Tri Tool 620SB User Manual

TABLE OF CONTENTS

CUSTOMER MESSAGE Inside Front Cover

SAFETY PRECAUTIONS 3

GENERAL DESCRIPTION 6

92-0282 Rev. 131230

Model 620SB Low Prole Clamshell, Hyd.

SPECIFICATIONS 7

MAINTENANCE 9

OPERATION 18

CUTTING SPEEDS 30

TOOL BITS 31

CLAMPING PAD SETS 39

TROUBLE SHOOTING 40

ACCESSORIES 43

ILLUSTRATED PARTS BREAKDOWN 44

RECOMMENDED SPARES 54

TOOL BIT RESHARPENING POLICY Inside Back Cover

WARRANTY INFORMATION Inside Back Cover

Copyright 2013

Proprietary property of TRI TOOL Inc.

No reproduction, use, or duplication of the information

shown hereon is permitted without the express written

consent of TRI TOOL Inc.

SAFETY PRECAUTIONS

IN GENERAL

When using rotating head cutting equipment, basic safety precautions should always

be followed to reduce the risk of personal injury.

Operate this tool only in accordance with specic operating instructions.

Do not override the deadman switch on the power unit. Locking down,

WARNING:

DRESS CONSIDERATIONS

obstructing, or in any way defeating the deadman switch on the power drive

unit may result in serious injury.

Model 620SB Low Prole Clamshell, Hyd.

Use standard safety equipment. Hard hats, safety shoes, safety harnesses,

protective clothes, and other safety devices should always be used when

appropriate.

Use safety glasses. Do not operate cutting tools without eye protection.

Dress properly. Do not wear loose clothing or jewelry. They can be caught in

rotating and moving parts. Avoid slippery oors or wear nonskid footwear. If you

have long hair, wear protective hair covering to contain it.

WORK AREA

Keep the work area clean. Keep the area well lit. Keep electrical cords, cables, rags,

rigging straps, and etc. clear of rotating equipment. Do not use power-cutting tools

in the presence of ammable liquids and gasses.

Keep visitors away. Do not let visitors or untrained personnel at or near operating

tools. Enforce eye protection requirements for all observers.

Do not over reach. Keep proper footing at all times.

Stay alert. Watch what you are doing. Use common sense. Do not operate tools

when you are tired.

92-0282 : Rev. 131230

3

TRI TOOL INC.

TOOL CARE

Maintain tools with care. Keep tools in good operating condition. Sharp tool bits

perform better and safer than dull tool bits. Well maintained tools function properly

when needed.

Check for damaged parts. If a tool has malfunctioned, been dropped or hit, it

must be checked for damage. Run no-load tests and feed function checks. Do a

complete visual inspection.

Electric motors. Use only with proper AC voltage power sources and observe all

normal electric shock hazard procedures.

Do not abuse power and control cords. Pulling or running over cords and cables can

result in electrical shock hazards and malfunctions. Keep control and power cords

out of all cutting uids and water.

Hydraulic drives. Observe proper procedures for electrically driven power sources.

Avoid damage to hydraulic lines. Keep quick-disconnects clean. Grit contamination

causes malfunctions.

Air tools. Check the exhaust mufer. Broken or damaged mufers can restrict

air ow or cause excessive noise. Use air motors only with a ltered, lubricated

and regulated air supply. Dirty air, low-pressure air or over pressure air will cause

malfunctions, including delayed starting.

AREA EQUIPMENT

Secure work. Whenever possible use clamps, vises, chains and straps to secure

pipe.

Make sure the tool is secured; it is safer to have both hands free to operate the tool.

TOOL USE

Use the right tool and tool bit for the job. Do not use a tool, which is incorrect for the

job you are doing.

Keep the tool bits fully engaged in the tool bit holders. Loose bits are a safety

hazard.

4

92-0282 : Rev. 131230

Model 620SB Low Prole Clamshell, Hyd.

Disconnect power supply during setup and maintenance. Use all ‘Stop’ or Shut off’

features available when changing or adjusting tool bits, maintaining the tool, or when

the tool is not in use.

Remove adjusting keys and wrenches before applying power to the equipment.

Develop a habit of checking the tool before turning it on to make sure that all keys

and wrenches have been removed.

Do not force tools. Tools and tool bits function better and safer when used at the

feed and speed rate for which they were designed.

Do not reach into rotating equipment. Do not reach into the rotating head stock to

clear chips, to make adjustments, or to check surface nish. A machine designed to

cut steel will not stop for a hand or an arm.

Handle chips with care. Chips have very sharp edges and are hot. Do not try to pull

chips apart with our hands; they are very tough.

Avoid unintentional starts. Do not carry or handle tools with your hand on the

operating switches or levers. Do not lay the tool down in a manner that will start the

drive. Do not allow the tool to ip around or move when adjusting or changing tool

bits.

Store idle tools properly. Disconnect tools from the power source and store in a safe

place. Remove tool bits for safe handling of the tool.

92-0282 : Rev. 131230

5

TRI TOOL INC.

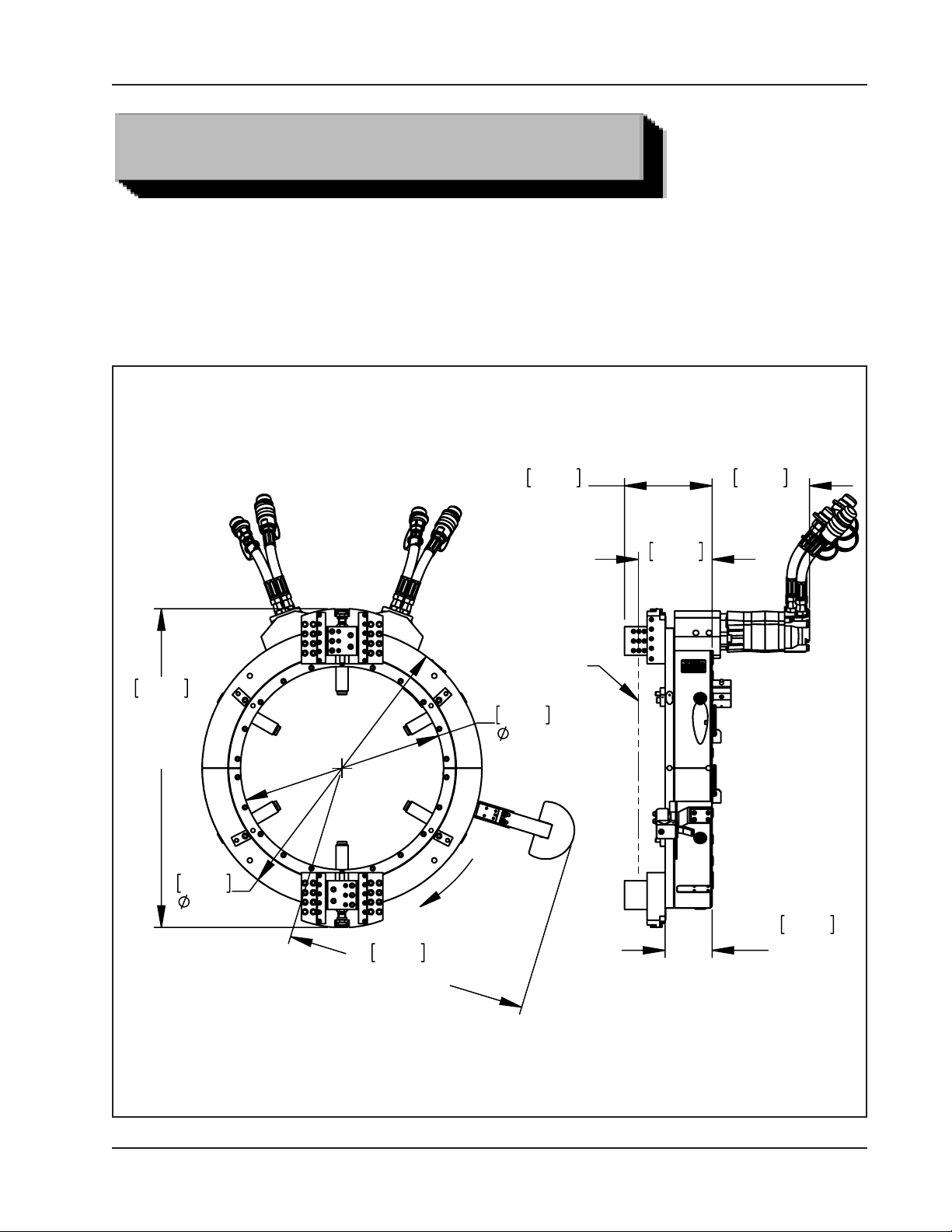

GENERAL DESCRIPTION

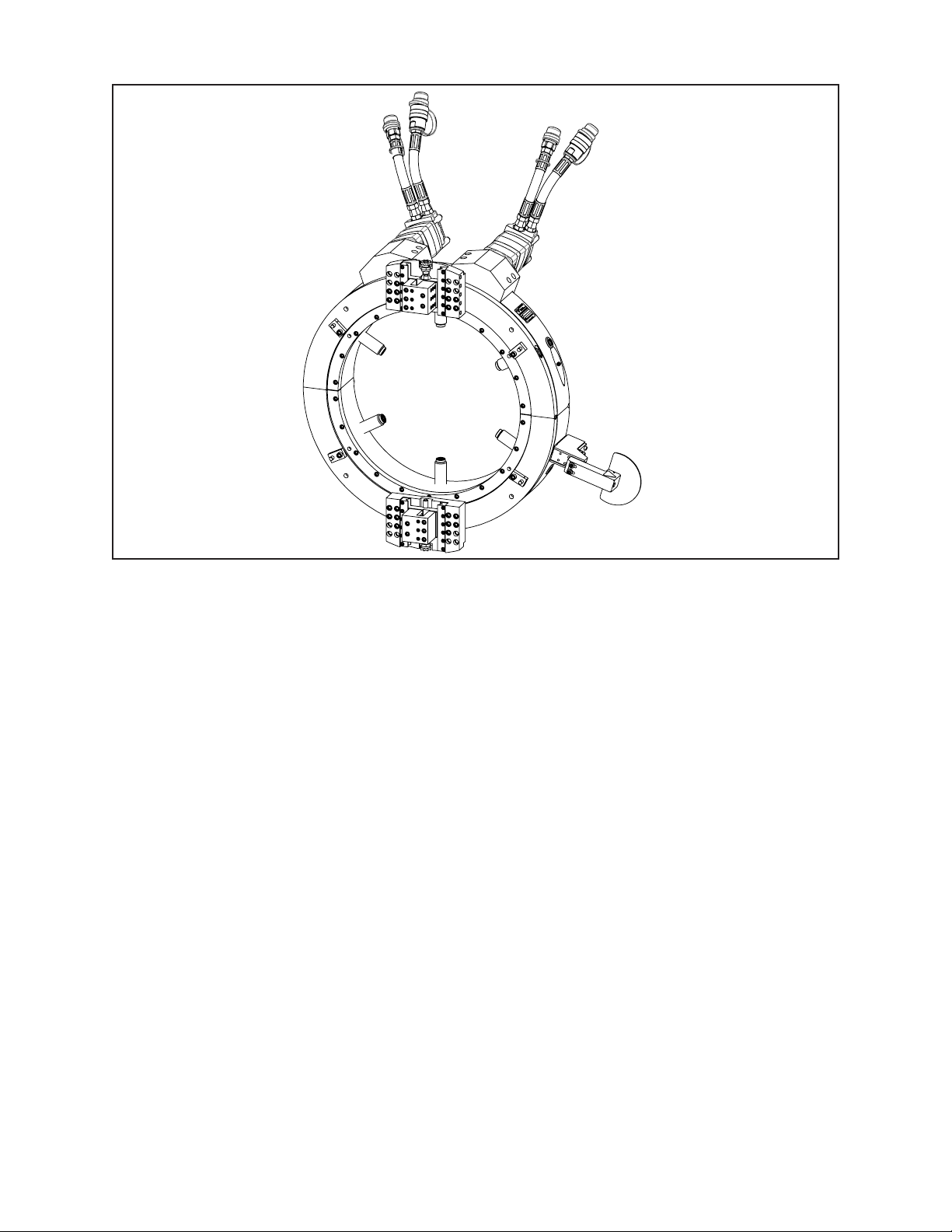

The Model 620SB Low-Prole Clamshell (P/N 01-1147) is a split-frame pipe lathe

designed for severing and beveling in-line pipe with a minimum range of 16” through

20” pipe with minimal radial and axial clearance.

Using standard Tool Blocks the Model 620SB may be congured to perform the

following operations:

Sever in-line pipe.

Sever and bevel in-line pipe.

Sever and double bevel in-line pipe.

DESIGN AND OPERATING FEATURES

The easily adjustable precision bearing surfaces pre-load and stabilize the rotating

head to provide long life, low maintenance, stability, and precision.

The Clamshell splits into two halves for mounting on closed loop systems.

All parts are secured to the two halves, thus avoiding the loss of parts and at the

same time providing maximum ease of handling.

The Clamshell is equipped with Adjustable Clamping Pads and Jackscrews for

out-of-round pipe conditions.

Dual Tool Blocks with Auto-feed Sprockets and Adjustable Slides provide maximum

maintainability, life, and operator safety, with a minimum of operator training.

The Auto-feed Sprockets provide .004” (.10 mm) of radial feed per revolution of the

Headstock for a controlled depth of cut.

The drive gears and bearing surfaces are covered for operator safety and are sealed

to provide protection from dust and chips.

The operator’s controls are located away from the rotating Headstock for the

operator’s safety.

A modular design concept provides quick, easy maintenance and maximum

versatility in the drive and tooling options.

Two detachable Hydraulic Motors provide maximum handling ease and low axial

clearance.

6

92-0282 : Rev. 131230

Model 620SB Low Prole Clamshell, Hyd.

ROTATING

231.9

258.4

SPECIFICATIONS

Model 620SB with the Hydraulic Motors.

Weight: 377 lbs. (171 kg) without the Hydraulic Motors attached.

Power Requirements: 20 gpm at 1250 psi with Hydraulic Motors.

(1.3 lt/sec at 84 kg/cm2)

Envelope, Model 620SB Clamshell, Hydraulic Drive

9.13

10.18

844.6

33.25

MAX

PARTS

741.7

29.20

ROTATION

640.6

25.22

MAX HEIGHT

NOMINAL

SEVER

LINE

538.5

21.20

195.1

7.68

124.5

4.90

BASIC

MACHINE

92-0282 : Rev. 131230

7

TRI TOOL INC.

Cutting Capacities* on 12" through 20" Pipe

Note: Capacity may exceed the maximum wall thickness for small pipe sizes

Severing with standard procedures 2.50" (63.5 mm) wall

Severing and single beveling 1.25" (31.8 mm) wall

Severing and double beveling 1.25" (31.8 mm) wall

Severing and beveling with special procedures 2.00" (50.8 mm) wall

Clearances

Rotating parts diameter 33.25" (844.6 mm)

Main Frame diameter 29.20" (741.7 mm)

Axial clearance required relative to center-line of the cut:

Mounting side 7.58" (192.5 mm)

Side opposite of the frame 1.56" (39.6 mm)

Radial Clearance Over the Pipe or Tube

Pipe Size True Diameter Clearance Tool Blocks

20" 20.00" 508 mm 6.63" 168.4 mm

18" 18.00" 457 mm 6.63" 168.4 mm

16" 16.00" 406 mm 6.63" 168.4 mm

8

92-0282 : Rev. 131230

Model 620SB Low Prole Clamshell, Hyd.

MAINTENANCE

All components should be cleaned and coated with a light lm of oil prior to use.

Use a clean, non-detergent oil, preferable SAE 10 (90 SSU or lighter).

The Motor warranty is void if damage occurs from contaminated hydraulic

NOTE:

uid.

Clean Up

If the Tool Blocks collect debris while cutting, clean the Tool Blocks and the Feed

Screws after each cutting operation.

RECOMMENDED MAINTENANCE SCHEDULE

Daily maintenance when the unit is in operation:

Wipe the unit down and spray with rust preventative under severe humidity

conditions.

Visually inspect for loose screws, missing screws, damage, etc.

After every 20 hours of actual operation:

Check adjustment of the Main Bearing pre-load.

Lubricate the male and female Tool Block Slides and the Feed Screw. Refer

to ‘Tool Block Maintenance’ located later in this section.

92-0282 : Rev. 131230

9

TRI TOOL INC.

After every 40 hours of actual operation:

Thoroughly clean and lubricate Main Gear, Drive Gear, male and female Tool

Slides, Feed Screws, and Tripper Block Assy.

Non-scheduled maintenance:

Readjust the Main Bearing pre-load if the Clamshell generates excessive

heat or if the Main Bearing becomes loose. Refer to ‘Adjustment of the Main

Bearing pre-load’ later in this section.

Thoroughly clean and check the Tool Blocks in the event of feed problems.

STORAGE

If the Clamshell is to be stored or if it will remain out of service for a signicant

period of time (30 days or more), it should be thoroughly cleaned lubricated and

sprayed with a rust preventative prior to storage.

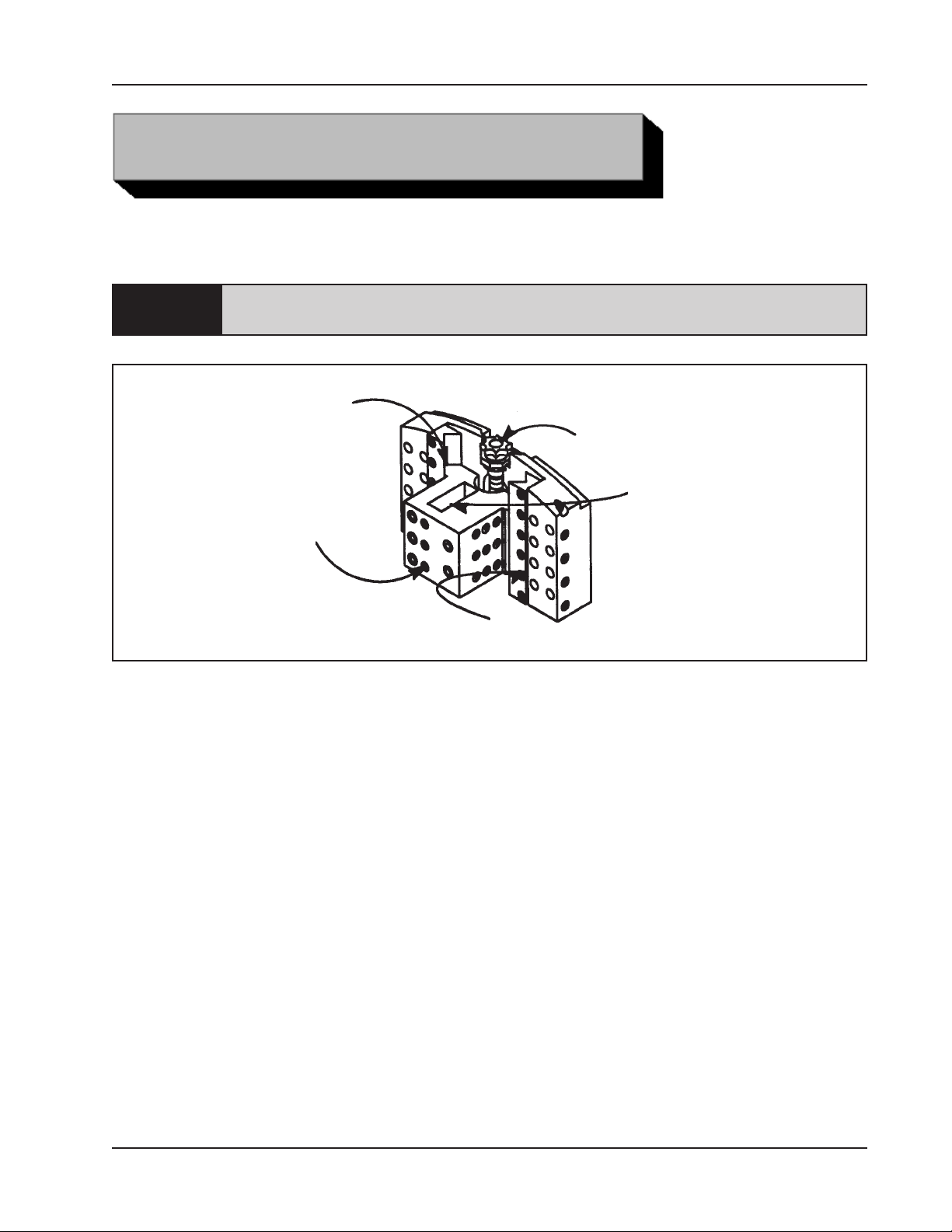

ADJUSTMENT OF THE MAIN BEARING PRE-LOAD

Loosen all Bearing Adjustment Lock Screws about 1/2 turn (1 through 24).

Turn in Bearing Adjustment Screws (1, 5, 9, 13, 17, and 21) so that they are

snugged tightly.

This ensures that the Bearings are fully pushed forward. Refer to the Bearing

Adjustment Screw locations.

Lightly turn in the remaining Bearing Adjustment Screws in the order shown until all

of the Bearings make contact with the Headstock.

Relax Bearing Adjustment Screws (1, 5, 9, 13, 17, and 21) and resnug them so that

all of the Bearing Adjustment Screws are evenly loaded against the Bearings.

Connect the hydraulic power supply and apply power to the Clamshell so that it is

running at full speed.

Adjust the Bearing Adjustment Screws (1 through 24) so that the Clamshell rotation

slows slightly.

Listen for a change in the sound of the Hydraulic Motors.

Adjust the Bearing Adjustment Screws in small increments so that the Bearings are

loaded evenly.

10

92-0282 : Rev. 131230

Model 620SB Low Prole Clamshell, Hyd.

All of the Bearing Adjustment Screws should be snugged to ensure that the

Bearings are uniformly loaded.

Bearing Adjustment Screw Locations

20

19

18

24

1

23

2

21

22

3

4

5

6

7

17

16

15

14

13

12

11

10

9

8

The safe torque range on the Bearing Adjustment Screws is 1 to 3 in-lbs

(.1 to .3 N-m).

Over-tightening the Bearing Adjustment Screws will result in accelerated bearing

wear and lower available power.

Lock the Bearing pre-load by tightening the Bearing Adjustment Lock Screws

(1 through 24).

The safe torque should be 8 to 10 ft-lbs. (11 to 14 N-m).

Too much torque may crack the Bearing while too little torque may allow the

WARNING:

Bearing pre-load to relax.

92-0282 : Rev. 131230

11

TRI TOOL INC.

INSPECTION OF THE MAIN GEAR

If the Headstock does not run smoothly, even after adjustment, inspect the Main

Gear to ensure that no chips, dirt or dust have damaged the gear.

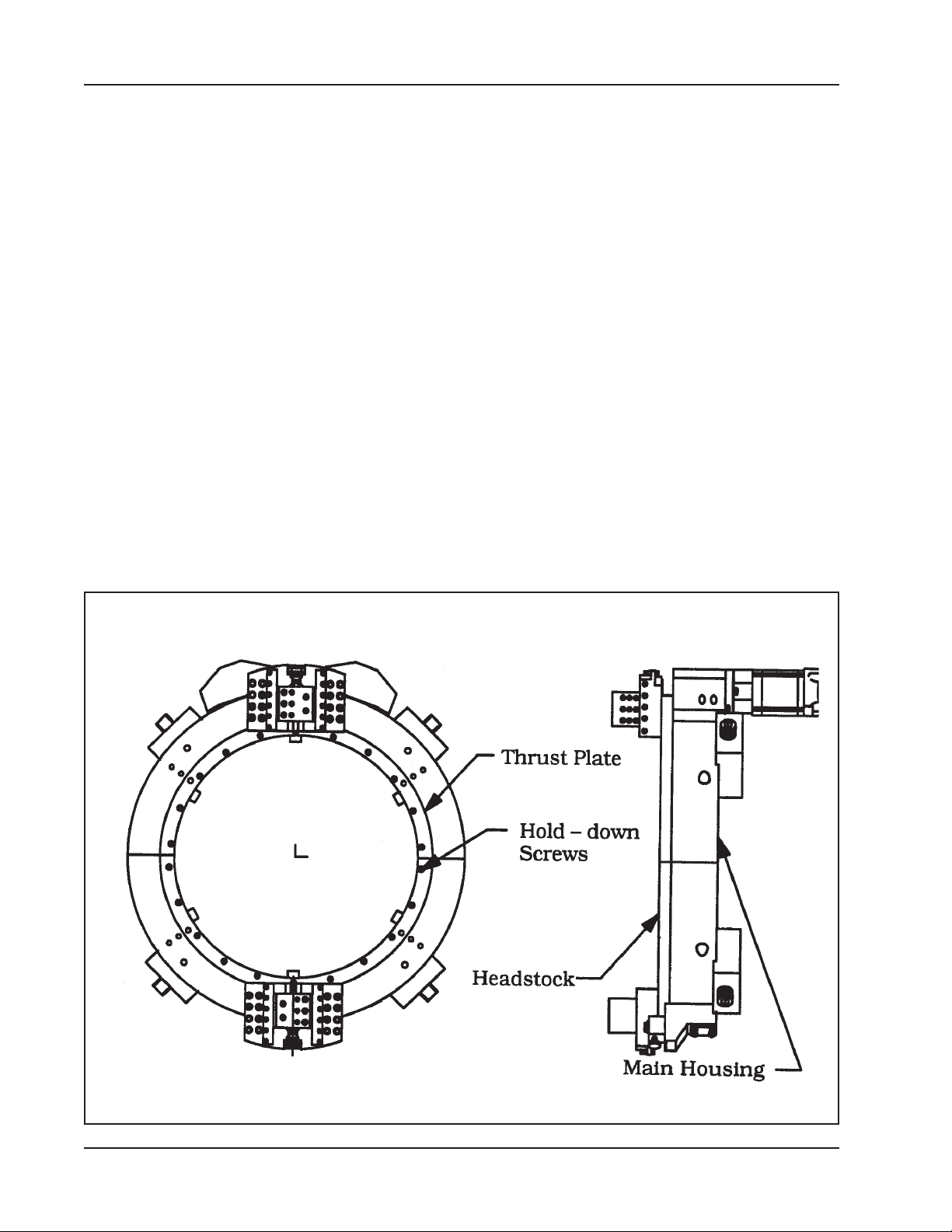

Remove both of the front Thrust Plates by removing the twenty-two (22) Hold Down

Screws.

Lift the Headstock from the Housing. Refer to the Clamshell Nomenclature.

The Main Gear and the Main Bearing may now be inspected.

Check the Bearing, Housing, and the race on the Gear.

All surfaces should be smooth, without scratches, and they should feature even

wear patterns over the entire surface.

Check the Housing cavity for chips, dirt and/or corrosion.

To reassemble, wipe clean all of the Bearing surfaces and clean the Housing cavity.

Clamshell Nomenclature

12

92-0282 : Rev. 131230

Model 620SB Low Prole Clamshell, Hyd.

Regrease the Gear using a lubricant approved by TRI TOOL Inc. Refer to ‘Lubricant

Recommendations’ located later in this section.

Place the Headstock carefully back into the Housing.

Bolt the Front Thrust Plates back into place.

If the bearing pre-load was properly adjusted before being disassembled, then it will

still be adjusted when reassembled.

DRIVE GEAR AND MAIN GEAR LUBRICATION

Remove the Drive Housing.

Inspect both Drive and Main Gears for chips or burrs and clean as required.

Coat the teeth of the Drive Gear and the Main Gear with a grease which is approved

by TRI TOOL Inc. Refer to the Tripper Block Assy. Lubrication and Tripper Shaft

adjustment located later in this section.

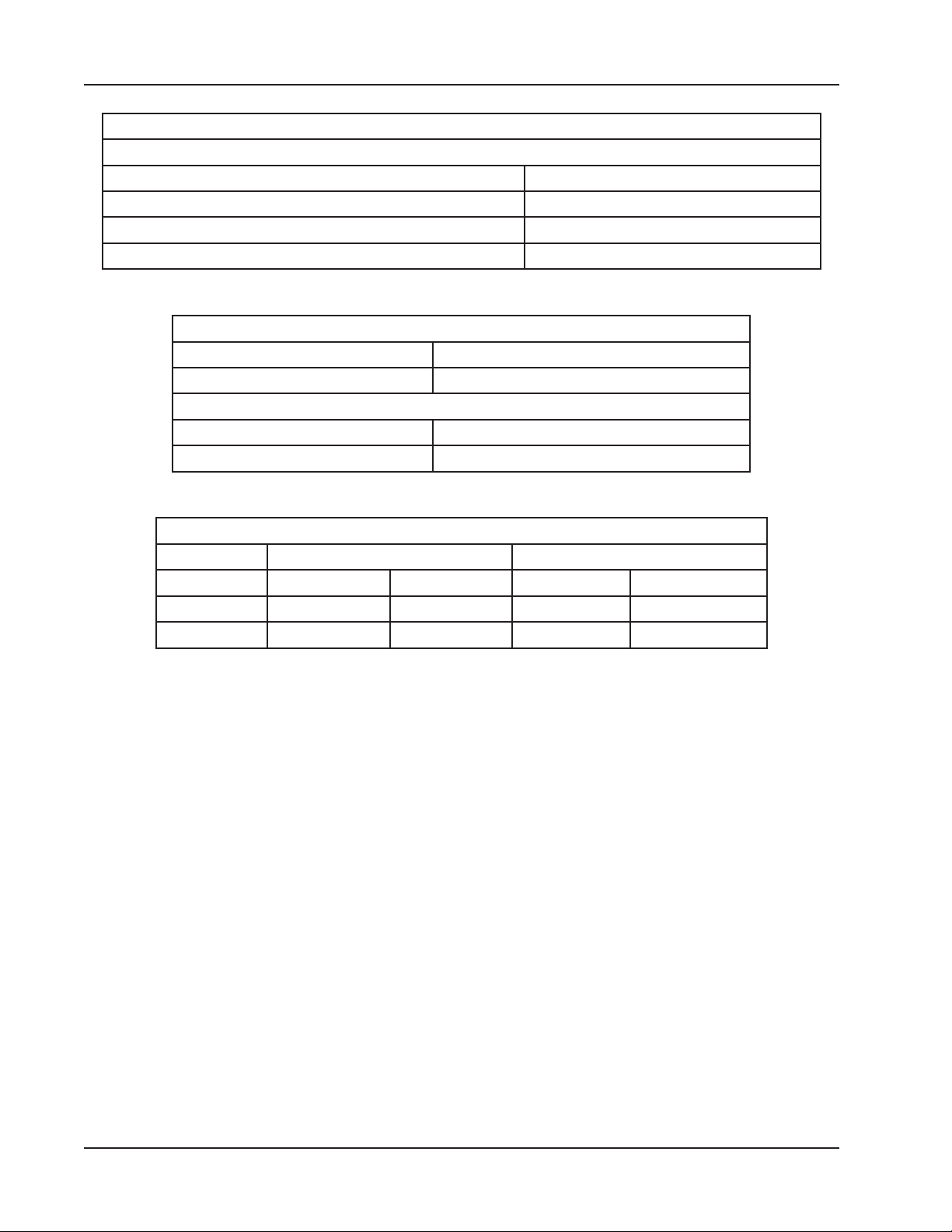

TOOL BLOCK MAINTENANCE

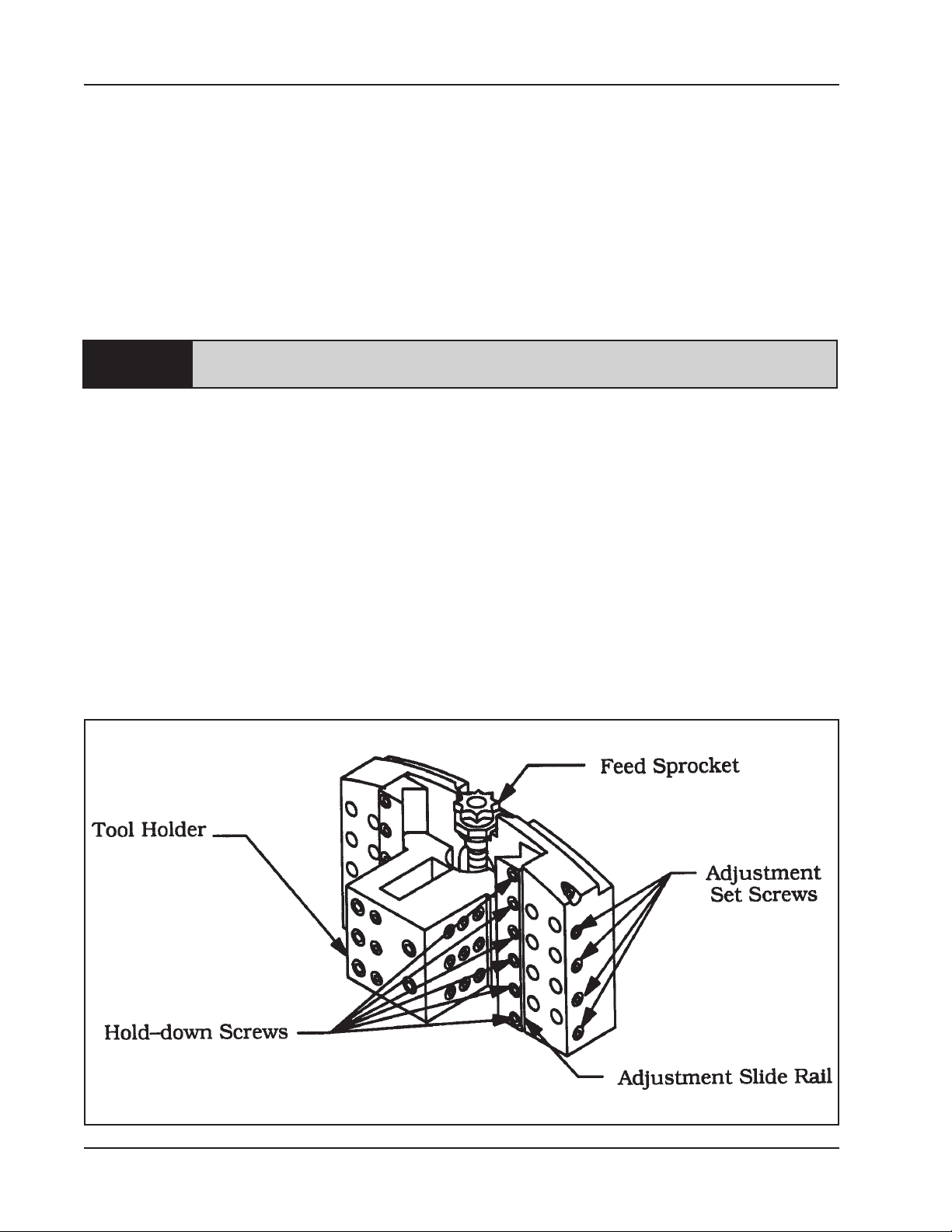

Clean the Slide Rails, the Feed Nut, the Sprocket Assy. and the Feed Screw.

Inspect these parts for damage and replace as required.

Lubricate and reassemble the Tool Block. Refer to the Tool Block Assembly.

Use lubricant on the Feed Screw sparingly or wipe to a lm condition.

NOTE:

Tool Block Assembly

92-0282 : Rev. 131230

13

TRI TOOL INC.

Excess lubricant will collect grit and/or chips and tend to cause thread jamming and/

or damage.

Adjust the Adjustable Slide Rail to provide a rm, but not excessive rotational

pressure on the Sprocket.

The Slide Rails must be over-tightened to squeeze the oil into a thin lm against the

male and female surfaces of the Slide Rails.

Reset for proper operation.

If the Mounting Bracket has been overstressed, the Slide Rails may appear to

NOTE:

loosen when mounted if they were adjusted off of the Clamshell.

Adjustment when mounted provides the most satisfactory results.

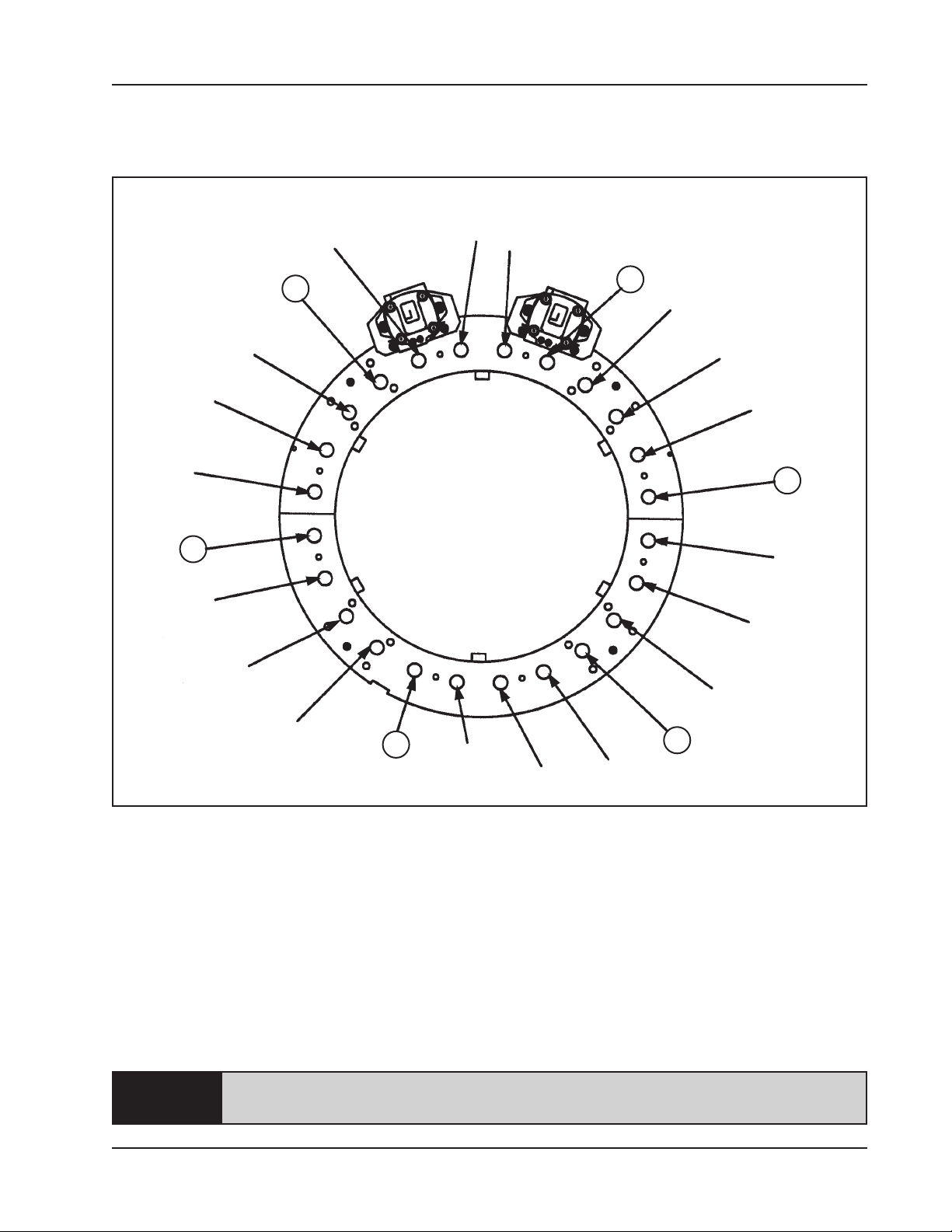

TOOL HOLDER ADJUSTMENT

Loosen the Hold-down Screws on the Adjustable Slide Rail.

Run the Tool Holder to the most outward position.

Using the Adjustment Set Screws, apply a light force to the side of the Adjustable

Slide Rail so that it is in positive contact with the Tool Holder.

Adjust only those screws, which bear directly in line with the Tool Holder.

Tool Holder Adjustment

14

92-0282 : Rev. 131230

Model 620SB Low Prole Clamshell, Hyd.

Tighten the Hold down Screws to about 12 to 24 in-lbs. (1.4 to 2.7 N-m). (Finger tight

using a hex key)

Using the Spanner Wrench, run the Tool Holder to the inward most position.

Note any changes in the feed pressure.

Adjust the remaining Adjustment Set Screws so that the Tool Holder has a smooth,

even feel.

Run the Tool Holder the full length of the Slide Rail.

Tightly lock the Adjustable Slide Rail in place with the Hold-down Screws and fully

snug the Adjustment Set Screws.

Check that the Tool Holder runs smoothly and evenly for the full length of travel.

Readjust as necessary.

The Tool Holder should move snugly.

In general, when the Slide Rail is set correctly, the Feed Sprocket cannot be turned

by hand but may be turned easily with the Spanner Wrench.

The torque on the Spanner Wrench should be about 2 to 5 ft-lbs. (2.7 to 6.8 N-m).

92-0282 : Rev. 131230

15

TRI TOOL INC.

BALL PLUNGER

SET SCREW

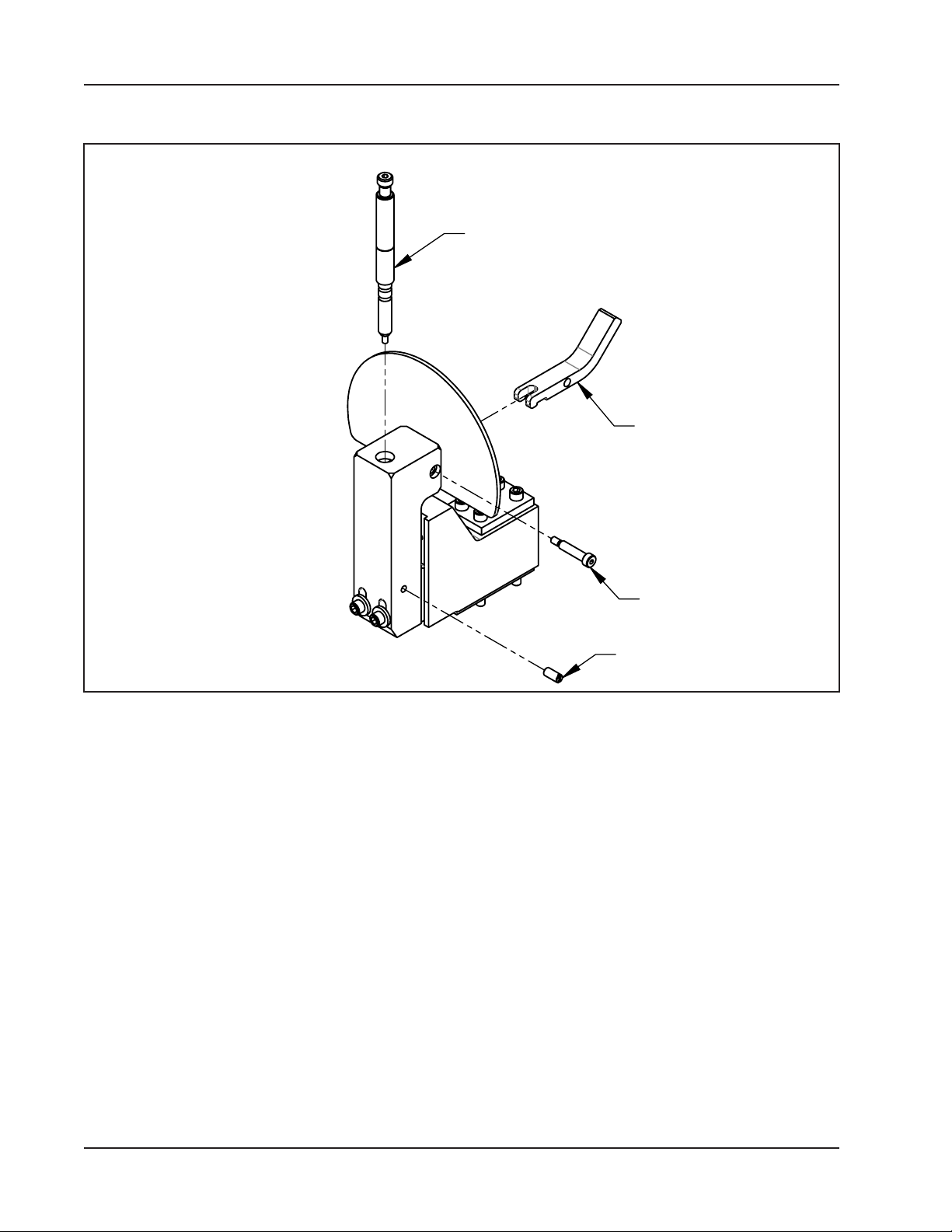

TRIPPER BLOCK ASSY LUBRICATION AND TRIPPER SHAFT ADJUSTMENT

Tripper Shaft Installation

TRIPPER SHAFT

ASSEMBLY

TRIPPER

LEVER

SHOULDER

BOLT

Back off the Ball Plunger Set Screw until it disengages from the Tripper Shaft

Assembly.

Remove the Shoulder Bolt, and then remove the Tripper Lever.

Remove the Tripper Shaft Assembly from the block, and then degrease and clean all

parts.

Apply fresh lubrication to the Tripper Shaft Assembly and to the Shoulder Bolt.

Reassemble in reverse order.

16

92-0282 : Rev. 131230

Model 620SB Low Prole Clamshell, Hyd.

LUBRICANT RECOMMENDATIONS

The Drive Gears require a high string lubrication grease such as “Chevron Utility

Grease, light, high string for gears” (P/N 68-0020).

The Slide Rails and Tool Blocks require a light oil such as SAE 10 light machine oil.

The Feed Screw for the Tool Block and the Tripper Block Assy require a SAE 10 light

machine oil for normal conditions and under dusty conditions a silicone, graphite or

molybdenum disulde ‘dry’ lubricant.

A light lm of all-purpose grease may be used, but it must be checked for grit

NOTE:

contamination frequently.

The Bearings in the Hydraulic Motor are sealed and do not require any lubrication.

92-0282 : Rev. 131230

17

Loading...

Loading...