TAC Vista

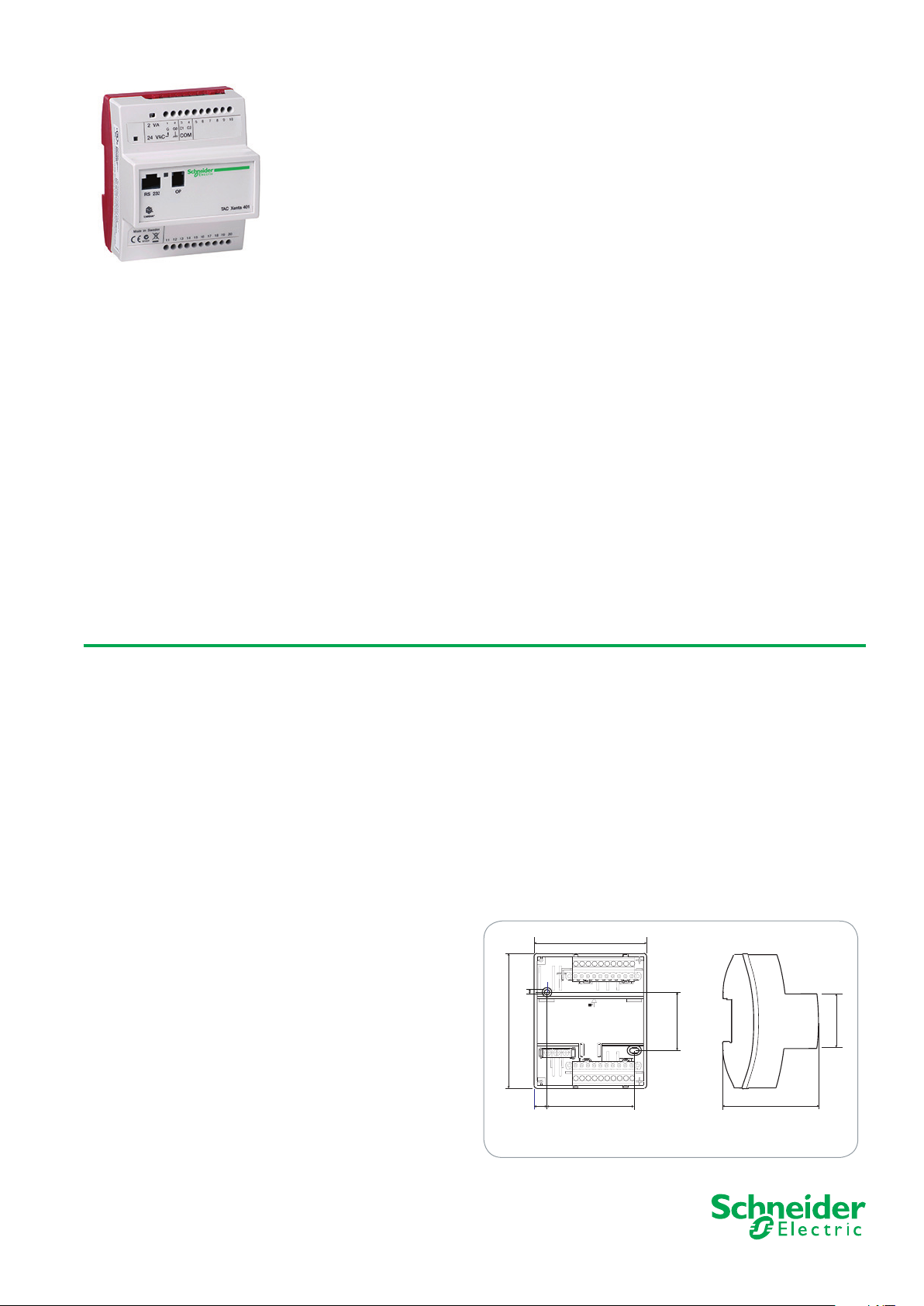

2 3 4 5 6 7 8 10

12 13 14 15 16 17 18 20

48 – 0.5

(1.89–0.02)

70 – 2.0

(2.75–0.08)10.1

(0.40)

4 (0.16)

90 (3.55)

110 (4.33)

77.4

(3.05)

45

(1.77)

TAC Xenta 401:B

Controller, Freely Programmable

TAC Xenta 401:B belongs to a family of freely programmable controllers, with communi cation features, designed for heating and

air handling systems.

A TAC Xenta 401:B holds full HVAC functionality including control loops, curves, time control, alarm handling, etc. The controller

does not have any physical inputs or outputs and no TAC Xenta 400 I/O modules can be connected.

This controller may serve as a data manager that can provide time scheduling, data logging, and other logical functions to less capable network nodes.

With the TAC Menta programming tool, a TAC Xenta controller is simple to program and place into operation.

The controller communicates on a LonTalk TP/FT-10 network via a twisted-pair, non-polarized cable. It is able to operate both as a

stand-alone unit and as part of a system.

TAC Xenta 401:B can be connected to a modem or the TAC Vista Building Management System.

The controller can be removed/inserted from/to the terminal part without disconnecting the power supply. When adding or replacing

a controller it’s also possible to pre-configure it in order to achieve Plug and Play functionality without any on-site configurations.

For local use, the TAC Xenta OP (Operator Panel) can be connected. The operator panel has a display and push buttons for

navigating and altering settings. The operator panel can be snapped onto the TAC Xenta controller unit, mounted on the front of

the cabinet, or used as a portable terminal.

TECHNICAL DATA

Supply voltage..... 24 V AC ±20%, 50/60 Hz or 19–40 V DC

Power consumption.......................... max. 2 W

Transformer sizing ...............................2 VA

Ambient Temperature

Storage ...............–20 °C to +50 °C (–4 °F to +122 °F)

Operation .............±0 °C to +50 °C (+32 °F to +122 °F)

Humidity ..................max. 90% RH non-condensing

Mechanical

Enclosure....................................ABS/PC

Enclosure rating.................................IP 20

Flammability class, materials ...................UL 94 5VB

Dimensions ................................ see Fig. 1

Weight ................................ 0.5 kg (1.2 lb)

CPU

CPU....32 bit, 12.28 MHz, 2 MB flash memory, 128 kB SRAM

Real Time Clock

Accuracy at +25 °C (77 °F) ............±12 minutes per year

Power outage protection ...........................72 h

Communication

TAC Menta; modem ..............9600 bps, RS-232, RJ-45

TAC Vista ......................TP/FT-10, screw terminal

(also for application program download)

TAC Xenta OP....................TP/FT-10, modular jack

LonMark Standard

Interoperability ...........LonMark Interop. Guidelines v 3.0

Application ......LonMark Functional Profile: Plant Controller

Agency Compliances

Emission:

CE ..................EN 61000-6-3, C-Tick, FCC Part 15

Immunity:

CE ..................................EN 61000-6-1

Safety:

CE ....................................EN 61010-1

UL 916, C-UL US, Enclosed Energy Management Equipment

Approved for plenum installations

RoHS directive............................ 2002/95/EG

Part Numbers

Electronics part TAC Xenta 401:B...............007301030

Terminal part TAC Xenta 400..................007309020

Operator panel TAC Xenta OP ................007309072

TAC Xenta: Programming Serial Kit .............007309200

Figure 1

03-00010-03-en

2

03-00010-03-en

DESIGN

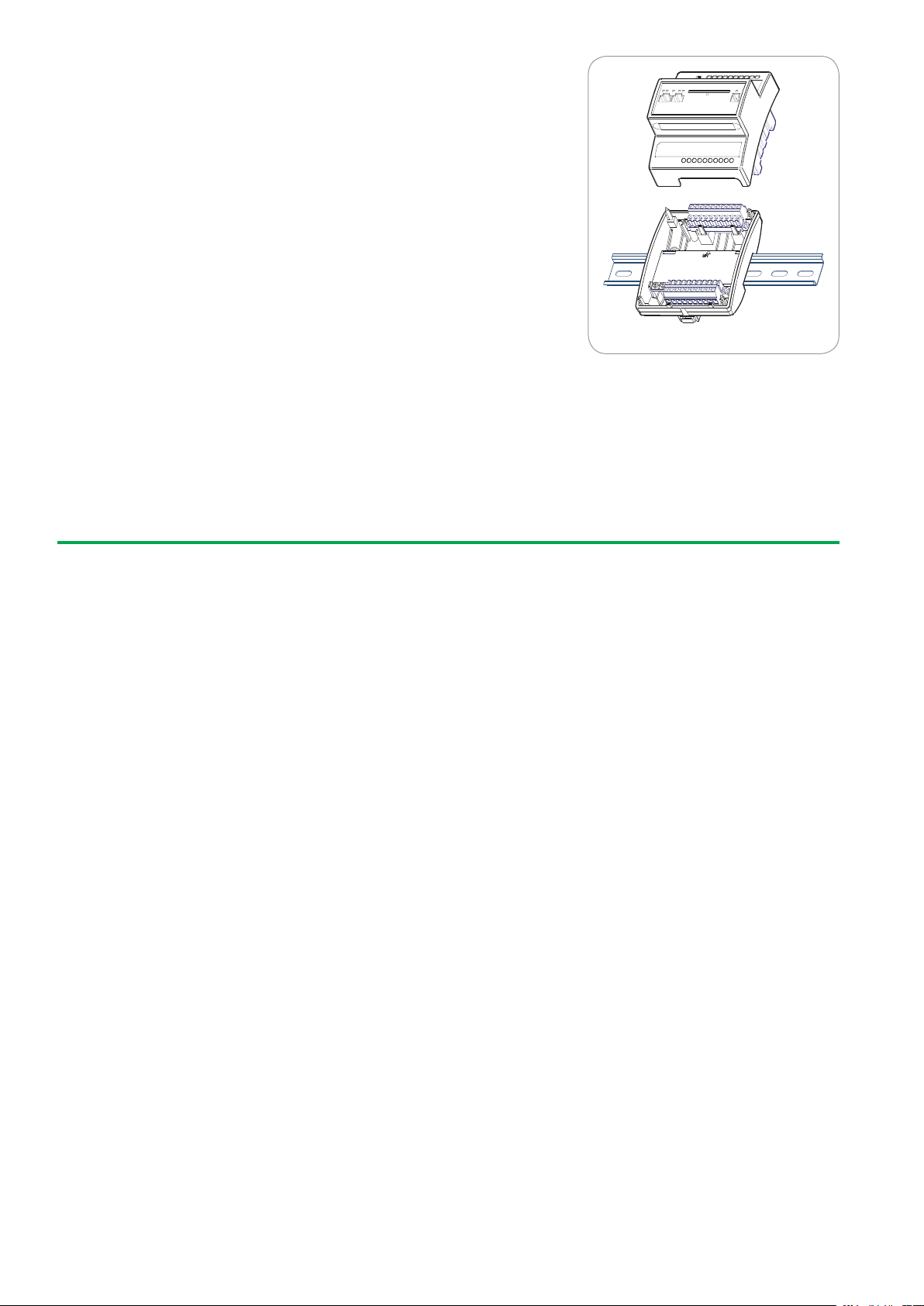

The TAC Xenta 401:B controller has been

designed as a general purpose controller.

It is normally mounted in a cabinet with

several controllers collected per floor or

per building.

The large network variable input capacity

makes TAC Xenta 401:B well suited for

zone system management applications.

TAC Xenta 401:B is microprocessor based.

It consists of a terminal and electronics

mounted together (Fig. 2).

TAC Xenta 401:B can, via network

variables, be interfaced with other LONbased field sensors/transducers and

controlled devices.

The 401:B does not, however, support

TAC Xenta I/O modules.

Local Operator Panel

The TAC Xenta OP (Operator Panel) is a

small operator panel which can be connected to the unit through its enclosure.

The operator can read the point status,

perform manual override, read measured

values, alter set points etc., from the

operator panel.

The functions are selected from menus.

Access to the unit is enabled by using an

access code. It is possible to access other

TAC Xenta units on the same network.

Power Outage Protection

With non-volatile (flash) memory, the

unit will start up with user settings and

work normally after a power outage.

Real Time Clock

The real time clock provides data such as

year, month, date, day, hour, minute and

second. A built-in capacitor maintains operation of the clock for at least 72 hours

in the event of a power outage.

Daylight Saving Time:

European, Australian or USA/Canada

Once set, Daylight Saving Time (DST) is

fully automatic. The change-over date

and the number of hours to change are

programmable. This function can also be

disabled.

Figure 2

LonWorks SNVT Support

The use of Standard Network Variable

Types (SNVT), in accordance with the

Echelon specification, makes it possible to

communicate with nodes made by other

manufacturers.

SOFTWARE FEATURES

With the assistance of TAC Menta,

a graphical programming tool using

Functional Block Diagrams (FBDs), the

TAC Xenta 401:B may be easily adapted

to different control and monitoring tasks.

The basic functions available with this

controller include:

• alarmhandling,alarmconditionsmay

be detected via LonWorks Network

variables

• equipmentruntimetotalsonselected

objects

• programsforoptimumstart/stop

• controlcharacteristiccurves

• PIDcontrolloops(loopsmaybecon-

nected in cascade)

• trendloggingforupto50channels

• localleveloperatorinterfacevia

TAC Xenta OP (Operator Panel)

• networkcommunicationaccordingto

the LonTalk protocol

• communicationwiththeTACVista

Building Management System via modem

The basic software is adapted to the

current application by connecting preprogrammed functional blocks and by

adjusting the relevant parameters. These

connections and parameters are stored in

non-volatile memory.

The parameters may be changed during ongoing operation either from the

TAC Vista Building Management System

or locally from the TAC Xenta OP

(Operator Panel).

Loading...

Loading...