Steele Products SP-PB130 User Manual

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to the State of California to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

Lead from lead-based paints.

Crystalline silica from bricks, cement, and other masonry products.

Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopic particles.

The Model SP-PB130 is specifically designed for cutting operations. DO NOT MODIFY AND/OR USE

THIS MACHINE FOR ANY OTHER PURPOSE. MODIFICATIONS OR IMPROPER USE OF THIS TOOL

WILL VOID THE WARRANTY. If you are confused about any aspect of this machine, DO NOT use it

until all your questions have been answered.

WARNING! To Reduce The Risk Of Injury, User

Must Read And Understand Instruction Manual.

2

Contents

INTRODUCTION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Your New Scroll Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Standard Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

4Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7Know Your Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8Safety Instructions for Your Scroll Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9ELECTRICAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11Shop Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11Dust Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11Initial Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12Mounting Scroll Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12Table Prep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12Blade Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13Installing Pin-End Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14Installing Pain-End Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15Drop Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15Sawdust Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18Blade Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18Blade Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18Blade Selection Table

19Standard Scroll Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19Interior Scroll Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20Arm Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20Motor Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Your New Scroll Saw

Your new STEELE ®Model SP-PB130 16" Scroll Saw is specially designed to provide many years of

trouble-free service. Close attention to engineering detail, ruggedly built parts, and a rigid quality

control program assure safe and reliable operation.

The STEELE Model SP-PB130 16" Scroll Saw features variable speed blade control, extra large

working table, and cast iron construction. The STEELE Scroll Saw also offers a gooseneck work light,

®

®

a dust blower, a dust port, a 45° table tilt capacity, and easy blade change system. Uses standard

plain and pin end saw blades.

For more features and details, refer to the Specifications section in this manual.

Steele products corp. is committed to customer satisfaction in providing this manual. It is

our intent to include all the information necessary for safety, ease of assembly, practical use and

durability of this product.

If you need the latest edition of this manual, you can download it from www.steele-products.com

If you still have questions after reading the latest manual, or if you have comments please contact

us at:

730 S.EPPERSON DR. CITY OF INDUSTRY,CA 91748

Specifications

Motor Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/8HP

Motor Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Variable

No Load Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 550-1700 SPM

Amp Draw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2A

Blade Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4"

Maximum Cutting Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16"

Minimum Cutting Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2"

Machine Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27.5 lbs

3

4

SAFETY

SAFETY

READ MANUAL BEFORE OPERATING MACHINE. FAILURE TO FOLLOW INSTRUCTIONS BELOW

WILL RESULT IN PERSONAL INJURY.

Indicates an imminently hazardous situation which, if not avoided, WILL

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, COULD

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, MAY

result in minor or moderate injury, MAY result in property damage.

NOTICE

Standard Safety Instructions

1.Thoroughly read the instruction manual before operating your machine. Learn the applications,

limitations and potential hazards of this machine. Keep manual in a safe, convenient place for

future reference.

2.Keep work area clean and well lit. Clutter and inadequate lighting invite potential hazards.

3.Ground all tools. If a machine is equipped with a three-prong plug, it must be plugged into a

threehole grounded electrical receptacle or grounded extension cord. If using an adapter to aid in

accommodating a two-hole receptacle, ground using a screw to a known ground.

4.Wear eye protection at all times. Use safety glasses with side shields or safety goggles that meet

the appropriate standards of the American National Standards Institute (ANSI).

5.Avoid dangerous environments. DO NOT operate this machine in wet or open flame environments.

Airborne dust particles could cause an explosion and severe fire hazard.

6.Ensure all guards are securely in place and in working condition.

7.Make sure the machine power switch is in the OFF position before connecting power to machine.

8.Keep the work area clean, free of clutter, grease, etc.

9.Keep children and visitors away. Visitors should be kept at a safe distance while operating unit.

10.Childproof your workshop with padlocks, master switches or by removing starter keys.

11.Stop and disconnect the machine when cleaning, adjusting or servicing.

This symbol is used to alert the user to useful information about proper

operation of the equipment.

12.DO NOT force tool. The machine will do a safer and better job at the rate for which it was designed.

13.Use correct tool. DO NOT force machine or attachment to do a job for which it was not designed.

14.Wear proper apparel. DO NOT wear loose clothing, neck ties, gloves, jewelry, and secure long hair

away from moving parts.

15.Remove adjusting keys, rags, and tools. Before turning the machine on, make it a habit to check

that all adjusting keys and wrenches have been removed.

16.Avoid using an extension cord. But if you must, examine the extension cord to ensure it is in good

condition. Use the “Extension Cord Requirements” table below to determine the correct length and

gauge of extension cord needed for your particular needs. The amp rating of the motor can be found

on its nameplate. If the motor is dual voltage, be sure to use the amp rating for the voltage you will

be using. If you use an extension cord with an undersized gauge or one that is too long, excessive

heat will be generated within the circuit, increasing the chance of a fire or damage to the circuit.

Always use an extension cord that uses a ground pin and connected ground wire. Immediately replace

a damaged extension cord.

17.Keep proper footing and balance at all times and lock mobile base from freely rolling before using

your machine.

18.DO NOT leave machine unattended. Wait until it comes to a complete stop before leaving the area.

19.Perform machine maintenance and care. Follow lubrication and accessory attachment instructions

in the manual.

20.Keep machine away from open flame. Operating machines near pilot lights and/or open flames creates a high risk if dust is dispersed in the area. Dust particles and an ignition source may cause an

explosion. DO NOT operate the machine in high-risk areas, including but not limited to, those mentioned above.

21.If at any time you are experiencing difficulties performing the intended operation, stop using the

machine! Contact our service department or ask a qualified expert how the operation should be performed.

22.Habits are hard to break. Develop good habits in your shop and consistent safety practices will

become second-nature to you.

Extension Cord Requirements

Length And Gauge

Amp Rating 25ft 50ft 100ft

0-6 #16 #16 #16

7-10 #16 #16 #14

11-12 #16 #16 #14

13-16 #14 #12 #12

17-20 #12 #12 #10

21-30 #10 #10 No

Operating this equipment creates the

potential for flying debris to cause eye

injury. Always wear safety glasses or goggles when operating equipment. Everyday

glasses or reading glasses only have impact

resistant lenses, they are not safety glasses.

Be certain the safety glasses you wear meet

the appropriate standards of the American

National Standards Institute (ANSI).

5

6

SAFETY

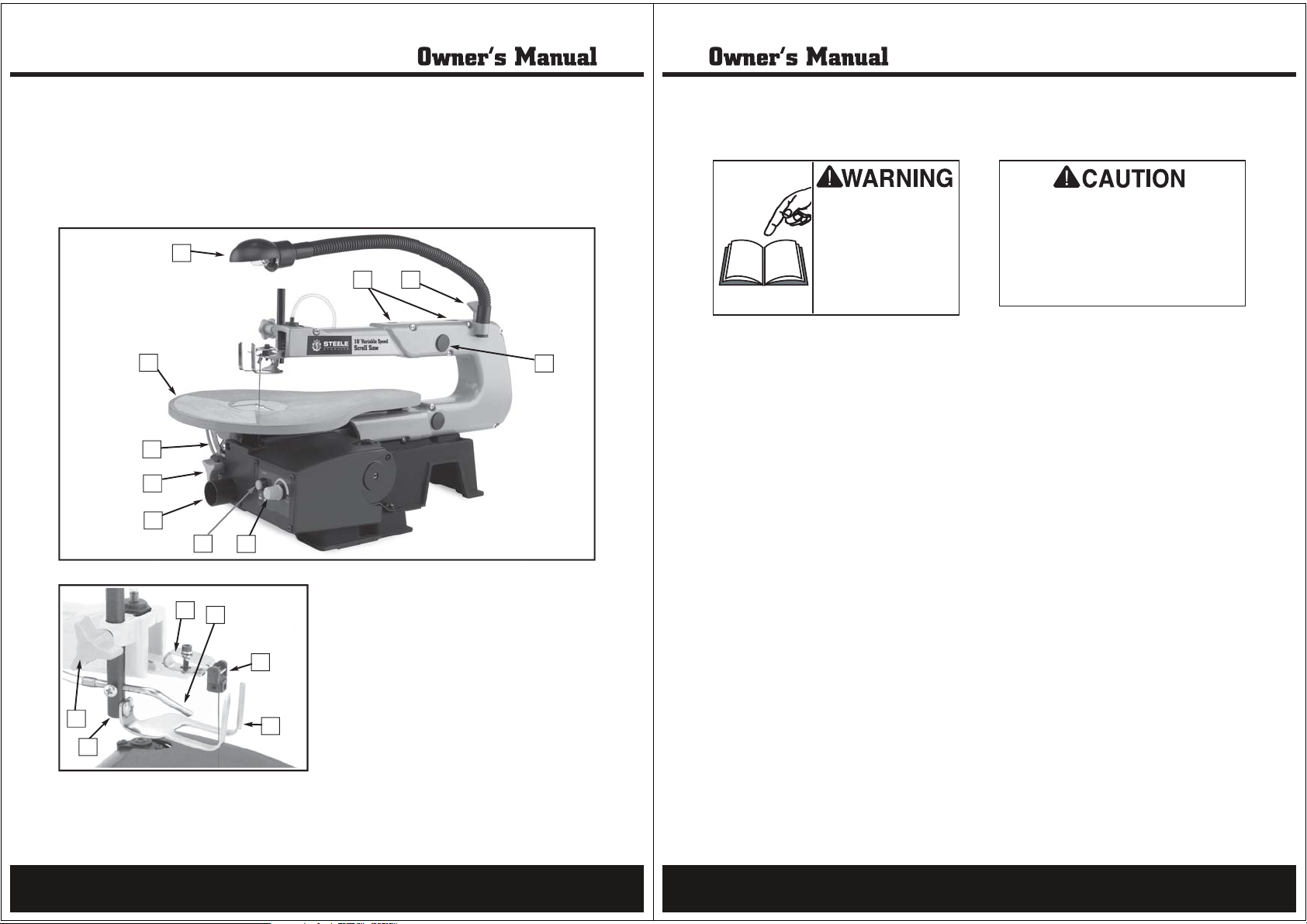

Know Your Machine

An important part of safety is knowing your machine and its components. Please take the time to

learn the items shown in the pictures below. The letters in the picture correspond to the following

descriptions in the list.

J

K

H

C

D

E

F

G

Q

P

O

L

M

N

A

B

A. Blade Tension Knob

B. Arm Bearing

C. Table Bevel Scale

D. Table Lock Knob

E. Dust Port

F. Light Button

G. Variable Speed/Power Knob

H. Table

J. Work Light

K. Blade Adapter Setting Position

L. Drop Foot Rod Lock Knob

M. Drop Foot Rod

N. Drop Foot

O. Blade Adapter (Mounted)

P. Sawdust Blower

Q. Upper Blade Holder

SAFETY

Safety Instructions for Your Scroll Saw

READ and understand this

entire instruction manual

before using this machine.

Serious personal injury

may occur if safety and

operational information is

not understood and followed. DO NOT risk your

safety by not reading!

1.SAW SAFETY BEGINS WITH YOUR LUMBER. Inspect your workpiece carefully before you feed it

into the saw. If you have any doubts about the stability or structural integrity of your workpiece,

DO NOT SAW IT!

2.AVOID AWKWARD OPERATIONS AND HAND POSITIONS where a sudden slip could cause your

hand to move into the blade. Always make sure you have good balance.

3.KEEP HANDS AWAY FROM CUTTING AREA. DO NOT hand hold pieces so small that your fingers

go under the blade guard. DO NOT reach underneath work or in blade cutting path with your hands

and fingers for any reason.

4.FIRMLY CLAMP OR BOLT your saw to a stable, level workbench or table. The best height is waist

level.

5.USE ONLY CORRECT BLADES. Use the correct blade size, style and cutting speed for the material

and type of cut.

6.ALWAYS SUPPORT LARGE WORKPIECES while cutting to minimize blade pinching and blade

breakage. The saw may slip, walk or slide when cutting large or heavy workpieces.

7.DO NOT REMOVE JAMMED CUT-OFF PIECES UNTIL THE BLADE HAS COME TO A COMPLETE STOP.

8.NEVER START THE SAW WHEN THE BLADE IS IN CONTACT WITH THE WORKPIECE.

9.BEFORE CHANGING THE SETUP, REMOVING COVERS, GUARDS OR BLADES,unplug the saw from

the power source and remove the switch safety key.

10.NEVER PERFORM CUTTING OPERATIONS WITH THE BLADE GUARD REMOVED.

11. BE AWARE THAT CERTAIN WOODS MAY CAUSE AN ALLERGIC REACTION in people and animals,

especially when exposed to fine dust. Make sure you know what type of wood dust you will be

exposed to and always wear an approved respirator.

Use this and other machinery with caution

and respect. Always consider safety first, as

it applies to your individual working conditions. No list of safety guidelines can be complete—every shop environment is different.

Failure to follow guidelines could result in

serious personal injury, damage to equipment or poor work results.

7

8

Loading...

Loading...