TOSHIBA MW27H62 Service Manual

SERVICE MANUAL

DOCUMENT CREATED IN JAPAN, April, 2006 GREEN

COLOR TELEVISION/

VIDEO CASSETTE RECORDER

/

DVD VIDEO PLAYER

MW27H62

FILE NO. 810-200657GR

The above model is classified as a green product (*1), as indicated by the underlined serial number.

This Service Manual describes replacement parts for the green product. When repairing this green

product, use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), see the next page.

REV.01

(*1) GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for recycling

and reuse of Waste Electrical and Electronic Equipment and for the Restriction of the use of

certain Hazardous Substances. From July 1, 2006, the RoHS Directive will prohibit any

marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba Corporation

recognizes environmental protection as a key management tasks, and is doing its utmost to

enhance and improve the quality and scope of its environmental activities. In line with this,

Toshiba proactively promotes Green Procurement, and seeks to purchase and use products,

parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts used in

manufacture must also be used as replacement parts.

(*2) LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the consumer

products industry at large to be environmentally responsible. Lead-free solder must be used in

the servicing and repair of this product.

WARNING

This product is manufactured using lead free solder .

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT !

The melting temperature of lead-free solder is higher than that of leaded solder by 86°F to 104°F

(30°C to 40°C). Use of a soldering iron designed for lead-based solders to repair product made

with lead-free solder may result in damage to the component and or PCB being soldered. Great

care should be made to ensure high-quality soldering when servicing this product ⎯ especially

when soldering large components, through-hole pins, and on PCBs ⎯ as the level of heat

required to melt lead-free solder is high.

A1-1

A1-2

PREPARATION OF SERVICING

The laser diode used for a pickup head may be destroyed with external static electricity.

Moreover, even if it is operating normally after repair, when static electricity discharge is received at the

time of repair, the life of the product may be shortened.

Please perform the following measure against static electricity, be careful of destruction of a laser diode

at the time of repair.

• Place the unit on a workstation equipped to protect against static electricity, such as conductive mat.

• Soldering iron with ground wire or ceramic type is used.

• A worker needs to use a ground conductive wrist strap for body.

Location of the required Marking

The rating sheet and the safety caution are on the rear of the unit.

CERTIFICATION: COMPLIES WITH FDA

RADIATION PERFORMANCE STANDARDS,

21 CFR SUBCHAPTER J.

CAUTION

THIS DIGITAL VIDEO PLAYER EMPLOYS A LASER SYSTEM.

TO ENSURE PROPER USE OF THIS PRODUCT, PLEASE READ THIS SERVICE MANUAL CARE-

FULLY AND RETAIN FOR FUTURE REFERENCE. SHOULD THE UNIT REQUIRE MAINTENANCE,

CONTACT AN AUTHORIZED SERVICE LOCATION-SEE SERVICE PROCEDURE.

USE OF CONTROLS, ADJUSTMENTS OR THE PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

TO PREVENT DIRECT EXPOSURE TO LASER BEAM, DO NOT TRY TO OPEN THE ENCLOSURE.

VISIBLE LASER RADIATION MAY BE PRESENT WHEN THE ENCLOSURE IS OPENED. DO NOT

STARE INTO BEAM.

A1-3

SERVICING NOTICES ON CHECKING

6. AVOID AN X-RAY1. KEEP THE NOTICES

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

3. USE THE DESIGNATED PARTS

5. TAKE CARE TO DEAL WITH THE

CATHODE-RAY TUBE

In the condition that an explosion-proof cathode-

ray tube is set in this equipment, safety is

secured against implosion. However, when

removing it or serving from backward, it is

dangerous to give a shock. Take enough care to

deal with it.

Safety is secured against an X-ray by consider-

ing about the cathode-ray tube and the high

voltage peripheral circuit, etc.

Therefore, when repairing the high voltage pe-

ripheral circuit, use the designated parts and

make sure not modify the circuit.

Repairing except indicates causes rising of high

voltage, and it emits an X-ray from the cathode-

ray tube.

PERFORM A SAFETY CHECK AFTER

SERVICING

7.

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.

2.

3.

4.

Unplug the plug from the AC outlet.

Remove the antenna terminal on TV and turn

on the TV.

Insulation resistance between the cord plug

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

If the insulation resistance is less than 1M

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

4. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

HOW TO ORDER PARTS

A1-4

IMPORTANT SAFEGUARDS

1.

2.

3.

4.

5.

6.

7.

8.

8A.

9.

10.

11.

12.

13.

14.

15.

16.

READ INSTRUCTIONS

All the safety and operating instructions should be read before the unit is operated.

RETAIN INSTRUCTIONS

The safety and operating instructions should be retained for future reference.

HEED WARNINGS

All warnings on the unit and in the operating instructions should be adhered to.

FOLLOW INSTRUCTIONS

All operating and use instructions should be followed.

CLEANING

Unplug this unit from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp

cloth for cleaning.

ATTACHMENTS

Do not use attachments not recommended by the unit’s manufacturer as they may cause hazards.

WATER AND MOISTURE

Do not use this unit near water. For example, near a bathtub, washbowl, kitchen sink, or laundry tub, in a wet

basement, or near a swimming pool.

ACCESSORIES

Do not place this unit on an unstable cart, stand, tripod, bracket, or table. The

unit may fall, causing serious injury, and serious damage to the unit. Use only

with a cart, stand, tripod, bracket, or table recommended by the manufacturer.

An appliance and cart combination should be moved with care. Quick stops,

excessive force, and uneven surfaces may cause the appliance and cart

combination to overturn.

VENTILATION

Slots and openings in the cabinet and in the back or bottom are provided for ventilation, to ensure reliable

operation of the unit, and to protect it from overheating. These openings must not be blocked or covered. The

openings should never be blocked by placing the unit on a bed, sofa, rug, or other similar surface. This unit

should never be placed near or over a radiator or heat source. This unit should not be placed in a built-in

installation such as a bookcase or rack unless proper ventilation is provided or the manufacturer’s instructions

have been adhered to.

POWER SOURCES

This unit should be operated only from the type of power source indicated on the rating plate. If you are not sure

of the type of power supply to your home, consult your appliance dealer or local power company. For units

intended to operate from battery power, or other sources, refer to the operating instructions.

GROUNDING OR POLARIZATION

This unit is equipped with a polarized alternating-current line plug (a plug having one blade wider than the other).

This plug will fit into the power outlet only one way. This is a safety feature. If you are unable to insert the plug

fully into the outlet, try reversing the plug. If the plug should still fail to fit, contact your electrician to replace your

obsolete outlet. Do not defeat the safety purpose of the polarized plug. If your unit is equipped with a 3-wire

grounding-type plug, a plug having a third (grounding) pin, this plug will only fit into a grounding-type power

outlet. This too, is a safety feature. If you are unable to insert the plug into the outlet, contact your electrician to

replace your obsolete outlet. Do not defeat the safety purpose of the grounding-type plug.

POWER-CORD PROTECTION

Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed upon

or against them, paying particular attention to cords at plugs, convenience receptacles, and the point where they

exit from the appliance.

LIGHTNING

To protect your unit from a lightning storm, or when it is left unattended and unused for long periods of time,

unplug it from the wall outlet and disconnect the antenna or cable system. This will prevent damage to the unit

due to lightning and power line surges.

POWER LINES

An outside antenna system should not be located in the vicinity of overhead power lines or other electric light or

power circuits, or where it can fall into such power lines or circuits. When installing an outside antenna system,

extreme care should be taken to keep from touching such power lines or circuits, as contact with them might be

fatal.

OVERLOADING

Do not overload wall outlets and extension cords, as this can result in a risk of fire or electric shock.

OBJECT AND LIQUID ENTRY

Do not push objects through any openings in this unit, as they may touch dangerous voltage points or short out

parts that could result in fire or electric shock. Never spill or spray any type of liquid into the unit.

PORT ABLE CART WARNING

(symbol provided by RETAC)

S3126A

A1-5

IMPORTANT SAFEGUARDS (CONTINUED)

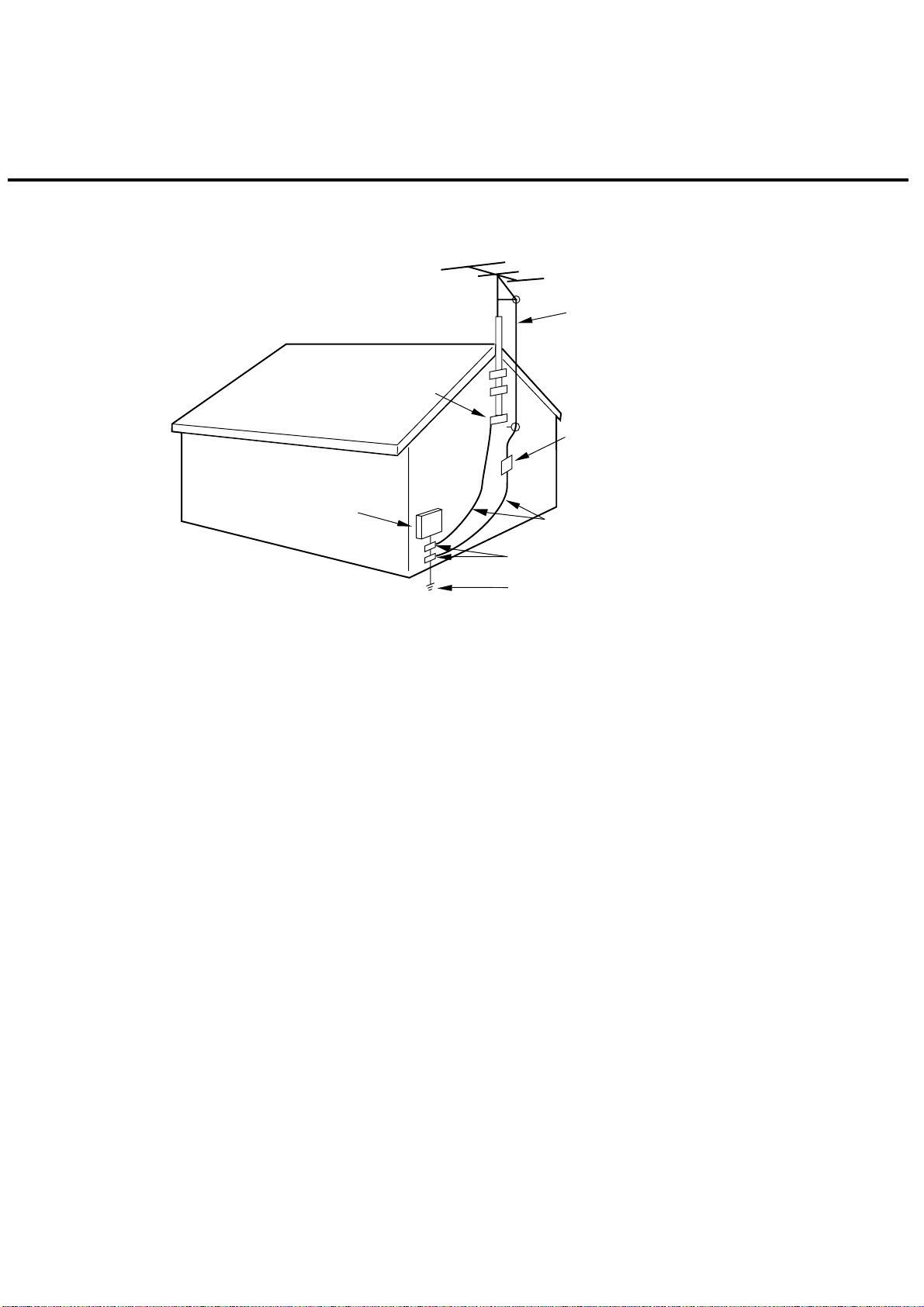

OUTDOOR ANTENNA GROUNDING

If an outside antenna or cable system is connected to the unit, be sure the antenna or cable system is grounded

so as to provide some protection against voltage surges and built-up static charges. Section 810 of the National

Electrical Code, ANSI/NFPA 70, provides information with respect to proper grounding of the mast and supporting

structure, grounding of the lead-in wire to an antenna discharge unit, size of grounding conductors, location of

antenna discharge unit, connection to grounding electrodes, and requirements for the grounding electrode.

SERVICING

Do not attempt to service this unit yourself as opening or removing covers may expose you to dangerous voltage

or other hazards. Refer all servicing to qualified service personnel.

DAMAGE REQUIRING SERVICE

Unplug this unit from the wall outlet and refer servicing to qualified service personnel under the following

conditions:

REPLACEMENT PARTS

When replacement parts are required, be sure the service technician uses replacement parts specified by the

manufacturer or those that have the same characteristics as the original parts.

Unauthorized substitutions may result in fire, electric shock or other hazards.

SAFETY CHECK

Upon completion of any service or repairs to this unit, ask the service technician to perform safety checks to

determine that the unit is in proper operating condition.

WALL OR CEILING MOUNTING

The product should be mounted to a wall or ceiling only as recommended by the manufacturer.

HEAT

The product should be situated away from heat sources such as radiators, heat registers, stoves, or other

products (including amplifiers) that produce heat.

DISC TRAY

Keep your fingers well clear of the disc tray as it is closing. It may cause serious personal injury.

CONNECTING

When you connect the product to other equipment, turn off the power and unplug all of the equipment from the

wall outlet. Failure to do so may cause an electric shock and serious personal injury. Read the owner's manual of

the other equipment carefully and follow the instructions when making any connections.

SOUND VOLUME

Reduce the volume to the minimum level before you turn on the product. Otherwise, sudden high volume sound

may cause hearing or speaker damage.

SOUND DISTORTION

Do not allow the product output distorted sound for a longtime. It may cause speaker overheating and fire.

HEADPHONES

When you use the headphones, keep the volume at a moderate level. If you use the headphones continuously

with high volume sound, it may cause hearing damage.

LASER BEAM

Do not look into the opening of the disc tray or ventilation opening of the product to see the source of the laser

beam. It may cause sight damage.

DISC

Do not use a cracked, deformed, or repaired disc. These discs are easily broken and may cause serious

personal injury and product malfunction.

NOTE TO CATV SYSTEM INSTALLER

This reminder is provided to call the CATV system installer’s attention to Article 820-40 of the NEC that provides

guidelines for proper grounding and, in particular, specifies that the cable ground shall be connected to the

grounding system of the building, as close to the point of cable entry as practical.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

a.

b.

c.

d.

e.

f.

When the power-supply cord or plug is damaged.

If liquid has been spilled, or objects have fallen into the unit.

If the unit has been exposed to rain or water.

If the unit does not operate normally by following the operating instructions. Adjust only those controls that

are covered by the operating instructions, as an improper adjustment of other controls may result in

damage and will often require extensive work by a qualified technician to restore the unit to its normal

operation.

If the unit has been dropped or the cabinet has been damaged.

When the unit exhibits a distinct change in performance, this indicates a need for service.

A1-6

EXAMPLE OF ANTENNA GROUNDING AS PER THE NATIONAL ELECTRICAL CODE

ANTENNA

DISCHARGE UNIT

(NEC SECTION 810-20)

ANTENNA LEAD

IN WIRE

GROUNDING CONDUCTORS

(NEC SECTION 810-21)

GROUND CLAMPS

POWER SERVICE GROUNDING

ELECTRODE SYSTEM

(NEC ART 250, PART H)

GROUND

CLAMP

ELECTRIC SERVICE

EQUIPMENT

NEC-NATIONAL ELECTRICAL CODE

S2898A

IMPORTANT SAFEGUARDS (CONTINUED)

A1-7

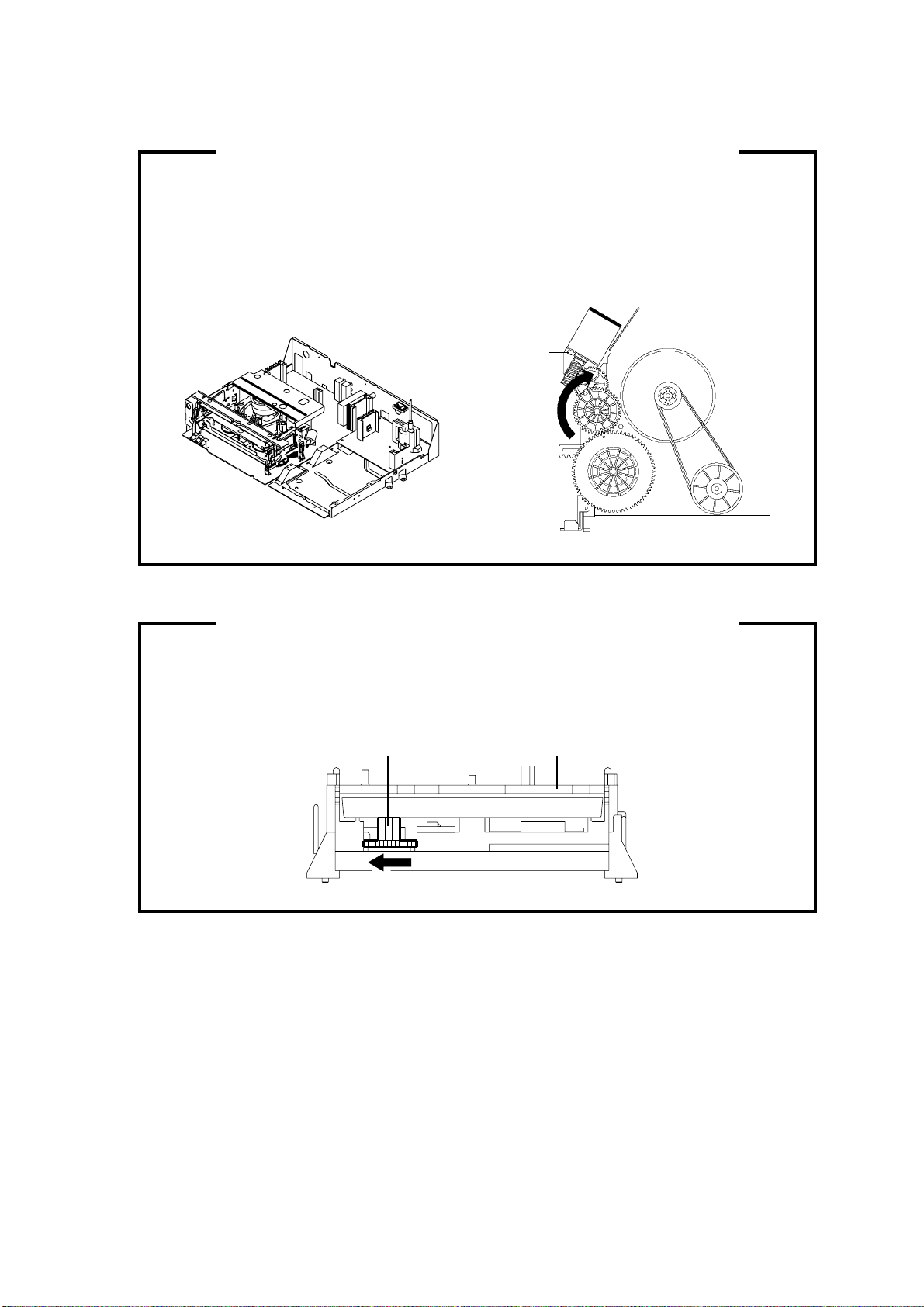

Before removing Pick Up PCB and DVD PCB connector, the short circuit the position shown in Fig. 1

using a soldering iron. If you remove the DVD Deck with no soldering, the Laser may be damaged.

WHEN REPLACING DVD DECK

[ When removing the DVD Deck ]

[ When installing the DVD Deck ]

Remove all the soldering on the short circuit position after the connection of Pick Up PCB and DVD

PCB connector.

NOTE

Fig. 1

Before your operation, please read “PREPARATION OF SERVICING”.

Use the Lead Free solder.

Manual soldering conditions

• Soldering temperature: 350 ± 5˚C

• Soldering time: Within 2 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

When Soldering/Removing of solder, use the draw in equipment over the Pick Up Unit to keep the

Flux smoke away from it.

•

•

•

•

Short circuit using a

soldering iron.

Pick Up PCB

A1-8

1.

2.

3.

Remove the Back Cabinet and AV PCB/DVD Block. (Refer to item 1 of the DISASSEMBLY

INSTRUCTIONS.)

Rotate the Main Gear in the direction of the arrow by hand.

(Refer to Fig. 1)

Manually open the Tray.

DISC REMOVAL METHOD AT NO POWER SUPPLY

Fig. 1

Deck CDMain Gear

1.

2.

3.

4.

5.

Remove the TV/DVD/VCR block from the main unit as shown in Fig. 1 below can be seen.

(Refer to item 1 of the DISASSEMBLY INSTRUCTIONS.)

Remove the screw 1 of the Deck Chassis and remove the Loading Motor.

Rotate the Pinch Roller Cam in the direction of the arrow by hand to slacken the Video Tape.

(Refer to Fig. 2)

Rotate the Clutch Ass'y either direction to wind the Video Tape in the Cassette Case.

Repeat steps 3~4. Then take out the Video Cassette from the Deck Chassis. Be careful not to scratch

the tape.

TAPE REMOVAL METHOD AT NO POWER SUPPLY

Fig. 1

Pinch Roller Cam

Main Cam

Clutch Ass'y

Main Chassis (Front Side)

Loading Motor

Screw 1

Capstan DD Unit

Fig. 2

A1-9

Tray cannot be opened by setting the Tray Lock, please follow the steps below.

Turn Unit ON.

Set the DVD to the Stop Mode.

Press it in order of 'SETUP', 'SUBTITLE', '3', 'AUDIO SELECT' and '0' key of a remote control unit.

The On Screen Display message ' ' will appear.

The Tray Lock has now been set up.

1.

2.

3.

4.

5.

TRAY LOCK

To unlock the Tray Lock, please follow the steps below.

Turn Unit ON.

Set the DVD to the Stop Mode.

Press it in order of 'SETUP', 'SUBTITLE', '3', 'AUDIO SELECT' and '0' key of a remote control unit.

The On Screen Display message ' ' will appear.

The Tray Lock has now been cleared.

1.

2.

3.

4.

5.

PARENTAL CONTROL - RATING LEVEL

4 DIGIT PASSWORD CANCELLATION

If the stored 4 digit password in the Rating Level menu needs to be cancelled, please follow the steps below.

Turn Unit ON.

Set the DVD Mode.

Confirm that the 'No Disc' will be appeared on the screen.

Press and hold the '7' key on the remote control unit.

Simultaneously press and hold the 'STOP' key on the front panel.

Hold both keys for more than 3 seconds.

The On Screen Display message 'PASSWORD CLEAR' will appear.

The 4 digit password has now been cleared

1.

2.

3.

4.

5.

6.

7.

8.

TABLE OF CONTENTS

A1-1

A1-1

A1-2

A1-3

A1-3

A1-4~A1-6

A1-7

A1-8

A1-8

A1-9

A1-9

A2-1

A3-1~A3-6

B1-1~B1-3

B2-1~B2-6

B3-1~B3-4

B4-1

B5-1, B5-2

C1-1, C1-2

C2-1

C3-1, C3-2

C4-1

D1-1

D1-1

D2-1~D2-4

D3-1~D3-6

E-1, E-2

E-3, E-4

E-5, E-6

E-7, E-8

E-9, E-10

E-11, E-12

E-13, E-14

E-15, E-16

E-17, E-18

E-19, E-20

E-21, E-22

F-1, F-2

F-3~F-6

F-7~ F-10

F-11, F-12

G-1, G-2

G-3, G-4

G-5, G-6

G-7, G-8

G-9, G-10

G-11, G-12

G-13, G-14

G-15, G-16

G-17, G-18

G-19, G-20

G-21, G-22

G-23, G-24

G-25, G-26

G-27, G-28

G-29, G-30

G-31, G-32

G-33, G-34

G-35, G-36

G-37, G-38

G-39, G-40

G-41, G-42

G-43, G-44

G-45, G-46

G-47, G-48

G-49, G-50

G-51, G-52

H-1~H-3

I1-1~I1-3

I2-1, I2-2

I3-1

J1-1, J1-2

J2-1

J3-1

J4-1~J4-8

A2-1

GREEN PRODUCT PROCUREMENT .....................................................................................

LEAD-FREE SOLDER .............................................................................................................

CAUTION .................................................................................................................................

SERVICING NOTICES ON CHECKING..................................................................................

HOW TO ORDER PARTS .......................................................................................................

IMPORTANT SAFEGUARDS..................................................................................................

WHEN PERLACING DVD DECK ............................................................................................

TAPE REMOVAL METHOD AT NO POWER SUPPLY .........................................................

DISC REMOVAL METHOD AT NO POWER SUPPLY ..........................................................

PARENTAL CONTROL RATING LEVEL ...............................................................................

TRAY LOCK.............................................................................................................................

TABLE OF CONTENTS...........................................................................................................

GENERAL SPECIFICATIONS ................................................................................................

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS AND P. C. BOARDS.........................................

2. REMOVAL OF VCR DECK PARTS ................................................................................

3. REMOVAL OF DVD DECK PARTS ................................................................................

4. REMOVAL OF ANODE CAP...........................................................................................

5. REMOVAL AND INSTALLATION OF FLAT PACKAGE IC ............................................

KEY TO ABBREVIATIONS .....................................................................................................

SERVICE MODE LIST .............................................................................................................

PREVENTIVE CHECKS AND SERVICE INTERVALS...........................................................

WHEN REPLACING EEPROM (MEMORY) IC ......................................................................

SERVICING FIXTURES AND TOOLS ....................................................................................

PREPARATION FOR SERVICING..........................................................................................

MECHANICAL ADJUSTMENTS .............................................................................................

ELECTRICAL ADJUSTMENTS...............................................................................................

BLOCK DIAGRAMS

DVD.......................................................................................................................................

SD DIGITAL MODULE .........................................................................................................

Y/C/AUDIO/HEAD AMP .......................................................................................................

MICON ..................................................................................................................................

IN/OUT ..................................................................................................................................

CHROMA/IF..........................................................................................................................

SOUND AMP/SURROUND/REGULATOR ..........................................................................

Hi-Fi/DEMODULATOR .........................................................................................................

TUNER/DIGITAL COMB FILTER/DVD IN/OUT...................................................................

REGULATOR........................................................................................................................

TV .........................................................................................................................................

PRINTED CIRCUIT BOARDS

DVD/USB ..............................................................................................................................

VCR.......................................................................................................................................

DEFLECTION/CRT/REGULATOR/OPERATION/VM COIL ................................................

DIGITAL/LOADING MOTOR/SW .........................................................................................

SCHEMATIC DIAGRAMS

MPEG/MICON/DSP/RF_AMP ..............................................................................................

MEMORY ..............................................................................................................................

MOTOR DRIVE ....................................................................................................................

AUDIO/VIDEO ......................................................................................................................

USB.......................................................................................................................................

Y/C/AUDIO/HEAD AMP .......................................................................................................

MICON ..................................................................................................................................

IN/OUT ..................................................................................................................................

CHROMA/IF..........................................................................................................................

Hi-Fi ......................................................................................................................................

TUNER/DVD IN/OUT ...........................................................................................................

REGULATOR........................................................................................................................

TV POWER...........................................................................................................................

COMB FILTER......................................................................................................................

ASIC......................................................................................................................................

SDRAM .................................................................................................................................

FLASH ..................................................................................................................................

FRONT END .........................................................................................................................

AV OUT.................................................................................................................................

DEFLECTION .......................................................................................................................

SOUND AMP/SURROUND ..................................................................................................

CRT / SVM............................................................................................................................

OPERATION.........................................................................................................................

DTV REGURATOR...............................................................................................................

LOADING MOTOR/SW ........................................................................................................

INTERCONNECTION DIAGRAM ............................................................................................

WAVEFORMS ..........................................................................................................................

MECHANICAL EXPLODED VIEWS........................................................................................

CHASSIS EXPLODED VIEWS ................................................................................................

DVD DECK EXPLODED VIEWS .............................................................................................

MECHANICAL REPLACEMENT PARTS LIST ......................................................................

CHASSIS REPLACEMENT PARTS LIST...............................................................................

DVD DECK REPLACEMENT PARTS LIST............................................................................

ELECTRICAL REPLACEMENT PARTS LIST........................................................................

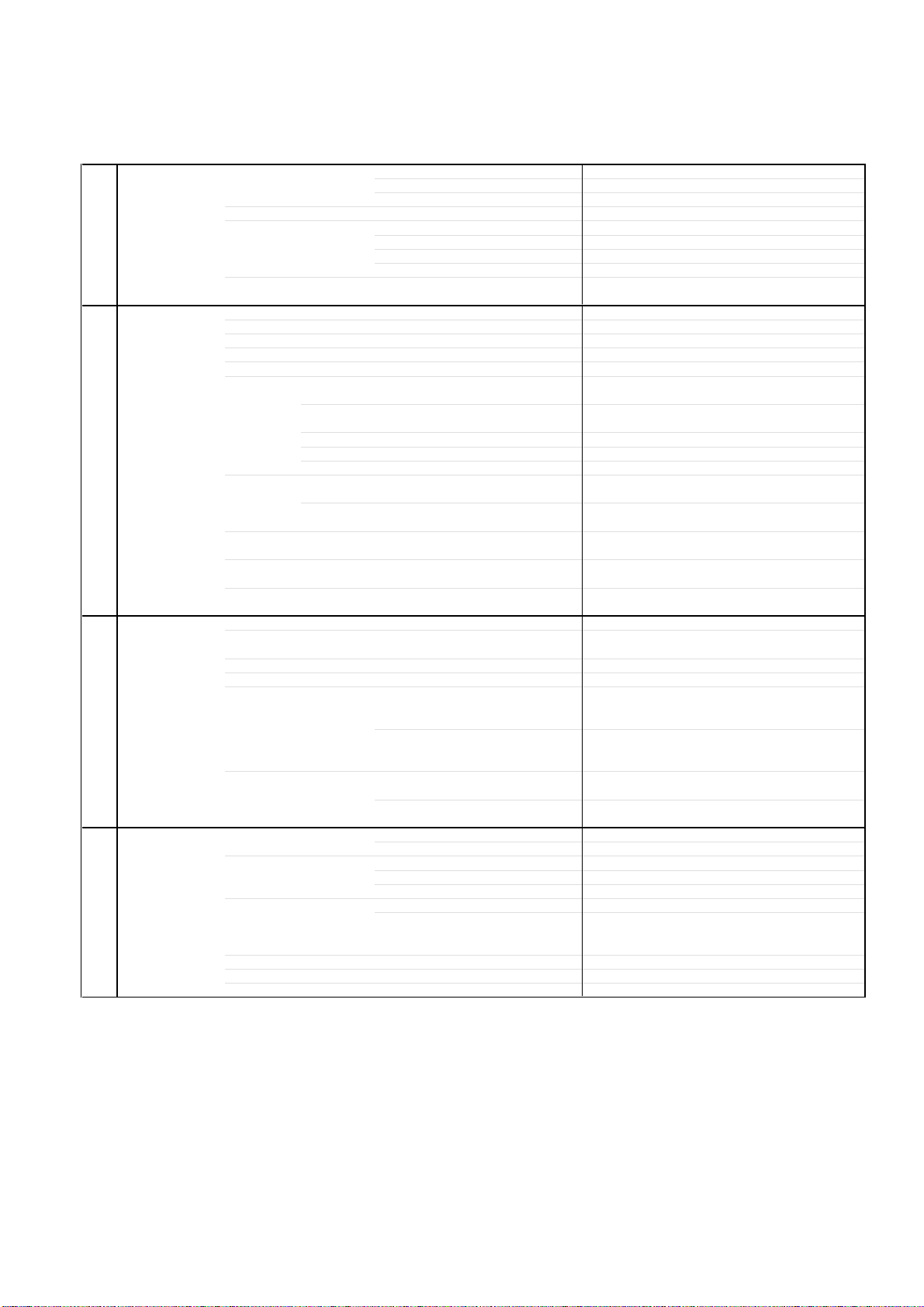

GENERAL SPECIFICATIONS

G-1 TV CRT CRT Size / Visual Size 27 inch / 676.6mmV

System CRT Type Flat

Magnetic Field BV/BH +0.45G / 0.18G

Color System NTSC

Speaker 2 Speaker

Position Front

Size 1.8 x 3.9 Inch

Impedance 8 ohm

Sound Output MAX 2.5W + 2.5W

10%(Typical) __

G-2 VCR System VHS Player / Recorder

System Video System NTSC

Hi-Fi STEREO Yes

NTSC PB -

Deck OVD-7

Heads Video Head 4 Heads

FM Audio Head 2 Heads

Audio /Control Mono /Yes

Erase(Full Track Erase) Yes

Erase (Normal Audio Track Erase) Yes

Tape Rec PAL -

Speed NTSC SP/SLP(EP)

Play PAL -

NTSC SP/SLP(EP)

Fast Forward / Rewind Time (Approx.) at 25oC FF:1'48"/REW:1'48"

with Cassette T-120

Forward/Reverse NTSC or PAL-M SP/SLP(EP)=3x,5x / 9x,15x

Picture Search

Frame Advance Yes

Slow Speed 1/10

G-3 DVD System Color System NTSC

Disc DVD, CD-DA, CD-R/RW, Video CD

DVD-R/RW (Video Format Only)

Disc Diameter 120 mm , 80 mm

Drive DM3SA

Search speed Fwd 4 step

Actual 2-120 times(DVD, VIDEO CD)

4-40 times (CD)

Rev 4 step

Actual 2-120 times(DVD, VIDEO CD)

4-40 times (CD)

Slow speed Fwd 1/7 - 1/2 times

Actual --

Rev --

Actual --

G-4 Tuning Broadcasting System Analog US System M

System Digital ATSC(8VSB), QAM

Tuner and System 1 Tuner

Receive CH Destination US(w/CABLE)

CH Coverage 2~69, 4A, A-5~A-1, A~I, J~W, W+1~W+84

Intermediate Digital 44.00MHz

Frequency Analog Picture(FP) 45.75MHz

Sound(FS) 41.25MHz

FP-FS 4.5MHz

Preset CH

No

Stereo/Dual TV Sound US-Stereo

Tuner Sound Muting Yes

A3-1

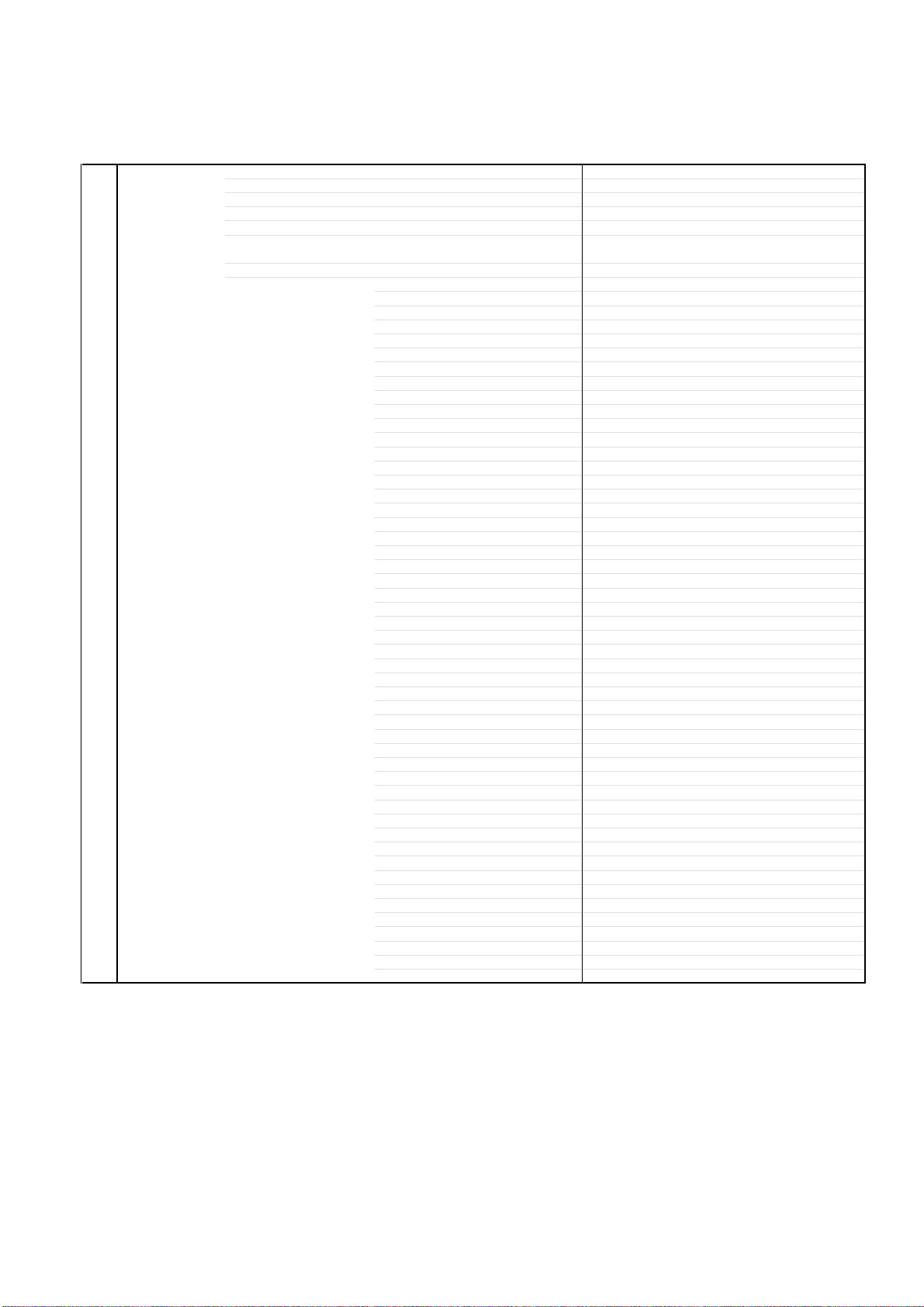

GENERAL SPECIFICATIONS

G-5 Signal Video Signal Input Level 1 V p-p/75 ohm

Output Level -

S/N Ratio (Weighted) at DVD Mode -

S/N Ratio (Weighted) at VCR Mode -

Horizontal Resolution at DVD Mode -

Horizontal Resolution at VCR(SP)Mode -

RGB Signal Output Level -

Audio Signal Input Level -8.0dBm/50k ohm

VCR Output Level(0dB=0.775Vrms) -

DVD Output Level(-20dBFs 0dBFs=2.0Vrms) -

Digital Output Level 0.5 V p-p/75 ohm(DVD/DTV)

S/N Ratio at DVD (Weighted) -

S/N Ratio at VCR (SP)(CCIR Filter:ON) -

Harmonic Distortion at DVD Mode -

Harmonic Distortion at VCR(SP) Mode -

Frequency Response :

DVD Mode at DVD -

at Video CD -

at SVCD -

at CD -

VCR Mode at SP -

at LP -

at SLP -

Hi-Fi Audio Signal Dynamic Range : More than 90 dB

Frequency Response : 20Hz - 20kHz

Wow And Flutter : Less than 0.01 %Wrms

Channel Separation : More than 60 dB

Harmonic Distortion : Less than 1.0 %

G-6 Power Power Source AC 120V,60Hz

DC -

Power Consumption at AC 150 W at 120 V 60 Hz

at DC -

Stand by (at AC) 4 W at 120 V 60 Hz

Per Year -

Energy Star

No

Protector Power Fuse Yes

Safety Circuit Yes

IC Protector(Micro Fuse) No

Dew Sensor

No

G-7 Regulation Safety UL

Radiation FCC

X-Radiation DHHS

Laser DHHS

G-8 Temperature Operation +5oC ~ +40oC

Storage -20oC ~ +60oC

G-9 Operating Humidity Less than 80% RH

G-10 OSD Language English French Spanish

G-11 Clock,Timer Calendar 1990/1/1 ~ 2081/12/31

and Timer Timer Events 8 Program/ 1 Month

Back-up One Touch Recording Max Time 6 Hours

Sleep Timer Max Time 120

Min

Step 10

Min

On/Off Timer Program(On Timer / Off Timer) 1

Program

Auto Shut Off No Signal 15

Min

No Operation -

Min

Timer Back-up (at Power Off Mode) 5

Sec

A3-2

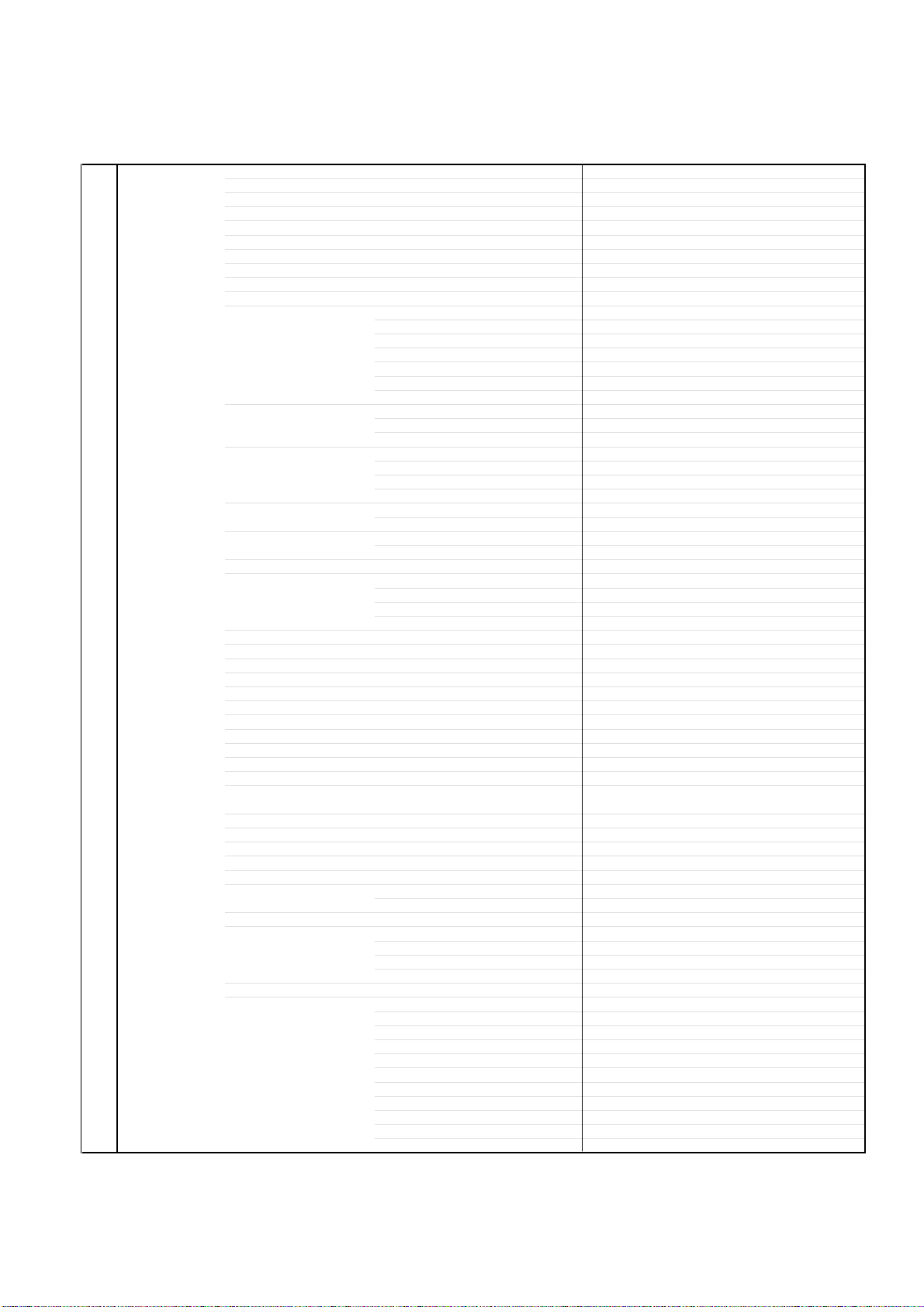

GENERAL SPECIFICATIONS

G-12 Remote Unit RC-KH

Control Glow in Dark Remocon No

Unit Remocon Format TOSHIBA

Format TOSHIBA

Custom Code 40-BFh, 44-BBh, 45-BAh

Power Source Voltage(D.C) 3V

UM size x pcs UM-4 x 2 pcs

Total Keys 50

Keys

TV/VCR

Yes

DVD

Yes

Power

Yes

1

Yes

2

Yes

3

Yes

4

Yes

5

Yes

6

Yes

7

Yes

8

Yes

9

Yes

0

Yes

Channel-

Yes

Channel+

Yes

Volume-

Yes

Volume+

Yes

Display/-

Yes

Sleep

Yes

Audio Select

Yes

Mute

Yes

Channel Return / Skip-

Yes

Closed Caption / Skip+

Yes

TIMER REC

Yes

REC/OTR

Yes

Slow+

Yes

Play

Yes

Stop

Yes

REV(Rew)

Yes

FF(F. Fwd)

Yes

Pause / Still /Step

Yes

CM Skip / Jump

Yes

Speed / Return

Yes

Counter Reset / Angle

Yes

Zero Return / Subtitle

Yes

Input Select / Zoom

Yes

Menu /Setup

Yes

Program / Repeat A-B / DVD/USB

Yes

D.Tracking / Top Menu

Yes

Tracking+ / DVD Menu

Yes

Tracking- / Play Mode

Yes

Cancel

Yes

Cursor Up

Yes

Cursor Down

Yes

Cursor Left

Yes

Cursor Right

Yes

Enter

Yes

Open/Close

Yes

Eject Yes

Picture Size

Yes

A3-3

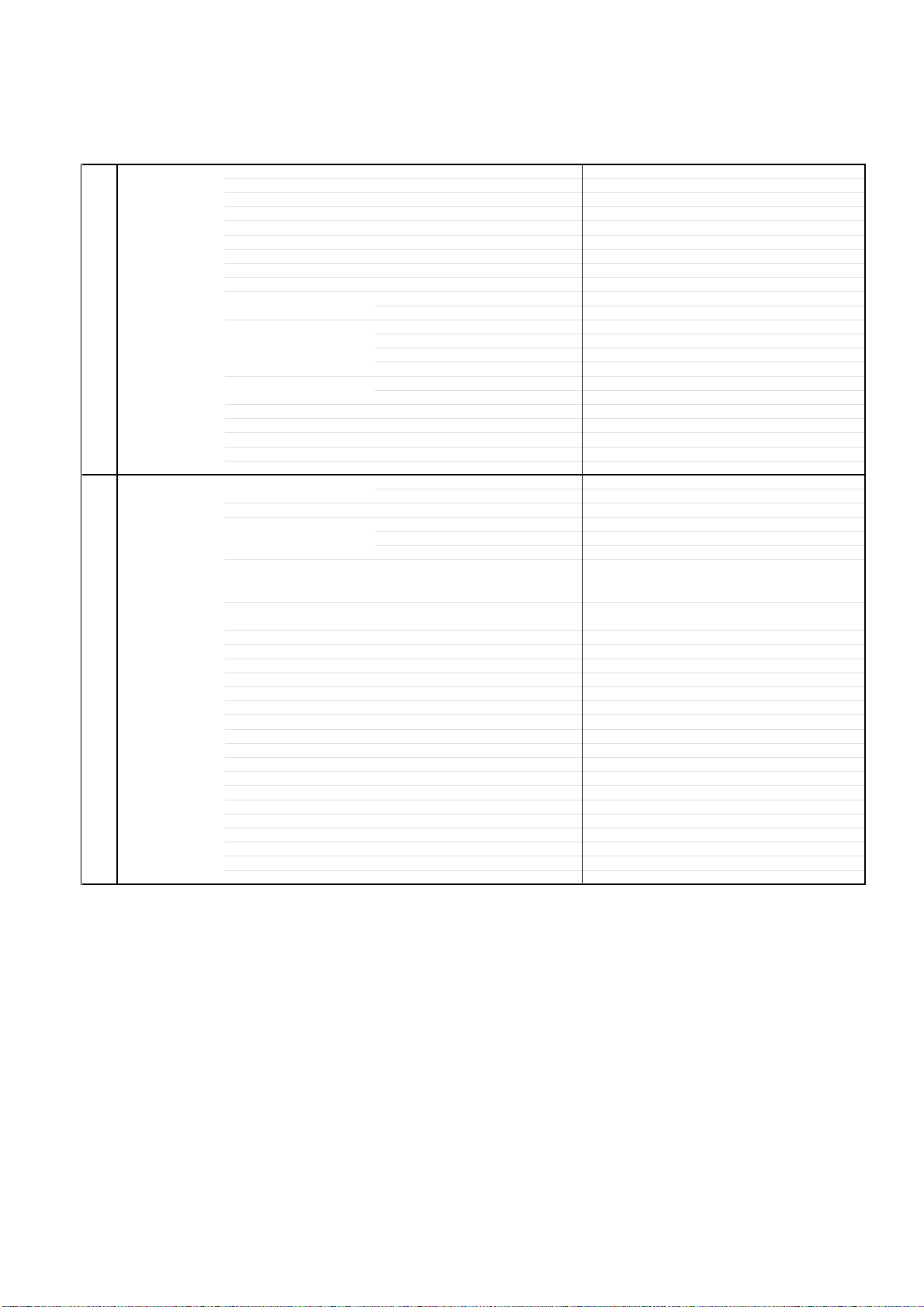

GENERAL SPECIFICATIONS

G-13 Features Auto Head Cleaning Yes

(TV/VCR) VIDEO PLUS+(SHOWVIEW,G-CODE)

No

Forward / Reverse Picture Search Yes

Index Search

No

SQPB

No

CM Skip(30sec x 6 Times) Yes

Zero Return Yes

End Call

No

TV Monitor

No

Program Extend

No

Picture Brightness , Contrast , Color, Sharpness Yes

Tint Yes

Mode (Picture Preference) Yes

Color Temperature Yes

CableClear

No

Cinema Mode

No

Aspect

No

Audio Tone Control (Bass/Treble/Balance) Yes

Stable Sound Yes

Surround Yes

Timer On Timer Yes

Off Timer Yes

Sleep Timer Yes

Game Timer

No

Tuning Auto CH Memory Yes

ADD/Delete Yes

Label CH Label

No

Video Label

No

Favorite CH

No

Lock Hotel Lock

No

Channel Lock

No

Video Lock

No

Front Panel Lock

No

Closed Caption (Analog & Digital) Yes

CC Advance Yes

Signal Mater Yes

Auto Setup Yes

Auto Clock Yes

Picture Size Yes

Picture Scroll

No

Zoom Yes

CABLE Yes

QAM Yes

SAP Yes

Comb Filter Yes

3 Lines

VM Circuit Yes

Protect of FBT Leak Circuit Yes

TV Auto Shut off Function Yes

Power On Memory

No

Choke Coil

No

V-chip USA V-chip Yes

CANADA V-chip

No

RRT Setup

No

Digital Out Dolby Digital Yes

MPEG

No

PCM Yes

DTS

No

HDMI Input

No

Component Input Yes

720x480i (4:3) Yes (60Hz)

720x480i (16:9) Yes (60Hz)

720x480p (4:3) No

720x480p (16:9) No

720x576i (4:3) No

720x576i (16:9) No

720x576p (4:3) No

720x576p (16:9) No

1280x720p No

1920x1080i No

A3-4

GENERAL SPECIFICATIONS

Features Tray Lock Yes

(DVD) Auto Stop (Pause, and Resume Stop after 5min.) Yes

USB (Some USB devices may not be usable.) Yes

Card Slot Reading (Not secured Data) No

Video CD Playback Yes

SVCD Playback

No

MP3 Playback Yes

WMA Playback Yes

JPEG Playback Yes

DivX Play back Yes

DMF Support

No

Digital Out (Dolby Digital) Yes

(MPEG) Yes

(PCM) Yes

(DTS) Yes

Down Mix Out (Dolby Digital) Yes

(DTS)

No

Surround

No

Closed Caption Signal in VBI (DVD Playback)

Yes

Screen Saver

No

Audio DAC 192kHz / 24bit

Copy (Disc to Tape) Yes (by Conditioning)

G-14 Accessories Owner's Manual Language English

w/Guarantee Card Yes

Remote Control Unit Yes

Battery Yes

UM size x pcs UM-4 x 2 pcs

OEM Brand

No

Rod Antenna

No

Poles -

Terminal -

Loop Antenna

No

Terminal -

U/V Mixer

No

300 ohm to 75 ohm Antenna Adapter Yes

Antenna Change Plug

No

DC Car Cord (Center+)

No

AC Plug Adapter

No

AC Cord

No

AV Cord (2Pin-1Pin)

No

Guarantee Card

No

Registration Card Yes

ESP Card

No

Warning Sheet Yes

Dew/AHC Caution Sheet

No

Quick Set-up Sheet Yes

Circuit Diagram

No

Service Facility List

No

Important Safeguard

No

Information Sheet (Return) Yes

Netflix Card No

A3-5

GENERAL SPECIFICATIONS

G-15 Interface Switch Front Power (Tact) Yes

Channel Up Yes

Channel Down Yes

Volume Up Yes

Volume Down Yes

Play (VCR) Yes

Stop / Eject (VCR) Yes

F.FWD/Cue (VCR) Yes

Rew/Rev (VCR) Yes

REC/OTR (VCR) Yes

Play (DVD) Yes

Stop (DVD) Yes

Skip+ /Search+ (DVD) Yes

Skip- /Search- (DVD) Yes

Open/Close (DVD) Yes

Input Select No

Main Power SW No

Indicator Power Yes (Red)

REC/OTR Yes (Red)

T-REC Yes (Red)

TV/VCR No

DVD No

Terminals Front Video Input RCA x 1 (Yellow)

Audio Input RCA x 2 (L/MONO,R White,Red)

S-Video Input

Yes

USB

Yes

Other Terminal No

Rear Video Input RCA x 1 (Yellow)

Audio Input RCA x 2 (L/MONO,R White,Red)

Video Output No

Audio Output No

Component Input

RCA x 3

Audio Input

RCA x 2 (L/MONO, R White,Red)

Digital Audio Output Coaxial (DTV & DVD Only)

VHF/UHF Antenna Input F Type

AC Inlet No

G-16 Set Size Approx. W x D x H (mm) 740 x 493 x 645

G-17 Weight Net (Approx.) 44.0kg (97.0lbs)

Gross (Approx.) 48.5kg (107.0lbs)

G-18 Carton Master Carton

No

Content -

Material -

Dimensions W x D x H(mm) -

Description of Origin -

Gift Box Material Double/Brown

Dimensions W x D x H(mm) 851 x 618 x 776

Description of Origin Yes

Drop Test Natural Dropping At 1 Corner / 2 Edges / 4 Surfaces

Height (cm) 40(ORION SPEC:25)

Container Stuffing(40' container) 156

Sets

G-19 Material Cabinet Front PS 94V0 DECABROM

Rear PS 94V0 DECABROM

Jack Panel -

PCB Non-Halogen Demand No

Eyelet Demand Yes

G-20 Environment Environmental standard requirement (by buyer) Green procurement of TOSHIBA

Pb-free Phase3(Phase3A)

Measures for Whisker Yes

A3-6

DISASSEMBLY INSTRUCTIONS

B1-1

1. REMOVAL OF MECHANICAL PARTS

AND P.C. BOARDS

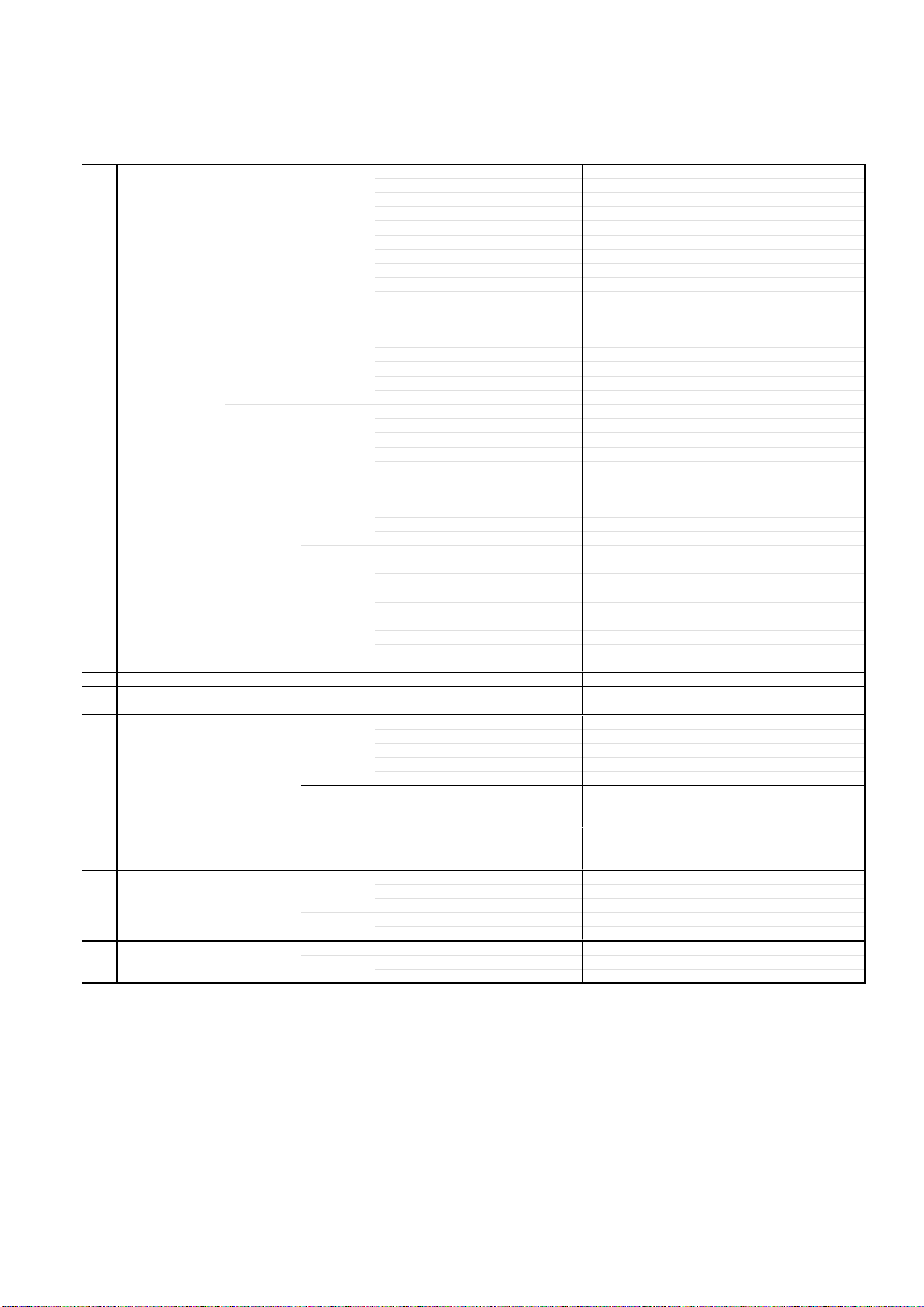

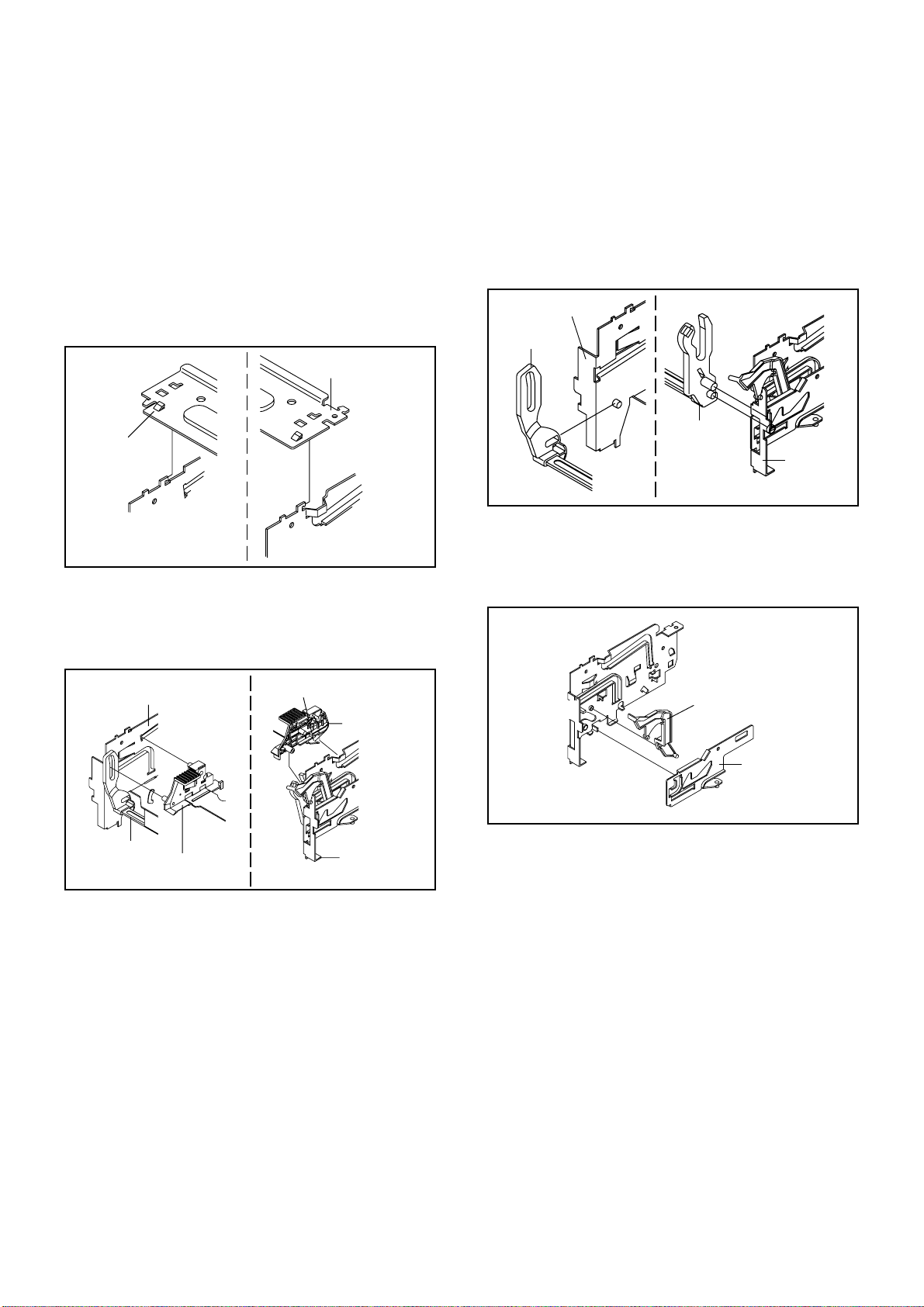

1-1: BACK CABINET (Refer to Fig. 1-1)

1.

2.

3.

Remove the 6 screws 1.

Remove the 2 screws 2.

Remove the Back Cabinet in the direction of arrow.

1-2: CRT PCB (Refer to Fig. 1-2)

CAUTION: BEFORE REMOVING THE ANODE CAP,

DISCHARGE ELECTRICITY BECAUSE IT

CONTAINS HIGH VOLTAGE.

BEFORE ATTEMPTING TO REMOVE OR

REPAIR ANY PCB, UNPLUG THE POWER

CORD FROM THE AC SOURCE.

1.

2.

3.

Remove the Anode Cap.

(Refer to REMOVAL OF ANODE CAP)

Disconnect the following connectors:

(CP801B, CP802B, CP803, CP806, CP851B and CP852A).

Remove the CRT PCB in the direction of arrow.

CRT PCB

Front Cabinet

Fig. 1-1

Fig. 1-2

Front Cabinet

1

1

1

1

Back Cabinet

1

1

2

2

1-3: TV/DVD/VCR BLOCK (Refer to Fig. 1-3)

1.

2.

3.

Remove the 2 screws 1.

Disconnect the following connectors:

(CP351, CP404, CP1704 and CP5902).

Remove the TV/DVD/VCR Block in the direction of arrow.

Fig. 1-3

CP801B

CP803

CP802B

CP404

CP1704

TV/DVD/VCR Block

1

1

Front Cabinet

CP351

CP851B

CP852A

CP806

CP5902

1-4: TV/DVD/VCR BLOCK (Refer to Fig. 1-4)

1.

2.

Remove the 5 screws 1.

Remove the USB PCB in the direction of arrow.

Fig. 1-4

1

Front Cabinet

1

1

1

USB PCB

1

DISASSEMBLY INSTRUCTIONS

B1-2

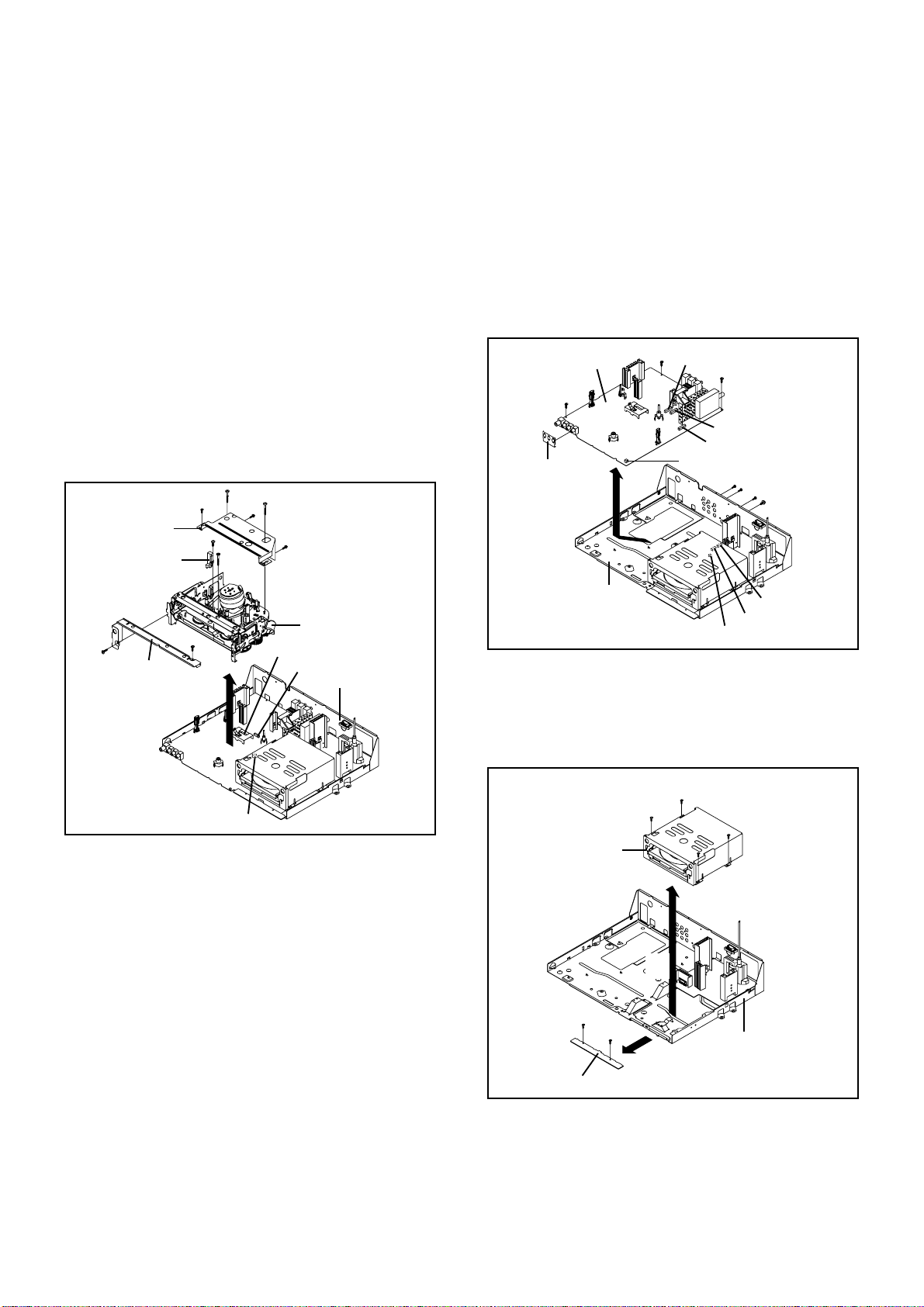

1-6: VCR PCB (Refer to Fig. 1-6)

1.

2.

3.

4.

5.

Remove the 6 screws 1.

Remove the screw 2.

Remove the AV Jack Shield.

Disconnect the following connectors:

(CP001, CP301, CP602B, CP604, CP2201, CP8001 and

CP8002).

Remove the VCR PCB in the direction of arrow.

Fig. 1-6

1

1

1

1

1

1

2

VCR PCB

Bottom Plate

AV Jack Shield

CP2201

CP8001

CP8002

CP602B

CP604

CP001

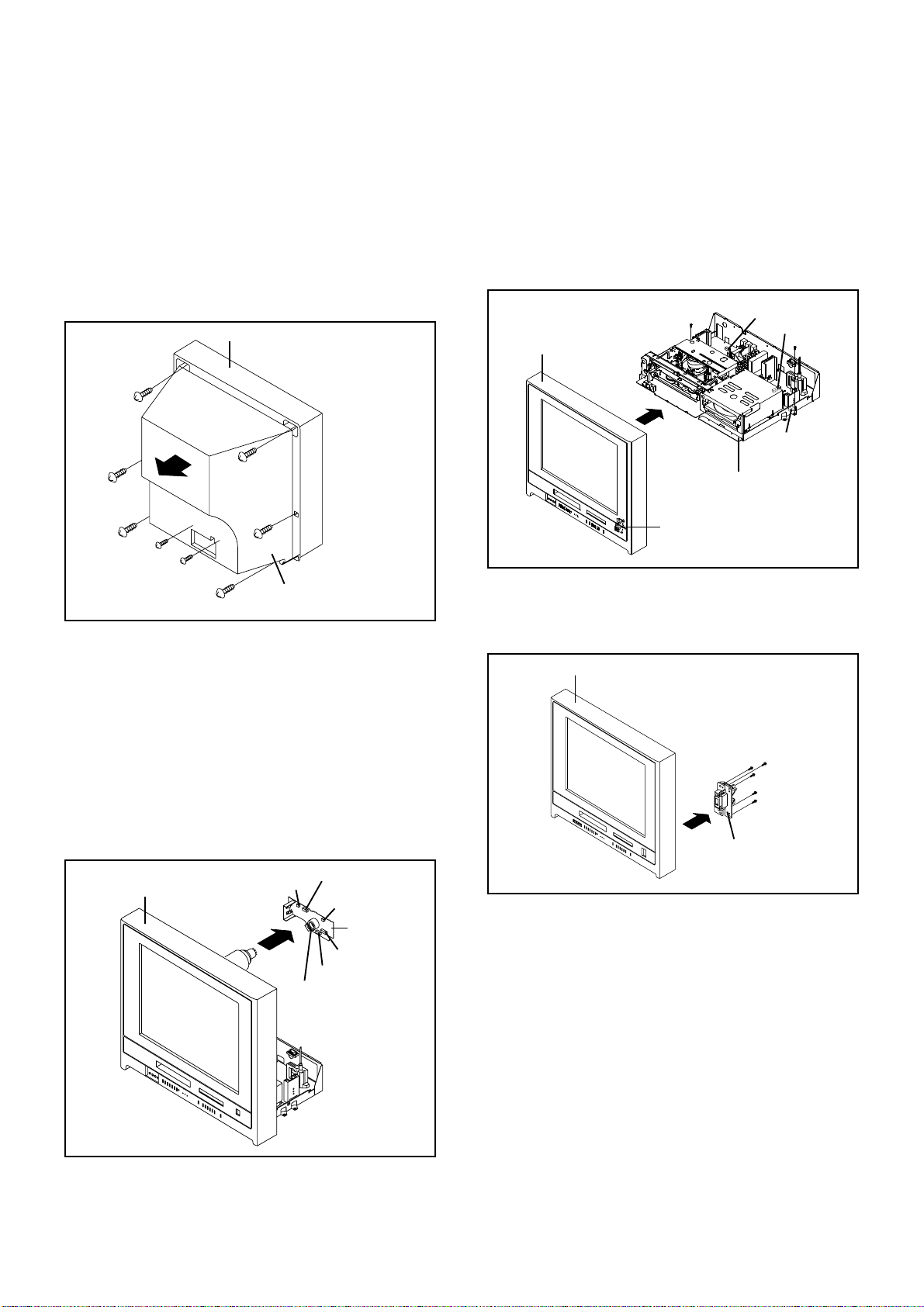

1-5: VCR DECK (Refer to Fig. 1-5)

NOTE

Do not remove the cable at the FE Head section. The FE

Head may be damaged if you remove the cable by force.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Remove the 2 screws 1.

Remove the VCR Top.

Move the Cassette Holder Ass'y to the back side.

Remove the 3 screws 2.

Remove the screw 3.

Remove the 2 screws 4.

Remove the Deck Shield Cover.

Remove the screw 5.

Remove the FE Head.

Disconnect the following connectors:

(CP101, CP4501 and CP4502).

Remove the VCR Deck in the direction of arrow.

Fig. 1-5

1

1

VCR Top

2

2

2

3

4

Deck Shield Cover

5

FE Head

VCR Deck

Bottom Plate

CP101

CP4501

CP4502

4

CP301

1-7: DVD BLOCK/OPERATION PCB (Refer to Fig. 1-7)

1.

2.

3.

4.

Remove the 4 screws 1.

Remove the DVD Block in the direction of arrow (A).

Remove the 2 screws 2.

Remove the Operation PCB in the direction of arrow (B).

Fig. 1-7

DVD Block

1

1

1

1

(A)

2

2

(B)

Operation PCB

Bottom Plate

DISASSEMBLY INSTRUCTIONS

B1-3

Deflection PCB

1

1

Bottom Plate

2

2

2

1-8: DVD PCB/DVD DECK (Refer to Fig. 1-8)

1.

2.

3.

4.

5.

6.

7.

8.

Short circuit the position shown in Fig. 1-8 using a

soldering iron. If you remove the DVD Deck with no

soldering, the Laser may be damaged.

Remove the 2 screws 1.

Remove the DVD Top in the direction of arrow (A).

Remove the 4 screws 2.

Remove the DVD Deck in the direction of arrow (B).

Disconnect the following connectors:

(CP2301, CP2302 and CP2303).

Remove the 2 screws 3.

Remove the DVD PCB in the direction of arrow (C).

1-9: DEFLECTION PCB (Refer to Fig. 1-9)

1.

2.

3.

Remove the 2 screws 1.

Remove the 3 screws 2.

Remove the Deflection PCB in the direction of arrow.

Fig. 1-9

Fig. 1-8

1

(A)

Angle Deck

2

(B)

(C)

3

DVD PCB

Pick Up PCB

1

DVD Top

2

2

2

Short circuit using a

soldering iron.

3

DVD Deck

NOTE

Before your operation, please read “PREPARATION OF

SERVICING”.

Use the Lead Free solder.

Manual soldering conditions

• Soldering temperature: 350 ± 5˚C

• Soldering time: Within 2 seconds

• Soldering combination: Sn-3.0Ag-0.5Cu

When Soldering/Removing of solder, use the drawing

equipment over the Pick Up Unit to keep the Flux smoke

away from it.

When installing the DVD Deck, remove all the soldering on

the short circuit position after the connection of Pick Up

PCB and DVD PCB connector.

1.

2.

3.

4.

5.

CP2301

CP2302

CP2303

DISASSEMBLY INSTRUCTIONS

B2-1

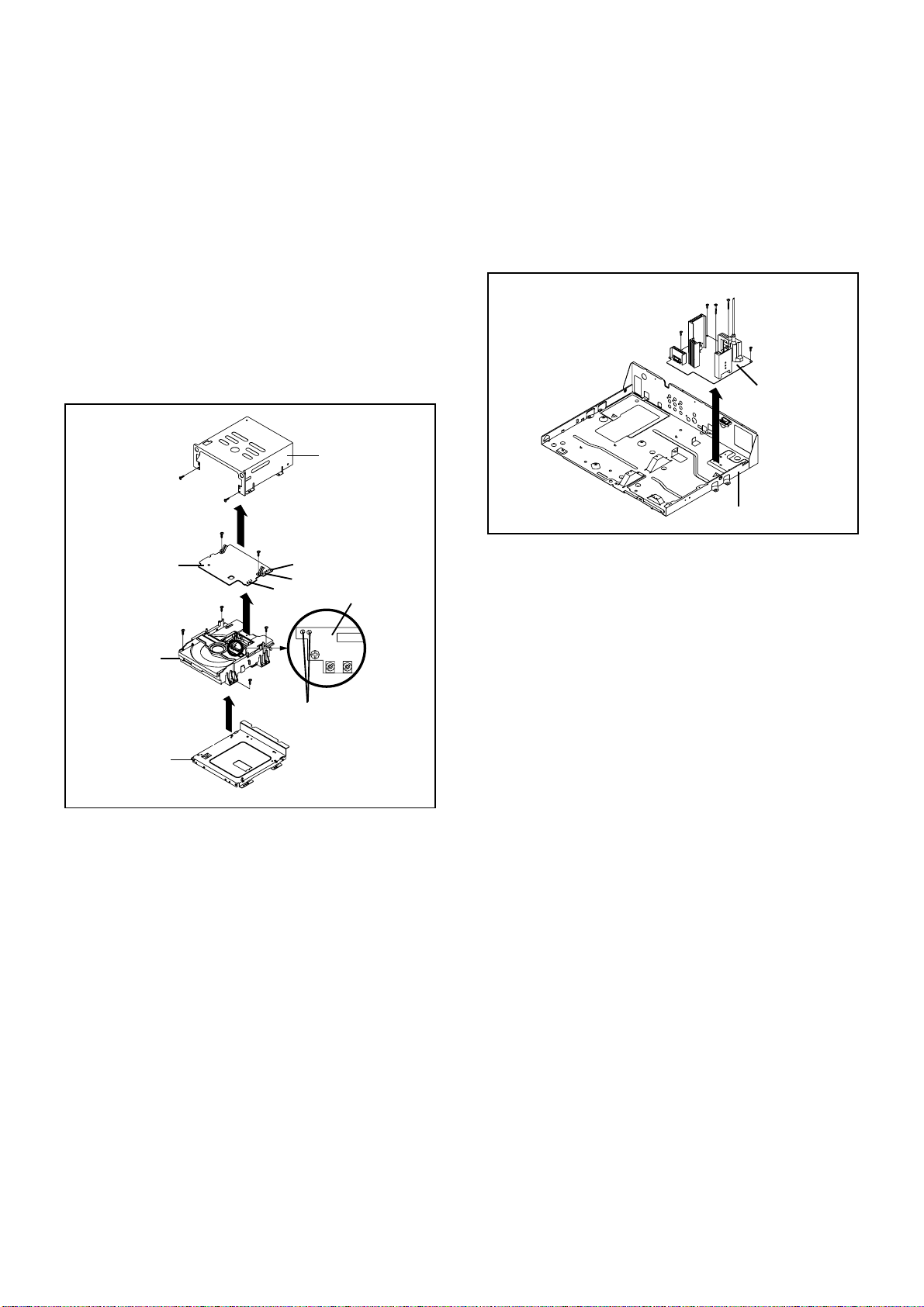

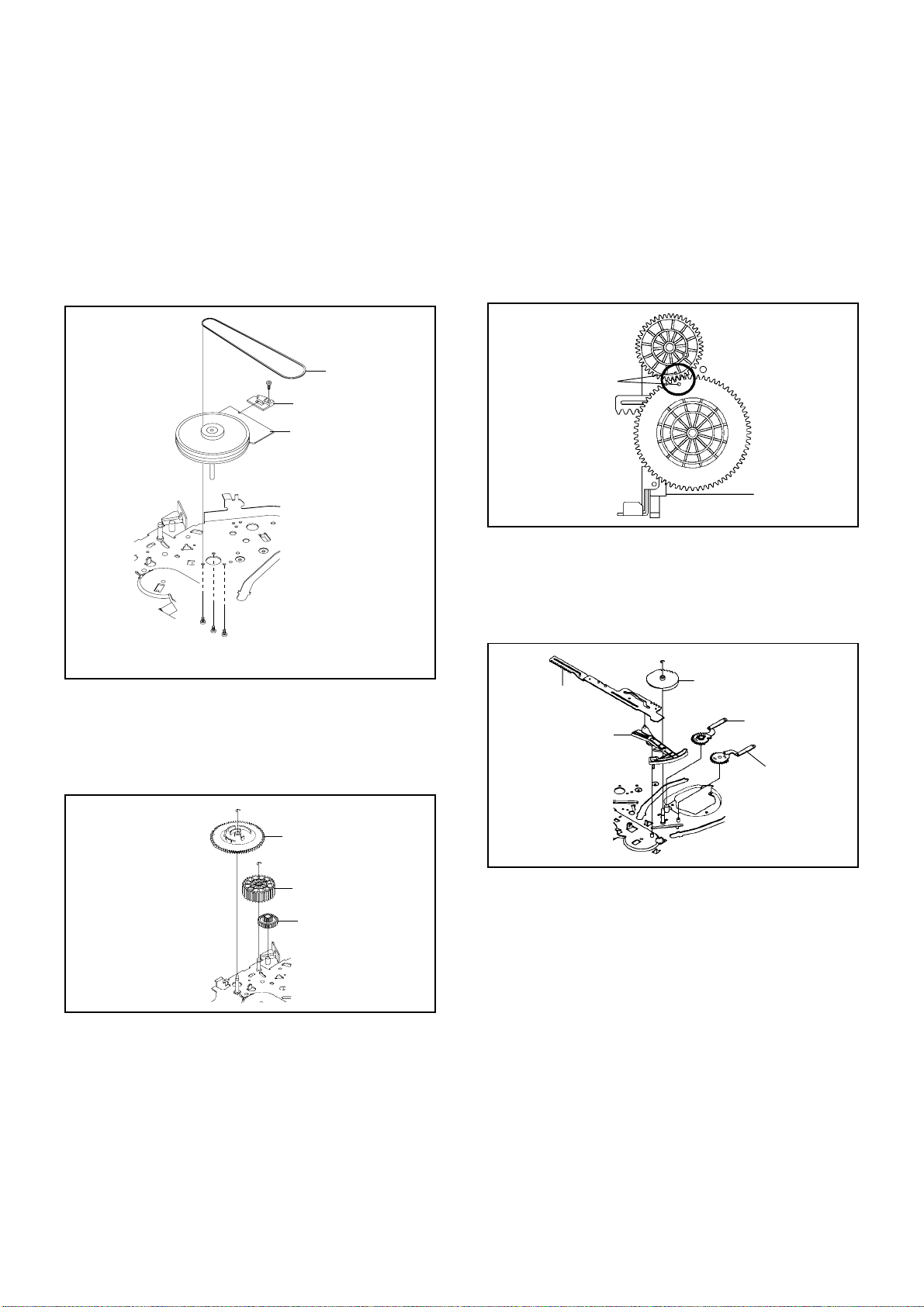

2. REMOVAL OF VCR DECK PARTS

2-1: TOP BRACKET (Refer to Fig. 2-1)

Extend the 2 supports 1.

Slide the 2 supports 2 and remove the Top Bracket.

1.

2.

2-2: CASSETTE HOLDER ASS'Y (Refer to Fig. 2-2)

Move the Cassette Holder Ass'y to the front side.

Push the Locker R to remove the Cassette Side R.

Remove the Cassette Side L.

1.

2.

3.

Fig. 2-1

2

2

Main Chassis

Main Chassis

Top Bracket

Top Bracket

Main Chassis

Main Chassis

Cassette Side L

Cassette Side R

Locker R

Fig. 2-2

Link Unit

2-3: LINK UNIT (Refer to Fig. 2-3)

Set the Link Unit to the Eject position.

Unlock the support 1.

Remove the (A) side of the Link Unit first, then remove

the (B) side.

1.

2.

3.

Fig. 2-3

(A)

Link Unit

Main Chassis

1

Link Unit

(B)

Main Chassis

1

1

NOTE

1. After installation of the Top Bracket, bend the support 1

so that the Top Bracket is fixed.

2-4: LINK LEVER/FLAP LEVER (Refer to Fig. 2-4)

Extend the support 1.

Remove the Link Lever.

Remove the Flap Lever.

1.

2.

3.

Fig. 2-4

Link Lever

Flap Lever

1

DISASSEMBLY INSTRUCTIONS

B2-2

2-5: LOADING MOTOR/WORM (Refer to Fig. 2-5-A)

1.

2.

3.

Remove the screw 1.

Remove the Loading Motor.

Remove the Worm.

Fig. 2-5-A

Loading Motor

Worm

• Screw Torque: 3 ± 0.5kgf•cm

Main Chassis

1

2-6: TENSION ASS’Y (Refer to Fig. 2-6-B)

1.

2.

3.

4.

5.

6.

Turn the Pinch Roller Cam clockwise so that the Tension

Holder hook is set to the position of Fig. 2-6-A to move

the Tension Arm Ass’y.

Remove the Tension Spring.

Unlock the 2 supports 1 and remove the Tension Band.

Unlock the support 2 and remove the Tension Arm Ass’y.

Unlock the support 3 and remove the Tension Connect.

Float the hook 4 and turn it clockwise then remove the

Tension Holder.

Fig. 2-6-B

Tension Band

Tension Connect

Tension Spring

Tension Arm Ass’y

Tension Holder

1

1

3

2

4

NOTE

1.

2.

3.

In case of the Tension Band installation, note the direc-

tion of the installation. (Refer to Fig. 2-6-C)

In case of the Tension Band installation, install correctly

as Fig. 2-6-D.

In case of the Tension Connect installation, install as the

circled section of Fig. 2-6-E.

Fig. 2-6-C

Tension Band

Tension Connect

Tension Arm Ass’y

Fig. 2-6-A

NOTE

1.

2.

3.

In case of the Worm installation, check if the value of the

Fig. 2-5-B is correct.

In case of the Loading Motor installation, slacken the wire

as shown Fig. 2-5-C.

When installing the wires between Capstan DD Unit and

Loading Motor, connect them correctly as shown Fig. 2-5-

D.

Loading Motor Capstan DD Unit

-

+

L2

L1

Pink

Fig. 2-5-D

White

Fig. 2-5-B

19.2 ± 0.1mm

Safety surface for pressing

of the insert.

Fig. 2-5-C

Loading Motor

Slacken the wire.

DISASSEMBLY INSTRUCTIONS

B2-3

Fig. 2-6-D

[OK]

[NG]

Tension Connect

Tension Band

Tension Connect

Tension Band

Fig. 2-6-E

Tension Connect

Main Chassis

2-7: T BRAKE ARM/T BRAKE BAND (Refer to Fig. 2-7-A)

Remove the T Brake Spring.

Turn the T Brake Arm clockwise and bend the hook

section to remove it.

Unlock the 2 supports 1 and remove the T Brake Band.

1.

2.

3.

Fig. 2-7-A

T Brake Band

Hook section

T Brake Arm

T Brake Spring

1

1

NOTE

1. In case of the T Brake Band installation, install correctly

as Fig. 2-7-B.

Fig. 2-7-B

[OK]

[NG]

T Brake Arm

T Brake Band

T Brake Arm

T Brake Band

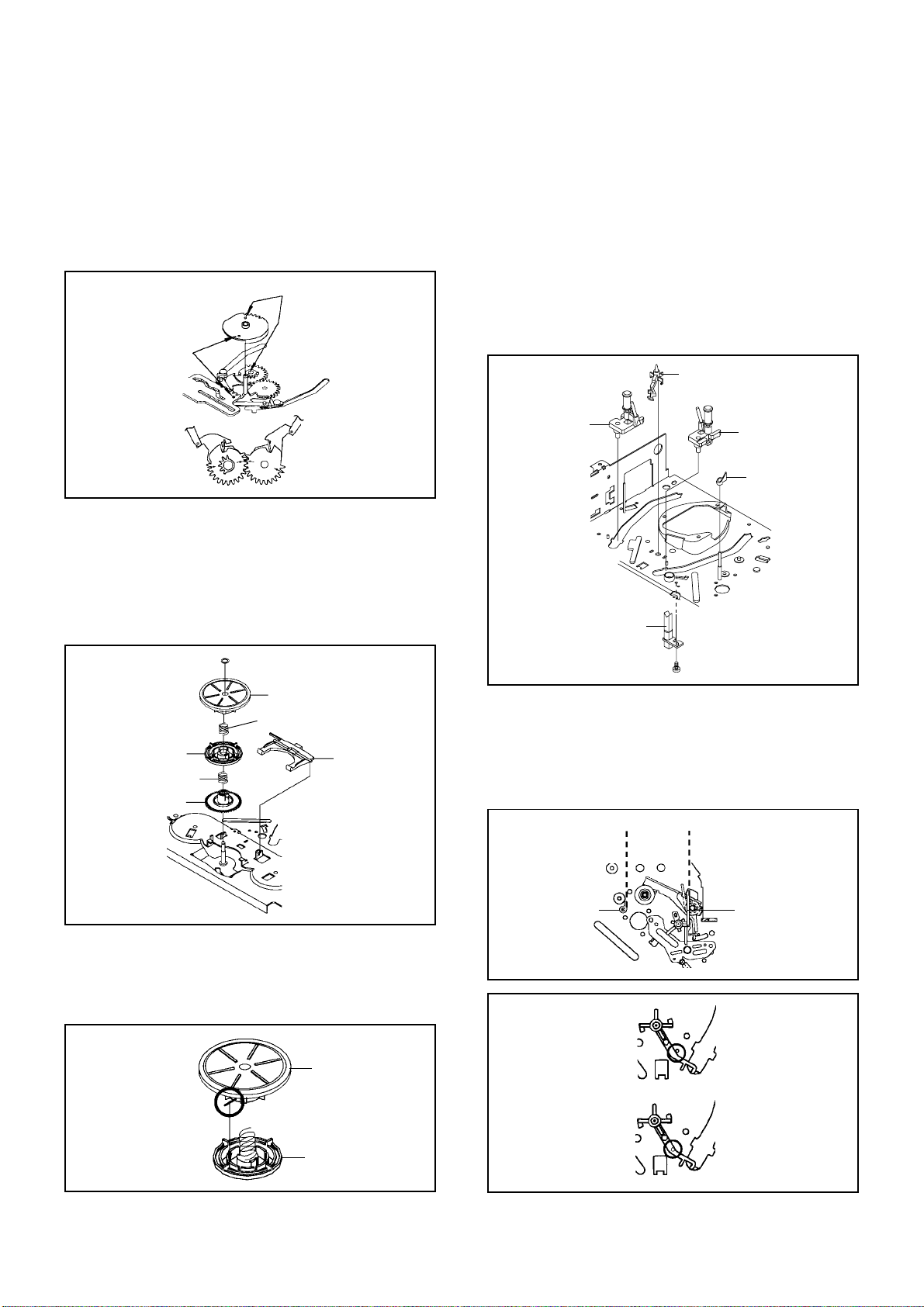

2-8: S REEL/T REEL/IDLER ARM ASS’Y/IDLER GEAR

(Refer to Fig. 2-8-A)

1.

2.

3.

Remove the S Reel and T Reel.

Remove the 2 Polyslider Washers 1.

Remove the Idler Arm Ass’y and Idler Gear.

NOTE

1.

2.

3.

4.

5.

6.

Take care not to damage the gears of the S Reel and T

Reel.

The Polyslider Washer may on the back of the reel.

Take care not to damage the shaft.

Do not touch section “A” of S Reel and T Reel. (Use

gloves.) (Refer to Fig. 2-8-A) Touching may leave stains

on section "A".

When you install the reel, clean the shaft and grease it. (If

you do not grease, noise may be heard in FF/REW

mode.)

After installing the reel, adjust the height of the reel.

(Refer to MECHANICAL ADJUSTMENT)

Fig. 2-8-A

Idler Gear

Idler Arm Ass’y

S Reel

T Reel

(A)

1

1

(A)

NOTE

1.

2.

In case of the S Reel and T Reel installation, check if the

correct parts are installed. (Refer to Fig. 2-8-B)

In case of the Idler Arm Ass’y installation, install correctly

as Fig. 2-8-C. And also set it so that the section “B” of

Fig. 2-8-A is placed under the Main Chassis tab.

Fig. 2-8-B

Big Hole

(S Reel)

Small Hole

(T Reel)

Fig. 2-8-C

[OK]

[NG]

Clutch Gear

Idler Arm Ass’y

Idler Arm Ass’y

Clutch Gear

(B)

DISASSEMBLY INSTRUCTIONS

B2-4

2-9: CASSETTE OPENER/PINCH ROLLER BLOCK/P5

ARM ASS’Y (Refer to Fig. 2-9-A)

1.

2.

Unlock the support 1 and remove the Cassette Opener.

Remove the Pinch Roller Block and P5 Arm Ass’y.

Fig. 2-9-A

Cassette Opener

1

Pinch Roller Block

P5 Arm Ass’y

Main Chassis

NOTE

1.

2.

Do not touch the Pinch Roller. (Use gloves.)

In case of the Pinch Roller Block and the Pinch Roller

Cam installation, install correctly as Fig. 2-9-B.

Fig. 2-9-B

Pinch Roller Block

Can be seen the hole of

the Pinch Roller Cam.

P5 Arm Ass’y

Can be seen the hole of the

Main Cam.

2-10: A/C HEAD (Refer to Fig. 2-10-A)

1.

2.

3.

4.

Remove the screw 1.

Remove the A/C Head Base.

Remove the 3 screws 2.

Remove the A/C Head and A/C Head Spring.

NOTE

1.

2.

3.

Do not touch the A/C Head. (Use gloves.)

When you install the A/C Head Spring, install as shown in

Fig. 2-10-B.

When you install the A/C Head, tighten the screw (1) first,

then tighten the screw (2), finally tighten the screw (3).

Fig. 2-10-A

(1)

2

A/C Head

A/C Head Spring

A/C Head Base

• Screw Torque: 5 ± 0.5kgf•cm (Screw 1 )

2

2

(3)

(2)

1

Fig. 2-10-B

Spring Position

2-11: FE HEAD (RECORDER ONLY) (Refer to Fig. 2-11)

Remove the screw 1.

Remove the FE Head.

1.

2.

FE Head

• Screw Torque: 5 ± 0.5kgf•cm

• The FE Head is not installed on the Video Cassette Player.

Fig. 2-11

1

2-12: CYLINDER UNIT ASS'Y (Refer to Fig. 2-12)

Unlock the support 1 and remove the AHC Ass'y.

Disconnect the following connector: (CD2001).

Remove the 3 screws 2.

Remove the Cylinder Unit Ass'y.

1.

2.

3.

4.

When you install the Cylinder Unit Ass'y, tighten the

screws from (1) to (3) in order while pulling the Ass'y

toward the left front direction.

NOTE

Fig. 2-12

1.

Cylinder Unit Ass'y

2

2

2

• Screw Torque: 3 ± 0.5kgf•cm

(1)

(3)

(2)

AHC Ass'y

1

CD2001

DISASSEMBLY INSTRUCTIONS

B2-5

2-14: MAIN CAM/PINCH ROLLER CAM/JOINT GEAR

(Refer to Fig. 2-14-A)

1.

2.

Remove the E-Ring 1, then remove the Main Cam.

Remove the E-Ring 2, then remove the Pinch Roller

Cam and Joint Gear.

Fig. 2-14-A

1

Main Cam

Pinch Roller Cam

Joint Gear

2

NOTE

1. In case of the Pinch Roller Cam and Main Cam installa-

tion, install them as shown in the circled section of Fig. 2-

14-B so that the markers meet. (Refer to Fig. 2-14-B)

And also can be seen the Main Chassis hole through the

Main Cam maker hole.

Fig. 2-14-B

Pinch Roller Cam

Marker

Main Cam

2-15: LOADING GEAR S/T UNIT (Refer to Fig. 2-15-A)

1.

2.

Remove the E-Ring 1 and remove the Main Loading

Gear.

Remove the Main Rod, Tension Lever, Loading Arm S

Unit and Loading Arm T Unit.

1

Main Loading Gear

Main Rod

Tension Lever

Loading Arm T Unit

Loading Arm S Unit

Fig. 2-15-A

2-13: CAPSTAN DD UNIT (Refer to Fig. 2-13)

Remove the Capstan Belt.

Remove the screw 1.

Remove the Capstan Holder.

Remove the 3 screws 2.

Remove the Capstan DD Unit.

1.

2.

3.

4.

5.

• Screw Torque: 4 ± 0.5kgf•cm

Capstan DD Unit

Capstan Belt

Fig. 2-13

1

2

Capstan Holder

2

2

DISASSEMBLY INSTRUCTIONS

B2-6

1

Clutch Ass’y

Ring Spring

Clutch Lever

Coupling Gear

Coupling Spring

Clutch Gear

NOTE

1. When you install the Loading Arm S Unit, Loading Arm T

Unit and Main Loading Gear, align each marker. (Refer

to Fig. 2-15-B)

Fig. 2-15-B

Marker

Main Loading Gear

Loading Arm T Unit Loading Arm S Unit

Marker

2-16: CLUTCH ASS’Y/RING SPRING/CLUTCH LEVER/

CLUTCH GEAR (Refer to Fig. 2-16-A)

1.

2.

3.

4.

Remove the Polyslider Washer 1.

Remove the Clutch Ass’y and Ring Spring.

Remove the Clutch Lever.

Remove the Coupling Gear, Coupling Spring and Clutch

Gear.

Fig. 2-16-A

NOTE

1. In case of the Clutch Ass’y installation, install it with

inserting the spring of the Clutch Ass’y into the dent of the

Coupling Gear. (Refer to Fig. 2-16-B)

Fig. 2-16-B

Clutch Ass’y

Coupling Gear

2-17:

Remove the P4 Cap.

Unlock the support 1 and remove the Cassette Guide

Post.

Remove the Inclined Base S/T Unit.

Remove the screw 2.

Remove the LED Reflector.

1.

2.

3.

4.

5.

Fig. 2-17-A

CASSETTE GUIDE POST/INCLINED BASE S/T

UNIT/P4 CAP/LED REFLECTOR

(Refer to Fig. 2-17-A)

P4 Cap

Cassette Guide Post

1

Inclined Base T Unit

Inclined Base S Unit

2

LED Reflector

NOTE

1.

2.

3.

Do not touch the roller of Guide Roller.

In case of the P4 Cap installation, install it with parallel

for “A” and “B” of Fig. 2-17-B.

In case of the Cassette Guide Post installation, install

correctly as the circled section of Fig. 2-17-C.

Fig. 2-17-B

“A” “B”

P4 Cap

Cassette Opener

[OK]

Cassette Guide Post

[NG]

Cassette Guide Post

Fig. 2-17-C

DISASSEMBLY INSTRUCTIONS

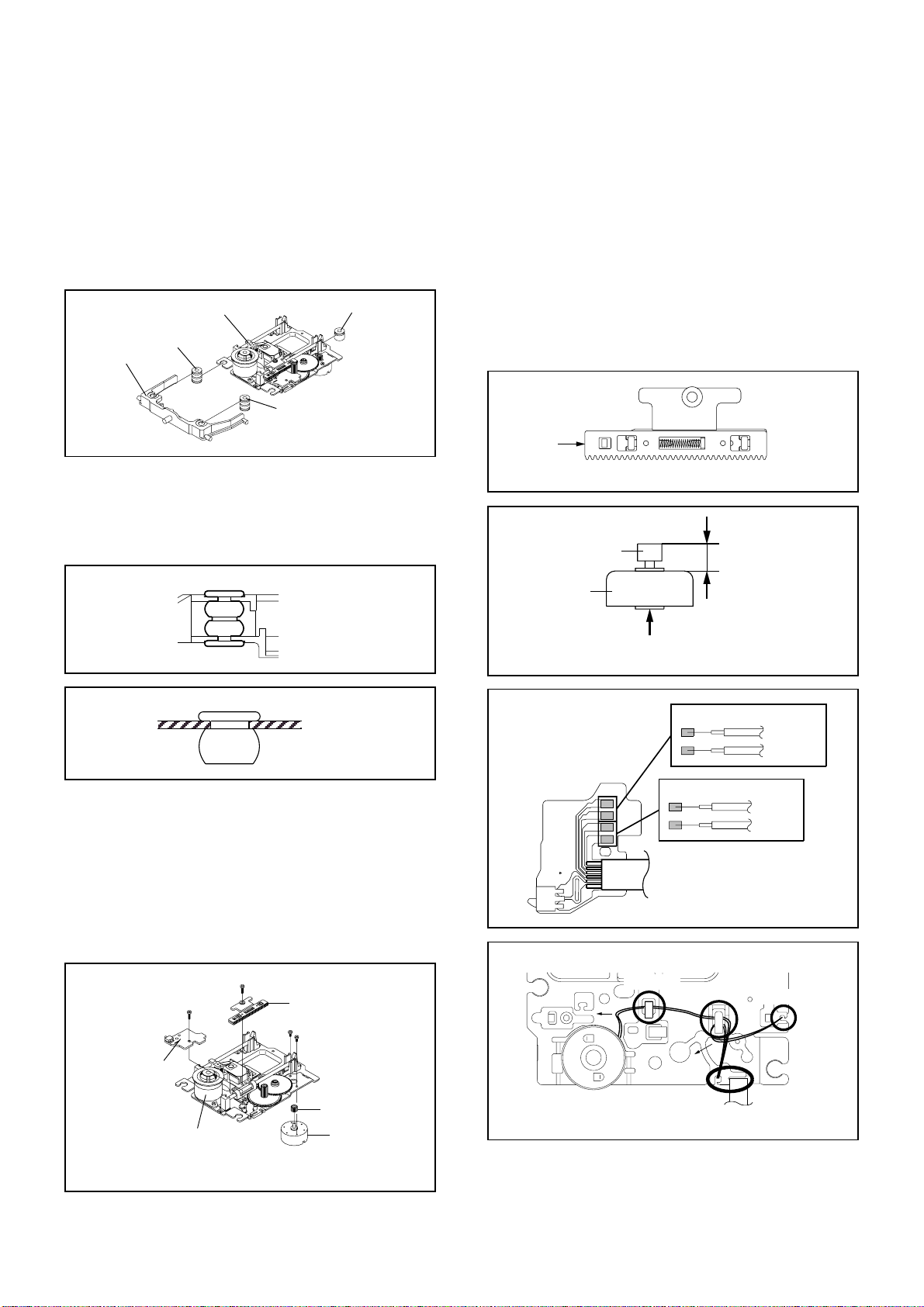

B3-1

Main Frame Ass'y

Check Hook

3. REMOVAL OF DVD DECK PARTS

3-1: TRAY (Refer to Fig. 3-1-A)

Set the Tray opened. (Refer to the DISC REMOVAL

METHOD AT NO POWER SUPPLY)

Unlock the 2 supports 1 and remove the Tray.

1.

2.

Fig. 3-1-A

Tray

Main Frame Ass'y

1

NOTE

1.

In case of the Tray installation, install them as the circled

section of Fig. 3-1-B so that the each markers are met.

3-2: MAIN CHASSIS ASS'Y (Refer to Fig. 3-2-A)

Remove the screw 1.

Unlock the 2 supports 2.

Remove the Insulator (R) from the Main Frame Ass'y.

Remove the Main Chassis Ass'y.

1.

2.

3.

4.

Fig. 3-2-A

Tray

Main Frame Ass'y

Fig. 3-1-B

Insulator (R)

NOTE

1. Do not disassemble the DVD DECK PARTS except listed

parts here. Minute adjustments are needed if the

disassemble is done. If the repair is needed except listed

parts, replace the DVD MECHA ASS'Y.

1

1

2

Main Frame Ass'y

Main Chassis Ass'y

2

• Screw Torque: 2.0 ± 0.5kgf•cm

NOTE

1.

2.

In case of the Main Chassis Ass'y, install it from (1) to (4)

in order. (Refer to Fig. 3-2-B)

In case of the Main Chassis Ass'y installation, hook the

wire on the Main Frame Ass'y as shown Fig. 3-2-C.

Fig. 3-2-B

Fig. 3-2-C

(1)

(2)

(3)

(3)

(4)

(3)

Check Lock

(4)

Main Chassis Ass'y

Rack Loading

Main Frame Ass'y (Bottom Side)

Traverse Holder

DISASSEMBLY INSTRUCTIONS

B3-2

NOTE

1.

2.

3.

In case of the Pulley Motor installation, check if the value

of the Fig. 3-3-B is correct.

When installing the Loading Motor PCB Ass'y, install it

correctly as Fig. 3-3-C.

In case of the Loading Motor PCB Ass'y installation, hook

the wire on the Main Frame Ass'y as shown Fig. 3-3-C.

Fig. 3-3-B

7.0 ± 0.1mm

Safety surface for pressing

of the insert.

Loading Motor

Pulley Motor

Fig. 3-3-C

Rack Loading

AB

The Lever should be position

between A and B.

Check Hook

3-4: RACK LOADING/MAIN GEAR/PULLEY GEAR

(Refer to Fig. 3-4-A)

1.

2.

3.

Press down the catcher 1 and slide the Rack Loading.

Unlock the support 2 and remove the Pulley Gear.

Remove the Main Gear.

Loading Motor PCB Ass’y

Loading Belt

Pulley Gear

1

Main Frame Ass’y

3-3: LOADING MOTOR PCB ASS'Y/ LOADING BELT

(Refer to Fig. 3-3-A)

1.

2.

3.

4.

5.

Remove the Loading Belt.

Remove the screw 1.

Remove the 2 screws 2.

Remove the Loading Motor PCB Ass'y.

Remove the Pulley Gear.

Fig. 3-3-A

2

2

Loading Motor PCB Ass’y

• Screw Torque: 2.5 ± 0.3kgf•cm (Screw 1)

• Screw Torque: 1.0 ± 0.3kgf•cm (Screw 2)

Rack Loading

1

Main Frame Ass’y

Main Gear

Pulley Gear

2

Fig. 3-4-A

Fig. 3-4-B

NOTE

1. In case of the Rack Loading installation, do not mesh it

to the Main Gear as shown the Fig. 3-4-B.

Check Hook

Main Gear

Rack Loading

3-5: CLAMPER ASS'Y (Refer to Fig. 3-5-A)

Press the Clamper and rotate the Clamper Plate

clockwise, then unlock the 3 supports 1.

Remove the Clamper Plate, Clamper Magnet and

Clamper.

1.

2.

Clamper Plate

Clamper Magnet

Fig. 3-5-A

Main Frame

Clamper

1

1

1

NOTE

1. In case of the Clamper Ass'y installation, install correctly

as Fig. 3-5-B.

Fig. 3-5-B

No gap

Clamper Plate

Clamper

DISASSEMBLY INSTRUCTIONS

B3-3

Fig. 3-6-C

Insulator (R)

Main Chassis Ass'y (Top Side)

3-7:

Remove the screw 1.

Remove the Rack Feed Ass'y.

Remove the screw 2.

Remove the Switch PCB Ass'y.

Remove the 2 screw 3.

Remove the Feed Motor.

Remove the Motor Gear.

1.

2.

3.

4.

5.

6.

7.

RACK FEED ASS'Y/SWITCH PCB ASS'Y/FEED

MOTOR (Refer to Fig. 3-7-A)

Traverse Holder

Insulator (F)

Main Chassis Ass'y

Insulator (F)

Insulator (R)

3-6:

Remove the Traverse Holder.

Remove the 2 Insulator (F).

Remove the Insulator (R).

1.

2.

3.

Fig. 3-6-A

TRAVERSE HOLDER/INSULATOR (F)/INSULATOR

(R) (Refer to Fig. 3-6-A)

NOTE

1.

2.

In case of the Insulator (F) installation, install correctly as

Fig. 3-6-B.

In case of the Insulator (R) installation, install correctly as

Fig. 3-6-C.

Fig. 3-6-B

Traverse Holder

Insulator (F)

Fig. 3-7-C

6.0 ± 0.2mm

Safety surface for pressing

of the insert.

Feed Motor

Motor Gear

NOTE

1.

2.

3.

4.

When pushing the Rack Feed in the direction of the

arrow, it should be restored to the original position by the

spring force. (Refer to Fig. 3-7-B)

In case of the Motor Gear installation, check if the value

of the Fig. 3-7-C is correct.

When installing the wire of the Switch PCB Ass'y, install it

correctly as Fig. 3-7-D.

After the assembly of the Main Chassis Ass'y, hook the

wire on the Main Chassis Ass'y as shown Fig. 3-7-E.

Fig. 3-7-B

Push

Rack Feed Ass'y

~ FEED MOTOR ~

BLUE (4)

ORANGE (3)

~ SPINDLE MOTOR ~

BLACK (2)

RED (1)

Fig. 3-7-D

Switch PCB Ass'y

• Install wire from (1) to (4) in order.

Main Chassis Ass'y (Bottom Side)

Check Hook

Check Hook

Fig. 3-7-E

Check Hook

Check Hook

• Loosen the wire in the direction of the arrow.

Fig. 3-7-A

• Screw Torque: 5.0 ± 0.3kgf•cm (Screw 1)

• Screw Torque: 3.0 ± 0.3kgf•cm (Screw 2)

• Screw Torque: 1.0 ± 0.3kgf•cm (Screw 3)

Main Chassis Ass'y

1

Rack Feed Ass'y

2

Switch PCB Ass'y

3

3

Motor Gear

Feed Motor

DISASSEMBLY INSTRUCTIONS

B3-4

Printing Surface

Reinforcement Plate

59 ± 1mm

Fold

(1)

Printing Surface

10 ± 1mm

Fold

(3)

Printing Surface

44 ± 1mm

Fold

(4)

Printing Surface

Printing Surface

10 ± 1mm

Fold

(2)

Reinforcement Plate

Reinforcement Plate

Printing Surface

Fold

43 ± 1mm

54 ± 1mm

Printing Surface

Pick Up Side

Fold it by 90˚

[ 24 pin FFC ]

When installing the FFC, fold it correctly and install it as

shown from Fig. 3-8-A to Fig. 3-8-C.

3-8: FFC WIRE HANDLING

1.

Do not make the folding lines except the specified

positions for the FFC.

1.

NOTE

Fig. 3-8-A

• Proceed the steps (1) through (4).

[ 6 pin FFC ]

Fig. 3-8-B

Printing Surface

Reinforcement Plate

55 ± 1mm

Fold

(1)

Printing Surface

10 ± 1mm

Fold

(3)

Printing Surface

60 ± 1mm

Fold

(4)

Printing Surface

Printing Surface

10 ± 1mm

Fold

(2)

Reinforcement Plate

Reinforcement Plate

• Proceed the steps (1) through (4).

[ 5 pin FFC ]

Fig. 3-8-C

Loading...

Loading...