tekmar 155 User Manual

- Data Brochure

Difference Setpoint Control 155

D 155

06/10

The Difference Setpoint Control 155 is a microprocessor-based control that allows the transfer of heat from a source

to a storage tank whenever the temperature difference between the two is greater than the selected ΔT setpoint.

Additional setpoints are also included to help prevent the storage tank from overheating or the source from freezing.

F

ΔT

Source

Diff'l

Storage

Item

Difference Setpoint

Control 155

Both drainback and draindown systems can be used with this control.

Minimum

Maximum

ΔT •hours

Several displays provide a variety of useful information. The control can display the Maximum and Minimum

temperatures measured by both the Storage and Source sensors as well as the total heat transferred from the source

to the storage.

• New Solar Sensor 085 immersion type sensor included!

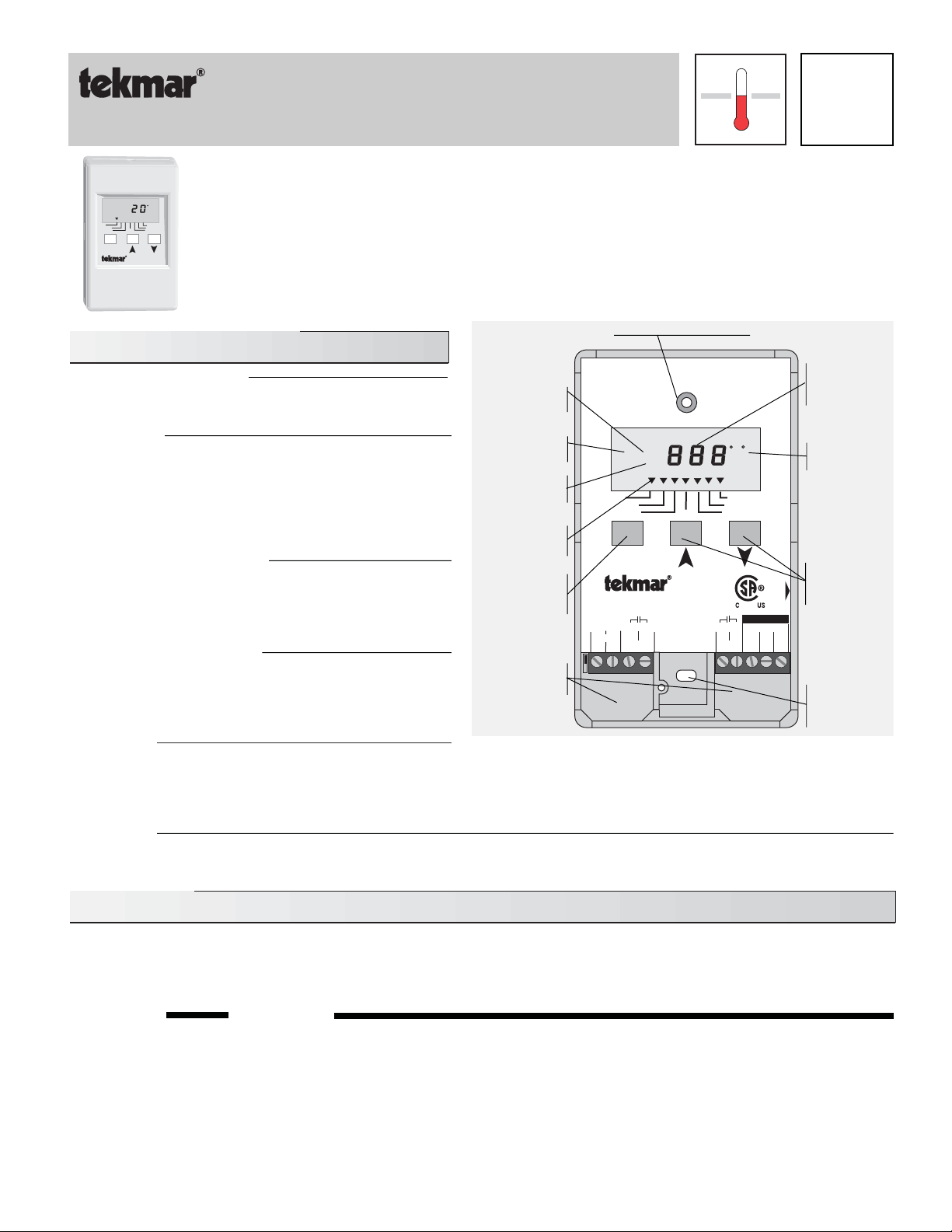

Hole for mounting screw

Sequence of Operation

Powering up the control

After the Difference Setpoint Control 155 is powered up,

the LCD segments are turned on for 3 seconds.

ΔT Setpoint

The control measures the difference between the Source

and the Storage temperatures (ΔT). When this ΔT is

greater than the ΔT setpoint, Relay 1 is turned on to

transfer heat from the source to the storage. If the ΔT drops

below the ΔT setpoint less the ΔT differential, Relay 1 is

turned off.

Maximum Storage Setpoint

If the Storage temperature rises above the Maximum

Storage setting, Relay 1 is turned off. This relay remains off

until the Storage temperature drops below the Maximum

Storage setting less its differential.

Minimum Source Setpoint

If the Source temperature drops below the Minimum Source

setting, Relay 1 is turned off. This relay remains off until the

Source temperature rises above the Minimum Source

setting plus its differential.

Relay 1

operation

Programming

mode indicator

Relay 2

operation

identifiers

Item selection

and display

button

Wiring Chamber

and terminals

Item

Meets Class B:

Canadian ICES

FCC Part 15

Made in Canada

tektra 906-08

PRGM

ΔT

Source

Storage

Item

Difference Setpoint

Control 155

34

21

Power

C –

R +

Relay 1

Drainback l Draindown

Power: 24 V (ac) ± 10% 50/60 Hz 3 VA

24 V (dc) ± 10% 0.03A

Relay: 240 V (ac) 10 A 1/3hp

1

2

HEAT

Diff’l

Signal wiring

must be rated

at least 300V

Minimum

Maximum

ΔT • hours

5

Relay 2

FC

6

Com

H11161E

No power

No Power

8

7

Src

Stor

9

Date Code

Display for

temperatures

and setpoints

°C or °F

indicators

Programming

and display

buttons

Hole for

mounting

screw

Draindown

When the DIP switch is set to draindown, Relay 2 is closed until the Source temperature drops below the Minimum Source setting.

If Relay 2 is connected to a drain valve, the heat transfer fluid can be drained from the source when Relay 2 is opened. Once the

Source temperature rises above the Minimum Source setting plus the Minimum Source Differential, Relay 2 is closed and the control

continues with ΔT setpoint operation. See the Application Brochures A 155 for the correct wiring of Relay 2.

Drainback

If the DIP switch is set to drainback, Relay 2 is turned on (closed) for 3 minutes whenever Relay 1 is turned on. Relay 2 is typically

connected to a booster pump to overcome gravity head and prime a siphon.

Installation

Caution

Step One Getting ready

Note: Carefully read the Sequence of Operation section in this brochure to ensure that you have chosen the proper control and understand

: Improper installation and operation of this control could result in damage to the equipment and possibly even

personal injury. It is your responsibility to ensure that this control is safely installed according to all applicable codes

and standards. This electronic control is not intended for use as a primary limit control. Other controls that are

intended and certified must be placed into the control circuit.

Check the contents of this package. If any of the contents listed are missing or damaged, please refer to the Limited Warranty

and Product Return Procedure on the back of this brochure and contact your wholesaler or tekmar sales agent for assistance.

Type 155 includes:

• One Difference Control 155 • One Universal Sensor 071, One Solar Sensor 085

• Data Brochures D 155, D 070, D 085, D 001

• Application Brochure A 155

Other information available:

• Essay E 001

its functions within the operational requirements of your system.

Step Two

Mounting

The control is mounted in accordance with the instructions in the Data Brochure D 001.

Step Three

Rough-in wiring

All electrical wiring terminates in the two wiring chambers at the bottom front of the control. If the control is to be mounted on

an electrical box, the wiring can be roughed-in at the electrical box prior to installation of the control (see Brochure D 001).

Standard 18 AWG solid wire is recommended for all low voltage wiring to this control.

Power should not be applied to any of the wires during the rough-in wiring stage.

• Install the Source Sensor 085 and Storage Sensor 071 according to the instructions in Data Brochure D 085 and D 070, and run

the wiring back to the control. Do not connect the wires to the terminals yet.

• EITHER: Install a 24 V (ac) Class 2 transformer with a minimum 5 VA rating and run the wiring from the transformer to the control.

A Class 2 transformer must be used.

OR: Install a 24 V (dc) source and run the wiring back to the control.

• Run wiring back to the control from the devices connected to Relay 1 and Relay 2.

Do not connect either of the transformer secondary wires to ground.

Step Four

Testing and connecting the wiring

Caution These tests are to be performed using standard testing practices and procedures and should only be carried out by properly

trained and experienced persons. A good quality electrical test meter, capable of reading from at least 0 — 200 Volts, and

at least 0 — 2,000,000 Ohms, is essential to properly test this control. At no time should voltages in excess of 27 V (ac or

dc) be measured at any of the wires connected to the control.

Test the sensors

• This test must be performed

power is applied to the control and

before

the sensors are connected to the terminal strip.

before

Test the sensors according to the instructions in the enclosed Data Brochure D 085 and D 070.

Test the power supply

• Ensure exposed wires are not grounded or in contact with other wires, then turn on the power supply. If a 24 V (ac) transformer

is used, make sure the voltmeter is set to AC. With the voltmeter leads connected to the secondary side of the transformer, you

should measure between 21 and 27 V (ac). If a DC power supply is used, make sure the voltmeter is set to DC. Connect the positive

lead from the voltmeter to the positive terminal on the DC source and the negative lead from the voltmeter to the negative terminal

on the DC source. The voltmeter should measure between 21 and 27 V (dc).

• Turn off the power and complete the electrical connections to the terminal strip of the control.

Power and output connections

The installer should test to confirm that no voltage is present at any of the wires.

• EITHER: Connect the 24 V (ac) power supply to terminals

Power C- and R+

OR: Connect the negative (-) lead from the 24 V (dc) source to the Power C- terminal

Connect the positive (+) lead from the 24 V (dc) source to the Power R+ terminal

Note: The control will not operate if the DC leads are reversed.

• Connect the Relay 1 controlled device to terminals

• Connect the Relay 2 controlled device to terminals

Relay1

Relay 2

(3 and 4)

(5 and 6)

Sensor connections — Caution, voltage is never applied to these terminals

• Connect the Source Sensor

• Connect the Storage Sensor

085 to terminals

071 to terminals

Com Sen and Src Sen

Com Sen and Stor Sen

(7 and 8)

(7 and 9)

(1 and 2)

1C-2R+34

Power

24 V

power

supply

10A

Relay 1

Relay 1 closes to

transfer heat

from the source

to the storage

10A

6

5

Relay 2

Relay 2 closes to

satisfy drainback

or draindown

requirements

Do not apply

power here

89

7

Com

Src

Sen

Sen

Source

Sensor

085

Stor

Sen

Storage

Sensor

071

Settings

PROGRAMMING

PRGM

ΔT

Source

Storage

Item

Press and Release

all three buttons at the

same time to begin

programming. The first

item displayed is the

“ΔT setpoint”.

PRGM

ΔT

Source

Storage

Item

Press and Release

the “Item” button to

change the display to

the “Maximum Storage

Setpoint”.

F

Use the arrow

Minimum

keys to set the

Maximum

Diff'l

ΔT • hours

“ΔT setpoint”.

F

Use the arrow

Minimum

keys to set the

Maximum

Diff'l

ΔT • hours

Item

Item

“Maximum

Storage

Setpoint”.

PRGM

ΔT

Source

Storage

Item

Press and Release

the “Item” button to

change the display to

the “ΔT Differential”.

PRGM

ΔT

Source

Storage

Item

Press and Release

the “Item” button to

change the display to

the “Maximum Storage

Differential”.

F

Minimum

Maximum

Diff'l

ΔT • hours

F

Minimum

Maximum

Diff'l

ΔT • hours

Item Item Item

Use the arrow

keys to set the

“ΔT Differential”.

Item Item

Use the arrow

keys to set the

“Maximum

Storage

Differential”.

PRGM

ΔT

Source

Storage

Item Item

Press and Release

the “Item” button to

change the display to

the “Minimum Source

Setpoint”.

PRGM

ΔT

Source

Storage

Item

Press and Release

the “Item” button to

change the display to

“°F” or “°C”.

F

Use the arrow

Minimum

keys to set the

Maximum

Diff'l

ΔT • hours

Minimum

Maximum

Diff'l

ΔT • hours

F

“Minimum

Source

Setpoint”.

Use the arrow

keys to switch

between “°F”

and “°C”.

PRGM

ΔT

Source

Storage

Press and Release

the “Item” button to

change the display to

the “Minimum Source

Differential”.

Note: The control automatically

exits programming when

the buttons are left alone

for 20 seconds.

F

Minimum

Maximum

Diff'l

ΔT • hours

2

Use the arrow

keys to set the

“Minimum Source

Differential”.

Loading...

Loading...