Cord Connection

2. Attach power supply cord to strain relief

Power Supply Cord Strain Relief:

1. Attach power supply cord strain relief

A |

B |

C |

D |

Remove the screws from a 3/4" (19 mm) UL Listed strain relief (UL marking on strain relief). Put the tabs of the two clamp sections (C) into the hole below the terminal block opening (B) so that one tab is pointing up (A) and the other is pointing down (D), and hold in place. Tighten strain relief screws just enough to hold the two clamp sections (C) together.

Put power supply cord through the strain relief. Be sure that the wire insulation on the power supply cord is inside the strain relief. The strain relief should have a tight fit with the dryer cabinet and be in a horizontal position. Do not further tighten strain relief screws at this point.

If your outlet looks like this:

Power supply cord 4-wire receptacle (NEMA Type 14-30R):

Go to “4-Wire Power Supply Cord Connection.”

Power supply cord 3-wire receptacle (NEMA Type 10-30R):

Go to “3-Wire Power Supply Cord Connection.”

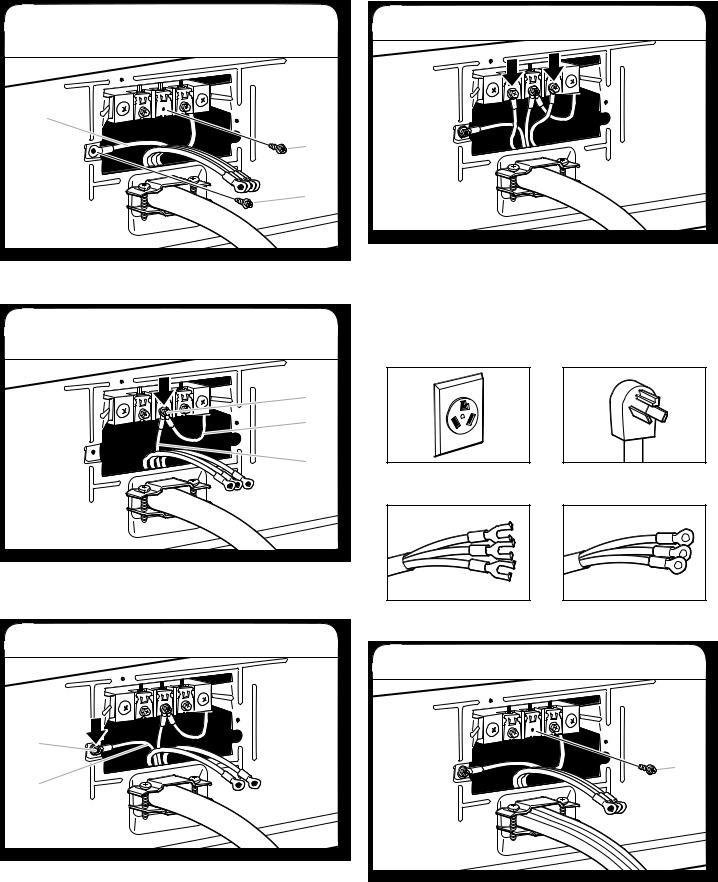

4-Wire Power Supply Cord Connection

IMPORTANT: A 4-wire connection is required for mobile homes and where local codes do not permit the use of 3-wire connections.

|

|

|

4-wire receptacle |

|

4 prong plug |

(NEMA type 14-30R) |

|

|

|

|

|

|

|

|

Spade terminals with |

Ring terminals |

upturned ends |

|

9

1. Prepare to connect neutral ground wire and neutral wire

E |

B |

A |

Remove center terminal block screw (B). Remove neutral ground wire (E) from green external ground conductor screw (A).

2. Connect neutral ground wire and neutral wire

B |

E |

C |

Connect neutral ground wire (E) and neutral wire (white or center) (C) of power supply cord under center terminal block screw (B). Tighten screw.

3. Connect ground wire

A |

F |

Connect ground wire (F) (green or bare) of power supply cord under green external ground conductor screw (A). Tighten screw.

4. Connect remaining wires

Connect remaining wires under outer terminal block screws. Tighten screws. Finally, reinsert tab of terminal block cover into slot of dryer rear panel. Secure cover with hold-down screw. Now, go to “Connect Outlet Hose.”

3-Wire Power Supply Cord Connection

Use where local codes permit connecting cabinet-ground conductor to neutral wire.

3-wire receptacle (NEMA type 10-30R)

Spade terminals with upturned ends

3 prong plug

Ring terminals

1. Remove center screw

B |

Remove center terminal block screw (B).

10

Loading...

Loading...