Viessmann Vitocrossal 300, CU3A Technical Manual

Technical Data Manual

Model Nos. and pricing: see Price List

For operation with natural gas and liquid propane gas Floor mounted, gas-fired condensing boiler

Heating input 19 to 199 MBH 5.6 to 58 kW

VITOCROSSAL 300

Product may not be exactly as shown

Vitocrossal 300

CU3A Series 26 to 57

Floor mounted, gas-fired condensing boiler with modulating MatriX gas burner. For room air dependent or independent operation.

H

5673 647 - 03 07/2015

Product Information |

Vitocrossal 300 CU3A 26 to 57 Technical Data |

Benefits

Equipped with the industry’s first intelligent combustion management system and powerful control technology, the new generation Vitocrossal 300 CU3A gas-fired Floor mounted condensing boiler delivers unparalleled performance, reliability and comfort.

The benefits at a glance:

■Best value in its class with new industry-leading technology and the most standard features.

■Highest Efficiency up to 98% at full modulation and up to 95% A.F.U.E.

■Lasting performance with industry-leading Viessmann made SA240 316 Ti stainless steel Inox-Crossal heat exchanger constructed to CSA B51 and ASME Section IV.

■Low Emission Combustion with Viessmann made stainless steel MatriX burner. Factory calibrated.

■Fast Installation and Reduced Maintenance with Lambda Pro, industry-first intelligent combustion management system: Adjusts automatically to gas type and quality. No fuel conversion kit required.

■Powerful and User-friendly

Viessmann Vitotronic on-board multi-function outdoor reset boiler and system control for multi-temperature space and DHW heating.

■Expanded Application Range with increased capacity up to 199 MBH (58 kW). Multi-boiler installation up to 1592 MBH (464 kW) with up to 8 boilers.

■Greater Venting Flexibility with increased vent length [up to 198 ft. (60 m)] and multiple venting options.

-Horizontal or vertical sealed combustion coaxial venting (field supplied).

-Horizontal, vertical or hybrid sealed combustion double-pipe venting (field supplied).

-Horizontal or vertical single-wall venting (field supplied).

■Compact, Esthetic Product Design and zero clearance to combustibles.

■Extremely Quiet Operation; quieter than most refrigerators.

■True High-Altitude Operation up to 10,000 ft. (3,000 m) with simple electronic adjustment.

■Efficiency up to 98% through intensive condensation. The flue gas temperature is only approximately 9-27ºF (5-15ºC) above boiler return temperature.

2

5673 647 - 03

Vitocrossal 300 CU3A 26 to 57 Technical Data |

Product Information |

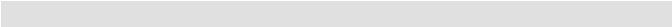

Cross-Section

Vitocrossal 300 CU3A 26 to 57

Vitocrossal 300 CU3A boiler efficiency dependent on system heating water return temperatures and load conditions

Product may not be exactly as shown

Legend

A Digital Vitotronic boiler control unit

B Water-cooled stainless steel combustion chamber C Modulating MatriX gas burner – for extremely clean

combustion

D Stainless steel Inox-Crossal heat exchanger E Highly effective thermal insulation

F Flue gas collector with condensate drain pipe G Combustion air intake for direct vent (two-pipe)

systems

5673 647 - 03

3

Technical Data |

|

|

Vitocrossal 300 CU3A 26 to 57 Technical Data |

||

|

|

|

|

|

|

Technical Data |

|

|

|

|

|

|

|

|

|

|

|

Boiler Model No. CU3A |

|

26 |

35 |

45 |

57 |

|

|

|

|

|

|

Natural Gas / Liquid Propane Gas |

MBH |

|

|

|

|

CSA input |

19-94 |

25-125 |

43-160 |

43-199 |

|

|

(kW) |

(5.6-27.5) |

(7.3-36.6) |

(12.6-47) |

(12.6-58) |

CSA output / DOE heating capacity*1 |

MBH |

17.7-87 |

23.3-116 |

40-149 |

40-185 |

|

(kW) |

(5.2-25.5) |

(6.8-34) |

(11.7-43.7) |

(11.7-54.2) |

Net AHRI Rating |

MBH |

76 |

101 |

129 |

161 |

|

(kW) |

(22) |

(30) |

(38) |

(47) |

|

|

|

|

|

|

Heat exchanger surface area |

ft.2 |

16.7 |

20.7 |

34.1 |

34.1 |

|

(m2) |

(1.5) |

(1.9) |

(3.2) |

(3.2) |

Min. gas supply pressure |

|

|

|

|

|

Natural gas |

“w.c. |

4 |

4 |

4 |

4 |

Liquid propane gas |

“w.c. |

10 |

10 |

10 |

10 |

|

|

|

|

|

|

Max. gas supply pressure *3 |

|

|

|

|

|

Natural gas |

“w.c. |

14 |

14 |

14 |

14 |

Liquid propane gas |

“w.c. |

14 |

14 |

14 |

14 |

|

|

|

|

|

|

A.F.U.E. |

% |

95 |

95 |

95 |

95 |

Weight |

lbs |

269 |

275 |

352 |

352 |

|

(kg) |

(122) |

(125) |

(160) |

(160) |

|

|

|

|

|

|

Boiler water content |

USG |

13.5 |

13.0 |

18.8 |

18.8 |

|

(L) |

(51) |

(49) |

(71) |

(71) |

|

|

|

|

|

|

Max. operating pressure |

psig |

30 |

30 |

30 |

30 |

at 210ºF (99ºC) |

(bar) |

(2) |

(2) |

(2) |

(2) |

|

|

|

|

|

|

Boiler water temperature |

|

|

|

|

|

- Adjustable high limit (AHL) range |

|

|

|

|

|

space heating (steady state) |

ºF |

68-194 |

68-194 |

68-194 |

68-194 |

|

(ºC) |

(20-90) |

(20-90) |

(20-90) |

(20-90) |

DHW production |

ºF |

194 |

194 |

194 |

194 |

|

(ºC) |

(90) |

(90) |

(90) |

(90) |

- Fixed high limit (FHL) |

ºF |

210 |

210 |

210 |

210 |

|

(ºC) |

(99) |

(99) |

(99) |

(99) |

|

|

|

|

|

|

Boiler connections |

|

|

|

|

|

Boiler heating supply and return |

NPTM |

1a” |

1a” |

1a” |

1a” |

Pressure relief valve |

NPTF |

¾” |

¾” |

¾” |

¾” |

Boiler drain |

NPTM |

1” |

1” |

1” |

1” |

Gas valve connection |

NPTF |

¾” |

¾” |

¾” |

¾” |

|

|

|

|

|

|

|

|

|

|

|

|

*1 Output based on 140ºF (60ºC), 120ºF (49ºC) system supply/return temperature. *2 Net AHRI rating based on piping and pick-up allowance of 1.15.

*3 If the gas supply pressure exceeds the maximum gas supply pressure value, a separate gas pressure regulator must be installed upstream of the heating system.

Note: For high altitude installation at 10,000 ft. the input for model Vitocrossal 300 CU3A will have an altitude de-ration of 18%.

4

5673 647 - 03

Vitocrossal 300 CU3A 26 to 57 Technical Data |

|

|

|

Technical Data |

|||

|

|

|

|

|

|

|

|

Technical Data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Boiler Model No. CU3A |

|

26 |

35 |

45 |

|

57 |

|

|

|

|

|

|

|

|

|

Dimensions |

|

|

|

|

|

|

|

Overall depth |

inches |

27 |

27 |

31b |

|

31b |

|

|

|

(mm) |

684 |

684 |

801 |

|

801 |

Overall width |

inches |

26 |

26 |

26 |

|

26 |

|

|

|

(mm) |

660 |

660 |

660 |

|

660 |

Overall height |

inches |

67 |

67 |

67 |

|

67 |

|

(with control interface open) |

(mm) |

1707 |

1707 |

1707 |

|

1707 |

|

Overall height |

inches |

61.5 |

61.5 |

61.5 |

|

61.5 |

|

|

|

(mm) |

1562 |

1562 |

1562 |

|

1562 |

|

|

|

|

|

|

|

|

Flue gas *4 |

|

|

|

|

|

|

|

Temperature (at boiler return |

|

|

|

|

|

|

|

temperature of 86ºF (30ºC) |

|

|

|

|

|

|

|

- |

at rated full load |

ºF (ºC) |

113 (45) |

113 (45) |

113 (45) |

|

113 (45) |

- |

at rated partial load |

ºF (ºC) |

90 (32) |

90 (32) |

90 (32) |

|

90 (32) |

Temperature (at boiler return |

ºF (ºC) |

167 (75) |

167 (75) |

167 (75) |

|

167 (75) |

|

temperature of 140ºF (60ºC) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. condensate flow rate *5 |

|

|

|

|

|

|

|

for NG and LPG |

|

|

|

|

|

|

|

TS/TR =104/86ºF (40/30ºC) |

USG/h |

0.9 |

1.2 |

1.6 |

|

2.1 |

|

|

|

(L/h) |

3.43 |

4.62 |

5.95 |

|

7.92 |

|

|

|

|

|

|

|

|

Condensate connection |

hose |

|

|

|

|

|

|

|

|

nozzle |

|

|

|

|

|

|

|

Ø in. |

¾ |

¾ |

¾ |

|

¾ |

Boiler flue gas connection *6 |

Ø |

|

|

|

|

|

|

|

|

in. (mm) |

3 (80) |

3 (80) |

4 (110) |

|

4 (110) |

Combustion air supply connection |

outer |

|

|

|

|

|

|

|

|

Ø in. (mm) |

3 (80) |

3 (80) |

3 (80) |

|

3 (80) |

|

|

|

|

|

|

|

|

Sound Rating (A scale) |

|

|

|

|

|

|

|

- at maximum input |

dB |

48 |

55 |

53 |

|

58 |

|

- at minimum input |

dB |

32 |

33 |

33 |

|

33 |

|

Standby losses *7 |

BTU/hr |

1128 |

1000 |

1120 |

|

995 |

|

|

|

W/hr |

330 |

292 |

328 |

|

291 |

|

|

|

|

|

|

|

|

*4 Measured flue gas temperature with a combustion air temperature of 68°F (20°C). *5 Based on maximum input rate.

*6 For side wall vent installations (coaxial system):

Do not exceed max. equivalent length specified in the Installation Instructions of the Vitocrossal 300 CU3A Venting System.

Do not attempt to common-vent Vitocrossal 300 CU3A with any other appliance. Side wall co-axial vent installation must include Viessmann protective screen!

For details refer to the Installation Instructions for the Vitocrossal 300 CU3A Venting System.

*7 Standby losses measured from the boiler temperature sensor well based on a boiler water temperature of 158°F (70°C) and a room temperature of 68°F (20°C).

For information regarding other Viessmann System Technology componentry, please reference documentation of respective product.

5673 647 - 03

5

Dimensional Information |

Vitocrossal 300 CU3A 26 to 57 Technical Data |

Models 300 CU3A 26 to 57

Legend

AOverall boiler height (boiler control open)

BOverall boiler height (boiler control closed)

CSafety header connection

DBoiler supply

EGas connection

FBoiler return

GBoiler drain

HVent connection

ICondensate drain connection

JCombustion air connection

Model 26 to 35 |

|

Model 45 and 57 |

|

||

|

|

|

|

|

|

a |

in. (mm) |

27 (684) |

a |

in. (mm) |

31b (801) |

|

|

|

|

|

|

b |

in. (mm) |

17 (430) |

b |

in. (mm) |

21b (545) |

|

|

|

|

|

|

c |

in. (mm) |

23b (595) |

c |

in. (mm) |

28 (712) |

|

|

|

|

|

|

d |

in. (mm) |

4¾ (120) |

d |

in. (mm) |

5b (140) |

|

|

|

|

|

|

Note: All height dimensions of the boiler have a tolerance of +.6 in. (+15 mm) due to the factory installed adjustable feet.

6

5673 647 - 03

Vitocrossal 300 CU3A 26 to 57 Technical Data |

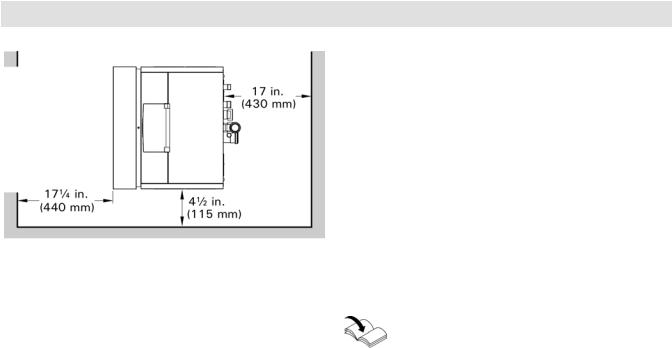

Minimum Clearances |

Recommended Minimum Service Clearances

Clearances

Top |

Front |

Rear |

Left |

Right |

Vent pipe |

|

|

|

|

|

|

0 |

0 AL CL |

0 |

0 |

0 |

0 |

|

|

|

|

|

|

AL = Alcove

CL = Closet

The Vitocrossal CU3A series boiler is approved for closet and alcove installation with the clearances to combustibles listed above.

Note: The Vitocrossal 300 CU3A series boiler conforms to the zero inches vent clearance to combustibles testing requirements dictated by the boiler Harmonized Standard ANSI Z21.13. CSA/4.9 and therefore is listed for zero clearance to combustibles when vented with a single-wall UL/ ULC certified special venting system. The zero inches vent clearance to combustibles for the Vitocrossal 300 CU3A boiler supercedes the clearance to combustibles listing that appears

on the special venting system label.

The back or side clearance shall be increased if piping installation is required.

Recommended minimum service clearances

For typical Vitocrossal CU3A series boiler installations, Viessmann recommends installing the boiler with the clearances shown in the illustration on the left.

See the Vitocrossal 300 CU3A Venting System Installation Instructions for details.

5673 647 - 03

7

Waterside Flow |

Vitocrossal 300 CU3A 26 to 57 Technical Data |

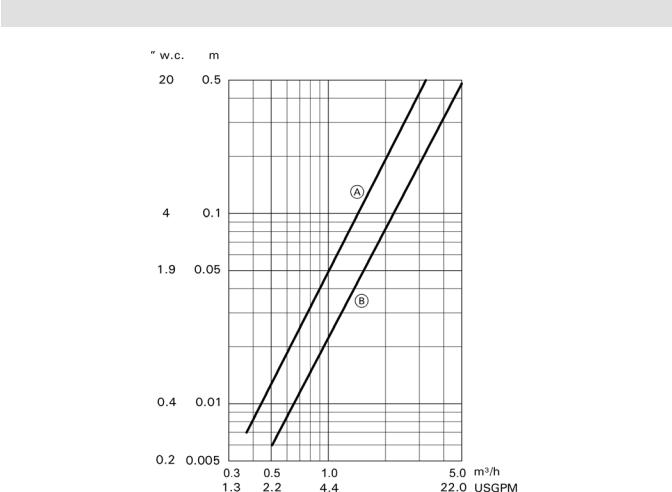

Pressure Drop (heating water side)

Pressure drop

Flow rate

Legend

ABoiler models CU3A 26 to 35 kW

BBoiler models CU3A 45 to 57 kW

The Vitocrossal 300 is only suitable for fully pumped hot water heating systems.

|

∆T = 20ºF (10 K) |

∆T = 30ºF (15 K) |

∆T = 40ºF (20 K) |

|

Boiler models CU3A |

|

|

|

|

Flow rate |

Flow rate |

Flow rate |

||

|

||||

|

USGPM (m3/h) |

USGPM (m3/h) |

USGPM (m3/h) |

|

26 |

9.9 (2.2) |

6.6 (1.5) |

4.9 (1.1) |

|

|

|

|

|

|

35 |

13.3 (3.0) |

8.9 (2.0) |

6.6 (1.5) |

|

|

|

|

|

|

45 |

17.0 (3.9) |

11.4 (2.6) |

8.5 (2.0) |

|

|

|

|

|

|

57 |

22.7 (5.2) |

15.0 (3.4) |

11.4 (2.6) |

|

|

|

|

|

Note: This boiler does not require a flow switch.

8

5673 647 - 03

Vitocrossal 300 CU3A 26 to 57 Technical Data |

Boiler Control |

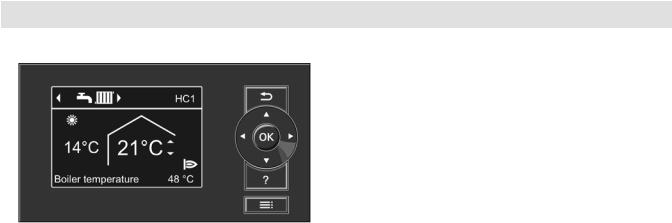

On-Board Vitotronic 200, HO1B Control

Modular structure

The control unit is integrated into the boiler. The control unit comprises a standard unit, electronics modules and a programming unit.

Standard unit:

■ON/OFF switch

■Optolink laptop interface

■Operating and fault indicators

■Reset button

■Fuses

Programming unit:

■Easy operation through:

–Plain text display with graphic ability

–Large font and black & white depiction for good contrast

–Context-sensitive help text

–Removable programming unit; can be mounted on the wall with separate accessory

■With digital time switch

■Control keys for:

–Navigation

–Confirmation

–Help and additional information

–Menu

■Setting the:

–Room temperature

–Reduced room temperature

–DHW temperature

–Heating program

–Time programs for central heating, DHW heating and DHW recirculation

–Economy mode

–Party mode

–Holiday program

–Heating curves

–Codes

–Actuator tests

–Test mode

■Displaying the:

–Boiler water temperature

–DHW temperature

–Operating details

–Diagnostic details

–Fault messages

5673 647 - 03

9

Boiler Control |

Vitocrossal 300 CU3A 26 to 57 Technical Data |

Design and Function

Functions

■Weather-compensated control of the boiler water and/or supply temperature

■Control of one heating circuit without mixer and two heating circuits with mixer (with accessory mixing valve extension modules)

■Demand-dependent heating circuit pump and burner off control

■Adjustment of a variable heating limit

■Anti-seizing pump protection

■Integral diagnostic system

■Maintenance display

■DHW temperature control with priority

■Auxiliary function for DHW heating (short-term heating to a higher temperature)

■0-10V External signal input

■0-10V Pump speed control output signal

Control Characteristics

PI characteristics with modulating output.

Time Switch

Digital time switch.

■Individual and 7-day program

■Automatic daylight savings time changeover

■Automatic function for DHW heating and DHW recirculation pump

■Time, day and standard switching times for space heating, DHW heating and the DHW recirculation pump are factory-set

■Switching times are individually programmable, i.e. up to four switching periods per day

Shortest switching interval: 10 minutes Power backup: 14 days.

Setting the Operating Programs

The heating system frost protection (see

frost protection function) applies to all heating programs. You can select the following heating programs with the program keys:

■Heating and DHW

■DHW only

■Standby mode

External heating program changeover.

Frost protection

■The frost protection function will be started when the outside temperature drops below approx. 34°F (1°C). With the frost protection function, the heating circuit

pump will be switched ON and the boiler water is maintained at a lower temperature of approx. 68°F (20°C).

The DHW tank will be heated to approx. 68°F (20°C).

■The frost protection function will be stopped when the outside temperature rises above approx. 37°F (3°C) (default settings).

Summer Operation

Heating program “w”

The burner is only activated upon a call for domestic hot water from the DHW storage tank (controlled by DHW tank temperature sensor).

10

5673 647 - 03

Loading...

Loading...