Steele Products SP-PB008 User Manual

CONTENTS

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specific Safety Rules For The Bench Grinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly And Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring Diagram and Know Your Bench Grinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Parts and List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Warranty

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PRODUCT SPECIFICATIONS

MODEL WHEEL

Rating Voltage 120 Vac

Frequency 60Hz

Amperes 4.8

No Load Speed 3450 RPM

Weight 38 lbs

HP 3/4

Diameter 8 in.

Face 1 in.

Hole 5/8 in.

WORK LIGHT

Rating Voltage 12V

Watt 10W

Base Cast Iron

WARNING! To Reduce The Risk Of Injury, User

Must Read And Understand Instruction Manual.

DESCRIPTION

Unique design with 2 fixed work light to illuminate your work area; Dry double end grinding wheels

can give rapid sharpening to various types of blades. Powerful motor quickly brings the coarse

and fine grinding wheels to their required operating speed.

WARNING

serious personal injury, assemble all parts to your bench grinder before connecting it to power

supply. The bench grinder should never be connected to power supply when you are assembling

parts, making adjustments, installing or removing grinding wheels, cleaning, or when not in use.

To prevent accidental starting or electrical shock that could cause possible

1

GENERAL SAFETY INFORMATION

To operate this tool, read this instruction manual and all the labels affixed to the bench grinder carefully

before using. Keep this manual available for future reference. Safety is a combination of common sense,

staying alert and knowing how your bench grinder works.

1. WORK AREA

Keep the work area clean and well lit. Cluttered benches and dark areas invite accidents.Do not use

the tool in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.Keep bystanders, visitors, and children

away while operating a power tool. Distractions can cause you to lose control.

2. ELECTRICAL SAFETY

Grounded tools must be plugged into an outlet properly installed and grounded in accordance with

all codes and ordinances. Never remove the grounding prong or modify the plug in any way. Do not

use any adapter plugs. Check with a qualified electrician if you are in doubt as to whether the outlet

is properly grounded. If the tool electrically malfunctions or breaks down, grounding provides a low

resistance path to carry electricity away from the user. Avoid contact with grounded surfaces such

as pipes, radiators, ranges, and refrigerators. There is an increased risk of electrical shock if your

body is grounded.Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the cord to carry the tool or pull the plug from an outlet. Keep

the cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of electric shock.

When operating a power tool outside, use an outdoor extension cord marked "W-A" or "W'. These

cords are rated for outdoor use and reduce the risk of electric shock.

3. PERSONAL SAFETY

Stay alert, watch what you are doing, and use common sense when operating a power tool. Do not

use the tool when you are tired or under the influence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in serious personal injury Dress properly. Do

not wear loose clothing or jewelry. Wear protective hair netting to contain long hair. Keep your hair,

clothing, and gloves away from moving parts. Rubber gloves and non-skid footwear are recommended

when working outdoors.

Avoid accidental starting. Make sure the switch is off before plugging in. Carrying tools with your

finger on the switch or plugging in tools that have the switch on invites accidents.

Remove adjusting keys or switches before turning the tool on. A wrench or a key that is left attached

to a rotating part of the tool may result in personal injury. Do not overreach. Keep proper footing

and balance at all times. Proper footing and balance enables better control of the tool in unexpected

situations. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for appropriate conditions.

4. TOOL USE AND CARE

Do not force the tool. Use the correct tool for your application.Do not use the tool if the switch does

not turn it on or off. Any tool that cannot be controlled with the switch is dangerous and must be

repaired. Disconnect the plug from the power source before making any adjustments, changing

accessories or storing the tool. Such preventive safety measures reduce the risk of starting the tool

accidentally. Store idle tools out of reach of children and other untrained persons.

GENERAL SAFETY INFORMATION

Tools are dangerous in the hands of untrained users. Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with sharp cutting edges are less likely to bind and are

easier to control.Check for misalignment or jamming of moving parts, breakage of parts and any

other condition that may affect the tools operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your model. Accessories that

may be suitable for one tool, may become hazardous when used on another tool.

5. SERVICE

Tool service must be performed only by qualified repair personnel.Service or maintenance performed

by unqualified personnel could result in a risk of injury. When servicing a tool, use only identical

replacement parts Follow instructions in the Maintenance section of this manual. Use of unauthorized

parts or failure to follow maintenance instructions may create a risk of electric shock or injury.Some

dust created by power grinding contains chemicals that may cause cancer, birth defects, or other

reproductive harm. Some examples of these chemicals are: Lead from lead-based paint Crystalline

silica from bricks, cement, and other masonry products Arsenic and chromium from chemically

treated lumber To reduce your exposure to these chemicals: work in a well-ventilated area, use

approved safety equipment, and use dust masks that are specially designed to filter out microscopic

particles.

SPECIFIC SAFETY RULES FOR THE BENCH GRINDER

Always use the eye shields, spark arrestors and wear safety goggles with side shields.Use of unauthorized

parts or failure to follow maintenance instructions may create a risk of electric shock or injury. Replace

a cracked grinding wheel immediately. Handle the grinding wheels carefully. When replacing, do not

tighten the spindle nut too tightly, the strain can damage the wheel. The wheel diameter decreases

with use. Adjust the tool rests whenever necessary to maintain a distance of 1/8" or less from the

grinding surface. Adjust the spark arrestors to maintain a 1/16" distance or less from the wheel's surface.

Pieces of stone may be thrown off the rotating wheel when first starting the grinder. Always stand to

one side of the grinder wheel when turning it on, and wait at the side until the wheel is at full speed.

Make sure there is no flammable material near the exhaust chutes. The chute will channel out sparks

and debris.Never apply pressure to the workpiece when the grinding wheel is cold. Allow the wheel to

warm up by applying the workpiece gradually. Never use the grinder without the wheel guards. Keep

fingers away from the wheel. Do not try to cut anything with the grinding wheel. When the wheel is

worn out of round, use a wheel dressing tool to resurface it.

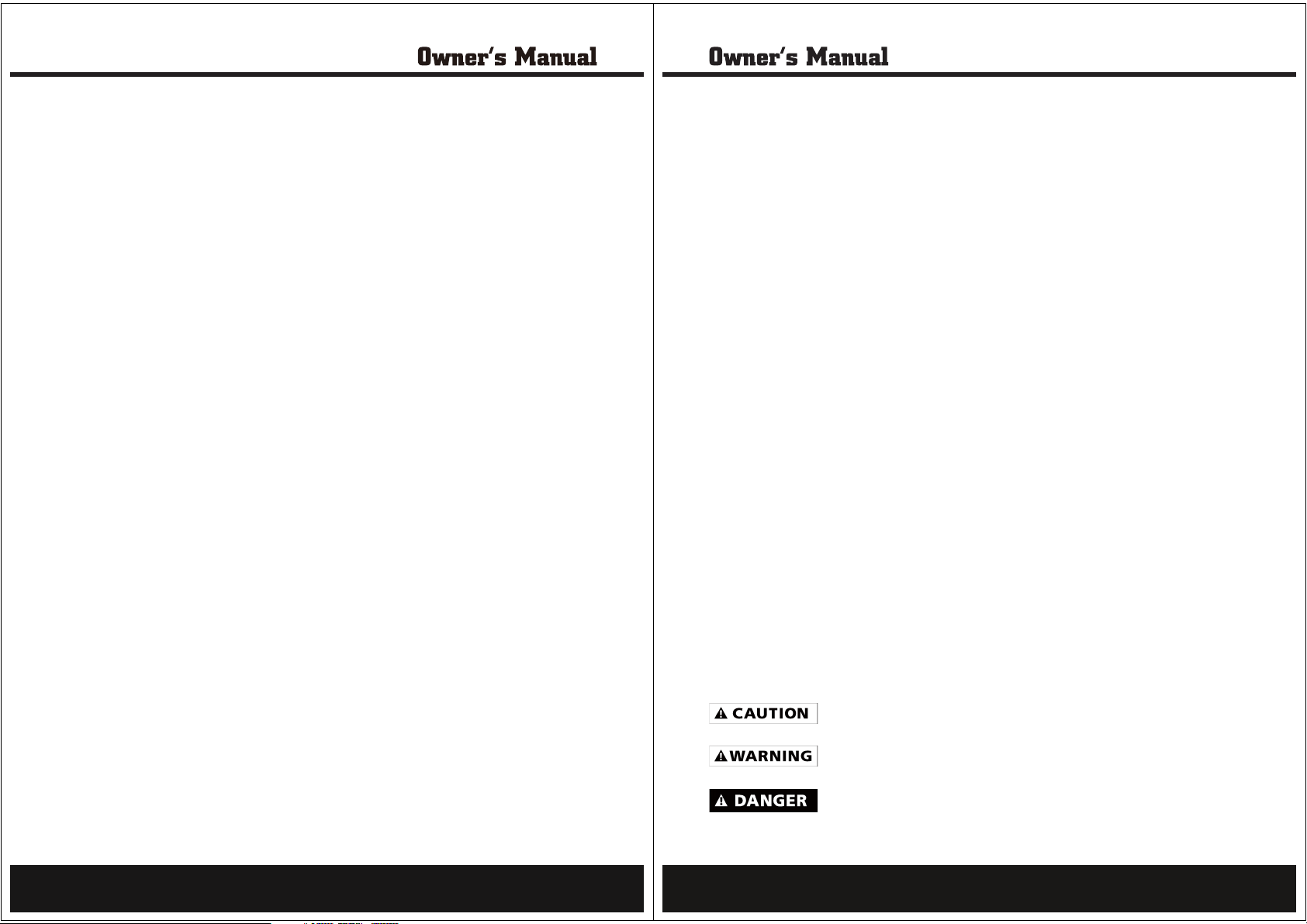

SYMBOLS USED THROUGHOUT THIS MANUAL:

Warns about hazards that may cause minor personal injury or property damage

if ignored.

Warns about hazards that can cause severe personal inJury, death, or major

property damage if ignored.

Warns about hazards that will cause serious personal injury, death, or major

property damage if ignored.

2

3

GENERAL SAFETY INFORMATION

GENERAL SAFETY INFORMATION

PROPERLY GROUNDED. IF YOU ARE NOT SURE HAVE A QUALIFIED ELECTRICIAN CHECK THE

RECEPTACLE.

DO NOT MODIFY THE PLUG PROVIDED.If it will not fit the outlet,

have the proper outlet installed by an electrician.IMPROPER

CONNECTION of the equipment ground conductor can result

in risk of electric shock. The conductor with the green insulation

(with or without yellow stripes) is the equipment grounding conductor.

If repair or replacement of the electric cord or plug is necessary,

DO NOT connect the equipment grounding conductor to a live terminal

a live terminal

EXTENSION CORDS

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type plug and matching receptacle which will accept

the machine's plug. When using an extension cord, be sure to use one heavy enough to carry the

current of the machine. An undersized cord will cause a drop in line voltage, resulting in loss of power

and overheating.The table , shows the correct gauge to use depending on the cord length. If in doubt,

use the next heavier gauge. The smaller the gauge number, the heavier the cord.

WARNING: IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN QUESTION IS

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINE~

Ampere Total Length Gauge of

Rating Volts of Cord in Feet Extension Cord

0-6 120

0-6 120 25-50 16 AWG

0-6 120 50-100 16 AWG

0-6 120 100-150 14 AWG

6-10 120

6-10 120 25-50 16 AWG

6-10 120 50-100 14 AWG

6-10 120 100-150 12 AWG

10-12 120

10-12 120 25-50 16 AWG

10-12 120 50-100 14 AWG

10-12 120 100-150 12 AWG

12-16 120

12-16 120 25-50 12 AWG

12-16 120

up to

25

up to

25

up to

25

up to

25

GREATER THAN 50 FEET NOT RECOMMENDED

18 AWG

18 AWG

16 AWG

14 AWG

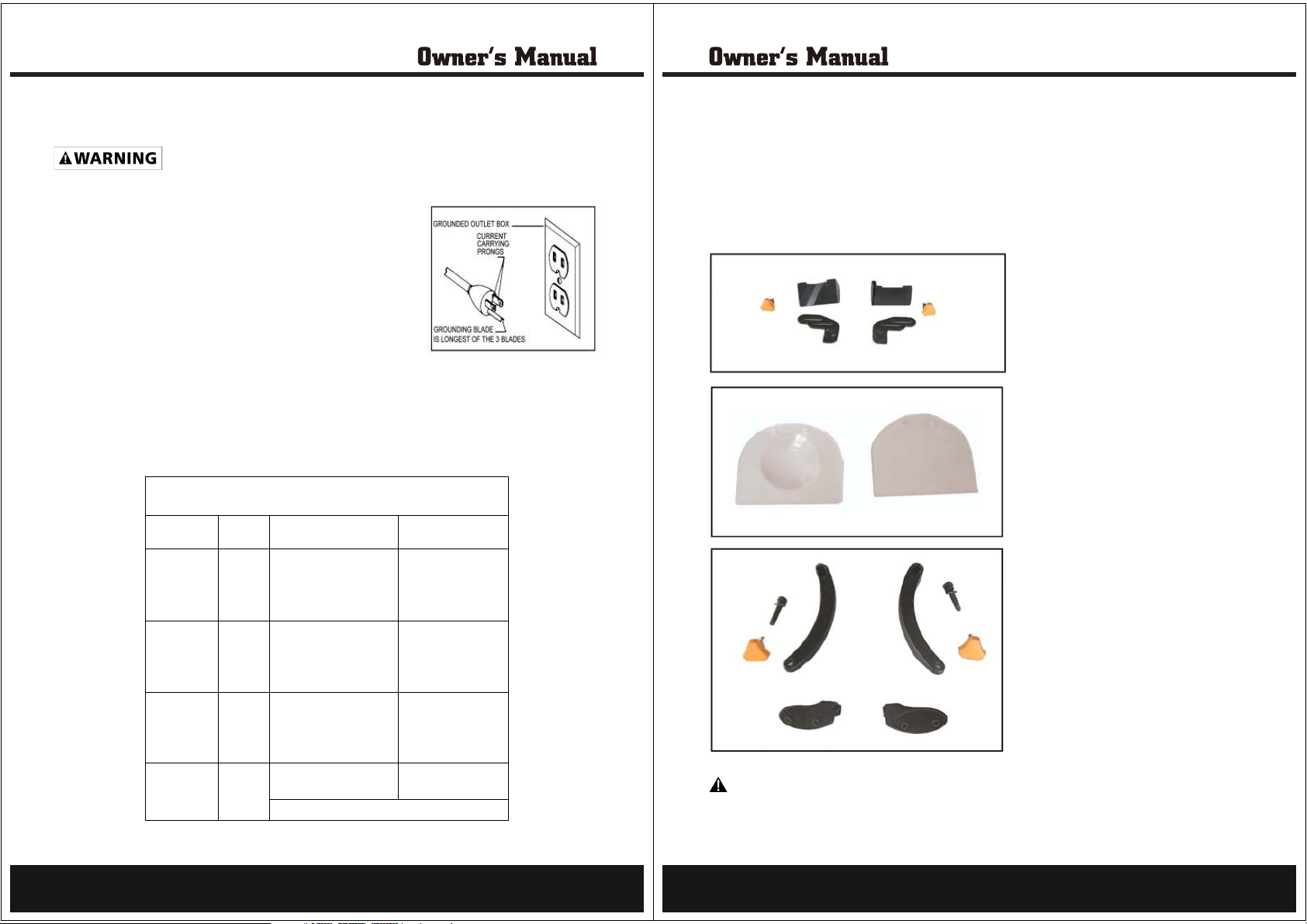

UNPACKING

After unpacking the unit, inspect all components for any damage that may have occurred in transit.

Read the following precautions and instructions before you attach. Failure to comply with these

instructions could result in personal injury or property damage. Keep these instructions in a convenient

location for future reference.The following items are included with your bench grinder.

Tool Rest (Left & Right) & Adjusting Knob

Eyeshields (Plain & with Magnifier)

Eyeshields Mounting Hardware Kit

WARNING

replaced. Failure to do so could result in possible serious personal injury.Call 888-896-6881

for replacement parts.

lf any parts are missing do not operate this tool until the missing parts are

4

5

Loading...

Loading...