Toshiba RAS-13SAX, RAS-13SKX, RAS-13SK-E, RAS-13SA-E SERVICE MANUAL

T O S H I B AF I L E N O . A

S E R V I C E M A N

A I R - C O

S P L I T W

RA S - 1R 3A SS K-

1R 3A SS K-

RA S -R1 A3 S K-

P R I N T E D I N J A P

|

|

CONTENTS |

|

1. SPECIFICATIONS ............................................................................................................ |

4 |

||

2. CONSTRUCTION VIEWS ................................................................................................ |

6 |

||

2-1. |

Indoor Unit .................................................................................................................................. |

6 |

|

2-2. |

Outdoor Unit ............................................................................................................................... |

7 |

|

3. WIRING DIAGRAM .......................................................................................................... |

8 |

||

4. SPECIFICATIONS OF ELECTRICAL PARTS ................................................................. |

9 |

||

4-1. |

Indoor Unit .................................................................................................................................. |

9 |

|

4-2. |

Outdoor Unit ............................................................................................................................... |

9 |

|

5. REFRIGERANT CYCLE DIAGRAM .............................................................................. |

10 |

||

6. MICRO-COMPUTER BLOCK DIAGRAM ....................................................................... |

11 |

||

7. OPERATION DESCRIPTIONS ....................................................................................... |

12 |

||

7-1. |

FAN ONLY Operation ............................................................................................................... |

12 |

|

7-2. |

COOL Operation ....................................................................................................................... |

12 |

|

|

7-2-1. |

Louver Control ...................................................................................................................................... |

13 |

7-3. |

DRY Operation .......................................................................................................................... |

13 |

|

7-4. |

AUTO Operation ....................................................................................................................... |

14 |

|

|

7-4-1. |

Temporary Auto ..................................................................................................................................... |

14 |

7-5. |

ECONO. Mode ........................................................................................................................... |

15 |

|

|

7-5-1. Cooling ................................................................................................................................................... |

15 |

|

7-6. Low-Temperature Limit Control (Cooling Operation) .......................................................... |

15 |

||

7-7. |

Auto Restart Function ............................................................................................................. |

16 |

|

|

7-7-1. How to Set the Auto Restart ................................................................................................................. |

16 |

|

|

7-7-2. How to Cancel the Auto Restart .......................................................................................................... |

17 |

|

|

7-7-3. In Case of Power Failure during the Timer Operation ....................................................................... |

17 |

|

8. INSTALLATION PROCEDURE ...................................................................................... |

18 |

||

8-1. |

Safety Cautions ........................................................................................................................ |

18 |

|

8-2. Installation Diagram of Indoor and Outdoor Units ............................................................... |

20 |

||

8-3. |

Installation ................................................................................................................................ |

21 |

|

|

8-3-1. |

Optional Parts ........................................................................................................................................ |

21 |

|

8-3-2. |

Installation Parts ................................................................................................................................... |

21 |

8-4. |

Indoor Unit ................................................................................................................................ |

22 |

|

|

8-4-1. Cutting a Hole and Mounting Installation Plate ................................................................................. |

22 |

|

|

8-4-2. |

Electrical Work ...................................................................................................................................... |

23 |

|

8-4-3. |

Wiring Connection ................................................................................................................................ |

24 |

|

8-4-4. Piping and Drain Hose Installation ...................................................................................................... |

26 |

|

|

8-4-5. |

Indoor Unit Installation ......................................................................................................................... |

27 |

|

8-4-6. Drainage ................................................................................................................................................. |

27 |

|

8-5. |

Outdoor Unit ............................................................................................................................. |

28 |

|

|

8-5-1. |

Refrigerant Piping Connection ............................................................................................................ |

29 |

|

8-5-2. |

Vacuum Pumping .................................................................................................................................. |

29 |

|

8-5-3. |

Wiring Connection ................................................................................................................................ |

30 |

8-6. |

Others ........................................................................................................................................ |

31 |

|

|

8-6-1. |

Gas Leak Test ........................................................................................................................................ |

31 |

|

8-6-2. |

Test Operation ....................................................................................................................................... |

31 |

|

8-6-3. |

Auto Restart Setting ............................................................................................................................. |

31 |

– 2 –

9. TROUBLESHOOTING CHART...................................................................................... |

32 |

9-1. What to be Prechecked First .................................................................................................. |

32 |

9-1-1. Power Supply Voltage ........................................................................................................................... |

32 |

9-1-2. Incorrect Cable Connection between Indoor and Outdoor Units ..................................................... |

32 |

9-1-3. Misleading but Good Operations ......................................................................................................... |

33 |

9-2. Primary Judgement of Trouble Sources ............................................................................... |

34 |

9-2-1. Role of Indoor Unit Controller .............................................................................................................. |

34 |

9-2-2. Display of Abnormalities and Judgement of the Abnormal Spots ................................................... |

34 |

9-3. Troubleshooting Flowcharts ................................................................................................... |

38 |

9-3-1. Power can not be Turned on ................................................................................................................ |

38 |

9-3-2. Power can not be Turned on after Replacing Indoor PC Board ....................................................... |

39 |

9-3-3. Outdoor Unit does not Operate ........................................................................................................... |

39 |

9-3-4. Only Compressor does not Operate ................................................................................................... |

40 |

9-3-5. Only Outdoor Fan does not Operate ................................................................................................... |

41 |

9-3-6. Only the Indoor Fan does not Operate ................................................................................................ |

42 |

9-4. How to Check the Remote Control (Including the Indoor PC Board) ................................ |

43 |

9-4-1. How to Check the PC Board ................................................................................................................. |

44 |

9-4-2. PC Board Layout ................................................................................................................................... |

46 |

9-4-3. How to Reduce the Operation Time of the Anti-Restart Timer ......................................................... |

47 |

10. PART REPLACEMENT ................................................................................................. |

48 |

10-1. Indoor Unit ................................................................................................................................ |

48 |

10-2. Microcomputer ......................................................................................................................... |

50 |

10-3. Outdoor Unit ............................................................................................................................. |

51 |

11. CAUTIONS ON REPLACEMENT OF PC BOARD ASSEMBLY .................................... |

52 |

12. EXPLODED VIEWS AND PARTS LIST ......................................................................... |

53 |

12-1. Indoor Unit (1) ........................................................................................................................... |

53 |

Indoor Unit (2) ........................................................................................................................... |

54 |

12-2. Outdoor Unit ............................................................................................................................. |

55 |

– 3 –

|

|

|

1. |

SPECIFICATIONS |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

RAS-13SK-E/13SA-E |

|

RAS-13SKX/13SAX |

||||

Item |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

COOLING |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Capacity |

|

|

|

*1 kW |

|

220V |

|

230V |

|

240V |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

3.70 |

|

3.70 |

|

3.75 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Phase |

|

|

|

Single |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power source |

|

|

|

|

|

|

V |

|

|

220/230/240 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hz |

|

|

50 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power consumption |

|

|

|

|

|

|

kW |

|

|

1.25/1.27/1.29 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power factor |

|

|

|

|

% |

|

|

98/97/95 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Running current |

|

|

|

|

|

|

A |

|

220V |

|

220V |

|

220V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indoor/Outdoor |

0.15/5.66 |

|

0.15/5.56 |

|

0.15/5.53 |

|||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Starting current |

|

|

|

|

|

|

A |

|

|

24 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Moisture removal |

|

|

|

|

|

|

lit/h |

|

|

2.0 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise |

Indoor (H/M/L) |

|

|

|

|

dB |

|

|

44/39/36 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor (220/230/240V) |

|

|

dB |

|

|

47/48/48 |

|

|

||||||

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Refrigerant |

Name of refrigerant |

|

|

|

|

|

|

|

|

R22 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated volume |

|

|

|

|

kg |

|

|

0.83 |

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Refrigerant control |

|

|

|

|

|

|

|

|

|

|

Capillary tube |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gas side size |

|

|

|

|

mm |

|

|

12.7 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Connection type |

|

|

|

|

|

|

|

|

Flare connection |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Liquid side size |

|

|

|

|

mm |

|

|

6.35 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Interconnection pipe |

Connection type |

|

|

|

|

|

|

|

|

Flare connection |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum length (of one way) |

|

|

m |

*2 |

|

15 |

|

|

||||||

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum height difference |

|

|

|

|

|

|

|

|

|

|

|||

|

Indoor unit |

|

|

|

|

|

|

|

6 |

|

|

|||

|

− |

|

|

m |

|

|

|

|

||||||

|

Outdoor unit |

↓ |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Condensate drain pipeOuter diameter |

|

|

|

|

mm |

|

|

16 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INDOOR UNIT |

|

|

|

|

|

|

|

|

|

RAS-13SK-E/RAS-13SKX |

||||

|

Height |

|

|

|

|

mm |

|

|

265 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions |

Width |

|

|

|

|

mm |

|

|

790 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Depth |

|

|

|

|

mm |

|

|

174 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Net weight |

|

|

|

|

|

|

kg |

|

|

8 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Evaporator type |

|

|

|

|

|

|

|

|

|

|

Finned tube |

|

|

|

Indoor fan type |

|

|

|

|

|

|

|

|

|

|

Cross flow fan |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

High fan |

|

|

|

|

m3/h |

|

|

650 |

|

|

|||

Air volume |

Medium fan |

|

|

|

|

m3/h |

|

|

560 |

|

|

|||

|

Low fan |

|

|

|

|

m3/h |

|

|

510 |

|

|

|||

Fan motor output |

|

|

|

|

|

|

W |

|

|

19 |

|

|

||

Air filter |

|

|

|

|

|

|

|

|

Polypropylene net filter (Washable) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUTDOOR UNIT |

|

|

|

|

|

|

|

|

|

RAS-13SA-E/RAS-13SAX |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Height |

|

|

|

|

mm |

|

|

538 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions |

Width |

|

|

|

|

mm |

|

|

780 |

|

|

|||

|

Depth |

|

|

|

|

mm |

|

|

300 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Net weight |

|

|

|

|

|

|

kg |

|

|

37 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Condenser type |

|

|

|

|

|

|

|

|

|

|

Finned tube |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor fan type |

|

|

|

|

|

|

|

|

|

|

Propeller |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Airflow volume |

|

|

|

|

|

|

m3/h |

|

|

1710/1800/1890 |

|

|||

Fan motor output |

(220/230/240V) |

|

|

|

|

W |

|

|

27 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Compressor |

Model |

|

|

|

|

|

|

|

|

PH160T2-4L2 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Output |

|

|

|

|

W |

|

|

1100 |

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Safety device |

|

|

|

|

|

|

|

|

|

|

Fuse, Overload relay |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Auto louver |

|

|

|

|

|

|

|

|

|

|

Yes |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Usable outdoor temperature range |

|

|

|

|

°C |

|

|

21 ~ 43 |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Specifications are subject to change without notice.

– 4 –

Note : *1

• Capacity is based on the following temperature conditions.

Condition |

JIS C9612-1994 |

Temperature |

Cooling |

(DB) |

27°C |

Indoor unit inlet air temperature |

|

(WB) |

19°C |

(DB) |

35°C |

Outdoor unit inlet air temperature |

|

(WB) |

24°C |

Notes : *2 CHARGELESS

•No additional refrigerant required.

•This air conditioner accepts a connection piping length of up to 15m and a head of up to 6m.

•There is no need to add the refrigerant as long as the total length of the connection piping is up to 15m.

– 5 –

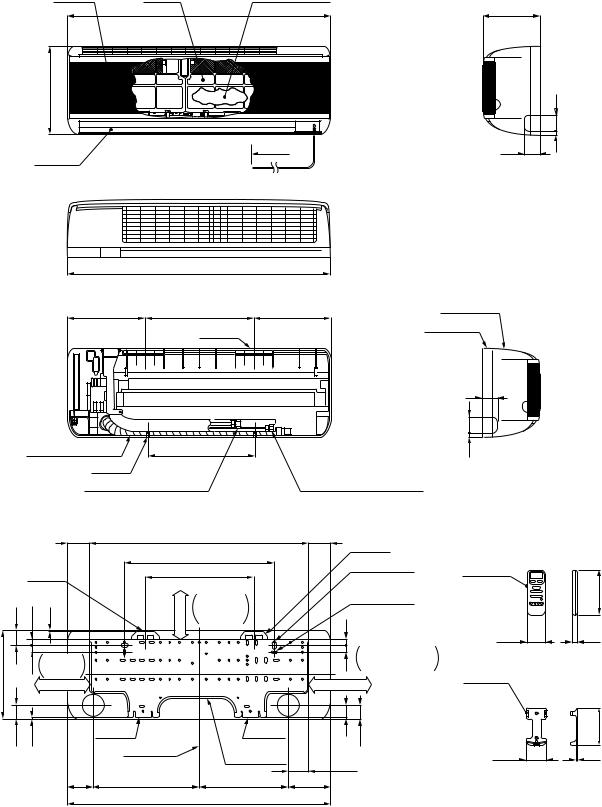

2. CONSTRUCTION VIEWS

2-1. Indoor Unit

RAS-13SK-E RAS-13SKX

Air inlet |

Air filter |

Heat exchanger |

|

790 |

174 |

265 |

АААААА€@@@@@@,,,,,,€€€€€ |

|

|

|

|

АААААА€@@@@@@,,,,,,€€€€€ |

|

|

50 |

|

|

|

|

|

|

1800 |

13SK-E : Without power cord |

47 |

10 |

Air outlet |

|

13SKX : With power cord |

|

|

Knock out system

|

790 |

|

|

232 |

326 |

232 |

Front panel |

|

|||

|

Hanger |

|

Back body |

|

|

|

|

|

47 |

|

|

50 |

Drain hose (0.54m) |

321 |

10 |

Hanger |

|

Knock out system |

|

|

|

Connecting pipe (0.39m) |

Connecting pipe (0.49m) |

|

|

(Flare ø12.7) |

(Flare ø6.35) |

|

|

65.5 |

|

659 |

65.5 |

Hanger |

Wireless |

|

|

|

|

450 |

|

||

|

|

|

|

|

For stud bolt |

remote |

|

|

Hanger |

|

326 |

|

control |

||

|

|

|

(ø8~ø10) |

||||

|

|

|

|

66 or more |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Minimum |

|

For stud bolt |

|

46 |

20 |

2.5 |

|

distance |

20 |

(ø6) |

|

|

to ceiling |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

55 |

|

|

Minimum |

|

|

20 |

Minimum |

Remote |

265 |

17 |

distance |

|

|

distance to wall |

control |

|

to wall |

|

|

|

holder |

|||

|

|

120 or more |

|

|

120 or more |

|

|

40.5 |

3.5 |

|

|

|

37 |

40.5 |

|

|

Hanger |

Hanger |

|

|

|||

|

|

|

|

|

|

||

|

|

|

Center line |

Installation |

|

|

59.6 |

|

|

|

plate outline |

|

|

||

|

|

|

|

60.5 |

|||

|

|

|

|

|

|||

|

|

|

|

|

|

||

|

|

76 |

319 |

269 |

126 |

|

|

|

|

|

|

790 |

|

|

|

136

16

112.8 5

– 6 –

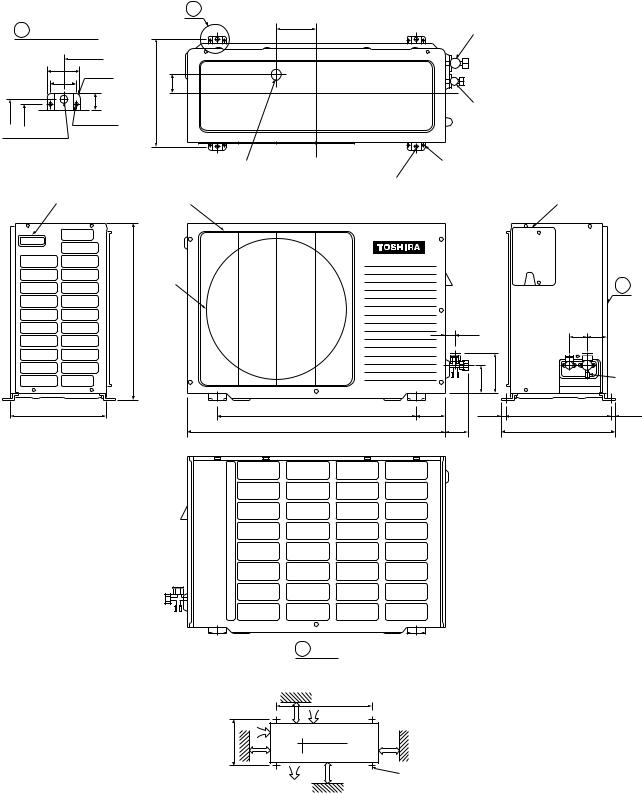

2-2. Outdoor Unit

RAS-13SA-E

RAS-13SAX

A Detail Drawing

|

|

|

600 |

|

|

50 |

R10 |

|

|

36 |

|

|

|

|

|

325 |

301 |

|

23 |

|

ø6 hole |

ø11x14 hole

Handle

A

|

|

|

120 |

|

|

|

Gas side (Flare ø12.7) |

325 |

52.5 |

|

Liquid side (Flare ø6.35) |

|

|

|

|

|

|

ø25Drain outlet |

8-ø6 hole ( (for fixing outdoor unit) |

|

|

|

|

|

|

|

6-ø11x14 hole (for ø8-ø10 anchor bolt) |

|

Fan guard |

|

Electric Parts cover |

538

300

ø420 |

, |

100 |

|

|

|

|

|

27 |

600 |

90 |

780 |

59 |

|

|

Z |

|

54 |

61 |

130 |

|

Service |

|

|

Port |

(8.5) |

325 (pitch) |

(8.5) |

|

342 |

|

|

Z View |

|

|

|

Installation dimension |

|

|

||

100 or more |

600 |

|

|

|

Air inlet |

600 or more |

|||

|

||||

325 |

|

|

|

|

100 or more |

600 or more |

4xø11x14 Long holes (for ø8-ø10 anchor bolt) |

||

Air outlet |

|

|

||

– 7 –

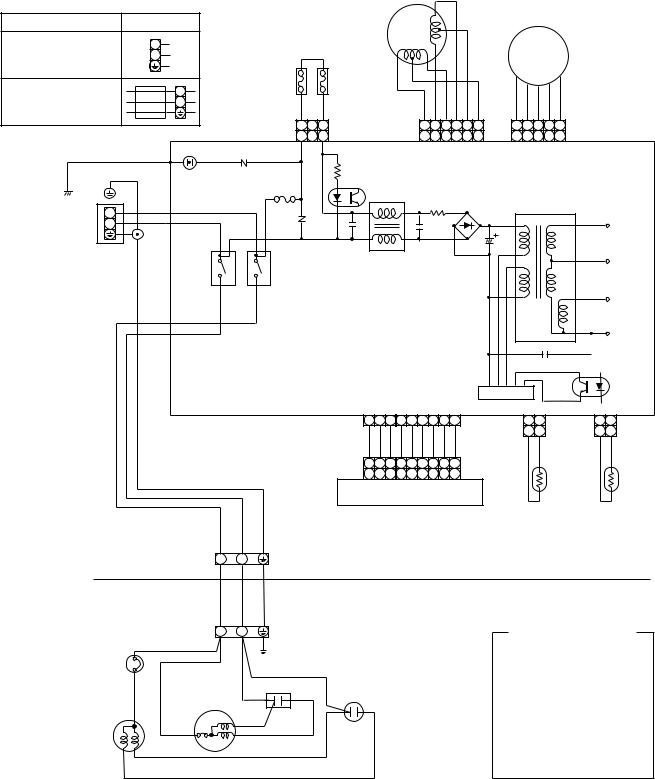

3. WIRING DIAGRAM

Model |

Section A |

|

RAS-13SK-E/SA-E |

L |

|

220/230/240V ~ |

N |

|

50Hz |

|

THERMAL FUSE |

|

|

|

RAS-13SKX/SAX |

L |

77˚C x 2 |

220/230/240V ~ |

N |

GRY |

|

||

50Hz |

|

|

1

1

BLK SG01 R109

GRN&YEL P04 DSA VARISTOR

F01 FUSE

|

LOUVER |

|

|

|

|

|

|

|

|

|

MOTOR |

|

|

|

|

|

DC |

|

FAN MOTOR |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

|

||

GRY |

|

BLU PNK YEL ORN RED BRW |

WHI BLU YEL BLK RED |

|

|||||

3 |

CN04 |

6 5 4 |

3 |

2 1 |

5 4 3 |

2 1 |

|

||

3 |

CN07 6 |

5 4 |

3 |

2 1 |

5 4 |

3 |

2 1 |

CN10 |

|

|

R116 |

|

|

|

|

|

MAIN P.C. BOARD |

||

|

|

|

|

|

|

|

MCC-713 |

||

|

IC04 |

|

|

|

|

|

|

|

|

|

L |

BRW |

T3.15A |

R01 |

DB01 |

T01 |

|

|

|||||

Section A |

N |

|

250V |

C01 |

C02 |

DC 35V |

BLU |

|

|||||

|

|

|

|

|

|

POWER |

|

3 |

|

3 R21 |

C15 |

L01 |

|

|

|

|

|

|

|

|

|

|

|

DC 12V |

||

TERMINAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

RY01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

BLOCK |

RY02 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DC 7V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

BLK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DC 0V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C06 |

|

IC02 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IC01 |

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 4 |

5 |

6 |

7 |

8 |

9 |

|

1 |

2 |

CN03 |

1 |

2 |

CN01 |

|

|

|

|

|

|

BLU BLU BLU BLU BLU BLU PNK BLK WHI |

CN13 |

1 |

2 |

|

|

1 |

2 |

|

|||||||

|

|

|

|

|

|

BLK BLK |

|

|

BLK BLK |

|

||||||||||

|

|

|

|

|

1 |

2 |

3 4 |

5 |

6 |

7 |

8 |

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 4 |

5 |

6 |

7 |

8 |

9 CN25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

INFRARED RAYS RECEIVE |

|

|

|

|

|

|

|

||||||||

|

TERMINALBLK |

WHI |

GRN&YEL |

AND INDICATION PARTS |

THERMO |

|

(TC) |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HEAT |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SENSOR |

EXCHANGER |

|||||

|

INDOOR |

|

|

|

|

|

|

|

|

|

|

|

|

(TA) |

|

|

SENSOR |

|||

|

BLOCK |

1 |

|

2 |

|

|

|

|

|

DSA : Surge absorber |

|

|

|

|

|

|||||

|

|

|

|

INDOOR |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

OUTDOOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUTDOOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TERMINAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BLOCK |

1 |

|

2 |

|

|

|

|

|

|

|

|

|

COLOR IDENTIFICATION |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

BLK |

|

|

GRN & YEL |

|

|

|

|

|

|

|

|

|

|

BRW : BROWN |

|

||||

OVER LOAD |

|

|

|

CHASSIS |

|

|

|

|

|

|

|

|

|

|

RED : RED |

|

|

|||

RELAY |

|

RED |

RED |

|

|

|

|

|

|

|

|

|

|

WHI : WHITE |

|

|

||||

|

|

CAPACITOR |

|

|

|

|

|

|

|

|

|

|

YEL : YELLOW |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

BLK BLK |

|

|

CAPACITOR |

|

|

|

|

|

|

|

BLU : BLUE |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

FAN MOTOR |

|

|

|

|

|

|

|

|

|

|

|

BLK : BLACK |

|

|

|||||

|

|

|

|

RED |

|

|

|

|

|

|

|

|

|

|

GRY : GRAY |

|

|

|||

COMPRESSOR |

|

|

|

WHI |

|

|

|

|

|

|

|

|

|

|

PNK : PINK |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ORN : ORANGE |

|

|||||

|

RED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

GRN&YEL : GREEN & |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

WHI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YELLOW |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 8 –

4. SPECIFICATIONS OF ELECTRICAL PARTS

4-1. Indoor Unit

RAS-13SK-E

RAS-13SKX

No. |

Parts name |

Type |

Specifications |

|

|

|

|

|

|

|

|

ICF-35-19-3 |

|

|

1 |

Fan motor (for indoor) |

or |

DC35V, 19W |

|

|

|

TICF-35-19-3 |

|

|

|

|

|

|

|

2 |

Thermo sensor |

(microprocessor) |

10kΩ at 25°C |

|

(TA-sensor) |

||||

|

|

|

||

|

|

|

|

|

3 |

DC-DC transformer (T01) |

SWT-34 |

DC390V, Secondary DC35V, 12V, 7V |

|

|

|

|

|

|

4 |

Microcomputer |

TMP87CK40F |

|

|

|

|

|

|

|

5 |

Power relay (RY01), |

DI1U |

Coil : DC12V 75mA, Rated AC250V 20A |

|

Common relay (RY02) |

||||

|

|

|

||

|

|

|

|

|

6 |

Heat exchanger sensor |

(microprocessor) |

10kΩ at 25°C |

|

(TC-sensor) |

||||

|

|

|

||

|

|

|

|

|

7 |

Line filter (L01) |

RF-103YOR6 |

10mH, AC 0.6A |

|

|

|

|

|

|

8 |

Diode (DB01) |

RBV-406 |

4A, 600V |

|

|

|

|

|

|

9 |

Capacitor (C02) |

CEAUF2W101M20 |

100μF, 450V |

|

|

|

|

|

|

10 |

Fuse (F01) |

MT3 |

T3.15A, 250V |

|

|

|

|

|

|

11 |

Power supply IC (IC01) |

MA2830-FJ |

4A, 600V |

|

|

|

|

|

|

12 |

Varistor (R21, R109) |

15G561K |

560V |

|

|

|

|

|

|

13 |

Resistor (R01) |

ERF-5TK5R6 |

5.6 Ω, 5W |

|

|

|

|

|

|

14 |

Louver motor |

MP35EA7 |

Output (Rated) 2W, 10poles, 1phase, DC12V |

|

|

|

|

|

4-2. Outdoor Unit

RAS-13SA-E

RAS-13SAX

No. |

Parts name |

Type |

Specifications |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Output (Rated) 1100W, 2pole, 1phase, 220/230/240V, 50Hz |

|||

|

|

|

|

|

|

|

|

1 |

|

Compressor |

PH160T2-4L2 |

Ω |

) |

Red-Black |

White-Black |

|

|

|

|

Winding resistance ( |

|

|

|

|

|

|

|

(at 20°C) |

|

2.38 |

3.65 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Output (Rated) 27W, 6pole, 1phase, 220/230/240V, 50Hz |

|||

|

|

|

|

|

|

|

|

2 |

|

Fan motor (for outdoor) |

UE6-31C5P |

Ω |

) |

Red-Black |

White-Black |

|

|

|

|

Winding resistance ( |

|

|

|

|

|

|

|

(at 20°C) |

|

210 |

435 |

|

|

|

|

|

|

|

|

3 |

|

Running capacitor |

SK-50FMP |

500V AC, 1.5μF |

|

|

|

|

(for fan motor) |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

Running capacitor |

SK-40CMP35U1 |

400V AC, 35μF |

|

|

|

|

(for compressor) |

|

|

|

|||

|

|

|

|

|

|

|

|

5 |

|

Overload relay |

J-MRA99253-9200 |

U/T 10.1A (80°C), OPEN 135±5°C, CLOSE 75±11°C |

|||

|

|

|

|

|

|

|

|

– 9 –

5. REFRIGERANT CYCLE DIAGRAM

RAS-13SK-E / RAS-13SA-E

RAS-13SKX / RAS-13SAX

Auxiliary pipe 0.39m

ø9.52 (ø3/8 in)

Connecting pipe ø12.7 (O.D.) (ø1/2 in)

P

T1

Indoor unit |

Evaporator |

Cross flow fan |

Auxiliary pipe 0.49m

ø6.35 (ø1/4 in)

Connecting pipe ø6.35 (O.D.) (ø1/4 in)

Allowable height 6m

Max. longth 15m

Accumulator |

|

Capillary tube |

|

|

|

|

|

||

|

|

|

ø1.7 x 900 |

|

Compressor PH160T2-4L2 |

|

|

|

|

|

|

|

Dryer |

|

|

Condenser |

|

|

|

|

Propeller fan |

|

|

|

|

|

|

Refrigerant |

|

|

|

|

R22 |

0.83kg |

Cooling |

Outdoor unit |

Mark ( |

) means check points of Gas Leak |

|

Fig. 5-1

Table 5-1

|

|

Standard pressure |

Surface temp. of heat |

|

Ambient temp. |

||||||

|

|

|

P |

|

exchanger interchanging |

|

|||||

|

|

|

|

Fan speed |

conditions DB/WB |

||||||

|

|

|

|

|

|

|

|

||||

|

50Hz |

(kg/cm²G) |

pipe |

T1 |

(°C) |

||||||

|

(indoor) |

|

(°C) |

||||||||

|

|

13SK-E |

13SK-E |

|

|||||||

|

|

|

|

|

|

||||||

|

|

13SKX |

13SKX |

|

Indoor |

|

Outdoor |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Standard |

5.0 |

10.0 |

|

High |

27/19 |

|

35/24 |

|||

|

|

|

|

|

|

|

|

|

|||

Cooling |

High temperature |

6.0 |

15.0 |

|

High |

32/23 |

|

43/26 |

|||

|

|

|

|

|

|

|

|

|

|||

|

Low temperature |

3.0 |

2.0 |

|

Low |

21/15 |

|

21/15 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

Note :

•Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.)

–10 –

– 11 –

Heat Exchanger Sensor

Thermo Sensor

Infrared Rays Signal Receiver

Infrared

Rays

Remote Control

Operation (START/STOP)

Operation Mode Selection

AUTO, COOL, DRY, FAN ONLY

Thermo Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver AUTO Swing

Louver Direction Setting

ECONO.

220/230/240V~

50Hz

Main Unit Control Panel |

C. P. U |

Functions

• Louver Control

• 3-minute Delay at Restart for Compressor

Initializing Circuit |

• Motor Revolution Control |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clock Frequency |

• Processing |

|

|

|

|

|||

Oscillator Circuit |

|

|

|

|

||||

(Temperature Processing) |

|

|

|

|

||||

|

|

|

|

|

|

|

||

|

|

|

• Timer |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power Supply |

|

Compressor, Outdoor Fan |

Louver |

|

|

|||

Circuit |

|

ON/OFF Signal |

ON/OFF Signal |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise Filter |

|

|

Relay Driver, Louver Driver |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Relay

RY01

Relay

RY02

Compressor |

|

Outdoor Fan Motor |

|

|

|

Operation

Display

Timer

Display

ECONO.

Sign Display

FAN-ONLY

Sign Display

Indoor

Fan Motor

Louver

Motor

DIAGRAM BLOCK COMPUTER-MICRO .6

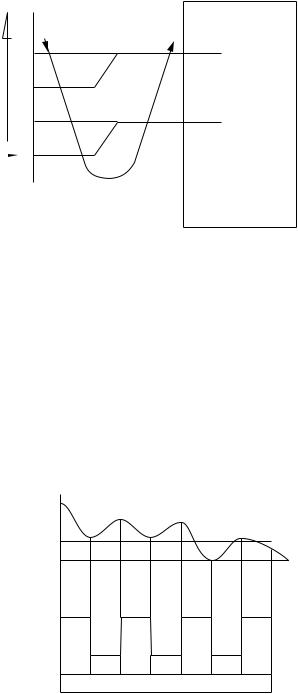

7. OPERATION DESCRIPTIONS

7-1. FAN ONLY Operation

(MODE of the remote control : FAN ONLY)

(1)During this mode, the relay RY01 is always turned off so that only the indoor fan is operated. RY02 is always turnd on.

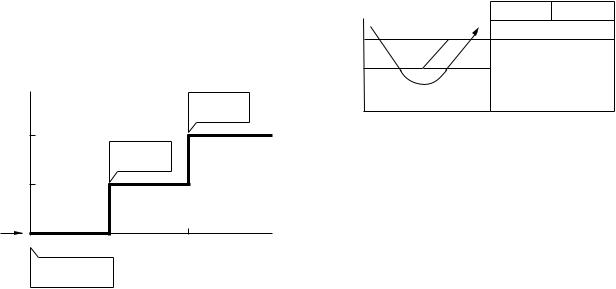

1)When the FAN is set to AUTO, the indoor fan motor operates as shown in Fig 7-1-1.

2)When the FAN is set to LOW, MED, or HIGH, the indoor fan motor operates with a constant in volume as listed in Table 7-1-1.

temp. |

28 |

|

|

|

|

||

Room |

27 |

HIGH |

|

|

|||

26 |

MED |

||

|

|||

|

LOW(+) |

||

|

25 |

||

|

|

||

|

24 |

LOW |

|

|

LOW |

||

|

|

||

|

|

|

Fig. 7-1-1 Auto setting of air volume

Table 7-1-1 Manual setting of FAN SPEED

Indication of |

HIGH Air volume |

FAN SPEED |

(m3/h) |

|

|

LOW |

510 |

|

|

MED |

560 |

|

|

HIGH |

650 |

|

|

(2)Once the setting is made, the operation mode is memorized in the microcomputer so that the same operation can be effected thereafter simply by

pushing the START/STOP button.

7-2. COOL Operation

(MODE of the remote control : COOL)

(1)Compressor, outdoor fan and operation display are controlled as shown in Fig. 7-2-1.

temp.) |

|

ON |

|

|

|

|

|

|

|||

Set– |

+1 |

|

|

||

|

|

|

|||

|

|

|

|

|

|

temp. |

|

OFF |

ON |

ON |

|

|

|

|

|||

(Room |

|

|

|

||

|

|

|

|

||

Set |

|

0 |

|

|

|

|

|

|

|

||

temp. |

|

Compressor Outdoor fan (RY01) |

Common relay (RY02) |

OPERATION display |

|

|

|

|

|||

|

|

|

|

|

|

Fig. 7-2-1

(2)Relays RY01 and RY02 are turned on to energize the outdoor unit, and a cool operation is carried out.

1)When the FAN is set to AUTO, the indoor fan motor operates as shown in Fig 7-2-2.

2)When the FAN is set to LOW, MED, or HIGH, the indoor fan motor operates with a constant in volume as listed in Table 7-1-1.

|

|

|

|

FAN |

|

temp.) |

|

|

|

|

|

|

|

AUTO |

Manual |

||

|

|

|

|

||

Set– |

+4 |

|

HIGH |

|

|

|

MED |

|

|||

|

|

|

|

|

|

temp. |

+3 |

|

LOW(+) |

to the set |

|

|

|

|

|

|

According |

(Room |

+2 |

|

|

position |

|

|

|

LOW |

|||

+1 |

|

|

|||

|

|

|

|

||

|

|

|

|

|

|

Set |

|

0 |

|

LOW |

|

|

|

(continuous) |

|

||

|

|

||||

temp. |

|

|

|

|

|

|

RY01 |

|

|||

|

|

|

|

||

|

|

|

OFF |

|

|

Fig. 7-2-2

(3)Once the setting is made, the operation mode is memorized in the microcomputer so that the same operation can be effected thereafter simply by pushing the START/STOP button.

– 12 –

7-2-1. Louver Control

(1)By pushing the SET button of the remote control during the operation, the louver can be set to the desired position.

And the louver position is stored in the microcomputer, the louvers will be set to the position automatically at the next operation.

(2)When the AUTO button is pushed, the louver vertically swings within range of 25deg.

7-3. DRY Operation

(MODE of the remote control : DRY)

(1)Compressor, outdoor fan and operation display are controlled as shown in Fig. 7-3-1.

temp.) |

+3 |

ON:6min. |

OFF:4min. |

|

|

||

temp.– Set |

ON:5min. |

OFF:5min. |

|

|

|||

+2 |

ON |

ON |

|||||

(Room |

|

|

|||||

+1 |

OFF |

|

|

||||

|

|

|

|

|

|

||

Set |

|

0 |

|

|

|

|

|

temp. |

|

Compressor fanOutdoor (RY01) |

relayCommon (RY02) |

OPERATION display |

|||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Fig. 7-3-1

•The microprocessor turns the compressor on and off at regular intervals (4 to 6 minutes on and/or off). During the compressor off, the indoor fan will operate in the super low position.

•The indoor fan will operate in the AUTO position.

(2)The pattern of operation depending on the relation between room temperature and set temperature is shown below:

Room temp.

Set temp.+1

Set temp.

Compressor |

ON |

ON |

|

ON |

|

ON |

|

|

|

|

|

|

|

|

|

Outdoor fan |

|

OFF |

|

OFF |

OFF |

||

|

|

|

|||||

Indoor fan |

|

|

|

|

|

|

|

L. |

*S.L. |

L. |

S.L. |

L. |

S.L. |

L. |

|

|

*Super Low |

|

|

|

|

|

|

Fig. 7-3-2

– 13 –

7-4. AUTO Operation

(MODE of the remote control : AUTO)

(1)One of the 2 modes, Cooling or Dry is selected according to room temperature at which operation is to start, as shown in Fig. 7-4-1. The Fan mode will continue until room temperature reaches a level at which another mode is selected.

7-4-1. Temporary Auto

When theTEMPORARY button is pushed, the set temperature is fixed at 24°C and controlled in accordance with the chart shown in Fig. 7-4-1.

(Room temp. – Set temp.)

|

Cooling mode |

(The same cooling mode as the room temperature control is set at set temp.) |

|

|

|

The Louver moved downward. |

|

+4 |

|

|

|

Cooling mode |

(The same cooling mode as the room temperature control is set at set temp. ) |

||

|

|||

+1 |

|

|

|

Dry mode |

(The same dry operation as the room temperature control is set at set temp. ) |

||

|

|||

|

|

|

Fig. 7-4-1

– 14 –

7-5. ECONO. Mode

When the ECONO. button is pushed, during COOL , and AUTO operation, the OPERATION display is turned off and the ECONO. display is lit and the indoor unit operates quietly and mildly with controlling airflow.

7-5-1. Cooling

(1)In the ECONO. mode, the set temp. by the remote control is changed automatically as shown in Fig. 7-5-1.

(2)Fan speed → LOW

(˚C) |

|

|

|

|

|

|

|

Set temp. |

|

|

|

|

is changed |

|

+2 |

|

|

|

|

|

|

Set temp. |

|

|

|

|

is changed |

|

|

+1 |

|

|

|

|

Set temp. |

0H |

1H |

2H |

TIME |

ECONO. button is pushed

Fig. 7-5-1

7-6. Low-Temperature Limit Control

(Cooling Operation)

The microprocessor detects the indoor heat exchanger temperature so as to prevent freezing up the indoor heat exchanger.

Control is performed as shown in Fig. 7-6-1.

Heat exchanger |

|

temperature |

Compressor Outdoor fan |

|

(˚C) |

ON |

|

6 |

||

Less than 2˚C continues |

||

|

||

2 |

for 5 minutes |

|

OFF |

Fig. 7-6-1

– 15 –

7-7. Auto Restart Function |

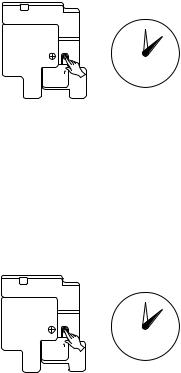

7-7-1. How to Set the Auto Restart |

This unit is equipped with an Automatic restarting facility which allows the unit to restart and resume the set operating conditions in the event of a power supply shutdown without the use of the hand control.

The operation will resume without warning three minutes after the power is restored.

The Auto Restart function is set not to work on shipment from the factory, and so it is necessary to set it to function as required.

• When the system is stand-by (not running)

To set the Auto Restart function, proceed as follows: Access the TEMPORARY button located in the lower right hand corner beneath the hinged front panel of the indoor unit (please refer to section on PARTS NAME). The power supply to the unit must be on - the function will not be set if the power is off.

To enable the Auto Restart function, press the TEMPORARY button continuously for three seconds. The unit will acknowledge the setting and beep three times. The system will now restart automatically.

The above Auto Restart settings can be carried out:

OPERATION |

|

MOTION |

|

|

|

|

|

Press the TEMPORARY button |

Stand-by |

|

|

continuously more than three |

↓ |

|

|

seconds. |

The system starts to operate. |

The green light will be lit. |

|

|

|

||

|

|

↓ about three seconds after |

|

0 |

The unit beeps three times. |

The orange light will be lit. |

|

|

3S |

↓ |

|

|

|

|

|

TEMPORARY |

The system is operating. |

The orange light is lighting. |

|

|

|

||

|

|

If the system is not required to run at this time, press the TEMPORARY |

|

|

|

button once more or use the remote control to stop it. |

|

|

|

|

|

• When the system is operating |

|

|

|

|

|

|

|

OPERATION |

|

MOTION |

|

|

|

|

|

Press the TEMPORARY button |

Operating |

The green light is lit. |

|

continuously more than three |

↓ |

|

|

seconds. |

The system stops to operate. |

The green light is turned off. |

|

|

|

||

|

|

↓ about three seconds after |

|

0 |

The unit beeps three times. |

|

|

|

3S |

↓ |

|

|

|

|

|

|

|

The system stops. |

|

TEMPORARY |

|

|

|

|

|

If the system is not required to stop at this time, use the remote control |

|

|

|

||

|

|

to restart it. |

|

|

|

|

|

During subsequent operation, the orange light is lit.

•The Auto Restart function will not accept an instruction if timer operation with the remote control is selected.

(Please refer to the section on setting the timer or setting the louver.)

•During louver swing (AUTO) operation, after restart by the Auto Restart function the louver swing stops.

– 16 –

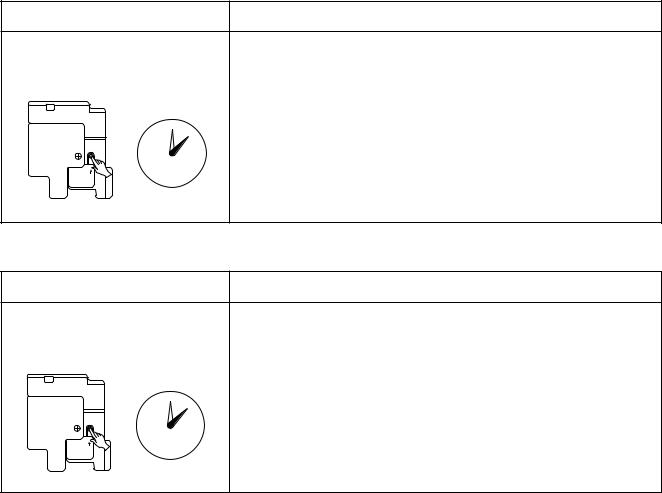

7-7-2. How to Cancel the Auto Restart

To cancel the Auto Restart function, proceed as follows:

Repeat the setting procedure: the unit will acknowledge the instruction and bleep three times.

• When the system is stand-by (not running)

The system will now be required to manually restart with the remote control after the main supply is turned off.

Cancellation is carried out:

OPERATION |

|

MOTION |

|

Press the TEMPORARY button |

Stand-by |

|

|

continuously more than three |

↓ |

|

|

seconds. |

The system starts to operate. |

The orange light will be lit. |

|

|

|||

|

↓ about three seconds after |

||

0 |

The unit beeps three times. |

The green light will be lit. |

|

3S |

|||

|

|

||

|

↓ |

|

|

TEMPORARY |

The system is operating. |

|

|

|

If the system is not required to run at this time, press the TEMPORARY |

||

|

button once more or use the remote control to stop it. |

||

• When the system is operating |

|

|

|

OPERATION |

|

MOTION |

|

Press the TEMPORARY button |

Operating |

The orange light is lit. |

|

continuously more than three |

↓ |

|

|

seconds. |

The system stops to operate. |

The orange light is turned off. |

|

|

|||

|

↓ about three seconds after |

||

0 |

The unit beeps three times. |

|

|

|

|

||

3S |

↓ |

|

|

|

|

||

TEMPORARY |

The system stops. |

|

|

|

|

||

|

If the system is not required to stop at this time, use the remote control |

||

|

to restart it. |

|

|

During subsequent operation, the green light is lighting.

7-7-3. In Case of Power Failure during the Timer Operation

(1)If ON-TIMER operation is reserved with setting of Auto Restart operation, it is cancelled with power failure. (The OPERATION lamp on the main unit goes on and off to inform of power failure.) In that case, try to reserve ON-TIMER operation once again.

(2)If OFF-TIMER operation is reserved without setting of Auto Restart operation, the reservation is cancelled with power failure. (The OPERATION lamp on the main unit goes on and off to inform of power failure.) In that case, try to reserve OFFTIMER operation. When Auto Restart operation is set, OFF-TIMER reservation is also cancelled with power failure.

– 17 –

Loading...

Loading...