Sharp 1490, 1600, MICROWAVE OVEN 1600, MICROWAVE OVEN 1490, 1750 Manual

...

OVER THE RANGE

MICROWAVE OVEN/HOOD SYSTEM

INSTALLATION

INSTRUCTIONS

Please read all instructions thoroughly before installing the Microwave Oven/Hood System. Two people are recommended to install this product.

If a new electrical outlet is required, its installation should be completed by a qualified electrician before the Microwave Oven/Hood is installed. See 3 ELECTRICAL GROUNDING INSTRUCTIONS on page 2.

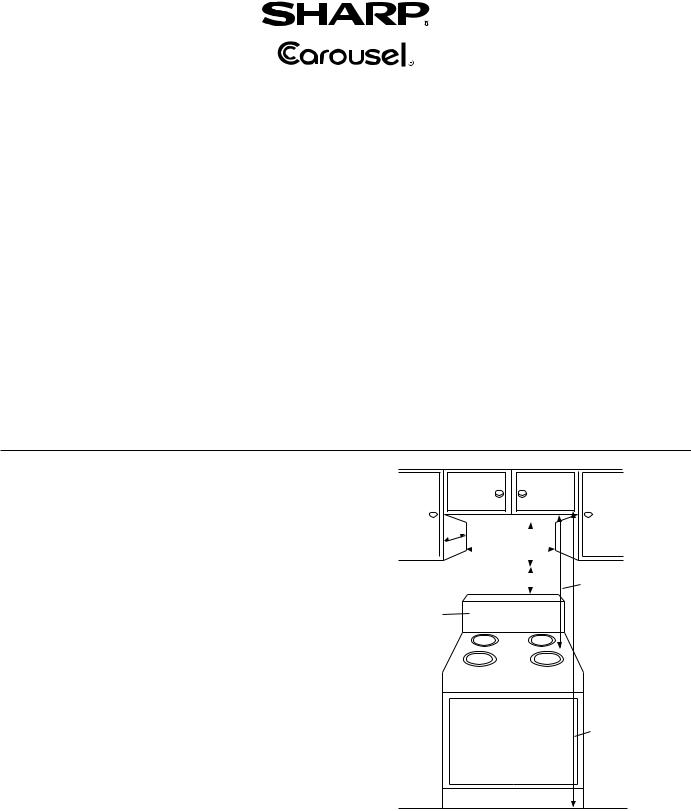

1 MOUNTING SPACE

This Microwave Oven/Hood requires a mounting space on a wall as shown in Figure 1. It is designed to be used with standard 12-inch wall cabinets.

If the space between the wall cabinets is 36 or 42 inches, |

12" |

15 |

1/2" |

|

|

|

|||

|

|

|

|

||||||

a Filler Panel Kit can be used to fill the gap. The metal |

|

|

|

30" |

|

|

|

|

|

|

|

|

|

|

|||||

filler panels come in 3-inch wide pairs. One set is needed |

|

|

|

|

|

|

|

|

|

|

|

|

|

At least 2" |

|

|

30" or more from |

||

for a 36-inch opening and 2 sets for a 42-inch opening. |

|

|

|

|

|

||||

White and black are available. See page 8 for ordering |

|

|

|

|

|

|

|

|

cooking surface |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

information. The Filler Panel Kit should be installed before |

Backsplash |

|

|

|

|

||||

the Microwave Oven/Hood is installed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

66" or more from floor

Figure 1

1

2 WALL CONSTRUCTION

This Microwave Oven/Hood should be mounted against and supported by a flat vertical wall. The wall must be flat for proper installation. If the wall is not flat, use spacers to fill in the gaps. Wall construction should be a minimum of 2” x 4” wood studding and 3/8” or more thick dry wall or plaster/lath. The mounting surfaces must be capable of supporting weight of 110 pounds—the oven and contents—AND the weight of all items which would normally be stored in the top cabinet above

the unit.

The unit should be attached to a minimum of one 2” x 4”

wall stud. |

2”x 4” Wood Studs |

|

16” or 24” |

To find the location of the studs, one of the following methods may be used:

A. Use a stud finder, a magnetic device which locates the

nails in the stud. |

|

B. Use a hammer to tap lightly across the mounting surface |

3/8” Dry Wall |

to find a solid sound. This will indicate stud location. |

|

The center of the stud can be located by probing the wall |

or Plaster/lath |

|

|

with a small nail to find the edges of the stud and then plac- |

|

ing a mark halfway between the edges. The center of any |

|

adjacent studs will normally be 16” or 24” to either side of |

|

this mark. |

|

Figure 2

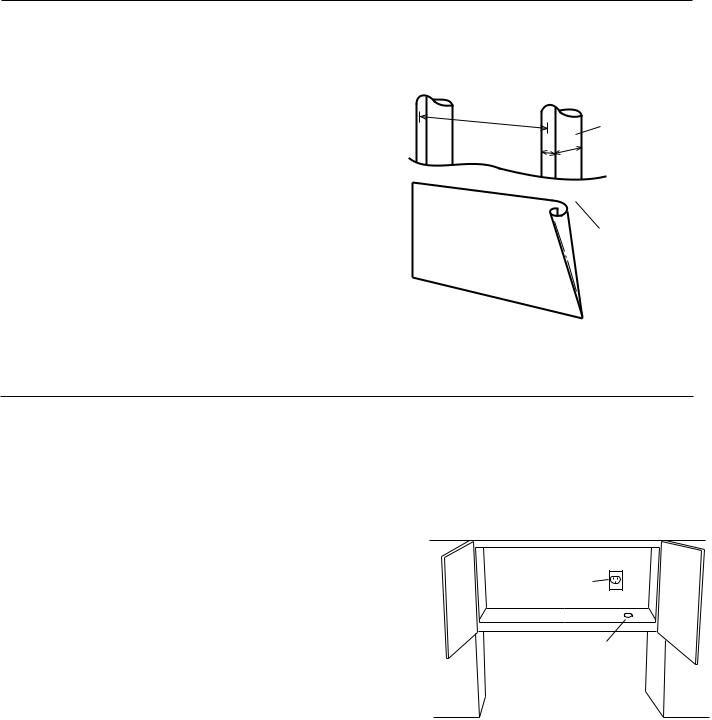

3 ELECTRICAL GROUNDING INSTRUCTIONS

This appliance must be grounded. This oven is equipped with a cord having a grounding wire with a grounding plug. It must be plugged into a wall receptacle that is properly installed and grounded in accordance with the National Electrical Code and local codes and ordinances. In the event of an electrical short circuit, grounding reduces risk of electric shock by providing an escape wire for the electric current.

WARNING - Improper use of the grounding plug can result in a risk of electric shock.

The oven is equipped with a 3-prong grounding plug. DO NOT UNDER ANY CIRCUMSTANCES CUT OR REMOVE THE GROUNDING PIN FROM THE PLUG.

The power supply cord and plug must be connected to a separate 120 Volt AC, 60 Hz, 15 Amp, or more branch circuit, single grounded receptacle. The receptacle should be located inside the cabinet directly above the Microwave Oven/Hood mounting location.

NOTE:

1.If you have any questions about the grounding or electrical instructions, consult a qualified electrician or serviceperson.

2.Neither Sharp nor the dealer can accept any liability for damage to the oven or personal injury resulting from failure to observe the correct electrical connection procedures.

Ground

Receptacle

Opening for

Power Cord

Figure 3

2

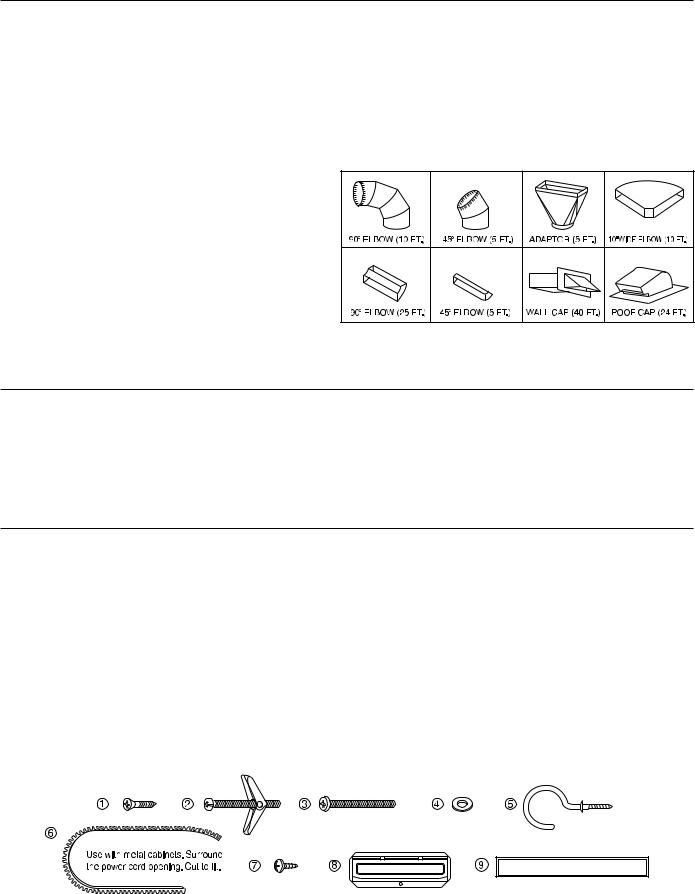

4 HOOD EXHAUST DUCT

When the hood is vented to the outside, a hood exhaust duct is required. All ductwork must be metal; absolutely do not use plastic duct. Check that all connections are made securely. Please read the following carefully:

Exhaust connection: The hood exhaust has been designed to connect to a standard 3-1/4” x 10” rectangular duct. If round duct is required, a rectangular-to-round adapter must be used.

Rear exhaust: If a rear or horizontal exhaust is to be used, care should be taken to align the exhaust with the space between the studs, or wall should be prepared at the time it is constructed by leaving enough space between wall studs to accommodate exhaust.

Maximum duct length: For satisfactory air movement, the total duct length of 3-1/4” X 10” rectangular or 6” diameter round duct should not exceed 140 feet.

Elbows, adapters, wall, roof caps, etc. present additional resistance to air flow and are equivalent to a section of straight duct which is longer than their actual physical size. When calculating the total

length, add the equivalent lengths of all transitions and adapters plus the length of all straight duct

sections. Figure 4 shows the approximate feet of equivalent length of some typical ductwork parts. Use the values in parentheses for calculating air

flow resistance equivalent, which should total less

than 140 feet.

Figure 4

5 TOOLS RECOMMENDED FOR INSTALLATION

• Phillips Screwdriver • Electric Drill • 1/2”, 5/8” and 3/32” Drill Bits

• 1-1/2” Wood Bit or Metal Hole Cutter (if metal cabinet is used) • Saw to cut exhaust opening (if needed)

• Protective Drop Cloth for product and range -you may also use carton for protection

• Scissors • Pencil • Measure • Tape

6 INSTALLATION HARDWARE

The INSTALLATION HARDWARE items 1-7 are in a small bag. Items 8 and 9 are packed separately. All items are in a small carton packed below the oven.

ITEM |

NAME |

QUANTITY |

PART CODE |

|

|

1 |

Wood Screw 5 X 30 mm |

|

6 |

XTSSD50P35000 |

|

2 |

Toggle Bolt #10 - 24 X 50 mm |

|

4 |

LX-BZ0195WRE0 |

|

3 |

Top Cabinet Screw 5 X 60 mm |

2 |

XBRSD50P60000 |

||

4 |

Flat Washer 5 mm diameter |

|

2 |

XWHSD50-16300 |

|

5 |

Cord Holder |

|

1 |

LX-MZB001MRE0 |

|

6 |

Grommet |

|

1 |

LBSHC0040MRE0 |

|

7 |

Tapping Screw 4 x 12 mm |

|

1 |

XOTSD40P12000 |

|

8 |

Exhaust Damper Assembly |

|

1 |

FFTA-B003MRK0 / FFTA-B005MRK0 |

|

9 |

Charcoal Filter |

|

1 |

PFIL-B004MRE0 |

|

Figure 5

3

Loading...

Loading...