Toshiba SX 2000 User Manual

Safety Precautions

This manual contains important information for the operator to operate this product safely and cor rectly and avoid bodily injury and property damage.

Grasp the meanings of the following marks and their descriptions before reading this manual.

•Hazard Classifications

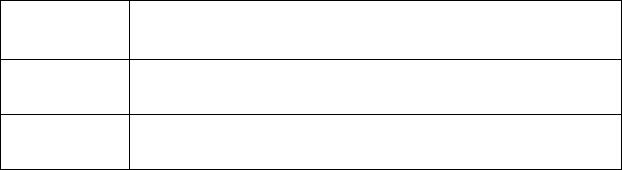

<^WARNING |

Indicates a potentially hazardous situation which, if not avoided, could result in |

|

serious injury or death. |

||

|

|

|

|

Indicates a potentially hazardous situation which, if not avoided, can result in |

|

/j\cAUTIQN |

minor or moderate injury, or property damage. It can also be used to alert |

|

against unsafe practices. |

||

|

||

|

|

(Note) 1. Serious injury means loss of sight, injury, burns (high temperature, low temperature), electrical shock, fracture, or intoxication which leaves aftereffects or requires hospitalization or need to go the hospital for a long time.

2.Injury means hurt, burn, or electric shock which does not require hospitalization orgoing to the hospital fora long time.

3.Property damage means extended breakdown of assets and materials.

•Notation of Markings

Q

O

A

Indicates a "may not" mark.

The concrete forbiddance is indicated with a pictograph or wording.

Indicate a mandatory action that you should never fail to do.

The concrete content is indicated inside or near the circle with a pictograph or wording.

Indicates a caution.

The concrete content is indicated inside or near the triangle.

(Note) The descriptions of forbiddance, mandatory, and caution marks are subject to change, depending on the labels on the main unit.

6F8C0926

Make sure warning markings are attached on the model 2000.

If any of them are missing or the wording is illegible, contact Toshiba’s Service Department.

[Warning Mark on the model 2000]

This is the warning mark for dangerous location. It is attached to the equipment at positions A where there is a risk of electric shock and at positions where there is a risk of damage to

the equipment through incorrect wiring.

Take the following precautions where this mark is found.

(1)Keep hands away from terminals, especially the input terminal of the power supply while power is on, to avoid the risk of electric shock.

(2)Turn off power before installing or removing modules, terminal blocks, or wires.

(3)Applying excess power voltage to the model 2000 can cause failure or malfunction. Apply power of the specified ratings described in this manual.

(4)Turn off the power of the tool (a personal computer, etc.) before connecting the connector to the tool port. Afterwards, turn on power.

Avoid short-circuiting between the tool connector pins with the cover, etc.

[Safety Label]

The safety label as shown on the left both in Japanese and English is attached to the power supply terminal of the model 2000. (exept the 24Vdc input power supply module)

Remove the mount paper before wiring

Peel off either of the Japanese and English labels from the mount paper and stick it to the model 2000 or near the power terminal where it can be readily seen.

In the event the seal is damaged, contact the dealer.

NOTE

Marks printed at pages in this manual should always be read carefully.

Be sure to read them in handling your model 2000.

Sequence Controller S2T

2. Precautions on Installation

^WARNING

Mandatory

Be sure to ground the model 2000. The protective ground terminal of the model 2000 must be connected to an external protective earth.

Operation without grounding may cause accidental fire or shock.

A CAUTION

»

Mandatory

Avoid the following locations when installing or storaging the model 2000.

•Locations where there is dust, salinity or ion particles

•Locations where there are corrosive gases (SO2, HjS) or flammable gases

•Locations where vibration or shock occurs beyond the allowance

•Locations where there is condensation due to sharp temperature variations

•Locations where the ambient temperature exceeds the allowance range

•Locations where the relative humidity exceeds the allowance range

•Locations where the model 2000 is exposed to direct sunlight

•Locations where strong electric radiation or magnetic field is generated

»

Mandatory

Improper the installation or wiring of the system can cause not only insufficient performance but also malfunction and failure of the model 2000.

Installation in an unspecified direction or improper installation can cause fall-off, fire, interference, or malfunction of the model 2000.

»

Mandatory

Install the model 2000 at a place where maintenance and inspection are easy to do. Otherwise, recovery from failure may take much more time, leading to a serious accidents.

Gr

Forbidden

Do not cover the hole of the model 2000, and the ventilator/air inlet of the system. Otherwise, overheating, etc. can cause fire or malfunction.

Mandatory

Avoid entering wire scraps or other foreign debris into the model 2000, and related equipment. Otherwise, it can cause fire, failure or malfunction.

6F8C0926 |

III |

|

3. Precautions on Wiring

<!>WARNING

Mandatory

Be sure to turn off power before wiring. Otherwise, it can cause electric shock or malfunction of the model 2000.

Mandatory

Be sure to use crimp-style terminal with insulating sheath or insulating tape to cover the conductive parts when wiring modules so that no conductive parts are exposed. Handle the terminal cover with care so as not to fall off or get damaged.

Be sure to fix the cover on the terminal block after wiring.

An exposed conductive part can cause electrical shock.

ACAUTION

Mandatory

Apply power of the specified ratings described in the manual.

Applying excess power voltage to the model 2000 can cause explosion or fire.

a

Mandatory

It is assumed that the users have general knowledge of industrial electrical control systems.

IV

Sequence Controller S2T

4. Precautions for Operation

^WARNING

»

Mandatory

Configure emergency stop interlocking circuit outside the model 2000. Otherwise, failure and malfunction of the model 2000 can cause human injury, machine damage or serious accidents.

»

Mandatory

Be sure to keep the terminal block covers closed during power ON. Do not touch the terminals. Otherwise, it can cause electrical shock or injury.

ACAUTION

o

Forbidden

The power supply modules, the CPU modules, the direct I/O modules and the expansion interface are dedicated to the model 2000. Mount them on the bases of the model 2000. Do not use them by themselves for other purposes.

Otherwise, it can cause electrical shock or injury or malfunction.

«

Mandatory

Mount the modules on the base securely until they click, and fix them on the base with screws.

Insufficient installation can cause failure or malfunction.

«

Mandatory

Sample programs and circuits described in this manual are provided for explaining the operations and applications of the S2T. You should test completely before using them as a part of your application system.

»

Mandatory

When you attempt to perform program change, forced output, RUN/HALT controls, etc during operation, carefully check for safety.

Improper operation or negligence in checking safety conditions can cause machine damage or serious accidents.

»

Mandatory

Set the operating switches of the model 2000 according to this manual. Improper setting can cause failure or malufunction.

»

Mandatory

Install fuses suited to the load current capacity in the external circuits for the relay output module, preventing from overload. Otherwise it can cause machine damage or accidents.

6F8C0926

O

Mandatory

Configure the external circuit to turn on power according to the following sequence.

Turn on the power of model 2000

^Turn on the power for the I/O module and external load power supplies

Otherwise, it can cause machine damage, malfunction or accidents.

»

Mandatory

It is recommended to use an external power supply that provides power for both the I/O module and the loads. If not possible, configure the external circuit so that the external power required for output modules and power to the loads are switched ON/OFF simultaneously.

Also, be sure to turn off power to the loads before turning off power to the S2 T for system safety.

Sr

Forbidden

Turn off power immediately if the S2T or related equipment emitting smoke or odor. Operation under such situation can cause f ire or electrical shock. Also unauhorized repairing will cause fire or serious accidents. Do not attempt to repair. Contact Toshiba for repairing.

5. Safety Precautions on Maintenance and Inspection

<!>WARNING

»

Mandatory

Turn off power when removing any units, modules, terminal blocks or wired cables after installing.

Otherwise exposed conductive pants of wire or on the rear of terminal blocks can cause electrical shock.

Sr

Forbidden

Do not disassemble or modify the S2T and related equipment in hardware nor software. Otherwise it can cause failure, malfunction, electrical shock or injury.

(Sr

Forbidden

Be sure not to connect the opposite electrode of the battery or charge, the battery.

Also, do not try to disassemble the battery or make it short-circuited or throw it into fire or use it in overheated condition.

Otherwise it can cause fire or explosion.

VI

Sequence Controller S2T

ACAUTION

0^

Forbidden

Be careful not to hit or fall off the model 2000 by accident.

Excess shock can cause failure.

Mandatory

Touch a grounded metal part to discharge the static electricity on your body before touching the model 2000.

Otherwise, charged static electricity on your body can cause malfunction or failure.

9

Mandatory

Place any modules removed from the unit on a conductive mat or conductive bag (containing a spare board, etc.) on an grounded desk. Otherwise, static electricity can damage components of the module.

Mandatory

Use soft cloth to clean the model 2000.

Use water-dipped and squeezed cloth to clean it if dirty.

Leaving the model 2000 dirty can cause mistaking or malfunction.

0

Forbidden

Do not apply benzene and thinner when cleaning the model 2000.

Otherwise, it can cause deformity or descoloration the panel or case of the model 2000.

6.Safety Precautions on Replacing Components

<^WARNING

Mandatory

Turn off power of the model 2000 before replacing the power fuse or warning fuse. Otherwise, it can cause electrical shock or fire.

Mandatory

Replace the fuse or battery with a new one specified.

Otherwise, it may malfunction or cause fire.

6F8C0926 |

VII |

|

»

Mandatory

The relays used in the relay output module have ON/OFF life mechanically.

Use them within their mechanical life times is described in this manual.

Replace the module if exceeded.

ACAUTION

a

Mandatory

In an annual average temperature of 30°C or less, replace the battery every four years; replace it every two years in an average annual temperature higher than 30°C.

An exhausted battery can cause malfunction and lose data and programs stored in S2T, resulting in machine damage or accidents, depending on the application.

7. Safety Precautions in Daily Operation

C^WARNING

«

Mandatory

Apply power of the specified ratings (voltage fluction range, frequency, output rating, etc.) described in this manual.

Otherwise, it can cause malfunction, machine damage or fire due to overheat.

«

Mandatory

Turn off power immediately if the ambient temperature or internal temperature exceeds beyond normal range or if failure is occurred in the model 2000.

Contact Toshiba for repairing.

Operation under such situation can cause fire or electrical schock.

Vili

Sequence Controller S2T

ACAUTION

0

Forbidden

Do not touch any components, terminals, connectors or printed circuit boards in the module.

Otherwise, it can cause the 1C or LSI or the like to be broken by static electricity, resulting in failure or malfunction.

Also, the edge of components can cause injury.

0

Forbidden

Do not disassemble or modify the S2T and related equipment.

Otherwise, it can cause malfunction or failure.

0

Forbidden

Do not forcibly bend or pull or distort the power cord and other cables. Otherwise, they can be cut off or cause overheat.

0

Forbidden

Do not enter wire scraps or other foreign debris into the S2T and related equipment. Also, do not insert metal parts into them. They can cause fire or accidents.

8. Safety Precautions on Disposal

^WARNING |

ACAUTION |

Forbidden

Do not throw lithium batteries into fire. Otherwise, they can explode.

Mandatory

Observe local regulations for disposal of the lithium batteries or the model 2000.

6F8C0926 |

IX |

|

Limitation of Appiications

■The model 2000 has been designed and manufactured for use in an industrial environment.

However, the model 2000 is not intended to be used for systems which can endanger human

life (note 1).

■Consult Toshiba if you intend to use the model 2000 for a special application which involves

human life and has great influence on the maintenance of the public function (note 2). This is

why such application requires special care on the operation, maintenance, and control of the system (note 3).

(Note |

1) |

The |

systems |

which can endanger human life are life maintenance systems, equip |

|

|

ment installed in the surgery, and other medical equipment. |

||

(Note |

2) |

The |

systems |

which involve human life and have great influence on the maintenance |

|

|

of the public |

function mean the main control system of a nuclear power plant, safety |

|

|

|

and |

protection |

system of a nuclear power facility, transport operation and control sys |

tems for mass transportation, control systems of aviation and space systems, and other systems and subsystems where safety is critical.

(Note 3) "Special care" means to build a safety system (foolproof design, fail safe design, redundancy design, etc.) in full consultation with Toshiba’s engineers.

Immunity

Toshiba is not liable for any loss caused by fire, earthquake, action by a third party, or other accidents, or the operator’s intentional or accidental misuse, incorrect use, or use under abnormal condition.

Toshiba is not liable for any incidental loss caused by the use or non-use of this product, such as loss of business profits, suspension of business, or loss or change of data on memory. Toshiba is not liable for the loss caused by an operation contradictory to any of the instructions stated in this manual.

Toshiba is not liable for the loss caused by an incorrect operation in combination with other equipment.

Toshiba is not liable for the loss caused by a malfunction in combination with an application program made by the customer.

NOTE:

Use cellular phones and PHSs at least one meter away from the working the model 2000 transmission cables, and I/O bus cable. Otherwise, the system can malfunction.

Sequence Controller S2T

About this manual

This manual describes an overview, specification, and installation, operation, and maintenance and inspection of the hardware of Toshiba’s sequence controller S2T for the Integrated Controller Vseries model 2000 (hereinafter called "S2T," which is also called "model 2000" or the "equipment" when no distinction is needed).

The following types of S2T are available to realize cost-performance suited to your application.

•PU662T: CPU station module, 32K-steps, 90 ns/basic instruction, RS485 port

•PU672T: CPU station module, 64K-steps, 90 ns/basic instruction, RS485 port, 1MB memory

At first, be sure to read "Safety Precautions" before operating the model 2000.

Read this manual throughly before using the S2T. Also, keep this manual and related manuals so that you can read anytime while the S2T is in operation.

This manual has been written for users who are familiar with Programmable Control lers and industrial control equipment. Contact Toshiba if you have any questions about this manual.

6F8C0926 |

XI |

|

The S2T Related Manual

The following documents are available for S2T .

S2T User’s Manual - Basic Hardware (6F8C0926)

Describes the S2T system configuration, and explains the specifications, installa tion, wiring, maintenance and troubleshooting for the S2T’s basic hardware.

S2T Use’s Manual - Functions (6F8C0928)

Provides the information for designing S2T user program, such as S2T internal operation, memory configuration, I/O allocation.

T Series Instruction Set (Ladder, SFC) (UM-TS03***-E004)

Detailed explanations of ladder and SFC programming, two of the languages of the S2T/T3H/T3/T2N/T2E/T2/T1S/T1 programmable controllers.

T-PDS for Windows Basic Operation Manual (UM-TS03***-E038)

Installation and basic key operations of the T-series Program Development System (T-PDS) software for windows.

T series Computer Link Function User’s Manual (UM-TS03***-E008)

Describes the Tseries computer link configuration, and explains the protocol, soft ware procedure, wiring to communicate between the Tseries PCs.

High Function Analog Mdule User’s Manual (6F8C0860)

Describes the specifications and operation of high function Analog Mudule (AD668/DA664/TC618/RT614).

Pulse Input Module Manual (PI632/PI672) (6F8C0841)

Describes the specifications and operation of Pulse Input Module (PI632/PI672).

Communication Interface Module Manual (CF611) (6F8C0843)

Describes the specifications and operation of Communication Interface Module (CF611).

2-Axis Positioning Controller Manual (MC612) (6F8C0842)

Describes the specifications and operation of 2-Axis Positioning Module(MC612).

TOSLINE-S20 User’s Manual (6F8C0890)

Describes the system configuration, and explains the functions, performance and operation of TOSLINE-S20.

XII

Sequence Controller S2T

TOSLINE-F10 User’s Manual (6F8C0844)

Describes the system configuration, and the specifications, wiring and operationg of remote I/O data link system TOSLINE-F10.

DeviceNet Scanner Module Manual (6F8C0845)

Describes the system configuration,and explains the specifications, installation, wiring of Device Net.

Ethernet Module Operation Manual (6F8C0879)

Describes the specifications, wiring and operating of Ethernet Module (EN611/ EN631/EN651)

6F8C0926 |

XIII |

|

CONTENTS

Safety Precautions....................................................................... |

i |

Limitation of Applications............................................................ |

x |

Immunity..................................................................................... |

X |

About this manual.................................................................................. |

xi |

The S2T Related Manual...................................................................... |

xii |

Chapti System Configuration......................... |

1 |

||

1.1 S2T configuration as Station Module................................ |

2 |

||

|

1.1.1 |

S2T basic configuration............................................................ |

2 |

|

1.1.2 |

S2T System configuration........................................................ |

3 |

|

1.1.3 |

Unit configuration...................................................................... |

5 |

1.2 |

S2T CPU Module............................................................ |

10 |

|

|

1.2.1 |

Overview................................................................................. |

10 |

|

1.2.2 |

Status display LEDs............................................................... |

11 |

|

1.2.3 |

Operation Mode Switch.......................................................... |

11 |

|

1.2.4 Setting Switches of Operation Mode...................................... |

12 |

|

|

1.2.5 Programmer port of RS232C.................................................. |

13 |

|

|

1.2.6 LINK port of RS485................................................................ |

14 |

|

1.3 |

Computer link mode........................................................ |

18 |

|

|

1.3.1 |

Computer link function............................................................ |

18 |

|

1.3.2 |

System configuration.............................................................. |

19 |

|

1.3.3 |

Setup procedure..................................................................... |

20 |

|

1.3.4 |

RS-485 cable connection....................................................... |

21 |

|

1.3.5 |

RS-232C cable connection..................................................... |

23 |

|

1.3.6 |

Mode setting........................................................................... |

23 |

|

1.3.7 |

Communication parameter setting......................................... |

24 |

|

1.3.8 |

Computer link protocol............................................................ |

25 |

1.4 |

Free ASCII mode............................................................. |

27 |

|

|

1.4.1 Free ASCII communication function....................................... |

27 |

|

|

1.4.2 |

System configuration.............................................................. |

29 |

|

1.4.3 |

Setup procedure..................................................................... |

30 |

|

1.4.4 |

RS-485 cable connection....................................................... |

31 |

|

1.4.5 |

Mode setting........................................................................... |

32 |

|

1.4.6 |

Communication parameter setting......................................... |

33 |

XIV |

Sequence Controller S2T |

------------ CONTENTS

|

1.4.7 |

Message format...................................................................... |

34 |

|

1.4.8 |

Programming.......................................................................... |

35 |

|

1.4.9 |

Related instruction.................................................................. |

40 |

|

1.4.10 |

Sample programs................................................................... |

48 |

1.5 |

Units................................................................................ |

51 |

|

|

1.5.1 |

Bases..................................................................................... |

51 |

|

1.5.2 |

Expansion interface................................................................ |

53 |

|

1.5.3 |

Expansion cables................................................................... |

53 |

1.6 |

Power Supply Module...................................................... |

54 |

|

|

1.6.1 |

Power Supply Module............................................................. |

54 |

|

1.6.2 |

Power capacity consideration................................................. |

57 |

1.7 |

I/O Modules..................................................................... |

60 |

|

1.8 |

Network Modules............................................................ |

62 |

|

Chapt2 Specifications................................. |

65 |

|

2.1 |

General Specifications.................................................... |

65 |

2.2 |

External dimensions........................................................ |

68 |

2.3 |

I/O Module Specification................................................. |

70 |

ChaptS Precautions for I/O Modules.......... |

111 |

|

3.1 |

Precautions for DC Input Modules................................... |

Ill |

3.2 |

Precautions for AC Input Modules................................. |

115 |

3.3 |

Precautions for DC Output Modules.............................. |

117 |

3.4 |

Precautions for AC Output Modules.............................. |

120 |

3.5 |

Precautions for Relay Output Modules......................... |

121 |

3.6 |

Precautions for Analog Input Modules.......................... |

122 |

3.7 |

Precautions for Analog Output Modules........................ |

123 |

Chapt4 Installation and Wiring.................. |

125 |

|

4.1 |

Operating environment.................................................. |

125 |

4.2 |

Installing bases............................................................. |

126 |

4.3 |

Mounting the Modules................................................... |

127 |

6F8C0926 |

XV |

CONTENTS------------- |

|

|

4.3.1 Basic procedure for mounting/removing the modules. . |

. 127 |

|

4.3.2 Installing/removing of the module cover.............................. |

131 |

|

4.4 |

Connecting expansion units.......................................... |

132 |

4.5 |

Grounding...................................................................... |

133 |

4.5.1 Check points for grounding................................................... |

133 |

|

4.5.2 Grounding methods.............................................................. |

134 |

|

4.6 |

Wiring of the power supply............................................ |

136 |

4.7 |

I/O wiring....................................................................... |

139 |

4.8 |

Wiring of the computer link........................................... |

141 |

4.9 |

Power up/down sequence............................................. |

143 |

4.10 |

Safety circuit.................................................................. |

144 |

ChaptS Maintenance and Checking............ |

145 |

|

5.1 |

Daily checking items...................................................... |

145 |

5.2 |

Periodical checking items.............................................. |

146 |

5.3 |

Maintenance parts......................................................... |

147 |

5.4 |

Battery Replacement..................................................... |

148 |

|

Disposal of the battery 150 |

|

5.5 |

Fuse Replacement........................................................ |

151 |

Chapt6 Troubleshooting............................. |

153 |

|

6.1 |

Troubleshooting procedure.......................................... |

153 |

6.2 |

Checking the power supply........................................... |

155 |

6.3 |

Checking the S2T CPU................................................. |

156 |

6.4 |

Checking user program................................................. |

157 |

6.5 |

Checking input............................................................... |

158 |

6.6 |

Checking output............................................................ |

159 |

6.7 |

Troubles due to external factors.................................... |

160 |

XVI |

Sequence Controller S2T |

|

1 |

|

Chapt.1 System Configuration |

||

|

The Integrated Controller Vseries has some features as mentioned before. The Sta tion Module with station bus (internal high-speed data bus) interface can perform to exchange common data between them on real time.

• Station Module

The Station Module is shown as below table. These can be mounted on the dedi cated basic base and perform complex control combining each functionality.

Table1-1 S2TCPU

Description |

Specification |

Type |

Remarks |

|

|

|

|

Sequence |

32K-step |

PU662T |

|

Controller |

|

|

|

64K-step |

PU672T |

|

|

|

|

||

|

|

|

|

Table1-2 Station Module

Item |

Description |

Specification |

Type |

No. of |

|

Occupied slot |

|||||

|

|

|

|

||

|

|

|

|

|

|

Controller |

Sequence |

32K-step |

PU662T |

1 |

|

|

Controller |

|

|

|

|

|

64K-step |

PU672T |

1 |

||

|

|

||||

|

|

|

|

|

|

|

Compute |

WIndows-NT HDD |

C2PU35 |

2 |

|

|

|

|

|

|

|

Network |

Ethernet |

10BASE5 |

EN611 |

1 |

|

|

|

|

|

|

|

|

|

10BASE2 |

EN631 |

1 |

|

|

|

|

|

|

|

|

|

100BASE-TX, 10BASE-T |

EN651 |

1 |

|

|

|

|

|

|

|

|

TC-netIO |

16KW, 10Mbps,co-axial |

CN611 |

1 |

|

|

|

|

|

|

|

|

|

16KW, 10Mbps,co-axial. Double bus |

CN612 |

1 |

|

|

|

|

|

|

|

|

TC-net20 |

16KW, 20Mbps,optical,Double Loop bus |

CN623*'' |

1 |

|

|

|

|

|

|

*1: underdevelopment

*2: The above modules are performed on the main base with station bus. Please refer to Section 1.1 or 1.3 for details of the ^stem configuration.

6F8C0926

Chapt.1 System Configuration

1.1S2T configuration as Station Module

1.1.1S2T basic configuration

According to variety of industrial applications, a basic unit or with expansion units are selected.

The basic unit is composed of a main base, a power supply module, station modules and direct I/O modules, and an expansion interface is added using expansion units.

The expansion unit is composed of an expansion base, a power supply module, direct I/O modules and an expansion interface.

Each expansion interface modules are connected with expansion cables.

Up to three expansion units can be connected in the S2T.

The S2T accesses direct I/O modules via the G2-bus in the model 2000.

Basic unit

Expansion unit

*4: The digital / analog I/O modules can be mounted in the *4 slots in place of the station modules.

Fig.1-1-1 An example of S2T basic configuration as station module

Sequence Controller S2T

|

1.1 S2T configuration as Station Module |

1.1.2 S2T System configuration |

|

The S2T provide a functional, |

economical and compact solution to user applications |

in automotive, machine control |

and process control, by using station modules and |

direct I/O modules. |

|

*5: DeviceNet is a registered trademark of the Open DeviceNet Vender Association, Inc.

Fig.1-1-2 An example of S2T system configuration as station module

6F8C0926

Chapt.1 System Configuration

• Basic configuration

Base

Main base |

|

BU648E |

|

|

|

|

|

BU643D |

|

|

|

Expansion base |

|

BU668 |

|

|

|

|

|

BU666 |

|

|

|

|

|

BU664 |

|

|

|

Power supply module |

|

|

100, 200Vac input |

|

PS691 |

|

|

|

100-240Vac input |

|

PS693 |

|

|

|

100-240Vac input |

|

PS694 |

|

|

|

24Vdc input |

|

PS632 |

|

|

|

tOOVdc input |

|

PS652 |

|

|

|

S2T CPU module |

|

|

|

|

|

32k-step |

|

PU662T |

|

|

|

64k-step |

|

PU672T |

|

|

|

Expansion interface |

|

|

|

|

|

Standard |

|

IF661 |

|

|

|

Optional |

|

|

|

|

|

Space module |

|

SP600 |

|

|

|

Unit cover |

|

SP601 |

|

|

|

Expansion cable for standard |

|

|

|

|

|

0.3m |

|

CS6R3 |

|

|

|

0.5m |

|

CS6R5 |

|

|

|

0.7m |

|

CS6R7 |

|

|

|

1.2m |

|

CS6*1 |

|

|

|

• station Module

Control module

Computer |

C2PU35 |

|

|

Network module |

|

|

|

TOSLINE-S20 |

SN625 |

|

|

|

SN626 |

|

|

|

SN627 |

|

|

TC-net10 |

CN611 |

|

|

|

CN612 |

|

|

TC-net20 |

CN623*'' |

|

|

Open Network module |

|

|

|

Ethernet |

EN611 |

|

|

|

EN631 |

|

|

|

EN651 |

|

|

Serial, CompactFash interface

Serial, Compact CF612 ■1 flash interface

•Software tool

Programming tool T-PDS

Windows-NT/98

MW33J2

(Japanese)

Windows-NT/98

MW33E2

(English)

TOSLINE-S20tool S-LS

Windows-/NT/98

MW23J*

(Japanese)

Windows-/NT/98

MW23E*

(English)

DDE server soft

Japanese Edition |

PV33J2 |

|

|

English Edition |

PV33E2 |

|

|

Connecting cable |

|

|

|

5m |

CJ905 |

|

|

*1: underdevelopment *4: function limited

• Direct I/O module

Digital input/output module

24Vdc input |

DI632D |

|

|

|

DI633 |

|

|

|

DI634 |

|

|

|

DI635 |

|

|

|

DI635H |

|

|

|

DI653 |

|

|

100-120Vac input |

IN653 |

|

|

200-240Vac input |

IN663 |

|

|

Transistor output |

D0633 |

|

|

|

D0634 |

|

|

|

D0635 |

|

|

(source type) |

D0633P |

|

|

Triac output |

AC663 |

|

|

Relay output |

R0662S |

|

|

|

R0663 |

|

|

Changect detect |

CD633 |

|

|

Analog input/output module |

|

Analog input |

AD624 |

|

AD674 |

|

AD628S |

|

AD638S |

|

AD668 |

|

RT614 |

|

TC618 |

Analog output |

DA622 |

|

DA672 |

|

DA664 |

Serial interface |

|

Serial interface |

CF611 |

Network module |

|

|

|

TOSLINE-S20 |

SN621*'’ |

|

|

|

SN622*“’ |

|

|

TOSLINE-F10 |

UN611 |

|

|

|

UN612 |

|

|

Network module |

|

|

|

DeviceNet |

DN611A |

|

|

FL-net |

FL611 |

|

|

|

FL612 |

|

|

Intelligent I/O module |

|

|

|

Pulse input |

PI632 |

|

|

|

PI672 |

|

|

Positioning control |

MC612 |

|

|

|

MC614*'' |

|

|

Sequence Controller S2T

1.1 S2T configuration as Station Module

1.1.3Unitconfiguration

Some examples of minimum/maximum configuration are shown as below.

Basic unit

The main base dedicated for station module is used. The control module S2T should be mounted on SO that is the left end slot of the base. Other station modules are mounted on from S1 to S4 (BU648E) where two connectors are.

The digital/analog input/output module can be mounted on slots for station module. These modules should be mounted on the right slot of station modules.

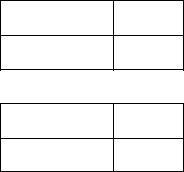

Table1-1-1 Main base

Type |

Description |

Slot No. |

Slot No. |

Remarks |

|

for station Module |

for Direct I/O Module |

||||

|

|

|

|||

|

|

|

|

|

|

BU648E |

For |

5 |

4 |

|

|

|

Basic unit |

|

|

|

|

|

4 |

5 |

|

||

|

|

|

|||

|

|

|

|

|

|

|

|

3 |

6 |

|

|

|

|

|

|

|

|

|

|

2 |

7 |

|

|

|

|

|

|

|

|

|

|

1 |

8 |

|

|

|

|

|

|

|

|

BU643D |

For |

4 |

0 |

|

|

|

Basic unit |

|

|

|

|

|

3 |

1 |

|

||

|

|

|

|||

|

|

|

|

|

|

|

|

2 |

2 |

|

|

|

|

|

|

|

|

|

|

1 |

3 |

|

|

|

|

|

|

|

Expansion unit

Table1-1-2 Expansion base

Type |

Description |

Space slot No. |

Slot No. |

Remarks |

|

for Direct I/O Module |

|||||

|

|

|

|

||

|

|

|

|

|

|

BU668 |

For |

1 |

8 |

|

|

|

Expansion |

|

|

|

|

BU666 |

0 |

6 |

|

||

|

|

|

|

|

|

BU664 |

unit |

0 |

4 |

|

|

|

|

|

|

|

Module implementation from base view

Tablel-1 -3 Basic unit Module implementation

|

|

|

|

|

|

Slot |

|

|

|

|

|

|

PIF |

PS |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

BU648E |

- |

- |

CPU |

ALL |

ALL |

ALL |

ALL |

10 |

10 |

10 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

BU643D |

- |

- |

CPU |

ALL |

ALL |

ALL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tablel-1-4 Expansion unit Module implementation

|

|

|

|

|

|

Slot |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PIF |

PS |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

|

|

|

|

|

|

|

|

|

|

|

BU668 |

- |

- |

X |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

BU666 |

- |

- |

lO |

10 |

10 |

10 |

10 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BU664 |

- |

- |

lO |

10 |

10 |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6F8C0926

Chapt.1 System Configuration

NOTE

PIF:Slot for expansion interface IF661

PS:Slot for power supply module

0 to 8:Slot number of base CPU:Slot for CPU module S2T IO:Slot for I/O module

AlhSlot for Station module,I/O module

Module implementation from each module view

Tablet-1-5 CPU module

|

One module |

|

|

Slot |

|

|

|

occupied slot |

BU648E |

BU643D |

BU668 |

BU666 |

BU664 |

|

|

|

|

|

|

|

PU672T |

1 |

0 |

0 |

X |

X |

X |

|

|

|

|

|

|

|

PU662T |

1 |

0 |

0 |

X |

X |

X |

|

|

|

|

|

|

|

C2PU35 |

2 |

1 ''-3 |

1 ' ^ 2 |

X |

X |

X |

|

|

|

|

|

|

|

S2T(PU672T,PU662T) used in Basic unit slot number "0".

Tablet-1-6 expansion interface

|

|

|

Slot |

|

|

|

BU648E |

BU643D |

BU668 |

BU666 |

BU664 |

|

|

|

|

|

|

IF661 |

|

|

PIF |

|

|

|

|

|

|

|

|

Tablet-1-7 Network module

|

|

|

Slot |

|

|

|

|

|

|

|

|

|

BU648E |

BU643D |

BU668 |

BU666 |

BU664 |

|

|

|

|

|

|

EN651 |

1 ~ 4 |

1 ~3 |

X |

X |

X |

|

|

|

|

|

|

EN611 |

1 ~ 4 |

1 ~3 |

X |

X |

X |

|

|

|

|

|

|

EN631 |

1 ~ 4 |

1 ~3 |

X |

X |

X |

|

|

|

|

|

|

SN625 |

1 ~ 4 |

1 ~3 |

X |

X |

X |

|

|

|

|

|

|

SN626 |

1 ~ 4 |

1 ~3 |

X |

X |

X |

|

|

|

|

|

|

SN627 |

1 ~ 4 |

1 ~3 |

X |

X |

X |

|

|

|

|

|

|

UN611 |

5~8 |

X |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

UN612 |

5 ~ 8 |

X |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

DN611A |

1 ~ 8 |

X |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

FL611 |

1 ~8 |

X |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

FL612 |

1 ~ 8 |

X |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

6 |

Sequence Controller S2T |

1.1 S2T configuration as Station Module

Table1-1-8 Direct I/O module, others

|

|

|

Slot |

|

|

|

|

|

|

|

|

|

BU648E |

BU643D |

BU668 |

BU666 |

BU664 |

|

|

|

|

|

|

DI632D |

1 ~8 |

1 ~ 3 |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

DI633 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

DI653 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

DI634 |

1 ~8 |

1 ~ 3 |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

DI635 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

DI635H |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

I N653 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

I N663 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

D0633 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

D0633P |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

D0634 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

D0635 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

AC663 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

R0662S |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

R0663 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

CD633 *■' |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

AD624L |

1 ~8 |

1 ~ 3 |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

AD634L |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

AD624 |

1 ~8 |

1 ~ 3 |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

AD674 |

1 ~8 |

1 ~ 3 |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

AD628S |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

AD638S |

1 ~8 |

1 ~ 3 |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

AD668 |

1 ~8 |

1 ~ 3 |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

TC618 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

RT614 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

DA622L |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

DA622 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

DA672 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

DA664 |

1 ~ 8 |

1 ~ 3 |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

PI632 *■' |

5~8 |

X |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

PI672 *■' |

5~8 |

X |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

MC612 |

5~8 |

X |

1 ~8 |

0 ~ 5 |

0~3 |

|

|

|

|

|

|

CF611 |

5 ~ 8 |

X |

1 ~ 8 |

0 ~ 5 |

0 ~ 3 |

|

|

|

|

|

|

*1: When you use CD633, PI632, PI672 with interrupt function, implement in the Basic unit in which S2T exists.

6F8C0926

Chapt.1 System Configuration

(1)Minimum Configuration

• Exampies of BU648E

|

|

|

so S1 S2 S3 S4 S5 S6 S7 S8 |

|

|

|

|

SO S1 S2 S3 S4 S5 S6 S7 S8 |

|

|||||||||||||||

u |

p s |

s |

T |

E |

E |

T |

1 |

1 |

1 |

1 |

|

u |

p s |

s |

E |

T |

1 |

1 |

1 |

1 |

1 |

1 |

||

c |

0 |

U |

2 |

L |

N |

N |

c |

/ |

/ |

/ |

/ |

|

c |

0 |

U |

2 |

N |

c |

/ |

/ |

/ |

/ |

/ |

/ |

’ |

W p |

T |

1 |

|

|

|

0 |

0 |

0 |

0 |

|

|

W p |

T |

|

|

0 |

0 |

0 |

0 |

0 |

0 |

||

|

e |

p |

|

S |

|

|

|

|

|

|

|

|

|

e |

p |

|

|

|

|

|

|

|

|

|

|

r |

|

|

2 |

|

|

|

|

|

|

|

|

|

r |

|

|

|

|

|

|

|

|

|

|

|

|

y |

|

0 |

|

|

|

|

|

|

|

|

|

|

y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

2 3 4 |

5 6 7 |

|

|

|

|

|

|

0 |

1 |

2 3 4 |

|

5 6 7 |

|

|||||

Main unit with 5 station moduies |

Main unit with 3 station moduies |

||||||||||||||||

and 4 i/0 moduies |

and 6 i/0 moduies |

||||||||||||||||

UC*: unit cover |

|

|

|

|

|

|

|

|

|

||||||||

Exampies of BU643D |

|

|

|

|

|

|

|

|

|

||||||||

|

|

so SI S2 S3 |

|

|

so SI S2 S3 |

||||||||||||

u |

P s |

s |

|

T |

c |

E |

|

U |

P s |

s |

|

T |

F |

1 |

|

|

|

c |

0 u |

2 |

|

L |

2 |

N |

|

C |

0 U |

2 |

|

L |

L |

/ |

|

|

|

* |

w p |

T |

|

i |

|

|

|

|

|

w p |

T |

|

i |

|

0 |

|

|

|

e p |

|

|

S |

|

|

|

|

|

e p |

|

|

S |

|

|

|

|

|

r 1 |

|

2 |

|

|

|

|

|

r 1 |

|

2 |

|

|

|

|

||

|

y |

|

0 |

|

|

|

|

|

y |

|

0 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 1 2 |

|

|

|

|

|

|

|

0 1 2 |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||||||||

Using |

high performance |

Using |

high |

performance |

|||||||||||||

CPU, 4 siots |

CPU, 2 siots |

|

|

|

|

||||||||||||

8 |

Sequence Controller S2T |

1.1 S2T configuration as Station Module

(2)Maximum Configuration

Number of I/O points (using 64-point I/O module)

SO S1 S2 S3 S4 S5 S6 S7 S8

Basic unit |

384 points/BU648E |

Expansion unit |

896 points/BU668 |

#1

Expansion unit |

1,280 points/BU666 |

#2

Expansion unit |

1,536 points/BU664 |

#3 |

|

0 12 3

NOTE

IV. The expansion interface should be mounted on each unit.

Two expansion connectors are fitted on the expansion interface. The upper side connector is for input from previous unit and the lower side connector is for output to the next unit.

V. Up to a maximum of 3 expansion units can be connected.

vi.There is no limit on combinations of the types of the rack.

vii.Using BU668, the SO slot can’t be used and a space module SP600 should be mounted on SO. The space module SP600 should be mounted on other vacant slots to avoid the risk of electri cal shock.

6F8C0926

Chapt.1 System Configuration

1.2S2T CPU Module

1.2.1Overview

The S2T CPU module performs user program, reading input data from the direct I/O module and writing output data to the direct I/O module.

The S2T has two types of CPU modules.

Type |

Program |

Program |

Battery |

Memory |

Expanded |

Link port |

|

language |

Capacity |

memory |

|||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

PU662T |

Ladder + |

32KS |

Built-in |

RAM + |

— |

RS485 |

|

PU672T |

SFC |

64KS |

FlashROM |

1MB |

Built-in |

||

|

|||||||

|

|

|

|

|

|

|

When user program and parameter data are kept in the built-in flash |

ROM of |

the |

S2T, user system will come back to be well quickly if any trouble occurs. |

|

|

The S2T has the built-in two communication ports, one Programmer |

port and |

one |

LINK port which is equipped for variety of peripherals, displays and PCs etc. |

|

|

The front view of the S2T is shown as below. The operation mode switch, setting switches of operation mode, status display LEDs are provided on the front panel.

P U 6 7 2 T

|

|

|

|

|

Status display LEDs |

|

|

|

|

|

(RUN, FauLT, BATtery) |

Operation |

Mode |

Switch |

|

□ |

|

(HALT, RUN) |

|

M |

□ |

|

|

|

|

|

|

n |

■ LINK port |

|

|

|

■ |

□ |

|

|

|

|

|

||

|

|

|

N |

□ |

|

|

|

|

i |

Ip |

|

Setting |

Switches |

|

|

||

Battery module cover

of Operation mode

w

Programmer port

PROG

Fig.1-2-1 S2T CPU front view

10 |

Sequence Controller S2T |

1.2 S2T CPU Module

1.2.2Status display LEDs

These LEDs show operation states of the S2T.

Status display LEDs

Name |

Display |

States |

Remark |

|

|

|

|

RUN (Green) |

Lit |

Operating state (RUN Mode) |

|

|

|

|

|

|

Blink |

HOLD Mode |

|

|

|

|

|

|

Out |

Stopped state (HALT Mode) or Error Mode |

|

|

|

|

|

FLT (Red) |

Lit |

CPU abnormal or I/O abnormal |

|

|

|

|

|

|

Blink |

CPU abnormal |

|

|

|

|

|

|

Out |

Normal |

|

|

|

|

|

BAT (Green) |

Lit |

Battery normal |

|

|

|

|

|

|

Blink |

Battery caution |

|

|

|

|

|

|

Out |

Battery abnormal or no battery |

|

|

|

|

|

1.2.3Operation Mode Switch

The Operation Mode Switch is provided on the CPU module.

This switch controls S2T operation (RUN/HALT).

A HALT-----------------Stop user program execution (HALT mode)

U |

-Start user program execution (RUN mode) |

RUN |

CPU status is shown below after power up or after the operation mode is changed to RUN from H ALT mode.

Setting |

Initial Load Program |

Operation |

Operation Mode |

||

exe: executed |

|

Change by the |

|||

Position |

|

mode |

|||

-: not executed |

|

Programming tool |

|||

|

|

|

|||

|

|

|

|

|

|

HALT |

SW-1=OFF |

|

exe |

HALT |

Not available |

|

|

|

|

|

|

|

SW-1=ON |

|

- |

|

|

|

|

|

|

|

|

RUN |

SW-1=OFF |

|

exe |

RUN |

available |

|

|

|

|

|

|

|

SW-1=ON |

|

- |

|

|

|

|

|

|

|

|

As shown the above table, initial load (user program transfer from Flash ROM to

RAM) performs when setting SW-1 to OFF.

NOTE

i.The operation mode switch is set to HALT at the factory.

ii.Normally the programming is activated in the HALT mode,

ill. For details of the operation mode, see "S2T user's manual".

iv. The RAM is back-up by both internal capacitor and built-in battery of the S2T. When they go down and the S2T can't keep retentive area in the RAM, CPU checks user program BCC. CPU registers error if error is occurred.

6F8C0926 |

11 |

Chapt.1 System Configuration

1.2.4Setting Switches of Operation Mode

These switches are provided under the battery cover on the CPU front panei.

They controi the foiiowing fanctions. (SW-1 is ON, SW2, 3, 4 are set to OFF at the factory.)

. ROM/RAM Switch |

:CPU reads this status when power is |

|

changed from OFF to ON or when operation |

|

mode is changed to RUN. |

_RUN/Stand-by Switch |

:CPU reads this status oniy when power |

|

turns to ON. |

•Programmer Port Parity :CPU reads this status oniy when power |

|

|

turns to ON. |

Reserved (fixed to OFF) |

|

SW-1 ROM/RAM Switch

Setting |

|

CPU operation |

|

Position |

Function |

||

at power up and at the beginning of the RUN mode |

|||

SW-1 |

|

||

|

|

||

|

|

|

|

OFF |

ROM |

Starts up after the content of the Flash ROM has been transferred to |

|

|

|

the RAM. (Initial Load) |

|

|

|

|

|

ON |

RAM |

Starts up on the content of the RAM. |

|

|

|

(No program transfer) |

|

|

|

|

SW-2 RUN/Stand-by Switch

Setting |

|

Operation |

Mode after |

|

|

Position |

Function |

Mode |

Remarks |

||

power up |

|||||

SW-2 |

|

Switch |

|

||

|

|

|

|||

|

|

|

|

|

|

OFF |

Automatic |

HALT |

HALT |

|

|

|

|

|

|

||

|

RUN |

RUN |

RUN |

Automatic RUN start occurs. |

|

|

|

|

|

|

|

ON |

Stand-by |

HALT |

HALT |

|

|

|

|

|

|

||

|

|

RUN |

|

Starts up in the HALT mode. Ready to start |

|

|

|

|

|

operation by an operate command from the |

|

|

|

|

|

programming tool or by shifting the operation |

|

|

|

|

|

mode switch.(^^LT^RUN) |

|

|

|

|

|

|

is OFF, mode is set to Automatic RUN.

SW-3 Programmer Port Parity

Setting |

|

|

Position |

Function |

Remarks |

SW-3 |

|

|

|

|

|

OFF |

Odd Parity |

8 bit Data, 9600bps, Data length is libit. |

|

|

|

ON |

No Parity |

8 bit Data, 9600bps, Data length is lObit. |

|

|

|

<J>CAUTION

Mandatory

Set the switches of the CPU and I/O modules according to each instructions.

Mis-setting can cause malfunction or system accidents.

12 |

Sequence Controller S2T |

1.2 S2T CPU Module

1.2.5Programmer port of RS232C

The programmer (T-PDS) is connected to this programmer port.

Connector type of CPU side is female , 9-pin D-SUB connector.

The S2T’s RS232C programmer port can accept the computer link protocol (data read/write). This results in easy connection to a higher level computer, an operator interface unit, etc. directly.

General specifications and the connector pin assignment of programmer port are shown below.

For details of T-series computer link protocol, see T-series User’s manual

- Computer Link (UM-TS03***-E008).

General specifications

Item |

|

|

Specifications |

|

|

||

Interface |

Conforms to RS232C |

||

|

|

|

|

Configuration |

One to One |

|

|

|

|

|

|

Transmission distance |

15m max. |

|

|

|

|

||

Transmission speed |

9600bps (fixed) |

||

|

|

||

Frame format |

Start bit 1 bit |

||

|

Data 8bit |

|

|

|

Parity odd/none (selected by SW.3) |

||

|

stop bit 1 bit |

||

|

|

|

|

Supported command |

DR |

(Data |

Read) |

|

DW |

(Data |

Write) |

|

ST |

(Status |

read) |

|

TS (Test text) |

||

|

|

|

|

Pin assignment of programmer port

Signals |

No. of pins |

Symbols |

Direction |

|

|

|

|

Transmission data |

3 |

TXD |

S2T ^ Host |

|

|

|

|

Receive data |

2 |

RXD |

S2T ^ Host |

|

|

|

|

Signal ground |

5 |

SO |

S2T - Host |

|

|

|

|

Request To Send |

7 |

RTS |

S2T ^ Host |

|

|

|

|

Clear To Send |

8 |

CTS |

S2T ^ Host |

|

|

|

|

NOTE

Other pins except the above table should not be connected.

6F8C0926 |

13 |

Loading...

Loading...