Viessmann Vitodens 200-W, B2HA Technical Manual

Technical Data Manual

Model Nos. and pricing: see Price List

For Natural Gas and Liquid Propane Gas

Gas-fired wall-mounted condensing boiler

12 to 285 MBH (3.5 to 83.5 kW)

Multi-boiler installation 480 to 2280 MBH

for models 45, 60 and 80

VITODENSr 200-W

Product may not be exactly as shown

Vitodens 200-W

Series B2HA, Models 19, 28, 35, 45, 60 and 80

Gas-Fired Wall-Mounted Condensing Boiler

with modulating MatriX cylinder burner for

room air independent operation (using a

direct vent system) or room air dependent

operation.

5683 717 - 04 04/2015

H

Product Information

Vitodens 200-W

Equipped with the industry’s first intelligent combustion

management system and powerful control technology,

the new generation Vitodens 200-W gas-fired wall-mount

condensing boiler delivers unparalleled performance,

reliability and comfort.

The benefits at a glance:

Vitodens 200-W, B2HA 19 to 80 Technical Data

■ Best value in its class with new industry-leading

technology and the most standard features.

■ Highest Efficiency up to 98% at full modulation and up

to 93.3% A.F.U.E.

■ Lasting performance with industry-leading Viessmann

made SA240 316 Ti stainless steel Inox-Radial heat

exchanger constructed to CSA B51 and ASME Section IV.

■ Low Emission Combustion with Viessmann made

stainless steel MatriX cylinder burner. Factory calibrated.

■ Fast Installation and Reduced Maintenance with Lambda

Pro, industry-first intelligent combustion management

system: Adjusts automatically to gas type and quality.

No fuel conversion kit required.

■ Powerful and User-friendly

Viessmann Vitotronic on-board multi-function outdoor

reset boiler and system control for multi-temperature

space and DHW heating.

■ Expanded Application Range with increased capacity

up to 285 MBH (83 kW). Multi-boiler installation up to

2280 MBH (668 kW) with up to 8 boilers (models B2HA

45, 60, 80).

■ Greater Venting Flexibility with increased vent length

up to 180 ft. (55 m) and multiple venting options.

- Horizontal or vertical sealed combustion coaxial

venting (field supplied).

- Horizontal, vertical or hybrid sealed combustion

double-pipe venting (field supplied).

- Horizontal or vertical single-wall venting (field

supplied).

■ Compact, Esthetic Product Design and zero clearance

to combustibles.

■ Extremely Quiet Operation; quieter than most

refrigerators.

■ True High-Altitude Operation up to 10,000 ft. (3,000 m)

with simple electronic adjustment.

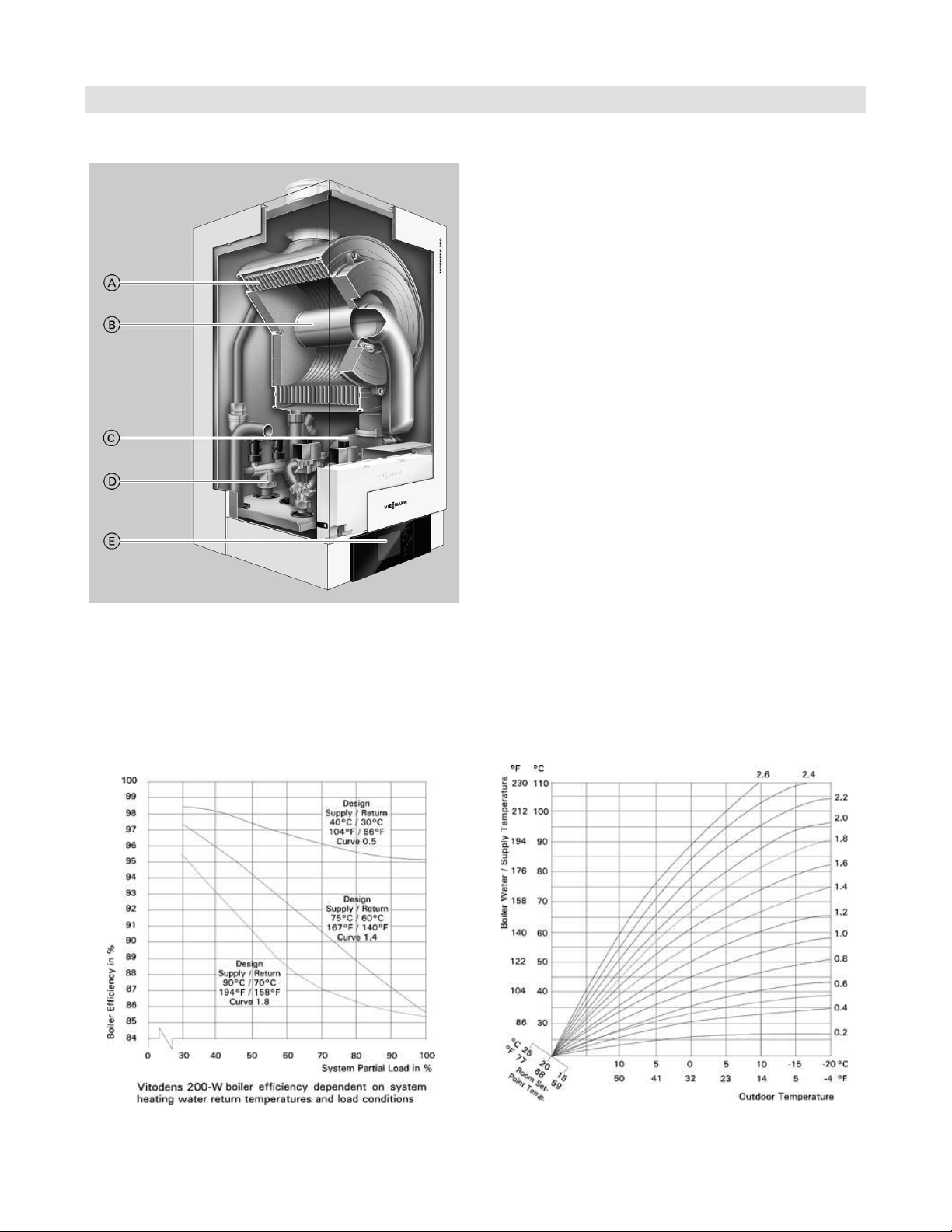

■ Efficiency up to 98% through intensive condensation.

The flue gas temperature is only approximately 9-27º F

(5-15º C) above boiler return temperature (see chart

below).

2

2

5683 717 - 04

Vitodens 200-W, B2HA 19 to 80 Technical Data

Cross-Section

Vitodens 200-W B2HA 19, 28, 35, 45, 60, 80

Product Information

A Inox-Radial heat exchanger made from stainless steel

– for high operational reliability and a long service life.

Large heating output in the smallest of spaces

B Modulating MatriX cylinder burner for extremely

clean combustion and quiet operation

C Variable speed combustion fan for quiet and

economical operation

D Gas and water connections

E Digital boiler control unit

Delivered condition

Wall mounted gas condensing boiler with Inox-Radial heat

exchanger, modulating MatriX cylinder burner for natural

gas and LPG, plus wall mounting bracket. Vitotronic 200

for weather-compensated operation. Preset for operation

with natural gas. Fully plumbed and wired. White epoxycoated casing.

Product may not be exactly as shown

The flue gas temperature is only approximately 9-27º F

(5-15º C) above boiler return temperature (see chart

below).

5683 717 - 04

3

3

Technical Data

Vitodens 200-W, B2HA 19 to 80 Technical Data

Technical Data

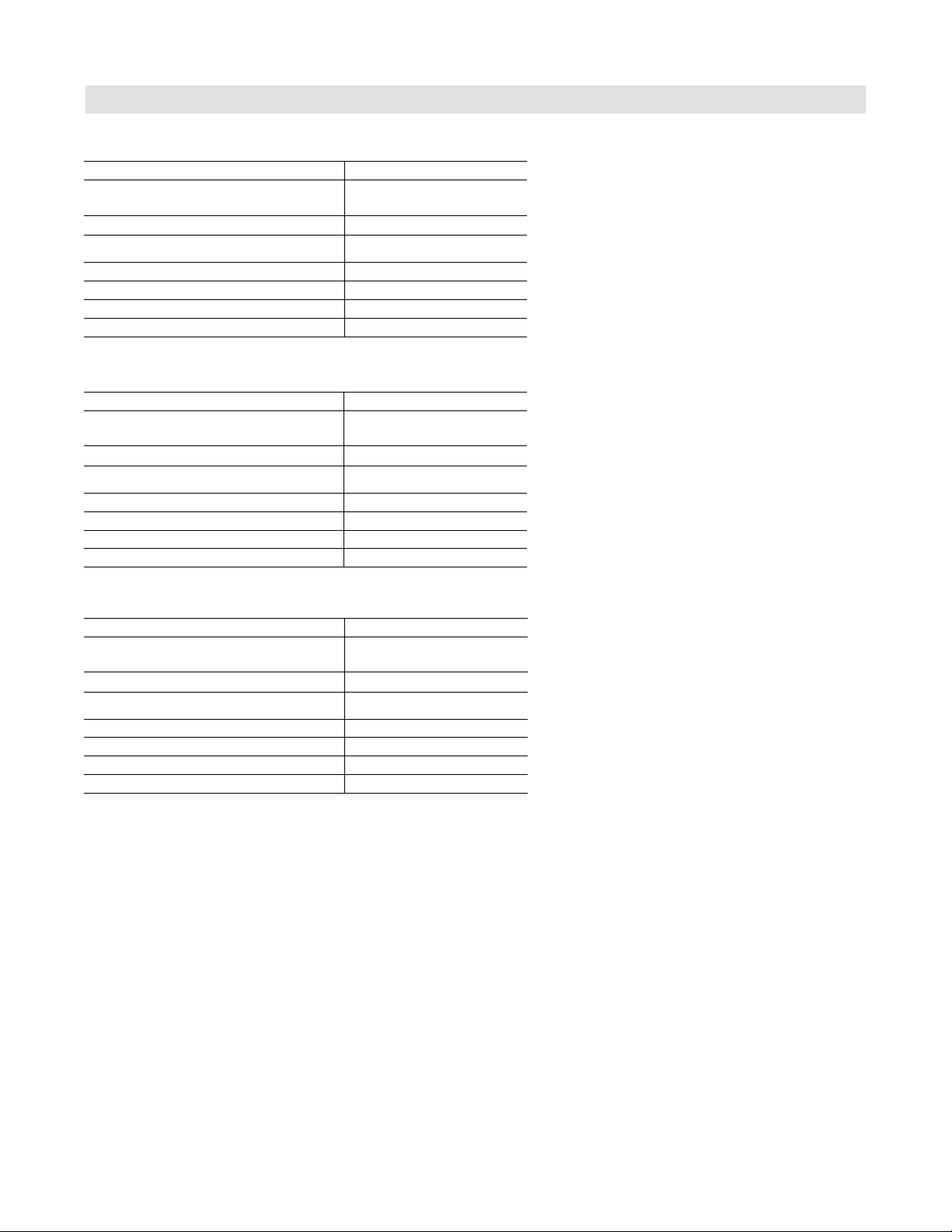

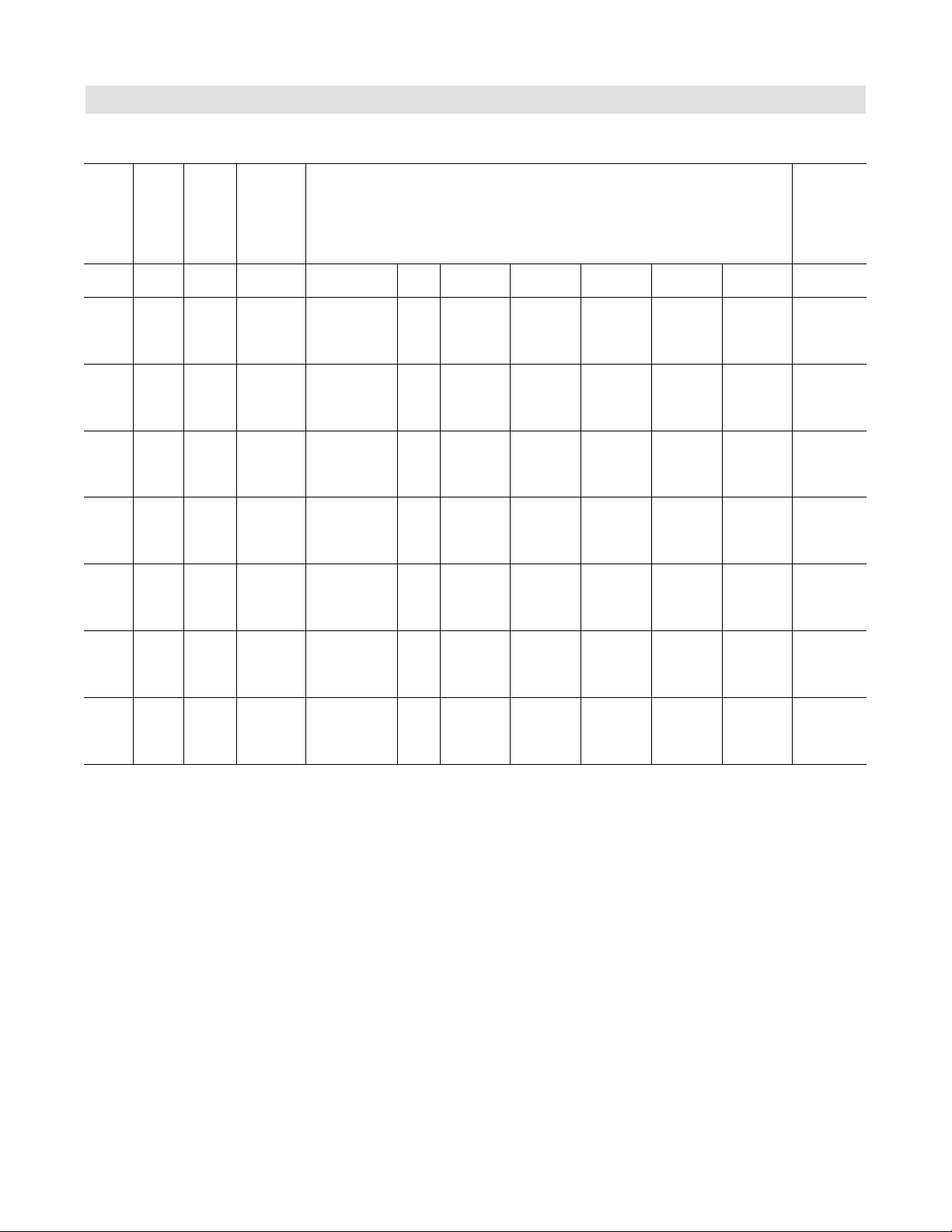

Boiler Model No. 200-W B2HA 19 28 35 45 60 80

Natural Gas / Liquid Propane Gas

CSA input

CSA output/DOE *1

heating capacity

Net AHRI rating *2

Heat exchanger surface area ft.

Min. gas supply pressure

Natural gas

Liquid propane gas

Max. gas supply pressure *3

Natural gas

Liquid propane gas

A.F.U.E. % 93.3 93.3 93.3 92.0 92.0 92.0

Weight lbs

Boiler water content USG

Boiler max. flow rate *4 GPM

Max. operating pressure

at 210º F (99º C)

Boiler water temperature

- Adjustable high limit (AHL) range

space heating (steady state)

DHW production

- Fixed high limit (FHL)

Boiler connections

Boiler heating supply and return

Pressure relief valve

Drain valve

Boiler supply/return for

indirect-fired DHW storage tank

(field supplied)

Gas valve connection

MBH

kW

MBH

kW

MBH

kW

m

“w.c.

“w.c.

“w.c.

“w.c.

kg

L/h

psig

bar

ºF

ºC

ºF

ºC

ºF (ºC)

NPTM”

NPTF”

(male

thread)

NPT”

NPTF”

2

2

L

12-67

3.5-20

10.9-61

3.2-18

53

15.5

10.89

1.01

10

14

14

101

46

0.87

3.27

6.2

1400

45

68 to 165

20 to 74

165

74

210 (99)

¾

¾

¾

¾

¾

17.4-91.2

4

3

19-100

5.5-29

5-27

79.3

23.2

10.89

1.01

10

14

14

106

48

0.87

3.27

6.2

1400

45

68 to 165

20 to 74

165

74

210 (99)

¾

¾

¾

¾

¾

4

3

19-125

5.5-37

17.4-114

5-33

99

29

10.89

1.01

10

14

14

106

48

0.87

3.27

6.2

1400

45

68 to 165

20 to 74

165

74

210 (99)

¾

¾

¾

¾

¾

4

3

68 to 165

60-160

17.5-47

55-146

16-43

127

37

15.76

1.46

10

14

14

155

72

1.9

7.0

15.4

3500

60

20 to 74

165

74

210 (99)

1b

¾

¾

1b

4

4

68 to 165

1

60-212

17.5-62

55-194

16-57

169

49.5

15.76

1.46

10

14

14

155

72

1.9

7.0

15.4

3500

60

20 to 74

165

74

210 (99)

1b

¾

¾

1b

104-285

30-83

95-260

28-76

226

66.2

28.88

2.68

4

194

12.8

5700

4

68 to 176

20 to 80

176

210 (99)

1

4

10

14

14

88

3.4

25

60

4

80

1b

¾

¾

1b

1

*1 Output based on 140º F (60º C), 120º F (49º C) system supply/return temperature.

*2 Net AHRI rating based on piping and pick-up allowance of 1.15.

*3 If the gas supply pressure exceeds the maximum gas supply pressure value, a separate gas pressure regulator

must be installed upstream of the heating system.

*4 See “Waterside Flow” starting on page 10 in this manual.

4

4

5683 717 - 04

Vitodens 200-W, B2HA 19 to 80 Technical Data

Technical Data

Technical Data

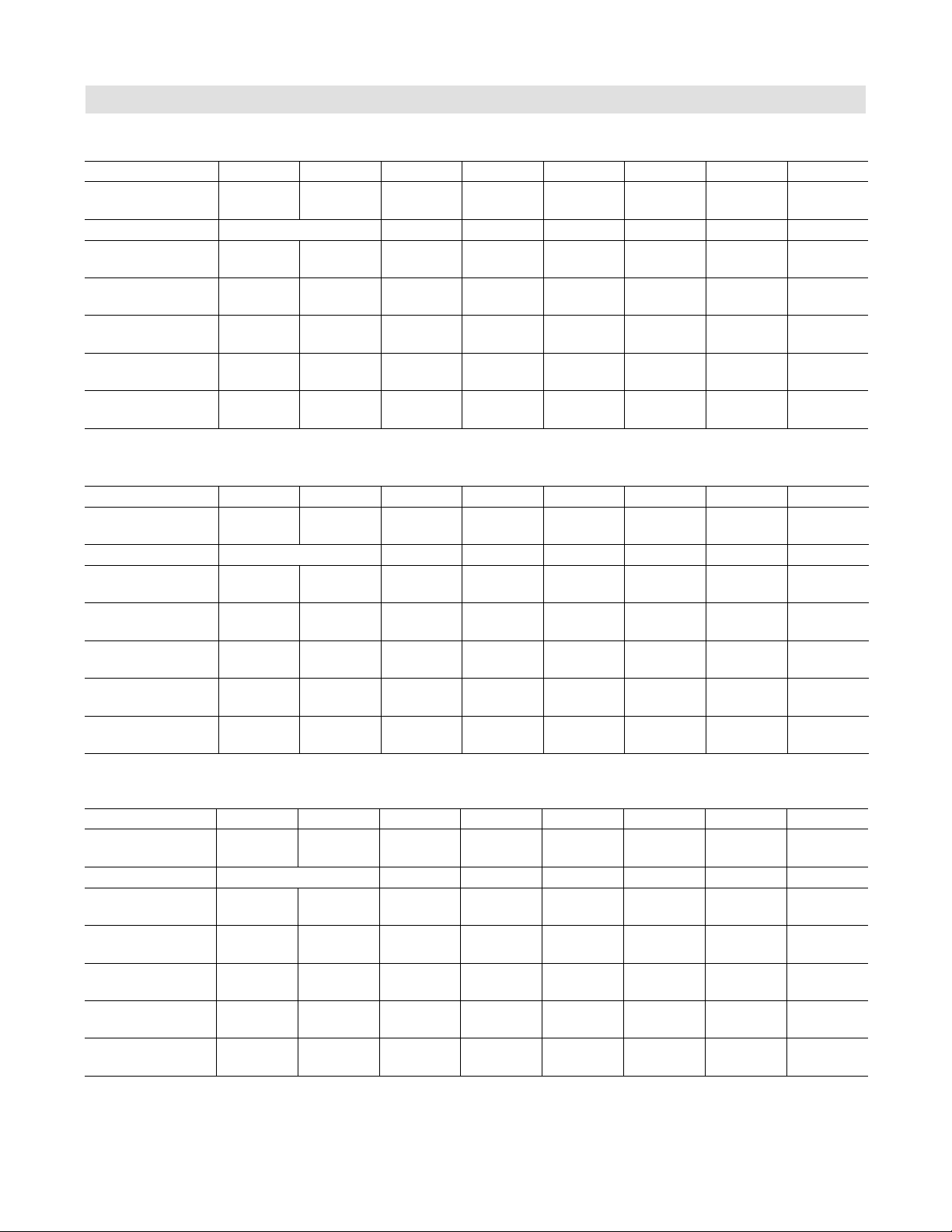

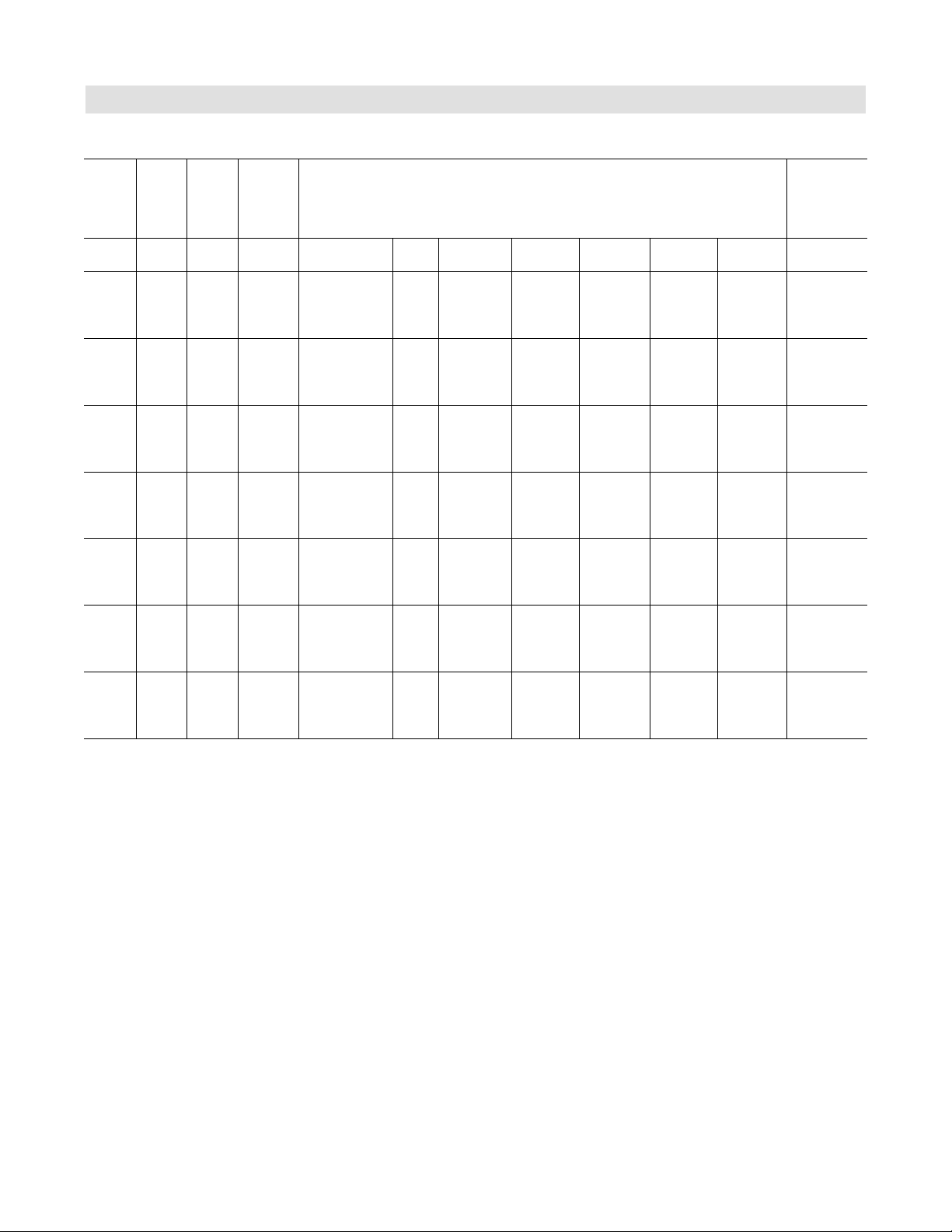

Boiler Model No. 200-W B2HA 19 28 35 45 60 80

Dimensions

Overall depth

inches

mm

Overall width

inches

mm

Overall height

inches

mm

Flue gas *5

Temperature (at boiler return

temperature of 86º F (30º C)

- at rated full load

- at rated partial load

Temperature (at boiler return

ºF (ºC)

ºF (ºC)

ºF (ºC)

temperature of 140º F (60º C)

Max. condensate flow rate *6

with natural gas and

T

=122/86º F (50/30º C) USG/h

S/TR

L/h

Condensate connection *7 hose

nozzle

Ø in

Boiler flue gas connection *8 Ø

in (mm) 23/8 (60) 23/8 (60) 23/8 (60)

Combustion air supply

connection (coaxial)

Sound Rating

outer

Ø in (mm) 4 (100) 4 (100) 4 (100) 5 (125) 5 (125) 6 (150)

- at maximum input

- at minimum input

dB

dB

14

360

17¾

450

41

1040

113 (45)

95 (35)

154 (68)

0.66

2.5

14

360

17¾

450

41

1040

113 (45)

95 (35)

154 (68)

0.97

3.7

14

360

17¾

450

41

1040

113 (45)

95 (35)

154 (68)

1.21

4.6

15

380

19

480

405/

1031

95 (35)

91 (33)

149 (65)

1.55

5.9

8

¾-1 ¾-1 ¾-1 ¾-1 ¾-1 ¾-1

3¼ (80) 3¼ (80)

41

35

48

36

51

36

56

39

15

380

19

480

405/

1031

104 (40)

95 (35)

158 (70)

2.0

7.9

67

39

8

149 (65)

43/8 (110)

530

480

43½

1105

95 (35)

91 (33)

2.77

10.5

21

19

56

38

*5 Measured flue gas temperature with a combustion air temperature of 68° F (20° C).

*6 Based on maximum input rate.

*7 Requires 1 inch (25 mm) tubing. See the Installation Instructions of the Vitodens 200-W, B2HA for details.

*8 For side wall vent installations (coaxial system):

Do not exceed max. equivalent length specified in the Installation Instructions of the Vitodens 200-W, B2HA

Venting System.

Do not attempt to common-vent Vitodens 200-W with any other appliance.

Side wall co-axial vent installation must include Viessmann protective screen!

For details refer to the Installation Instructions for the Vitodens 200-W, B2HA Venting System.

For information regarding other Viessmann System Technology componentry, please reference documentation

of respective product.

Note: For high altitude installation at 10,000 ft. the input for model B2HA 19-80 will have an altitude

de-ration of 21%.

5683 717 - 04

5

5

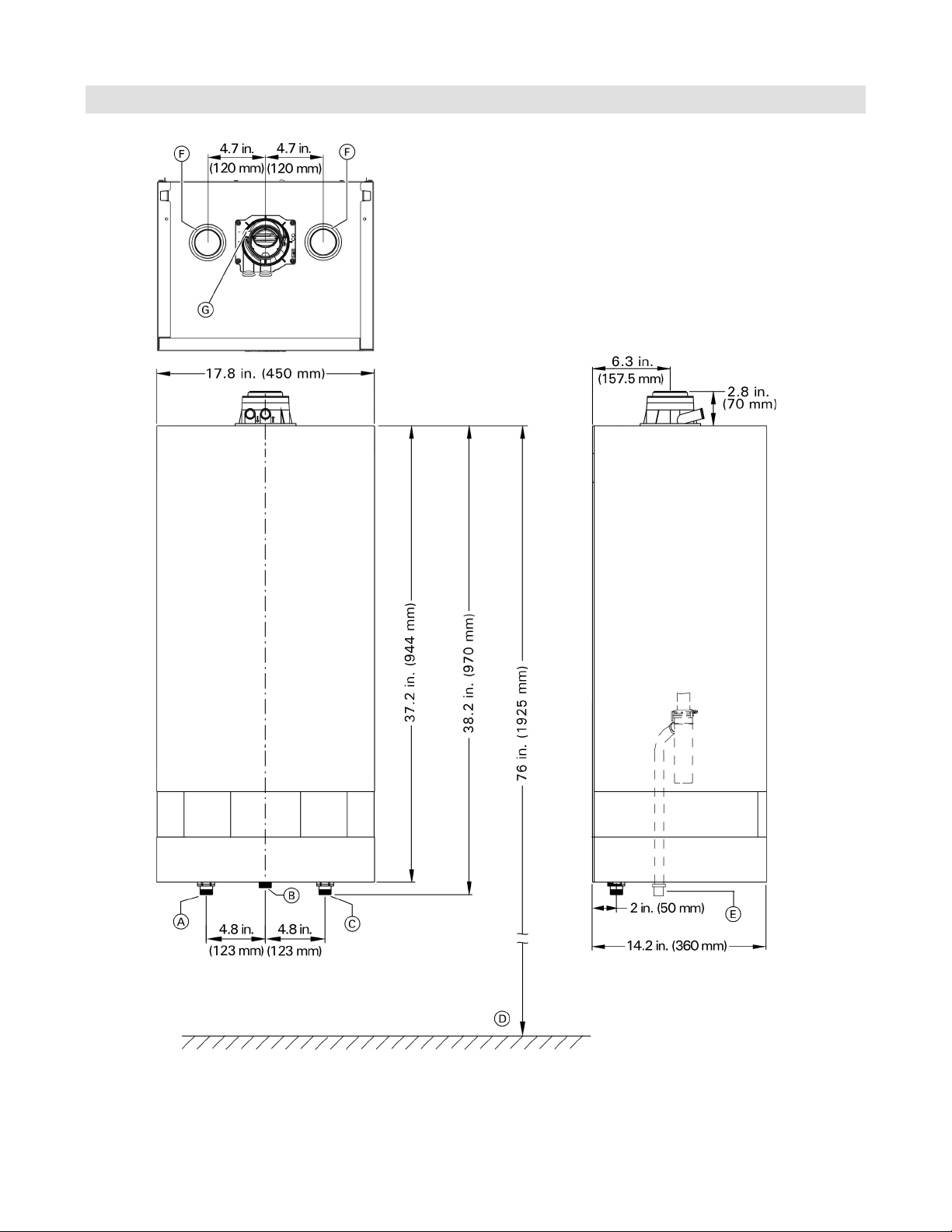

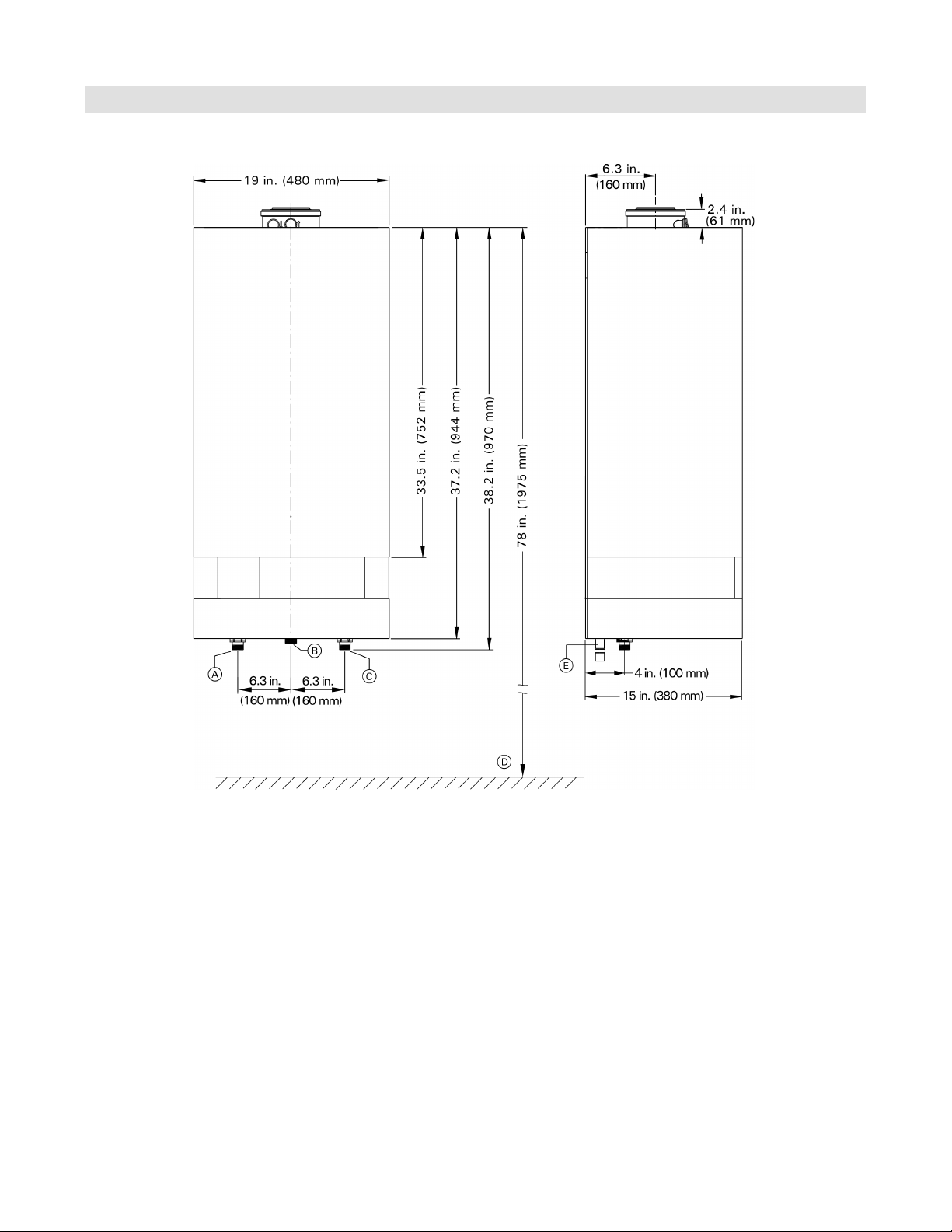

Dimensional Information

Models 200-W, B2HA 19, 28, 35

Vitodens 200-W, B2HA 19 to 80 Technical Data

Legend

A Boiler Supply

B Gas Connection,

C Boiler Return

D Recommended height (single boiler system)

6

6

¾” NPTF

E Condensate drain

F Combustion air intake (left or right)

G Combustion air intake (through co-axial)

5683 717 - 04

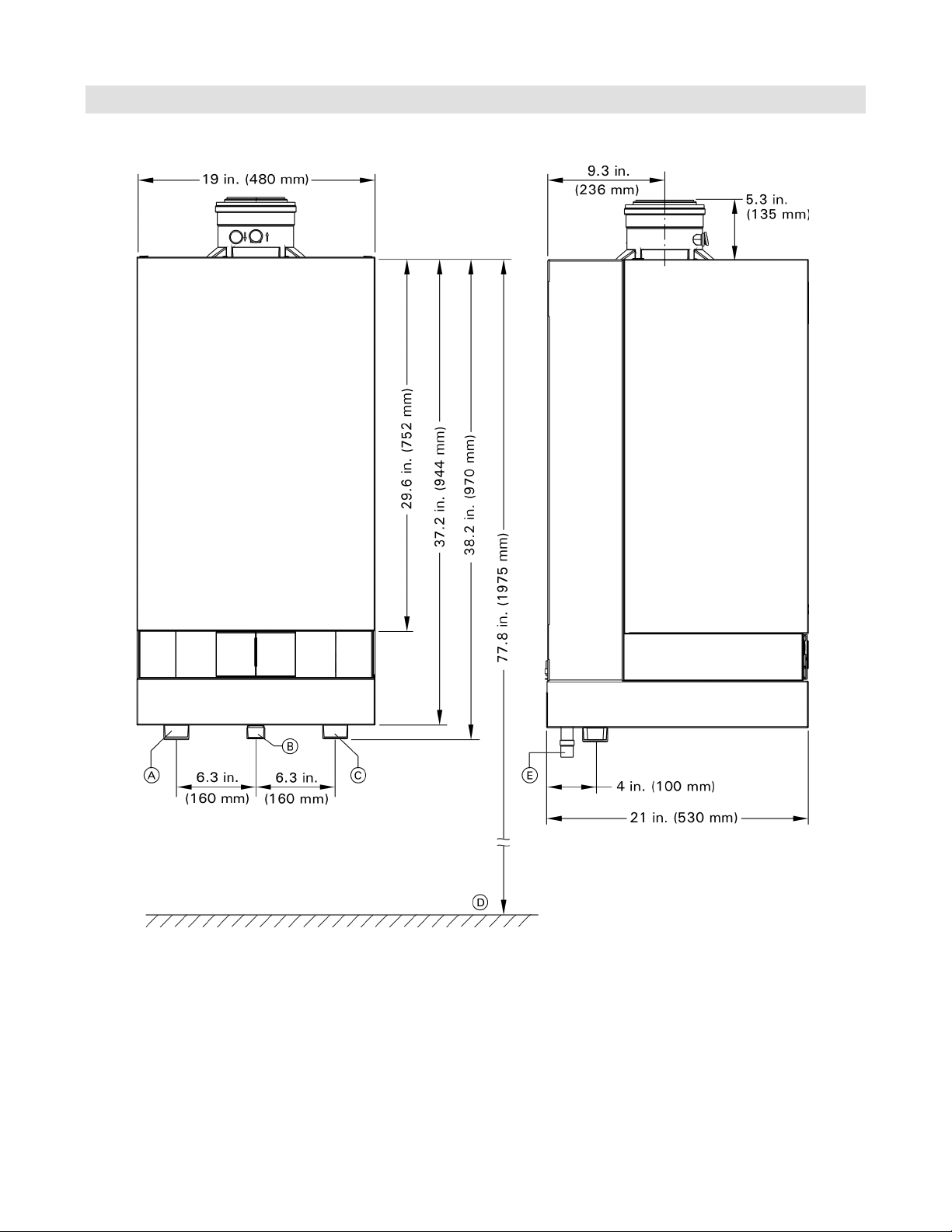

Vitodens 200-W, B2HA 19 to 80 Technical Data

Models 200-W, B2HA 45, 60

Dimensional Information

Legend

A Boiler Supply

B Gas Connection, 1” NPTF

C Boiler Return

D Recommended height (single boiler system)

E Condensate drain

5683 717 - 04

7

7

Dimensional Information

Model B2HA 80

Vitodens 200-W, B2HA 19 to 80 Technical Data

Legend

A Boiler Supply

B Gas Connection, 1” NPTF

C Boiler Return

D Recommended height (single boiler system)

E Condensate drain

8

8

5683 717 - 04

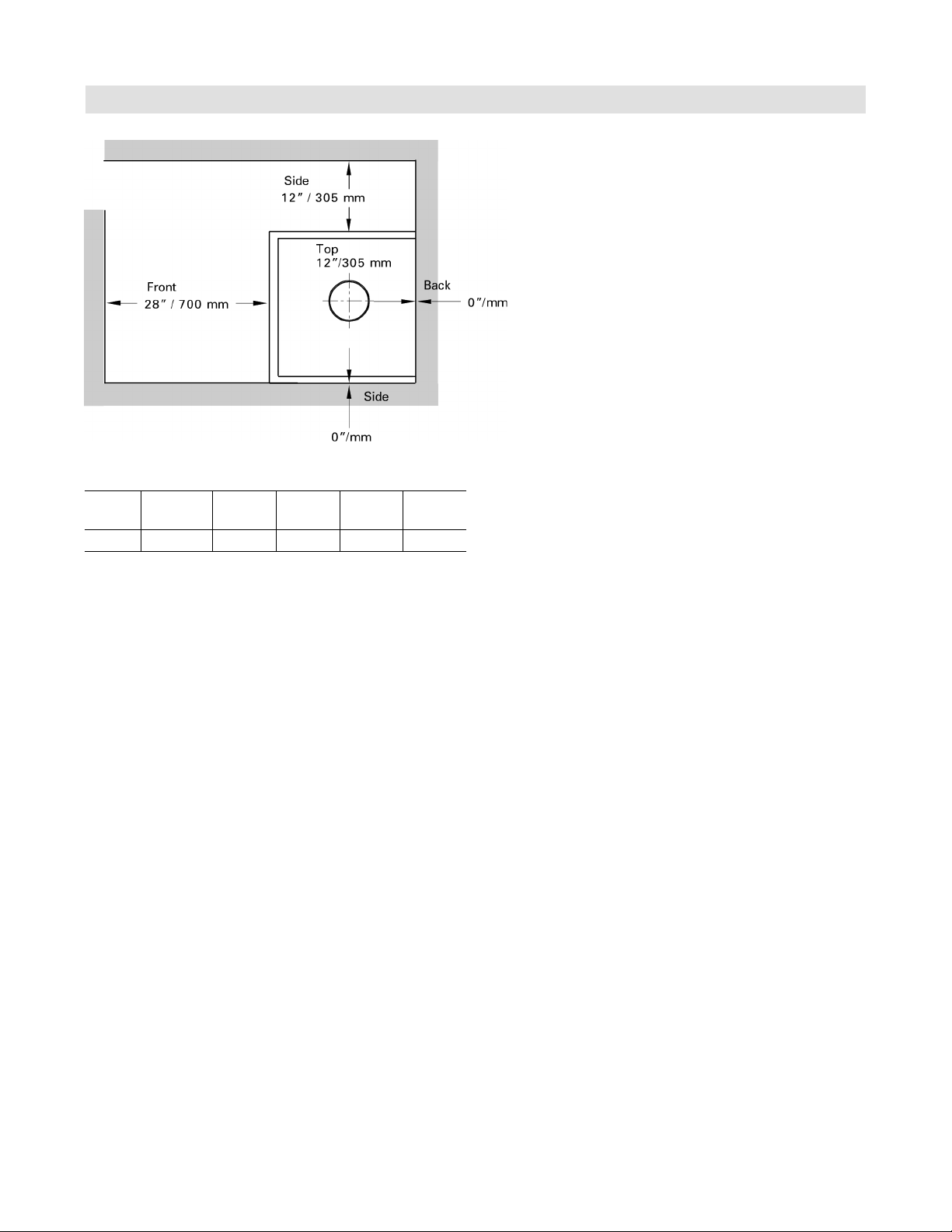

Vitodens 200-W, B2HA 19 to 80 Technical Data

Recommended Minimum Service Clearances

Minimum Clearances to Combustibles

Top Front Rear Left Right Vent

pipe *1

0 0 AL, CL 0 0 0 0

Minimum Clearances

AL= Alcove

CL= Closet

*1 Refer to the Installation Instructions of the Vitodens

200-W, B2HA Venting System for details.

Note:The Vitodens boiler has passed the zero inches

vent clearance to combustibles testing requirements

dictated by the Harmonized Standard ANSI Z21.13.

CSA 4.9.2000 and therefore is listed for zero

clearance to combustibles when vented with a

single wall special venting system (AL-29-4C

material). The zero inches vent clearance to

combustibles for the Vitodens boiler supercedes

the clearance to combustibles listing that appears

on the special venting system label.

5683 717 - 04

9

9

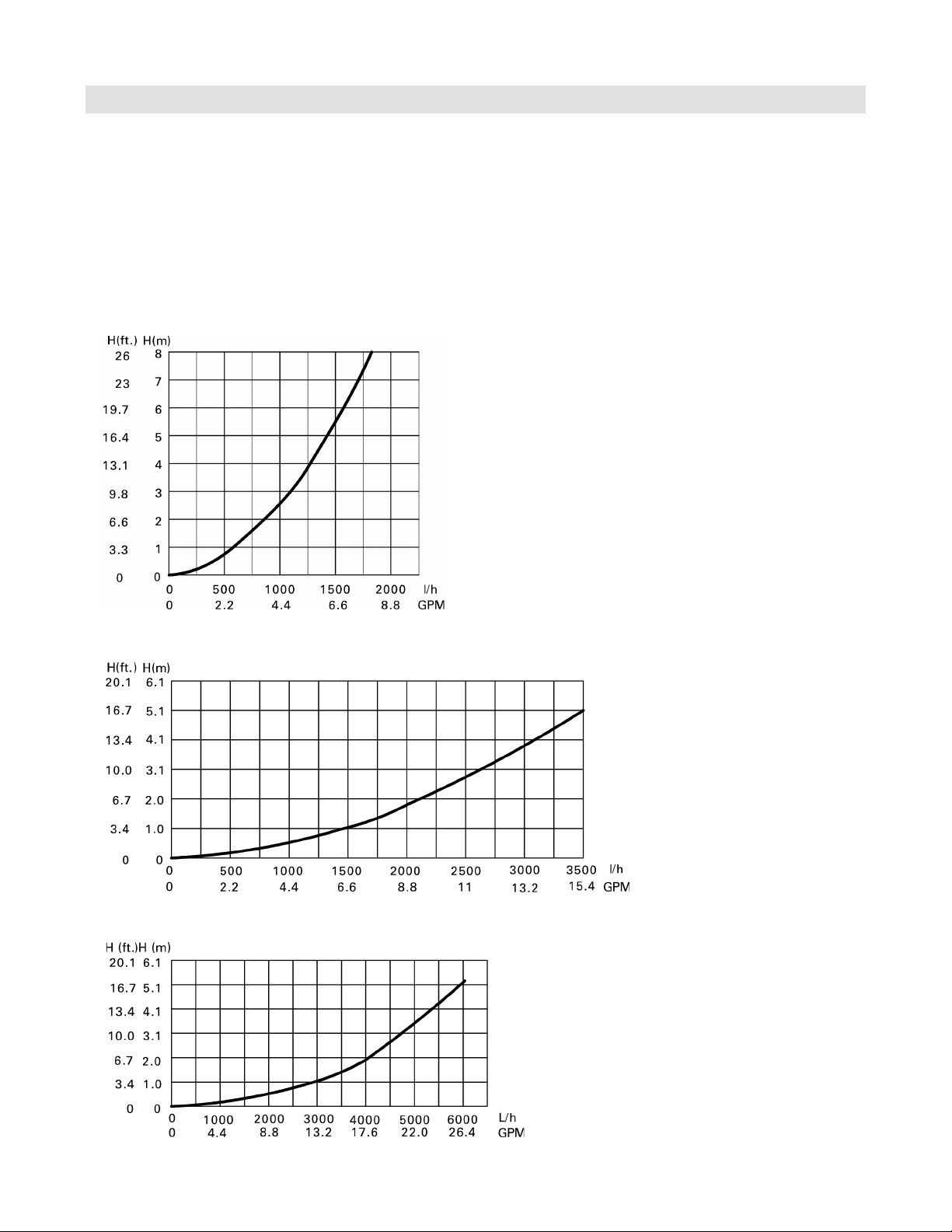

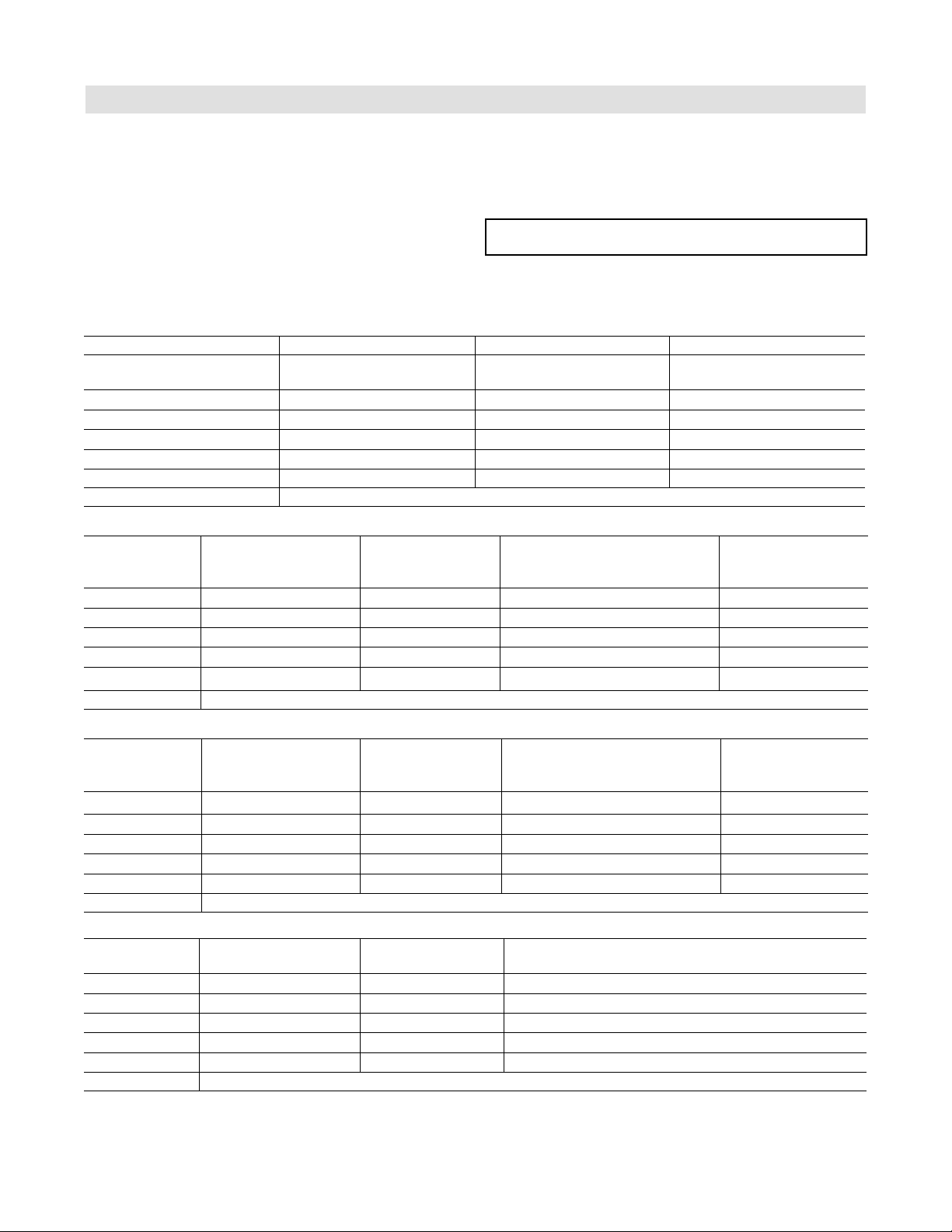

Waterside Flow

Waterside Flow (primary circuit)

Vitodens 200-W, B2HA 19 to 80 Technical Data

The Vitodens 200-W, B2HA is designed for closed loop,

forced circulation hot water heating systems only. Use

standard friction loss method for pipe sizing. Observe

boiler maximum and minimum flow rate limitations. If

system flow rate exceeds boiler maximum flow rate

(as stated above), falls below the minimum flow rate

or if system flow rate is unknown, Viessmann strongly

recommends the installation of a low-loss header.

An alternative method may be used, such as primary

secondary piping using closely spaced tees.

Supply head pressure (water)

A low-loss header offers additional benefits not provided

by a pair of closely spaced tees. Viessmann therefore

strongly recommends and prefers the use of a low-loss

header over closely spaced tees. See pages 32 and 33

for low-loss header information. Once the low-loss header

is connected, the built-in low-loss header logic of the

Vitodens 200-W boiler ensures the required rt across the

system through the sensory communication between the

low-loss header and the boiler.

Pressure drop (primary circuit) for

Vitodens 200-W, B2HA 19, 28, 35

For sizing an on-site circulation system.

Max. flow rate: 6.2 GPM (1400 L/h)

Flow rate

Supply head pressure (water)

Pressure drop (primary circuit) for

Vitodens 200-W, B2HA 45, 60

For sizing an on-site circulation system.

Max. flow rate 15.4 USGPM (3500 L/h)

Flow rate

Pressure drop (primary circuit) for

Vitodens 200-W, B2HA 80

For sizing an on-site circulation system.

Max. flow rate 25 USGPM (5700 L/h)

Supply head pressure (water)

10

Flow rate

5683 717 - 04

Vitodens 200-W, B2HA 19 to 80 Technical Data

Typical System Flow Rates

Boiler maximum flow rate 6.2 GPM (1400 L/h)

Model B2HA 19 1 boiler

Output (NG/LPG)

MBH 61

rt for NG/LPG

20º F rise GPM (L/h) 6.1 (1385)

25º F rise GPM (L/h) 4.9 (1113)

30º F rise GPM (L/h) 4.0 (909)

35º F rise GPM (L/h) 3.5 (795)

40º F rise GPM (L/h) 3.1 (704)

Boiler maximum flow rate 6.2 GPM (1400 L/h)

Model B2HA 28 1 boiler

Output (NG/LPG)

MBH 91.2

rt for NG/LPG

20º F rise GPM (L/h) 9.1 (2100)

25º F rise GPM (L/h) 7.3 (1700)

30º F rise GPM (L/h) 6.1 (1400)

35º F rise GPM (L/h) 5.2 (1200)

40º F rise GPM (L/h) 4.6 (1000)

System Flow Rates

Boiler maximum flow rate 6.2 GPM (1400 L/h)

Model B2HA 35 1 boiler

Output (NG/LPG)

MBH 114

rt for NG/LPG

20º F rise GPM (L/h) 11.4 (2589)

25º F rise GPM (L/h) 9.1 (2067)

30º F rise GPM (L/h) 7.6 (1726)

35º F rise GPM (L/h) 6.5 (1476)

40º F rise GPM (L/h) 5.7 (1295)

5683 717 - 04

11

11

System Flow Rates

Vitodens 200-W, B2HA 19 to 80 Technical Data

Typical System Flow Rates

Boiler maximum flow rate 15.4 GPM (3500 L/h)

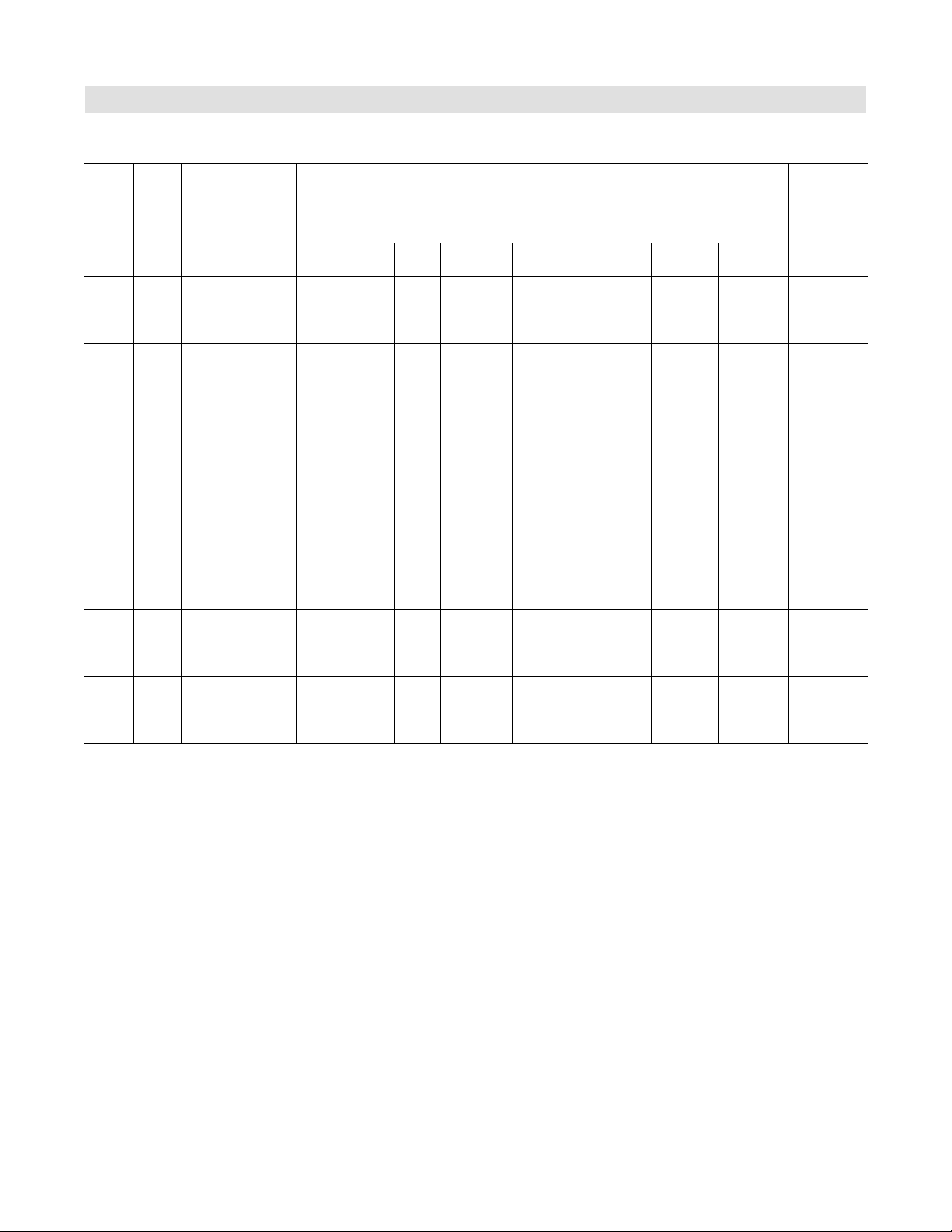

Model B2HA 45 1 boiler 2 boilers 3 boilers 4 boilers 5 boilers 6 boilers 7 boilers 8 boilers

Output (NG/LPG)

MBH 146 292 438 584 730 876 1022 1168

rt for NG/LPG

20º F rise GPM

(L/h)

25º F rise GPM

(L/h)

30º F rise GPM

(L/h)

35º F rise GPM

(L/h)

40º F rise GPM

(L/h)

Boiler maximum flow rate 15.4 GPM (3500 L/h)

Model B2HA 60 1 boiler 2 boilers 3 boilers 4 boilers 5 boilers 6 boilers 7 boilers 8 boilers

Output (NG/LPG)

MBH 194 388 582 776 970 1164 1358 1552

rt for NG/LPG

20º F rise GPM

(L/h)

25º F rise GPM

(L/h)

30º F rise GPM

(L/h)

35º F rise GPM

(L/h)

40º F rise GPM

(L/h)

14.6

(3316)

11.7

(2653)

9.7

(2211)

8.3

(1805)

7.3

(1658)

19.4

(4406)

15.5

(3525)

12.9

(2937)

11.1

(2518)

9.7

(2203)

29.2

(6632)

23.4

(5306)

19.5

(4421)

16.7

(3790)

14.6

(3316)

38.8

(8813)

31

(4050)

26

(5875)

22.2

(5036)

19.4

(4406)

43.8

(9949)

35

(7959)

29.2

(6633)

25

(5685)

22

(4974)

58.2

(13220)

46.6

(10576)62(14101)

38.8

(8813)

33.3

(7554)

29

(6610)

58.4

(13265)73(16580)

46.7

(10612)

39

(8843)

33.4

(7580)

29.2

(6632)

77.6

(17626)97(22031)

51.7

(11750)

44.3

(10072)

38.8

(8813)

58.4

(13264)

48.7

(11053)

41.7

(9474)

36.5

(8290)

77.6

17625)

64.7

(14687)

55.4

(12589)

48.5

(11015)

87.6

(19898)

70.1

(15918)

58.4

(13265)

50.1

(11370)

43.8

(9949)

116.4

(26439)

93.1

(21151)

77.6

(17626)

66.5

(15108)

58.2

(13220)68(15423)

102.2

(23214)

81.8

(18571)

68.1

(15476)78(17687)

58.4

(13265)

51.1

(11607)

135.8

(30846)

108.6

(24677)

90.5

(20564)

77.6

(17626)

116.8

(26530)

93.4

(21224)

66.7

(15160)

58.4

(13265)

155.2

(35252)

124.2

(28202)

103.5

(23502)

88.7

(20144)

77.6

(17626)

Boiler maximum flow rate 25 GPM (5700 L/h)

Model B2HA 80 1 boiler 2 boilers 3 boilers 4 boilers 5 boilers 6 boilers 7 boilers 8 boilers

Output (NG/LPG)

MBH 260 520 780 1040 1300 1560 1820 3960

rt for NG/LPG

20º F rise GPM

(L/h)

25º F rise GPM

(L/h)

30º F rise GPM

(L/h)

35º F rise GPM

(L/h)

40º F rise GPM

(L/h)

12

26.0

(5905)52(11811)78(17717)

20.8

(4724)

17.3

(3937)

15

(3374)

13

(2953)

41.6

(9449)

35

(7874)52(11811)

30

(6749)

26

(5906)

62.4

(14174)

44.6

(10124)

39

(8859)52(11811)65(14763)

104

(23223)

83.2

(18898)

69.3

(15749)87(19684)

59.4

(13499)

130

(29526)

104

(23621)

74.3

(16872)

156

(35434)

125

(28347)

104

(23623)

89

(20248)

78

(17717)

182

(41340)

145.6

(33072)

121.3

(27560)

104

(23623)

91

(20670)

208

(47246)

166.4

(37797)

138.7

(31497)

119

(26997)

104

(23623)

5683 717 - 04

Vitodens 200-W, B2HA 19 to 80 Technical Data

Heating Circuit / Boiler Pumps

Pump Information

Viessmann offers a variety of Grundfos heating circuit/

boiler pumps which meet typical Vitodens system

installation requirements (see “Heating circuit pump

(field supplied)” or “Boiler pump (field supplied)” in the

Installation Examples starting on page 35). See tables

below for recommended pumps. Refer to the graphs on

page 10 and 11 for the proper waterside boiler friction

loss calculations. The following pumps have been selected

based on boiler heat exchanger head loss and boiler piping

to a low-loss header.

Model B2HA 19 B2HA 28 B2HA 35

Flow rate

20º F rt GPM (L/h)

25º F rt GPM (L/h)

30º F rt GPM (L/h)

35º F rt GPM (L/h)

40º F rt GPM (L/h)

Flow limitation GPM (L/h) 4.4 (1200) 6.2 (1400) 6.2 (1400)

Recommended boiler pumps Grundfos UPS 15-58 (3-speed), Taco 0015, Wilo Star S 21 FX

Model B2HA 45 Flow rate

GPM (L/h)

20º F rt

25º F rt

30º F rt

35º F rt

40º F rt

Flow limitation 15.4 GPM (3500 L/h)

14.6 (3316) 15.8 (4.8) UPS 26-99FC, 115V, Speed3 --

11.7 (2653) 10.0 (3.1) UPS 26-99FC, 115V, Speed2 UP 26-64F, 115V

9.7 (2211) 7.5 (2.3) UPS 26-99FC, 115V, Speed2 --

8.3 (1805) 5.8 (1.8) UPS 26-99FC, 115V, Speed1 --

7.3 (1658) 4.2 (1.3) UPS 26-99FC, 115V, Speed1 --

6.1 (1385) -- --

4.9 (1113) -- --

4.0 (909) 6.1 (1381) --

3.5 (795) 5.2 (1184) 6.5 (1476)

3.1 (704) 4.6(1035) 5.7 (1295)

Boiler pressure drop

ft. (m)

Before using the following pumps for a DHW tank

application, find out the proper pressure drop through the

tank, the required temperature difference through the coil

and system piping head loss of the domestic hot water.

IMPORTANT

Pump selection must be based on accurate system flow

and pressure drop calculations (includes DHW sizing).

Recommended

pump option 1

Grundfos

Recommended

pump option 2

Grundfos

Model B2HA 60 Flow rate

GPM (L/h)

20º F rt

25º F rt

30º F rt

35º F rt

40º F rt

Flow limitation 15.4 GPM (3500 L/h)

Model B2HA 80 Flow rate

20º F rt

25º F rt

30º F rt

35º F rt

40º F rt

Flow limitation 25 GPM (5700 L/h)

5683 717 - 04

-- -- -- --

15.4 (3500) 16.7 (5.1) UPS 26-99FC, 115V, Speed3 --

12.9 (2937) 12.6 (3.8) UPS 26-99FC, 115V, Speed3 UP 26-64F, 115V

11.1 (2518) 9.2 (2.8) UPS 26-99FC, 115V, Speed2 UP 26-64F, 115V

9.7 (2203) 7.5 (2.3) UPS 26-99FC, 115V, Speed2 --

GPM (L/h)

-- -- --

20.8 (4724) 9.2 (2.8) UPS 26-99FC, 115V, Speed3

17.3 (3937) 6.5 (2.0) UPS 26-99FC, 115V, Speed2

15 (3374) 4.8 (1.5) UPS 26-99FC, 115V, Speed2

13 (2953) 3.4 (1.0) UPS 26-99FC, 115V, Speed2

Boiler pressure drop

ft. (m)

Boiler pressure drop

ft. (m)

Recommended

pump option 1

Recommended

pump option 2

Grundfos

Recommended pump Grundfos

Grundfos

13

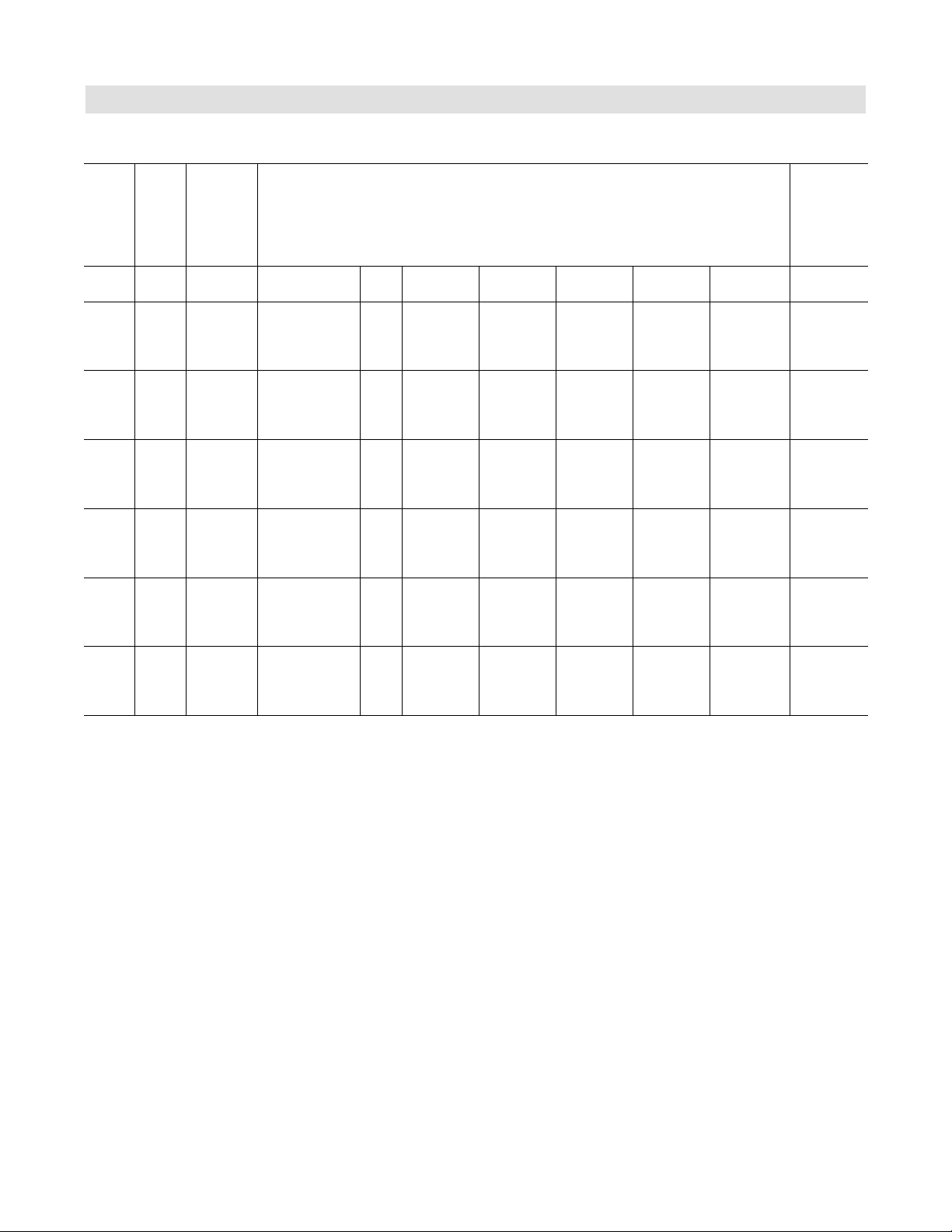

Low-Loss Header Information

Low-Loss Header Application

Sizing of Low-Loss Header in a Residential Single-Boiler Application

Vitodens 200-W, B2HA 19 to 80 Technical Data

Boiler

Model

B2HA 191 6.2

B2HA 281 6.2

B2HA 351 6.2

B2HA 451 15.4

B2HA 601 15.4

B2HA 801 25

No. of

Boilers

Boiler

Max.

Flow

Rate

GPM

(L/h)

(1400)

(1400)

(1400)

(3500)

(3500)

(5700)

Typical System Flow Rates

rt *1

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

°F

(°C)

GPM

(L/h)

Optional

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

120/80

20

(11.0)

6.1

(1385)

80/60

9.1

(2071)

Yes

80/60

11.4

(2589)

Yes

80/60

14.6

(3316)

Yes

80/60

19.4

(4406)

Yes

80/60

26

(5905)

Yes

25

(14.0)

4.9

(1108)

Optional

80/60

7.3

(1657)

Yes

80/60

9.1

(2071)

Yes

80/60

11.7

(2653)

Optional

80/60

15.5

(3525)

Yes

80/60

20.8

(4724)

Yes

120/80

30

(17.0)

4.1

(924)

Optional

80/60

6.1

(1381)

Optional

80/60

7.6

(1726)

Yes

80/60

9.7

(2211)

Optional

80/60

12.9

(2937)

Optional

80/60

17.3

(3937)

Optional

120/80

35

(19.5)

3.5

(792)

Optional

80/60

5.2

(1184)

Optional

80/60

6.5

(1480)

Optional

80/60

8.3

(1895)

Optional

80/60

11.1

(2518)

Optional

80/60

15

(3374)

Optional

120/80

40

(22.0)

3.1

(693)

Optional

80/60

4.6

(1035)

Optional

80/60

5.7

(1295)

Optional

80/60

7.3

(1658)

Optional

80/60

9.7

(2203)

Optional

80/60

13

(2953)

Optional

120/80

Viessmann

Low-loss

Temp.

Sensor

Required*2

Yes

Yes

Yes

Yes

Yes

Yes

*1 For system rt < 20° F use low-loss header sizes for rt 20° F.

*2 Low-Loss temperature sensor - optional equipment for use in single-boiler applications.

14

5683 717 - 04

Vitodens 200-W, B2HA 19 to 80 Technical Data

Low-Loss Header Application (continued)

Sizing of Low-Loss Header in a Commercial Multiple-Boiler Application

Low-Loss Header Information

14.6

Yes

80/60

22

Yes

29.2

Yes

36.5

Yes

43.8

Yes

51.1

Yes

58.4

Yes

Viessmann

Low-loss

Temp.

Sensor

Required*2

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Boiler

Model

B2HA 452 15.4

B2HA 453 15.4

B2HA 454 15.4

B2HA 455 15.4

B2HA 456 15.4

B2HA 457 15.4

B2HA 458 15.4

Note: for multiple boiler applications when using the Vitodens 200-W, B2HA boilers, refer to the multiple boiler

low-loss distribution manifold installation instructions.

No. of

Boilers

Boiler

Max.

Flow

Rate

GPM

(L/h)

(3500)

(3500)

(3500)

(3500)77(17500)

(3500)

(3500)

(3500)

Total

Flow

Rate

GPM

(L/h)

30.8

(7000)

46.2

(10500)

61.6

(14000)

92.4

(21000)

107.8

(24500)

123.2

(28000 )

Typical System Flow Rates

rt *1

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

°F

(°C)20(11.0)25(14.0)30(17.0)35(19.5)40(22.0)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)73(16580)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

(6632)

120/80

(9949)

160/80

(13265)

200/120

200/120

(19898)

250/150

102.2

(23214)

250/150

116.8

(26530)

250/150

29.2

Yes

43.8

Yes

58.4

Yes

Yes

87.6

Yes

Yes

Yes

23.4

(5306)

Yes

120/80

35

(7959)

Yes

120/80

46.7

(10612)

Yes

200/120

58.4

(13264)

Yes

200/120

70.1

(15918)

Yes

200/120

81.8

(18571)

Yes

250/150

93.4

(21224)

Yes

250/150

19.5

(4421)

Yes

80/60

29.2

(6633)

Yes

120/80

39

(8843)

Yes

160/80

48.7

(11053)

Yes

200/120

58.4

(13265)

Yes

200/120

68.1

(15476)

Yes

200/120

78

(17687)

Yes

200/120

16.7

(3790)

Yes

80/60

25

(5685)

Yes

120/80

33.4

(7580)

Yes

120/80

41.7

(9474)

Yes

160/80

50.1

(11370)

Yes

200/120

58.4

(13265)

Yes

200/120

66.7

(15160)

Yes

200/120

(3316)

(4974)

120/80

(6632)

120/80

(8290)

160/80

(9949)

160/80

(11607)

200/120

(13265)

200/120

*1 For system rt < 20° F use low-loss header sizes for rt 20° F.

*2 Low-Loss temperature sensor - standard equipment of the cascade control Vitotronic 300-K MW2B:

for use in multiple boiler applications.

5683 717 - 04

15

Low-Loss Header Information

Vitodens 200-W, B2HA 19 to 80 Technical Data

Low-Loss Header Application

Sizing of Low-Loss Header in a Commercial Multiple-Boiler Application

Boiler

Model

B2HA 602 15.4

B2HA 603 15.4

B2HA 604 15.4

B2HA 605 15.4

B2HA 606 15.4

B2HA 607 15.4

B2HA 608 15.4

Note: for multiple boiler applications when using the Vitodens 200-W, B2HA boilers, refer to the multiple boiler

low-loss distribution manifold installation instructions.

No. of

Boilers

Boiler

Max.

Flow

Rate

(3500)

(3500)

(3500)

(3500)77(17500)

(3500)

(3500)

(3500)

Total

Flow

Rate

30.8

(7000)

46.2

(10500)

61.6

(14000)

92.4

(21000)

107.8

(24500)

123.2

(28000)

Typical System Flow Rates

rt *1

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

(continued)

°F

(°C)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)97(22031)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

(8813)

160/80

(13220)

200/120

(17626)

200/120

250/150

(26439)

250/150

(30846)

300/200

(35252)

300/200

20

(11.0)25(14.0)30(17.0)35(19.5)40(22.0)

38.8

Yes

58.2

Yes

77.6

Yes

Yes

116.4

Yes

135.8

Yes

155.2

Yes

31

(4050)

Yes

120/80

46.6

(10576)

Yes

200/120

62

(14101)

Yes

200/120

77.6

(17625)

Yes

200/120

93.1

(21151)

Yes

250/150

108.6

(24677)

Yes

250/150

124.2

(28202)

Yes

300/200

26

(5875)

Yes

120/80

38.8

(8813)

Yes

160/80

51.7

(11750)

Yes

200/120

64.7

(14687)

Yes

200/120

77.6

(17626)

Yes

200/120

90.5

(20564)

Yes

250/150

103.5

(23502)

Yes

250/150

22.2

(5036)

Yes

120/80

33.3

(7554)

Yes

120/80

44.3

(10072)

Yes

200/120

55.4

(12589)

Yes

200/120

66.5

(15108)

Yes

200/120

77.6

(17626)

Yes

200/120

88.7

(20144)

Yes

250/150

19.4

(4406)

Yes

80/60

29

(6610)

Yes

120/80

38.8

(8813)

Yes

160/80

48.5

(11015)

Yes

200/120

58.2

(13220)

Yes

200/120

68

(15423)

Yes

200/120

77.6

(17626)

Yes

200/120

Viessmann

Low-loss

Temp.

Sensor

Required*2

Yes

Yes

Yes

Yes

Yes

Yes

Yes

*1 For system rt < 20° F use low-loss header sizes for rt 20° F.

*2 Low-Loss temperature sensor - standard equipment of the cascade control Vitotronic 300-K MW2B:

for use in multiple boiler applications.

16

5683 717 - 04

Vitodens 200-W, B2HA 19 to 80 Technical Data

Low-Loss Header Information

Low-Loss Header Application

Sizing of Low-Loss Header in a Commercial Multiple-Boiler Application

Boiler

Model

B2HA 802 25

B2HA 803 25

B2HA 804 25

B2HA 805 25

B2HA 806 25

B2HA 807 25

B2HA 808 25

Note: for multiple boiler applications when using the Vitodens 200-W, B2HA boilers, refer to the multiple boiler

low-loss distribution manifold installation instructions.

No. of

Boilers

Boiler

Max.

Flow

Rate

(5700)50(11400)

(5700)75(17100)

(5700)

(5700)

(5700)

(5700)

(5700

Total

Flow

Rate

100

(22800)

125

(28500)

150

(34200)

175

(39900)

200

(45600)

Typical System Flow Rates

rt *1

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

System Flow

Rate

LLH Required

LLH Model

(continued)

°F

(°C)

GPM

(L/h)

GPM

(L/h)78(17717)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

GPM

(L/h)

(11811)

200/120

200/120

(23223)

250/150

(29526)

300/200

(35434)

300/200

(41340)

300/200

(47246)

400/200

20

(11.0)25(14.0)30(17.0)35(19.5)40(22.0)

52.0

Yes

Yes

104

Yes

130

Yes

156

Yes

182

Yes

208

Yes

41.6

(9449)

Yes

200/120

62.4

(14174)

Yes

200/120

83.2

(18898)

Yes

250/150

104

(23621)

Yes

250/150

125

(28347)

Yes

300/200

145.6

(33072)

Yes

300/200

166.4

(37797)

Yes

300/200

35

(7874)

Yes

120/80

52

(11811)

Yes

200/120

69.3

(15749)

Yes

200/120

87

(19684)

Yes

250/150

104

(23623)

Yes

250/150

121.3

(27560)

Yes

300/200

138.7

(31497)

Yes

300/200

30

(6749)

Yes

120/80

44.6

(10124)

Yes

200/120

59.4

(13499)

Yes

200/120

74.3

(16872)

Yes

200/120

89

(20248)

Yes

250/150

104

(23623)

Yes

250/150

119

(26997)

Yes

250/150

26

(5906)

Yes

120/80

39

(8859)

Yes

160/80

52

(11811)

Yes

200/120

65

(14763)

Yes

200/120

78

(17717)

Yes

200/120

91

(20670)

Yes

250/150

104

(23623)

Yes

250/150

Viessmann

Low-loss

Temp.

Sensor

Required*2

Yes

Yes

Yes

Yes

Yes

Yes

Yes

*1 For system rt < 20° F use low-loss header sizes for rt 20° F.

*2 Low-Loss temperature sensor - standard equipment of the cascade control Vitotronic 300-K MW2B:

for use in multiple boiler applications.

5683 717 - 04

17

Loading...

Loading...