Toshiba RAS-13NKH-AS2 SERVICE MANUAL

FILE NO. SVM-06027

SERVICE MANUAL

AIR CONDITIONER

SPLIT WALL TYPE

RAS-13GKHP-ES2 / RAS-13GAH-ES2 RAS-13GKP-ES2 / RAS-13GA-ES2 RAS-13NKHP-AS2 / RAS-13N2AH-AS2 RAS-13NKP-AS2 / RAS-13N2A-AS2

May, 2006

FILE NO. SVM-06027

CONTENTS

1.SPECIFICATIONS

2.CONSTRUCTION VIEWS

2-1 Indoor Unit

2-2 Outdoor Unit

3.WIRING DIAGRAM

3-1 RAS-13GKHP-ES2 / RAS-13GAH-ES2 3-2 RAS-13GKP-ES2 / RAS-13GA-ES2 3-3 RAS-13NKHP-AS2 / RAS-13N2AH-AS2 3-4 RAS-13NKP-AS2 / RAS-13N2A-AS2

4.SPECIFICATION OF ELECTRICAL PARTS

4-1 Indoor Unit (RAS-13GKHP-ES2, RAS-13NKHP-AS2) 4-2 Outdoor Unit (RAS-13GAH-ES2,RAS-13N2AH-AS2)

4-3 Indoor Unit (RAS-13GKP-ES2,RAS-13NKP-AS2) 4-4 Outdoor Unit (RAS-13GA-ES2,RAS-13N2A-AS2)

5.REFRIGERATION CYCLE DIAGRAM

5-1 RAS-13GKHP-ES2 / RAS-13GAH-ES2 RAS-13NKHP-AS2 / RAS-13N2AH-AS2

5-2 RAS-13GKP-ES2 / RAS-13GA-ES2 RAS-13NKP-AS2 / RAS-13N2A-AS2

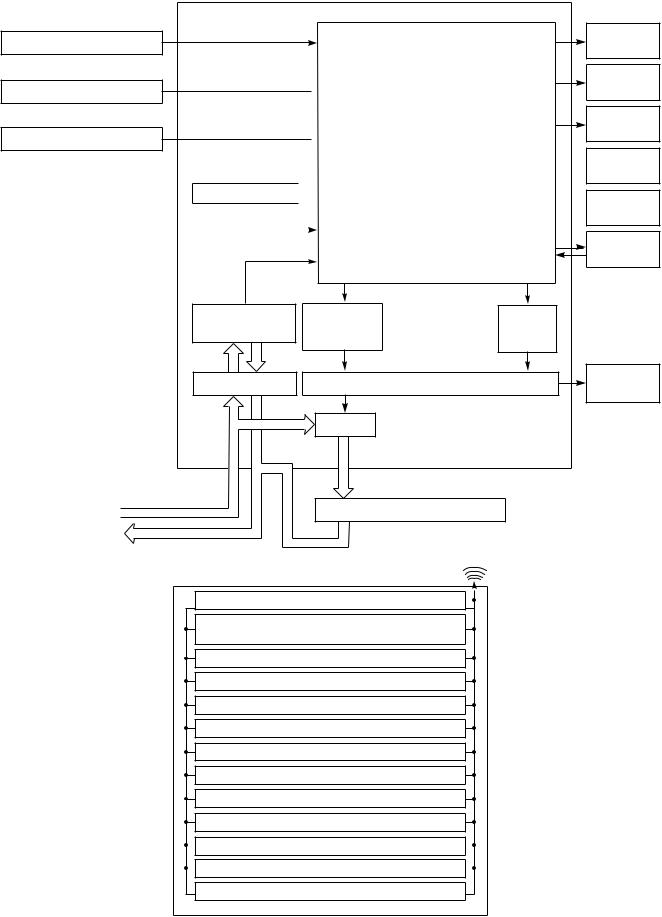

6.CONTROL BLOCK DIAGRAM

6-1 RAS-13GKHP-ES2 / RAS-13GAH-ES2, RAS-13NKHP-AS2 / RAS-13N2AH-AS2

6-2 RAS-13GKP-ES2 / RAS-13GA-ES2, RAS-13NKP-AS2 / RAS-13N2A-AS2

7.OPERATION DESCRIPTION

7-1 Outline of Air Conditioner Control

7-2 Description of Operation Circuit

7-3 Hi POWER Mode

7-4 High-Temperature Limit Control

7-5 Low-Temperature Limit Control

7-6 Defrost Operation

7-7 Current Limit Control

7-8 Auto Restart Function

7-9 Filter Check Lamp

7-10 Self-Cleaning function

7-11 QUIET Mode

7-12 COMFORT SLEEP mode

− 1 −

FILE NO. SVM-06027

8.INSTALLATION PROCEDURE

8-1 Safety Cautions

8-2 Installation Diagram of Indoor and Outdoor Units 8-3 Installation

8-4 Indoor Unit

8-5 Outdoor Unit

8-6 How to Set Remote Control Selector Switch 8-7 Others

9.TROUBLESHOOTING CHART

9-1 Troubleshooting Procedure

9-2 Basic Check Items

9-3 Primary Judgement

9-4 Self-Diagnosis by Remote Control (Check Code) 9-5 Troubleshooting Flowcharts

9-6 Troubleshooting for Remote Control (Including The Indoor P.C. Board)

10.PARTS REPLACEMENT

10-1 Indoor Unit

10-2 Outdoor Unit

11.EXPLODED VIEWS AND PARTS LIST

11-1 Indoor Unit (E-Parts Assy) (For RAS-13GKHP-ES2) 11-2 Indoor Unit (E-Parts Assy) (For RAS-13NKHP-AS2) 11-3 Indoor Unit (E-Parts Assy) (For RAS-13GKP-ES2)

11-4 Indoor Unit (E-Parts Assy) (For RAS-13NKP-AS2) 11-5 Indoor Unit

11-6 Outdoor Unit (RAS-13GAH-ES2,RAS-13N2AH-AS2) 11-7 Outdoor Unit (RAS-13GA-ES2,RAS-13N2A-AS2)

∙ This air conditioner is charged with

HFC (R410A) that doesn't deplete the Ozone layer.

∙ This air conditioner requires special installation for the refrigerant R410A.

− 2 −

FILE NO. SVM-06027

1. SPECIFICATIONS

|

MODEL |

|

RAS-13GKHP-ES2 / RAS-13GAH-ES2 |

|

RAS-13GKP-ES2 / RAS-13GA-ES2 |

|||

|

|

RAS-13NKHP-AS2 / RAS-13N2AH-AS2 |

RAS-13NKP-AS2 / RAS-13N2A-AS2 |

|||||

|

|

|

||||||

ITEM |

|

|

Cooling |

Heating |

|

|

Cooling |

|

Capacity |

|

220V |

240V |

220V |

240V |

220V |

240V |

|

kW |

3.74 |

3.82 |

4.20 |

4.26 |

3.75 |

3.75 |

||

|

||||||||

|

Phase |

|

|

1 |

|

|

|

|

Power source |

V |

|

|

220 − 240 |

|

|

|

|

|

Hz |

|

|

50 |

|

|

|

|

Power consumption |

kW |

1.15 |

|

1.19 |

|

1.14 |

|

1.18 |

1.13 |

|

1.17 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power factor |

|

% |

98 |

|

96 |

|

96 |

|

95 |

98 |

|

97 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Running |

Indoor |

A |

|

|

|

|

|

0.15 |

|

|

|

|

|

||

current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor |

A |

5.20 |

|

5.00 |

|

5.27 |

|

5.18 |

5.10 |

|

4.90 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Starting current |

A |

|

|

|

30 |

|

|

|

26 |

|

|||||

Moisture removal |

lit/h |

|

|

|

|

|

2.0 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise |

Indoor (H/M/L) |

dB |

|

|

|

|

|

41/35/31 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Outdoor (220-240V) |

dB |

50 |

|

51 |

|

50 |

|

51 |

50 |

|

51 |

|

|||

|

|

|

|

|

|

|

|||||||||

Refrigerant |

Name of refrigerant |

|

|

|

|

|

|

R410A |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Rated amount |

kg |

|

|

|

|

|

1.08 |

|

0.98 |

|

|||||

|

|

|

|

|

|

|

|

|

|||||||

Refrigerant control |

|

|

|

|

|

Capillary tube |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gas side size |

mm |

|

|

|

|

|

12.7 |

|

|

|

|

|

|

|

|

Connection type |

|

|

|

|

|

Flare connection |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Liquid side size |

mm |

|

|

|

|

|

6.35 |

|

|

|

|

|

|

Interconnection |

Connection type |

|

|

|

|

|

Flare connection |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pipe |

Maximum length |

m |

|

|

|

|

|

15*1 |

|

|

|

|

|

||

(One way) |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

Maximum height |

m |

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

difference |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INDOOR UNIT |

|

|

|

|

RAS-13GKHP-ES2 |

|

|

RAS-13GKP-ES2 |

|

||||||

|

|

|

|

RAS-13NKHP-AS2 |

|

|

RAS-13NKP-AS2 |

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

Height |

mm |

|

|

|

|

|

275 |

|

|

|

|

|

|

Dimensions |

Width |

mm |

|

|

|

|

|

790 |

|

|

|

|

|

||

|

|

Depth |

mm |

|

|

|

|

|

218 |

|

|

|

|

|

|

Net weight |

|

kg |

|

|

|

|

|

10 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Evaporator type |

|

|

|

|

|

Finned tube |

|

|

|

|

|

||||

Indoor fan type |

|

|

|

|

|

|

Cross flow fan |

|

|

|

|

|

|||

|

|

High fan |

m3/h |

630 |

|

|

|

650 |

|

630 |

|

||||

Airflow volume |

Medium fan |

m3/h |

520 |

|

|

|

550 |

|

520 |

|

|||||

|

|

Low fan |

m3/h |

430 |

|

|

|

490 |

|

430 |

|

||||

Fan motor output |

W |

|

|

|

|

|

20 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air filter |

|

|

|

|

|

Honeycomb woven filter with PP frame |

|

|

|

|

|||||

OUTDOOR UNIT |

|

RAS-13GAH-ES2,RAS-13N2AH-AS2 |

RAS-13GA-ES2,RAS-13N2A-AS2 |

|

|||||||||||

|

|

Height |

mm |

|

|

|

|

|

550 |

|

|

|

|

|

|

Dimensions |

Width |

mm |

|

|

|

|

|

780 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Depth |

mm |

|

|

|

|

|

290 |

|

|

|

|

|

|

Net weight |

|

kg |

|

|

|

39 |

|

|

|

|

38 |

|

|||

Condenser type |

|

|

|

|

|

Finned tube |

|

|

|

|

|

||||

Outdoor fan type |

|

|

|

|

|

Propeller fan |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Airflow volume |

|

m3/h |

2120 |

|

2200 |

|

2120 |

|

2200 |

2030 |

|

2150 |

|

||

Fan motor output |

W |

|

|

|

42 |

|

|

|

30 |

|

|||||

Compressor |

|

Model |

|

|

|

|

|

PA150X2C-4FT |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Output |

W |

|

|

|

|

|

1100 |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

Safety device |

|

|

|

|

|

|

Fuse, Overload relay |

|

|

|

|

|

|||

Louver type |

|

|

|

|

|

|

Automatic louver |

|

|

|

|

|

|||

Usable outdoor temperature range |

°C |

15 ~ 43 |

|

|

|

−10 ~ 24 |

|

15 ~ 43 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

− 3 −

FILE NO. SVM-06027

Note : 1

∙ Capacity is based on the following temperature conditions.

Temperature |

Condition |

|

JIS B8615-1 |

|

|

Cooling |

Heating |

||

Indoor unit inlet air temperature |

(DB) |

27°C |

20°C |

|

(WB) |

19°C |

15°C |

||

|

||||

Outdoor unit inlet air temperature |

(DB) |

35°C |

7°C |

|

(WB) |

24°C |

6°C |

||

|

||||

Note : 2 |

|

|

|

*1 No need to charge extra refrigerant.

− 4 −

2. CONSTRUCTION VIEWS

2-1. Indoor Unit

− 5 −

|

|

|

|

|

|

|

|

FILE NO. SVM-06027 |

|||

|

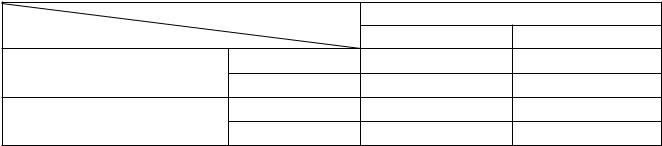

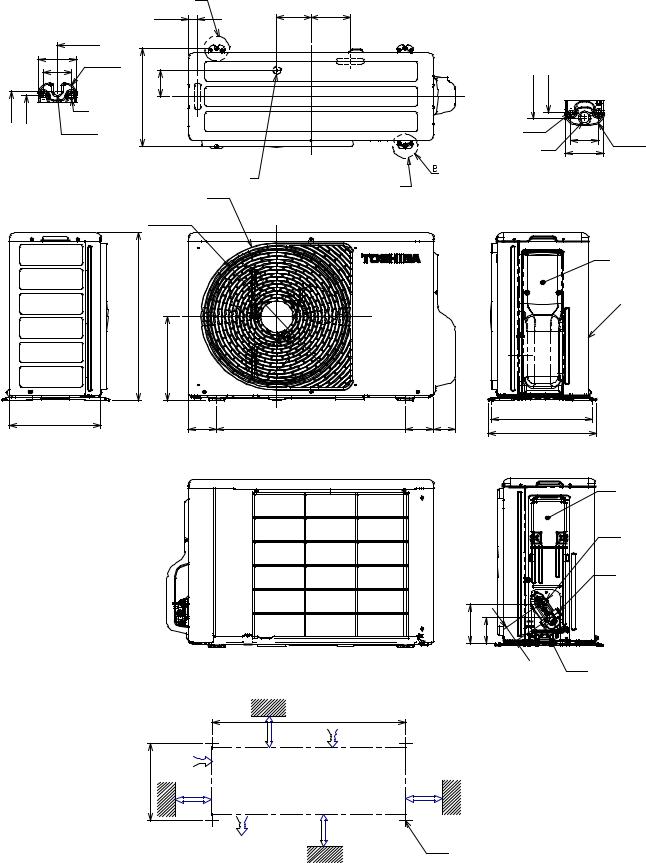

2.2. Outdoor Unit |

|

|

|

|

|

|

|

|||

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

28 |

109 |

124 |

|

|

|

|

|

|

|

|

600 |

|

|

|

|

|

|

|

|

|

|

50 |

R15 |

|

|

|

|

|

|

|

|

|

|

36 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

307 |

|

|

|

|

|

|

321 |

86 |

|

|

|

321 |

|

|

|

321 |

307 |

|

Ø6 hole |

|

|

|

|

|

|

|

|

|

R5.5 |

|

|

|

|

Ø6 hole |

|

|

|

||

|

|

|

|

|

|

|

|

36 |

R15 |

||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Ø11x14 hole |

|||

A detail Drawing (Back leg) |

|

|

|

|

50 |

|

|||||

Ø25 Drain outlet |

2- Ø11 x 14 |

Hole |

|

|

|

|

|||||

|

|

|

|

B Detail Drawing (Front leg) |

|||||||

|

|

|

|

|

(For Ø8 -Ø10 anchor bolt) |

|

|

|

|

||

550 |

290 |

FAN-GUARD |

|

|

|

Ø 436 |

|

|

|

275 |

|

|

|

90 |

600 |

90 |

69 |

321 |

342 |

COVER-PV

Z

|

|

Electrical part cover |

|

|

Liquid side |

|

|

(Flare Ø6.35) |

|

|

Gas side |

|

|

(Flare Ø12.7) |

129 |

84 |

5 |

4 |

|

Z View |

Service port |

|

600 |

|

100 or more |

|

Air intlel |

|

|

600 or more |

321 |

|

|

100 or more |

Air outlel |

600 or more |

|

|

|

|

|

4x Ø11 Long holes(For Ø8Ø10 anchor bolt) |

− 6 −

FILE NO. SVM-06027

3. WIRING DIAGRAM

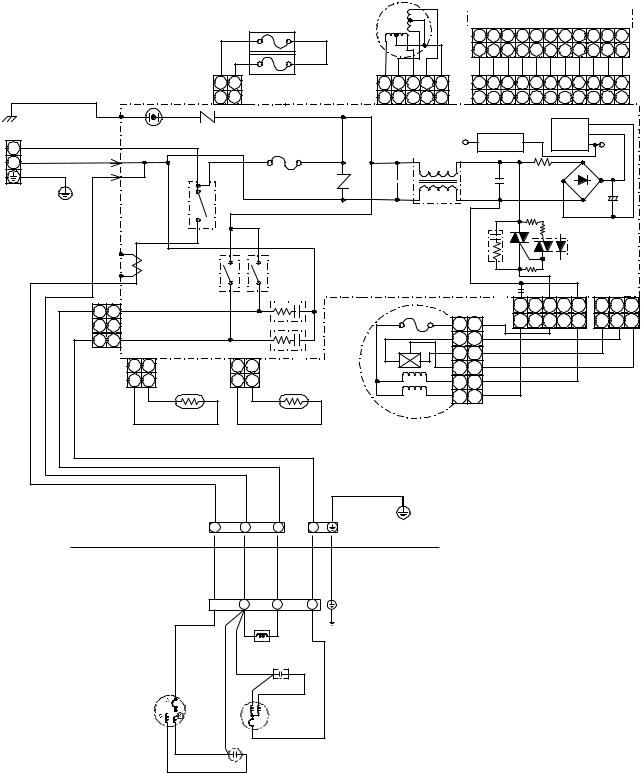

3-1. RAS-13GKHP-ES2 / RAS-13GAH-ES2

|

|

|

|

|

73°Cx2 |

|

|

|

|

|

THERMAL FUSE |

|

|

|

PNK |

PNK |

|

|

|

|

|

1 |

2 |

|

|

|

|

1 |

2 |

|

|

BLK |

|

|

CN04 |

|

|

P04 |

|

|

|

|

|

SG01 |

R22 |

|

|

L |

BRW(L) |

DSA |

VARISTOR |

T6.3A 250VAC |

|

|

|

|

FUSE F01 |

||

N |

BLU(N) |

|

|

|

|

|

GRN & YEL |

|

3 |

|

|

|

|

|

|

|

|

SINGLE PHASE |

|

RY01 |

|||

220-240V~, 50Hz |

|

||||

|

|

|

|

||

Louver |

|

|

|

|

Motor |

|

|

|

|

YEL |

YEL |

YEL |

YEL |

WHI |

5 |

4 |

3 |

2 |

1 |

5 |

4 |

3 |

2 |

1 |

|

CN07 |

|

|

|

INFRARED RAYS RECEIVE

AND INDICATION PARTS

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

CN25 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

WHI |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

|

|

|

|

|

|

|

|

|

|

CN14 |

VARISTOR

R21

C01

|

DC5V |

|

|

Micro |

|

|

Voltage |

|

Power |

|

|

|

|

|

Module |

|

|

|

|

Regulator |

|

DC12V |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

C02 |

R319 |

|

|

|

|

|

|

+ |

|

|

|

|

|

|

|

L01 |

|

IC03 |

R26 |

DB01 |

C63 |

|

|

|

|||

|

|

|

|

|

|

|

|

BLK |

4 |

|

|

|

|

|

|

|

T02 |

|

|

|

|

|

C.T. |

|

|

|

RY03 |

1 |

1 |

|

|

|

|

3 |

3 |

|

|

|

|

CN27 |

CN03 |

|

|

||

|

|

1 |

2 |

THERMO |

|

|

|

1 |

2 |

||

|

|

SENSOR (TA) |

|||

|

|

BLK |

BLK |

||

|

|

|

|

||

MAIN P.C. BOARD |

R25 |

|

CR03 |

||

WP-003 |

||

RY04 |

R27 |

|

|

CR01 |

|

|

|

C15 |

|

|

|

CN11 |

|

|

|

|

|

|

|

CN10 |

5 |

3 |

1 |

1 |

2 |

3 |

|

|

|

|

150°C |

|

|

|||||||

|

|

|

1 |

1 |

BLK |

5 |

3 |

1 |

1 |

2 |

3 |

|

|

|

|

|

|||||||||

|

|

|

|

2 |

2 |

GRY |

|

|

|

|

|

|

CN01 |

CR02 |

|

3 |

3 |

YEL |

|

|

|

|

|

|

|

1 |

2 |

HEAT EXCHANGER |

|

4 |

4 |

BRW |

|

|

|

|

|

|

1 |

2 |

|

5 |

5 |

RED |

|

|

|

|

|

|

|

SENSOR (TC) |

|

|

|

|

|

|

|

|||||

BLK |

BLK |

|

|

6 |

6 |

WHI |

|

|

|

|

|

|

AC FAN MOTOR

INDOOR

TERMINAL

BLOCK

OUTDOOR

TERMINAL

BLOCK

BLK

COMPRESSOR

PNK

BLK |

WHI |

RED |

BLU |

|

GRN&YEL |

1 |

2 |

3 |

|

4 |

INDOOR |

|

|

|

|

|

OUTDOOR

1(L) 2(N) |

3 |

4 |

CHASSIS |

|

BLU |

BLU |

|

SOLENOID COIL |

|

|

RED |

CAPACITOR |

RED |

RED |

WHI BLK |

|

|

|

|

|

FAN |

|

|

MOTOR |

|

CAPACITOR |

|

WHI

− 7−

FILE NO. SVM-06027

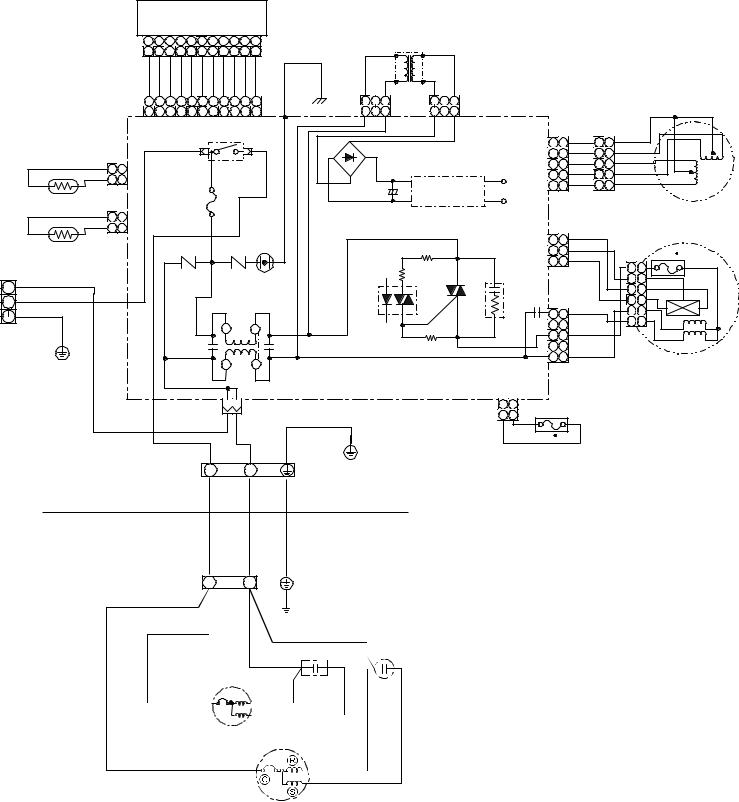

3-2. RAS-13GKP-ES2 / RAS-13GA-ES2

Infrared rays receiver and indication parts.

CN25 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 10 11 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 10 11 |

||

|

|

|

|

BLU BLU |

BLU |

BLU BLU |

BLU |

BLU BLU |

BLU |

BLU WHI |

|

|||

|

|

CN14 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 11 |

BLK |

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 10 11 |

|||

|

|

|

|||||||||||

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

P04 |

|

|

|

|

|

|

|

3 |

|

|

|

4 |

|

|

Heat Exchanger |

CN01 |

|

|

|

|

|

|

|

|

|

|

|

|

Sensor (TC) |

|

|

|

|

|

|

|

|

|

|

|

||

1 |

1 |

|

|

|

|

|

|

RY01 |

|

|

|||

|

|

|

|

|

|

|

|

|

|||||

|

2 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F01 |

|

|

|

|

|

|

|

Thermo Sensor (TA) |

CN03 |

|

|

|

T6.3 A |

|

|

|

|

|

|

||

1 |

1 |

|

|

250 VAC |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

2 |

2 |

|

|

|

|

|

|

|

|

|

SG01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DSA |

|

|

BRW (L) |

R21 |

R22 |

L |

|

|

|

|

|

|

|

N |

BLU (N) |

|

|

|

|

|

|

|

GRN&YEL |

|

L01 |

SINGLE PHASE |

|

2 |

1 |

220-240V~, 50Hz |

C15 |

C01 |

|

|

|

||

|

|

3 |

4 |

CN31 |

|

|

BLK |

WHI |

GRN&YEL |

INDOOR |

1 |

2 |

TERMINAL

BLOCK

OUTDOOR

TERMINAL

BLOCK

|

TRANS (TT-10) |

|

|

||

RED |

|

|

|

|

GRY |

|

|

WHI |

BLU |

|

|

1 |

3 |

CN05 |

1 |

3 |

CN06 |

1 |

3 |

1 |

3 |

||

|

|

MCC-920 |

CN07 |

|

||

|

|

|

WHI |

|||

|

|

|

1 |

1 |

||

DB50 |

|

|

YEL |

|||

|

|

2 |

2 |

|||

|

|

|

YEL |

|||

|

|

|

3 |

3 |

||

|

|

|

YEL |

|||

C50 |

|

|

4 |

4 |

||

|

DC 12 V |

YEL |

||||

+ |

Regulator |

5 |

5 |

|||

|

|

|||||

|

circuit |

DC 5 V |

|

|

|

|

|

|

|

|

|

||

1 |

1 |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

|

|

|

CN11 |

||

|

|

|

1 |

1 |

|

|

R47 |

|

2 |

2 |

|

|

|

|

3 |

3 |

|

|

R46 |

|

|

|

|

IC03 |

|

CR03 |

|

|

|

D38 |

C58 |

CN10 |

|||

|

|||||

|

|

5 |

5 |

||

|

|

|

|||

|

|

|

3 |

3 |

|

|

R48 |

|

|

|

|

|

|

|

1 |

1 |

|

Louver motor

YEL |

|

|

GRY |

|

|

BRW |

|

150 C |

|

1 |

1 |

|

2 |

2 |

|

3 |

3 |

|

4 |

4 |

WHI |

5 |

5 |

|

6 |

6 |

BLK |

|

|

RED |

|

|

Indoor FAN motor

1 |

2 |

TEMP FUSE |

CN04 1 |

2 |

|

PNK |

PNK |

|

|

73 C |

|

|

|

INDOOR

OUTDOOR

1(L) |

2(N) |

CHASSIS |

|

|

|

RED |

|

||

BLK |

BLK |

RED |

CAPACITOR |

CAPACITOR |

||

|

|

|

||||

|

|

|

|

|

|

|

FAN MOTOR

RED

WHI

COMPRESSOR

PNK

WHI

− 8 −

FILE NO. SVM-06027

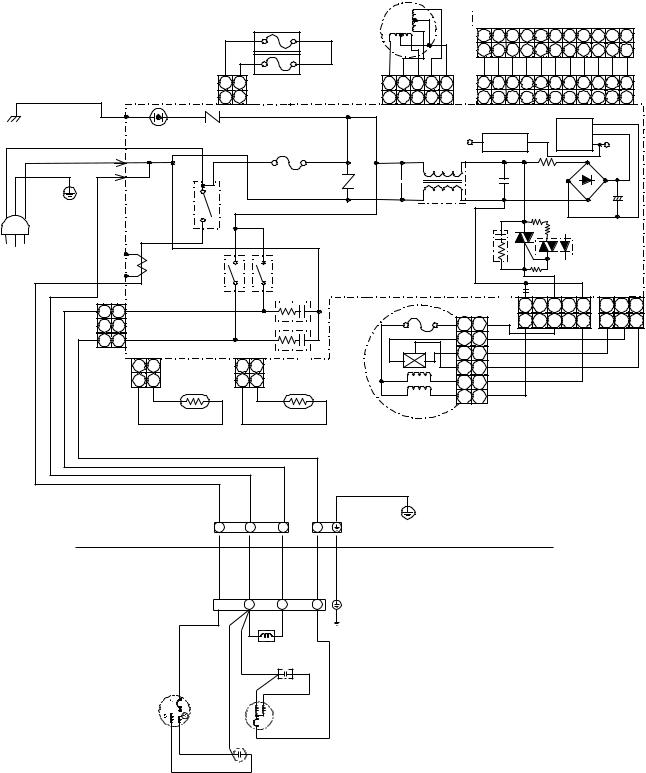

3-3. RAS-13NKHP-AS2 / RAS-13N2AH-AS2

|

|

|

|

73°Cx2 |

|

|

|

|

THERMAL FUSE |

|

|

PNK |

PNK |

|

|

|

|

1 |

2 |

|

|

|

1 |

2 |

|

BLK |

|

|

CN04 |

|

P04 |

|

|

|

|

SG01 |

R22 |

|

|

BRW(L) |

DSA |

VARISTOR |

T6.3A 250VAC |

|

|

|

|

FUSE F01 |

|

BLU(N) |

|

|

|

|

|

|

|

|

|

GRN & YEL |

|

3 |

|

|

|

|

|

|

|

|

|

RY01 |

||

Louver |

|

|

|

|

Motor |

|

|

|

|

YEL |

YEL |

YEL |

YEL |

WHI |

5 |

4 |

3 |

2 |

1 |

5 |

4 |

3 |

2 |

1 |

|

CN07 |

|

|

|

INFRARED RAYS RECEIVE

AND INDICATION PARTS

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

CN25 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

BLU |

WHI |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

|

|

|

|

|

|

|

|

|

|

CN14 |

VARISTOR

R21

C01

|

DC5V |

|

|

Micro |

|

|

Voltage |

|

Power |

|

|

|

|

|

Module |

|

|

|

|

Regulator |

|

DC12V |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

C02 |

R319 |

|

|

|

|

|

|

+ |

|

|

|

|

|

|

|

L01 |

|

IC03 |

R26 |

DB01 |

C63 |

|

|

|

|||

|

|

|

|

|

|

|

|

BLK |

4 |

|

|

|

|

|

|

SINGLE PHASE |

T02 |

|

|

|

|

220-240V~, 50Hz |

|

|

|

RY03 |

|

|

C.T. |

|

|

|

|

1 |

1 |

|

|

|

|

3 |

3 |

|

|

|

|

CN27 |

CN03 |

|

|

||

|

|

1 |

2 |

THERMO |

|

|

|

1 |

2 |

||

|

|

SENSOR (TA) |

|||

|

|

BLK |

BLK |

||

|

|

|

|

||

MAIN P.C. BOARD |

R25 |

|

CR03 |

||

WP-003 |

||

RY04 |

R27 |

|

|

CR01 |

|

|

|

C15 |

|

|

|

CN11 |

|

|

|

|

|

|

|

CN10 |

5 |

3 |

1 |

1 |

2 |

3 |

|

|

|

|

150°C |

|

|

|||||||

|

|

|

1 |

1 |

BLK |

5 |

3 |

1 |

1 |

2 |

3 |

|

|

|

|

|

|||||||||

|

|

|

|

2 |

2 |

GRY |

|

|

|

|

|

|

CN01 |

CR02 |

|

3 |

3 |

YEL |

|

|

|

|

|

|

|

1 |

2 |

HEAT EXCHANGER |

|

4 |

4 |

BRW |

|

|

|

|

|

|

1 |

2 |

|

5 |

5 |

RED |

|

|

|

|

|

|

|

SENSOR (TC) |

|

|

|

|

|

|

|

|||||

BLK |

BLK |

|

|

6 |

6 |

WHI |

|

|

|

|

|

|

AC FAN MOTOR

INDOOR

TERMINAL

BLOCK

OUTDOOR

TERMINAL

BLOCK

BLK

COMPRESSOR

PNK

BLK |

WHI |

RED |

BLU |

|

GRN&YEL |

1 |

2 |

3 |

|

4 |

INDOOR |

|

|

|

|

|

OUTDOOR

1(L) 2(N) |

3 |

4 |

CHASSIS |

|

BLU |

BLU |

|

SOLENOID COIL |

|

|

RED |

CAPACITOR |

RED |

RED |

WHI BLK |

|

|

|

|

|

FAN |

|

|

MOTOR |

|

CAPACITOR |

|

WHI

− 9 −

FILE NO. SVM-06027

3-4. RAS-13NKP-AS2 / RAS-13N2A-AS2

Infrared rays receiver and indication parts.

CN25 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 10 11 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 10 11 |

||

|

|

|

|

BLU BLU |

BLU |

BLU BLU |

BLU |

BLU BLU |

BLU |

BLU |

WHI |

|

||

|

|

CN14 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 10 11 |

BLK |

|

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 10 11 |

|||

|

|

|

|||||||||||

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

P04 |

|

|

|

|

|

|

|

3 |

|

|

|

4 |

|

|

Heat Exchanger |

CN01 |

|

|

|

|

|

|

|

|

|

|

|

|

Sensor (TC) |

|

|

|

|

|

|

|

|

|

|

|

||

1 |

1 |

|

|

|

|

|

|

RY01 |

|

|

|||

|

|

|

|

|

|

|

|

|

|||||

|

2 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F01 |

|

|

|

|

|

|

|

Thermo Sensor (TA) |

CN03 |

|

|

|

T6.3 A |

|

|

|

|

|

|

||

1 |

1 |

|

|

250 VAC |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

2 |

2 |

|

|

|

|

|

|

|

|

|

SG01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DSA |

|

|

|

|

|

|

|

R21 |

|

|

|

R22 |

|

|

|

BRW (L) |

|

|

|

|

|

|

|

|

|

|

|

|

|

BLU (N) |

|

|

|

|

|

|

|

|

|

|

|

|

|

GRN&YEL |

|

|

|

|

|

|

|

|

|

|

L01 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

2 |

|

1 |

|

|

|

|

|

|

|

|

C15 |

|

|

|

|

C01 |

|

|

|

|

|

|

|

|

|

|

|

3 |

|

4 |

|

SINGLE PHASE |

|

|

|

|

|

|

|

|

|

|

|

|

|

220-240V~, 50Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CN31 |

|

|

|

|

||

|

|

|

|

|

|

|

BLK |

|

|

WHI |

|

GRN&YEL |

|

|

|

|

INDOOR |

|

|

1 |

|

|

2 |

|

|||

TERMINAL

BLOCK

OUTDOOR

TERMINAL

BLOCK

|

TRANS (TT-10) |

|

|

||

RED |

|

|

|

|

GRY |

|

|

WHI |

BLU |

|

|

1 |

3 |

CN05 |

1 |

3 |

CN06 |

1 |

3 |

1 |

3 |

||

|

|

MCC-920 |

CN07 |

|

||

|

|

|

WHI |

|||

|

|

|

1 |

1 |

||

DB50 |

|

|

YEL |

|||

|

|

2 |

2 |

|||

|

|

|

YEL |

|||

|

|

|

3 |

3 |

||

|

|

|

YEL |

|||

C50 |

|

|

4 |

4 |

||

|

DC 12 V |

YEL |

||||

+ |

Regulator |

5 |

5 |

|||

|

|

|||||

|

circuit |

DC 5 V |

|

|

|

|

|

|

|

|

|

||

1 |

1 |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

|

|

|

CN11 |

||

|

|

|

1 |

1 |

|

|

R47 |

|

2 |

2 |

|

|

|

|

3 |

3 |

|

|

R46 |

|

|

|

|

IC03 |

|

CR03 |

|

|

|

D38 |

C58 |

CN10 |

|||

|

|||||

|

|

5 |

5 |

||

|

|

|

|||

|

|

|

3 |

3 |

|

|

R48 |

|

|

|

|

|

|

|

1 |

1 |

|

Louver motor

YEL |

|

|

GRY |

|

|

BRW |

|

150 C |

|

1 |

1 |

|

2 |

2 |

|

3 |

3 |

|

4 |

4 |

WHI |

5 |

5 |

|

6 |

6 |

BLK |

|

|

RED |

|

|

Indoor FAN motor

1 |

2 |

TEMP FUSE |

CN04 1 |

2 |

|

PNK |

PNK |

|

|

73 C |

|

|

|

INDOOR

OUTDOOR

1(L) |

2(N) |

CHASSIS |

|

|

|

RED |

|

||

BLK |

BLK |

RED |

CAPACITOR |

CAPACITOR |

||

|

|

|

||||

|

|

|

|

|

|

|

FAN MOTOR

RED

WHI

COMPRESSOR

PNK

WHI

− 10 −

|

|

|

|

FILE NO. SVM-06027 |

|

4. SPECIFICATION OF ELECTRICAL PARTS |

|||

4-1. Indoor Unit (RAS-13GKHP-ES2, RAS-13NKHP-AS2) |

||||

|

|

|

|

|

No. |

Parts name |

|

Type |

Specifications |

1 |

Fan motoror(f indoor) |

|

SKF-220-20-4A-1 |

° |

|

AC Motor with 150C thermo fuse |

|||

|

|

|

|

° |

2 |

Thermo sensorA(T-sensor) |

|

|

10kW at 25C |

3 |

Micro Power Module (M01) |

|

μRM1260V |

DC 390V, Secondary DC 12V |

|

|

|

|

|

4 |

Microcontroller unit (IC30) |

|

TMP87CM40AN |

|

|

|

|

|

|

5 |

Heat xchanger sensor |

|

|

10kW at 25C |

|

(TC-sensor) |

|

|

° |

|

|

|

|

|

|

|

|

|

|

6 |

Line filter (L01) |

|

LC*SS11V-06270 |

27mH, 600mA |

|

|

|

|

|

7 |

Bridge rectifier (DB01) |

|

D3SBA60 |

4A, 600 V |

|

|

|

|

|

8 |

Capacitor (C63) |

|

KMH400VSSN47M22S |

47mF, 400 V |

|

|

|

|

|

9 |

Fuse (F01) |

|

BET 6.3A |

T6.3A, 250VAC |

|

|

|

|

|

10 |

Varistor (R21, R22) |

|

TND15G561K |

560 V |

|

|

|

|

|

11 |

Resistor (R319) |

|

RF-2TK5R6 |

5.6 W , 2 W |

|

|

|

|

|

12 |

Louver motor |

|

MP24Z |

12VDC |

|

|

|

|

|

13 |

Relay (Comp., RY01) |

|

DI1U |

Rating 25A/AC250 V, 3-48VDC |

|

|

|

|

|

14 |

Relay (Fan, RY03) |

|

G5NB-1A |

Rating 3A/AC250 V, 12VDC |

|

|

|

|

|

15 |

Relay (Solenoide, RY04) |

|

G5NB-1A |

Rating 3A/AC250 V, 12VDC |

|

|

|

|

|

4-2. Outdoor Unit (RAS-13GAH-ES2, RAS-13N2AH-AS2)

No. |

Parts name |

Type |

Specifications |

|

|

|

|

|

Output (Rated) 1100W, 2poles, 1 phase, 220 − 240V, 50Hz |

||

1 |

Compressor |

|

|

|

|

PA150X2C-4FT |

Winding resistance (Ω) |

C-R |

C-S |

||

|

|

|

(at 20°C) |

|

|

|

|

|

2.35 |

3.22 |

|

|

|

|

|

|

|

|

Fan motor |

HF-240-42A or |

Output (Rated) 42W, 6poles, 1 phase, 220 − 240V, 50Hz |

||

2 |

|

|

|

||

Winding resistance (Ω) |

Red-Black |

White-Black |

|||

|

(for outdoor) |

WLF-240-42A |

(at 20°C) |

|

|

|

176.2 or 188 |

290.5 or 289 |

|||

|

|

|

|||

|

|

|

|

|

|

3 |

Running capacitor |

DS451155NPQB |

AC 450V, 1.5μF |

|

|

(for fan motor) |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Running capacitor |

RS44B306U0214S |

AC 440V, 30μF |

|

|

(for compressor) |

|

|

|||

|

|

|

|

|

|

|

Solenoid coil |

|

|

|

|

5 |

(for 4-way valve) |

STF-01AJ503H1 |

AC 220 − 240V, 50Hz |

|

|

(for Heat pump |

|

|

|

||

|

|

|

|

|

|

|

model) |

|

|

|

|

|

|

|

|

|

|

− 11 −

FILE NO. SVM-06027

4-3. Indoor Unit (RAS-13GKP-ES2, RAS-13NKP-AS2)

No. |

Parts name |

|

Type |

Specifications |

1 |

Fan motoror(f indoor) |

|

SKF- 220-20-4A-1 |

° |

|

AC Motor with 150C thermo fuse |

|||

2 |

Thermo sensorA(T-sensor) |

|

|

10kW at 25C° |

|

|

|

|

|

3 |

Transformer |

|

TT-10 |

|

4 |

Microcontroller unit (IC30) |

|

TMP87CM40AN |

|

|

|

|

|

|

5 |

Heat xchanger sensor |

|

|

10kWat 25C° |

|

(TC-sensor) |

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

Line filter (L01) |

|

*SS11V-06270 |

27mH, 600mA |

|

|

|

|

|

7 |

Bridge rectifier (DB50) |

|

KBP06M/51 |

1.5A, 600 V |

|

|

|

|

|

8 |

Capacitor (C50) |

|

PF1E222MNN1625 |

2200mF, 25 V |

|

|

|

|

|

9 |

Fuse (F01) |

|

BET6.3A |

T6.3A, 250VAC |

|

|

|

|

|

10 |

Varistor (R21, R22) |

|

TND15G561K |

560 V |

11 |

Louver motor |

|

MP24Z |

12VDC |

|

|

|

|

|

12 |

Relay (Comp., RY01) |

|

DI1U |

Rating 25A/AC250 V, 3~48VDC |

|

|

|

|

|

4-4. Outdoor Unit (RAS-13GA-ES2, RAS-13N2A-AS2)

No. |

Parts name |

Type |

Specifications |

|

||

|

|

|

Output (Rated) 1100W, 2poles, 1 phase, 220 − 240V, 50Hz |

|||

1 |

Compressor |

PA150X2C-4FT |

|

|

|

|

Winding resistance (Ω) |

C-R |

C-S |

||||

|

|

|

(at 20°C) |

|

|

|

|

|

|

2.35 |

3.22 |

||

|

Fan motor |

WLF-240-30A |

Output (Rated) 30W, 6poles, 1 phase, 220 − 240V, 50Hz |

|||

|

|

|

|

|||

2 |

Winding resistance (Ω) |

Red-Black |

White-Black |

|||

(for outdoor) |

|

|||||

|

|

(at 20°C) |

|

|

||

|

|

237 |

380 |

|||

|

|

|

||||

|

|

|

|

|

|

|

3 |

Running capacitor |

DS451155NPQB |

AC 450V, 1.5μF |

|

|

|

(for fan motor) |

|

|

||||

|

|

|

|

|

||

4 |

Running capacitor |

RS44B306U0214S |

AC 440V, 30μF |

|

|

|

(for compressor) |

|

|

||||

|

|

|

|

|

||

− 12 −

FILE NO. SVM-06027

5. REFRIGERATION CYCLE DIAGRAM

5-1. RAS-13GKHP-ES2 / RAS-13GAH-ES2 RAS-13NKHP-AS2 / RAS-13N2AH-AS2

|

|

|

Indoor unit |

T1 |

|

|

|

|

|

|

Cooling |

Heat exchanger |

|

|

|

|

|

||

0.39m |

|

Heating |

|

0.49m |

(Connecting pipe) |

|

(Connecting pipe) |

||

|

|

|||

12.7 |

|

|

Cross flow fan |

6.35 |

|

|

|

|

|

O.D.:12.7mm |

|

P |

|

O.D.:6.35mm |

|

|

Packed valve |

|

Packed valve |

|

|

( 12.7) |

|

( 6.35) |

|

|

Heating |

|

|

Cooling |

|

4-way valve |

|

|

Heating |

Cooling Compressor |

PA150X2C-4FT |

|

|

|

|

|

|

Capillary tube |

Capillary tube |

|

|

|

|

1.0x400l |

||

|

Accumulator |

1.5x1500l |

|||

|

|

||||

|

|

Heat exchanger |

|

|

|

|

|

|

|

Refrigerant |

|

|

|

Propeller fan |

|

R410A : 1.08 kg. |

|

|

Cooling |

Outdoor unit |

Mark( |

)means check points of Gas Leak. |

|

|

Heating |

|

|

|

|

|

|

Standar d |

Surface temp. of heat |

|

Ambient temp. |

||

|

|

Fan speed |

conditions DB/WB |

||||

|

50Hz |

pressure P |

exchang er inter changing |

(indoor) |

|

(°C) |

|

|

|

(MPaG) |

pipe T1 (°C) |

|

|

|

|

|

|

|

Indoor |

|

Outdoor |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Standard |

2.70 |

44.5 |

High |

20/15 |

|

7/6 |

Heating |

|

|

|

|

|

|

|

Overload*1 |

3.12 ~ 3.77 |

52.0 ~ 56. 8 |

Low |

27/− |

|

24/18 |

|

|

|

|

|

|

|

|

|

|

Low temperature |

2.20 |

35.0 |

High |

20/− |

|

−10/−10 |

|

|

|

|

|

|

|

|

|

Standard |

0.90 |

10.0 |

High |

27/19 |

|

35/24 |

Cooling |

|

|

|

|

|

|

|

Overload |

0.99 |

14.0 |

High |

32/23 |

|

43/26 |

|

|

|

|

|

|

|

|

|

|

Low temperature |

0.65 |

2.0 |

Low |

21/15 |

|

21/15 |

|

|

|

|

|

|

|

|

Note :

∙ Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)

*1 ∙ During heating overload operation, a value for the high temperature limit control operation is included.

− 13 −

FILE NO. SVM-06027

5-2. RAS-13GKP-ES2 / RAS-13GA-ES2 RAS-13NKP-AS2 / RAS-13N2A-AS2

|

|

Indoor unit |

T1 |

|

|

|

|

|

Cooling |

Heat exchanger |

|

|

|

|

|

0.39m |

|

|

0.49m |

(Connecting pipe) |

|

(Connecting pipe) |

|

12.7 |

|

Cross flow fan |

6.35 |

|

|

|

|

O.D.:12.7mm |

P |

|

O.D.:6.35mm |

|

Packed valve |

|

Packed valve |

|

( 12.7) |

|

( 6.35) |

Cooling |

|

Cooling Compressor |

PA150X2C-4FT |

Accumulator |

|

Heat exchanger

Capillary tube1.7x700l

|

|

|

Refrigerant |

|

Propeller fan |

|

R410A : 0.98 kg. |

Cooling |

Outdoor unit |

Mark( |

)means check points of Gas Leak. |

|

|

Standar d |

Surface temp. of heat |

|

Ambient temp. |

||

|

|

Fan speed |

conditions DB/WB |

||||

|

50Hz |

pressure P |

exchang er inter changing |

(indoor) |

|

(°C) |

|

|

|

(MPaG) |

pipe T1 (°C) |

|

|

|

|

|

|

|

Indoor |

|

Outdoor |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Standard |

0.80 |

10.0 |

High |

27/19 |

|

35/24 |

Cooling |

|

|

|

|

|

|

|

Overload |

1.04 |

15.0 |

High |

32/23 |

|

43/26 |

|

|

|

|

|

|

|

|

|

|

Low temperature |

0.72 |

2.0 |

Low |

21/15 |

|

21/15 |

|

|

|

|

|

|

|

|

Note :

∙ Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor)

− 14 −

FILE NO. SVM-06027

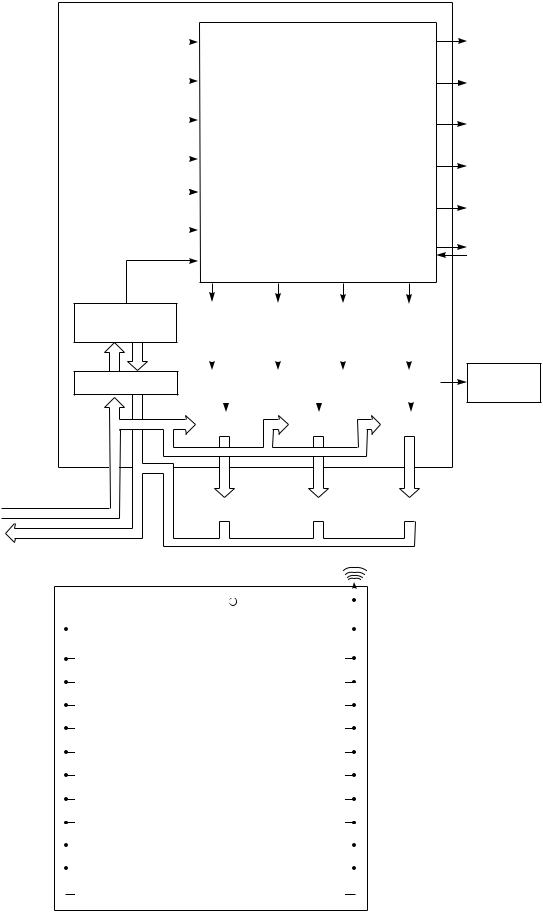

6. CONTROL BLOCK DIAGRAM

6-1. RAS-13GKHP-ES2 / RAS-13GAH-ES2, RAS-13NKHP-AS2 / RAS-13N2AH-AS2

|

Main Unit Control Panel |

|

M.C.U. |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Operation |

Heat Exchange sensor |

|

|

|

|

Functions |

|

|

|

|

|

Display |

||

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Timer |

Thermo. Sensor |

|

|

|

|

∙ Louver Control |

|

|

|

|

|

Display |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Current Sensor |

|

|

|

|

∙ 3-minutes Delay at Restart |

Filter Sign |

|

|

|

|

Display |

||

|

|

|

|

|

for Compressor |

|

(Compressor Current) |

|

|||||

|

|

|||||

|

||||||

Infrared Rays Signal Reciver |

|

|

|

|

|

Hi Power |

|

|

|

|

|

||

|

|

|

|

|

∙ Motor Revolution Control |

Sign Display |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Initiallizing Circuit |

|

|

|

|

|

|

|

|

PRE DEF. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Sign Display |

|

|

Clock Frequency |

|

|

∙ Processing |

|

|

|

|

|

|

||

|

|

|||||

|

|

Oscillator Circuit |

|

|

(Temperature Processing) |

Indoor Fan |

|

|

|

|

|

||

|

|

|

|

|

∙ Timer |

Motor |

Power Supply

Circuit

Noise Filter

Compressor |

|

Outdoor Fan |

|

4-Way Valve |

|

|

|

|

|

|||||||||

Louver |

|

|

||||||||||||||||

ON/OFF |

|

|

ON/OFF |

|

|

ON/OFF |

|

ON/OFF |

|

|

||||||||

|

Signal |

|

|

Signal |

|

|

Signal |

|

Signal |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Relay Driver, Louver Driver |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||||||

|

Relay |

|

|

Relay |

|

Relay |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

RY01 |

|

|

|

|

|

RY03 |

|

|

RY04 |

|

|||||

Louver

Motor

220-240 V~, 50Hz |

|

|

Compressor |

|

Outdoor Fan Motor |

|

4-Way Valve |

|||

REMOTE CONTROL |

|

|

|

|

Infrared Rays |

|||||

|

Remote Control |

|||||||||

|

|

|

|

|||||||

|

|

Operation ( ) |

|

|

|

|

|

|||

|

|

Operation Mode Selection |

|

|

|

|

|

|||

|

|

AUTO, COOL, DRY, HEAT, FAN ONLY |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Temperature Setting |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Fan Speed Selection |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

ON TIMER Setting |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

OFF TIMER Setting |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Louver Auto Swing |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Louver Direction Setting |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ECO |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

Hi power |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

TIMER 1.3.5.9H |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

|

|

COMFORT SLEEP |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

QUIET |

|

|

|

||||

|

|

|

|

|||||||

− 15 −

FILE NO. SVM-06027

6-2. RAS-13GKP-ES2 / RAS-13GA-ES2,RAS-13NKP-AS2 / RAS-13N2A-AS2

Heat Exchange sensor

Thermo. Sensor

Infrared Rays Signal Reciver

220-240 V~, 50Hz

REMOTE CONTROL

Main Unit Control Panel |

M.C.U. |

Functions

∙ Louver Control

∙ Louver Control

∙ 3-minutes Delay at Restart

∙ 3-minutes Delay at Restart

for Compressor

Initiallizing Circuit  ∙ Motor Revolution Control

∙ Motor Revolution Control

Clock Frequency |

|

∙ Processing |

Oscillator Circuit |

|

|

|

(Temperature Processing) |

|

|

|

|

|

|

∙ Timer |

Operation

Display

Timer

Display

Filter Sign

Display

Hi Power

Sign Display

Sign Display

Fan Only

Sign Display

Sign Display

Indoor Fan

Motor

Power Supply |

Compressor |

Louver |

|

Circuit |

ON/OFF |

ON/OFF |

|

|

Signal |

Signal |

|

Noise Filter |

Relay Driver, Louver Driver |

Louver |

|

Motor |

|||

|

|

||

|

Relay |

|

|

|

RY01 |

|

Compressor, Outdoor Fan Motor

Infrared Rays

Remote Control

Operation ( )

)

Operation Mode Selection

AUTO, COOL, DRY, FAN ONLY

Temperature Setting

Fan Speed Selection

ON TIMER Setting

OFF TIMER Setting

Louver Auto Swing

Louver Direction Setting

ECO

Hi power

TIMER 1.3.5.9H

COMFORT SLEEP

QUIET

−16 −

FILE NO. SVM-06027

7. OPERATION DESCRIPTION

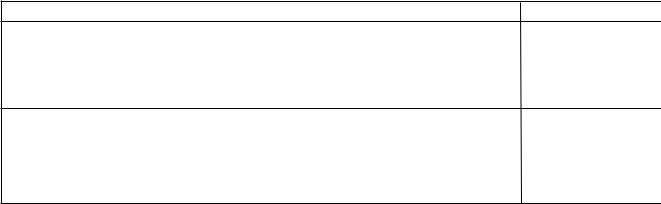

7-1. Outline of Air Conditioner Control |

7-1-1. Louver control |

This is a fixed capacity type air conditioner, which uses AC motor for an indoor fan. The AC motor drive

circuit is mounted in the indoor unit. And electrical parts which driving the compressor and the outdoor fan motor, are mounted in the outdoor unit.

The air conditioner is controlled by the controller mounted in the indoor unit. The controller operates all components based on the commands transmitted from the remote control and the feedback data of the sensor is as follow:

∙The temperature measurement at the air inlet of the indoor heat exchanger by the indoor temperature sensor

∙ The temperature measurement at the indoor heat exchanger by the indoor heat exchanger temperature sensor

∙Indoor fan motor operation control

∙Louver motor control

∙LED display control

∙Outdoor fan motor operation control

∙4-WAYS-VALVE operation control

(Heat pump model only)

∙Compressor operation control

∙Receiving the information of the operation status and judging the information or the indication of errors

(1)Vertical air flow louver

Position of veritcal air flow louver is automatically controlled according to the operation mode. Besides, position of vertical air flow louver can be arbitrarily set by pressing [FIX] button.

The louver position which is set by [FIX] button is stored in the microcontroller, and the louver is automatically set at the stored position for the next operation.

(2)Swing

If [SWING] button is pressed when the indoor unit is in operation, the vertical air flow louver starts swinging. When [SWING] button is pressed again, it stops swinging.

7-1-2. Indoor fan control (AC Fan motor)

(1)The indoor fan is operated by the stepless speed change AC motor.

(2)For air flow level, speed of the indoor fan motor is controlled in five steps (LOW, LOW+, MED, MED+ and HIGH). If AUTO mode is selected, the fan motor speed is automatically controlled by the difference between the preset temperature and the room temperature.

LOW+ = LOW+MED 2

MED+ = MED+HIGH 2

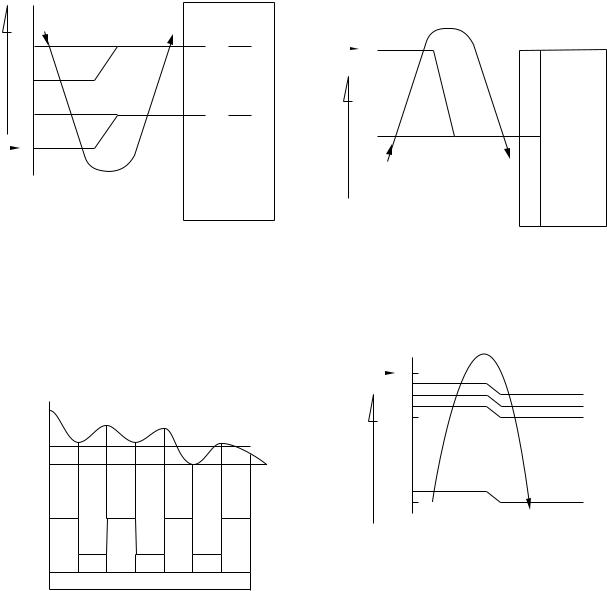

Table 7-1-1

Model

|

|

|

|

|

|

|

|

FAN TAP |

|

|

|

|

|

|

|

|

Cooling |

|

|

UH |

H |

|

M |

|

|

L |

L- |

UL |

SL |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPERATION |

Fan only |

|

|

|

H |

|

M |

|

|

L |

L- |

|

|

|

|

MODE |

Dry |

|

|

|

|

|

M |

|

|

L |

L- |

UL |

|

SL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat |

UH |

H |

|

|

M |

|

L |

L- |

|

UL |

|

|

|

SL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RAS-13GKP Series |

rpm |

1350 |

|

1300 |

1150 |

1100 |

1050 |

1000 |

950 |

900 |

850 |

800 |

750 |

700 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RAS-13NKP Series |

Air flow volume (m3/h) |

650 |

|

630 |

550 |

520 |

490 |

460 |

430 |

400 |

370 |

340 |

310 |

280 |

|

RAS-13GKHP Series |

rpm |

1350 |

|

1300 |

1150 |

1100 |

1050 |

1020 |

950 |

900 |

850 |

800 |

700 |

550 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RAS-13NKHP Series |

Air flow volume (m3/h) |

650 |

|

630 |

550 |

520 |

490 |

470 |

430 |

400 |

370 |

340 |

280 |

190 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

− 17 −

7-2. Description of Operation Circuit

(1)When turning on the breaker, the operation lamp blinks. This means that the power supply is on.

(2) When pressing [ ] button on the remote control, receiving beep sounds from the indoor unit, and the next operation is performed together with opening the vertical air flow louver.

(3)Once the operation mode is set, it is memorized in the microcontroller so that the previous operation can be effected thereafter simply by pressing

[ |

] button. |

7-2-1. Fan only operation

([MODE] button on the remote control is set to the fan only operation.)

(1)When [FAN] button is set to AUTO, the indoor fan motor operates as shown in Fig. 7-2-1. When [FAN] button is set to LOW, LOW+, MED, MED+ or HIGH, the motor operates with a constant air flow.

FILE NO. SVM-06027

7-2-2. Cooling operation

([MODE] button on the remote control is set to the cooling operation.)

(1)The compressor, 4-way valve, outdoor fan and operation display on the remote control are controlled as shown in Fig. 7-2-2.

-(Presettemp.) |

|

°C |

|

|

|

|

|

|

|

|

|

ON |

|

ON |

|

|

|

||

|

0.5 |

|

|

|

temp.) |

|

OFF |

OFF |

OFF ON |

(Room |

|

|||

|

|

|

|

|

Preset |

|

0 |

|

|

|

|

|

||

temp. |

|

Compressor |

valveway-4 |

fanOutdoor OPERATION |

|

|

|||

|

|

|

|

display |

|

|

|

|

|

temp.) |

|

°C |

|

|

+3 |

|

|

||

|

|

|||

(Preset |

|

M+ |

||

+2.5 |

|

|||

|

*1 |

|||

|

|

|

||

- |

+2 |

|

*1 |

|

temp.) |

+1.5 |

|

||

|

*1 |

|||

|

|

|

||

(Room |

+1 |

|

L- |

|

+0.5 |

|

|||

|

|

|

|

|

Preset |

|

0 |

|

|

|

|

|

||

temp. |

|

|

|

|

|

|

|

(Preset temp.: 22°C) |

|

NOTE : |

|

|

|

|

|

|

|

|

|

*1: The values marked with *1 are calculated and controlled by the difference in motor speed between M+ and L-.

(2)The Hi POWER, ECO and COMFORT SLEEP operation cannot be set.

Fig. 7-2-1 Setting of air flow [FAN:AUTO]

Fig. 7-2-2

(2)When [FAN] button is set to AUTO, the indoor fan motor operates as shown in Fig. 7-2-3. When [FAN] button is set to LOW, LOW+, MED, MED+ or HIGH, the motor operates with a constant air flow.

temp.) |

|

°C |

|

|

+3 |

M+ |

|||

|

||||

(Preset |

+2.5 |

|||

|

||||

|

|

|||

|

+2 |

*1 |

||

− |

|

|||

|

|

*1 |

||

temp.) |

+1.5 |

|||

*1 |

||||

|

|

|||

(Room |

+1 |

|

||

+0.5 |

L- |

|||

|

||||

|

|

|||

Preset |

|

0 |

|

|

|

|

|||

temp. |

-0.5 |

|

||

|

|

|||

NOTE :

*1: The values marked with *1 are calculated and controlled by the difference in motor speed between M+ and L-.

Fig. 7-2-3 Setting of air flow [FAN:AUTO]

- 18-

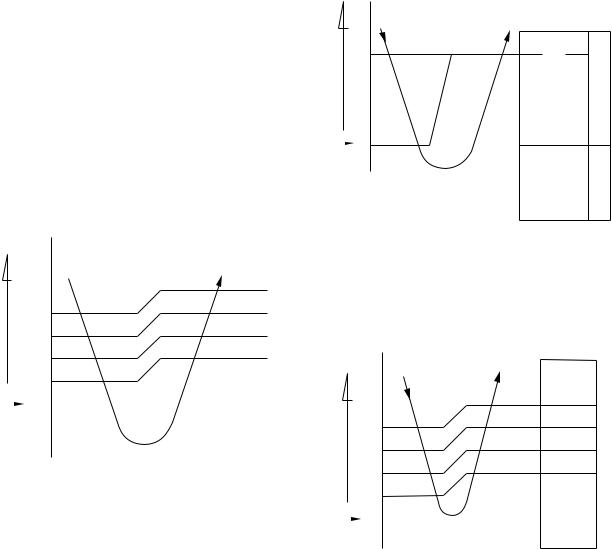

7-2-3. Dry operation

([MODE] button on the remote control is set to the dry operation.)

(1)The compressor, 4-way valve, outdoor fan and operation display on the remote control are controlled as shown in Fig. 7-2-4.

-(Presettemp.)temp.) |

°C |

ON:5min.ON:6min. OFF:5min.OFF:4min. |

|

ON:5min.ON:6min. OFF:5min.OFF:4min. |

|

|

+3 |

|

|

||||

|

|

|

|

|

||

|

+2 |

|

OFF |

|

ON |

|

(Room |

+1 |

|

|

|

|

|

|

|

OFF |

|

OFF |

|

|

|

|

|

|

|

||

Preset |

|

0 |

|

|

|

|

|

|

|

|

OPERATION |

||

temp. |

|

|

Compressor |

valveway-4 |

fanOutdoor |

|

|

|

|

||||

|

|

|

|

|

|

display |

|

|

|

|

|

|

|

Fig. 7-2-4

(2)The microcontroller turns the compressor on and off at the regular intervals (4 to 6 minutes). While the compressor is turning off, the indoor fan motor operates in the SUPER LOW position.

The pattern of operation depending on the relation between room temperature and preset temperatures is shown in Fig. 7-2-5.

Room temp.

Preset temp.+1

Preset temp.

Compressor |

ON |

|

ON |

ON |

ON |

|||

|

|

|

|

|

|

|

|

|

Outdoor fan |

|

OFF |

|

|

OFF |

|

OFF |

|

|

|

|

|

|

|

|||

Indoor fan |

|

*SL |

|

L |

|

|

|

|

L |

|

SL |

L |

SL |

L |

|||

|

*Super Low |

|

|

|

|

|

|

|

Fig. 7-2-5

(3)[FAN] button on the remote control is set to AUTO only.

(4)The Hi POWER, ECO, COMFORT SLEEP and QUIET operations cannot be set.

FILE NO. SVM-06027

7-2-4. Heating operation *Heat pump model only ([MODE] button on the remote control is set to the heating operation.)

(1)The compressor, 4-way valve, outdoor fan and operation display on the remote control are controlled as shown in Fig. 7-2-6.

Preset |

|

°C |

|

|

|

|

|

|

|

|

|

|

|||||

|

0 |

|

|

|

|

|

|

|

temp. |

|

|

|

|

|

|

|

|

temp.) |

|

|

|

|

OFF ON |

OFF |

ON |

|

(Preset |

-0.5 |

|

|

|

|

|

|

|

- |

|

|

ON |

|

ON |

|

||

|

|

|

|

|

|

|||

(Roomtemp.) |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Compressor |

way-4 valve |

Outdoorfan |

OPERATION |

|

|

|

|

|

|

|

|

|

display |

Fig. 7-2-6

(2)When [FAN] button is set to AUTO, the indoor fan motor operates as shown in Fig. 7-2-7. When [FAN] button is set to LOW, LOW+, MED, MED+ or HIGH, the motor operates with a constant air flow.

°C

Preset |

|

0 |

L |

|

|

||||

temp. |

-0.5 |

|

||

temp.) |

-1 |

*1 |

||

-1.5 |

||||

|

*2 |

|||

|

-2 |

|||

(Preset |

|

|||

|

|

M+ |

||

temp.)- |

-5.0 |

|

||

(Room |

-5.5 |

H |

||

[FAN AUTO] |

||||

|

||||

|

|

|||

*1, *2 : The values marked with *1 and *2 are calculated and controlled by the difference in motor speed between M+ and L.

Fig. 7-2-7 Setting of air flow [FAN:AUTO]

- 19 -

(3)The indoor heat exchanger restricts revolving speed of the fan motor to prevent a cold draft. The upper limit of the revolving speed is shown in Fig. 7-2-8 and Table 7-2-1.

Indoor heat exchanger temperature

°C

45 34

34 33

32 21

31 20

*2 A+8 A+8 A−4 A−4

*6 *5

Manual

AUTO (One of 5 steps)

*4 L-H (Up to seting speed)

SL*3

SL*1

Stop

Fig. 7-2-8 Cold draft preventing control

NOTES :

*1: The fan stops for 2 minutes after thermostat-OFF

*2: A is 24°C when the preset temperature is 24°C or more and A is the preset temperature when it is under 24 °C.

*3: SL means Super Low.

*4: Calculated from difference in motor speed between SL and H.

*5 and *6:

Fan |

*5 |

*6 |

. |

speed |

Starting period |

Stabilized period |

|

|

|

|

|

AUTO |

· Up until 12 minutes |

· From 12 to 25 minutes |

|

|

passed after starting |

passed after starting |

|

|

the unit |

the unit and room |

|

|

· From 12 to 25 minutes |

temperature is |

|

|

passed after starting |

between preset |

|

|

the unit and room |

temperature and 3 °C |

|

|

temperature is 3 °C |

lower than preset |

|

|

lower than preset |

temperature |

|

|

· temperature |

· 25 minutes or more |

|

|

|

passed after starting |

|

|

|

the unit |

|

|

|

|

|

Manual |

· Room temperature |

· Room temperature |

|

(L - H) |

< Preset temperature |

Preset temperature |

|

|

- 4 °C |

-3.5 °C |

|

|

|

|

|

Table 7-2-1

FILE NO. SVM-06027

7-2-5. Automatic operation