Steele Products SP-PB140 User Manual

Contents

Introduction 3

Description of symbols 3

Specifications 3

Safety rules for laser lights 4

General safety instructions 4

Electrical safety 5

Additional safety rules for band saws 6

Extension cords 6

Accessories 7

Unpacking 7

Assembly time 7

R

equired tools 7

Know your product

Components 9

Assembly 10

Mounting to a workbench 11

Upper blade guide adjustment 11

Lower blade guide adjustment 12

Housing Doors 12

Adjusting the rip fence 13

Adjusting the miter gauge 13

Adjusting the bevel angle 13

Adjusting the saw blade tension 14

Adjusting the blade tracking 14

Setting the table square with the blade 15

Dust collector connection 15

Turning on and off 15

Turning the worklight on and off 15

Fitting the light bulb 16

Turning the laser on and off 16

Installing and removing band saw blades 16

Operation 17

Using the REDEYE laser line generator 17

Maintenance 18

Troubleshooting 18

Parts and parts listing 19

Warranty 22

8

WARNING! To Reduce The Risk Of Injury, User

Must Read And Understand Instruction Manual.

2

Dear Customer

If you require any help with your product,

whether it is a Warranty claim, spare part or

user information, please phone our Help Line

888-896-6881 for an immediate response.

Introduction

Your new Steele® power tool will more

than satisfy your expectations. It has been

manufactured under stringent Steele® Quality

Standards to meet superior performance criteria.

You will find your new tool easy and safe to

operate, and, with proper care, it will give you

many years of dependable service.

Caution.

Instruction

Steele® Power Tool. Take special care to

heed the Cautions and Warnings.Your

Steele® power tool has many features that

will make you job faster and easier. Safety

performance and depend ability have been given

top priority to the development of this tool, making

it easy to maintain and operate.

Carefully read through this entire

Manual before using your new

Environmental protection

Recycle unwanted materials instead

of disposing of them as waste. All

tools, hoses and packaging should

be sorted, taken to the local

recycling center and disposed of in

an environmentally safe way.

WARNING.It may be more difficult to see the

laser line in conditions of bright

sunshine and on cer tain surfaces.

Description of symbols

The rating plate on your tool may show symbols. These

represent important information about the product or

instructions on its use.

Wear hearing protection.

Wear eye protection.

Wear breathing protection.

The ‘C’ and ‘US’ indicators adjacent to the

CSA Mark signify that the product has been

evaluated to the applicable CSA and ANSI/UL

Standards, for use in Canada and the U.S.,

respectively.

Specifications

Amp: 2.0

RPM: 2650 ft/min

Throat Depth: 9”

Cutting Capacity: 3-1/2”

Table Size: 11-13/16” x 11-13/16”

Blade Size: 59-1/2”

Bevel Angle: 0° to 45°

Laser class: I

Laser wavelength: 650nm

Laser output power: ᱽ 1mW

Replacement lamp: 120V Max 15W E12

Insulation class: I “Earthed Appliance”

ight: 40.3 lbs

We

V : volts ~ : alternating current

Hz : hertz nm : nanometers

A : ampere mW : milliwatt

Safety rules for laserlights

The laser guide used in the tool is Class I with a

maximum output of 1mw and a wavelength of

650nm. The laser guide does not normally present

an optical hazard, although staring at the beam may

cause flash blindness.

USER INFORMATION

CAUTION.

this laser product will increase the chance of eye

damage.

Do not stare into the laser beam.

The laser shall be used and maintained in

accordance with the manufacturer’s instructions.

Never aim the beam at any person or an object

oth

Always ensure the laser beam is aimed at a

sturdy work piece without a reflective surface,

i.e. wood or rough coated surfaces are

acceptable. Bright shiny reflective sheet or the

like is not suitable for laser use as the reflective

surface could direct the beam back at the

operator.

General safety instructions

WARNING.

Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious personal

injury.

Save these instructions.

1. Keep guards in place and in working order.

2. Remove adjusting keys and wrenches.

The use of optical instruments with

er than the work piece.

Read and understand all instructions.

3. Keep work area clean.Cluttered areas and benches

invite accidents.

4. Don’t use in dangerous environment. Don’t use

ols in damp or wet locations, or expose

power to

them to rain. Keep work area well lighted.

5. Keep children away. All visitors should be kept

safe distance from work area.

6. Make the workshop kid proof with padlocks,

master switches, or by removing starter keys.

7. Don’t force the tool. It will do the job better and

safer at the rate for which it was designed.

8. Use the right tool. Don’t force tool or attachment

to do a job for which it was not designed.

9. Use the proper extension cord. Make sure your

extension cord is in good condition. When using

an extension cord, be sure to use one heavy

enough to carry the current your product will

draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating. The table on page 7 of this manual

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller the gage

number, the heavier the cord.

10. Wear proper apparel. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving

parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long

hair.

11. Always use safety glasses. Also use face or

dust mask if cutting operating is dusty.

Everyday eyeglasses only have impact

resistant lenses: they are not safety glasses.

12. Secure work. Use clamps or a vise to hold

work when practical. It’s safer than using your

hand and it frees both hands to operate the tool.

13. Don’t overreach. Keep proper footing and

balance at all times.

3

4

14. Maintain tools with care. Keep tools sharp and

clean for best and safest performance. Follow

instructions for lubricating and changing

accessories.

15. Disconnect tools before servicing; when

changing accessories, such as blades, bits,

cutters, and the like.

16. Reduce the risk of unintentional starting.

Make sure switch is in “off” position before

plugging in.

17. Use recommended accessories. Consult the

owner’s manual for recommended accessories.

The use of improper accessories may cause

risk of injury to persons.

18. Never stand on tool. Serious injury could

occur if the tool is tipped or if the cutting tool

is unintentionally contacted.

19. Check damaged parts. Before further use of

the tool, a guard or other part that is damaged

should be carefully chec

kedtodetermineifit

will operate properly and perform its intended

function – check for alignment of moving par ts,

binding of moving parts, breakage of parts,

mounting, and any other conditions that may

affect its operation. A guard or other part that

is damaged should be properly repaired or

replaced.

20. Direction of feed. Feed work into a blade or

cutter against the direction of rotation of the

blade or cutter only.

21. Never leave the tool running unattended.

Turn power off. Don’t leave tool until it comes

to a complete stop.

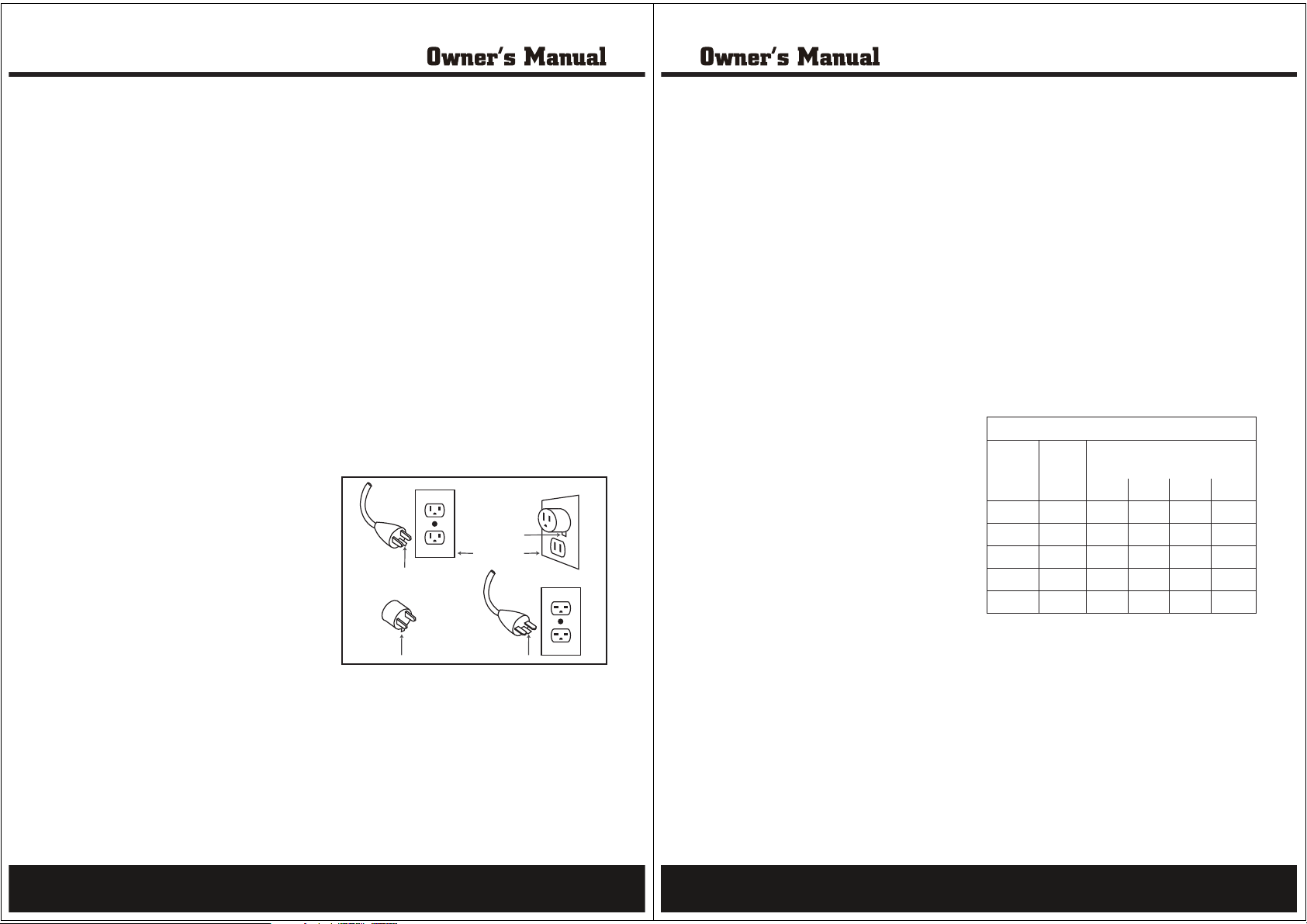

Electrical safety

• In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electrical current to reduce the risk of electric

shock. This tool is equipped with an electric cord

that has an equipment grounding conductor and

a grounding plug. The plug MUST be plugged

into a matching outlet that is properly installed

and grounded in accordance with ALL local

codes and ordinances.

• Do not modify the plug provided. If it will not fit

the outlet, have the proper outlet installed by a

qualified electrician.

• Improper connection of the equipment grounding

conductor can result in a risk of electric shock.

The conductor with the green insulation (or

without yellow stripes) is the equipment

grounding conductor. If repair or replacement of

the electric cord or plug is necessary, DO NOT

connect the equipment grounding conductor

to

aliveterminal.

• Check with a qualified electrician or service

personnel if you do not completely understand

the grounding instructions, or if you are not sure

the tool is properly grounded.

• Use only a three wire extension cord with a

3-prong grounding type plug and 3-hole

receptacles that accept the tool’s plug as shown

in the diagram.

• Repair or replace damaged or worn cords

immediately.

Metal Screw

Cover of Grounded

Grounding

Pin

Adapter

Grounding

Means

Outlet Box

Grounding

Pin

Additional safety rules for band saws

Ensure that the lighting is adequate.

For your own safety read Instruction Manual

Before Operating Saw

Wear eye protection.

Do not remove jammed cutoff pieces until the

blade has stopped.

Maintain proper adjustment of blade tension,blade

guides,and thrust bearings.

Adjust upper guide to just clear workpiece.

Hold workpiece firmly against table.

Ensure that the lighting is adequate.

Keep the area free of tripping hazards.

Do not let anyone under 18 years operate this saw.

Always stand to one side when operating the saw.

Never use a cracked or distor ted saw blade. Only

use sharp blades.

Never use your hands to remove sawdust, chips

or waste close by the saw blade.

Use only blades as recommended.

Rags, cloths, cord, string and the like should

never be left around the work area.

Avoid cutting nails. Inspect the workpiece and

remove all nails and other foreign objects before

beginning sawing.

Do not attempt to free a jammed blade before

first switching off the machine.

Do not slow or stop a blade with a piece of wood.

Let the blade co

If you are interrupted when operating the saw,

complete the process and switch off before

looking up.

Periodically check that all nuts, bolts and other

fixings are

Do not store materials or equipment above a

machine in such a way that they could fall into it.

me to rest naturally.

properly tightened.

Ensure that your work is always on the table.

Never make a cut with the work off the table.

Wear goggles

Wear ear protection

Wear a breathing mask

Extension cords

Replace damaged cords immediately. Use of

damaged cords can shock, burn or electrocute.

If an extension cord is necessary, a cord with

adequate size conductors should be used to

prevent excessive voltage drop, loss of power or

overheating. The table shows the correct size to

use, depending on cord length and nameplate

amperage rating of tool. If in doubt, use the next

heavier gauge. Always use U.L. and CSA listed

extension cords.

RECO MMENDED SIZES OF EXTEN SIO N COR DS

Tool’s

Ampere

rating

3–6 120V~ 18 16 16 14

6–8 120V~ 18 16 14 12

8–10 120V~ 18 16 14 12

10–12 120V~ 16 16 14 12

12–16 120V~ 14 12 - -

Volts Total length of cord in feet

Cord size in A.W.G.(minimum)

25ft 50ft 100ft 150ft

5

6

Accessories

The STEELE®Band Saw is supplied with the

following accessories as standard

• 59 -1/ 2” band saw blade (fiited)

• Rip Fence

• Miter Gauge

• Light Bulb

• Wrench

• Hex Keys (x2)

• Instruction Manual

• Receipt Holder

Unpacking

Due to modern mass production techniques, it is

unlikely that your STEELE® Power Tool is faulty or

that a part is missing. If you find anything wrong,

do not operate the tool until the parts have been

replaced or the fault has been rectified. Failure to do

so could result in serious personal injury.

Assembly Time

Assembly consists of attaching the table, table

insert, rip fence and miter gauge. Assembly will

take approximately 10-15 minutes.

RequiredTools

The following tools are required:

• 0.16”(4mm)Hex Key(supplied)

• 0.12”(3mm)Hex Key(supplied)

• Wrench (supplied)

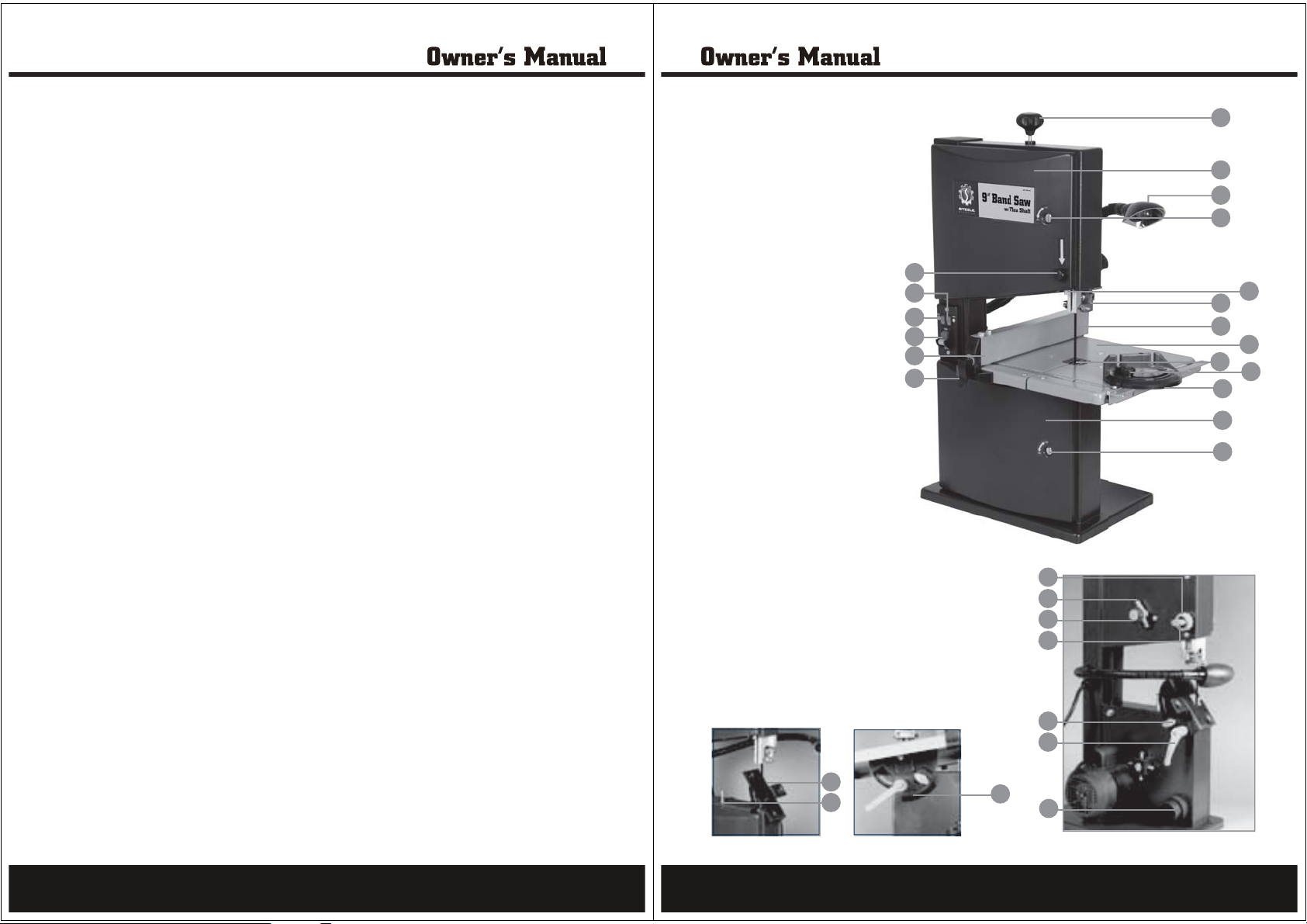

Know your product

1. On/Off switch

2. Laser light on/off switch

3. Light on/off switch

4. Laser adjustment knob

5. Laser aperture

6. Work table trunnion

7. Work table

8. Table insert

9. Table tilt adjustable screw stop

10.Upper housing locking screw

11.Upper housing door

12.Lower housing locking screw

13.Lower housing door

14.Saw blade

15.Blade tension knob

16.Rip fence

17.Rip fence locking handle

18.Miter gauge

19.Miter gauge locking knob

20.Upper blade guide

21.Blade guide adjustment knob

22.Blade guide locking knob

23.Blade tracking adjustment knob

24.Blade tracking locking nut

25.Table locking knob

26.Table setting lever

27.Bevel adjustment scale

28.Dust extraction

29.Adjustable worklight

port

16

17

15

11

29

10

4

3

2

1

21

24

23

22

20

14

8

18

13

12

5

7

19

25

26

6

9

7

27

28

8

Loading...

Loading...