Page 1

a^`=molcbppflk^i

lйЙк~нбеЦ=fелнкмЕнбзел

пбнЬ=мебн=лзСнп~кЙ=оЙклбзе=QKMT

Page 2

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

2 D 3554.201.01.03.02

61 33 826 D 3554

Page 3

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

Contents

1 Warning and safety information ................................................................................ 7

2 Electromagnetic compatibility ................................................................................... 12

3 System description ..................................................................................................... 14

3.1 Device views..................................................................................................................................... 14

4 Technical data ............................................................................................................. 15

4.1 Primary technical data ...................................................................................................................... 15

4.2 Capacity / weights............................................................................................................................. 15

4.3 Operating media ............................................................................................................................... 15

4.4 Operating parameters....................................................................................................................... 15

4.5 Installation examplel ......................................................................................................................... 16

5 Control panel ............................................................................................................... 17

6 Performance features of unit ..................................................................................... 18

6.1 Preliminary air removal by subatmospheric pulsing ......................................................................... 18

6.2 Sterilization categories...................................................................................................................... 18

6.3 Separate steam generation .............................................................................................................. 18

6.4 One-way system / conductivity measurement / water supply ........................................................... 18

6.5 Electronic parameter control............................................................................................................. 19

6.6 Vacuum drying.................................................................................................................................. 19

6.7 Preheating ........................................................................................................................................ 19

6.8 Documentation of batch results ........................................................................................................ 19

7 Installation ................................................................................................................... 20

7.1 Installation requirements................................................................................................................... 20

7.2 Transport straps................................................................................................................................ 21

7.3 Alignment.......................................................................................................................................... 21

7.4 Power supply connection.................................................................................................................. 21

7.5 Outlet connection for one-way water ................................................................................................ 21

7.6 Internal water supply with feed water ............................................................................................... 21

7.7 Water treatment system.................................................................................................................... 22

7.8 Emptying the water storage tank ...................................................................................................... 22

8 Startup.......................................................................................................................... 23

8.1 Printer connection and initialization (optional) .................................................................................. 23

8.2 Vacuum test...................................................................................................................................... 23

8.3 Test run............................................................................................................................................. 24

8.4 Installation log................................................................................................................................... 25

61 33 826 D 3554

D 3554.201.01.03.02

3

Page 4

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

9 For each sterilization cycle ........................................................................................ 26

9.1 Operating media .............................................................................................................................. 26

9.2 Preparation of instruments............................................................................................................... 27

9.3 Loading the autoclave ...................................................................................................................... 28

9.4 Closing the door............................................................................................................................... 30

9.5 Program selection ............................................................................................................................ 30

9.6 Program start ................................................................................................................................... 31

9.7 Program cycle .................................................................................................................................. 32

9.8 Record printout ................................................................................................................................ 34

9.9 Removing the sterilized items .......................................................................................................... 35

9.10 Sterile storage.................................................................................................................................. 35

9.11 Sterilization frequency / interval periods .......................................................................................... 36

9.12 Manual abort of the program............................................................................................................ 36

9.12.1 Interruption of sterilization................................................................................................. 36

9.12.2 Abort of drying................................................................................................................... 37

9.13 Response in case of warnings and error messages ........................................................................ 39

9.14 Periods of disuse ............................................................................................................................. 39

10 Putting the autoclave out of operation / transport / putting the autoclave back into

operation...................................................................................................................... 40

11 Special functions ........................................................................................................ 41

11.1 Display of water quality (conductivity) / preheating temperature of chamber .................................. 41

11.2 Selection of additional drying ........................................................................................................... 41

11.3 Logging/Documentation of batch results.......................................................................................... 42

11.3.1 Output of records .............................................................................................................. 42

11.3.2 Connection to a computer ................................................................................................. 44

11.3.3 Immediate printout yes/no................................................................................................. 44

11.4 Setting the date and time ................................................................................................................. 49

11.5 Automatic preheating....................................................................................................................... 50

11.6 Total cycle counter........................................................................................................................... 51

11.7 Feed water supply............................................................................................................................ 52

11.8 Program modifications ..................................................................................................................... 53

12 Operating errors/ Malfunctions.................................................................................. 54

12.1 What do do in case of malfunctions ................................................................................................. 54

12.2 Malfunctions without an error message ........................................................................................... 54

12.2.1 Empty display window....................................................................................................... 54

12.2.2 The autoclave uses too much feed water ......................................................................... 54

12.2.3 Poor drying........................................................................................................................ 55

12.3 Warning messages .......................................................................................................................... 56

12.4 Error messages................................................................................................................................ 58

13 Preserving the value of this device ........................................................................... 63

13.1 Preparation of instruments............................................................................................................... 63

13.2 Rust formation = drag-in rust ........................................................................................................... 64

13.3 Regular care of the DAC Professional ............................................................................................. 64

13.4 Functional testing of the autoclave .................................................................................................. 66

14 Appendix...................................................................................................................... 68

14.1 Drying instructions ........................................................................................................................... 68

4 D 3554.201.01.03.02

61 33 826 D 3554

Page 5

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

Dear Customer,

Thank you for purchasing the DAC PROFESSIONAL

class B sterilizer from Sirona. This autoclave

corresponds to the requirements of all valid safety

standards. The manufacturer has checked the unit using

the parameters for sterilization with the unit properly

loaded.

It is extremely important to read the following Operating

Instructions very carefully prior to startup, since

improper use may impair the sterilization effect

considerably.

Thank you for your trust in us.

Your Hygiene Team

61 33 826 D 3554

D 3554.201.01.03.02

5

Page 6

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

Maintenance of the unit’s operational reliability

and value depend on:

1. Correct processing of the instruments being sterilized

2. Careful care of the unit

3. The use of high-quality feed water

6 D 3554.201.01.03.02

61 33 826 D 3554

Page 7

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

1 Warning and safety information

Retention of documentation It is very important to make sure that this manual is

stored together with the unit so that it will also be

available at any time in the future. In case the unit is sold

or the right to use it is transferred to a different owner,

make sure that the manual always remains located near

the unit. This is necessary to ensure that the new owner

can use the unit properly and has all required

information.

Read carefully before starting! These instructions serve to promote safety. Be sure to

read them carefully before installing and using the unit.

This symbol appears on the rating plate to remind the

user to observe the manual.

Medical electrical devices may be used only with

reference to the risk of electrical shock, fire or

mechanical hazards according to IEC 60601-1.

Intended use The DAC PROFESSIONAL may be used only by

qualified dental personnel.

Disclaimer

The manufacturer assumes no liability whatsoever in

cases involving:

• work or repairs performed by any personnel not

authorized by the manufacturer or importer.

• an application which does not correspond to the

ones described in this manual.

• the use of non-OEM components or any

components not described in the section entitled

Parts list.

Electromagnetic compatibility In order to prevent possible risks caused by

electromagnetic interference, no medical electrical

or other equipment should be used near the

DAC PROFESSIONAL. The unit complies with the

currently valid directives concerning electromagnetic

compatibility

(IEC 60601-1-2).

Only medical devices which comply with IEC 60601-1

may be connected to the DAC PROFESSIONAL. Any

non-medical devices connected also must comply with

the IEC 60601-1-1 standard for medical devices.

• This unit does not cause any harmful interferences.

It can, however, pick up interferences from other

devices, including interferences which cause

undesirable operation.

61 33 826 D 3554

D 3554.201.01.03.02

7

Page 8

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

Operating environment Never use this unit in the presence of flammable

anesthetics or anesthetic agents mixed with air, oxygen

or nitrogen.

Inspection and maintenance This point should be implemented according to the

relevant Sirona maintenance documents.

Power supply The DAC PROFESSIONAL must be operated with a

power supply of 230 V, 50 - 60 Hz.

• As the manufacturer, Sirona Dental Systems GmbH

provides on written request qualified technical

personnel, wiring diagrams, parts lists, and other

useful information for the repair and maintenance of

those parts which the manufacturer considers to be

repairable.

Disposal It generally applies that any disposal of this product must

comply with the relevant national regulations.

Please observe the regulations applicable in your

country.

Within the European Economic Community, Council

Directive 2002/96/EU (WEEE) requires environmentally

sound recycling/disposal of electrical and electronic

devices.

Your product is marked with the adjacent symbol.

Disposal of your product with domestic refuse is not

compatible with the objectives of environmentally sound

recycling/disposal.

The black bar underneath the "garbage can" symbol

means that it was put into circulation after Aug. 13,

2005. (see EN 50419:2005)

Please note that this product is subject to Council

Directive 2002/96/EU (WEEE) and the applicable

national law of your country and must be recycled or

disposed of in an environmentally sound manner.

Please contact your dealer if final disposal of your

product is required.

ESD protective measures ESD stands for ElectroStatic Discharge.

ATTENTION!

Connector pins or sockets bearing ESD warning labels

must not be touched or interconnected without ESD

protective measures.

8 D 3554.201.01.03.02

61 33 826 D 3554

Page 9

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

ESD protective measures include:

• Procedures for preventing electrostatic charge

build-up (e.g. air conditioning, air moistening,

conductive floor coverings and non-synthetic

clothing)

• Discharging the electrostatic charges of your own

body on the frame of the UNIT, the protective ground

wire or large metallic objects

• Connecting yourself to ground using a wrist band.

We therefore recommend that all persons working with

this system be instructed on the significance of this

warning label. Furthermore, they also should receive

training in the physics of electrostatic discharges which

can occur in the practice and the destruction of

electronic components which may result if such

components are touched by electrostatically charged

USERS.

ESD stands for ElectroStatic Discharge. Electrostatic

discharge must be preceded by electrostatic charging.

Static electric charges generally build up whenever two

bodies are rubbed against each other, e.g. when walking

(shoe soles against the floor) or driving a vehicle (tires

against the street pavement). The amount of charge

depends on several factors:

1 nanosecond

= 1/1,000,000,000 second

= 1 billionth of a second

Thus the charge is higher in an environment with low air

humidity than in one with high air humidity; it is also

higher with synthetic materials than with natural

materials (clothing, floor coverings).

The following rule of thumb can be applied to assess the

transient voltages resulting from an electrostatic

discharge.

An electrostatic discharge is:

• perceptible at 3,000 V or higher

• audible at 5,000 V or higher (cracking, crackling)

• visible at 10,000 V or higher (arc-over)

The transient currents resulting from these discharges

have a magnitude of 10 amperes. They are not

hazardous for humans because they last for only several

nanoseconds.

Voltage differentials exceeding 30,000 volts per

centimeter may lead to a charge transfer (electrostatic

discharge, lightning, arc-over).

Integrated circuits (logical circuits and microprocessors)

are used in order to implement a wide variety of

functions in dental/X-ray/CEREC systems. The circuits

must be miniaturized to a very high degree in order to

include as many functions as possible on these chips.

This leads to structure thicknesses as low as a few ten

thousandths of a millimeter.

61 33 826 D 3554

D 3554.201.01.03.02

9

Page 10

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

It is obvious that integrated circuits which are connected

to plugs leading outside of the unit via cables are

sensitive to electrostatic discharge. Even voltages which

are imperceptible to the user can cause breakdown of

the structures, thus leading to a discharge current which

melts the chip in the affected areas. Damage to

individual integrated circuits may cause malfunction or

failure of the system.

To prevent this from happening, the ESD warning label

next to the plug warns of this hazard.

Voltage differentials exceeding 30,000 volts per

centimeter may lead to a charge transfer (electrostatic

discharge, lightning, arc-over).

Integrated circuits (logical circuits and microprocessors)

are used in order to implement a wide variety of

functions in dental/X-ray/CEREC systems. The circuits

must be miniaturized to a very high degree in order to

include as many functions as possible on these chips.

This leads to structure thicknesses as low as a few ten

thousandths of a millimeter.

It is obvious that integrated circuits which are connected

to plugs leading outside of the unit via cables are

sensitive to electrostatic discharge. Even voltages which

are imperceptible to the user can cause breakdown of

the structures, thus leading to a discharge current which

melts the chip in the affected areas. Damage to

individual integrated circuits may cause malfunction or

failure of the system.

To prevent this from happening, the ESD warning label

next to the plug warns of this hazard.

Safety information ¾ Be careful when opening the door of the autoclave,

especially if you are interrupting a drying cycle.

Small amounts of residual steam can escape

through the door and burn operating personnel.

¾ After opening the autoclave door, do not touch

exposed hot metal parts. – burning hazard! Be

sure to use the tray handle when removing still-hot

trays from the autoclave. Be sure to use a suitable

hand protection (e.g. potholders or gloves) when

removing other sterilizing containers.

¾ It is recommended to install a leak detector in the

water inlet (see installation instructions, chapter 7).

We also recommend using the

SIRODEM water treatment system from Sirona.

¾ This unit is not suitable for the sterilization of

liquids.

¾ According to the currently valid VDE regulations,

this device is not suitable for operation in areas

subject to explosion hazards.

10 D 3554.201.01.03.02

61 33 826 D 3554

Page 11

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

¾ Empty the water supply tank before transporting

the autoclave. If the autoclave has water inside, do

not tilt it.

¾ This device may be repaired only by an authorized

dealer or service department. The persons

performing such repairs must use original spare

parts and observe the relevant servicing

instructions.

¾ Disconnect the power plug before opening the

housing!

¾ This autoclave will properly sterilize only if the

operating personnel observe these Operating

Instructions, and especially, follow the instructions

regarding program-specific loading of the autoclave.

¾ The autoclave is designed for use outside of the

patient’s immediate vicinity (radius of 1.5 meters

around the treatment center).

61 33 826 D 3554

D 3554.201.01.03.02

11

Page 12

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

2 Electromagnetic compatibility

The UNIT is intended for operation in the

electromagnetic environment specified below.

The customer or user of the UNIT should make sure that

it is used in such an environment.

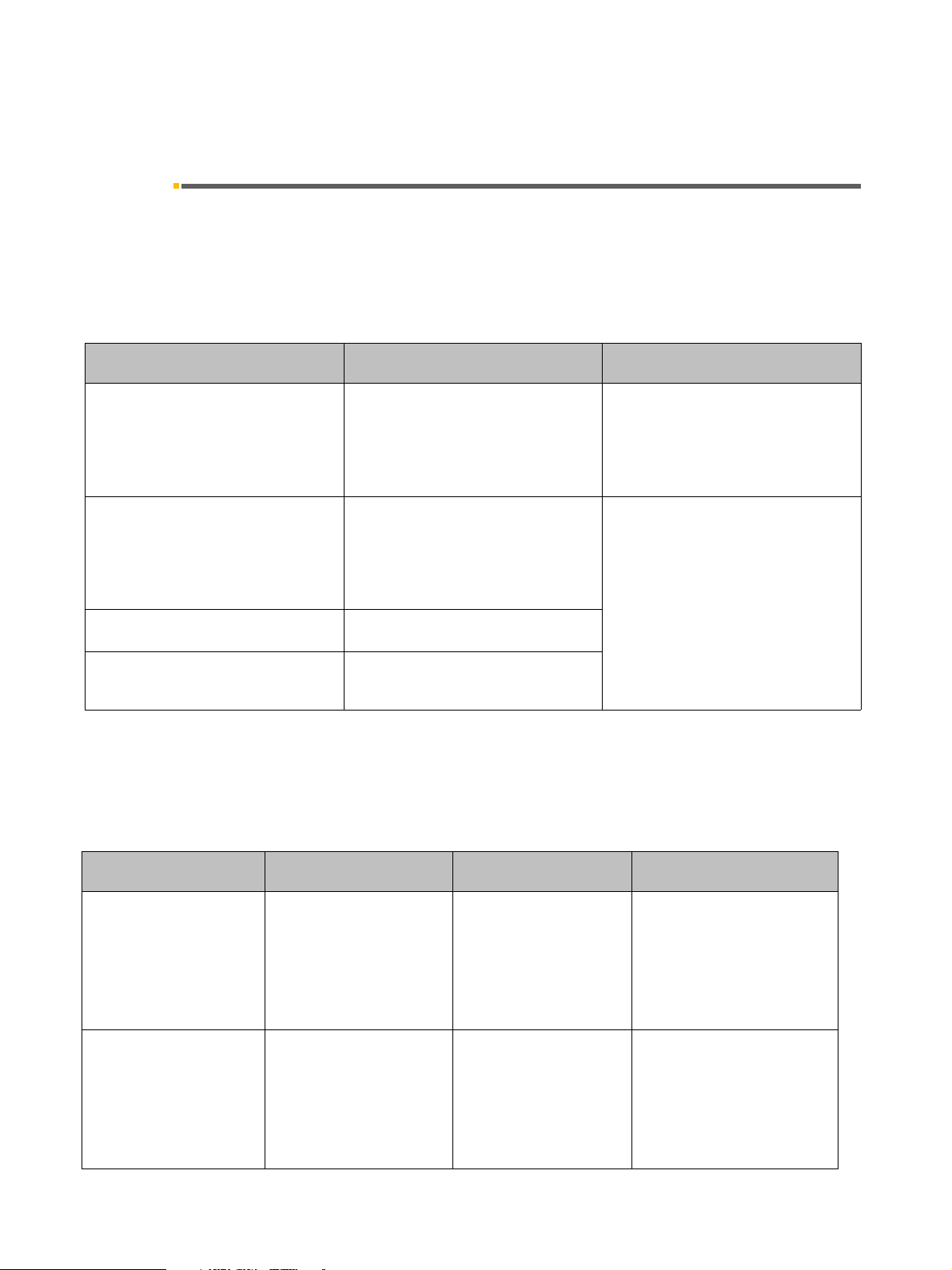

Emission test Conformity Electromagnetic environment

guidelines

RF emissions according to CISPR 11 Group 1 The UNIT uses RF energy only for its

internal function. Therefore, its RF

emissions are very low and are not

likely to cause any interference in

nearby electronic equipment.

RF emissions according to CISPR 11 Class B

The UNIT is intended for use in all

facilities, including residential areas

and in any facilities connected directly

to a public power supply providing

Harmonics

according to IEC 61000-3-2

Voltage fluctuations/flicker according

to IEC 61000-3-3

not applicable

Power output < 50 W

not applicable

no significant

flicker

electricity to buildings used for

residential purposes.

Interference immunity The UNIT is intended for operation in the

electromagnetic environment specified below.

The customer or user of the UNIT should make sure that

it is used in such an environment.

Interference

immunity tests

Electrostatic discharge

(ESD) according to

IEC - 61000-4-2

Electrical fast transient/

burst according to

IEC 61000-4-4

IEC 60601-1-1-2

test level

± 6kV contact discharge

± 8 kV air discharge

± 1kV for input and output

lines

± 2kV for power cables

Conformance

level

± 6kV contact discharge

± 8 kV air discharge

± 1kV for input and

output lines

± 2kV for power cables

Electromagnetic

environment guidelines

Floors should be wood,

concrete, or ceramic tile. If

floors are covered with

synthetic material, the relative

humidity should be at least

30%.

The quality of the line power

supply should be that of a

typical commercial or hospital

environment.

12 D 3554.201.01.03.02

61 33 826 D 3554

Page 13

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

Surge voltages

according to

IEC 61000-4-5

Voltage dips, short

interruptions and

variations of the power

supply according to

IEC 61000-4-11

Magnetic field of power

frequencies (50/60 Hz)

according to

IEC 61000-4-8

± 1kV differential mode

± 2kV common mode

± 1kV differential mode

± 2kV common mode

The quality of the line power

supply should be that of a

typical commercial or hospital

environment.

<5% UT for ½ period

(>95% dip of UT)

40% UT for 5 periods

(60% dip of UT)

70% UT for 25 periods

(30% dip of UT)

<5% UT for 5 sec.

(>95% dip of UT)

<5% UT for ½ period

(>95% dip of UT)

40% UT for 5 periods

(60% dip of UT)

70% UT for 25 periods

(30% dip of UT)

<5% UT for 5 sec.

(>95% dip of UT)

The quality of the line power

supply should be that of a

typical commercial

or hospital environment.

If the user of the UNIT

requires it to continue

functioning following

interruptions of the power

supply, it is recommended to

have the UNIT powered by an

uninterruptible power supply

or a battery.

3 A/m 3 A/m Power frequency magnetic

fields should be at levels

characteristic of a typical

location in a typical

commercial or hospital

environment.

Remarks: UT is the AC supply voltage prior to application of the test level.

Device views: DAC PROFESSIONAL

61 33 826 D 3554

D 3554.201.01.03.02

13

Page 14

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

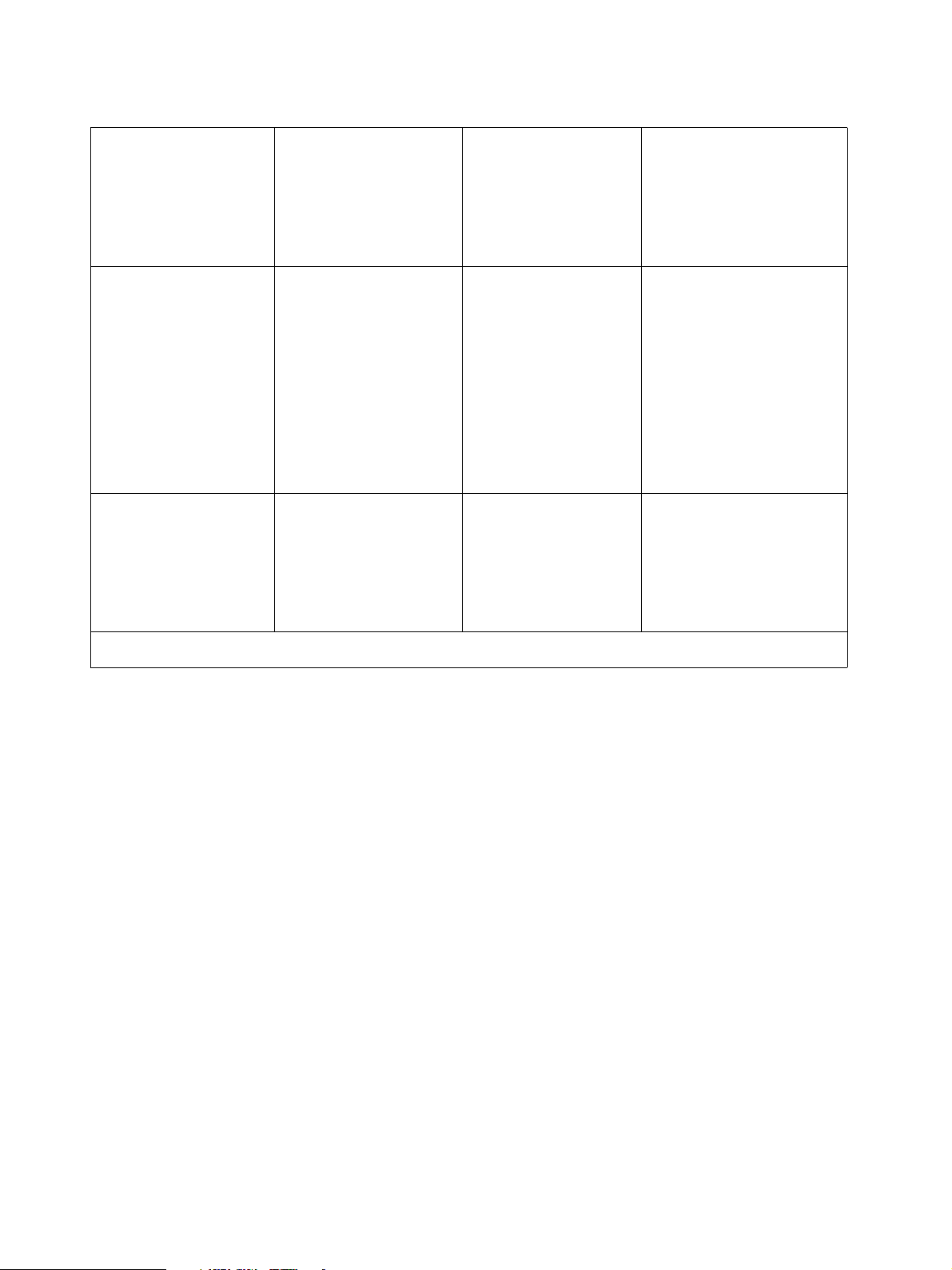

3 System description

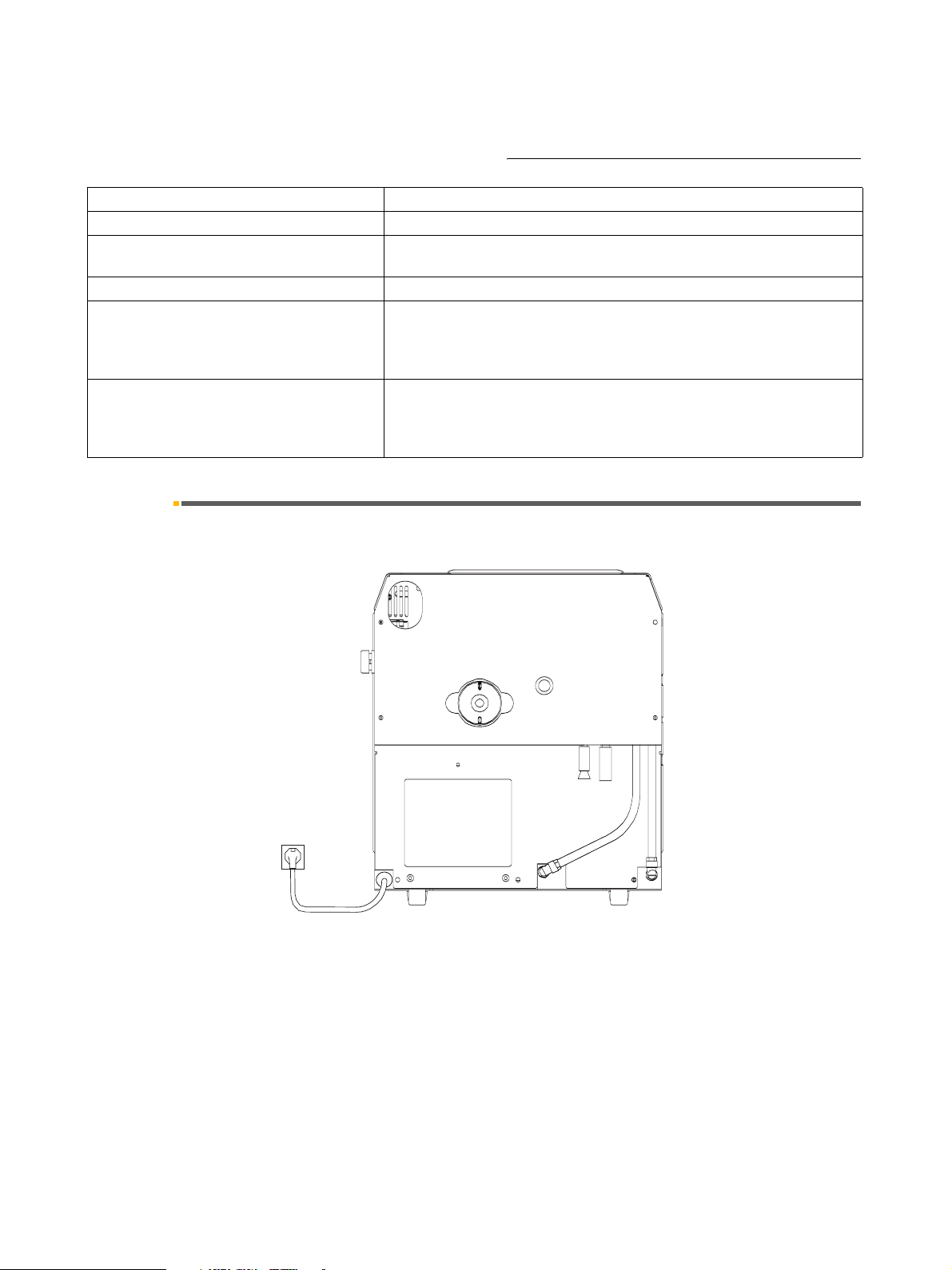

3.1 Device views

rearview

1

2

3

4

6

5

79 8

10

11

12

13

14

15

16

17

18

19

lateral view

1. Control and display panel 11. Elongated hole for optional upgrading with the safety

11. combination EN1717

2. Hinged door (opens to the left) 12. Sterile filter

3. Sliding closing handle 13. Spring-operated safety valve

4. Power switch 14. Without function on DAC PROFESSIONAL (sealed)

14. Option: one-way outlet

5. Adjustable front feet of unit 15. Emergency overflow (OUT)

6. Serial data and printer port (RS 232) 16. Cooler

7. Device fuses - 2 x 16 A / FF 17. Feed water connection (IN) (quick connector f.

17. hose 8x1)

8. Drain hose for water tank, feed water side (OUT) 18. Waste water pressure release for hose 8x1 (OUT)

9. Drain hose for water tank, drain side (OUT) 19. Power cable

10. Tank cover

14 D 3554.201.01.03.02

61 33 826 D 3554

Page 15

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

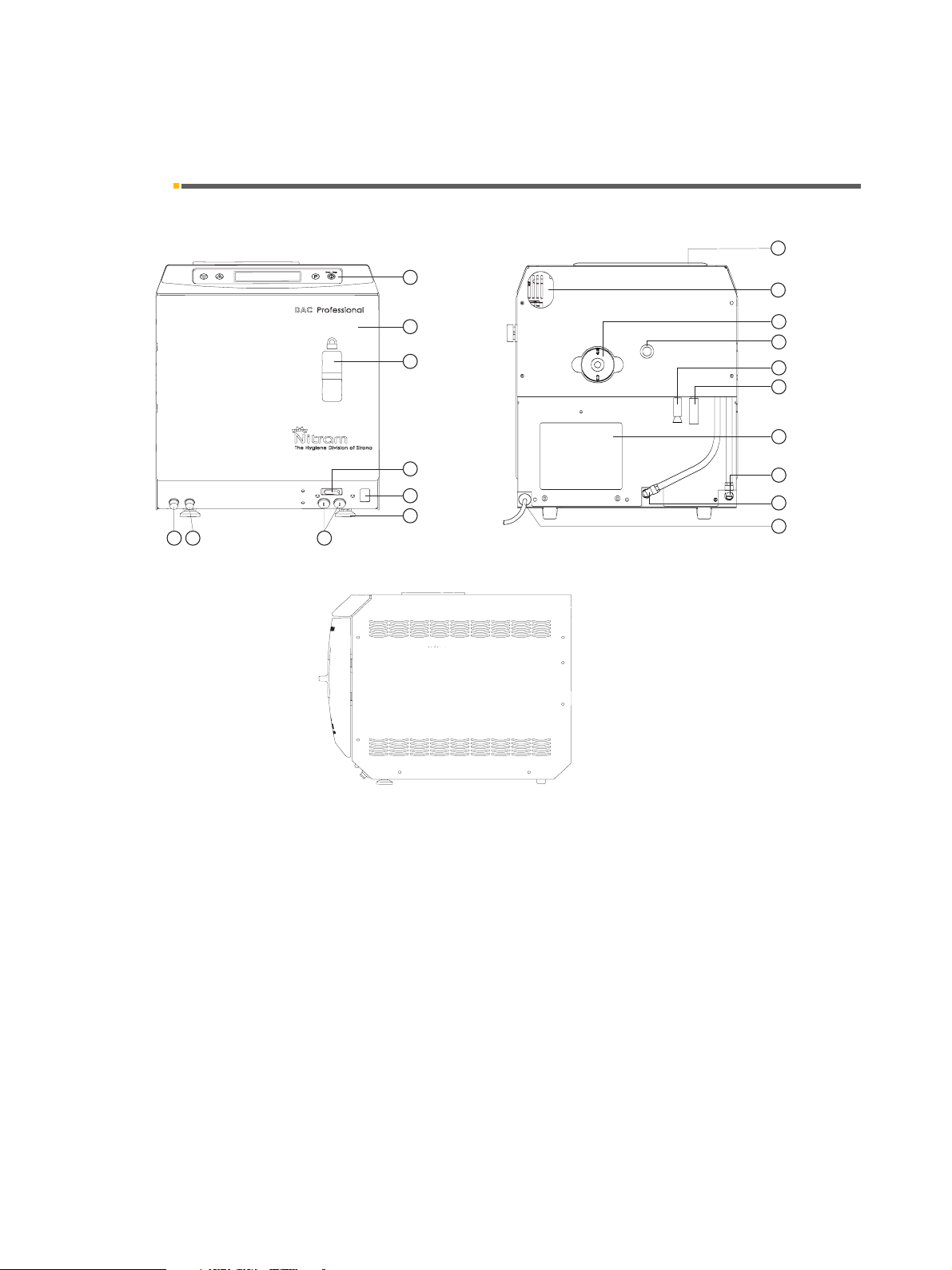

4 Technical data

4.1 Primary technical data

Model DAC PROFESSIONAL

Sterilization chamber (dia. x depth) 25 cm x 36 cm

Power ratings 2100 W / 230 V AC / 9.2 A / 50....60 Hz

Sterilization pressure / temperature 2.1 bar/134°C; 1.1 bar/121°C

Maximum load: 5 kg of instruments or 1.8 kg of textiles

Outside dimensions (HxWxD) 48.5 cm x 42.5 cm x 59.5 cm

4.2 Capacity / weights

Weight (without load) 43 kg

Volume of chamber 17.6 liters

Maximum loading 5 kg of instruments or 1.8 kg of textiles

Water tank (feed water) Fresh-water side: 5 liters (approx.7 cycles); drain side:3 liters

4.3 Operating media

Power ratings

Power supply 230 V AC / 9.2 A / 50...60 Hz

Power ratings 2100 W; fuse 16 A, RCCB (resid. current circuit breaker); 30 mA

Feed water Demineralized / steam distilled water in compliance with VDE 0510

4.4 Operating parameters

Programs / operating times

Program Operating time

(not incl. drying period)

“Universal program“ (134°C, 2.1 bar) 30 min 20 min 5 kg

“Quick program S“ (134°C, 2.1 bar) 15 min 5 min 5 kg

“Quick program B“ (134°C, 2.1 bar) 28 min 10 min 5 kg (unwrapped)

“Gentle program“ (121°C, 1.1 bar) 45 min 20 min 1.8 textiles

“Prion program“ (134°C, 2.1 bar) 45 min 20 min 5 kg

"Bowie&Dick" (134°C, 2.2 bar) 33 min 40 min 5 min

“Vacuum test” -- 18 min (empty) --

Drying period Loading

1.5 kg (wrapped)

61 33 826 D 3554

D 3554.201.01.03.02

15

Page 16

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

Consumption of energy / water *

Power consumption

"Preheating"

One-time heating up to preheating

temperature (134°C)

"Standby" operation per hour approx. 0.2 kWh

"Program cycle" (incl. drying) 0.3 kWh for "Quick program S", warm start, low load until

Feed water consumption 300 ml for "Quick program S"

approx. 0.12 kWh

1.1 kWh for "Gentle program", cold start, full load

2.1 kWh "Quick program B"

500 ml for "Universal program" and "Prion program"

600 ml for "Gentle program"

*) These values apply to a constant 230V power supply

4.5 Installation example

)

DAC PROFESSIONAL rear view

Standard version = version as supplied

(with internal water supply)

2 x 20-character alphanumeric LED display for indication

of program status and parameters and for user guidance

of basic and special functions

61 33 826 D 3554

16 D 3554.201.01.03.02

Page 17

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

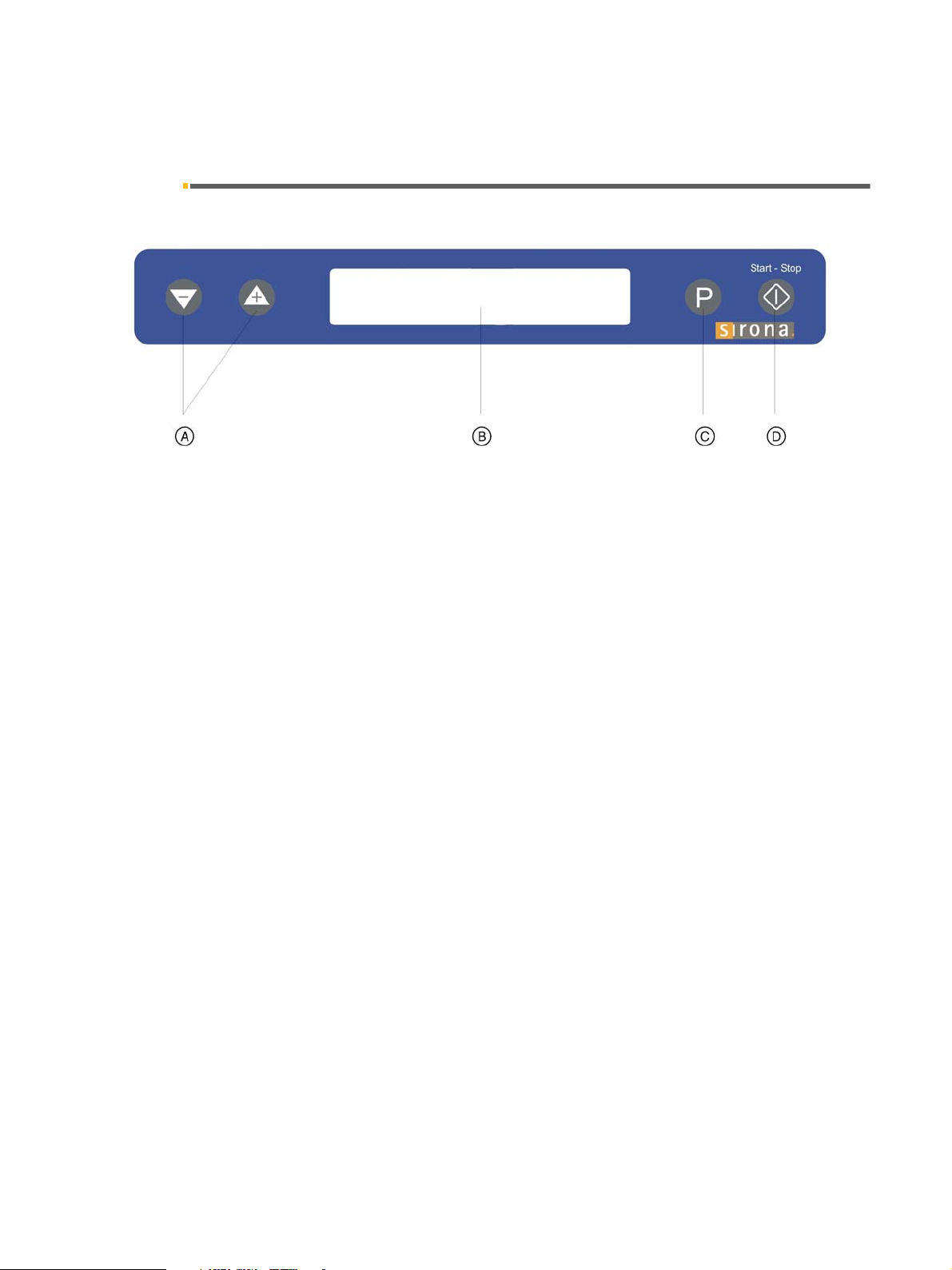

5 Control panel

A) Function keys

for selecting, setting and displaying special

functions: printing, date/time, preheating, sum batch

numbers, conductivity, error report

acknowledgement

B) 2 x 20-character alphanumeric LED display

for indication of program status and parameters and

for user guidance of basic and special functions

C) Program selection key

for selection of the sterilization and test programs

and for selecting/setting options (submenus) for the

special functions

D) Start - Stop key

for starting and stopping programs, for drying, and

for control of special functions

61 33 826 D 3554

D 3554.201.01.03.02

17

Page 18

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

6 Performance features of unit

6.1 Preliminary air removal by subatmospheric pulsing

Preliminary air removal by subatmospheric pulsing

repeatedly evacuates the air from the autoclave and

alternately introduces steam between evacuations, thus

providing the required penetration of the sterilized

objects with saturated steam.

This ensures fast and effective execution of difficult

sterilization tasks: e.g. instruments with narrow bores

and large amounts of textiles.

Steam penetration can be confirmed via the Bowie &

Dick test (a recognized procedure used in large-scale

sterilization). A special test program has been

implemented for this purpose.

6.2 Sterilization categories

The DAC PROFESSIONAL features four sterilization

programs for temperatures of 134°C: the "Universal

program" for wrapped objects, the "Fast program B", the

"Prion program" (a special Universal program) and the

"Quick program S" for unwrapped items. The “Gentle

program” is a program for sterilizing textiles and rubber

articles at 121°C. The user can at any time perform

additional functional checks of the autoclave by running

the Bowie & Dick test for steam penetration and the

Vacuum test for leak testing.

6.3 Separate steam generation

The powerful steam generator outside the actual

sterilization chamber makes it possible to sterilize large

loads of instruments or textiles in a short time. No waiting

periods are necessary between sterilization cycles, and

excess temperatures cannot occur within the

sterilization chamber.

6.4 One-way system / conductivity measurement / water supply

The DAC PROFESSIONAL operates with the tried and

proven one-way system: this means that all evaporated

water and all impurities contained in this water are

removed from the autoclave upon pressure release.

Clean feed water is therefore used for the following

program cycle.

An integrated conductivity measurement system

monitors the quality of the feed water used in steam

generation. We recommend using a water supply with

feed water.

If the instruments are carefully prepared, this

arrangement prevents spots on the items sterilized and

avoids fouling of the autoclave.

18 D 3554.201.01.03.02

61 33 826 D 3554

Page 19

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

6.5 Electronic parameter control

The microprocessor installed in the

DAC PROFESSIONAL implements an electronic

parameter control system which continuously monitors

pressure, temperature and time in the programs. The

total operating times can thus be optimized according to

the load and the temperature of the autoclave.

The process evaluation and monitoring system

contained in the program control system compares

momentary process parameters with standard

processing data and monitors the process with respect

to limit temperatures, limit times and limit pressures.

This function detects malfunctions in the program cycle

and guarantees the security of the sterilization result.

6.6 Vacuum drying

The vacuum drying feature ensures good drying results,

even for wrapped items.

6.7 Preheating

6.8 Documentation of batch results

Activating the preheating function warms up the cold

autoclave chamber before sterilization or maintains the

temperature between sterilization cycles. This shortens

the duration of cycles and considerably reduces the

formation of condensation, thus optimizing drying

results.

Batch results can be documented via the following

output media:

• NITRAprint

•NITRAflash

• Computer with NITRAwin

• Modem

The memory of the electronic control system

permanently stores records of the last 40 programs.

For effective hard-copy documentation of batches and

for checking previously executed programs, a

NITRAprint printer can be connected to print out a record

immediately after completion of a program, or to print out

records from the memory. If a PC is connected, the

NITRAwin program can also transfer the records to the

PC for permanent archiving of all results and print out

any results as required.

61 33 826 D 3554

D 3554.201.01.03.02

19

Page 20

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

7 Installation

For the steps required to prepare for and carry out the

setup and installation of the autoclave, see the separate

instructions contained in "Setting up the

DAC PROFESSIONAL".

7.1 Installation requirements

The autoclave should be set up in a dry place which is

protected against dust.

The base should be stable and flat and capable of

supporting the weight of the unit

(unloaded weight = 43 kg).

The space required by the autoclave can be seen from

the external dimensions (see Section 4.1). A minimum

additional space of 10 cm should be allowed on both

sides and above the autoclave in order to ensure that

heat can escape.

The electrical power supply should be a separate

230V AC circuit with a 16A fuse.

This autoclave operates with a blower for the cooling

system, on the rear side of the unit. If there is a

restriction of the escape of heat above the unit, this can

impair the functioning and shorten the service life of the

autoclave. We therefore urgently advise our users not to

install the autoclave in an area where there is not

sufficient circulation of air.

If the user decides to install an automatic one-way

system, it is necessary to have a connection to the waste

water plumbing near the autoclave, preferably a wall

outlet (NW 40) or a sink drain (standard length of drain

hose = 2m, with an outer hose diameter = 15 mm).

A 2 meter long drain hose (Art. No. 61 26 556) is

supplied with the unit. The required connectors must be

ordered according to the given practice situation. The

work surface on which the autoclave stands must be

higher than the outlet so that the drain hose can be run

to the drain continuously downward and without bends

and twists which could prevent the water flowing out

freely. At the same time, the work surface must provide

convenient access to the autoclave and the display must

be clearly visible.

The autoclave must be supplied with feed water from the

integrated dual-chamber water tank, with fresh water

and waste water chambers. However, please note that

this will require additional space for the water treatment

system.

20 D 3554.201.01.03.02

61 33 826 D 3554

Page 21

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

7.2 Transport straps

Lift the autoclave out of the packaging using the

transport straps. The straps themselves are each

removed by unscrewing the two retaining screws, which

must then be screwed firmly back in place without

washers.

7.3 Alignment

In order to operate properly, and to allow unimpeded

return flow of condensate into the steam generator, the

autoclave must be installed so that it definitely slopes

toward the rear. First install the autoclave in a horizontal

(level) position and check that this position is in fact

horizontal with a spirit level at the chamber flange. Then

extend the front feet to lift up the front side of the

autoclave by screwing them out by at least three turns.

7.4 Power supply connection

The unit power cord must be connected to a

230 V, 50 Hz electric outlet. The power rating of the

autoclave is 2100 W. In order to avoid overloading the

building electricity supply, we recommend using a

separate electrical circuit fitted with a 16 A fuse and

optionally protected with a type RCCB (residual current

circuit breaker) with a tripping current of 30 mA.

7.5 Outlet connection for one-way water

The DAC PROFESSIONAL operates only in the

one-way water system, i.e. used feed water

(hereinafter referred to as "waste water") is not

recycled. Waste water is collected in the drain tank. As

an option, the autoclave can be connected directly to the

waste water plumbing via the one-way outlet. A retrofit

kit is connected to the rear wall of the autoclave for this

purpose. Its drain hose must be run to the drain

continuously downward and without bends or twists

and must not exceed a max. length of 2 meters. The

outlet must be connected to an existing sink drain, or to

a separate NW40 drain pipe with use of the

wall-mounted drain.

7.6 Internal water supply with feed water

61 33 826 D 3554

D 3554.201.01.03.02

If the user decides for internal supply of the autoclave

with feed water, this water is taken from the right

chamber of the built-in water storage tank. To install the

internal feed water supply system, connect the hose to

the feed water connection of the water tank on the rear

side of the autoclave. For this variation of water supply,

the autoclave is delivered ready for installation. To fill the

feed water tank, remove the cover of the tank and fill the

right chamber with feed water up to the maximum mark.

21

Page 22

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

7.7 Water treatment system

We recommend the SIRODEM treatment unit for the

water supply of the autoclave.

7.8 Emptying the water storage tank

Empty both chambers of the water storage tank as

follows:

• Plug the drain hose onto a quick coupling (drain tank

on the left, feed water tank on the right) until it

perceptibly snaps into place.

• Drain the water into a vessel or container with a

capacity of at least 5 liters.

To remove the drain hose, press the gray release button

on the quick coupling. The hose automatically

disengages from the coupling.

ATTENTION!

Please note the following when removing the quick

coupling:

– When emptying the supply chambers, stand to one

side in front of the connection.

– When pushing the gray release button of the quick

coupling, be sure to hold the hose securely in place with

your other hand in order to stave off the spring force of

the catch.

Failure to observe this precaution may result in

injury.

• Repeat this procedure for the other chamber.

22 D 3554.201.01.03.02

61 33 826 D 3554

Page 23

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

8 Startup

8.1 Printer connection and initialization (optional)

Connection of the NITRAPrint 42 (REF 61 17 324) A NITRAPrint 42 (REF 61 17 324) log printer can be

connected to the autoclave. It is not included in the

scope of supply of the autoclave.

When connecting the printer to the autoclave, please

proceed as described in Section "Connection of the

NITRAPrint®42 printer", page 42 .

Initializing the printer / adjustment for immediate

printout

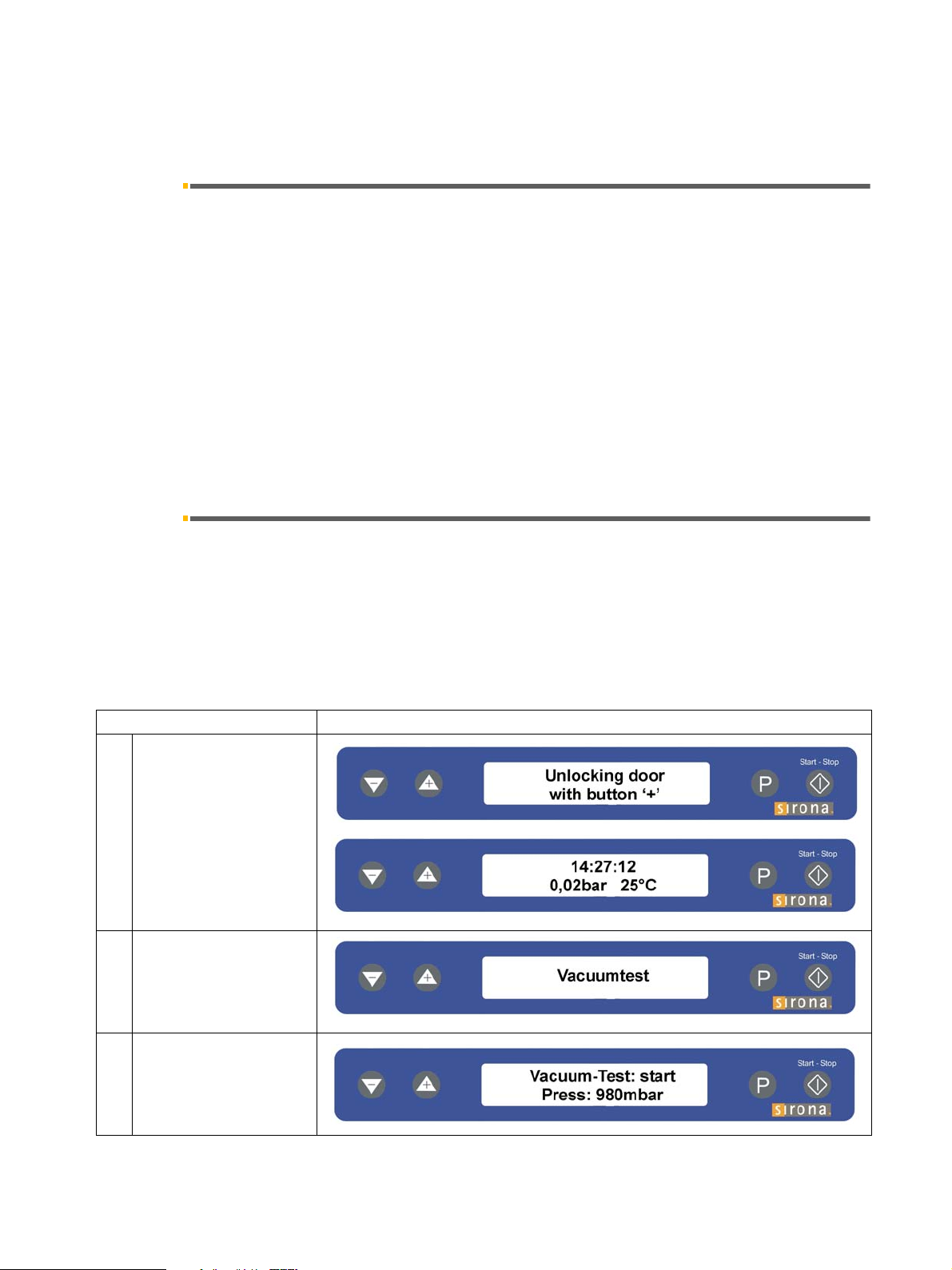

8.2 Vacuum test

Operator action Display reading

1..

Switch the unit on at the

power switch. After the

following message

Perform the initialization of the connected printer

(registration in the computer control of the autoclave)

according to Section "Initializing the printer", page 42 .

Follow the instructions in Section 11.3.3 of this manual

to set the immediate printout option to “Yes”. This means

that the system will automatically print out a report when

the system program has come to an end.

A vacuum test (leak test) should be conducted to check

the function of the autoclave once during the initial

startup, after longer periods of disuse, when moving the

unit to a new location and periodically as part of routine

operations.

The vacuum test should preferably be performed on the

cold autoclave as follows:

the initial state is indicated

on the display

2..

Press the "Program" key

repeatedly until the

"Vacuum test" program

appears on the display

3.

Press the "Start - Stop" key

61 33 826 D 3554

D 3554.201.01.03.02

23

Page 24

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

4..

Vacuum pressure has been

reached.

The compensation time

(waiting period prior to start

of measurement) starts

5.

Once the waiting period

has expired (5 min), the

measuring time begins

(here e.g. 7 min, 52 s)

6.

After the measuring time

(10 min) has expired, the

chamber is vented and

then the leak rate is output

(if a printer is connected

and "immediate printout is

set to yes", a report will be

printed out immediately)

After the message “Please

wait – door unlocking”, the

following display appears:

7.8.

Opening the door:

The door can be opened

after pressing the "+" key.

8.3 Test run

If the leak rate determined is greater than the maximum

permissible value, the message "Test not successful"

will appear on the display and on the printed log. In such

a case, follow the instructions given in this manual under

Section 12.3.

To continue the functional check of the autoclave, carry

out a test run by loading the autoclave with a typical load

for your daily work and then running “Universal program,

134°C, wrapped”. After loading the autoclave and

selecting the program with the “Program” key, you can

start the program by pressing the “Start/Stop” key. If the

program runs correctly (also see Section 9.7) the

following message with the attained maximum pressure

and temperature values will appear as confirmation at

the end of the program. If a printer is connected and

"immediate printout is set to yes", a logfile will be printed

out immediately.

24 D 3554.201.01.03.02

61 33 826 D 3554

Page 25

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

8.4 Installation log

As proof that the autoclave has been properly installed

and started up, an installation record should be

produced by an authorized person and a copy sent to

your dental depot. This is important in the event that you

wish to make claims under warranty provisions.

61 33 826 D 3554

D 3554.201.01.03.02

25

Page 26

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

9 For each sterilization cycle

9.1 Operating media

Distilled/demineralized feed water The autoclave automatically checks to make sure that

enough feed water is available and that the quality of the

water is sufficient to start a program.

In order to start a program without delay, avoid error

messages and prevent a program from being canceled

before it is completed (see Sections: 12.3 and 12.4)

please proceed as follows:

• Before starting the first sterilization cycle each day,

check to make sure that there is enough water in the

right side of the dual-chamber water supply tank. If

there is not enough water in the tank, fill with water of

sufficient quality (see Section "Use of feed water",

page 65).

• If you use the autoclave often, we recommend using

the SIRODEM water treatment system.

Power supply Turn on the power switch at the bottom right on the front

panel. The unit is in its initial state:

A) Time (h:min:s)

B) Chamber pressure (bar) (steam) temperature (°C)

26 D 3554.201.01.03.02

61 33 826 D 3554

Page 27

Sirona Dental Systems GmbH

DAC Universal

Operating Instructions DAC PROFESSIONAL

9.2 Preparation of instruments

Non-rusting materials All parts of the DAC PROFESSIONAL which come into

contact with steam are made of non-rusting materials:

The sterilization chamber and the chamber door are

made of stainless steel, steam lines are made of teflon

and threaded connections and solenoid valves are made

of brass.

Drag-in rust The non-rusting parts used in the autoclave ensure that

the autoclave itself cannot cause rust to form. In cases

where rust has developed on the autoclave or on items

sterilized inside, investigations have consistently shown

that extraneous rust has been dragged into the

autoclave from the outside by rusty instruments.

We must point out that rust can form on stainless steel

instruments made by even the best manufacturers. One

main cause of instrument rusting is improper treatment

with chemical cleaning and disinfecting agents during

preparation for sterilization.

Preparation of instruments for sterilization The problem of drag-in rust shows how important it is to

properly prepare items for sterilization. It is urgently

necessary to observe the following procedures:

Perform cleaning and care of straight and contra-angle

handpieces as described in the instructions provided by

their manufacturers (e.g. by oiling them).

DAC Universal

For dental handpieces, it is recommended to use the

DAC UNIVERSAL from Sirona for automated cleaning,

disinfection and care.

All other instruments must be placed in a disinfection

and/or cleaning solution immediately after use and

properly cleaned and disinfected there. Always be sure

to use the correct dosage and soaking times for these

solutions. We also recommend the use of ultrasonic

equipment and thermodisinfectors.

The proper cleaning of instruments is also essential in

preventing particles of soiled matter from separating

from the instruments during sterilization and from

clogging the filters, nozzles and valves of the autoclave.

It is especially important to use a brush to thoroughly

clean locks, joints and hinges. Use a brush under

running water to completely rinse all cleaning and

disinfecting agents from instruments before placing

them in the autoclave. Residue of chemical cleaning and

disinfecting agents must by no means be allowed to

enter the autoclave, since they will cause corrosion

there. As a final step before placing the instruments into

the autoclave, rinse them with demineralized 5water and

dry them well. Be sure to oil highspeed handpieces and

transmission instruments as specified by their

manufacturers to prolong their service life.

61 33 826 D 3554

D 3554.201.01.03.02

27

Page 28

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

Brand new instruments Be sure to follow the cleaning procedure described

above even for brand new instruments. Traces of oil,

grease and impurities resulting from production

processes can often still be found on new instruments.

i

NOTE

It is essential to carefully follow the instrument

manufacturer’s instructions for preparation and

resterilization.

9.3 Loading the autoclave

Correct loading of the autoclave is essentially important

in guaranteeing the sterilization effectiveness and the

proper drying of the items being sterilized.

Be sure to observe the following basic instructions when

loading the autoclave:

Tray holders / (tray rack) The DAC PROFESSIONAL is supplied with a tray rack

that can accommodate max. 5 trays or 3 standard tray

cassettes.

In normal cases the autoclave should always be

operated with a tray rack, since this ensures optimal

steam penetration and drying. In exceptional cases and

after consulting with your specialized dealer, it may be

possible to remove the tray rack and place the suitable

containers directly into the sterilization chamber

(e.g. when using sterilization containers purchased from

other manufacturers).

For sterilization of instruments sealed in see-through

sterilization packaging, we recommend using the

package stand (REF No.: 61 17 340). This package

stand considerably improves the results of the drying

process for instruments wrapped in this way.

Tray s Trays used to load sterilized items must be perforated in

order to allow the condensate to run off. The trays

supplied with the autoclave fulfill this requirement. We

cannot advise the use of non-perforated trays or bowls

(e.g. unperforated standard-tray supports), since they do

not allow proper drying.

Closed sterilization containers Closed sterilization containers must be perforated on at

least one side (preferably the bottom), or they must have

valves, in order to allow the steam to properly penetrate

and the condensate to flow out.

We cannot recommend sterilization using sterilization

containers with holes only on the top, since they do not

allow proper drying.

When using several (stacked) sterilization containers,

make sure that the steam penetration is not hindered

due to obstructed perforations.

28 D 3554.201.01.03.02

61 33 826 D 3554

Page 29

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

See-through sterilization packaging

If you use see-through sterilization packaging, it should

be placed on the tray or in the package stand (REF No.:

61 17 340) in an upright position for sterilization. You

should never stack the see-through sterilization

packages horizontally on top of each other.

If the sealing seam of the package breaks during

sterilization, please use a longer sealing pulse on the

package sealing device or seal the package with a

double seam.

If standard tray cassettes are sealed, clamps or tape

must be used to reinforce the side seam and prevent it

from breaking open. In addition, be sure to press excess

air out of the package before sealing it.

Multiple wrapping Air removal by subatmospheric pulsing allows multiple

wrapping.

Loading limits Be careful not to exceed the prescribed maximum

loading amounts: 5 kg of instruments or 1.8 kg of textiles.

Mixed loads of textiles and instruments If you are sterilizing textiles and instruments at the same

time, place the textiles above the instruments and do not

allow the textiles to come into direct contact with the

instruments. Avoid sterilizing textiles and instruments in

the same sterilization container wherever possible.

Do not by any means allow the textiles to come into

direct contact with the wall of the sterilization chamber.

When using different types of packaging within a single

sterilization cycle:

• Place the instruments and sterilization containers at

the bottom

• Place the see-through sterilization and paper

packaging on top (exception: place them at the

bottom in combination with textiles).

Sterilization of liquids The DAC PROFESSIONAL autoclave is not suitable for

the sterilization of liquids.

61 33 826 D 3554

D 3554.201.01.03.02

29

Page 30

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

9.4 Closing the door

To close the door, gently press it toward the sterilization

flange while simultaneously pressing down on the sliding

handle until it will go no farther. The following message

appears:

The door can be opened by pressing the '+' key.

9.5 Program selection

The program should be selected based on the physical

properties of the items to be sterilized (especially their

ability to resist high temperatures) and the type of

packaging used (you must use the “Universal program”

or the “Gentle program” if part or all of the load is

wrapped).

You can select one of the following programs (and the

initial position) by pressing the "Program" key:

Program name/Display message Parameter/Application

Universal program at 134°C, 2.1 bar, 3 pre-vacuum

phases and a sterilization time of 05:30 minutes for

sterilization of all kinds of wrapped items, especially

instruments, or mixed loads (wrapped and unwrapped)

Quick program B at 134°C, 2.1 bar, 3 pre-vacuum

phases and Sterilization time 03:30 minutes for

unwrapped instruments (no textiles) up to 5 kg (full load)

or singly wrapped instruments weighing up to 1.5 kg.

Quick program S at 134°C, 2.1 bar, 2 pre-vacuum

phases and a sterilization time of 03:30 minutes for

sterilization only of unwrapped instruments (and no

textiles), for fast reuse of the sterilized items (you must

interrupt the drying cycle manually)

Gentle program at 121°C, 1.1 bar, 3 pre-vacuum

phases and a sterilization time of 20:30 minutes for

sterilization of all kinds of wrapped items, especially

larger amounts of textiles, and of items sensitive to heat

(plastic and rubber articles), and for mixed loads

(wrapped and unwrapped)

30 D 3554.201.01.03.02

61 33 826 D 3554

Page 31

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

Prion program (= special Universal program) at 134°C,

2.1 bar, 3 pre-vacuum phases and an extended

sterilization time of 20:30 minutes for sterilizing wrapped

items, especially instruments or mixed loads (wrapped

and unwrapped).

This program is recommended for sterilization of

instruments used in situations where the danger of

infection by pathologically modified proteins is suspected

(e.g. Creutzfeld-Jacob’s disease and BSE or mad cow

disease).

Bowie & Dick test program at 134°C, 2.2 bar,

3 pre-vacuum phases and a sterilization time of

03:50 minutes for functional testing of the autoclave

(verification of steam penetration via special indicators),

18:00 minutes empty

Vacuum test program for functional testing of the

autoclave (verification of the vacuum seal of the

autoclave by determining the leak rate).

Start this program when the autoclave is cold; vacuum

test takes approx. 16:00 minutes with cold unit

9.6 Program start

Initial state of autoclave (no program selected)

Start the selected program by pressing the “Start – Stop“

key. When you press this key, the autoclave will

automatically begin to check the feed water and run a

conductivity test.

When you start Quick program S, the display will also

show the warning message: “Warning: only unwrapped

instruments”. This message must be acknowledged by

pressing the "Start" key once again.

61 33 826 D 3554

D 3554.201.01.03.02

31

Page 32

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

9.7 Program cycle

After you start the program, it will continue running fully

automatically. The display will continuously show the

status of the running program as follows:

Program status Display reading

1.

Fractionation consisting of

evacuation (air removal) until a

programmed evacuation pressure is

reached and steam injection until a

slight overpressure is reached.

The display shows the chamber

pressure and the steam temperature

2.

and additional fractionation steps

Additional fractionation (as described

above) will take place, depending on

the program selected. This continues

until the required vacuum is achieved

and the required penetration of the

items being sterilized with saturated

steam has taken place.

3.

Heat-up phase

The heat-up phase follows

fractionation. Continuous injection of

steam into the chamber increases the

pressure and temperature in

accordance with the saturated steam

curve until the programmed

parameters are achieved.

4.

Sterilization phase

When the pressure and temperature

correspond to the saturated steam

curve and the programmed required

values have been reached, the actual

sterilization time starts running.

The display changes between

showing the pressure and

temperature and indicating the

remaining sterilization time.

5.

Pressure release

When the sterilization phase has

expired, pressure release and

simultaneous emptying of the steam

generator will follow. The pressure

and temperature fall.

61 33 826 D 3554

32 D 3554.201.01.03.02

Page 33

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

6.

Drying phase

After the pressure has been

released, the drying phase begins.

Once the drying phase begins, it is

possible to interrupt the program

without triggering an error message,

since the actual sterilization phase is

complete. However, you should wait

until the drying has come to an end,

unless you are using the “Quick

program”.

7.

Ventilation

At the end of the drying phase, the

sterilization chamber is vented until

the pressure has been regulated to a

normal atmospheric level.

8.

End of program

When the venting of the sterilization

chamber is complete, the program

cycle is finished.

If a printer is connected and

"immediate printout is set to yes", a

logfile will be printed out immediately.

Following the automatic door release

and after pressing the "+" key, you

can open the door to remove the

sterilized items.

61 33 826 D 3554

D 3554.201.01.03.02

33

Page 34

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

9.8 Record printout

The printout of the cycle record contains the following

information:

DAC Professional

------------------------------------------

Program : Universal program

134°C wrapped

Date : 19.09.2007

Time : 16:54:58 (Start)

Batch No.: 2

Preheating 108.7 °C

AIN6: Conductivity 7 mS/cm

Program step Pressure Temp. Time

bar °C min

Start 0.03 31.1 00:00

1.Fractionation

Evacuation -0.92 31.9 02:39

Steam entry 0.41 105.6 06:06

2.Fractionation

Evacuation -0.82 59.2 07:41

Steam entry 0.40 109.0 09:48

3.Fractionation

Evacuation -0.82 59.2 11:44

Steam entry 0.40 108.9 13:49

Heat up 2.09 134.1 16:17

Steriliz.begin 2.09 134.1 16:17

Steriliz.end 2.16 135.3 21:47

Press. release 0.21 104.9 22:33

Vacuum-drying

Drying begin. -0.33 93.0 22:42

Drying pressure -0.90 54.1 24:40

Drying end -0.83 56.4 42:42

Ventilate -0.26 58.7 42:53

End 0.01 59.9 43.05

Started program

Current date

Time at program start

Daily cycle number

Preheating temperature

Feed water conductivity

Program sequence phases with respective values for

steam pressure, steam temperature and time (relative to

start of program).

------------------------------------------

PROGRAM PROPERLY EXECUTED!

Temperature : 135.3 +0.3 /-0.4 °C

Pressure : 2.18 +0.03/-0.04 bar

Sterilizate time: 5 min 30 s

Time : 17:38:03 (End)

==========================================

2 200700000 4.06 4.06

CRC: 0xE952 MF V1.600A

Control message

Mean sterilization temperature/ deviations

Mean sterilization pressure/ deviations

Maintained sterilization time

Time at end of program

Info line with total cycle counter, works number and

software version no.

61 33 826 D 3554

34 D 3554.201.01.03.02

Page 35

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

9.9 Removing the sterilized items

After pressing the '+' key and opening the door, you can

remove the sterilized items

CAUTION!

Burning hazard!

Do not touch the hot sterilization chamber or the

door with unprotected hands. Be sure to protect

your hands by using a standard tray lifter or pot

holders or by wearing gloves when removing hot

sterilized items from the autoclave.

9.10 Sterile storage

After removing sterilized items that are wrapped, check

their packaging for damage. If it is damaged (e.g. its

weld seams are broken) you must sterilize its contents

once again. The contents must be wrapped in a new

package before they are resterilized.

The sterilized items must be sufficiently dry before

proper sterile storage is possible. The

DAC PROFESSIONAL provides excellent drying if the

complete program is allowed to run (without interrupting

the drying process), and if the loading instructions given

in this manual are properly observed (see Section 9.3).

Immediately after sterilization it can occur that

condensation residue remains on the sterilized items or

on their package. The heat from the still-hot sterilized

items will evaporate this condensate after completion of

sterilization. DIN 58953, Part 7, Section 7 contains the

following on moisture residue on paper wraps or

see-through sterilization paper after sterilization:

“...Small amounts of water on the outside of the

packages are harmless if they have dried away within 30

minutes after taking them out of a steam sterilizer...”.

After they have cooled down, provide sterile storage for

wrapped sterilized items where they are protected

against dust (e.g. in an instrument cabinet). Under

conditions of dust-protected storage, DIN 58953, Part 7,

provides a rule of thumb for the maximum shelf life of

sterilized items: six months for sterilized items in single

wrapping (e.g. see-through sterilization packages), and

five years for sterilized items in double sterilization

packages.

61 33 826 D 3554

D 3554.201.01.03.02

35

Page 36

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

9.11 Sterilization frequency / interval periods

After the drying phase is completed or interrupted by the

user, the autoclave can be reloaded and started again

immediately without any waiting intervals.

9.12 Manual abort of the program

9.12.1 Interruption of sterilization It is possible to terminate any started program

prematurely by pressing the "Start-Stop" key. If you

abort a program before it reaches the “Drying” step, then

the items inside the autoclave must be considered not

sterile.

ATTENTION!

Depending on the operating status of the unit, steam can

escape from the sterilization chamber when you open

the door. If you abort a program before it reaches the

“Sterilization” program phase, we recommend that you

run the next program without any items in the sterilization

chamber.

Operator action Display reading

1.

Press the “Start-Stop” key

A query to confirm that you really

want to abort the program is

displayed for 5s.

If you take no further action, the

program continues as usual.

2.

If you press the “Start-Stop“ key

again before the above confirmation

query disappears, the program will be

aborted:

Depending on when you abort a

program, pressure release (unit in

overpressure) or ventilation (unit in

vacuum) will then occur.

36 D 3554.201.01.03.02

61 33 826 D 3554

Page 37

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

3.

After pressure compensation has

been achieved, a "Stop/ end"

message and a prompt to

acknowledge the program abort will

alternate on the display.

4.

Press the "-" key

to acknowledge the program abort.

The door can be opened after

pressing the "+" key.

9.12.2 Abort of drying The program can be interrupted after the “Drying” step

has started, e.g. in case an instrument is urgently

required for an application. Since the actual sterilization

has been completed, the items in the autoclave are

sterilized at this time. The drying phase is important for

sterile storage. Depending on the point of time when the

drying phase was interrupted, the user must realize that

the items have not yet sufficiently dried. This is

especially true for wrapped sterilized items.

ATTENTION!

EN13060 prescribes a very good drying phase for the

type B procedure which cannot be ensured in case of a

program abort (see above); i.e. in this case as well,

sterilization has not been properly performed according

to the type B procedure.

With "Quick program S", it is possible to interrupt the

drying phase so that the items can be used again

immediately. Once the interrupted program comes to a

stop, take the unpacked instruments out of the

autoclave. The intrinsic heat of the instruments will dry

the moisture on them as they cool down.

ATTENTION!

Depending on the operating status of the unit, steam can

escape from the sterilization chamber when you open

the door.

61 33 826 D 3554

D 3554.201.01.03.02

37

Page 38

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

Operator action Display reading

1.

The autoclave is in the drying phase.

The display alternates between the

drying time already elapsed and

the message showing how to

interrupt the drying phase.

2.

Press the “Start-Stop” key

A query to confirm that you really

want to abort the program is

displayed for 5s.

If you take no further action, the

program continues as usual.

3.

If you press the “Start-Stop“ key

again before the above confirmation

query disappears, the program will be

stopped.

The system will then vent the

sterilization chamber.

When the venting of the sterilization

chamber is complete, the program

cycle is finished. The following status

message will appear on the display:

It will alternate with the following

message:

And with the following message:

If a printer or another output medium

is connected and immediate printout

is set to "yes", a log stating that

drying has been aborted will be

printed out.

38 D 3554.201.01.03.02

61 33 826 D 3554

Page 39

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

9.13 Response in case of warnings and error messages

The DAC PROFESSIONAL has safety features as well

as an extensive checking and monitoring system

integrated in the computer control. These functions

guarantee maximum reliability of the sterilization

process and eliminate risks arising from the autoclave

for the patient and the autoclave operator.

For example, the system continuously tests a number of

autoclave functions, e.g. the pressure and temperature

sensors, after the power switch is turned on.

The autoclave system also checks to make sure that

further conditions are met for a successful program start.

For example, that power and water are present in

sufficient quantity and quality. The program cannot be

started if these conditions are not fulfilled.

In the next phase after the program starts, the system

will monitor all parameters relevant for sterilization, as

well as the additional limit values for the individual

program phases. If these limit values are exceeded, the

system will display the respective error messages and

will automatically interrupt the program.

In addition to the instructions, warnings and error

messages on the display, if a printer is connected, an

additional log will be output, depending on the type of

error involved and the time when it occurred.

9.14 Periods of disuse

If any of the above-stated messages appear, please

refer to Section 12. This section also contains

instructions concerning possible operator errors.

If the autoclave is not in use for a certain period of time,

you should generally leave its door slightly open to

prevent premature material fatigue or sticking of the door

gasket.

In case of longer inactive periods, shut off the water

supply from the water treatment system.

61 33 826 D 3554

D 3554.201.01.03.02

39

Page 40

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

10 Putting the autoclave out of operation

/ transport / putting the autoclave

back into operation

To put the autoclave out of operation or transport it,

proceed as follows:

• Switch the autoclave off at the power switch.

• Pull the power plug and let the autoclave cool down.

• Drain both chambers of the water supply tank

(see Section 7.8). Or, if you have a direct connection

to a water treatment system, shut off the supply of

feed water from this system.

• Disconnect the hoses at the rear of the autoclave

(external water supply).

• When transporting the autoclave with its tray racks

and trays still inside, protect the surface of the door

window by inserting a layer of foam rubber or some

other suitable material (e.g. bubble wrap) between

the door and the sterilization chamber.

ATTENTION!

To prevent transport damage, be sure to use the

original autoclave packing materials.

If there is any danger of frost damage during

transport, be sure to follow the relevant service

instructions.

• To put the autoclave back into service after transport

or repair, follow the instructions given in

Chapters 7 and 8.

40 D 3554.201.01.03.02

61 33 826 D 3554

Page 41

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

11 Special functions

11.1 Display of water quality (conductivity) / preheating temperature

of chamber

By repeatedly pressing the "-" key, you can alternately

display the pre-heat temperature of the sterilization

chamber and the conductivity of the feed water being

used at any time:

Operator action Display reading

Press and hold the '–' key

Display of the feed water conductivity in

µS/cm

Let go of the '–' key:

This will return you to the normal display

(initial state, selected program or

program status). Shown here: initial

state.

Press and hold the '–' key repeatedly:

This will show the pre-heat temperature

of the sterilization chamber in °C.

11.2 Selection of additional drying

Operator action Display reading

Press the '+' key simultaneous to the

program start. The display will confirm

the selection of additional drying. Then

the program will run as described in

Section 9.7. The drying times will be

extended by 50%.

The standard drying times for each specific program

guarantee sufficient drying of the sterilized items if all

loading instructions are followed (see Section 9.3). If,

however, residual moisture remains on the sterilized

items after you have used special loading variations, you

can select the “Additional drying“ function to increase the

drying time by 50%:

61 33 826 D 3554

D 3554.201.01.03.02

41

Page 42

Sirona Dental Systems GmbH

Operating Instructions DAC PROFESSIONAL

11.3 Logging/Documentation of batch results

The nonvolatile memory of the autoclave computer

control system archives the records of the last 40

programs.

The user can print out these logs immediately or

whenever required by using the serial interface (RS232).

If the computer memory is full with 40 records, the

system will overwrite the oldest record automatically

when the next program starts. If an external printer is

connected for logging and has been initialized, and if the

printout option setting under “Immediate printout” is

“No”, then the system will ask the user if he or she really