Page 1

$

7IVZMGI1ERYEP

IMPORTANT:

• Please note that we have revised this version of the Service

Manual.

It is therefore necessary that you no longer use the first edition.

• In case of faults which you are unable to eliminate with the help

of this manual, please contact our Customer Service.

• It is essential that you take this Service Manual with you for

every visit to a customer.

Furthermore, you must always have the spare parts list and

the wiring diagrams with you as well.

You can order additional copies of this Service Manual under the

• order number

department

See reverse side of manual for address.

58 35 694

in Bensheim.

GZP

from our

:IVWMSR

D 3344.076.01.04.02 03.2002

Page 2

Page 3

$

7IVZMGI1ERYEP

Page 4

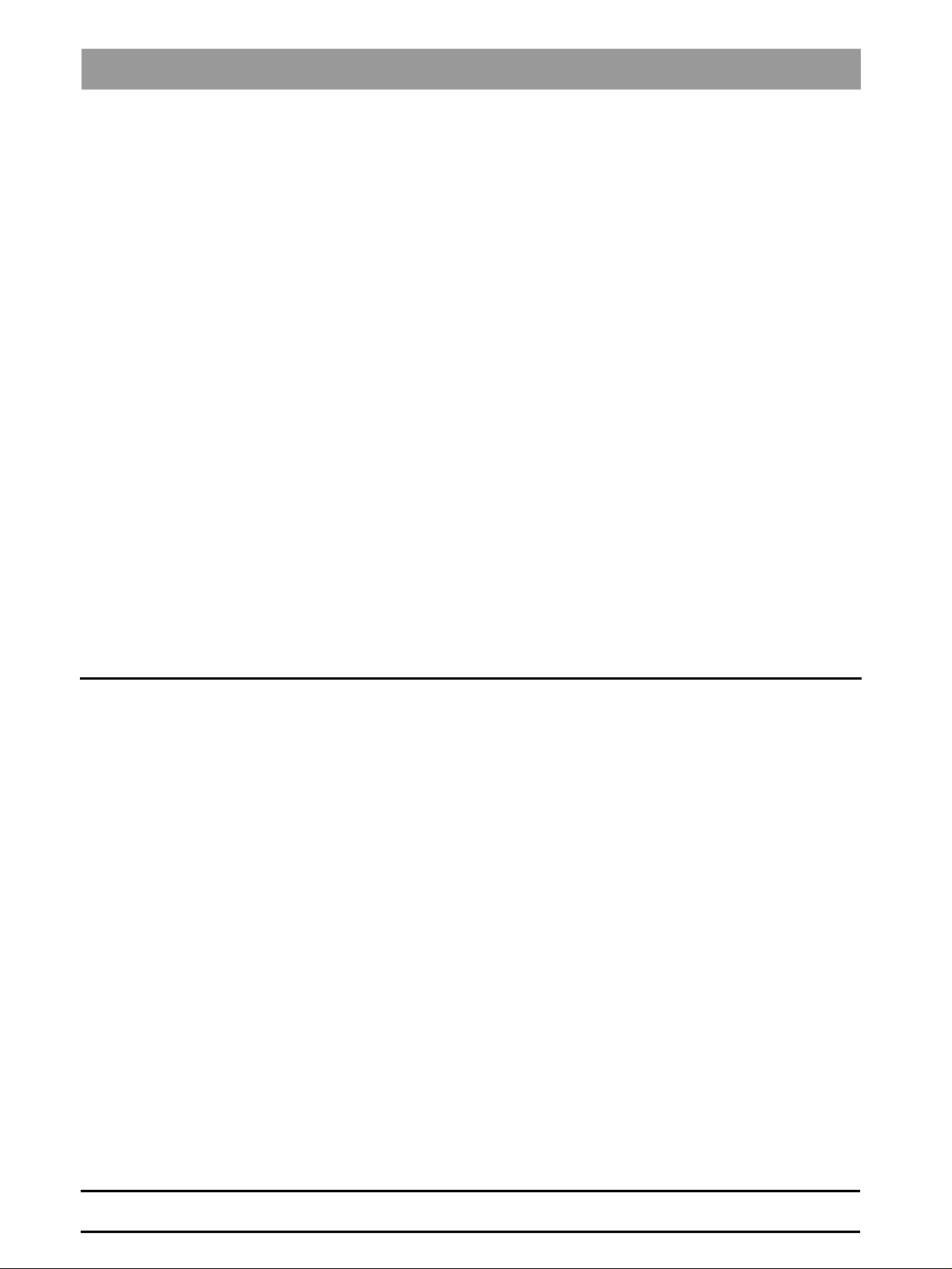

Additional requirements:

• Spare parts list

Order No. 58 62 581

• Circuit diagrams

Acquisition unit: Order No. 58 35 710

Milling unit: Order No. 58 35 728

CEREC 3 / CEREC Scan

• Tools

– Hexagonal screwdriver (90° offset): Sizes 1.5; 2; 2.5; 4; 6

– Fork wrench, sizes 5.5; 8; 10; 14

– Torque screw driver, sizes 5, 6, 20, 25, 40

– Philips-head screw driver Size 1

– Slot screw driver, insulated, Size 2, 3

– Socket wrench 8mm

– Cutting pliers

– Special tool for monitor nut

– Special tool for locking button: Order No.: 59 08 947

• Accessories

– Digital multimeter, accuracy class: 1

– Soldering tool for repairing cables

– Side cutting pliers

– Cable ties

– Teflon tape

– PS2 mouse (recommended)

– PS2 keyboard (recommended)

– 3.5” disk

– Calibration piece and pins (recommended)

– Fuses (recommended):

F1/F2 (2 pcs.) 5AT, Order No.: 20 33 111

F1/F2 (2 pcs) for acquisition unit starting with Ser. No.: 3300

6,3 AT, Order No.: 10 77 452

F3 1.25AL Order No.: 59 15 181

F4 2AT Order No.: 10 80 522

Page 5

General 1

Service Software

Trouble Shooting: Milling Unit

Trouble shooting: Acquisition Unit

Settings

2

3

4

5

Acquisition Unit: Repairs

Milling Unit: Repairs

Installing Software

6

7

8

Page 6

Page 7

List of Contents

General ................................................................................................................................... 1-1

1

1.1 General Notes .............................................................................................................. 1-3

Service Software .................................................................................................................... 2-1

2

2.1 General Notes .............................................................................................................. 2-3

2.2 Basic Structure of Test Dialogs .................................................................................... 2-5

2.3 Individual Test Points ................................................................................................. 2-10

Trouble Shooting: Milling Unit................................................................................................. 3-1

3

3.1 Device cannot be switched ON. Green LED (Ready for operation) not illuminated... 3-5

3.2 No connection to PC / acquisition unit. Software cannot be installed .......................... 3-7

3.3 No air pressure ............................................................................................................. 3-9

3.4 Fan not running. Unit shuts down completely after a short time ................................ 3-11

3.5 Water pump: Pressure too low ................................................................................... 3-13

3.6 Defective light barrier ................................................................................................. 3-15

3.7 Door switch. Please close milling chamber door........................................................ 3-17

3.8 Motor locking positions: Problems changing grinders ................................................ 3-19

3.9 Stepping motors (milling unit). Loss of steps.............................................................. 3-21

3.10 Touch errors ............................................................................................................... 3-23

3.11 Trouble shooting. Defective CCP board..................................................................... 3-25

Trouble shooting: Acquisition Unit.......................................................................................... 4-1

4

4.1 System cannot be switched ON ................................................................................... 4-7

4.2 PC not booting properly I.............................................................................................. 4-9

4.3 PC not booting properly II........................................................................................... 4-11

4.4 PC does not respond during switch-on, PC power supply does not start .................. 4-12

4.5 Further PC faults ........................................................................................................ 4-14

4.6 Monitor image flickering ............................................................................................. 4-15

4.7 No monitor display...................................................................................................... 4-17

4.8 Incorrect monitor display format size.......................................................................... 4-19

4.9 Monitor: Color shade/gray scale is too weak.............................................................. 4-21

4.10 Trackball not functioning ............................................................................................ 4-23

4.11 Trackball buttons not functioning................................................................................ 4-25

4.12 Pedal not functioning .................................................................................................. 4-27

4.13 Keyboard not functioning /defective ........................................................................... 4-29

4.14 No camera image ....................................................................................................... 4-31

4.15 Incorrect measuring sensor setting ............................................................................ 4-33

4.16 Camera calibration: messages................................................................................... 4-35

4.17 Interference at radio interface .................................................................................... 4-37

4.18 No sound or sound level too low ................................................................................ 4-41

4.19 No Sirocam camera image......................................................................................... 4-43

4.20 Sirocam camera image interference .......................................................................... 4-45

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

V

Page 8

List of Contents

4.21 SIROCAM camera: Incorrect image settings .............................................................. 4-47

4.22 Digital X-ray problems ................................................................................................. 4-49

Settings....................................................................................................................................5-1

5

5.1 Monitor Settings ............................................................................................................ 5-3

5.2 Calibrating the 3D camera ............................................................................................ 5-4

5.3 Pairing the DECT-radio interface (EU) .......................................................................... 5-5

5.4 Replacing a module of the DECT radio interface (EU) ................................................. 5-8

5.5 Pairing the Futaba radio interface (USA/Japan) ........................................................... 5-9

Acquisition Unit: Repairs .........................................................................................................6-1

6

6.1 Electrical and Electromechanical Components............................................................. 6-4

6.2 Mechanical components ............................................................................................. 6-30

Milling Unit: Repairs.................................................................................................................7-1

7

7.1 Milling Unit: General Activities....................................................................................... 7-3

7.2 Replacing the Scanner.................................................................................................. 7-5

7.3 Replacing the Drive and/or Motor ............................................................................... 7-11

7.4 Checking / Adjusting Stop positions ............................................................................ 7-13

7.5 Stepping Motors: Replacing / Adjustment ................................................................... 7-15

Installing Software ...................................................................................................................8-1

8

8.1 Acquisition Unit: Network Installation ............................................................................ 8-3

8.2 How to install an MO drive .......................................................................................... 8-25

VI

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 9

CEREC 3

1

General

Page 10

List of Contents

General

List of Contents

1.1 General Notes ..................................................................................................................... 1-3

1 - 2

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 11

1.1 General Notes

1.1 General Notes

Nominal line voltage ranges

Faults in electronic medical

equipment caused by mobile

phones

Opening the device

Measurements

The CEREC® 3 acquisition unit can be used in the following

voltage ranges

• Europe 230VAC / 50Hz

• USA 115VAC / 60Hz

• Japan 100VAC / 50Hz and 60Hz

The CEREC 3 / CEREC Scan milling unit can be used in the following

nominal line voltage ranges

• 100V

When opening the device:

Always switch OFF the device before connecting the measuring instrument.

Select the correct current/voltage type and adjust the measuring range to

match the expected readings.

:

:

230VAC; 50/60Hz

–

In order to ensure safe operation of electronic medical equipment,

the use of mobile phones in practices and hospital areas is strictly

prohibited.

Please observe the necessary precautions when handling

printed circuit boards (ESD).

Touch a ground point to discharge static electricity before

handling any components.

nominal line

1.1

When replacing parts

Repairing and/or upgrading the

PC drawer

Disposal

Perform continuity tests only on devices which are switched off.

Switch OFF the device before replacing any parts.

For safety reasons

supply when replacing parts around the line transformer.

The item numbers for ordering spare parts can be found in the

spare parts list, Order No. 58 62 581.

The diagrams contained in the spare parts list provide a useful guide when

replacing parts.

Replace the broken warranty seal on the bottom side of the PC drawer with

the supplied seal of conformity.

Please observe the instructions found in the relevant user guide.

the device should be disconnected from the power

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

1 - 3

Page 12

Page 13

CEREC 3

2

Service Software

Page 14

List of Contents

Service Software

List of Contents

2.1 General Notes ..................................................................................................................... 2-3

2.2 Basic Structure of Test Dialogs ........................................................................................... 2-5

2.3 Individual Test Points .......................................................................................................... 2-10

2 - 2

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 15

2.1 General Notes

NOTE

i

2.1 General Notes

Test requirements

Service Software Log File

Requirement for all tests:

• PC / acquisition unit are switched on and ready for operation.

• PC / acquisition unit and milling unit are interconnected (per interface ca-

ble or radio link)

• The software has been loaded for the milling unit (see Operating Instructions for Milling Unit/Milling Unit Scan, Switching the units on,

start-up

• The door of the milling chamber must remain closed as long as any motors or the water pump are running.

If the door of the milling chamber is opened during the test, all motors and

the water pump will switch off immediately (same function as pressing the

Stop button).

• The tools (burs) must be installed already during operation of the water

pump.

• During operation of the water pump, the air pump must always be running

to protect the gearing against water damage, i.e. the air pump is started

first. If the air pressure switch detects no air pressure, an error message

will appear and the test can not be performed.

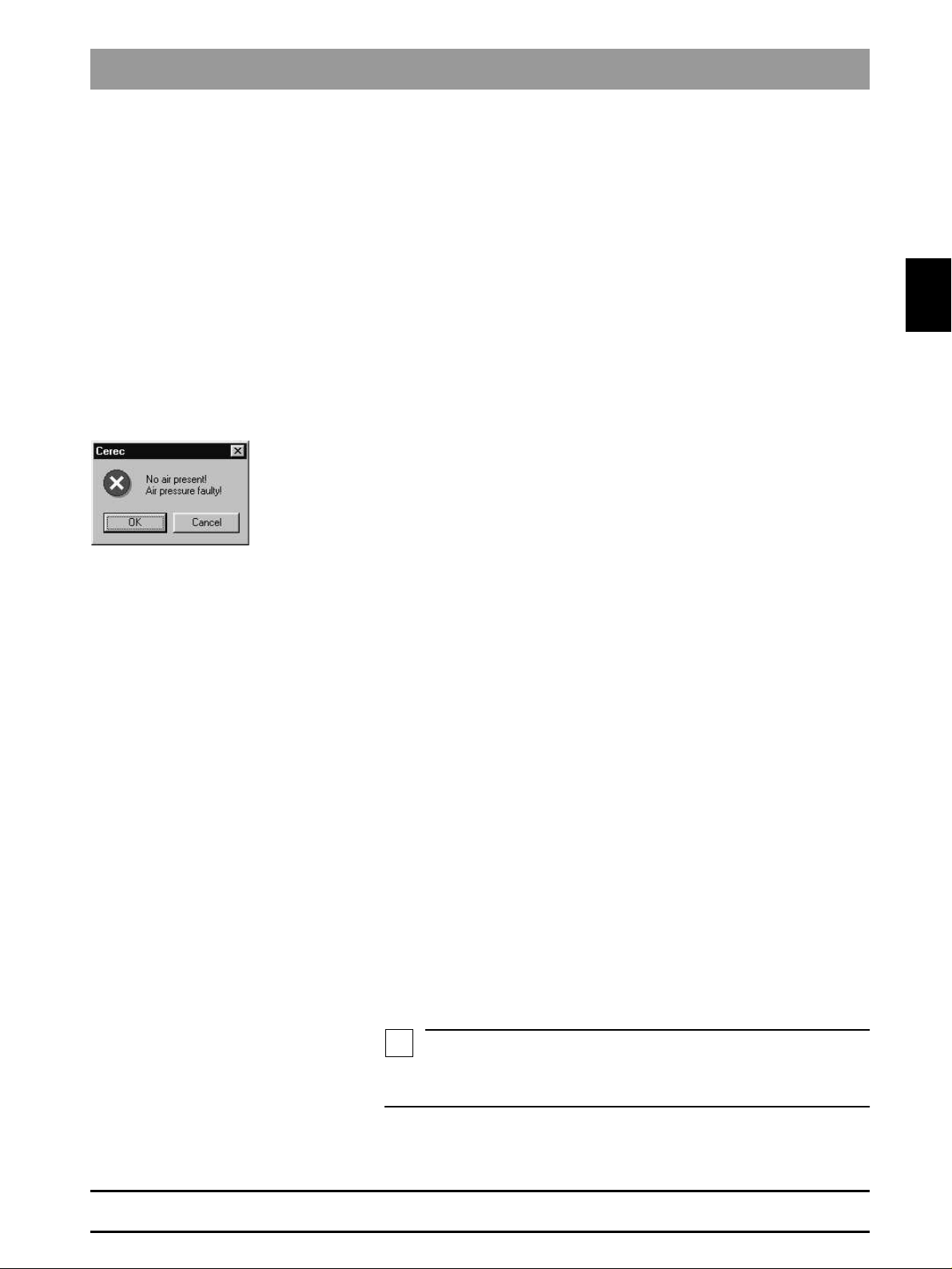

The service software is a component of the product software. This software

generates a log file for all tests performed.

This log file is located on delivery in the directory

c:\programme\Cerec\System\Service\Protocols

Test file_XXXXXXXXXXXX.TXT

The Xs here denote the serial no. of the controller board.

Each time the service software is started, a confirmation query appears asking whether this file (if it already exists) should be deleted. If NO (do not

delete) is selected, the tests subsequently performed will be appended to the

ones previously saved. Each test is labeled with a starting and ending date.

The test file can be viewed with the editor at any time. If the user exits from a

test without saving it, he will be asked if he really wants to quit without saving.

If Yes (Quit without saving) is then selected, the data just measured will be

lost.

).

and is named

Initial

2.1

Assessment scores

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

After completing a test section, the log file must be saved under a new name

to a diskette belonging to the corresponding unit.

There are three different scores which can be assigned to test results:

• Passed fully (green label)

• Passed (yellow label)

• Not passed (red label)

These assessment categories apply starting with

R600

The score

case

n.a.

Passed

(not applicable) will be written to the log file for this score.

(yellow label) may be irrelevant for a specific test. In this

software version V1.1

2 - 3

Page 16

2.1 General Notes

CAUTION

To ensure trouble-free operation of the system, all test results should be labeled

"Passed fully"

If the test results are marked

this point of time.

If the test results are labeled

fault(s)

.

"Passed"

"Not passed"

, uncritical changes have occurred at

, you must find and correct the

Example of test protocol:

Path:

c:\programme\Cerec\System\Service\Protocols

i

NOTE

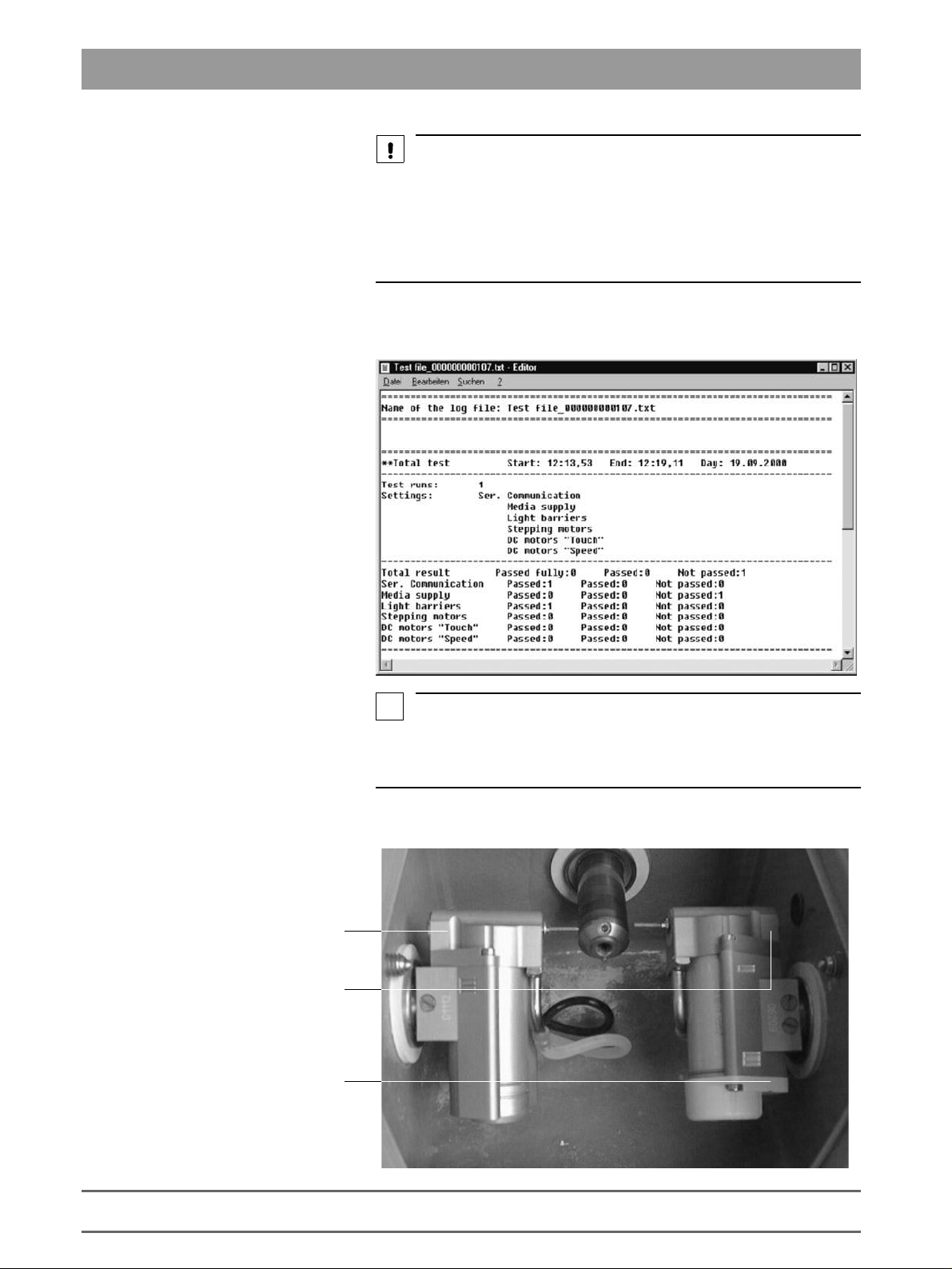

If the milling unit housing is left open, the temperature switch on the CC PC

board may cut out after a short time (T>90°C). The cooling fan can work properly only with the cover closed.

Overview of gearing unit:

Gearing 3

Gearing 1

Gearing 2

(without function)

2 - 4

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 17

2.2 Basic Structure of Test Dialogs

NOTE

i

CAUTION

NOTE

i

CAUTION

NOTE

i

2.2 Basic Structure of Test Dialogs

For a functional description of the menu items, see the user’s manual.

Password protection

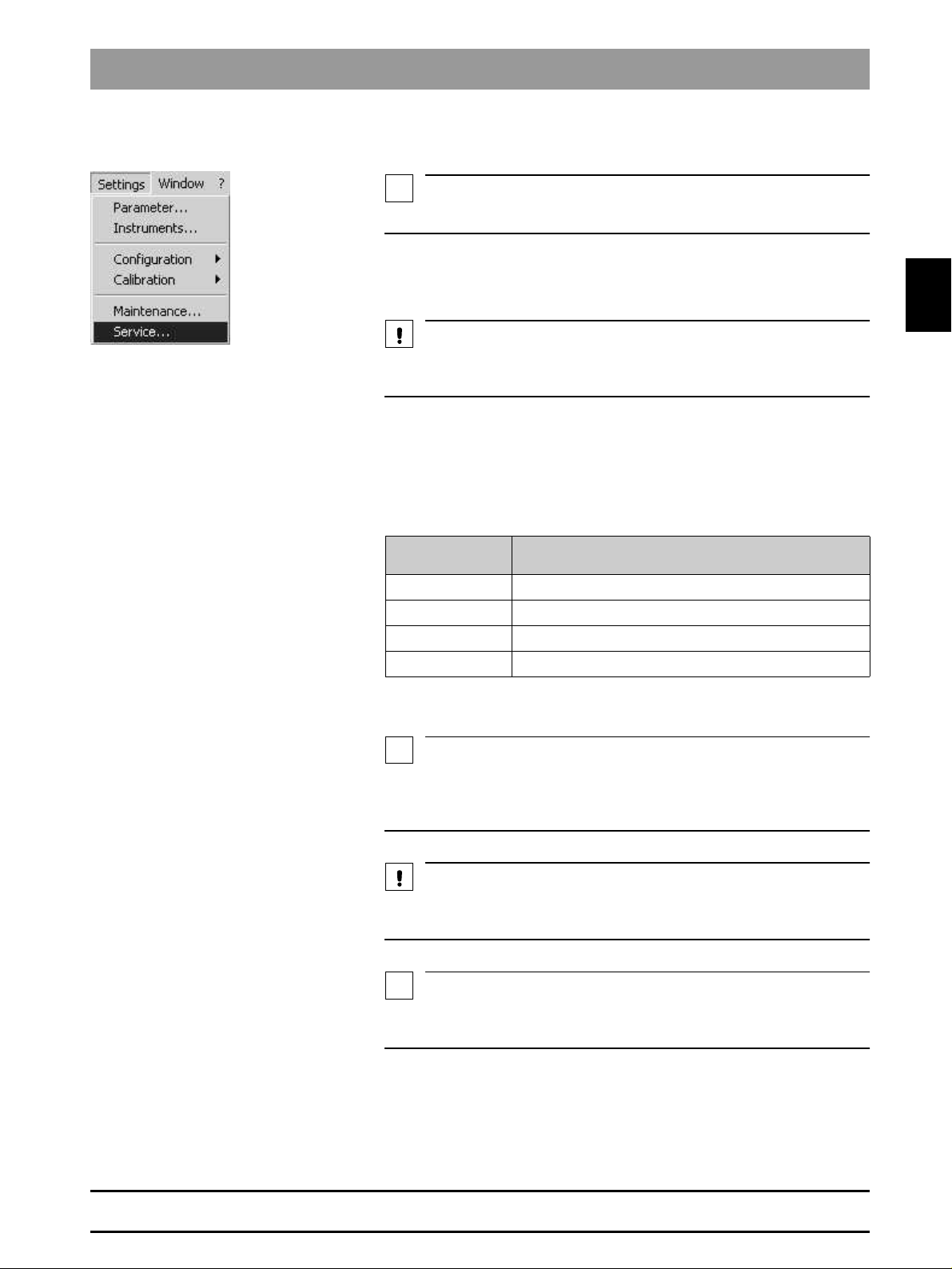

Via the

• select a wide range of Service functions with

The Service functions may be used only by authorized service technicians

who have been trained by Sirona.

The service software test dialogs are protected by a password to prevent

manipulations by unauthorized users.

The password has four digits. It changes daily and is generated from the system date of the computer according to the following scheme:

Example: 24.05.2001 becomes 5042

Service

Password

number

1 2. number of the current month

2 1. number of the current month

3 2. number of the current day

4 1. number of the current day

menu you can ...

Settings/Service...

Generated from

2.2

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Since the password is thus valid for only one day, it may be passed on to the

user in exceptional cases, e.g. when providing him with emergency help over

the phone.

The password should always be treated confidentially. Before entering the

password, always determine the date as inconspicuously as possible.

If you enter the correct password, and the commands are nevertheless not enabled, first check the system date of the computer.

The dialog for setting the system time can be called up in all Windows operating systems by double-clicking the time displayed in the status line.

2 - 5

Page 18

2.2 Basic Structure of Test Dialogs

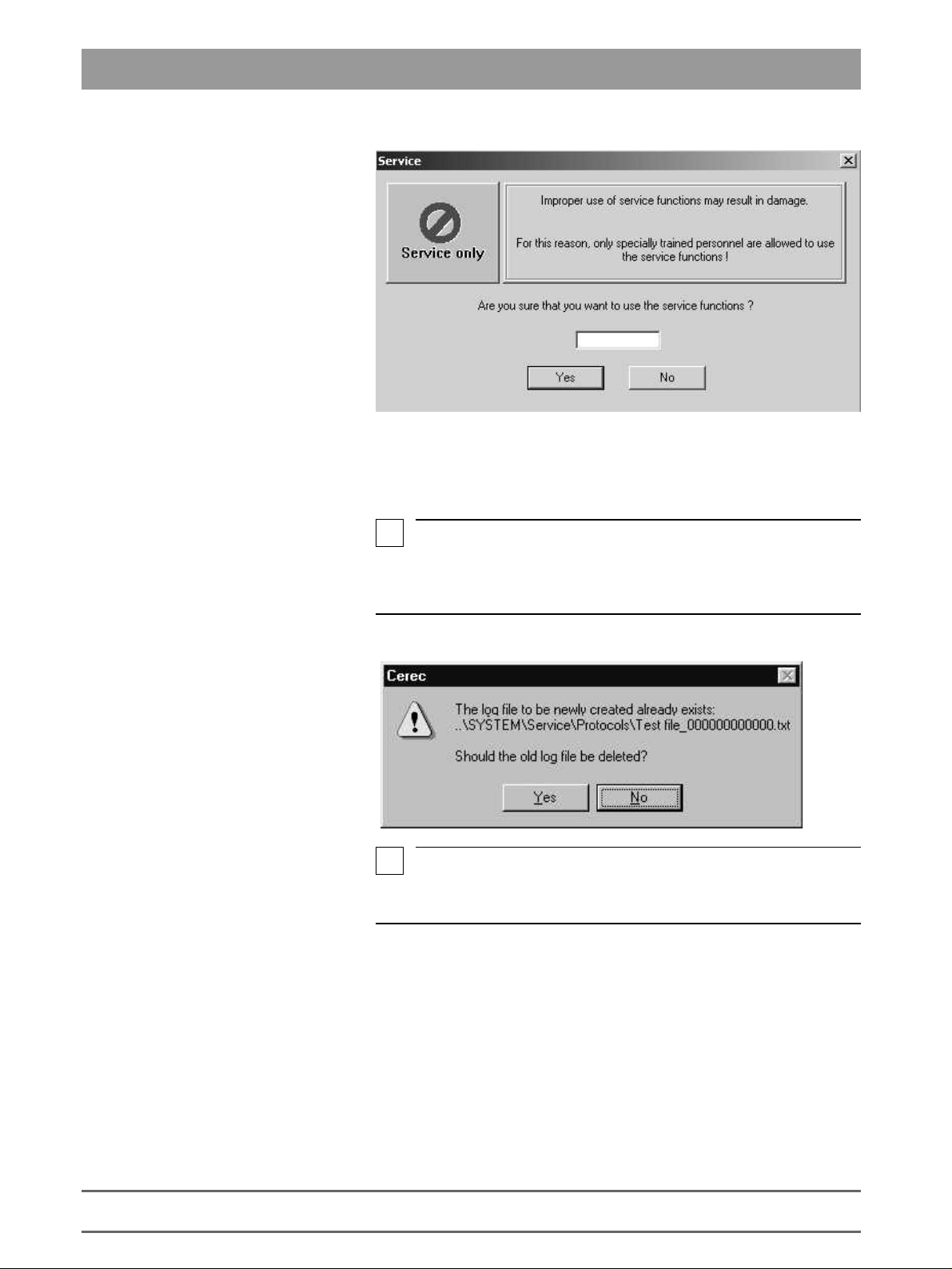

Now enter the password.

Log file

If you confirm this

open.

i

NOTE

If a log file named after the milling unit already exists at the time of the program

start, a confirmation query will appear asking if the data from the new test run

should be appended to the existing file or it should be deleted first.

i

NOTE

If the display "…0000.txt" appears, this means that there is no connection to

the milling unit.

Service

dialog with

Yes

, the

Test selection

dialog box will

2 - 6

Possible causes:

• The CEREC 3 program has been started more than once

• There is no (cable or radio-link) connection between the milling unit and

the acquisition unit/PC

• The software download to the milling unit has not been completed.

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 19

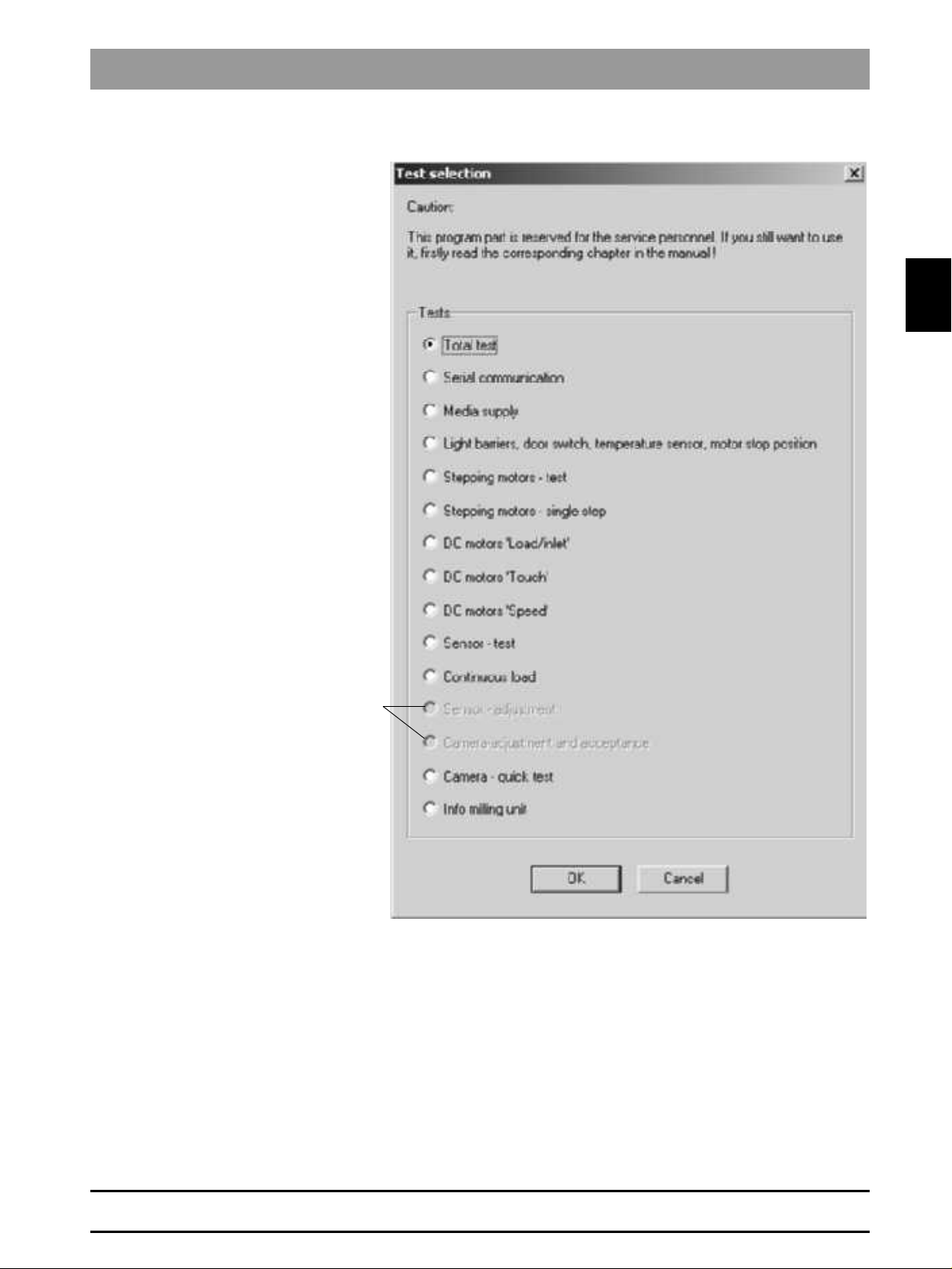

Test selection dialog

Tests performed only at

the factory

2.2 Basic Structure of Test Dialogs

2.2

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

In the

Test selection

• a

Total test

• an individual test.

The selected test dialog is then opened by clicking on

dialog you can select …

(default selection on delivery) or

OK

.

2 - 7

Page 20

2.2 Basic Structure of Test Dialogs

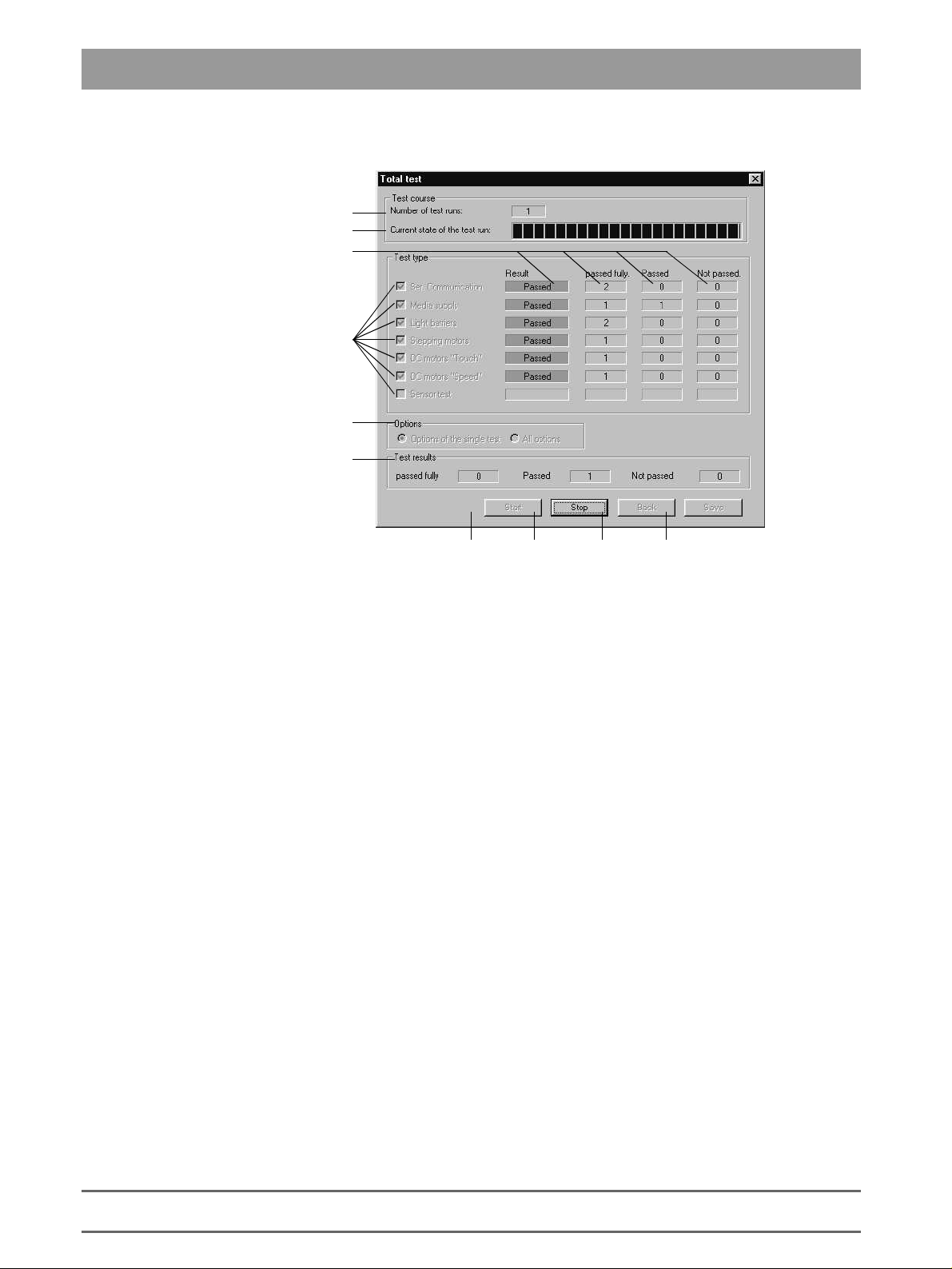

Example: Total test

1

2

10

3

4

5

6 789

Number of test runs completed since the last time the

1.

tuated.

Status bar for current state of test run.

2.

Check boxes for selecting (activating/deactivating) the tests available in

3.

this test dialog.

Check box for selecting the options possible in this test dialog.

4.

Number of test results since the last

5.

– Passed fully

– Passe d

– Not passed

Pressing

6.

The test run will be repeated until it is interrupted with the Stop button.

The test run counter is then reset to 0.

Once started, the test run can be halted only with Stop. No other inputs are

possible during the test run.

The test is canceled as soon as possible with

7.

The test in progress at the time of cancellation is not counted. All inputs are

now possible again.

stores all existing data to the log file. The data are appended to the

Save

8.

previously existing log file (if the current test run has not yet been saved).

If no data exist, a message to that effect will appear (confirm with

Once a test run has been saved to the log file, a new test run must be started before selecting the save function again.

initiates the test run with the selecting settings.

Start

Start:

Stop

.

button was ac-

Start

OK

).

2 - 8

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 21

2.2 Basic Structure of Test Dialogs

Press

9.

If any data exist and have not yet been saved, you will be queried whether

or not the test data should be saved.

Result:

10.

• No color =>

• Green => Measurement shows that test was

• Yellow => Measurement shows that test was

• Red => Measurement shows that test was

to quit the test dialog and return to the service dialog.

Back

measurement available yet

No

fully

passed

Passed

Passed

Not

2.2

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

2 - 9

Page 22

2.3 Individual Test Points

g

2.3 Individual Test Points

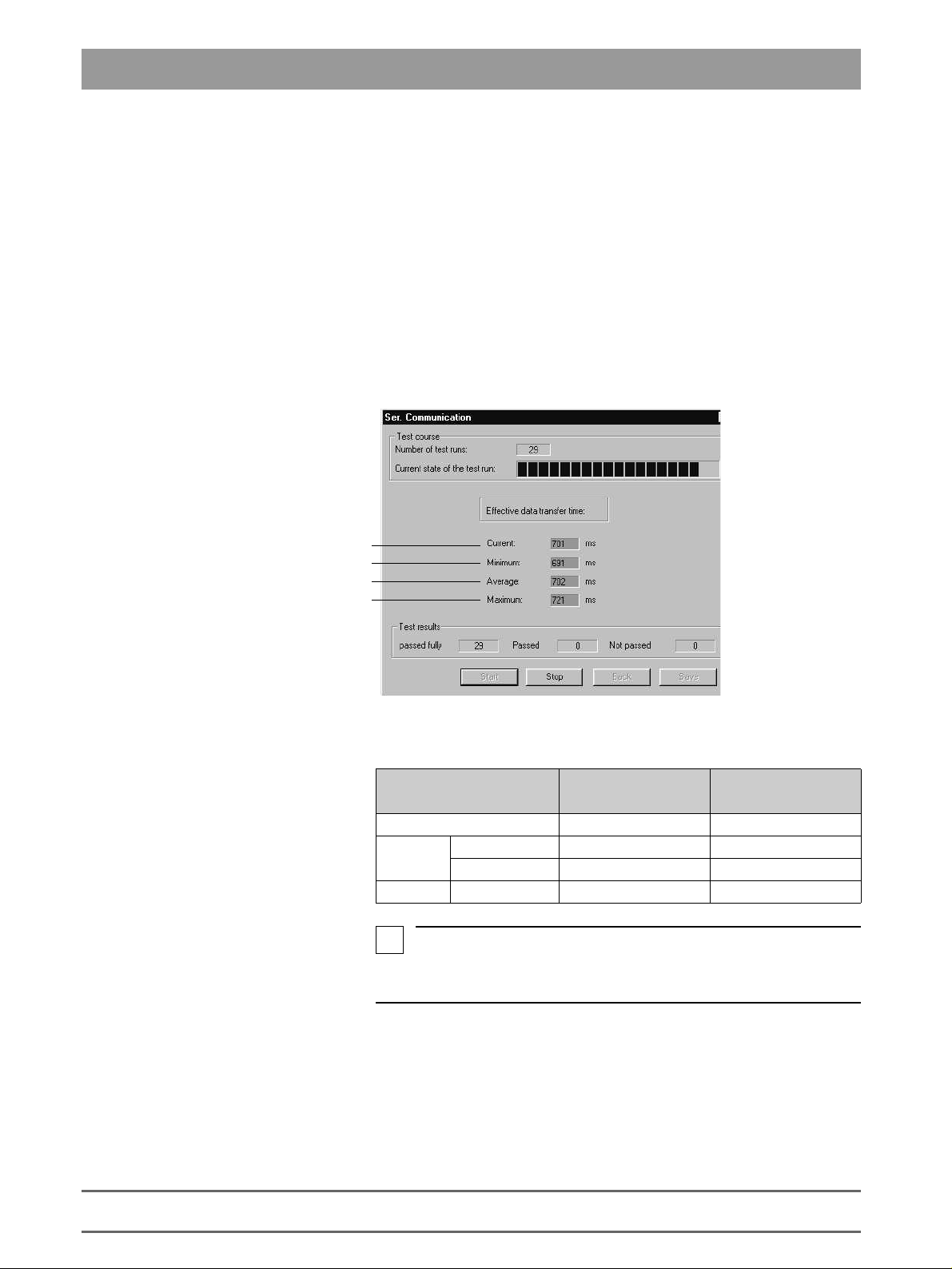

2.3.1 Serial Communication

The test is primarily used to measure the speed and quality of data transmission. This is especially important if the system is not operated through the

standard line (RS-232 max. 10 m), but via other types of connections instead

e.g. an infrared link, a DECT coupling or over longer distances via interface

converters e.g. RS-422.

The transmission time between the beginning of transmission and the end of

reception is calculated for a specific data record on the PC. A test run comprises one complete transmission in both directions.

The values thus measured are then saved to the log file.

Result of last test run

Minimum measured transmission time

e measured transmission time

Avera

Maximum measured transmission time

Typical values:

COM1

Baud rate: 115200

Cable 400-500ms –

Radio

i

The limiting values and color coding refer to a

baud rate of 115200.

Europe 600-750ms –

USA/Japan – 2-3s

NOTE

COM1

Baud rate: 19200

Purpose of Test:

2 - 10

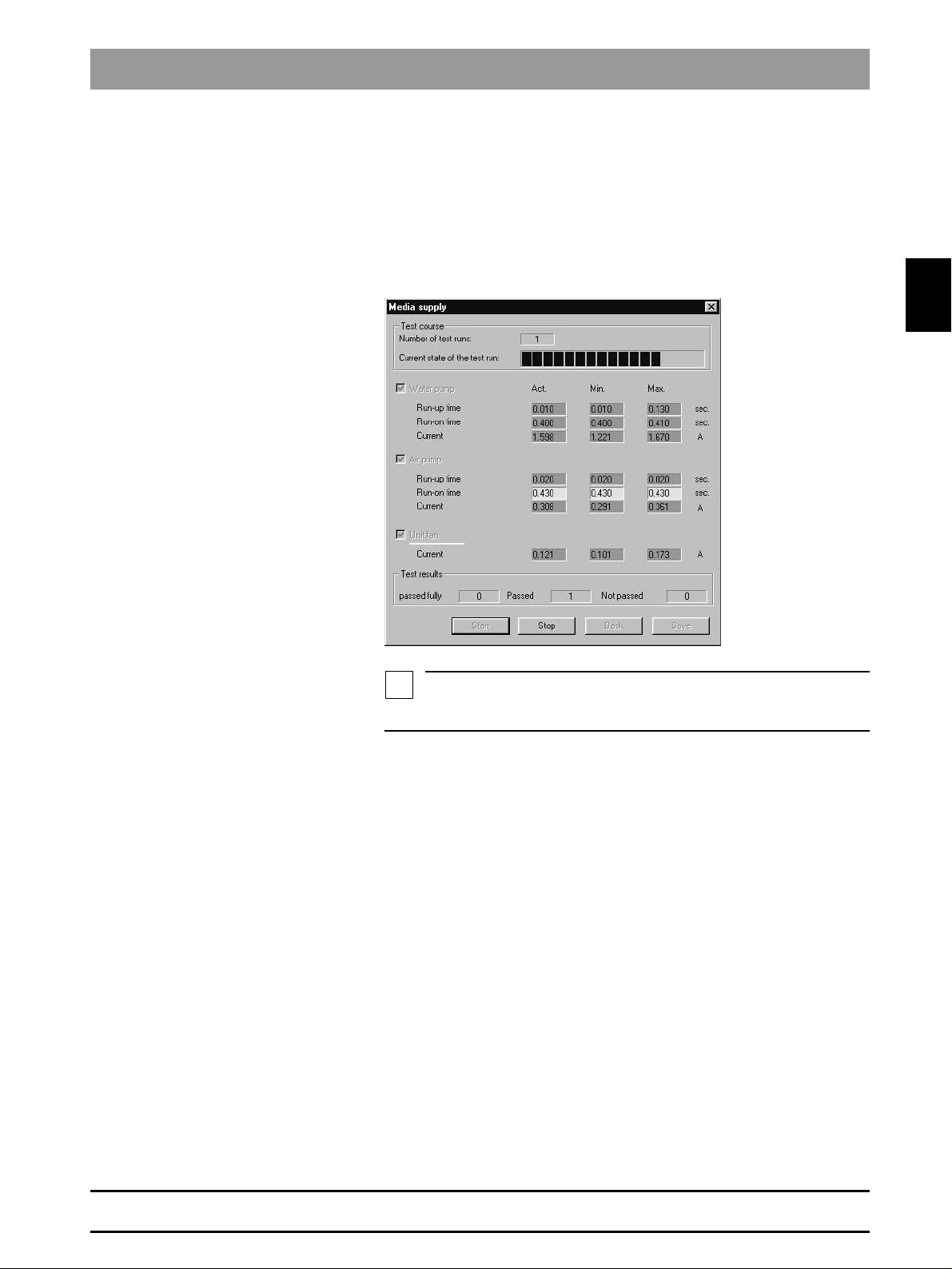

2.3.2 Media supply

To check the media supply (air, water, fan) for proper functioning and test the

pressure switches and the run-up time of the pump.

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 23

2.3 Individual Test Points

NOTE

i

Procedure

Save

The pumps and the fan are switched on by nominal select control depending

on selection. The motor currents and the condition of the pressure switches

are registered. The points of time when the pressure detectors respond are

measured. After approx. 5 seconds the pumps are switched off and the time

required until the pressure switch responds is measured and evaluated.

Save stores the measured values to the log file under the heading of Media

supply.

2.3

Deviations of measurements

The limiting values apply to a completely filled water circuit.

Deviations may occur:

• During the first test run (if any air is still in the water circuit)

• If the amount of water in the water tank is insufficient

• After filling the water tank.

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

2 - 11

Page 24

2.3 Individual Test Points

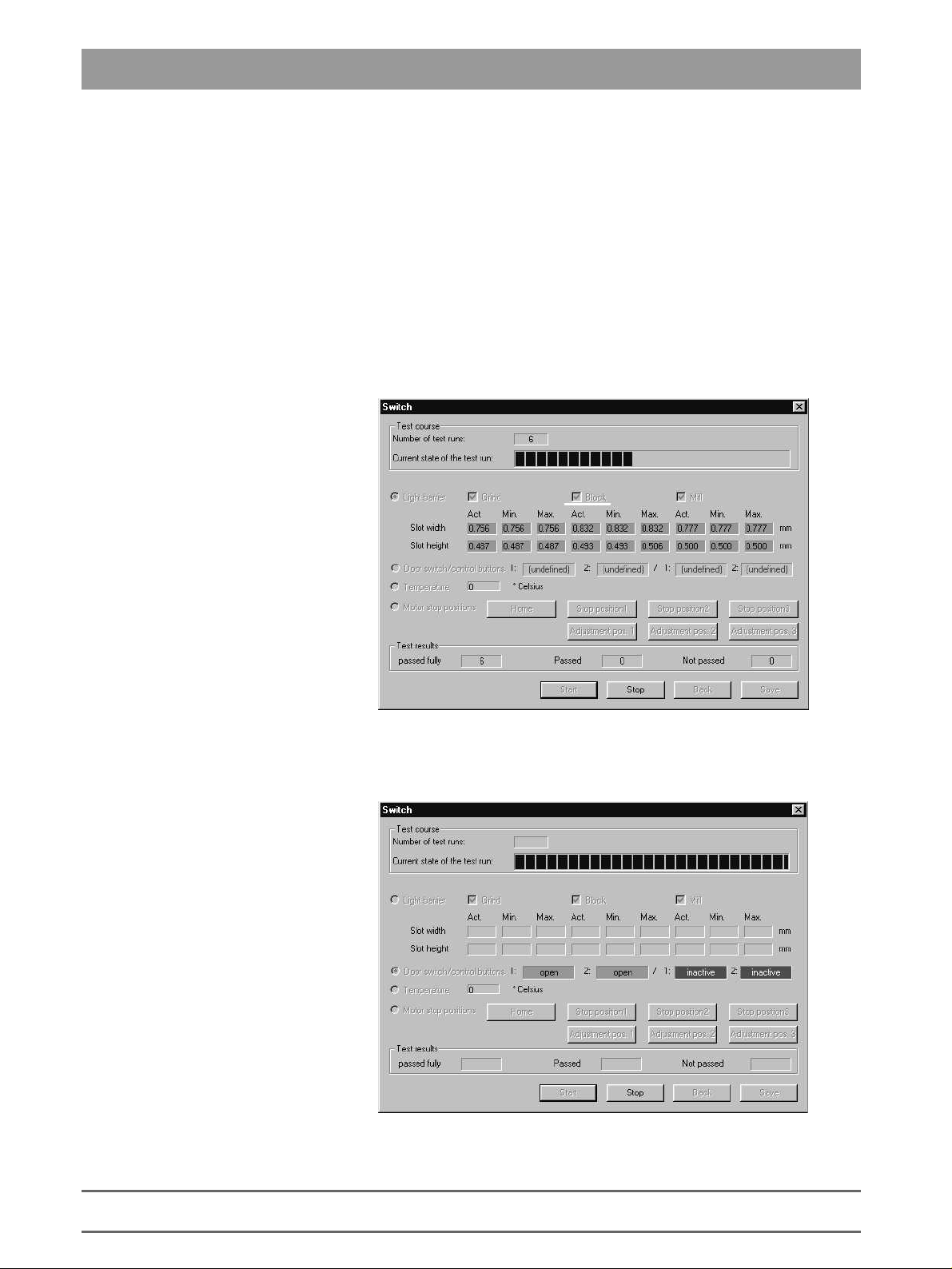

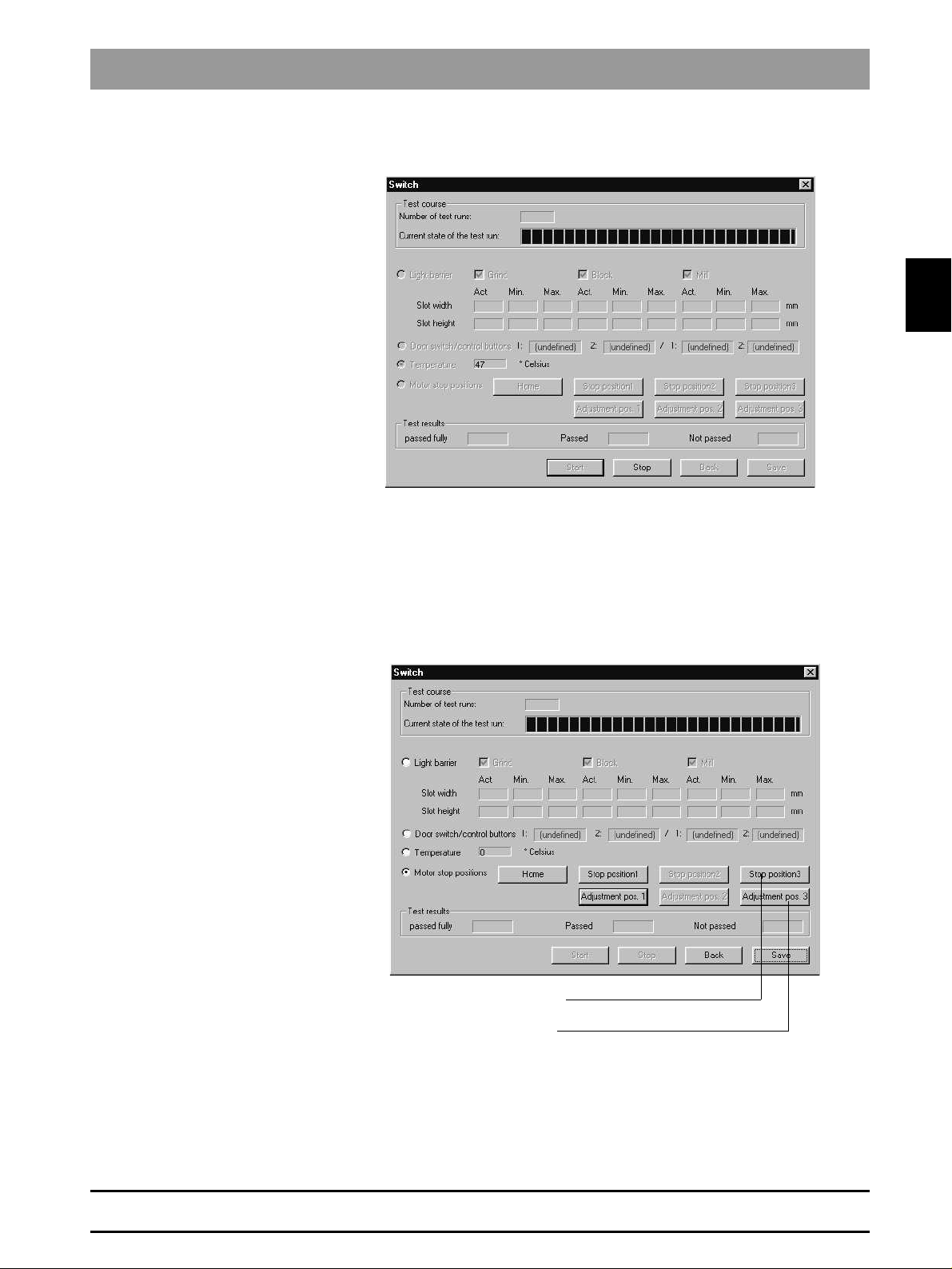

2.3.3 Light Barriers, Door Switch, Temperature Sensor and Motor Stop Positions

Purpose of Test:

Light Barriers

This test serves to evaluate the safe functioning of the light barriers and check

the door switch, the temperature sensor and the motor stop positions.

When the end position is located, the slot of the gear is measured via the

width and height at which the stepping motor positions are registered with the

flanks.

The light barriers to be tested can be selected in all variations. If no light barrier is selected, the Start button is not active.

Default setting: All light barriers selected.

Door Switch/Control Keys

2 - 12

The current state of the door switch and control keys can be checked via a

status bar display.

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 25

2.3 Individual Test Points

Temperature

Motor Stop Positions

A temperature display has been realized to check the temperature of the milling machine.

In the

Test selection

setting.

The motors are moved to these positions to test the motor stop positions.

Depending on which button is selected, the motors move to the corresponding position and stop there.

The motors can be reset to their home positions by pressing the

dialog,

Motor stop positions

is defined as the default

button.

Home

2.3

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Stop position for tool change

Aux. position for replacing components

If the home position can not be reached or lost steps occur during motor

movement, this will be reported.

2 - 13

Page 26

2.3 Individual Test Points

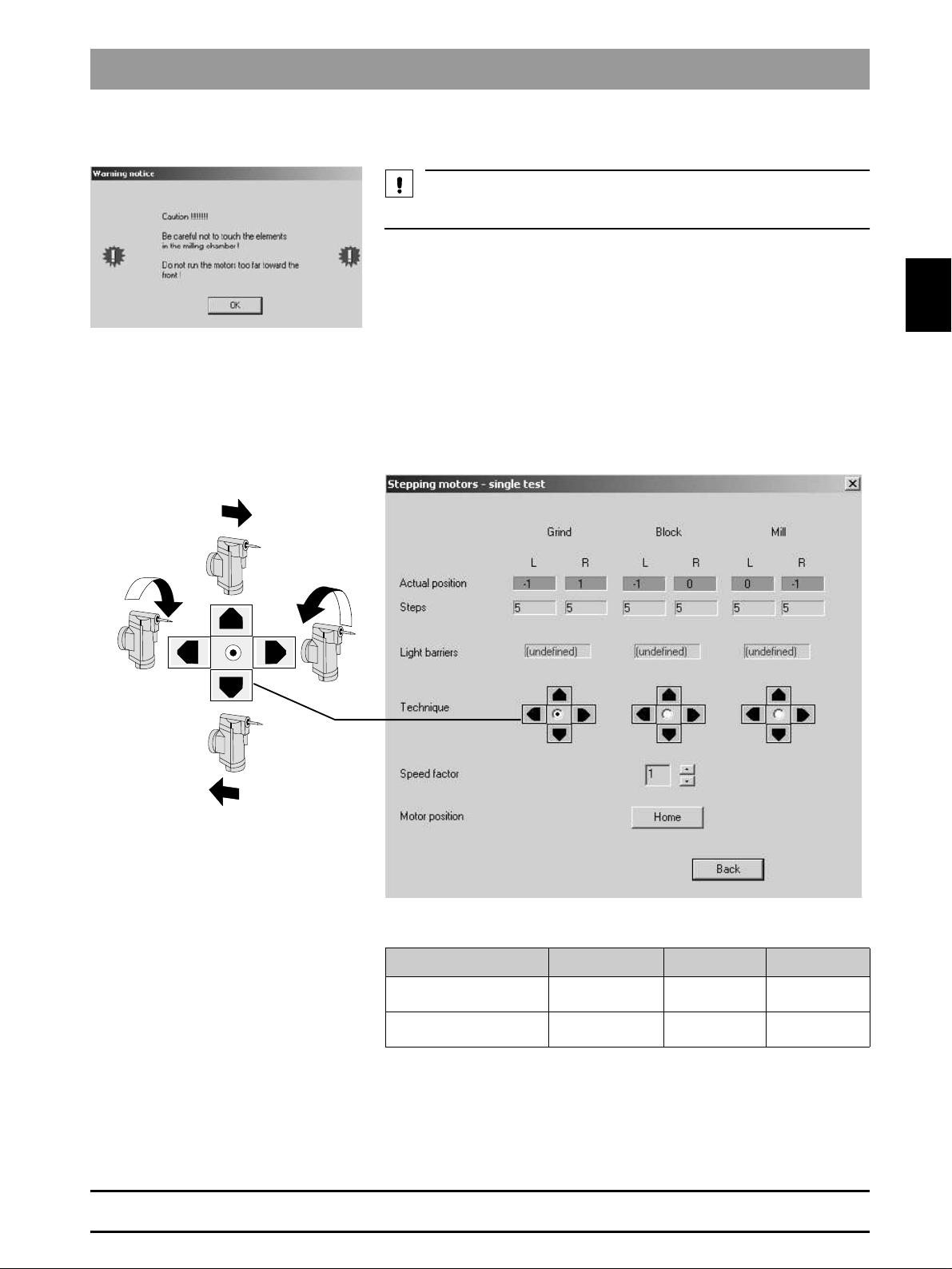

2.3.4 Stepping Motor Test

CAUTION

Observe the warnings in the

Testpiece

dialog.

Purpose of Test:

Procedure

Display of Test Results

Longit. movement

This test serves to evaluate the functioning of the stepping motors. The stepping motors are tested and evaluated for this purpose. The evaluation is made

based on a factor for the reserve capacity of each stepping motor. In addition,

this test can also be used for installation and adjustment purposes as well as

to break in the milling machine.

It is possible to individually trigger and test the stepping motors in various

combinations.

The stepping motors are run at various speed settings via an acceleration

table and the resulting step losses are measured. The number of step loss

events is then registered and evaluated. Finally, a reserve capacity is

assigned to each motor based on this data.

In order to satisfy different requirements for adjustment and testing purposes,

this test also offers the option of choosing between data summation and display of the results for individual test runs.

Rotation

2 - 14

Standard

Refers to Stage 2

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 27

2.3 Individual Test Points

CAUTION

2.3.5 Stepping Motors - Single Step

Observe the warnings in the opened dialog.

2.3

Purpose of Test:

Procedure

The test is used to control the motors individually in case of malfunction.

Using the

nal and rotation directions.

buttons, you can move the individual motors in the longitudi-

Move

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

One longitudinal step (L)

equals

One rotational step (R)

equals

Grind Block Mill

12.5µm 12.5µm 12.5µm

approx. 0.04°

(2.5’)

approx. 0.13°

(7.7’)

approx. 0.04°

(2.5’)

2 - 15

Page 28

2.3 Individual Test Points

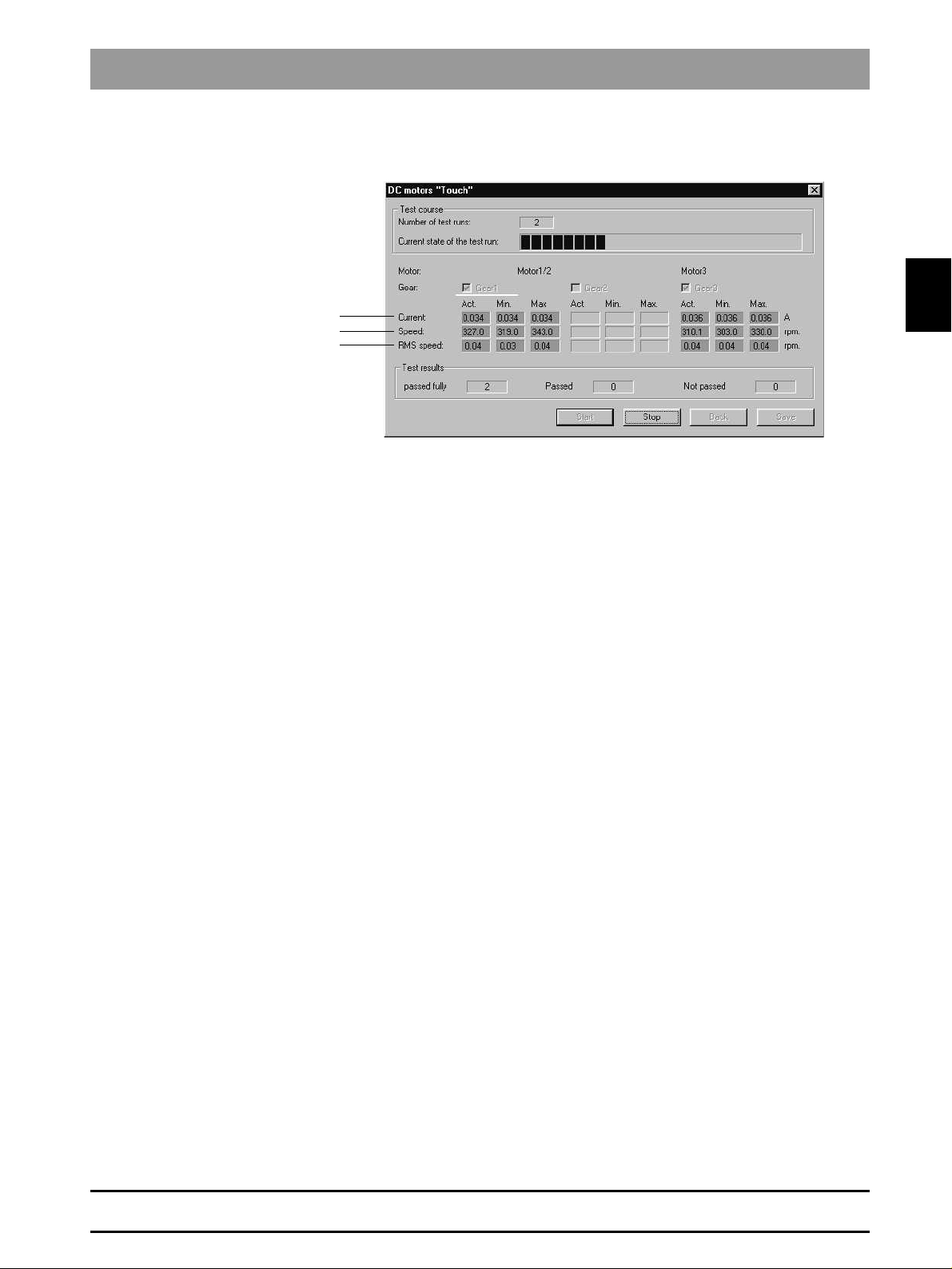

2.3.6 DC Motors "Inlet/Load"

Purpose of Test:

Procedure

Motor current

Always 0, since motor current preset

Actual speed

Measure of speed fluctuation

This test serves to run in the DC motors and check them for proper functioning

under continuous load.

The DC motors are tested through operation at a constant current. The resulting speed provides an indication of the running resistance of the gearing units.

The two motors (Motor 1 and Motor 3) can be selected together or separately.

If no motor is selected, the Start button is not active. Default: Both motors

selected.

The test runs in an endless loop until the

Test Run

The current measured values are displayed. A test run consists of one part

run time and one part pause for each motor.

:

button is actuated.

Stop

Purpose of Test:

2 - 16

2.3.7 DC motors "Touch"

This test is used to check the two DC motors for proper functioning in the Lowspeed mode.

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 29

2.3 Individual Test Points

Procedure

Measured motor current

Measured speed

Fluctuation of speed

The DC motors are tested by adjusting them to the touch speed (in the relevant directions of rotation). Then the relevant data are determined.

The possible gearing units (1,3) can be selected either together or separately.

The

Default: Both motors selected.

button remains inactive as long as no gearing has been selected.

Start

2.3

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

2 - 17

Page 30

2.3 Individual Test Points

(

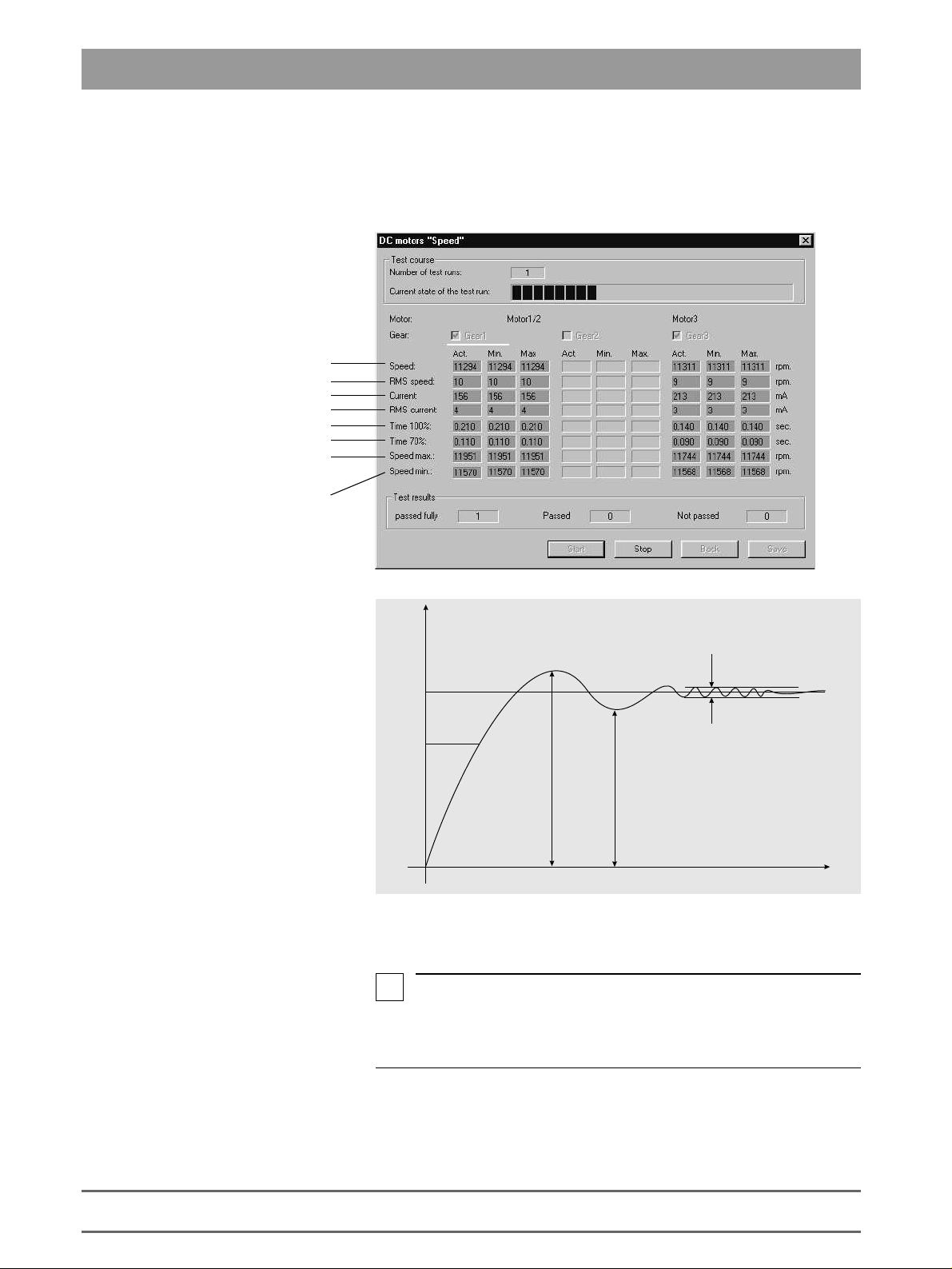

2.3.8 DC motors ”Speed”

Purpose of Test:

Fluctuation of speed

Measured motor current

Fluctuation of motor current

Run-up time to 100%

Run-up time to 70%

This test is used to check the two DC motors and their gearings for flawless

functioning in the High-speed mode.

Measured speed

Maximum value of

measured speed

Minimum value of

measured speed

n

r.p.m.)

Max. speed

100%

70%

Procedure

The DC motors are tested by accelerating them from a standing start to working speed and then measuring the relevant data.

i

NOTE

The current is monitored during all measurements. The maximum current

must not stop for longer than 2 seconds; otherwise the test will immediately be

interrupted by an error message.

Min. speed

RMS speed

t (s)

2 - 18

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 31

2.3 Individual Test Points

2.3.9 Scanner test (Scan)

Purpose of Test:

Distance between scanner and measuring point

scanner

scanner

Procedure

This test serves to evaluate the functioning and accuracy of the scanner.

Laser active signal level

Laser inactive signal level

Focal size

Selection of laser diode

Measuring angle

Dimension of noise level

Measuring error

The various required measurements are performed with the help of the calibration phantom.

The functions to be tested can be selected in different variations. If no function

is selected, the Start button remains inactive. Default setting: Test all functions.

2.3

Purpose of Test:

Milling machine temperature

2.3.10Continuous load

This test serves to simulate a maximum load for the power supply and intentionally heat up the entire system.

All loads can be operated simultaneously. The temperature rise of the system

is then measured.

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

2 - 19

Page 32

2.3 Individual Test Points

2.3.11Camera quick test

The camera quick test consists of a series of individual test steps, which can

be carried out both in the specified order and individually.

Experienced service

technicians!

Some test steps are made up of several partial steps, some of which can be

activated individually. These functions should only be used by trained technicians.

Operate by clicking the buttons in the bottom right-hand section of the screen.

2 - 20

When carrying out the test steps in the specified order, it is easier to use only

Next

NOTE

Stop

button.

to stop the process. After clicking

or double

Jump

Next, previous

, the button remains high-

Stop

Stop

D 3344.076.01.04.02 03.2002

or

repeat

then returns to its nor-

58 35 694 D 3344

.

the

i

In many cases "Next" is the same as pressing RETURN.

To select individual test steps, either mark the test step (by clicking it with the

left trackball button, to highlight it in blue) and then select

click on the test step.

Test steps can also be selected by choosing

Select

lighted until the sequence has actually stopped.

mal shading and the sequence can be continued by selecting the corresponding buttons.

Page 33

2.3 Individual Test Points

CAUTION

Side

A

Flat surface

A

Calibration Set A

Select

• "Close Frame Grabber" or

• "Service/Protocol/ Save",

no protocol (log file) is saved.

If a blue dialog box appears, you must select

after following the instructions contained in the box.

If Box A appears, please set Calibration Set A to the 3D camera.

to exit the test run.

Exit

If you exit the test run without selecting the test step

Next

to continue the sequence

2.3

Calibration Set B

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

If Box B appears, please set Calibration Set B to the 3D camera.

B

Side

B

Surface with cross

2 - 21

Page 34

2.3 Individual Test Points

If a yellow results box appears, select

The results of the completed test steps are shown in the LOG box during the

sequence.

The entire LOG box can be viewed by scrolling up/down.

to continue the sequence.

Next

2 - 22

Errors can occur while you are carrying out the test steps. Here, it is important

to follow the instructions.

The camera quick test also includes several

selected in the

i

NOTE

Service functions can only be selected when the test run is stopped.

To end a service function, select a button to continue the test run (e.g.

Service functions consist of:

• Protocol

• Live image

Service

menu and in the pull-down menus.

Service functions

D 3344.076.01.04.02 03.2002

, which can be

Next

58 35 694 D 3344

).

Page 35

Protocol

2.3 Individual Test Points

• Lifting magnet

• LED

• Slide alignment

2.3

Live image

Select

Service/Protocol/Save

run.

To view the protocol, select

Select RETURN to close the protocol (log file) display.

Moving grid = Search image

Int. LED on (standing grid) = Search image with standing grid - visible grid

stripes

Int. LED off (standing grid) = Search image with internal LED deactivated, so

that objects can only be seen when they are illuminated externally.

to create a protocol (log file) during the test

Service/Protocol/Display

.

Lifting magnet

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

The lifting magnet is attracted approximately every 3 sec. for a period of

approx. 1 sec. A clicking sound can be heard.

LED

and

Slide alignment

are not required in the camera quick test.

2 - 23

Page 36

2.3 Individual Test Points

The camera quick test

below.

Camera calibration data obtained from successfully completed tests are

saved and used in the following camera quick test. These data are not used

for camera operation outside the service program, so that the recording process is not affected by the program.

This also means that the camera must be calibrated before it is used in the

camera quick test. This enables the test steps to produce correct results.

Checking the RGB adjustment

rect results without the calibration process being completed.

The test results are indicated in three colors: Green = fully passed, Yellow =

passed, Red = not passed.

Sequence

comprises the test steps (functions) listed

is the only test step which can produce cor-

CAUTION

Failed tests may be due to a badly prepared calibration set. The uniformity of

the powder coating should then be checked.

It should also be noted that test failures may be the result of a faulty camera

cable or PC drawer (Refer to Chapter 4.14 - 4.16).

In the test step labelled

be entered for the serial number (card).

Carrying out the

protocol of the completed tests to be stored as a file in the \CEREC\SYSTEM\SERVICE\PROTOCOLS folder. The file name includes the date and

time of the test as well as the camera serial number, if this was entered in the

Entry of the header data

times, the latest result is entered in the protocol.

Entry of the header data

Closing the frame grabber

test step. If a test step has been carried out several

, a 4-6 figure number must

test step involves generating a

2 - 24

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 37

2.3 Individual Test Points

2.3.12 Info milling unit

This dialog box contains information on the connected milling unit and the

milling times of the burs.

2.3

•

Serial number

•

Milling unit ID

Identifier 0

Identifier 1

Identifier 2

Identifier ??

•

Parallel sided burr (min.)

•

Cone Shaped (Tapered) burr (min.)

bur

•

Total milling time (min.)

•

Total scan time (min.)

– Serial no. of CC PC board

:

= CEREC 3 milling unit / scanner (serial number <5000)

= CEREC inLab milling unit (serial number >5000)

= CEREC 3 milling unit / scanner (serial number >5000)

= no milling machine connected

: – elapsed milling time of parallel-sided bur

: – elapsed milling time of milling unit

: – elapsed scanning time of milling unit

: – elapsed milling time of tapered

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

2 - 25

Page 38

Page 39

CEREC 3

3

Trouble Shooting: Milling Unit

Page 40

List of Contents

Trouble Shooting: Milling Unit

List of Contents

3.1 Device cannot be switched ON. Green LED (Ready for operation) not illuminated .......... 3-5

3.2 No connection to PC / acquisition unit. Software cannot be installed.................................. 3-7

3.3 No air pressure .................................................................................................................... 3-9

3.4 Fan not running. Unit shuts down completely after a short time.......................................... 3-11

3.5 Water pump: Pressure too low ............................................................................................ 3-13

3.6 Defective light barrier........................................................................................................... 3-15

3.7 Door switch. Please close milling chamber door................................................................. 3-17

3.8 Motor locking positions: Problems changing grinders ......................................................... 3-19

3.9 Stepping motors (milling unit). Loss of steps....................................................................... 3-21

3.10 Touch errors ........................................................................................................................ 3-23

3.11 Trouble shooting. Defective CCP board.............................................................................. 3-25

3 - 2

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 41

Personal notes

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

3 - 3

Page 42

3 - 4

LED on power supply unit

V204

V205

V206

V200

Battery

Page 43

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

• Line power supply connected to electric outlet?

• Line voltage fuses OK? If not: Always replace both fuses.

• Check line voltage on power supply unit terminal: 100-240V

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

Green LED on power

supply unit

illuminated?

Yes

CC

CC

Turn ON main switch

IV204

Pos.

(42V)

illuminated?

Yes

CC

Lamps

(5V) and

V200

(24V) and

V205

(12V)?

V206

Yes

Board battery

defective/run down

Replace battery

No

No

No

Replace power

Replace board

Replace board

3.1 Device cannot be switched ON. Green LED (Ready for operation) not illuminated

3 - 5

3.1

Page 44

3 - 6

V292

Page 45

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

• CAUTION: Fault may also be on PC/acquisition unit.

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

• Check

1. Cable version

configuration

Communication

in the

Check:

• Serial connecting cable

• Interface settings on PC / acquisition Unit

Connection

OK

Yes

No

Connection OK?

Unit OK

2. Radio controlled version

NOTE: When updating software, it may be necessary

to make several (2-3) attempts at starting.

Connect up using the

cable:

No

Connection OK?

Yes

menu.

Replace board

Yes

Unit OK

Replace board

Connection OK?

Yes

No

Check:

Replace cable harness

• Interface settings on PC / acquisition unit

No

Replace cable harness

Unit OK

Connect radio module

V 292 (10V)

illuminated?

Yes

No

Replace board

Replace radio module

3.2 No connection to PC / acquisition unit. Software cannot be installed

3 - 7

3.2

Page 46

3 - 8

Air pressure switch

Air pump

Page 47

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

• Select Settings/Service/Test selection/Media supply/

Run-up time too short

(0.00)

and

Run-on time too long (0.49)

Run-up time too long (4.50)

and

Run-on time too short

(0.00)

Run-on time too long

Current draw too low (0.00)

Check plug

connections on air

pressure switch.

Replace air pressure switch

Check air hoses Eliminate fault

Check plug

connections on air

pump

Air pump

(* see page 2 - 10) Carry out test

Connect plugs.

Test passed?

Yes

Device OK

Connect plugs.

Test passed?

Yes

Device OK

No

No

Replace air pressure switch

Replace air pump

Current draw too high

(>0.60)

3.3 No air pressure

3 - 9

Replace air pump

Test passed?

Yes

Device OK

No

Replace board

Test passed?

Yes

Device OK

No

Replace cable harness

3.3

Page 48

3 - 10

Fan unit

Page 49

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

• Select Settings/Service/Test selection/Media supply/

Normal current input level,

Fan unit not running

Current input too low

Check plug connections on fan

Fan unit

Mechanical

unit.

Plug connections OK?

Yes

Are the following LEDs

on?

(L_FAN)

V320

Is

42VDC

X8.1

and

Yes

applied at

and

X8.2

Yes

Replace fan unit

Fan unit

?

(* see page 2 - 10) Carry out test

Remove mechanical

obstruction

No

No

No

Replace CC board

Check line L8.

Connect plugs

Line OK?

Yes

Replace CC board

No

Repair line or replace

cable harness

Current draw too high

Disconnect X8.

No

Replace fan unit

Current draw still too

high?

Yes

Check

short circuits.

X8.1

&

X8.2

for

No

Replace board

Short circuit?

Yes

Replace cable harness

3.4 Fan not running. Unit shuts down completely after a short time

3 - 11

3.4

Page 50

3 - 12

Water pressure switch

Water pump

Page 51

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

• Preliminary test: Water tank full. Tank connection button locked in place

• Select Settings/Service/Test selection/Media supply/

Water pump

(* see page 2 - 10) Carry out test

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

Run-up time too short

If the test is not passed, a "damping box upgrade kit" must be ordered. Order No.: 58 85 673

(0.00)

and

Check plug

connections on water

pressure switch

Connect plugs.

Test passed?

Run-on time too long (0.49)

Run-up time too long (4.50)

Run-on time too short

and

Replace water pressure switch

Device OK

(0.00)

Run-on time too long

and / or

Check nozzles on

gearing units and water

water hoses

Remove clogging

current input too high

Run-up time too long

Check water hoses

(suction end)

Remove clogging

and

Current input too low

Current input too low (0.00)

Check connection:

Tank connector Æ tank

Check plug

connections on water

Replace tank connector

Connect plugs.

Test passed?

pump

Yes

Yes

No

No

Replace water pressure switch

Replace water pump

Current input too high

Replace water pump

Test passed?

Yes

Device OK Device OK

3.5 Water pump: Pressure too low

3 - 13

No

Device OK

Replace board

Test passed?

Yes

No

Replace cable

3.5

Page 52

3 - 14

Light barriers

L_B

L_M

L_G

V503

L_B

V703

L_G

V503

L_M

Page 53

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

• Select Settings/Service/Test selection/Light barriers, …/

Light barriers

Light barriers defective

contaminated?

Check plug connections

V703 (L_G) illuminated?

V503 (L_B) illuminated?

No

No

Replace corresponding

light barrier in G / B/ M axis.

Test passed?

V603 (L_M) illuminated?

No

Yes

Unit OK

CAUTION

stepping motors Total

: May be due to

failure!

Check all plug

connections

Test passed?

Light barriers

No

(* see page 2 - 12) Carry out test.

Remove contamination

Connect plugs

No

Replace board

Test passed?

Yes

Unit OK

Replace board

No

Test passed?

No

Replace

cable

harness

Replace

cable

harness

3.6 Defective light barrier

3 - 15

Yes

Unit OK

Yes

Unit OK

3.6

Page 54

3 - 16

Slide door switch to upper stop

Door switch

Page 55

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

• Select Settings/Service/Test selection/Light barriers, …/

Test the door switch function:

Door switch/Operating keys

• When the milling chamber door is opened at both contacts, "

• When the milling chamber door is closed at both contacts, "

Check position of door

switch.

Door switch

positioned at upper

stop?

Yes

Unit OK

Slide the door

switch to the

stop.

Door switch

functioning?

Yes

Unit OK

NoNo

Open

" must appear in the display before the door has moved a distance of 5 mm.

Closed

" must appear in the display before the door is locked in place.

Check plug

connections on

door switch.

Connect plugs.

Test passed?

Yes

Unit OK

(* see page 2 - 12) Carry out test

Test door switch using

No

another magnet

Test passed?

Yes

Test magnet in door.

Replace magnet.

Replace door.

Test passed?

Yes

Unit OK

No

No

Replace door switch

Replace board

Test passed?

Yes

Unit OK

No

Replace

cable

harness

3.7 Door switch. Please close milling chamber door

3 - 17

3.7

Page 56

3 - 18

Locking pins

Page 57

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

• Select Settings/Service/Test selection/Light barriers, …/

• Move grinder to stop position. Replace grinder

Grinder not locked in position (drive

rotates with grinder when attempting to

release the grinder from the drive).

Move grinder to home position.

Locking pins loosened?

Yes

Reposition and seal locking pins

(* see “Checking / Adjusting Stop

positions” on page 1 - 13)

No

spring be pressed in?

Motor stop positions

Check drive.

Can the pressure

(* see page 2 - 13) Carry out a test.

No

Replace gearing

*

Yes

Replace locking pins

(Checking and adjustment of locking

pins

*

see “Checking / Adjusting Stop

positions” on page 1 - 13)

page 1 - 11

see “Replacing the Drive and/or Motor” on

3.8 Motor locking positions: Problems changing grinders

3 - 19

3.8

Page 58

3 - 20

Page 59

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

• Select Settings/Service/Test selection/

If step losses occur

in stages 1 to 3

Stepping motors

Replace the corresponding stepping

Step losses still indicated?

(* see page 2 - 14) Carry out test

motor

Yes

Replace board

Test passed?

Yes

Unit OK

No

No

Unit OK

Replace cable

harness

Yes

Unit OK

No

Replace milling machine

3.9 Stepping motors (milling unit). Loss of steps

3 - 21

3.9

Page 60

3 - 22

Page 61

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

• Select Settings/Service/Test selection/

RMS speed too high,

severe speed fluctuations,

low current (< 0.20)

Current too high (> 0.10)

and motor not turning.

Replace DC motor

Current too low (0.00)

DC Motors “Touch”

Replace gearing

Check locking

position.

Movement?

Yes

Check plug

connections on

DC motor

(* see page 2 - 16) Carry out test

No

Replace gearing

Connect plugs.

Test passed?

Yes

Unit OK

No

Replace DC motor

3.10Touch errors

3 - 23

3.10

Page 62

3 - 24

Page 63

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

NOTE: If a CCP board is defective, it must be assumed that this is due to a defective motor rather than a fault on the CCP board.

The motors must therefore be checked first of all.

Do the following:

Remove the milling machine PE conductor connector from the bus point.

1.

Connect the measuring device between the milling machine PE conductor connector and the PE conductor bus point (DC voltage > 50 V).

2.

NOTE: In all the following tests:

– No fault: U: < 3 V

– Fault: U: > 3 V

Install a new CCP board.

3.

Switch on the unit.

4.

Carry out a stepping motor test

Defective motor test (interwinding fault to ground). Adjust voltage to approx. 39V.

5.

DC motor test (run-in / load)

If the defective motor (interwinding fault to ground) is tested, a voltage of approx. 22V results.

6.

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

Other causes

If approx. 5V is registered, this indicates a defective light barrier, milling chamber lighting or Hall sensor on one of the DC motors.

7.

Locate the cause by disconnecting the individual leads.

8.

Switch off the unit. Disconnect from the line power supply.

9.

Replace the corresponding part and repeat the test.

10.

11. CAUTION: After repairing the PE conductor - milling machine connection to PE conductor - reconnect the bus point.

3.11Trouble shooting. Defective CCP board

3 - 25

3.11

Page 64

Page 65

4

CEREC 3

Trouble shooting: Acquisition Unit

Page 66

List of Contents

Trouble shooting: Acquisition Unit

List of Contents

4.1 System cannot be switched ON .......................................................................................... 4-7

4.2 PC not booting properly I..................................................................................................... 4-9

4.3 PC not booting properly II .................................................................................................... 4-11

4.4 PC does not respond during switch-on, PC power supply does not start............................ 4-12

4.5 Further PC faults ................................................................................................................. 4-14

4.6 Monitor image flickering....................................................................................................... 4-15

4.7 No monitor display............................................................................................................... 4-17

4.8 Incorrect monitor display format size................................................................................... 4-19

4.9 Monitor: Color shade/gray scale is too weak....................................................................... 4-21

4.10 Trackball not functioning...................................................................................................... 4-23

4.11 Trackball buttons not functioning......................................................................................... 4-25

4.12 Pedal not functioning........................................................................................................... 4-27

4.13 Keyboard not functioning /defective .................................................................................... 4-29

4.14 No camera image ................................................................................................................ 4-31

4.15 Incorrect measuring sensor setting ..................................................................................... 4-33

4.16 Camera calibration: messages ............................................................................................ 4-35

4 - 2

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

Page 67

4.17 Interference at radio interface............................................................................................. 4-37

4.18 No sound or sound level too low ........................................................................................ 4-41

4.19 No Sirocam camera image ................................................................................................. 4-43

4.20 Sirocam camera image interference................................................................................... 4-45

4.21 SIROCAM camera: Incorrect image settings...................................................................... 4-47

4.22 Digital X-ray problems ........................................................................................................ 4-49

58 35 694 D 3344

D 3344.076.01.04.01 03.2002

4 - 3

Page 68

Page 69

Personal notes

58 35 694 D 3344

D 3344.076.01.04.02 03.2002

4 - 5

Page 70

4 - 6

Main switch on rear

LED

of device

L3

Supply line

Keyboard board

X4

DV

DECT supply board

F1/F2

F3

Page 71

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

• Line power supply connected to socket?

• Power plug connected?

• Power switch on rear of unit switched ON?

• Power cable attached to PC drawer?

• Keyboard board cable plug X4 connected to DECT power supply board (DV)?

D 3344.076.01.04.01 03.2002

58 35 694D 3344

LED above ON

pushbutton is

Is the LED

when the ON button

is pressed?

Yes

green

Yes

yellow

Unit OK

?

No

fuses. Replace if

necessary.

Is the LED

when the ON button

green

Yes

No

Device OK

Check F1, F2 and F3

No

Replace keyboard board

TT

Disconnect the plug on

the keyboard board

lead and check for 5 V

on socket

X4

(between pins 1 & 6).

5V present?

Yes

Replace keyboard board

TT

No

Check fuse F4

(on DV).

OK?

Replace

supply board

Yes

DECT power

DV

No

Replace fuse F4

4.1 System cannot be switched ON

4 - 7

4.1

Page 72

4 - 8

VGA

Page 73

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

• Are the keyboard, trackball and VGA cable connected to the monitor on the PC drawer?

• Is there a disk in the disk drive? If there is, remove it.

• Is the LED above the ON button

Is the boot-up process interrupted when you try

to access the hard disk during the BIOS startup

or

does a "blue screen" error message appear

when Windows is started?

Yes

Boot with restore disk (from PC hardware version

BA) or with bootable image CD-ROM.

yellow or green

? – * see page 4 - 7

No

No

Unit OK

Replace PC drawer

D 3344.076.01.04.01 03.2002

58 35 694D 3344

(

CAUTION

PC booting correctly?

, loss of data!).

Yes

Unit OK

4.2 PC not booting properly I

4 - 9

4.2

Page 74

4 - 10

Table 1:

List of beep-tone error codes

Beep tone sequence Cause of error

1x short OK beep following graphics card test.

no image

If

Is the monitor switched on and the control LED

illuminated?

If not:

Check the monitor voltage supply.

red control LED

If the

cable connecting the graphics card to the monitor.

If the

detects an input signal), check the brightness and

contrast settings of the monitor.

1x long and 3x short The graphics card is defective or not correctly plugged

in to the motherboard.

Repeatedly long The memory module on the motherboard is defective

or not correctly plugged in.

is visible yet, check the following points:

is illuminated, check the VGA

green control LED

is illuminated (monitor

Table 2:

Error messages during boot-up and possible causes of errors:

Error message Cause of error

Floppy disk(s) fail (40): Voltage supply or data cable to floppy not correctly

plugged in or defective. If the cable is OK, the floppy

disk drive may be defective.

Disk Boot Failure, insert System

Disk and press Enter:

Press a key to reboot: Boot sector of hard disk can not be found. Boot with

If the primary master disk was not found: Check the

data cable and voltage supply of the hard disk and the

CD/DVD drive.

restore disk (from PC HW version BA) or with bootable

image CD-ROM. If this fails, replace the PC.

Page 75

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

PC power supply starts. PC

begins boot-up procedure.

Boot-up procedure not

correctly completed.

D 3344.076.01.04.01 03.2002

58 35 694D 3344

Does the system detect the graphic

card and display it on the monitor?

Yes

Is a short beep emitted?

Yes

Does the memory test run without

Does one of the error messages from

Correct error as specified in Table 2,

"Error messages during boot-up".

errors?

Yes

the error list appear?

Yes

Yes

No

No

No

Next, * see page 4 - 13 -->

Remove memory module, clean

contact strip

(e.g. rubber eraser).

Plug memory module

in again.

Is the PC now functioning perfectly?

Yes

Unit OK.

a

No

Are the beep tones audible?

Yes

Eliminate errors as outlined in

Table 1,

"List of beep-tone error codes".

Copying a new image

(CAUTION, loss of data!).

Is the PC now functioning

perfectly again?

Yes

Unit OK.

No

No

Next,

see page 4 - 13

*

-->

a

Replace

PC

4.3 PC not booting properly II

4 - 11

4.3

Page 76

4 - 12

4.4 PC does not respond during switch-on, PC power supply does not start

PC does not respond during switchon, PC power supply does not start.

Is the yellow Standby LED at the top

right of the keyboard illuminated?

Yes

Test: Briefly connect

pin5

and

pin9

to X4 on the DECT power supply

board.

Does the PC boot now?

Yes

Keyboard, lead L3 or

lead L4 defective.

Replacement of the defective

component.

No

No

Is a voltage of 230 VAC present at the

power input of the PC?

Yes

Remove and open the PC drawer.

Check the plug connections of the

boards, the memory banks and the

No

No

CPU.

Check the fuses, connectors and

main switch.

Is the blue

cable between

the motherboard

No

and the DECT

Connect the

cable. Can the PC

be booted now?

No

power supply

ATTENTION

! Do not press against

the CPU fan. Temporarily connect the

board plugged in

at both ends?

PC power supply and leads L1, L2

and L3.

Yes

Can the PC now be booted by

pressing the ON key on the

keyboard?

Yes

Yes

Device OK.

Unit OK

Reassemble the PC, slide it into the

Reassemble the PC, slide it into the

acquisition unit and connect the

acquisition unit and connect the

cables.

cables.

Continued on next page

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

Page 77

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

Continued from previous page

a

D 3344.076.01.04.01 03.2002

58 35 694D 3344

Disconnect power cord from PC.

Unplug power supply from drives and

from auxiliary fan.

Disconnect ribbon cable for drives

from motherboard

Plug power cord back in.

Does the PC power supply start?

running?

Yes

Reconnect drives and fans in

succession.

Replace defective component

No

Disconnect power cable from PC.

Remove all boards except for the

graphic card and the DECT power

supply board.

Plug the power cable back in to the

PC.

Does the PC power supply start

running this time?

Yes

Reinstall boards in succession.

Replace defective board.

Reconnect PC.

No

Connect a replacement power supply

to the motherboard and plug in the

power cord.

Does the PC power supply start

running this time?

Yes

Reassemble PC with

replacement power supply.

Install PC in acquisition unit.

No

Replace complete PC.

4.4 PC does not respond when switched on, PC power supply does not start

4 - 13

4.4

Page 78

4 - 14

4.5 Further PC faults

Case of defect/fault How to detect / measure to take

COM port not functioning Try replacing the radio interface with a cable connection.

If this fails, check whether the COM port is enabled in the BIOS. If it is, replace the PC.

No mouse pointer displayed on screen Trackball defective or not connected.

No keyboard input possible Keyboard (keyboard controller) defective or improperly connected.

Check to make sure this fault is not due to bent plug contacts.

Network can not be accessed LED "10" or LED "100" on the slot plate of the network card must always be illuminated green. If not:

• The network cable between the network card and the hub / switch is defective.

• Hub / switch defective (check whether other PCs connected to hub / switch can access the network).

• Network card defective

The "TX Data Act" LED flashes during data communication via the network.

CD-ROM / DVD-ROM missing in list of system

drives (Explorer)

No audio playback Only a musical CD or only a wave file can not be played back:

Data cable and/or voltage supply disconnected and/or defective.

If this is not the case, the drive is defective. Test via BIOS: It must be possible to select the drive.

• Check the software settings.

• Wrong sound card driver installed.

• Cable between CD-ROM / DVD-ROM drive and sound card loose or defective.

• Sound card defective.

• CD-ROM / DVD-ROM drive defective.

No audio playback at all: No audio playback at all:

Test: Connect loudspeaker directly to sound card without the amplifiers on the DECT power supply board. If an audio playback occurs

then, check the cables to and from the DECT power supply board. Then replace these cables or the DECT power supply board if

necessary. If the sound playback functions without the DECT power supply board: Then the loudspeakers (including the lead) or the

sound card are/is defective, or there is an error in the software setting, or the wrong driver was installed for the sound card.

Warning on monitor indicating that fan RPM is too

low

Check whether the fan brushes against an obstruction. If not, replace the fan. If replacement of the fan does not eliminate fault, replace

thePC. In this case, there is probably a defect on the motherboard.

D 3344.076.01.04.02 03.2002

58 35 694 D 3344

Page 79

If the image on the monitor flickers, a distinction must be made between two causes:

a) Flickering of the image brightness and

b) Flickering of the image due to incorrectly set monitor parameters

Adjustment of monitor parameters (all types except PV751)

D 3344.076.01.04.01 03.2002

58 35 694D 3344

• Select the mode

• Press the

The monitor then automatically sets the adjustment parameters.

• Then exit the

The monitor is now correctly adjusted.

For

type PV751

• Set image brightness to

• Set contrast to

If the monitor still flickers following both of these checks, you must then replace

• the monitor (if monitor type PV751 is not involved) and/or

• the assembly "power supply, complete" REF 58 09 889, Rep 58 65 550 (see Chapter ‘6.1.5 Complete power supply unit” ).

SELECT/AUTO

"Quit Windows"

monitors only (see name plate on rear side of monitor):

Start ÖExit in Windows.

Ö

monitor button twice in succession while in this mode.

window with

maximum value of 130

maximum value of 140

"Cancel"

.

4.6 Monitor image flickering

4 - 15

4.6

Page 80

4 - 16

F2

Voltage supply

Monitor

DV

VGA

up to HW Version AB

from HW Version AC

F4

F4

Page 81

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

• Are the power supply and the VGA cable connected to the monitor?

• Is the monitor switched on (LED to the right of the ON switch is red or green)?

• Is the PC switched on (LED above the ON button is green)?

• Switch off the monitor and switch it on again after a few moments.

D 3344.076.01.04.01 03.2002

58 35 694D 3344

Monitor dark?

Yes

Is the LED on the

monitor green or red?

Yes

Is the LED

on the

monitor

?

green

Yes

Yes

Is the LED

on the

monitor

red

Yes

No

Press the "Y" and "S" keys to switch on the monitor.

No

Replace monitor

Does monitor carry out a self-test?

Switch off the monitor and disconnect the VGA cable.

Yes

Device OK. Reconnect VGA cable

No

Is the

monitor

ON

Yes

switched

?

No

Switch monitor on. Unit OK.

from HW Version AC

to Hardware Version

Disconnect the power

supply cable and check

for 12V.

No

12V present?

?

Yes

Replace monitor

Check and replace F2 fuse on

p.c.b. (DECT supply board).

DP

Monitor screen ON?

Yes

Unit OK

No

Replace DECT DP

power supply board.

Monitor screen ON?

Yes

Unit OK

No

Replace PC

power supply

Replace

monitor

Check VGA cable.

OK?

Yes

Replace PC drawer

4.7 No monitor display

4 - 17

No

Replace VGA cable.

4.7

Page 82

4 - 18

Page 83

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.01 03.2002

58 35 694D 3344

• In Windows, select

is set to between 56Hz and 75Hz.

• When the resolution is set to exactly 1024x768 (VESA XGA), press the SELECT/AUTO button twice to automatically adjust the monitor to the correct setting.

If this does not happen, replace the monitor.

• When using screen resolutions lower than 1024x768 (VESA XGA): Press the MENU button.

Then press the SELECT/AUTO key

If this is not possible, replace the monitor.

START -> SETTINGS-> CONTROL PANEL> DISPLAY-> SETTINGS

once.

Select

for Full screen mode.

to check that the resolution is

set to above 1024X768 (VESA XGA) and that the refresh rate

not

4.8 Incorrect monitor display format size

4 - 19

4.8

Page 84

4 - 20

Brightness

Contrast

Page 85

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.01 03.2002

58 35 694D 3344

• Check Windows color pallet setting in the

In the color pallet, a setting between 16Bit (High Color = 65536 colors) and 24Bit (True Color = 16777216 colors) must be selected (only applies to 3dfx Voodoo3 graphics card). If other

graphics cards are used, the color pallet setting must be > 16Bit.

• Adjust the monitor brightness to 140 and the contrast to 130.

Start -> Settings -> Control -> Display -> settings

.

Poor color shading/

gray scale?

Yes

Replace VGA cable.

Poor color shading/

gray scale?

Yes

No

Unit OK

Replace monitor.

Poor color shading/

gray scale?

No

Unit OK

Yes

Replace PC drawer.

4.9 Monitor: Color shade/gray scale is too weak

4 - 21

4.9

Page 86

4 - 22

PS/2 plug

Trackball

PS/2 plug

Keyboard

Trackball

Page 87

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

D 3344.076.01.04.01 03.2002

58 35 694D 3344

Switch device OFF and

ON again.

Is the trackball

Yes

Unit OK

No

functioning?

Is the PS/2 plug for

the trackball properly

connected?

Keyboard

Yes

Yes

No

Have the PS/2 plugs

for the keyboard and

the trackball been

switched?

Swap PS/2 plugs.

Device OK.

Connect trackball PS/2

No

Trackball functioning?

Yes

plug correctly.

Yes

Unit OK

No

No

Attach replacement

trackball or mouse to

the PC drawer with a

PS/2 plug and test.

Trackball/Mouse

functioning?

Yes

Replace trackball

No

Replace

PC drawer

4.10Trackball not functioning

4 - 23

4.10

Page 88

4 - 24

Keyboard

board

TT

L7

L3

DP

Page 89

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

• Check whether trackball is functioning

• Disconnect the pedal and reboot the PC.

• Check continuity of keyboard board lead L3 (between DECT supply board DP and keyboard board TT).

• Check trackball power supply.

D 3344.076.01.04.01 03.2002

58 35 694D 3344

Check for short circuits of the two pedal

sockets and the pedal

Short circuit occurred?

Yes

Replace pedal or lead L3 between DECT

supply board DP and keyboard board

TT

Trackball buttons functioning?

Yes

Unit OK

Check continuity on L7 keyboard cable

between trackball and keyboard board.

No

OK?

Yes

Replace keyboard board

TT

No

Repair lead L7 or

Replace trackball

.

No

Replace keyboard board

TT

4.11Trackball buttons not functioning

4 - 25

4.11

Page 90

4 - 26

Right-handed

Left-handed

Pedal lead

L8

Page 91

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

• Refer to "Changing from Right-Handed to Left-Handed Operation" in the Operating Instructions for the Acquisition Unit.

Software changeover via

• Is the plug of pedal lead L8 connected properly?

• Is the pedal not mechanically obstructed?

Start -> Settings -> Control -> Mouse

Pull off the plug L8.

Both trackball buttons

functioning?

No

Both trackball buttons

functioning?

Yes

.

No

Replace keyboard board (TT)

D 3344.076.01.04.01 03.2002

58 35 694D 3344

Yes

Repair/replace pedal lead

(Microswitch, compl.)

Repair/replace pedal lead

(Microswitch, compl.)

4.12Pedal not functioning

4 - 27

4.12

Page 92

4 - 28

Keyboard

PS/2 plug

Trackball

PS/2 plug

Keyboard

L3 DECT

Page 93

CAUTION: Switch OFF the unit before connecting a measuring instrument or replacing parts!

• Check whether the trackball and keyboard PS/2 plugs are properly connected to the PC drawer and not in the wrong sockets (switched).

• Check continuity on L3 cable to the keyboard board.

D 3344.076.01.04.01 03.2002

58 35 694D 3344

LED above ON button

green

Yes

?

Replace keyboard

No

Check the supply voltages at the

output socket of the DECT power

supply board (X4.1: +5V and

X4.2:+12V).

Supply voltage OK?

Yes

Check the supply voltages at the

PS/2 output socket

(PIN 4: +5V and PIN 3: GND) on the

PC drawer.

Supply voltage OK?