Steele Products SP-PB113 User Manual

WARNING! Read and understand all the instructions before attempting to as-

semble or operate the tool. Failure to follow the instructions listed below could

result in electric shock, fire and/or serious personal injury.

SAVETHESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

WORK AREA

1. KEEPYOUR WORK AREA CLEAN AND WELL LIT. Cluttered benches and dark

areas invite accidents. DO NOT leave tools or pieces of wood on the saw while it

is in operation.

2. DO NOT OPERATE POWERTOOLS IN EXPLOSIVE ENVIRONMENTS, SUCH

AS IN THE PRESENCE OF FLAMMABLE LIQUIDS, GASES OR DUST. Power

tools create sparks, which could ignite dust or fumes.

3. KEEP BYSTANDERS, CHILDREN AND VISITORS AWAYWHILE OPERATING

A POWERTOOL. Distractions could cause you to lose control.

4. STORE IDLETOOLS OUT OF THE REACH OF CHILDREN AND OTHER UNTRAINED PERSONS. Tools are dangerous in the hands of untrained users.

5. NEVER LEAVETHE TOOL RUNNING UNATTENDED.TURN THE POWER OFF.

Don’t leave the tool until it comes to a complete stop.

6. MAKE THE WORKSHOP CHILDPROOF – with padlocks, master switches, or by

removing starter keys.

ELECTRICAL SAFETY

1. BEFORE PLUGGING IN THE TOOL, BE CERTAIN THE OUTLETVOLTAGE

SUPPLIED IS COMPATIBLE WITHTHE VOLTAGE MARKED ON THE NAMEPLATEWITHIN 10%. An outlet voltage incompatible with that specified on the

nameplate can result in serious hazards and damage to the tool.

2. GROUNDINGTOOLS ARE EQUIPPED WITH THREE-PRONG PLUG (THE

GROUNDING BLADE IS THE LONGEST OFTHE 3 BLADES). This plug will fit

into a three-hole electrical receptacle. Do not modify the plug provided. If the plug

does not fit the outlet, have the proper outlet installed by a qualified electrician.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is

properly grounded.

3. AVOID BODY CONTACT WITH GROUNDED SURFACES SUCH AS PIPES,

RADIATORS, RANGES AND REFRIGERATORS. There is an increased risk of

electric shock if your body is grounded.

4. DO NOT EXPOSE POWERTOOLS TO RAIN ORWET CONDITIONS. Water

entering a power tool will increase the risk of electric shock.

5. DO NOT ABUSETHE CORD. Never use the cord to carry the tool or pull the plug

from an outlet. Keep the cord away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged cords increase the risk of electric

shock.

6. WHEN OPERATING A POWERTOOL OUTSIDE, USE AN OUTDOOR EXTENSION CORD MARKED “W-A” OR “W”. These cords are rated for outdoor use

and reduce the risk of electric shock.

2

PERSO

NAL SAFETY

1

a

o

-

o

2

-

g

d

n

.

3

G.

Make sure the switch is “OFF” before plugging

O

.

4

OOL.

r

5

r

f

.

6. DO NOT STAND ON TOOL OR ITS STAND.

f

o

h

.

Dust masks,

-

s

N

.

TOOL US

1

-

PO

h

2

Use the correct tool for your application.The correct

use the tool for purpose for which it was not intended.

3

.

4

SCO

SOURC

G

S

.

5. KEEP CUTTING TOOLS SHARP AND CLEAN.

g

g

r

SPEC

d i

f

C

OO

a

.

8

mi

.

9

SSO

C

c

1

AND GREASE.

g

g

plastic housing.

1

c

g

blade.

1

GOOD CO

g

a

f

p

-

edf

r

g

d.

13

D

b

y

r

p

.

1

S.

D

use blades with inc

les

Never use bladewashers

defec

b

.

5

.

1

6

cutting.

OUC

18

W

.

19

S.

Mak

c

.

. STAY ALERT.Watch what you are doing and use common sense when operating

power tool. Do not use a tool while tired or under the influence of drugs, alcohol

r medication. A lack of attention while operating power tools could result in seri

us personal injury.

. DRESS PROPERLY.Do not wear loose clothing or jewelry.Keep your hair, cloth

ing and gloves away from moving parts. Loose clothes, jewelry, or long hair could

et caught in moving parts. Roll long sleeves above the elbow. Rubber gloves an

on-skidfootwear are recommended when working outdoors

.AVOID ACCIDENTAL STARTIN

in. Carrying tools with your finger on the switch or plugging in tools that have the

switch “

N” invites accidents

. REMOVE ADJUSTING KEYS OR WRENCHES BEFORE TURNING ON THE

A wrench or a key that is left attached to a rotating part of the tool could

T

esult in personal injury.

. DO NOTOVERREACH.Keep proper footing and balance at all times. Prope

ooting and balance enables better control of the tool in unexpected situations

is tipped or i

7. USE SAFETY EQUIPMENT. ALWAYSWEAR EYE PROTECTION.

. USE CLAMPS OR OTHER PRACTICAL MEASURESTO SECURE AND SUP

. DO NOT FORCE THETOOL.

. DO NOT USETOOL IF THE SWITCH DOES NOT TURN IT ON OR OFF. Any tool

. DI

6. IN

the cutting tool is accidentally contacted. Do not store materials on

r near the tool such that is necessary to stand on the tool or its stand to reac

them

safety shoes, hard hat or hearing protection must be used for appropriate condi

tions. Everyday eyeglasses only have impact resistant lenses, they are NOT

afety glasses.These safety glasses must conform to ANSI Z87.1 requirements.

OTE: Approved glasses have Z87 printed or stamped on them

E ANDCARE

RT THEWORK PIECETO A STABLE PLATFORM. Holding the work piece by

and or against your body is unstable and could lead to a loss of control.

tool will do the job better and safer at the rate for which it was designed. Do not

that cannot be controlled with the switch is dangerous and must be repaired

NNECT THE PLUG FROM THE POWER

ANY ADJUSTMENTS, CHANGING ACCESSORIES OR STORINGTHE TOOL.

uch preventive safety measures reduce the risk of starting the tool accidentally

edges, are less likely to bind and easier to control. When mountin

sharp cuttin

saw blades be certain that the arrow on the blade matches the direction of the ar-

ow marked on the tool and that the teeth are also pointing in the same direction.

T THE GUARDS BEFORE USING ATOOL. KEEP GUARDS IN PLACE

an

n working order. Never operate the tool with any guard or cover removed.

Make sure all guards are operating properly be

3

Serious injury may occur if the tool

E BEFORE MAKIN

Properly maintained tools, with

ore each use.

7. CHECK MOVINGPAR TS FOR BINDING OR ANY OTHER CONDITION THAT

. DO NOT ALTER OR MISUSE THETOOL. Any alteration or modification is a

THE USE OF ANY OTHER ACCE

0. KEEP THE TOOL AND ITS HANDLE DRY, CLEAN AND FREE FROM OIL

1. INSPECT THETOOL CORDS PERIODICALLY. If your cord is damaged, have

2. MAKE SURE YOUR EXTENSION CORD IS IN

. THE DUST GENERATE

4. USE ONLY CORRECT BLADE

. BEFORE MAKING A CUT, BE SURE ALL ADJUSTMENTS ARE SECURE

.AVOID CUTTING NAILS. Inspect for and remove all nails from lumber before

. NEVER T

. NEVER STAR T A TOOL WHEN ANY ROTATING COMPONENT IS IN CONTACT

. DOUBLE CHECK ALL SETUP

T THE NORMAL OPERATION OR SAFETY FEATURES OF THE

MAY AFFE

T

L. If damaged, have the tool serviced before using the tool. Many accidents

re caused by poorly maintained tools

suse and may result in serious personal injury

REATE A HAZARD. Accessories that may be suitable for one type of tool,

MAY

ould create a risk of injury when used on an inappropriate tool.

asoline, petroleum-based products, or any strong solvents to clean your tool.

Followin

it repaired by a qualified service technician at an authorized service facility. Stay

onstantly aware of the cord location and keep it well away from the rotatin

n extension cord, be sure to use one heavy enough to carry the current your tool

will draw. An undersized cord will cause a drop in line voltage resulting in loss o

ower and overheating. A wire gauge size (A.W.G.) of at least 14 is recommend

auge.The smaller the gauge number, the heavier the cor

to

roper dust removal. Use wood dust collection systems whenever possible

lade capacity of your saw is 10” (254 mm)

ITH THEWORKPIECE

ontact with the saw or workpiece before connecting to a power supply

Always use a clean cloth when cleaning. Never use brakefluids,

this rule will reduce the risk or loss of control and deterioration of the

or an extension cord 25 feet or less in length. If in doubt, use the next heavie

our health. Always operate machinery in well ventilated areas and provide fo

or bolts that are

H THE BLADE or other moving parts during use.

RIES NOT SPECIFIED IN THIS MANUAL

NDITION.When usin

y certainwoods and wood products can be injurious

o not

e sure the blade is tight and not making

orrect size ho

tive or incorrect. The maximum

4

.

SAVETHESE INSTRUCTIONS.

Ref

.

1

DO NOT OPERATETHIS MACHINE

u

he i

fi

f y

.

3

4

.

5

OSS

,

H

O

OO

S

Hands”

.

O

y

.

OSSYOU

p-

ith

ight hand i

.

SCO

O

SSO-

.

C

G

S, USE O

O

.

1

If the workpiece is bowed

o

c

o

f

obj

.

1

SC

C.

S

.

1

”

C

The s

aw blade must be fed through the workpiece

r

.

W

ARNING!Read and understand all the instructions before attempting to as-

s

/

13. CUT O

e

.

1

WO

r

1

h

W

-

p

b

1

-

SION O

c

p

1

ANYO

i

.

18

-

PO

“

y

1

K

SO

HAND

r

.

20

-

PIEC

Thi

ill hel

2

,

g

-

.

2

K

DO

r

.

2

DO

CUTO

2

idl

d th

ff

2

:

.

f

.

.

•

.

6

26

.

N

O

.

2

k

a

28. ALWAYS TURNTHE MACHINE “OFF”,

r

S

.

2

M

.

3

SENS

S

.

31

-

ING

h

.

W

-

ING,

S

c

k

th

Ŗ

L

,

Ŗ

Cry

Ŗ

A

.

r

.

S

The saw has a precision-built electric motor. It should be connected to a power

the power supply.

.

G

The no-load speed of this tool is approximately 4500 rpm. This speed is not con-

for lights cannot properly carry a power tool motor.Wire that is heavy enough for

hile i

-

.

tions are not completely understood, or if in doubt as to whether the machine is

d.

emble or operate the tool. Failure to follow the instructions listed below could

result in electric shock, fire and

.

to t

2. OBTAIN ADVICE FROM YOUR SUPERVISOR, instructor, or another quali

person i

. FOLLOW ALL WIRING CODESand recommended electrical connections.

. ALWAYS KEEP THE BLADE GUARD IN PLACE and in working order

. USE CLAMPSTO SUPPORT THEWORKPIECE WHENEVER P

SUPPORTING THEWORKPIECE BY HAND

AND OUTSIDE OF THE“NO HAND” AREA AS MARKED WITH A SYMBOL

N THE BASE. DO NOT USE THIS SAW TO CUT PIECESTHAT ARET

MALL TO BE SECURELY CLAMPED. Your hand, if placed inside the “No

6. DO NOT REACH IN BACK OF THE SAW BLADE BEHINDTHE FENCE WITH

EITHER HAND F

our hand may not be obvious and you may be seriously injured

7. NEVER CR

porting the workpiece “cross handed” i.e. holding the left side of the workpiece

w

8. ALWAYS DI

BEF

RIES.You may unintentionally start the saw, leading to serious personal injury

9. MITER SAWS ARE INTENDEDTO CUT WOOD OR WOODLIKE PRODUCTS,

THEY

FERROUS MATERIAL SUCH AS BARS,RODS, STUDS, ETC. HOWEVER

, IF CUTTING MATERIALS LIKE ALUMINUM OR OTHER NON-FERROUS

METAL

N

sparking and will damage the lower guard and will overload the motor

0. INSPECTYOUR WORKPIECE BEFORE CUTTING.

r warped, clamp it with the outside bowedface toward the fence. Always make

ertain that there is no gap between the workpiece, fence and table along the line

f the cut. Bent or warped workpieces can twist or lock and may cause binding on

the spinning saw blade while cutting. Also, make sure there are no nails or

ects in the workpiece

1. DO NOT USE THE SAW UNTILTHE TABLE IS CLEAR OF ALL TOOLS,WOOD

RAPS, ET

the revolving blade can be thrown with high speed at the operator

2. DO NOT FEED THEWORKPIECE INTOTHE BLADE OR CUT “FREEHAND

IN ANY WAY. THE WORKPIECE MUST BE STATIONARY AND CLAMPED OR

BRA

smoothly and at a ratewhich will not overload the saw’s moto

er to them often and use them to instruct others

nstructions.

ou are not familiar with the operation of this machine

region, can easily slip or be pulled into the blade

your r

RE MAKING ANY ADJUSTMENTS OR ATTACHING ANY ACCE

ANNOT BE USED WITH ABRASIVE CUTOFF WHEELS FOR CUTTIN

N-FERROUS METAL CUTTING.Cuttingferrous materials causes excessive

ED BY YOUR HAND.

or serious personal injury.

ntil it is assembled and installed according

ed

YOU MUST ALWAYS KEEP YOUR

R ANY REASON. The proximity of the spinning saw blade to

R HAND OVER THE INTENDED LINE OF CUTTING.Su

s very dangerous

NNECT THE POWER CORD FROM THE POWER SOURCE

NLY SAW BLADES SPECIFICALLY RECOMMENDED FOR

mall debris or loose pieces of wood or other objects that contact

IBLE. IF

oreign

NLY ONE WORKPIECE AT ATIME.Multiple workpieces cannot be ad-

quately clamped or braced and may bind on the blade or shift during cutting

4. BE CERTAIN THE MITER SAW IS MOUNTED OR PLACED ON A LEVEL, FIRM

RK SURFACE BEFORE USING. A level and firm work surface reduces the

isk of the miter saw becoming unstable.

5. PLANYOUR WORK.Provide adequate support accessories such as tables, saw

orses, table extension, etc.for workpieces wider or longer than the table top.

orkpieces longer or wider than the miter saw table can tip if not securely sup

orted. If the cutoff piece or workpiece tips it can lift the lower guard or be thrown

y the spinning blade.

6. DO NOT USE ANOTHER PERSON AS A SUBSTITUTE FOR A TABLE EXTEN

R AS ADDITIONAL SUPPORT.Unstable supportfor the workpiece can

ause the blade to bind or the workpiece to shift during the cutting operation

ulling you and the helper into the spinning blade.

7. THE CUTOFF PIECE MUST NOT BE JAMMED AGAINST OR PRESSURED BY

THER MEANS AGAINST THE SPINNING SAW BLADE. If confined, i.e.

ng length stops, it could get wedged against the blade and thrown violently

us

. ALWAYS USE A CLAMP OR A FIXTURE DESIGNED TO PROPERLY SUP

RT ROUND MATERIAL SUCH AS DOWEL RODS, OR TUBING.Rods have a

tendency to roll while being cut, causing the blade to

our hand into the blade.

9. WHEN CUTTING IRREGULARLY SHAPED WORKPIECES, PLANYOUR WOR

IT WILL NOT SLIP AND PINCH THE BLADE AND BETORN FROMYOUR

. A piece of molding, for example, must be lie flat or be held by a fixture o

jig that will not let it twist., rock or slip while being cut

. LET THE BLADE REACH FULL SPEED BEFORE CONTACTINGTHE WORK

E.

s w

1. IF THE WORKPIECE OR BLADE BECOMES JAMMED OR BOGGED DOWN

TURN THE MITER SAW “OFF” BY RELEASING SWITCH.Wait for all movin

parts to stop and unplug the miter saw, then work to free the jammed material.

Continued sawing with a jammed workpiece could cause a loss of control or dam

age to the miter saw

2. THE BRAKING ACTION OF THE SAW CAUSESTHE SAW HEADTO JER

WNWARD. Be ready for this reaction when making an incomplete cut or when

eleasing the switch before the head is completely in the down position

3. AFTER FINISHINGTHE CUT, RELEASE THE SWITCH, HOLD THE SAW ARM

WN AND WAIT FOR BLADE TO STOP BEFORE REMOVINGWORK OR

FF PIECE.Reaching with your hand under a coasting blade is dangerous.

4. GUARD AGAINST KICKBACK.Kickback occurs when the blade stalls rap

an

e workpiece is driven back towards the operator. It can pull your hand into

the blade resulting in serious personal injury. Stay out of the blade path and turn

the switch o

5. AVOID KICKBACK (work thrown back toward you) by

• Keeping the blade sharp and free of rust and pitch

• Never cut a workpiece that is twisted or warped, or does not have a straight

edge to guide along the

• Never saw a large workpiece that cannot be controlled

Never saw a workpiece with loose knots or other flaws

p avoid thrown workpieces.

immediately if the blade binds or stalls.

ence

bite” and pull the work with

y

5

EVER attempt to free a stalled saw blade without ſrst turning the machine

FF”

“

7. NEVER PERFORM LAYOUT,assembly or set-up the workpiece on the table/wor

rea when the machine is running.

source, and clean the table/work area before leaving the machine. LOCK THE

WITCH IN THE“OFF” POSITION to prevent unauthorized use

9. DO NOT ALLOW FAMILIARITY GAINED FROM FREQUENT USE OFYOUR

ITER SAW TO BECOME COMMONPLACE.Always remember that a careless

fraction of a second is sufſcient to inƀict severe injury

0. THINK SAFETY! SAFETY IS A COMBINATION OF OPERATOR’S COMMON

E, KNOWLEDGE OF THE SAFETY AND OPERATING INSTRUCTION

AND ALERTNESSAT ALLTIMESWHEN THE MITER SAW IS BEING USED

ARNING! SOME DUST CREATED BY POWER SANDING, SAWING, GRIND

DRILLING, AND OTHER CONSTRUCTIONACTIVITIE

nown to cause cancer, birth defects or other reproductive harm Some examples of

ese chemicals are:

ead from lead-based paints

stalline silica from bricks and cement and other masonry products, and

rsenic and chromium from chemically-treated lumber

our risk from these exposures varies, depending on how often you do this type of work,

o reduce your exposure to these chemicals: work in a wellventilated area, and work with

pproved safety equipment, such as those dust masks that are specially designed to ſlte

ut microscopic particles

.FORYOUROWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERAT

THE TOOL. Learn the tool’s application and limitations as well as the speciſc

azards that accompany it

32. SAFETY RULES FOR LASER LIGHTS

6JGNCUGTIWKFGWUGFKPVJGVQQNKU%NCUU+YKVJCOCZKOWOQWVRWVQHŭOYCPFC

wavelength of 650nm.The laser guide does not normally present an optical hazard,

although staring at the beam may cause flash blindness.

CAUTION.The use of optical in struments with this laser product will increase the

chance of eye damage.

Ŗ Do not stare into the laser beam .

Ŗ The laser shall be used and maintained in accordance with the manufacturer’s instructions.

Ŗ Never aim the beam at any person or an obj ect other than the work piece.

Ŗ Always ensure the laser beam is aimed at a sturdy work piece without a reflective surface,

i.e. wood or rough coated surfaces are acceptable.Bright shiny reflective sheet or the like

is not suitable for laser use as the reflective surface could direct the beam back at the

operator.

disconnect the machine from the powe

ontains chemicals

WER CONNECTION

operate this tool on direct current (DC). A substantial voltage drop will cause a

ine, make sure the switch is in the “OFF” position and be sure that the electric

WARNING!

damp locations

PEED AND WIRIN

n a shop is as important as the motor’s horsepower rating. A line intended only

a short distance will be too light for a greater distance. A line that can support

WARNING!

s machine must be grounded w

n use to protect the opera

s equipped with an electric cord having an equipment-grounding conductor and

outlet installed by a qualiſed electrician

heck with a qualiſed electrician or service personnel if the grounding instruc-

roperlygrounde

7

8

Repair or replace damaged or worn cord immediately

.

T

fi

.

th

ill

ill h

-

d

T

t

.

C

.

n

.

S

tion and is a 3-wire extension cord which has a 3-prong ground type plug and

An undersized cord will cause a drop in line voltage, resulting in loss of power

the minimum wire size required in an extension cord. Only round jacketed cords

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25’ 16 1616161414

50’ 16 1616141412

100’ 16 16141210 -

ge

When working with the tool outdoors, use an extension cord that is designed for

.

worn insulation.

-

y.

10

Thi

S

k

C

g

-

®

.

fl

.

f

r

lained i

l.

ition.

.

-

cause a fire.

y

bly i

il-

y

lid

.

his tool is intended for use on a circuit that has an outlet like the one shown in

gure 1. It also has a grounding pin like the one shown

2. Grounded, cord-connected machines intended for use on a supply circuit

f the machine is intended for use on a circuit that has an outlet that looks like

e one

ustrated in Fig. 2, the machine w

ary adapter, which looks like the adapter illustrated in Fig. 2, may be used to

onnect this plug to a matching 2-conductor receptacle as shown in Fig. 2 if a

roperly grounded outlet is not available.The temporary adapter should be use

only until a properlygrounded outlet can be installed by a qualified electrician.

he green-colored metal “ear”, extending from the adapter must be connected

o a permanent ground such as a properly grounded outlet box.Whenever the

adapter is used, it must be held in place with a metal screw

TE: In Canada, the use of a temporary adapter is not permitted by the Cana-

dian Electric

WARNING!

rounded. To prevent possible electrical hazards, have a qualified electricia

heck the receptacle if you are not sure

ode

n all cases, make certain the receptacle in question is properly

GROUNDING

PIN

COVER OF GROUNDED

.

OUTLET BOX

ave a grounding plug. A tempo

GROUNDED OUTLET BOX

METAL “EAR”

GROUNDING

MEANS

ADAPTER

g.

XTENSION CORD

and causing the motor to overheat. Use the chart provided below to determine

TE: AWG = American Wire Gau

outside use. This is indicated by the letters“WA” on the cord’s jacket

WARNING! Keep the extension cord clear of the working area. Position the

you are working with a power tool.Failure to do so can result in serious per

onal injur

WARNING!

9

s product requires assembly.

. Remove the packing materials from around your tool. Do not discard the

packing material until you have carefully inspected and satisfactorily oper-

ted the tool.

2.

eparate and remove all loose parts from the shipping container(s). Chec

parts against the list of loose parts.

arefully lift the tool from the carton by using the carrying handle and place it

3.

4. Remove the protective oil that is applied to all unpainted metal surfaces. This

may be removed with a soft cloth moistened with kerosene or WD

coatin

(do not use acetone, gasoline or lacquer thinner for this purpose)

. After cleaning, cover the unpainted surfaces with a good quality household

oor paste wax

. Inspect the tool carefully to make sure no breakage or damage occurred

7. The saw is

. When boxed or during storage and transportation the saw head is locked

WARNING!

parts are replaced. Failure to do so could result in serious personal injur

uring shipping.

actory set for accurate cutting. After assembling it, checkfo

ccuracy. If shipping has influenced the settings, refer to specific procedures

n this manua

exp

in the down position. To release the head apply downward pressure to the

andle and pull out the lock pin and allow the head to rise gently to its upper

pos

f any parts are missing do not operate this tool until the missing

.

Before attempting to use this product, familiarize yourself with all operating

features and safety rules.

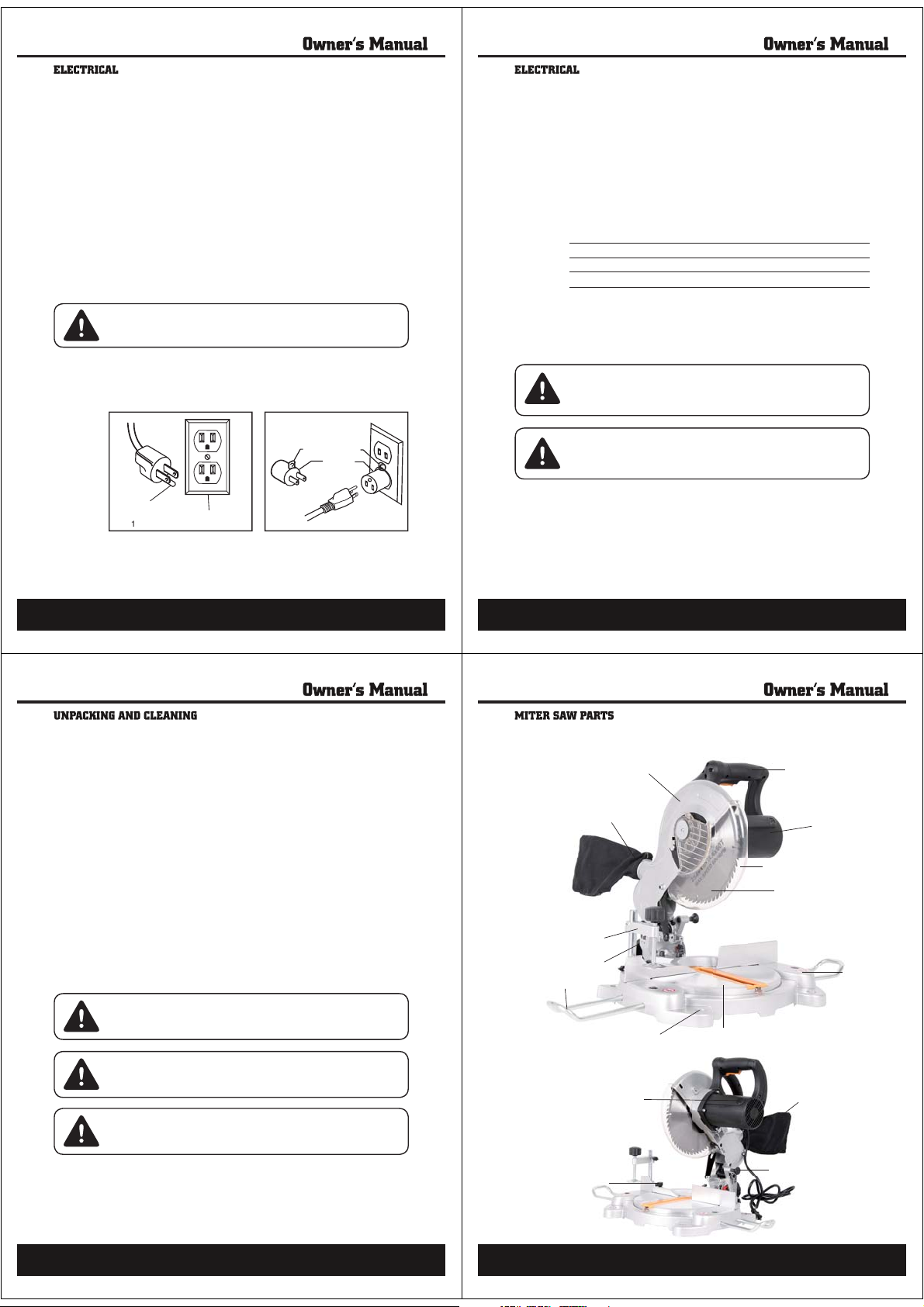

Upper Blade Guard

Dust Extraction Port

Work Clamp

Bevel Lock Wheel

Extension Bar

Bench Mounting Holes

Rotating Table

Main Handle

Motor

Lower Blade Guard

Saw Blade

Base

WARNING!

re to comply could result in accidental starting and serious personal injury.

WARNING! Before moving the saw: Lock the miter lock knob in 45° position.

Lock bevel lock lever. Pull the head assembl

ever carry the tool by the slide rails, this may cause blade damage

ever carry the tool by the cord or head assembly power switch handle. Dam

age to insulation could cause an electric shock. Damage to wire connections

ould

o not connect to power supply until assem

ten the s

e rail lock knob. Lock head assembly in the down position

completely towardyou and

11

s complete.Fa

Carbon Brush Cap

Tab l e Lock Pin

Dust Bag

Head Lock Pin

12

Loading...

Loading...