Sony CAST-AU4, B2521E User Manual

Sony Desktop Robot

OPERATION MANUAL

CAST-AU4/B2521E |

GA |

About this Operation Manual

This Operation Manual is intended as a guide for users of the Sony Desktop Robot ROBOKIDS.

Before operating this system, you should first throughly read this manual. You may not understand all of the explanations the first time through, but be on the lookout for any special directions.

It should be used in conjuction with the RK card manual for your specifications.

•This manual may not be replicated in whole or in part without the prior written authorization of Sony Corporation.

•The information described herein is subject to change without notice.

•The information described herein has been checked for both reliability and accuracy. However, if you have any questions, or notice any errors or omissions in this manual, please contact the following offices of Sony Corporation.

[Singapore]

Sony Electronics (Singapore) Pte. Ltd

SPEC, No.52 Tuas Avenue 9, Singapore 639193

TEL : 8615858 |

FAX : 8621521 |

[Europe]

Sony Wega Produktions GmbH Production Technology Division Europe

Hedelfinger Str. 61 |

|

D-70327 Stuttgart Germany |

|

TEL : +49 (0)711 5858-420 |

FAX : +49 (0)711 574153 |

[Japan]

Sony Manufacturing Systems Corporation FA Service Department

1-10, Kiyoku-cho, Kuki-shi

Saitama, 346-0035 JAPAN

TEL : 0480-23-1956 FAX : 0480-23-1706

CAST-AU4/B2521E

How to Use this Operation Manual

First Time Users

Read this manual form chapter 1 through chapter 4 before starting any operation. The manual describes the procedures required in setting up ROBOKIDS for users who have little experience with FA (Factory Automation) equipment.

Routine Assembly

Follow the respective application manuals for routine assembly task operations.

Replacing the Unit or Memory Card

Remove the existing unit. Attach the new unit and replace the memory card. References of the memory card may be found in this Operation manual or the respective application manuals.

This manual describes the ROBOKIDS base machine. Details for application unit installations may be found in the operation manuals that are attached when purchasing the application units.

CAST-AU4/B2521E

Manual Configuration

This operation manual describes the procedures required to operate the desktop robot ROBOKIDS Various types of applications such as dispensing and soldering may be accomplished by exchanging the memory cards (RK card) which stores the programs required to run an application. The semi-programmable specification allows the user to modify an operation program and peripheral task program to perform a specific work. The full open programmable specification enables the use to freely write any program to perform an unique application. This manual contains the common contents between dispensing, soldering, semi-programmable and the full open programmable specification. For further details refer to the memory card (RK Card) operation manual (or the Full Open Programmable operation manual for the full open programmable specifications.)

Safety Instruction

Describes the safety precautions for user’s safety.

Unpacking

Describes the precautions during unpacking, and lists the supplied accessories.

1.Outline

Outlines features, names and functions of controls, and its specifications.

2.Preparation

Helps you set up the base machine. Beside the supplied accessories, you also may need to purchase the dispensing unit, soldering unit, air compressor, workpiece fixing tool (including fixing screws) depending on the configuration.

3.Maintenance

Describes daily maintenance.

4.Troubleshooting

Describes countermeasure (only the contents which are in common in applications) when an error occurs during operation. The Operation Manual of each memory card (RK card) describes countermeasures for dispensing errors and soldering errors.

5.Replacement Parts

Shows list of main replacement parts of the base machine.

6.Appendix

Described input and output specifications of each connector.

CAST-AU4/B2521E

Contents

Safety Instruction ............................................................................................................... |

S-1 |

Unpacking ........................................................................................................................... |

U-1 |

1.Outline

1-1 |

Nomenclature .................................................................................................................... |

1-2 |

|

1-2 |

Outline Drawings .............................................................................................................. |

1-4 |

|

1-3 |

Specifications .................................................................................................................... |

1-9 |

|

|

1-3-1 |

Machine Specification ........................................................................................ |

1-9 |

|

1-3-2 |

Control Specifications ...................................................................................... |

1-10 |

2.Preparation

2-1 |

Attaching the Units ........................................................................................................... |

2-1 |

|

|

2-1-1 |

Attaching the Z-unit ........................................................................................... |

2-1 |

|

2-1-2 |

Attaching the ZR-unit ......................................................................................... |

2-4 |

2-2 |

Connecting the External Signal ........................................................................................ |

2-7 |

|

2-3 |

Connecting to an Electrical Outlet .................................................................................. |

2-12 |

|

2-4 |

Starting Up the Base Machine ........................................................................................ |

2-13 |

|

|

2-4-1 |

Full-open Programmable Specification ............................................................ |

2-13 |

|

2-4-2 |

When Using Memory Card “RK card” ............................................................ |

2-13 |

3.Maintenance

3-1 |

Maintaining the Machine .................................................................................................. |

3-1 |

3-2 |

Greasing the Machine and Removing Fallen Materials ................................................... |

3-1 |

3-3 |

Cleaning and Replacing the Air Filter .............................................................................. |

3-4 |

3-4 |

Replacing the Battery ....................................................................................................... |

3-6 |

4.Troubleshooting

4-1 |

Common Items.................................................................................................................. |

4-1 |

|

|

4-1-1 |

Stepping Out ....................................................................................................... |

4-1 |

|

4-1-2 |

External Noise .................................................................................................... |

4-3 |

|

4-1-3 |

Abnormal Sound from Unit’s Motors ................................................................ |

4-3 |

4-2 |

Full-open Programmable Specifications........................................................................... |

4-4 |

|

4-3 |

When Memory Card (RK Card) is Used .......................................................................... |

4-7 |

|

Trouble Check Sheet ................................................................................................................. |

4-10 |

||

5.Repair Parts Lists

5-1 |

ROBOKIDS Body ............................................................................................................ |

5-1 |

5-2 |

Z-axis Unit ........................................................................................................................ |

5-1 |

5-3 |

ZR-axis Unit ..................................................................................................................... |

5-2 |

6. Appendix .................................................................................................................................... |

6-1 |

|

CAST-AU4/B2521E

Safety Instruction

Safety Instruction

Sony Corporation designs and manufactures all its equipment with strict attention to safety. However, if the machine is operated or maintained without regard to the safety guidelines, damage or injury to the machine or operator may occur.

To prevent accidents, those in charge of operation and maintenance must follow the safety work rules when using the machine. Always read the safety precautions carefully before reading the Operation Manual, and carefully note the following safety rules.

Observe all precautions to ensure safety.

Read the precautions on pages 3 to 6 thoroughly.

Perform regular inspections.

Inspect the machine referring to chapter “3. Maintenance”.

In the event of accidents....

Consult with the dealer that is indicated on warranty card after filling in the trouble check sheet which is attached to the end of the Operation Manual.

CAST-AU4/B2521E |

S-1 |

|

Definition of warning symbols

Pay particular attention to the following symbols and conventions shown on the machine and on the Operation Manual. Fully understand the contents of symbols and conventions before reading the Operation Manual.

Machine Symbols

Indicates a protective terminal of mechanical parts to which an external protective earth wire is connected.

When the part with this mark is removed, the high voltage appears.

Check the operation manual before using the part with this mark.

Be cautious not to pinch your hands or fingers into the units moving parts. Before you perform any maintenance and/or check, disconnect the unit from the main power supply.

Operation Manual Symbols

Indicates that mis-operations or mis-handling may result in unexpected danger (fire, etc.,)

and the that operator is at risk (of major injury).

Warning

Indicates that mis-handling may result in unexpected danger (electric shock, etc.,) and that

the operator is at risk of injury or the equipment at risk of damage.

Caution

|

S-2 |

CAST-AU4/B2521E |

Safety Instruction

■Important Safeguards

The tool driving mechanism are subject to unexpected movement. Pay attention to safety measures.

Turn off the main power prior to performing maintenance or inspections. Failure to observe this may result in severe injury through electric shocks or unexpected movement of the machine.

Mistakes during maintenance and inspections may result in accidents.

|

Observe the followings prior to starting maintenance or inspections: |

Warning |

1. Read the Operation Manual thoroughly and following all instructions and warnings closely. |

|

2.Implement inspections on a daily basis to prevent accidents arising from damaged equipment.

3.Pay attention so that the power cord is not pinched by the machine and the peripheral equipment when installing the machine system.

Ensure to connect the primary power supply to the three-pin AC power outlet using the power cord (supplied with earth wire) supplied with the equipment. Electrical potential difference will occur with surrounding equipment if the electrical earth is not connected and may result in electrical leakage or electrical shocks.

Heavy object. Move and transport with two or more persons, and pay attention to safety measures.

To maintain safety do not make any modifications to the equipment in order.

Be careful so that hands must not be pinched by the movable blocks.

(Movable parts of each axis, tool attachment block, table block, belt beneath the units, tools, works, etc.)

Avoid installing in the following locations:

○ In places which receive direct sunlight or which experience temperature ranges exceeding 0 degrees °C and 40 degrees °C.

○ In places which experience relative humidity ranges exceeding 35% and 90%, and

|

places in which condensation is generated by rapidly changing humidity. |

|

○ In places where corrosive gas or inflammable gas exists. |

Caution |

○ In places where the unit will be subject to direct vibrations or impact. |

○Close to machinery which emits electrical noise, such as welders, electric dischargers or high-frequency generators.

○In places where any obstacles are anticipated during maintenance and inspection.

Precautions during operation, movement, maintenance and inspection

During operation the machine may look as if it has stopped. Be careful when certain conditions are met, the machine will resume motion automatically.

Connect the earth wiring (FG) to the tools.

Electrical potential difference will occur with surrounding equipment if the electrical earth is not connected and may result in electrical shocks.

Be careful that motor gets very hot.

CAST-AU4/B2521E |

S-3 |

|

Precautions on Usage

Operate on the specified voltage

Operate the ROBOKIDS only on AC power voltage as specified on the label of the machine. The power cord must be directly connected to the electrical output, and grounded. The ROBOKIDS conforms with the safety requirements of the target country to which it is shipped.

When a machine will not be used for extended period of time

If the machine is not in use for a long period, unplug the power cord from the electrical output. To unplug, pull on the plug. Never pull on the cord.

Do not drop any foreign material into the machine

Dropping any flammable liquid or metal, object into the machine can cause errors and trouble of the machine. Should any of them drop into the machine, unplug the power cord and contact your local Sony dealer.

Do not place any obstacles in front of the fans.

Heat dissipation will be insufficient and the accumulated heat can cause malfunctions.

Precautions on Transportation

•Avoid excessive shock. Excessive shock such as dropping the machine may cause damage.

•Do not hit the units or work table during operation. Also be careful so that hands and/or clothes are not pinched by the machine. It can cause unexpected physical injury.

•Be sure to hold the bottom panel when moving the machine.

|

S-4 |

CAST-AU4/B2521E |

Safety Instruction

Precaution on memory cards

Before inserting or removing a memory card, always turn the power off.

The data stored in the memory card may be damaged if a memory card is inserted or removed while the power is on.

Precaution on the teaching pendant

ROBOKIDS uses a teaching pendant for the CAST-PRO or SRX. The CAST-U teaching pendant and CAST-PRO teaching pendant are not compatible. Do not use the CAST-U teaching pendant with the ROBOKIDS.

If the CAST-U teaching pendant is used with the ROBOKIDS., the ROBOKIDS cannot exit the emergency stop state and can be damaged. Do not use the CAST-U teaching pendant with the

ROBOKIDS.

Caution If the SRX teaching pendant (SRX-P006) is used with the ROBOKIDS. the ROBOKIDS can be damaged. Do not use the SRX teaching pendant with the ROBOKIDS.

Precaution on maintenance

Periodic inspection of the following items is recommended once every six months.

Operation check of the fan attached to the controller

Be sure to check the operation of the fan attached to the controller before starting operation.

Equipment can be seriously damaged by heat accumulated in ICs in certain operating environments in which equipment is used without sufficient heat dissipation.

CAST-AU4/B2521E |

S-5 |

|

On handling batteries

The following battery is used in the base machine controller.

Lithium battery (primary battery) of type : CR17335SE-CN21 Manufactured by Sanyo Electric Co.

Incorrect handling of the battery may result in dangerous situation.

Do not perform the actions as listed below for safety. Sony Corporation is not responsible for the troubles related to the operation of the following precautions.

(1)Shorting

Do not short the batteries.

Shorting the battery may damage the equipment or may result in thermal injury due to overheating.

(2)Disassembling

Do not disassemble the batteries.

Gas will be generated irritating the throat. Lithium metal may be generated. The batteries can be heated internally resulting in explosion or fire if the batteries are subject to shock.

(3)Throwing into fire or water

The battery may explode, generate fire due to liquid leakage or internal shorting if the Caution battery is heated. Never throw the battery into fire. The batteries can explode if they are

The battery may explode, generate fire due to liquid leakage or internal shorting if the Caution battery is heated. Never throw the battery into fire. The batteries can explode if they are

thrown into fire. Throwing the batteries into water may lose the battery function.

(4)Soldering

Do not make any soldering directly to the batteries. The batteries can explode or generate fire due to liquid leakage or internal shorting inside the batteries caused by heat.

(5)Do not connect the batteries with reverse polarities between (+) and (-)

(6)Using the batteries for other applications

Do not use the batteries for other applications. The batteries may be damaged or the equipment can be damaged due to specification differences.

(7)Charging

Do not charge the lithium battery (primary battery). Gas will be generated inside causing explosion and fire.

Life and replacement of batteries

The nominal life of the lithium battery (primary battery) used in the controller is 3 to 5 years. Replace it every 3 years as a guide line. (Refer to section “3-4 Replacing the Battery” for the replacement procedure.) Life, however, can be shorter than the nominal life depending upon the ambient environments.

The front POWER indicator changes from green to red when a battery runs out.

|

S-6 |

CAST-AU4/B2521E |

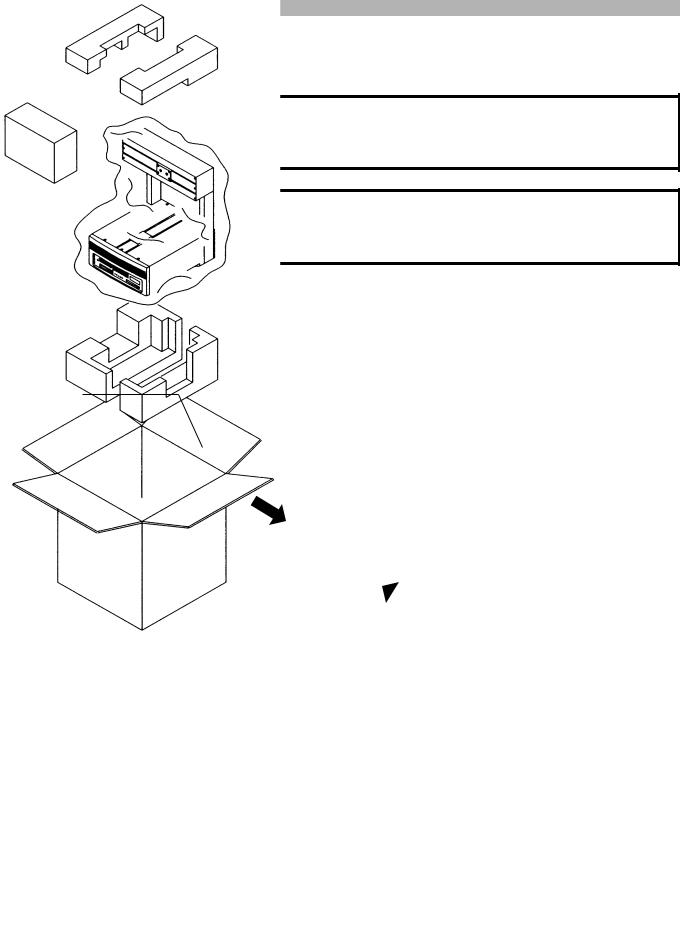

Unpacking

Unpacking

Transport it to the installation position while taking care not to drop or fall. Pay extra

attention not to give any vibration or shock because the controller contains precision Caution electronic parts.

attention not to give any vibration or shock because the controller contains precision Caution electronic parts.

Be sure to use the packaging material specified by Sony Corporation when transporting the

NOTE

machine.

Accsesory box

Remove by holding hands at the bottom as shown by the arrows.

Remove by holding hands at the bottom as shown by the arrows.

CAST-AU4/B2521E |

U-1 |

|

When the machine is unpacked, make sure the following items are in the package.

Base machine |

Power cable |

Operation box |

USER I/O connector |

|

(For AC 200V to 240 V) |

|

PCR-E68FS (connector) |

|

|

|

PCS-E68LA (connector cover) |

|

|

|

(Honda Communications Company) |

Operation Manual |

External supply power |

|

connector for USER I/O |

|

MC 1.5/2-ST-3.81 |

|

(Phoenix Contact Inc.) |

|

U-2 |

CAST-AU4/B2521E |

1. Outline

1. Outline

ROBOKIDS is a desktop assembly tool designed to automate cell production systems saving a significant amount of power consumed by assembly lines. It may be used in a variety of applications by simply exchanging the work unit and memory card. The basic operation procedures are common throughout the applications enabling a smooth migration from one work to another.

•The programs required for an application are stored in the memory card “RK Card”.

Operation is started by inserting the specific memory card into the base machine and teaching the work points. The machine may be switched to perform a different application be exchanging the memory card.

•The work points and the working speed may be set by using the simple operation teaching pendant (option) even by someone who has just purchased ROBOKIDS.

•The power supply and controller are built inside the machine thus making the system transportable to the place where it is needed.

•The machine is equipped with an external switch connector and also an USER I/O connector allowing synchronous operation with external equipment. Remote operation is also possible.

NOTE

The external switch and connector enabling operation of the machine by two operators, must be prepared by the user.

■ Product Configuration

The base machine consists of two axes X-axis and Y-axis. It may be upgraded to three and four axes by installing the optional Z-unit and ZR-unit respectively.

CAST-AU4/B2521E |

1-1 |

|

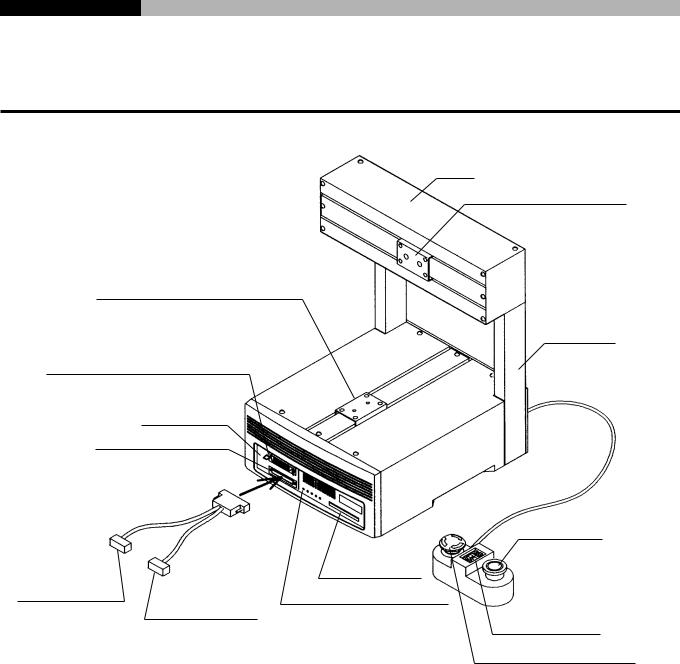

1-1 Nomenclature

Front View

X-axis

Unit or tool mounting bracket

Work table mounting bracket (Y-axis)

X-axis stand

TECH. PEN. connector

(for teaching pendant of CAST-PRO)

*EJECT button

Debug station connector

*To debug station

START button

SRX teaching

pendant connector RS 232C program transfer connector

Memory card slot

5-gang LED display (POWER, TASK, ROBOT, ONLINE, ERROR indications from the left)

Operation box

Operation box

PROGRAM switch STOP button

*Debug station • • • Option

Either the “SRX teaching pendant” or the program transfer cable can be directly connected to the debug station connector.

*EJECT button • • • When inserting or removing the CAST-PRO teaching pendant, insert it or remove it while pressing the EJECT button.

5-gang LED Display

The following machine conditions are indicated on the 5-gang LED display.

1.ERROR ........Illuminates during the error state.

2.ONLINE .......Illuminates during the on-line state. (Illuminates normally.)

3.ROBOT ........Illuminates while the servo is on. (Illuminates continually after home position is checked.

Turned off during stop.)

4.TASK ...........Illuminates while any of the robot task, or PLC task, or peripheral task is being executed.

5.POWER .......Illuminates in green while power is on. Illuminates in red when a battery runs out.

|

1-2 |

CAST-AU4/B2521E |

1. Outline

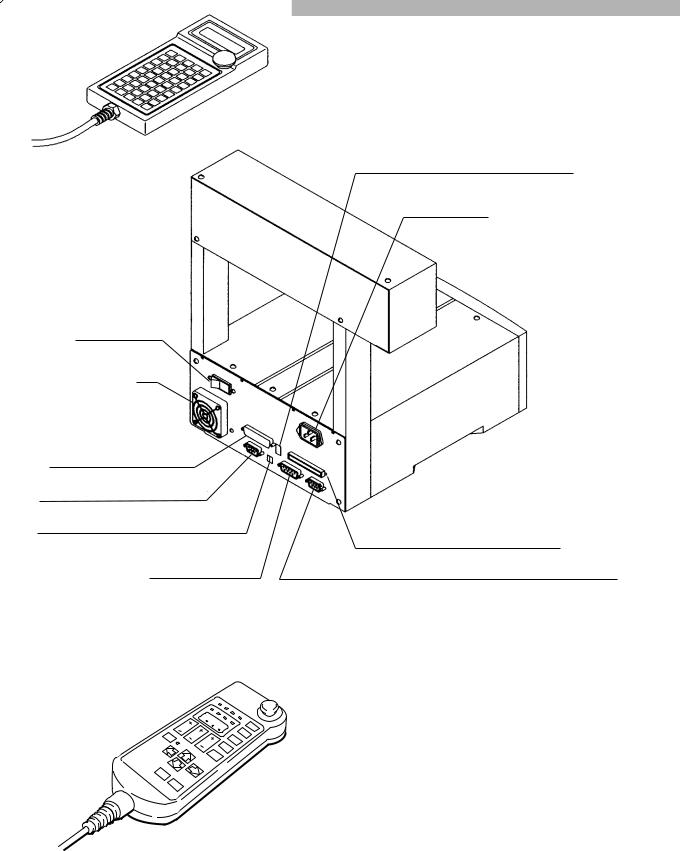

Rear View

POWER switch

Fan

Z- and ZR-axis connector

OPERATION BOX connector

DC24V INPUT (I/O power) connector (Up to maximum 1.5 A)

SAFETY connector

Internal/external selecting switch for I/O (Upper : OUTSIDE, Lower : INSIDE)

INLET (power)

USER INPUT/OUTPUT connector (External I/O connector)

RS232C connector

(Used only when the full open programmable specification is used.)

CAST-PRO Teaching Pendant |

|

SRX Teaching pendant |

|

|

|

|

|

|

8 88

CAST-P06 (option) |

SRX-P005/S (option) |

CAST-AU4/B2521E |

1-3 |

|

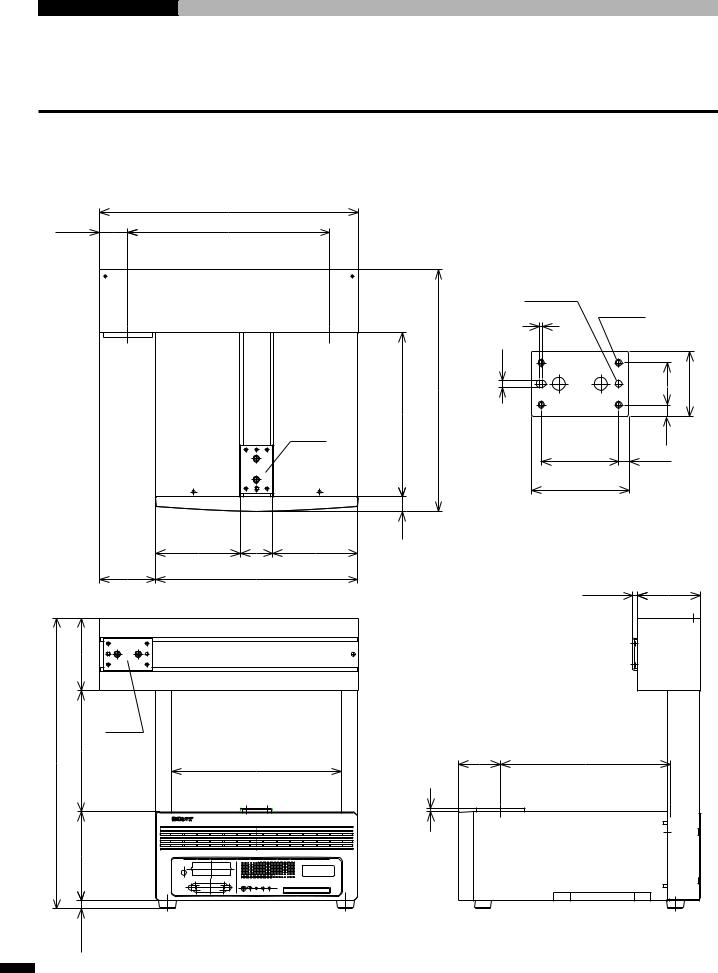

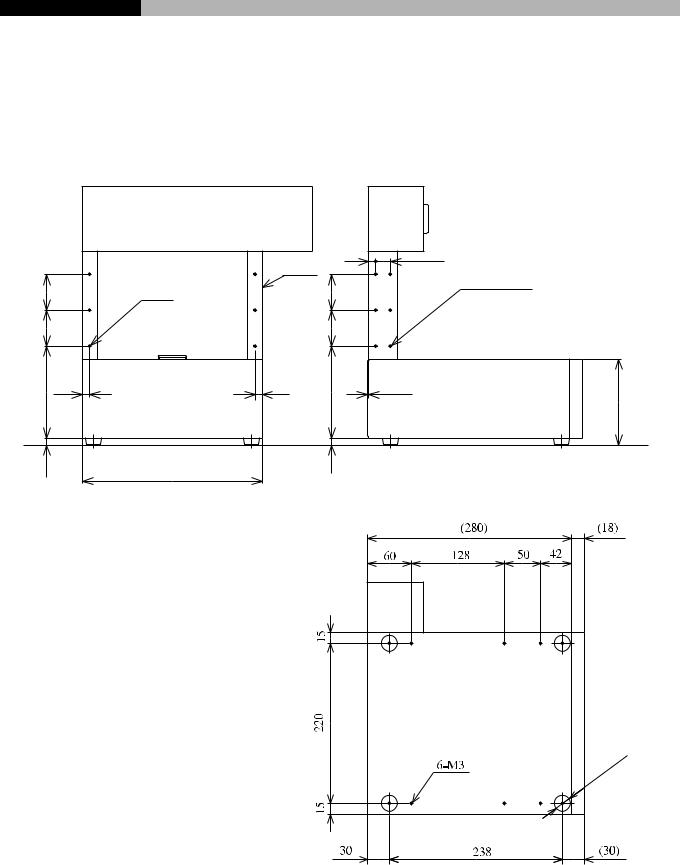

1-2 Outline Drawings

■ROBOKIDS

Standard Type (CAST-AU4/B2521E)

|

320 |

(35) |

250 |

|

|

|

(Stroke) |

|

|

|

(300) |

|

|

A |

203 |

|

|

|

|

105 |

40 |

105 |

18 |

|

|||

(69) |

(250) |

|

|

90 |

|

A |

(360) |

150 |

|

210 |

|

(4.5) |

10 110

1-4

φ4 + 00.03

2 4-M4

0.03 |

0 |

|

|

+ |

|

|

(40) |

4 |

26 |

||

|

|

(7) |

|

|

48 |

(6) |

|

|

(60) |

|

|

Detailed view of "A"

(6) (78)

(52) |

210 |

|

(Stroke) |

|

CAST-AU4/B2521E |

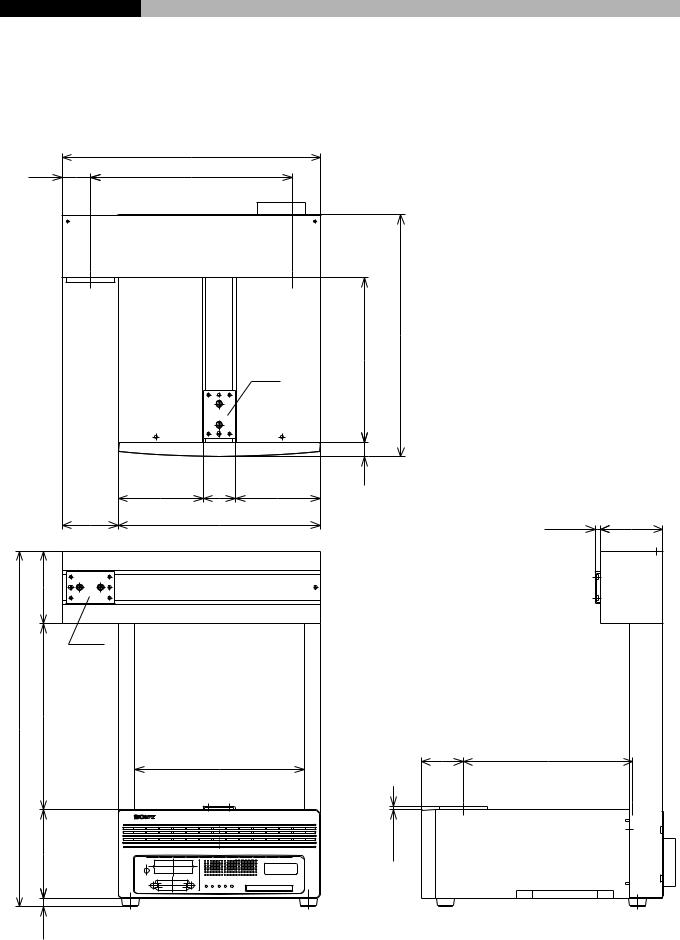

1. Outline

Height Adjustable Type (CAST-AU4/BT2521E)

|

320 |

(35) |

250 |

(Stroke)

|

|

A |

203 |

(300) |

|

|

|

|

|

|

|

105 |

40 |

105 |

18 |

|

|

|

|

|

|||

(69) |

(250) |

|

|

(6) |

(78) |

|

|

|

|

90

A

(440) |

230 |

210 |

|

(52) |

|

|

210 |

(Stroke) |

|

|

110 |

(4.5) |

10 |

|

CAST-AU4/B2521E |

1-5 |

|

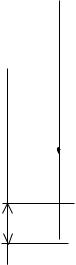

■3-Axes Model Z-unit

179

14 26 10 (13)

■4-Axes Model ZR-unit

50 Tool attachment position

162

70 |

97 |

(202)

5 76 26

5 76 26

68 |

45 |

11 |

58

4-M4

48

162

63 |

97 |

280 144.5 45

5

5 |

|

φ12h7 |

30 |

|

57 |

|

1-6 |

CAST-AU4/B2521E |

1. Outline

Service Tapped-Hole Position

50 |

|

50 |

|

128 |

10 |

|

10

|

|

10 |

20 |

|

Side A |

|

6-M3 |

6-M3 |

|

50 |

|

|

(Side A only) |

||

|

|

|

|

|

|

50 |

|

|

10 |

128 |

(1.6) |

|

|

(120) |

|

(250) |

|

10 |

|

|

|

|

-φ22 4

CAST-AU4/B2521E |

1-7 |

|

Loading...

Loading...