Watson-Marlow 205S User Manual

205S, 205U

205suca-gb-02.pdf

Declarations

Declaration of conformity

Declaration of

Incorporation

When this pump unit is used as a stand alone pump it complies with: Machinery Directive 2006/42/EC, EMC Directive 2004/108/EC.

When this pump unit is to be installed into a machine or is to be assembled with other machines for installations, it must not be put into service until the relevant machinery has been declared in conformity with the Machinery Directive 2006/42/EC.

Responsible person: Christopher Gadsden, Managing Director, Watson-Marlow Limited, Falmouth, Cornwall TR11 4RU, England. Telephone 01326 370370 Fax 01326 376009.

Two year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through either Watson-Marlow Limited, its subsidiaries, or its authorised distributors, to repair or replace free of charge, including labour, any part of this product which fails within two years of delivery of the product to the end user. Such failure must have occurred because of defect in material or workmanship and not as a result of operation of the product other than in accordance with the instructions given in this manual.

Conditions of and specific exceptions to the above warranty are:Consumable items such as tubing and rollers are excluded.

Products must be returned by pre-arrangement carriage paid to Watson-Marlow Limited, its subsidiaries, or its authorised distributor.

All repairs or modifications must have been made by Watson-Marlow Limited, its subsidiaries, or its authorised distributors or with the express permission of Watson-Marlow Limited, its subsidiaries, or its authorised distributors.

Products which have been abused, misused, or subjected to malicious or accidental damage or electrical surge are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by any person, including representatives of Watson-Marlow Limited, its subsidiaries, or its distributors, which do not accord with the terms of this warranty shall not be binding upon Watson-Marlow Limited unless expressly approved in writing by a Director or Manager of Watson-Marlow Limited.

Information for returning pumps

Equipment which has been contaminated with, or exposed to, body fluids, toxic chemicals or any other substance hazardous to health must be decontaminated before it is returned to Watson-Marlow or its distributor.

A certificate included at the rear of these operating instructions, or signed statement, must be attached to the outside of the shipping carton.

This certificate is required even if the pump is unused. If the pump has been used, the fluids that have been in contact with the pump and the cleaning procedure must be specified along with a statement that the equipment has been decontaminated.

Safety

In the interests of safety, this pump and the tubing selected should only be used by competent, suitably trained personnel after they have read and understood this manual, and considered any hazard involved.

Any person who is involved in the installation or maintenance of this equipment should be fully competent to carry out the work. In the UK this person should also be familiar with the Health and Safety at Work Act 1974.

There are dangerous voltages (at mains potential) inside the pump. If access is required, isolate the pump from the mains before removing the cover.

2

Recommended operating procedures

DO keep delivery and suction lines as short as possible using a minimum number of swept bends.

DO use suction and delivery pipelines with a bore equal to or larger than the bore of the tube fitted in the pumphead. When pumping viscous fluids, the losses caused by increased friction can be overcome by using pipe runs with a cross sectional area several times greater than the pumping element.

DO fit an extra length of pump tube in the system to enable tube transfer. This will extend tube life and minimise the downtime of the pumping circuit.

DO keep the track and rollers clean.

The self-priming nature of peristaltic pumps means valves are not required. Any valves fitted must cause no restriction to flow in the pumping circuit.

When using Marprene tubing, after the first 30 minutes of running, re-tension the tube in the pumphead by releasing the tube clamp on the delivery side a little and pulling the tube tight. This is to counteract the normal stretching that occurs with Marprene which can go unnoticed and result in poor tube life.

Tube selection The chemical compatibility list published in the Watson-Marlow catalogue is only a guide. If in doubt about the compatibility of a tube material and the duty fluid, request a tube sample card for immersion trials.

Installation

The 205S and 205U are suitable for single phase mains electricity supplies only.

To ensure correct lubrication of the gearbox the pump should be run only while its feet are standing on a horizontal surface. The pump should be positioned to allow a free flow of air around it.

Set the voltage selector to either 120V for 100-120V 50/60Hz supplies or 240V for 220-240V 50/60Hz supplies.

A mains cable fitted with a moulded plug is supplied with the pump. The wires are colour coded in accordance with the following code:

220-240V: Live - Brown; Neutral - Blue; Earth - Green/Yellow.100-120V: Live - Black; Neutral - White; Earth - Green.

Troubleshooting

Should the pump fail to operate, make the following checks to determine whether or not servicing is required.Check that the power switch is on.

Check the mains supply is available at the pump.

Check the voltage selector switch is in the correct position.Check the fuse in the mains socket.

Check that the pump is not stalled by incorrect fitting of tubing.

205S / 205U Manual operation

Press the Man/Auto key (205U). When the AUT symbol is not flashing the pump is in manual mode.

Change the set speed by pressing the or key. The 205S & 205U speed control ratio is 180:1.This will give a minimum gearbox speed of 0.5rpm and a maximum of 90rpm.

Change direction by pressing the CW/CCW key. Check the flashing CW/CCW symbol for actual direction setting (CW: clockwise CCW: counter clockwise).

Select the maximum speed: press the key and the Max key together. Select the minimum speed: press the key and the Max key together.

Select the low pulse speed (approx 0.01rpm) indicated by "Lo" on the display by pressing the key again. One more press of the key and the pump will stop and display 0.0rpm.

The keypad has a locking facility to avoid resetting or tampering. If the pump is stopped, press Stop until the padlock symbol illuminates. If the pump is running, press Start until the padlock symbol illuminates. All keys will be disabled except for Start and Stop. Press these keys until the padlock symbol extinguishes to unlock the keypad.

The pump can be set to automatically restart in its operating state set prior to interruption, or set so that after power is reconnected the pump will remain stopped. To invoke the Auto-restart facility switch off power to the pump at the mains supply. Press the Start key down when the mains supply is switched back on until the ! symbol illuminates. Now press Start to start the pump. This facility can be cancelled by turning the mains supply off and then pressing the Stop key whilst turning the mains supply back on. The ! symbol will not be illuminated.

Press Start to start the pump. Press Stop to stop the pump.

3

205U Automatic operation

Press the Man/Auto key. When the AUT symbol flashes the pump is in manual mode.

The pump is controllable by an analogue process signal of up to 30V or 32mA. The pump will provide an increasing flow rate for rising control signal (non-inverted response ) or an increasing flow rate for falling control signal (inverted response ).

Signal offset is the process signal level which has to be reached in order for the pump rotor to start rotating.

Signal range is the change in process signal level necessary to produce the required change in pump rotor speed. For example, when using a 4mA to 20mA process signal:

Pump response |

Signal offset |

Signal range |

Non-Inverted |

4mA |

16mA |

Inverted |

20mA |

16mA |

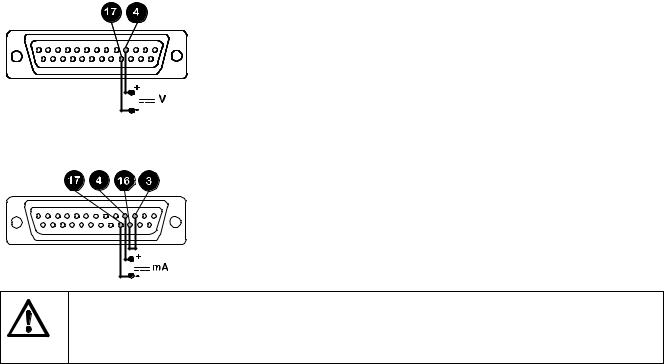

For voltage modes a stable variable DC voltage source can be used in conjunction with a DC voltmeter, (maximum 30V DC). (Refer to 25D pin connector wiring detail as an example of control circuitry) Circuit impedance 100 kohms. Polarity set for non-inverted response. Reverse polarity for inverted response.

For current modes the same DC source can be used in conjunction with a DC milliampere meter, (maximum 32mA). (See 25 pin Dee connector detail). Circuit impedance 250 ohms. Polarity set for non-inverted response. Reverse polarity for inverted response.

Never apply mains voltage across any pins on the 25D socket. Up to 30V may be applied across pins 4 and 17, and 5V TTL on pins 7 and 5, but no voltage should be applied across other pins. Permanent damage, not covered by warranty may result in both instances. Do not use the mains power switch to control the pump for a high repetition of stop/starts. The auto-control facility should be used.

Calibration procedure

Turn the signal offset potentiometer (marked "Offset" on back panel) clockwise until the slider traverse limit is reached and is signified by a clicking noise. Now turn the potentiometer ten turns anticlockwise. Repeat for the signal range potentiometer. This ensures correct potentiometer set up for calibration.

Set the process signal offset.

Turn the signal offset potentiometer clockwise to set the drive shaft speed to the desired minimum. Set the process signal at its upper range limit (not exceeding 30V or 32mA).

Turn the signal range potentiometer (marked "Range" on back panel) clockwise to set the drive shaft speed to the desired maximum.

If the process signal or drive speed are set above their designated maximums the drive will be overloaded which is signified by the flashing of AUT. This is an indication of the limiting control and speed levels of the drive. Reset to operate within these levels.

Repeat the procedure until pump response coincides exactly with the process signal.

4

Loading...

Loading...