SHARP 21V1-L Diagram

SERVICE MANUAL

COLOUR TELEVISION

Chassis No. GA6

21V1-L

In the interests of user safety (Required by safety regulations in some countries) the set should be restored to its original

condition and only parts indentical to those specified should be used.

S8811021V1L

MODEL

ELECTRICAL SPECIFICATIONS

Chassis No. GA8

CONTENTS

IMPORTANT SERVICE SAFETY PRECAUTION ................................................................................................... 1-1

Page

LOCATION OF USER’S CONTROL ...................................................................................................................... 2-1

INSTALLATION AND SERVICE INSTRUCTIONS ................................................................................................. 3-1

SERVICE MODE ..................................................................................................................................................... 4-1

ADJUSTMENT METHOD ........................................................................................................................................ 5-1

WAVEFORMS ......................................................................................................................................................... 6-1

CHASSIS LAYOUT ................................................................................................................................................. 7-1

BLOCK DIAGRAM .................................................................................................................................................. 8-1

DESCRIPTION OF SCHEMATIC DIAGRAM .......................................................................................................... 9-1

SCHEMATIC DIAGRAMS ......................................................................................................................................10-1

PRINTED WIRING BOARD ASSEMBLIES ........................................................................................................... 11-1

Parts Guide

POWER INPUT............................AC 110-220 V, 50/60 Hz

POWER RATING .....................................................76W

PICTURE SIZE .............................1,239 cm

2

(192sq inch)

CONVERGENCE ............................................. Magnetic

SWEEP DEFLECTION .................................. .. Magnetic

FOCUS ......................................................... Electrostatic

INTERMEDIATE FREQUENCIES

Picture IF Carrier Frequency ...................... 45.75 MHz

Sound IF Carrier Frequency ...................... 41.25 MHz

Color Sub-Carrier Frequency ......................42.17 MHz

(Nominal)

AUDIO POWER

OUTPUT RATING... ...................... 3.0 W(RMS) x 1pc

SPEAKER

SIZE ........................................................ 2” X 3.5”, 1pc

VOICE COIL IMPEDANCE .................16 ohm at 400 Hz

ANTENNA INPUT IMPEDANCE

VHF/UHF ........................................75 ohm Unbalanced

TUNING RANGES

VHF-Channels ................................................. 2 thru 13

UHF-Channels ................................................14 thru 69

CATV Channels ............................................. 1 thru 125

(EIA, Channel Plan U.S.A.)

Specifications are subject to change without

prior notice.

SHARP CORPORATION

This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

21V1-L

21V1-L

1 – 1

TV21V1-LService Manual21V1-LMarketE

CHAPTER 1. IMPORTANT SERVICE SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and the servicing guidelines which follow:

X-RADIATION AND HIGH VOLTAGE LIMITS

1. Be sure all service personnel are aware of the

procedures and instructions covering X-radiation.

The only potential source of X-ray in current solid

state TV receivers is the picture tube. However, the

picture tube does not emit measurable X-Ray

radiation, if the high voltage is as specified in the

"High Voltage Check" instructions.

It is only when high voltage is excessive that X-

radiation is capable of penetrating the shell of the

picture tube including the lead in the glass material.

The important precaution is to keep the high voltage

below the maximum level specified.

2. It is essential that servicemen have available at all

times an accurate high voltage meter.

The calibration of this meter should be checked

periodically.

3. High voltage should always be kept at the rated value

−no higher. Operation at higher voltages may cause

a failure of the picture tube or high voltage circuitry

and;also, under certain conditions, may produce

radiation in exceeding of desirable levels.

4. When the high voltage regulator is operating properly

there is no possibility of an X-radiation problem.

Every time a color chassis is serviced, the brightness

should be tested while monitoring the high voltage

with a meter to be certain that the high voltage does

not exceed the specified value and that it is regulating

correctly.

5. Do not use a picture tube other than that specified

or make unrecommended circuit modifications to the

high voltage circuitry.

6. When trouble shooting and taking test

measurements on a receiver with excessive high

voltage, avoid being unnecessarily close to the

receiver.

Do not operate the receiver longer than is necessary

to locate the cause of excessive voltage.

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

3. Semiconductor heat sinks are potential shock

hazards when the chassis is operating.

4. The chassis in this receiver has two ground systems

which are separated by insulating material. The non-

isolated (hot) ground system is for the B+ voltage

regulator circuit and the horizontal output circuit. The

isolated ground system is for the low B+ DC voltages

and the secondary circuit of the high voltage

transformer.

To prevent electrical shock use an isolation

transformer between the line cord and power

receptacle, when servicing this chassis.

SERVICING OF HIGH VOLTAGE SYSTEM

AND PICTURE TUBE

When servicing the high voltage system,

remove the static charge by connecting a

10k ohm resistor in series with an insulated

wire (such as a test probe) between the pic-

ture tube ground and the anode lead. (AC

line cord should be disconnected from AC

outlet.)

1. Picture tube in this receiver employs integral

implosion protection.

2. Replace with tube of the same type number for

continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing

shatterproof goggles and after discharging the high

voltage anode completely.

21V1-L

1 – 2

SAFETY NOTICE

Many electr ical and mechanical parts in television

receivers have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by "

"

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams.

IMPORTANT SERVICE SAFETY PRECAUTION

(Continued)

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

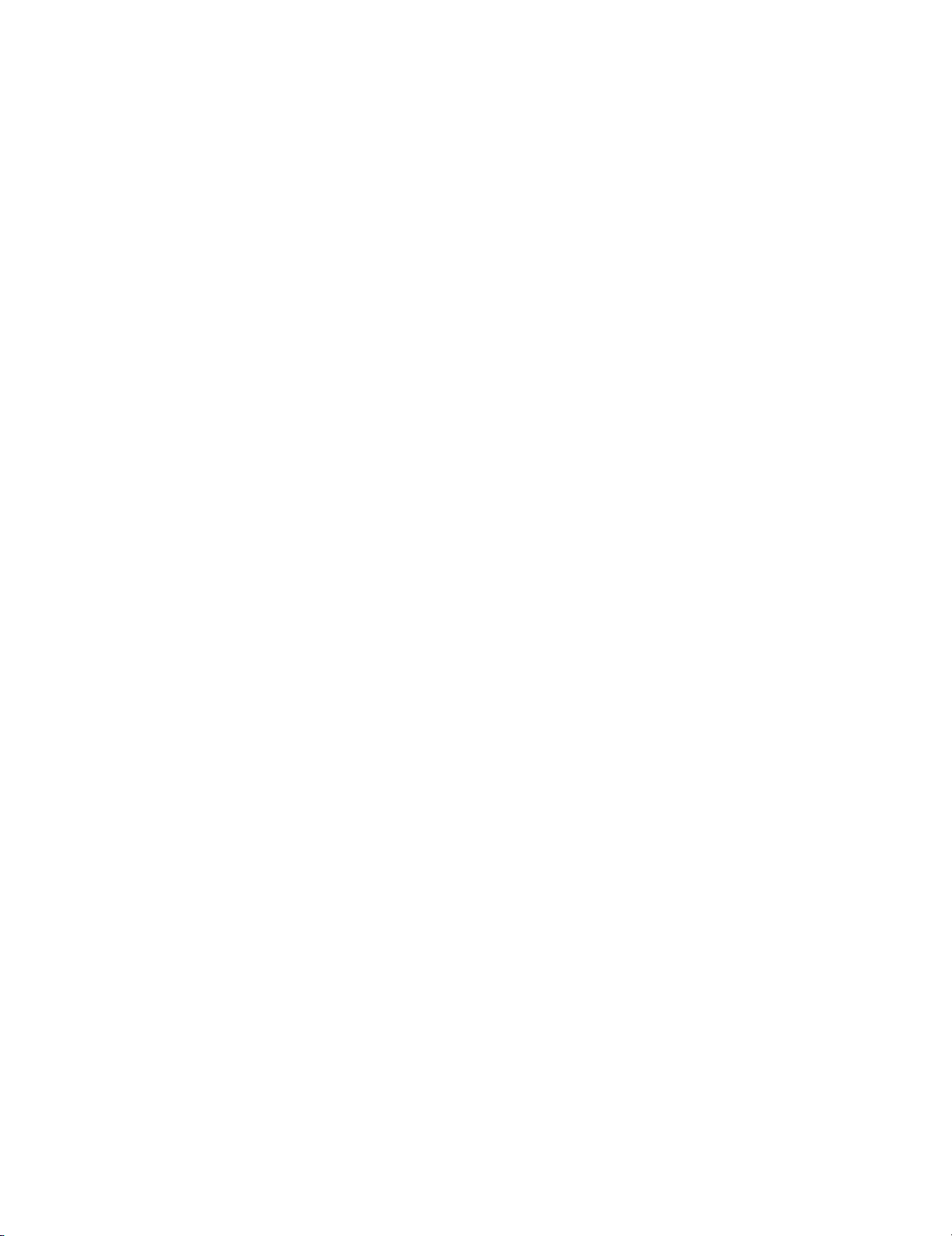

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

Plug the AC cord directly into a 110~220 volt AC

outlet, (Do not use an isolation transformer for this

test).

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as electrical conduit or electrical

ground connected to earth ground.

Use an AC voltmeter having with 5000 ohm per volt,

or higher, sensitivity to measure the AC voltage drop

across the resistor.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks.

Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

AII checks must be repeated with the AC line cord

plug connection reversed. (If necessary, a non-

polarized adapter plug must be used only for the

purpose of completing these check.)

Any current measured must not exceed 0.5 milliamp.

Any measurements not within the limits outlined

above indicate of a potential shock hazard and

corrective action must be taken before returning the

instrument to the customer.

For continued protection, replacement parts must be

identical to those used in the or iginal circuit. The use of

substitute replacement parts which do not have the same

safety characteristics as the factory recommended

replacement parts shown in this service manual, may

create shock, fire, X-radiation or other hazards.

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

•

•

•

•

21V1-L

2 – 1

TV21V1-LService Manual21V1-LMarketE

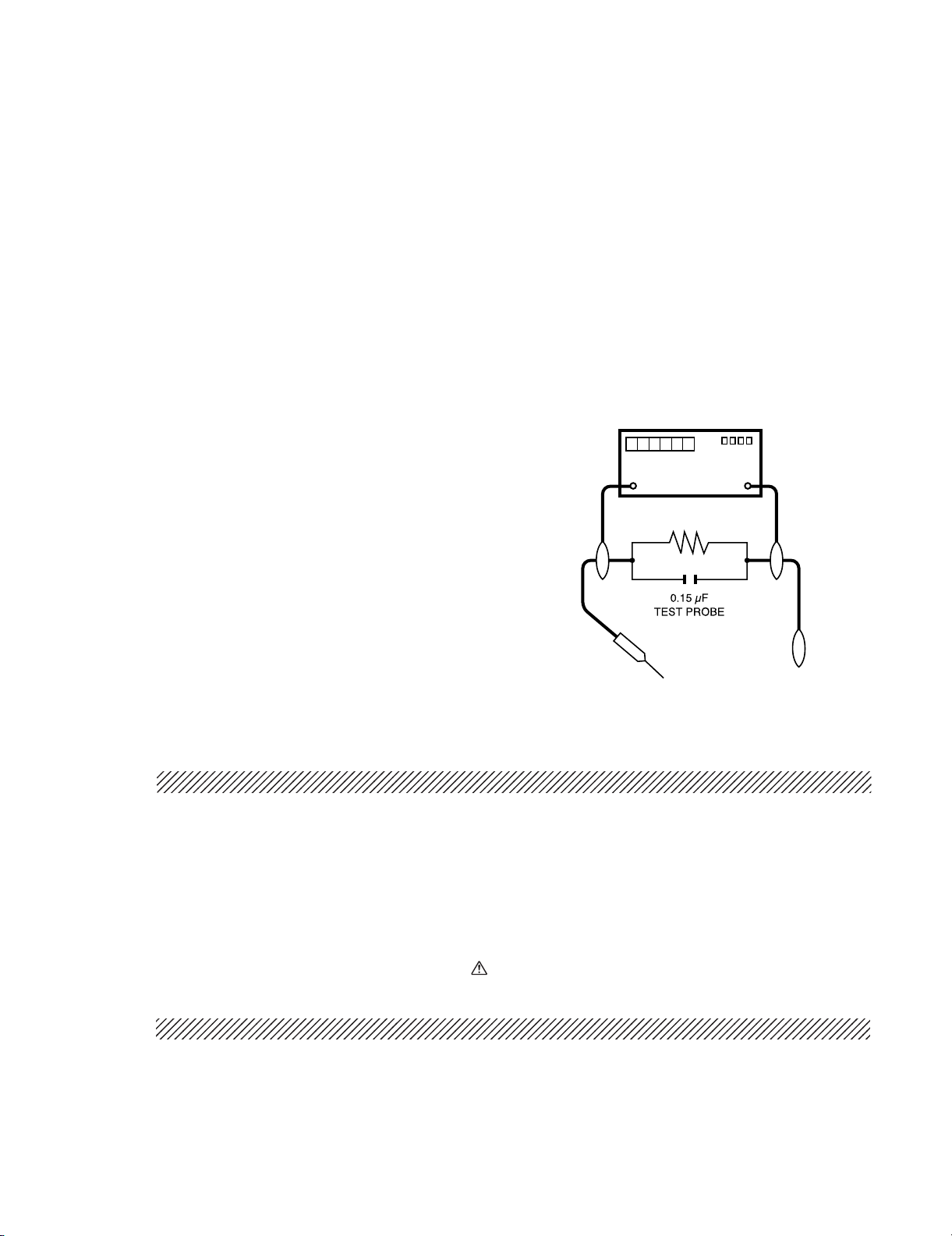

CHAPTER 2. LOCATION OF USER'S CONTROL

[1] LOCATION OF USER'S CONTROL

21V1-L

3 – 1

TV21V1-LService Manual21V1-LMarketE

CHAPTER 3. INSTALLATION AND SERVICE INSTRUCTIONS

CIRCUIT PROTECTION

The receiver is protected by a 3.15A fuse (F701),

mounted on PWB-A, wired into one side of the AC

line input.

X-RADIATION PROTECTOR CIRCUIT TEST

After service has been performed on the horizontal

deflection system, high voltage system, B+ system,

test the X-Radiation protection circuit to ascertain

proper operation as follows:

1. Apply 110~220V AC using a variac transformer for

accurate input voltage.

2. Allow for warm up and adjust all customer controls

for normal picture and sound.

3. Receive a good local channel.

4. Connect a digital voltmeter to C602 +ve and make

sure that the voltmeter reads 20 ±1.1V.

5. Apply external 27V DC at C602 +ve by using an

external DC supply, TV must be shut off.

6. To reset the protector, unplug the AC cord and make

a shor t circuit between C602 -ve and C602 +ve.

Now make sure that normal picture appears on the

screen.

7. If the operation of the horizontal oscillator does not

stop in step 5, the circuit must be repaired before the

set is returned to the customer.

HIGH VOLTAGE CHECK

High voltage is not adjustable but must be checked

to verify that the receiver is operating within safe

and efficient design limitations as specified checks

should be as follows:

1. Connect an accurate high voltage meter between

ground and anode of picture tube.

2. Operate receiver for at least 15 minutes at 110~220V

AC line voltage, with a strong air signal or a properly

tuned in test signal.

3. Enter the service mode and set Y-mute ON by using

Service R/C.

4. The voltage should be approximately 27.5kV (at zero

beam).

If a correct reading cannot be obtained, check circuitry

for malfunctioning components. After the voltage test,

make Y-mute off to the normal mode.

INSTALLATION AND SERVICE INSTRUCTIONS

Note: (1) When performing any adjustments to resistor controls and transformers use non-metallic

screwdrivers or TV alignment tools.

(2) Before performing adjustments, the TV set must be on at least 15 minutes.

21V1-L

4 – 1

TV21V1-LService Manual21V1-LMarketE

CHAPTER 4. SERVICE MODE

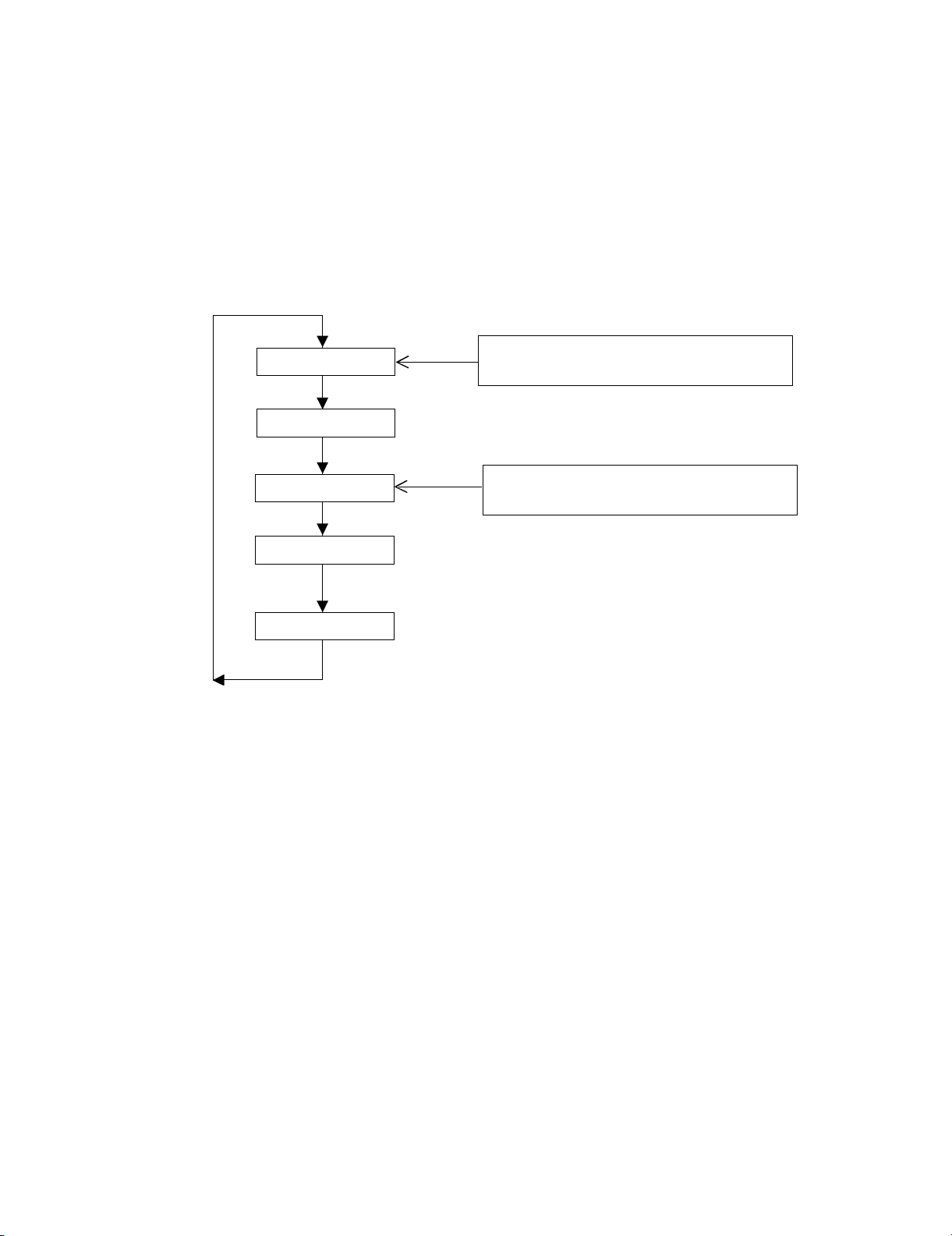

SERVICE MODE

Adjustment mode

Setting mode

First mode of service when entering by

SERVICE key.

First mode of service when entering by

2 local keys.

Option mode

Confirmation mode

1. Service mode is switched by SERVICE key, CH UP + VOL DOWN when reset.

2. Service mode is c ancelled by SERVICE key during Service mode.

3. Service mode can be switched to the following 5 modes via MENU k ey:

4䋮During Service mode, AFT operation is prohibited. The setting data for PLL is always set to fo data.

5䋮During Service mode, the following user data are set to default value and stored as last memory.

PICTURE䋯TINT䋯COLOR䋯BRIGHT䋯SHARP䋯COLOR TEMP.

BASS䋯TREBLE䋯BALANCE䋯MTS䋯FAO䋯SPEAKER䋯ENERG Y SAVE

6䋮During Service mode, OSD display for ON/OFF is toggled via [CH CALL] key.

䊶At display OFF condition, if changing adjustment data, channel, input source, it remains display OFF.

䊶At display OFF condition, if changing adjustment item, it returns to display ON.

7䋮During Service mode, the following operation are prohibited.

CLOSED CAPTION䋯No si gnal BLUE SCREEN

8䋮During Service mode, sound is muted(only MTSIC) except when selecting the following items.

V24, M01

NVM Edit mode

21V1-L

4 – 2

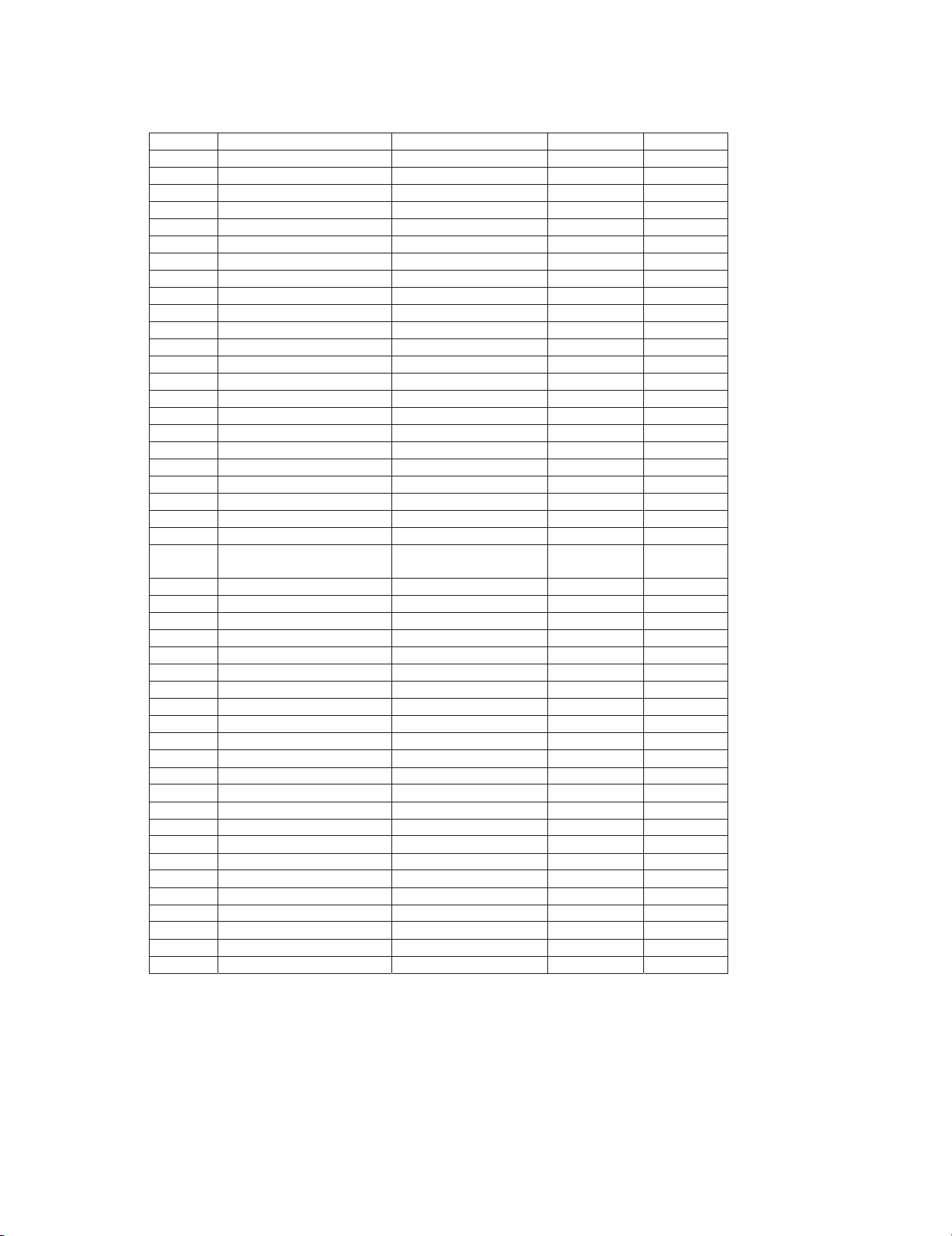

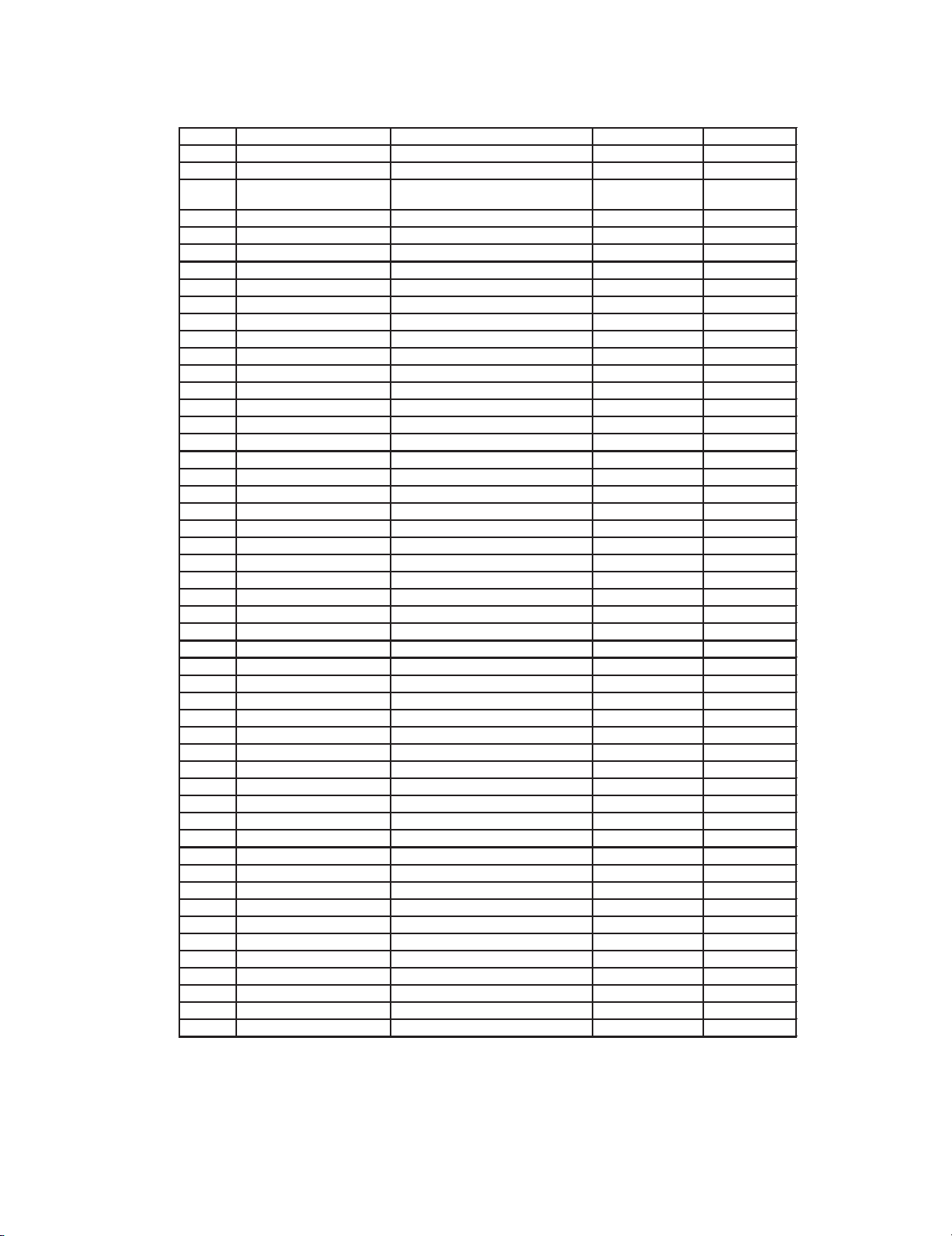

Adjustment Mode Items

Data Service Mode Function Range Default Data

V01 SUB-CON CONTRAST 0~127 127

V02 SUB-TINT TINT 0~127 64

V03 SUB-COL COLOR 0~127 64

V04 SUB-BRI BRIGHT 0~255 128

V05 SUB-SHP-PRE VIDEO-TONE(PRE) 0~63 41

V06 SUB-SHP-OVER VIDEO-TONE(OVER) 0~63 41

V07 V-SHIFT V-SHIFT 0~7 4

V08 H-SHIFT H-PHASE 0~31 16

V09 RF-AGC RF-DELAY 0~127 127

V10 V-SIZE V-SIZE 0~63 32

V11 V-SHIFT50 V-SHIFT(OFFSET) -7~+7 0

V12 H-SHIFT50 H-PHASE(OFFSET) -15~+15 0

V13 V-SIZE50 V-SIZE(OFFSET) -31~+31 0

V14 VIF-VCO VIF-VCO 0~63 32

V15 R-CUT R-CUTOFF 0~255 127

V16 G-CUT G-CUTOFF 0~255 127

V17 B-CUT B-CUTOFF 0~255 127

V18 R-DRI R-DRIVE 0~127 64

V19 B-DRI B-DRIVE 0~127 64

V20 SUB-COLOR-YUV COLOR 0~127 64

V21 SUB-TINT-YUV BASEBAND-TINT 0~127 64

V22 CC-POS CC-POS 0~255 32

V23 SCREEN CUT OFF CUT OFF 0~2 0

V24 SUB-VOL A-ATT

0~127 (O20=0)

0~255 (O20=1)

127

255

V25 H-VCO H-VCO 0~7 4

V26 S-TRAP S-TRAP ADJ 0~127 64

V27 VS-CORRECT VS-CORRECTION 0~63 36

V28 VS-CORRECT50 VS-CORRECTION -13~+13 0

V29 V LINEARITY V-LINEARITY 0~63 35

V30 V LINEARITY50 V-LINEARITY -13~+13 0

V31 PARABOLA E/W PARABOLA 0~63 32

V32 PARABOLA50 E/W PARABOLA -13~+13 0

V33 TRAPEZIUM E/W TRAPEZIUM 0~63 32

V34 TRAPEZIUM50 E/W TRAPEZIUM -13~+13 0

V35 H-SIZE E/W H-SIZE 0~63 32

V36 H-SIZE50 E/W H-SIZE -13~+13 0

V37 UPPER CORNER E/W UPPER CORNER 0~63 32

V38 UPPER CORNER50 E/W UPPER CORNER -13~+13 0

V39 LOWER CORNER E/W LOWER CORNER 0~63 32

V40 LOWER CORNER50 E/W LOWER CORNER -13~+13 0

V41 ANGLE ADJ ANGLE ADJ 0~63 31

V42 ANGLE ADJ50 ANGLE ADJ -13~+13 0

V43 BOW ADJ BOW ADJ 0~63 31

V44 BOW ADJ50 BOW ADJ -13~+13 0

V45 S-TRAP ADJ START S-TRAP ADJ 0~127 25

V46 S-TRAP STOP S-TRAP ADJ 0~127 95

M01 MTS-ATT DIRECT OUT LEVEL ADJ 0~15 10

㩷㩷㩷㩷Note 䋱䋩 V23 = "1" … HORIZONTAL MODE

V23 = "2" … Y-MUTE MODE

㩷㩷㩷㩷Note 䋲䋩 V24䋺These registers are set to maximum value.

21V1-L

4 – 3

AUTO ADJUSTMENT

H-VCO

RF-AGC

PIF-VCO

1. When there is H-VCO auto adjustment key input at item

H-VCO, auto adjustment will be implemented.

2. H-FREE (1chip) is set to 1.

3. H-OUT (1chip) is set by intelligent monitor output.

4. IM input becomes TIM input.

5. H-VCO (1chip) data is changed so that the number is 126 inside 8ms interval.

6. When adjustment is completed, OSD display and H-VCO auto adjustment data of EERPOM are updated.

7. H-FREE

(

1chip

)

, intelli

g

ent monitor output, IM input mode are recovered.

1. If there is RF-AGC auto adjustment key input at item RF-AGC, auto adjustment will be implemented.

2. AGC-OUT (MONITOR(1chip)is set by intelligent monitor output.

3. IM input becomes AD input.

4. RF-AGC(1chip) is decreased from current RF-AGC value to 0, the maximum AFT input voltage is obtained.

5. RF-AGC(1chip) is increased until at the point of AFT input voltage is (max. 0.3V), adjustment is completed.

6. When adjustment is completed, OSD display and RFGC auto adjustment status in EEPROM are updated.

7. Intelli

g

ent monitor output, IM input mode are recovered.

1. If there is PIF-VCO auto adjustment key input at item PIF- VCO, auto adjustment will be implemented.

2. VIF-DEF (1chip) is set to 1.

3. AFT output (1chip) is set by intelligent monitor output.

4. IM input becomes AD input.

5. VIF-VCO (1chip) is changed so the input voltage becomes 2.5V.

6. When adjustment is completed, OSD display and PIF-VCO auto adjustment status in EEPROM are updated.

7. VIF-DEF

(

1chip

)

intelli

g

ent monitor output, IM input mode are recovered.

S-TRAP

1. If there is S-TRAP auto adjustment key input at item S-TRAP, auto adjustment will be implemented.

2. S-TRAP OUTPUT is set by intelligent monitor output.

3. IM input becomes AD input.

4. S-Trap (1chip) is set to the value of V45(S-TRAP ADJ Start).

5. S_Trap_Result is set to the value of V45(S-TRAP ADJ Start).

6. S-Trap (1chip) is increased until the minimum input voltage becomes minimum.

7. Wait 20ms before sampling the new_ AD_data.

8. When adjustment is completed, OSD display and S-TRAP auto adjustment status in EEPROM are updated.

9. S-TRAP

(

1chip

)

intelli

g

ent monitor output, IM input mode are recovered.

21V1-L

4 – 4

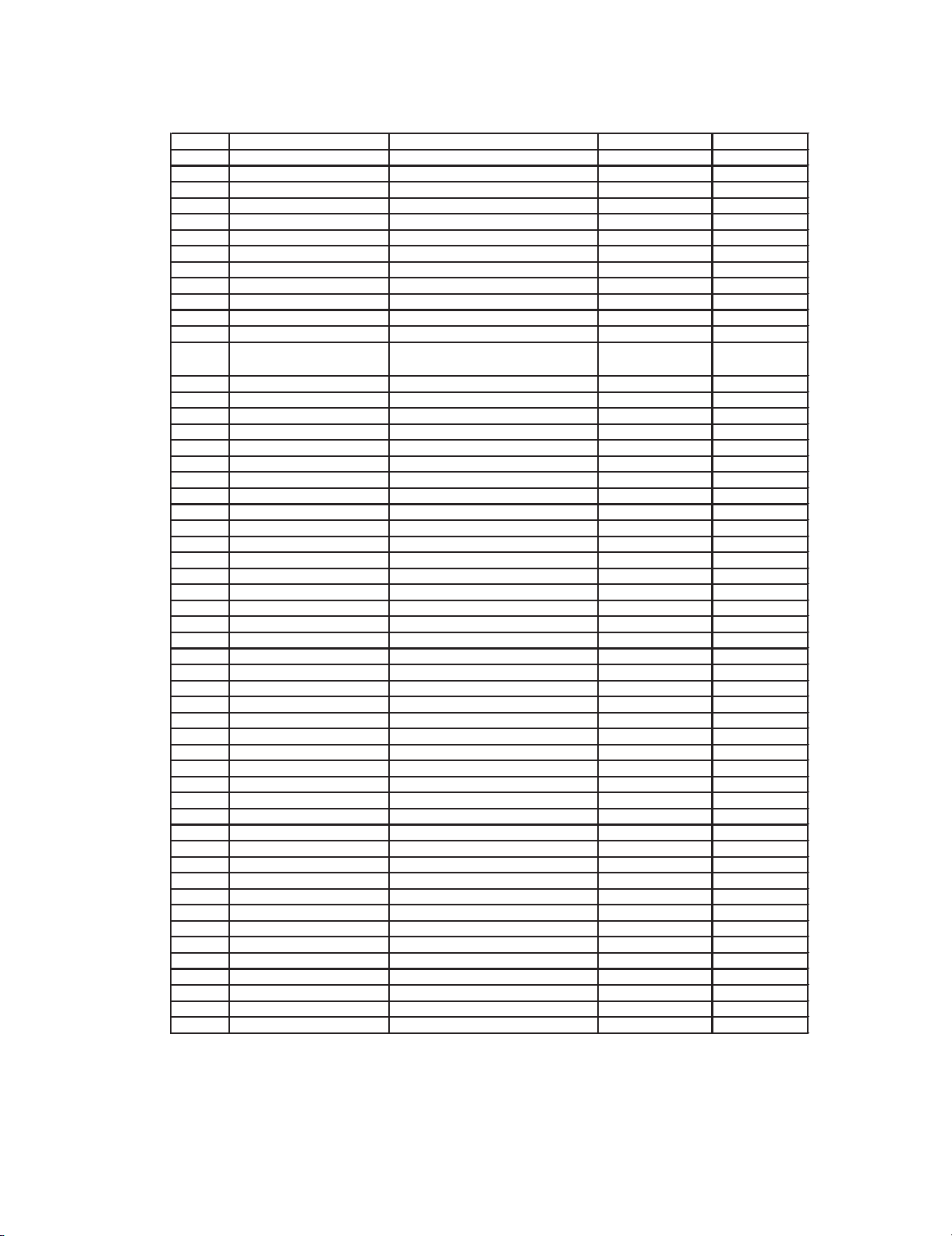

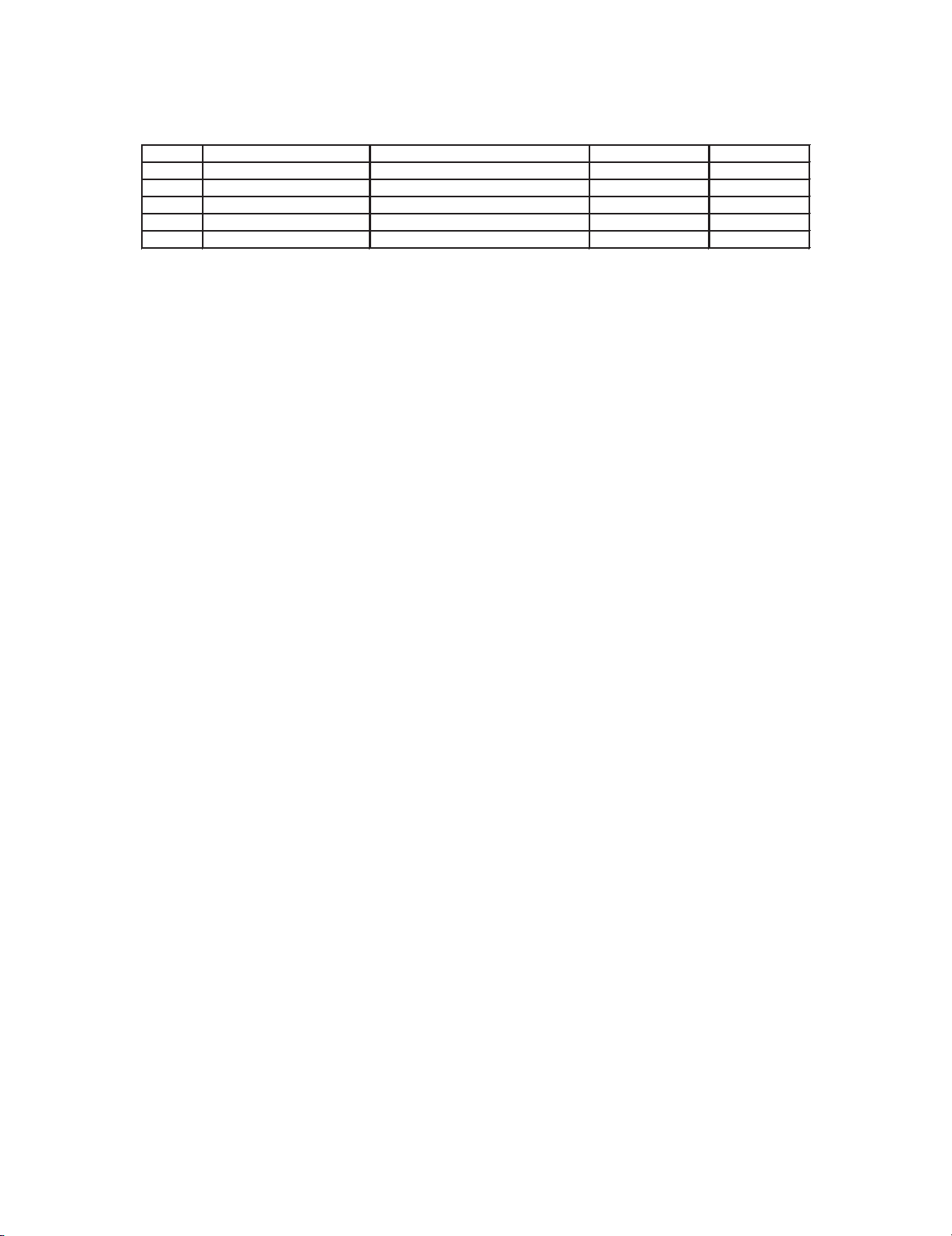

Setting Mode Items

Data Service Mode Function Range Default Data

F01 ABCL-Gain ABCL-G 0/1 0

F02 SHP-AV-PRE VIDEO-TONE (PRE) -16~+16 0

F03 SHP-YUV-PRE VIDEO-TONE (PRE) -16~+16 0

F04 SHP-P-PRE VIDEO-TONE (PRE) -31~+31 0

F05 SHP-N3-PRE VIDEO-TONE (PRE) -31~+31 0

F06 SHP-AV-OVER VIDEO-TONE (OVER) -16~+16 0

F07 SHP-YUV-OVER VIDEO-TONE (OVER) -16~+16 0

F08 SHP-P-OVER VIDEO-TONE (OVER) -31~+31 0

F09 SHP-N3-OVER VIDEO-TONE (OVER) -31~+31 0

F10

SHP ANT-ON II OFFSET

VIDEO-TONE -15~0 -10

F11 RGB-CLIP EXTRGB-CLIP 0/1 0

F12 E-SAVE CONTRAST(OFFSET) 0~63 30

F13 FAO-VOL A-ATT

0~127 (O20=0)

0~255 (O20=1)

120

246

F14 VIF-G VIF-GAIN 0~7 5

F15 YDL-TV Y-DELAY 0~7 5

F16 YDL-TV-P Y-DELAY 0~7 5

F17 YDL-TV-N3 Y-DELAY 0~7 5

F18 YDL-AV Y-DELAY 0~7 5

F19 YDL-AV-P Y-DELAY 0~7 5

F20 YDL-AV-N3 Y-DELAY 0~7 5

F21 YDL-YUV Y-DELAY 0~7 0

F22 TINT-AV TINT(OFFSET) -32~+32 6

F23 COL-AV COLOR(OFFSET) -32~+32 0

F24 COL-P COLOR(OFFSET) -31~+31 24

F25 COL-N3 COLOR(OFFSET) -31~+31 0

F26 R-R R-DRI(OFFSET) -32~+32 3

F27 R-B R-DRI(OFFSET) -32~+32 -2

F28 B-R B-DRI(OFFSET) -32~+32 -8

F29 B-B B-DRI(OFFSET) -32~+32 6

F30 GAMMA GAMMA 0~3 1

F31 BS-D BS-DISCHARGE 0~3 0

F32 BS-C BS-CHARGE 0~3 0

F33 SL-TV S-SLICE DOWN 0~7 2

F34 SL-AV S-SLICE DOWN 0~7 2

F35 SL-YUV S-SLICE DOW N 0~7 0

F36 AFC2 AFC2-G 0/1 0

F37 VD-T V VSYNC-DET 0~7 5

F38 VD-AV VSYNC-DET 0~7 7

F39 VD-YUV VSYNC-DET 0~7 1

F40 AS-TV AUTO-SLICE 0/1 1

F41 AS-AV AUTO-SLICE 0/1 1

F42 AS-YUV AUTO-SLICE 0/1 0

F43 FBP-TV FBP VTH 0/1 0

F44 FBP-AV FBP VTH 0/1 0

F45 FBP-YUV FBP VTH 0/1 0

F46 C.Clip Level C.CLIP LEVEL 0/1 0

F47 CP CP 0/1 1

F48 CC LEVEL CC LEVEL 0~31 0

F49 OSD POS-H OSD POS 0~31 0

F50 OSD POS-V50 OSD POS 1~55 38

F51 OSD POS-V60 OSD POS 1~50 23

F52 OFFSET-ADJ-COLOR COLOR -32~+32 10

F53 OFFSET-ADJ-TINT TINT -32~+32 2

F54

WAIT

㵘

MD

㵘

TIMER

(SLOW MODE) 0/1 1

21V1-L

4 – 5

F55 R-CUT-YUV R-CUT (OFFSET) -63~+63 0

F56 G-CUT-YUV G-CUT (OFFSET) -63~+63 0

F57 B-CUT-YUV B-CUT (OFFSET) -63~+63 0

F58 R-DRI-YUV R-DRI (OFFSET) -63~+63 0

F59 B-DRI-YUV B-DRI (OFFSET) - 63~+63 0

F60 CONTRAST OFFSET CONTRAST(OFFSET) -63~+63 0

F61

CONTRAST(OFFSET) -63~+63 0

F62 BRIGHT OFFSET BRIGHT (OFFSET) -63~+63 0

F63 BRIGHT AV2 OFFSET BRIGHT (OFFSET) -15~+15 1

F64 BRIGHT YUV OFFSET BRIGHT (OFFSET) -63~+63 0

F65 T RAP

TRAP-FINE 0~3 2

F66 TRAP-P

TRAP-FINE 0~3 2

F67 TRAP-N3

TRAP-FINE 0~3 2

F68 AFC1-Gain-TV

AFC1-G

0~3 0

F69 AFC1-Gain-AV

AFC1-G

0~3 3

F70 AFC1-Gain-YUV

AFC1-G

0~3 3

F71 OM-DET

OM-Det 0/1 0

F72

BS-Gain 0/1 0

F73 C-ANGLE

C.ANGLE 0/1 0

F74

V-DL Fine 0~3 0

F75

U-DL Fine 0~3 0

F76 AS-SPEED-DN

AS-SPEED-DN 0/1 0

F77 AS-SPEED-UP

AS-SPEED-UP 0/1 0

F78 CR-PEDESTEL-ADJ

Cr Pedestal Adj. 0~15 8

F79 CB-PEDESTEL-ADJ

Cb Pedestal Adj. 0~15 8

F80 SIF-BPF-W IDE

SIF BPF WIDE 0~7 3

F81 SIF-BPF-WIDE-LOW

SIF BPF WIDE LOW

0/1 0

F82 SIF-BPF-WIDE-HIGH

SIF BPF WIDE HIGH

0/1 0

F83 COL-SYSTEM

COL-SYSTEM

0: 11XX (AUTO)

1: 0011 (PAL-M)

2: 0111 (PAL-N)

3: 0110 (N358)

3

F84 Pow-Storage

CONTRAST/BRIGHTNESS

INCREASE GRADUALLY

0/1 1

F85 SIF45 GAIN DOWN

SIF45 GAIN DOWN 0/1 0

F86 S-TRAP OFF

S-Trap 0/1 1

F87 BASS OFFSET

BASS -4~+4 0

F88 MID1 OFFSET

AUDIOEQMID1 -4~+4 0

F89 MID2 OFFSET

AUDIOEQMID2 -4~+4 0

F90 MID3 OFFSET

AUDIOEQMID3 -4~+4 0

F91 TREBLE OFFSET

TREBLE -4~+4 0

F92 AVL LEVEL

AUDIO AVL LEVEL 0~3 0

F93 AVL OPTION

AVL ON

0: fix to 0

1: fix to 1

2: AVL in

SOUND MENU

2

F94 AU-ATT AMP

AU ATTOUT GAIN 0 (0dB)/1(3dB) 0

F95 OSD LEVEL

OSD LEVEL

0: 10%

1: 30%

2: 50%

3: 70%

4: 90%

3

F96 R MTX UP

RMTXUP 0/1 0

F97 MATRIX ADJ

MATRIX ADJ 0~3 0

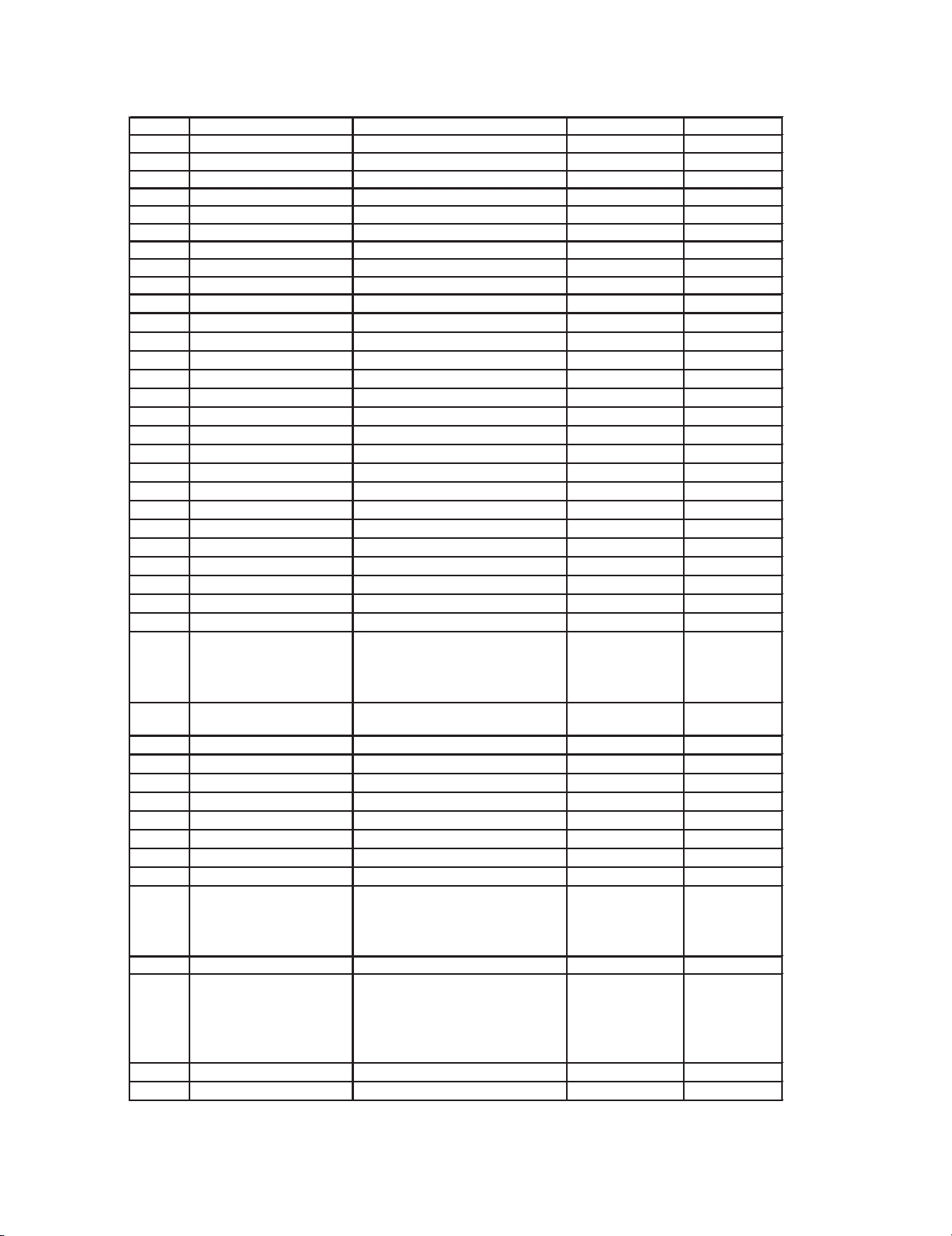

Setting Mode Items (Continued)

BS-Gain

V-DL

U-DL

21V1-L

4 – 6

Setting Mode Items (Continued)

F98 SAP LEVEL

SAP LEVEL 0/1 0

F99 STEREO SENS

STEREO SENS 0/1 0

F100 SAP SENS

SAP SENS 0/1 0

F101 MER

S-BOOSTER FREQ.

CHARACTERISTIC CONTROL

0~255 70

F102 MEL1

S-BOOSTER LEVEL1

0~255 150

F103 MEL2

S-BOOSTER LEVEL2

0~255 156

F104 MEL3

S-BOOSTER LEVEL3

0~255 163

F105 MEL4

S-BOOSTER LEVEL4

0~255 165

F106 MEL5

S-BOOSTER LEVEL5

0~255 170

F107 MEL6

S-BOOSTER LEVEL6

0~255 180

F108 S-St-Point

S-BOOSTER START POINT

0~60 21

F109 S-Sp-Point

S-BOOSTER STOP POINT

0~60 60

F110 S-Step

S-BOOSTER STEP

0~60 7

F111 CONT NEWS

CONTRAST SETTING- NEWS

0~60 40

F112 CONT MUSIC

CONTRAST SETTING- MUSIC

0~60 50

F113 CONT MOVIE

CONTRAST SETTING- MOVIE

0~60 60

F114 BRIGHT NEW S

BRIGHTNESS SETTING- NEWS

-30~+30 0

F115 BRIGHT MUSIC

BRIGHTNESS SETTING- MUSIC

-30~+30 0

F116 BRIGHT MOVIE

BRIGHTNESS SETTING- MOVIE

-30~+30 0

F117 COL NEWS

COLOUR SETTING- NEWS

-30~+30 0

F118 COL MUSIC

COLOUR SETTING- MUSIC

-30~+30 0

F119 COL MOVIE

COLOUR SETTING- MOVIE

-30~+30 10

F120 SHARP NEWS

SHARPNESS SETTING- NEWS

-30~+30 -10

F121 SHARP MUSIC

SHARPNESS SETTING- MUSIC

-30~+30 0

F122 SHARP MOVIE

SHARPNESS SETTING- MOVIE

-30~+30 5

F123 SURR NEW S

SURROUND SETTING- NEWS

0(OFF)/1(ON) 0

F124 SURR MUSIC

SURROUND SETTING- MUSIC

0(OFF)/1(ON) 0

F125 SURR MOVIE

SURROUND SETTING- MOVIE

0(OFF)/1(ON) 0

F126 T REBLE NEWS

TREBLE SETTING- NEWS

-10~+10 -10

F127 TREBLE MUSIC

TREBLE SETTING- MUSIC

-10~+10 0

F128 TREBLE MOVIE

TREBLE SETTING- MOVIE

-10~+10 5

F129 BASS NEWS

BASS SETTING- NEWS

-10~+10 -5

F130 BASS MUSIC

BASS SETTING- MUSIC

-10~+10 0

F131 BASS MOVIE

BASS SETTING- MOVIE

-10~+10 10

F132 EQ BASS NEWS

EQ BASS SETTING- NEWS

-10~+10 0

F133 EQ BASS MUSIC

EQ BASS SETTING- MUSIC

-10~+10 0

F134 EQ BASS MOVIE

EQ BASS SETTING- MOVIE

-10~+10 0

F135 EQ MID1 NEWS

EQ MID1 SETTING- NEW S

-10~+10 0

F136 EQ MID1 MUSIC

EQ MID1 SETTING- MUSIC

-10~+10 0

F137 EQ MID1 MOVIE

EQ MID1 SETTING- MOVIE

-10~+10 0

F138 EQ MID2 NEW S

EQ MID2 SETTING- NEW S

-10~+10 0

F139 EQ MID2 MUSIC

EQ MID2 SETTING- MUSIC

-10~+10 0

F140 EQ MID2 MOVIE

EQ MID2 SETTING- MOVIE

-10~+10 0

F141 EQ MID3 NEW S

EQ MID3 SETTING- NEW S

-10~+10 0

F142 EQ MID3 MUSIC

EQ MID3 SETTING- MUSIC

-10~+10 0

F143 EQ MID3 MOVIE

EQ MID3 SETTING- MOVIE

-10~+10 0

F144 EQ TRE NEWS

EQ TRE SETTING- NEW S

-10~+10 0

F145 EQ TRE MUSIC

EQ TRE SETTING- MUSIC

-10~+10 0

F146 EQ TRE MOVIE

EQ TRE SETTING- MOVIE

-10~+10 0

F147 S-BOOST NEW S

S-BOOSTER SETTING- NEWS

0(OFF)/1(ON) 0

F148 S-BOOST MUSIC

S-BOOSTER SETTING- MUSIC

0(OFF)/1(ON) 1

F149 S-BOOST MOVIE

S-BOOSTER SETTING- MOVIE

0(OFF)/1(ON) 1

21V1-L

4 – 7

Setting Mode Items (Continued)

F150 CORNER UP-LOW EN EW CNUPLOW EN 0/1 1

F151 BOW /ANGLE-ON/OFF BOW/ANGLE 0(OFF)/1(ON) 1

F152 SHP-NR-OFFSET VIDEO TONE -15~0 0

F153 V-FREE60 V-FREE60 0/1 1

F154 TAKEOFF TV TAKE-OFF 0/1 0

F155 STRAP OFFSET S-TRAP ADJ -16~+16 0

21V1-L

5 – 1

TV21V1-LService Manual21V1-LMarketE

CHAPTER 5. ADJUSTMENT METHOD

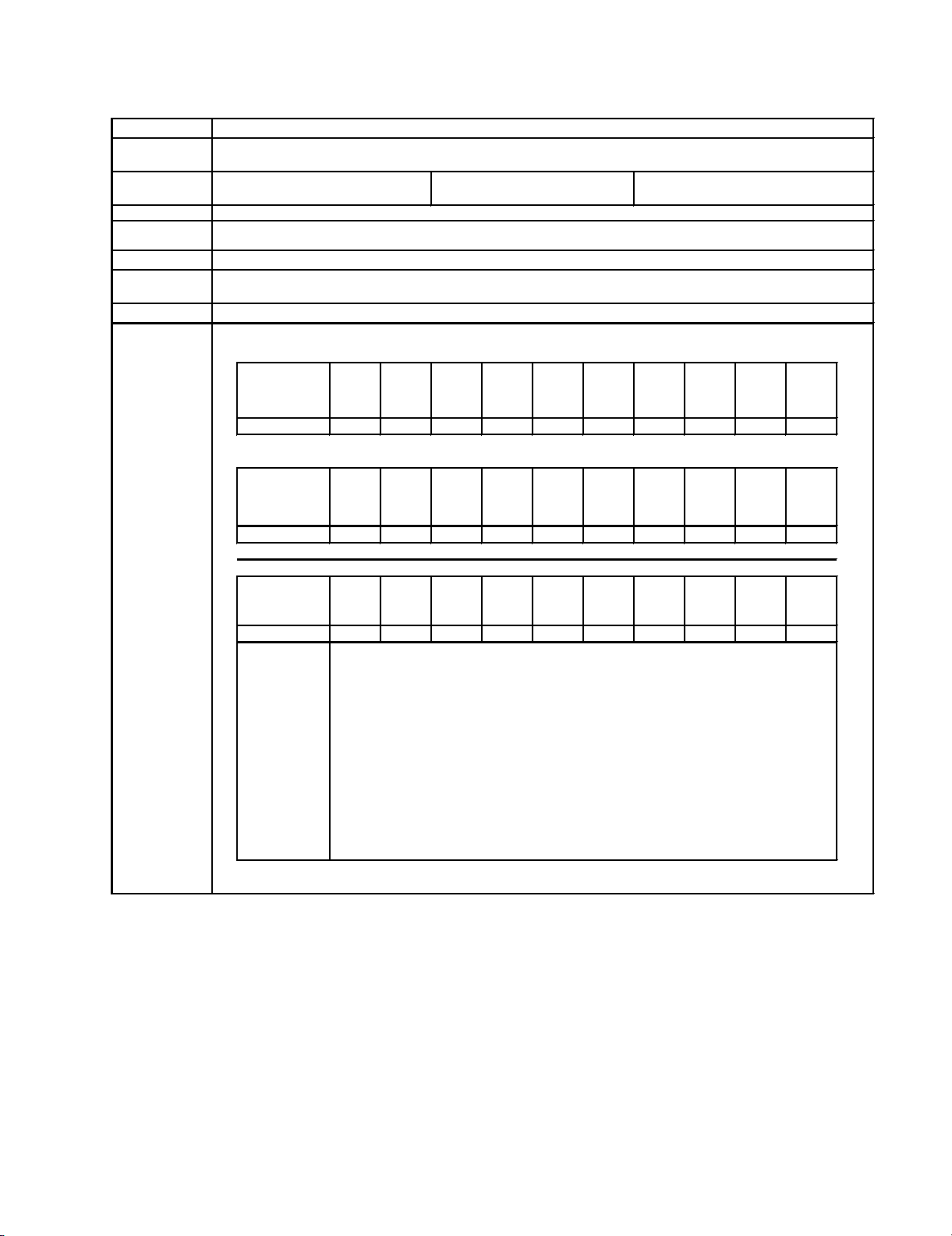

MODEL NAME

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INPUT

CONDITION

OUTPUT

BUS OPTION

FOR THIRD STAGE SERVICE DATA

ADJUSTMENT FUNCTION

O01 O02 O03 O04 O05 O06 O07 O08 O09 O10

PROCEDURE

LNA FAO PON-CH

ANT-

BOOSTER

AV AV2 MTS COMP

TONE-CTRL AUTO- OFF

21V1-L 0010110001

FUNCTION

O11 O12 O13 O14 O15 O16 O17 O18 O19 O20

LAST

POWER

SETUP

FLAG

AV MODE MP IN

S-

BOOSTER

F-COL INIT LANG

LANG SEL

ARROW

KEY

VOL-TABLE

21V1-L 0100001100

FUNCTION

O21 O22 O23 O24 O25 O26 O27 O28

AUTO

JUDGMENT

WHITE-OUT

H-SYNC

JUDGE

CHSET

COLOR

DEMO FLAT F/R-AV SPEAKER

21V1-L 10101030

DEF

"0"= DISABLE

O04 --> "0"= WITHOUT ANTENNA BOOSTER "1"= W ITH ANTENNA BOOSTER

O06 --> "0"=AV1 "1"= AV2

O08 --> "0"=COMP DISABLE "1"=COMP (INPUT) "2"=COMP (INDIVIDUAL)

O09 --> "0"=WITHOUT SOUND MENU "1"= WITH TONE "2" WITH EQUALIZER

O12 --> "0"=NO SETUP "1"=AUTO SETUP

O17 --> "0"=ENGLISH "1"=SPANISH "2"=PORTUGESE

O18 --> "1"=SPANISH "2"=FRENCH "4"=PORTUGESE

O19 --> "0"=VOL+/- "1"= /

O20 --> "0"=7 BIT VOLUME TABLE "1"=8 BIT VOLUME TABLE

O21 --> "0"=EZ SETUP SAME AS GA6 BRAZIL "1"=EZ SETUP SAME AS GA6 LAG

O27 --> "0"=NO AV "1"=REAR "2"=FRONT "3"=REAR & FRONT

ˉ

ˉ

OSD CHECKING

"1"=ENABLE

21V1-L

OPTION SET UP

REFER AS BELOW

STEP RANGE

REFER AS BELOW

ˉ

21V1-L

5 – 2

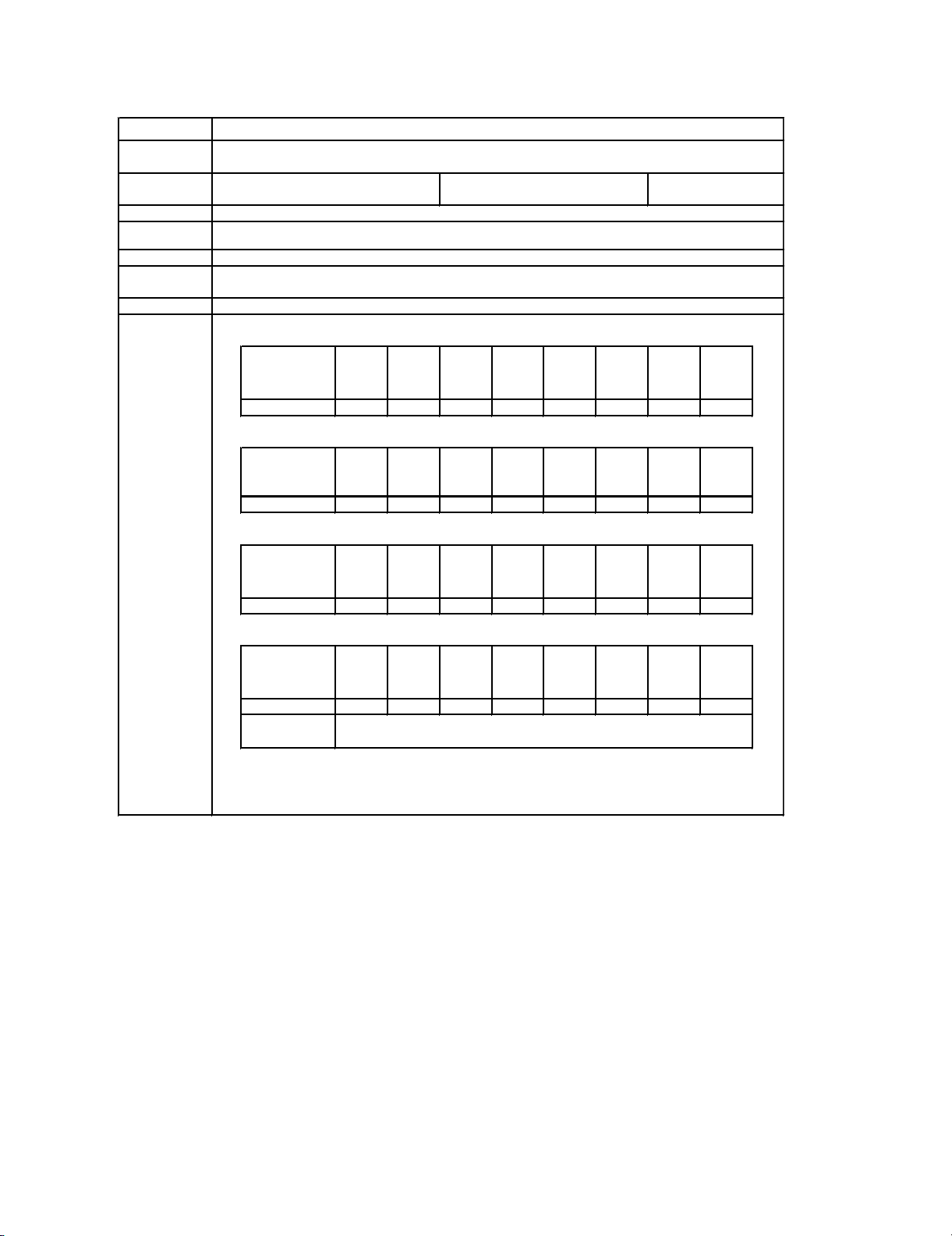

MODEL NAME

ADJ US TMENT

ITE M

ADJ US TMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INP UT

CONDITION

OUTPUT

DATA SE TUP

FOR FIRSTANDSECONDSTAGESERVICEDATA

ADJUS TMENT FUNCTION

V05 V06 V27 V29

F02 F06

F14 F22

PROCEDURE

SHARP

(PR E)

SHARP

(OVER)

VS C O R V- LIN

SHP-AV-PRE

S HP - AV-

OVER

VIF -G T INT -AV

21V1-L 42 37 44 40 -5 -5 4 -9

FUNCTION

F23F26F27F28F29F30F33F37

COL-AV R-R R-B B-R B-B GAMMA SL-TV VD-TV

21V1-L +1 0 +7 0 -20 +9 3 1 1

FUNCTION

F38F39F49F50F51F52F53F63

VD-AV VD-YUV O S D P O S - H

OSD POS-

V50

OSD-POS-

V60

OFFSET-ADJ

COL

OFFSET-ADJ

TINT

BRI AV2

OFFSET

21V1-L 2 0 17 48 30 +15 +9 +3

FUNCTION

F65 F80 F86 F93

TRAP

SIF-BPF-

WIDE

S-TRAP OFF AVL OPTION

21V1-L 0101

DEF

BUS SET UP

REFER AS BELOW

STEP RANGE

21V1-L

䋭

OSD CHECKING

䋭

䋭

REFER AS BELOW

21V1-L

5 – 3

ADJ US T ME N T

ITE M

ADJ US T ME N T

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INP UT

CONDITIO N

OUTPUT

ADJ US TMENT

PROCEDURE

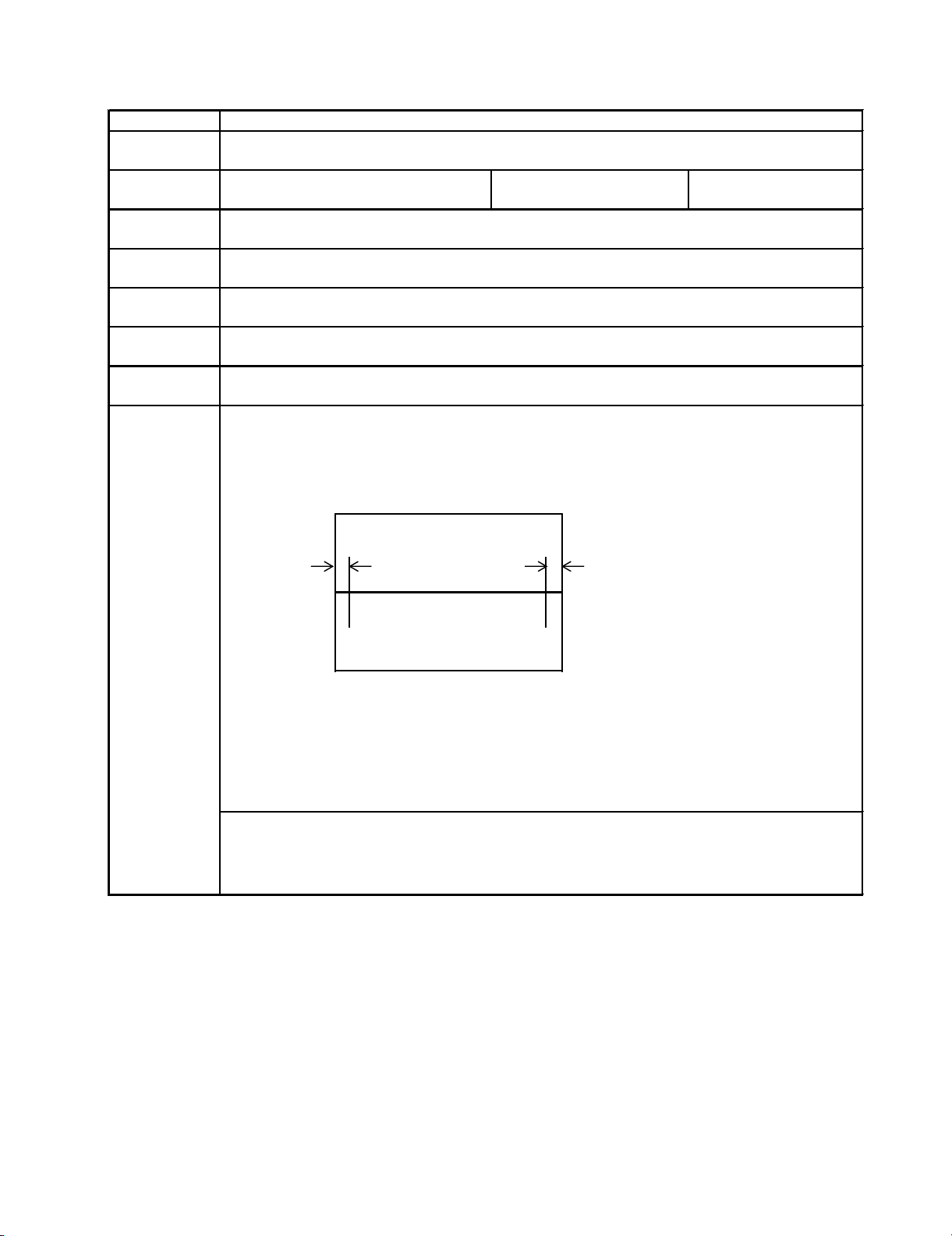

LEF T AND RIG HT S YMME T R IC AL

US 4CHLIONHEAD(MONOSCOPE)

AC 220V, US MAG NETIC FIELD

1.ADJUST THE

V08

BUS DATA TO HAVE A BALANCE POSITION TO SPEC OF

A=B

.

2.IF CANNOT MAKE IT TO

A=B

, ADJ FROM THE BEST POINT SO THAT

B

SLIGHTLY SMALLER

THAN

A

[CHECKING SPEC]

CONFIRMATION BY CRT SCREEN

I2C BUS CONTR OL

OPTION SET UP,BUSSETUP,CRT-P URITY

MODEL NAME

H-POS ITION

STEP RANGE

V08

0-31

21V1-L

B

A

21V1-L

5 – 4

ADJ US TME NT

ITE M

ADJ US TME NT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INP UT

CONDITION

OUTPUT

ADJ US TMEN T

PROCEDURE

MODEL NAME

V-S IZE

V10

STEP RANGE

0~63

21V1-L

CONFIRMATION BY CRT SCREEN

ADJUST THE V10 BUS DATA UNTILL THE OVERSCAN BECOME AS SPECIFIED BELOW.

CAUTION:- PLEASE AGING TV MORE THAN 10 MINUTES BEFORE ADJUSTMENT.

[CHECKING SPEC]

OVERSCAN 10 ± 2.5%

I2C CONTROL

OPTION SET UP, BUS SET UP,CR T PURITY, V-PHASE , +B ADJUST

US4CHLIONHEAD(MONOSCOPE)

AC 2 2 0

21V1-L

5 – 5

ADJ US TME NT

ITE M

ADJ US TME NT

POSITION

CONTOROL

PRE-ADJUST

REQUIREMENT

CONTENT

INP UT

CONDITION

OUTPUT

ADJ US TME NT

PROCEDURE

MODEL NAME

V-P HAS E

V07

STEP RANGE

0-7

21V1-L

CONFIRMATION ON CRT S CREEN

ADJUST V07 BUS DATA TO HAVE A MOST ACCEPTABLE VERTICAL POSITION.

THE MONOSCOPE PATTERN SHOULD BE BALANCE IN VERTICAL POSITION

NOTE: THE DATA FOR V07 LIMIT AT <= 0

4,

EVEN POSITION NOT GOOD ENOUGH

[CHECKING CONFIRMATION ]

I2C CONTROL

OPTION SET UP, BUS SET UP, CRT PURITY

US 4CHLIONHEAD(MONOSCOPE)

220V,RFINPUT,ZEROMAGNETICFIELD

21V1-L

5 – 6

ADJ US T ME NT

ITE M

ADJ US T ME NT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INP UT

CONDITION

OUTPUT

ADJ U S TMEN T

PROCEDURE

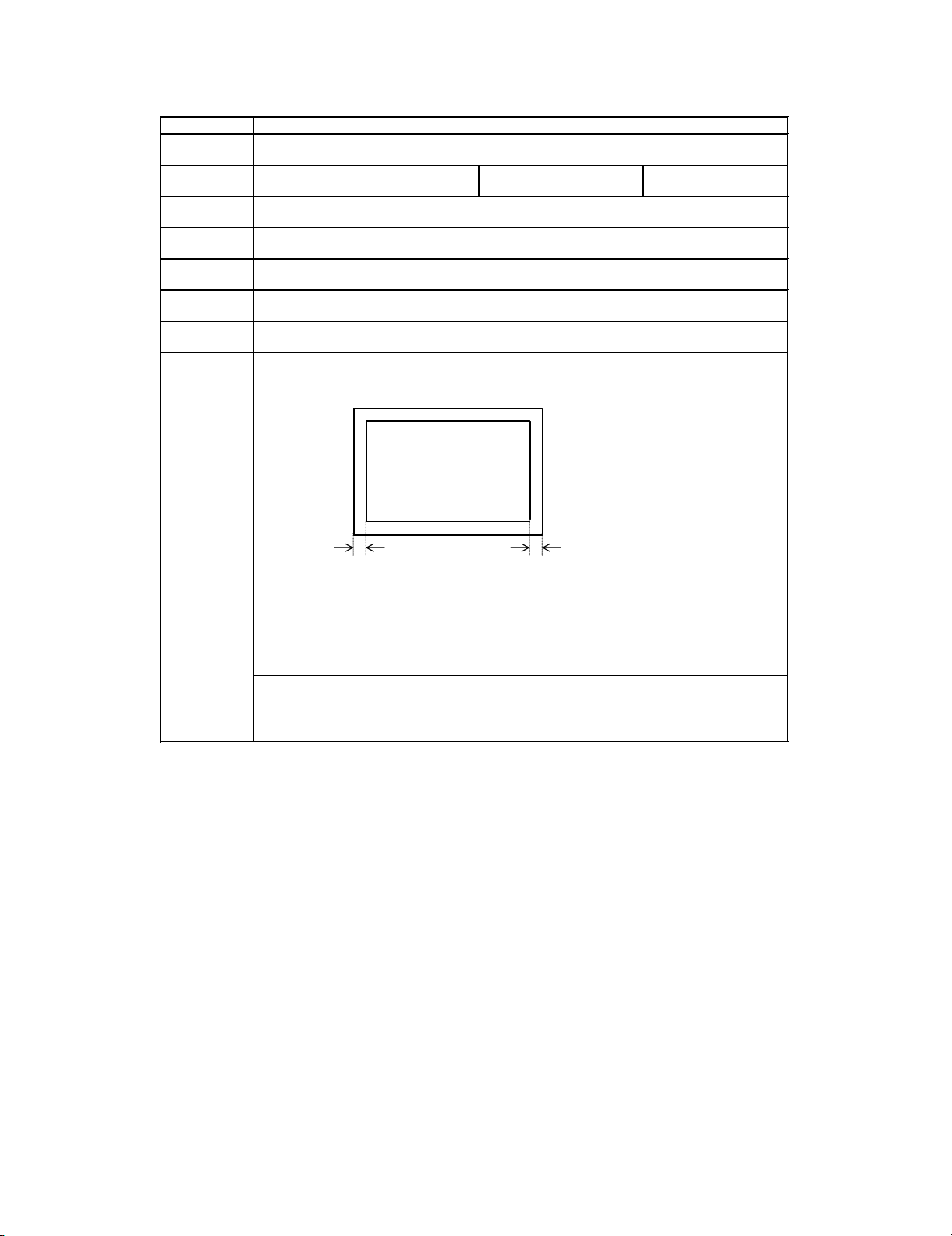

LEFT AND RIGHT S YMMETRICAL THEN V22 DATA REDUCE 5 STEP.

CONFIRMATION ON CRT DISP LAY.

1) BY SELECTING THE

V22

, BOX BLK TEXT W ILL BE APPEARED.

2) ADJUST THE

V22

BUS DATA TO HAVE A BALANCE POSITION TO SPEC OF A=B.

[CHECKING SPEC]

I2C CONTROL

OPTION SET UP, BUS S ET UP

US 4CHLIONHEAD(MONOSCOPE)

AC 220

MODEL NAME

CLOSED CAPTION S ET UP

V22

STEP RANGE

0-255

21V1-L

A

TEXT BOX BLK

B

Loading...

Loading...