Page 1

©

TAC Xenta® 400 I/O Modules

TAC Xenta

Page 2

Page 3

©

TAC Xenta® 400 I/O Modules

TAC Xenta

Page 4

Copyright © 2003 TAC AB. All rights reserved.

This document, as well as the product it refers to, is only intended for licensed users. TAC AB owns the copyright of this document and reserves

the right to make changes, additions or deletions. TAC AB assumes no responsibility for possible mistakes or errors that might appear in this

document.

Do not use the product for other purposes than those indicated in this document.

Only licensed users of the product and the document are permitted to use the document or any information therein. Distribution, disclosure,

copying, storing or use of the product, the information or the illustrations in the document on the part of non-licensed users, in electronic or

mechanical form, as a recording or by other means, including photo copying or information storage and retrieval systems, without the express

written permission of TAC AB, will be regarded as a violation of copyright laws and is strictly prohibited.

Trademarks and registered trademarks are the property of the ir respective owners. Microsoft

®

and Windows® are registered trademarks of

The Microsoft Corporation.

Trademarks and registered trademarks are the property of their respective owners.

TAC Vista

®

, TAC Menta®, TAC Xenta® and TAC I-talk® are registered trademarks of TAC AB.

Page 5

TAC Xenta, TAC Xenta® 400 I/O Modules Contents

Contents

INTRODUCTION

1 Introduction 9

1.1 Structure..................................................................................................................... 9

1.2 Terminology............................................................................................................... 9

1.3 New in this Edition..................................................................................................... 9

1.4 Typographic Conventions.......................................................................................... 10

1.5 More information ....................................................................................................... 10

REFERENCE

2 I/O Modules in the TAC Xenta 400 series 13

2.1 Hardware Units .......................................................................... ................................ 13

2.2 Configurations............................................................................................................ 15

3 Technical Description 17

3.1 Common Features .......................................................................... ..... .... ................... 17

3.1.1 Terminals.................................................................................................................... 17

3.1.2 Indicators and Service pin.......................................................................................... 17

3.1.3 Technical data, common to all ................................................................................... 18

3.2 TAC Xenta 411/412 Digital Input module................................................................. 19

3.3 TAC Xenta 421/422 Digital Input and Output module.............................................. 20

3.4 TAC Xenta 421A/422A Universal Input and Digital Output module ....................... 22

3.5 TAC Xenta 451/452 Analog Input and Output module............................................. 24

3.6 TAC Xenta 451A/452A Universal Input and Analog Output module....................... 26

3.7 TAC Xenta 471 Analog Input module....................................................................... 29

3.8 TAC Xenta 491/492 Analog Output module............................................................. 31

4 Installation 33

4.1 Mounting.................................................................................................................... 33

4.2 Electrical installation.................................................................................................. 34

4.2.1 General considerations............................................................................................... 34

4.2.2 Input/Output Circuit Principles.................................................................................. 34

4.2.3 Terminals and units.................................................................................................... 38

4.2.4 Cables......................................................................................................................... 42

4.3 Commissioning .......................................................................................................... 44

Index 45

TAC AB, Dec 2004 5 (48)

0-004-7771-3 (EN)

Page 6

Contents TAC Xenta, TAC Xenta® 400 I/O Modules

6 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 7

INTRODUCTION

1 Introduction

Page 8

Page 9

TAC Xenta, TAC Xenta® 400 I/O Modules 1 Introduction

1 Introduction

The TAC Xenta 400 is a series of input/output modules designed to be

nected to the TAC Xenta 300 or 401 type controllers.

con

The installation procedures and technical data are similar between the

different modules.

For information on how to install software, we refer to the instructions

delivered with the software.

1.1 Structure

The manual is divided into the following parts:

• Introduction

The Introduction section contains information on

is structur

• Reference

The Reference section contains comprehensive in

the products. It also

lectrical installation.

and e

1.2 Terminology

Term Description

ASIC Application Specific Integrated Circuit

1.3 New in this Edition

In this edition the new ASIC-based modules TAC Xenta 421A/422A

and TAC Xenta 451A/452A have been added, mainly in chapter 3.

how this manual

ed and where to find additional information.

formation about

provides you with in

formation on mounting

TAC AB, Dec 2004 9 (48)

0-004-7771-3 (EN)

Page 10

1 Introduction TAC Xenta, TAC Xenta® 400 I/O Modules

1.4 Typographic Conventions

Throughout the manual four specially marked texts may occur.

Warning

Used to emphasize operations that can cause serious personal injury or

damage to property if not handled correctly.

Caution

Used to emphasize operations that can cause serious problems if not

handled correctly.

Note

Used to emphasize certain information.

Hint

Used to emphasize processes that may ease operation.

1.5 More information

The TAC Xenta 400 I/O modules and the other TAC Xenta units are

also described in the following documents:

• the “TAC Xenta 280/300/401 Handbook”, part no. 0-004-7768

• the “TAC Xenta OP Handbook”, part no. 0-004-7506

• the “Engineering Classic Networks”, part no. 0-004-7841

• the “Endangering LNS Networks”, part no. 0-004-7842

• the “Engineering Applications in TAC Menta”,

part no. 0-004-7843 (to be replaced by 0-004-7896)

• data sheets for the TAC Xenta 4xx range (C-92-nn)

• the TAC Xenta OP Operator panel data sheet (C-98-05)

• a brief installation instruction, “0FL”, included at delivery

10 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 11

REFERENCE

2 I/O Modules in the TAC Xenta 400

series

3 Technical Description

4 Installation

Page 12

Page 13

TAC Xenta, TAC Xenta® 400 I/O Modules 2 I/O Modules in the TAC Xenta 400 series

2 I/O Modules in the TAC Xenta 400

series

2.1 Hardware Units

Warning

The TAC Xenta 400 I/O modules and the other products of the

TAC Xenta family must not be used for any other purpose than those

for which they were designed.

Installation, connection and repair may only be performed by authorized personnel.

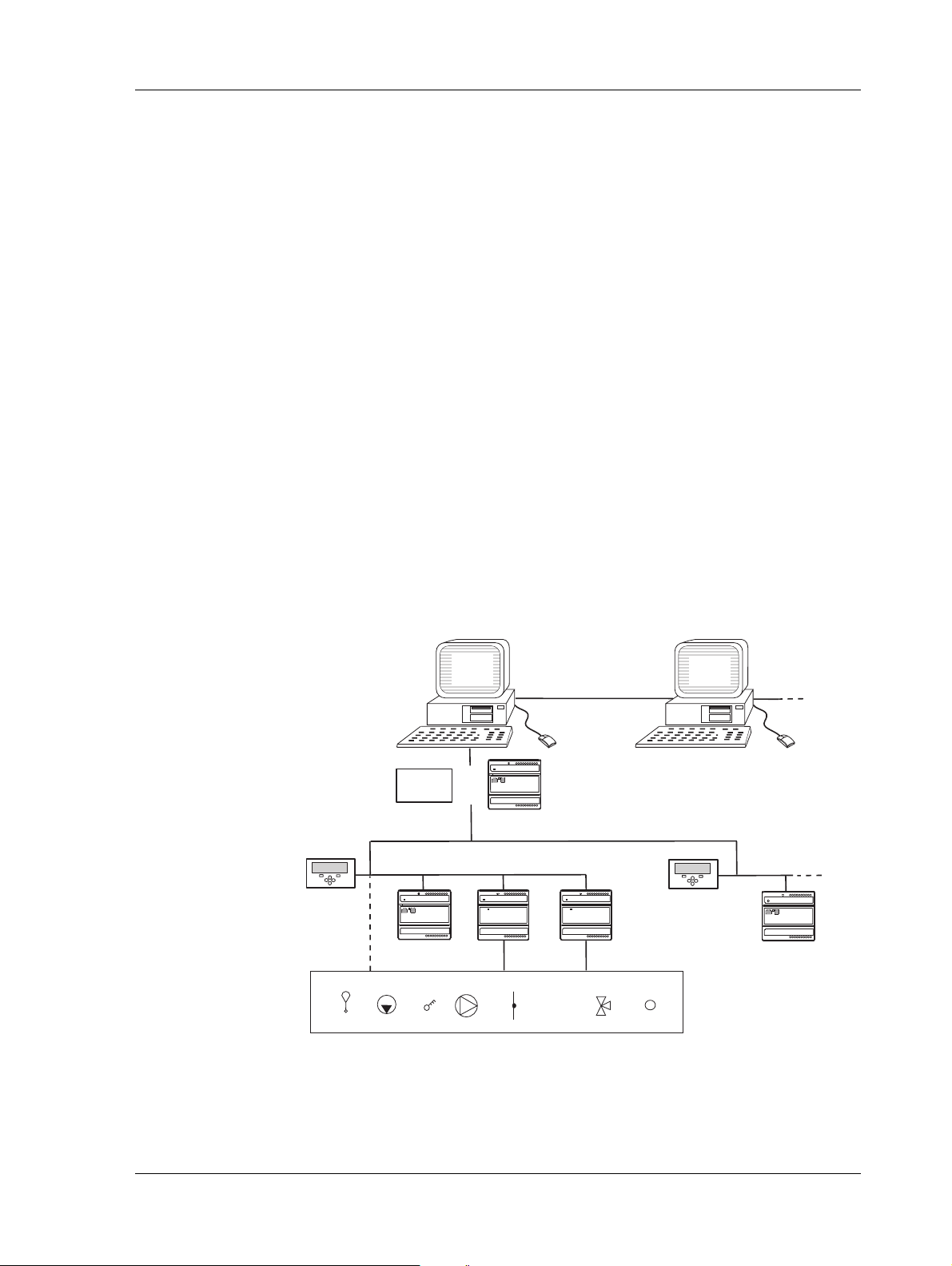

The TAC Xenta freely-programmable controllers consist of the following units.

•The TAC Xenta 301/302/401 controller . The controller is the brain

of the system. It contains the database of the inputs and outputs of

the plant. It also contains the system and application software for

all the functions that are to be performed by the controller and

connected peripheral units.

• I/O expansion modules, which provide the inputs and outputs of

the TAC Xenta controller.

•The TAC Xenta OP is an easy-to-us e operator panel, with a dis-

play . The values are presented in plain language in a menu system.

The OP can be connected to any controller in the network.

TAC Xenta controller

12 13 14 15 16 17 18 20

Operator panel

Fig. 2.1: TAC Xenta units; the Operator panel, the TAC Xenta controller

(here: 401) and an I/O expansion module

TAC AB, Dec 2004 13 (48)

0-004-7771-3 (EN)

TAC Xenta 400

Input/Output module

12 13 14 15 16 17 18 20

Page 14

2 I/O Modules in the TAC Xenta 400 series TAC Xenta, TAC Xenta® 400 I/O Modules

A number of controllers and I/O modules can form a local network and

exchange data.

The TAC Xenta OP operator panel is used to give the user access to certain parameters and make it possible to present alarms without communicating with a central system. The most important functions of the

operator panel are status monitoring, adjustment of setpoints and time

channels and the display of alarms.

A maximum of two OPs may be connected to each controller.

The I/O modules are used as expansion modules for the TAC Xenta

controllers, connected to these via the common TP/FT-10 network.

The modules have different I/O configurations to suit different applications. Some models have indicators for the digital input status and a

manual override for the digital or analog outputs. An overview of the

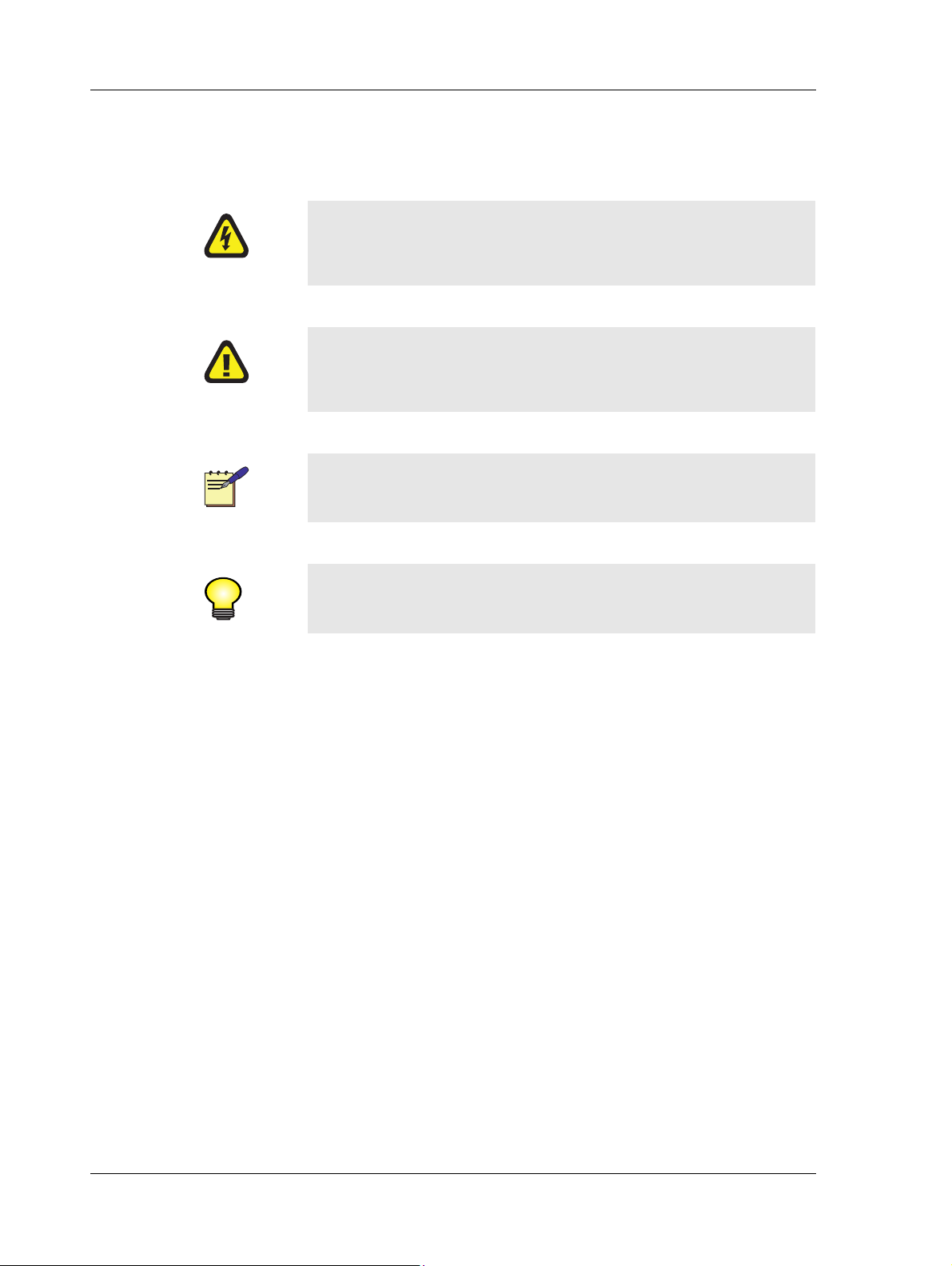

available models is shown below.

Table 2.1: Available I/O modules and their I/O configuration

I/O Module

TAC

DI

DI

status

DO

DO

override

UI TI AO

AO

override

Xenta 411 10 - - - - - - Xenta 412 10 10 - - - - - Xenta 421 4 - 5 - - - - Xenta 422 4 4 5 5 - - - Xenta 421A - - 5 - 4

Xenta 422A - 4

b

554a-- Xenta 451 - - - - 4

Xenta 452 - 4

b

--4c42 2

Xenta 451A - - - - 8

Xenta 452A - 8

b

--8a-2 2

Xenta 471 - - - - 8

a

c

a

d

-- -

42 -

-2 -

-- Xenta 491 - - - - - - 8 Xenta 492 - - - - - - 8 8

a. DI, 0–10 V DC or 0–20 mA, 1.8/10 kohm TI

b. Status indication only when the corresponding universal inputs (UI) are being used as digital

inputs.

c. DI, 0–10 V DC, 1.8 kohm TI

d. 0–10 V DC or 0–20 mA

14 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 15

TAC Xenta, TAC Xenta® 400 I/O Modules 2 I/O Modules in the TAC Xenta 400 series

where

DI: Digital input

DO:Digital output

UI: Universal input

TI: Thermistor input

AO:Analog output

2.2 Configurations

The I/O modules of the TAC Xenta 400 series can be used in different

configurations, for example:

• Together with a stand-alone controller.

• With controllers and OPs in a network.

• Controllers, OPs, I/O modules and other equipment in a full network with suitable adapters, possibly connected to a TAC Vi

Central System.

sta

Management

level

Automation

level

TAC Xenta OP

Field

level

For further information, ple

ase consult the “Engineering Network”

guides.

TAC

Vista

PCLTA

card

TAC Xenta 401 I/O- module I/O- module

or

TAC Xenta 901

+

TP/FT-10

-

TAC

Vista

TAC Xenta OP

TAC Xenta 401

Fig. 2.2: An example of a TAC Xenta network

TAC AB, Dec 2004 15 (48)

0-004-7771-3 (EN)

Page 16

2 I/O Modules in the TAC Xenta 400 series TAC Xenta, TAC Xenta® 400 I/O Modules

16 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 17

TAC Xenta, TAC Xenta® 400 I/O Modules 3 Technical Description

3 Technical Description

3.1 Common Features

3.1.1 Terminals

In all the modules, the first four screw terminals are used in the same

way, i.e. two for the power supply and two for network communication.

24 V AC

(19-40 V DC)

Fig. 3.1: Terminals 1-4 of the TAC Xenta I/O modules

Comm

}

~ 0

G G0 C1C2

1 2 3 4 5 6 7 8 9 10

3.1.2 Indicators and Service pin

On the front, there is a small hole through which the Service pin may be

activated. There are also two LED indicators, one red and one green.

LED: red light = hw fault

or unconfigured node

}

Service pin

LED: green blinking light, ~1 Hz =

communication running

Fig. 3.2: LEDs and Service pin of the I/O modules

TAC AB, Dec 2004 17 (48)

0-004-7771-3 (EN)

Page 18

3 Technical Description TAC Xenta, TAC Xenta® 400 I/O Modules

3.1.3 Technical data, common to all

Ambient temperature (except TAC Xenta 421XT and 422XT, page 21):

Storage...................................–20 °C to +70 °C (–4 °F to +158 °F)

Operation......... ..... .................. 0 °C to +50 °C (+32 °F to +122 °F)

Mechanical:

Enclosure........................................................................... ABS/PC

Enclosure rating.......................................................................IP 20

Flammability class, materials.........................................UL 94 V-0

Dimensions.................................90×110×77 mm (3.5x4.3x3.1 in.)

Weight ...................................................................0.2 kg (0.44 lbs)

Communication (C1–C2; transceiver type FTT10A; pol. insensitive):

TAC Xenta Controller............................TP/FT-10, screw terminal

Agency compliances:

Please refer to the data sheet for the corresponding product.

Part numbers:

Electronics part TAC Xenta 401...................................0-073-0101

Terminal part TAC Xenta 400.......................................0-073-0902

Operator terminal TAC Xenta OP.................................0-073-0907

Connection cable TAC Xenta – RS232.........................0-073-0903

Electronics part TAC Xenta 411 (10 DI) ......................0-073-0201

Electronics part TAC Xenta 412 (10 DI)

(with LED indicators) ............................................0-073-0203

Electronics part TAC Xenta 421 (4 DI, 5 DO)..............0-073-0241

Electronics part TAC Xenta 421XT..............................0-073-0242

Electronics part TAC Xenta 422 (4 DI, 5 DO)

(with LED indicators and DO override).................0-073-0243

Electronics part TAC Xenta 422XT..............................0-073-0244

Electronics part TAC Xenta 421A (4 UI, 5 DO)...........0-073-0245

Electronics part TAC Xenta 422A (4 UI, 5 DO)

(with LED indicators and DO override).................0-073-0246

Electronics part TAC Xenta 451 (4 UI, 4 TI, 2 AO)..... 0-073-0281

Electronics part TAC Xenta 452 (4 UI, 4 TI, 2 AO)

(with LED indicators and AO override).................0-073-0283

Electronics part TAC Xenta 451A (8 UI, 2 AO)........... 0-073-0285

Electronics part TAC Xenta 452A (8 UI, 2 AO)

(with LED indicators and AO override).................0-073-0286

Electronics part TAC Xenta 471 (8 UI, mA/VDC).......0-073-0291

Electronics part TAC Xenta 491 (8 AO).......................0-073-0301

Electronics part TAC Xenta 492 (8 AO)

(with AO override).................................................0-073-0303

18 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 19

TAC Xenta, TAC Xenta® 400 I/O Modules 3 Technical Description

3.2 TAC Xenta 411/412 Digital Input module

The modules have ten digital inputs, these inputs can also be used as

pulse counters.

The TAC Xenta 412 is also equipped with LED status indicators, one

for each digital input. The LED colors, red or green, can be selected

individually by the setting switches under the front cover.

Terminals (411, 412) and Indicators (412)

24 V AC/DC

Comm

}

}

~ 0

G G0 C1C2 X1 M X2 X3 M X4

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

X5 M X6 X7 M X8 X9 M X10

DI

2 3 4 5 6 7 8 9 10

TAC Xenta 412

Fig. 3.3: TAC Xenta 411/412 terminals and TAC Xenta 412 DI indicators

Table 3.1: TAC Xenta 411/412 summary

Type No. TAC Menta Block type Terminal ref. Indicators (412)

Digital input 10 DI - Digital input or

CNT - Pulse counter

X1 - X10

X1 - X10

10 DI Indicators:

⇑ red

⇓ green

red or green

red or green

Technical data TAC Xenta 411 and 412

Supply voltage (G, G0) .................................24 V AC ±20%, 50/60 Hz

or..........................................................................19–40 V DC

Power consumption.................................................................max. 2 W

Transformer sizing .........................................................................2 VA

Digital inputs (X1–X10):

Quantity........................................................................................10

Voltage across open contact..............................................33 V DC

Current through closed contact ...............................................4 mA

Pulse input duration (TAC Menta CNT block)..............min. 20 ms

LED digital input status indicators (TAC Xenta 412 only):

Quantity........................................................................................10

Color.................................red or green, selected with a DIP switch

TAC AB, Dec 2004 19 (48)

0-004-7771-3 (EN)

Page 20

3 Technical Description TAC Xenta, TAC Xenta® 400 I/O Modules

3.3 TAC Xenta 421/422 Digital Input and Output module

The modules have four digital inputs and five digital outputs. The inputs

can also be used as pulse counters.

The TAC Xenta 422 is also equipped with LED status indicators, one

for each digital input and manual override switches for the digital outputs. The LED colors, red or green, can be selected individually by

altering the DIP switch settings under the front cover.

Terminals (421, 422) and Switches/Indicators (422)

24 V AC/DC

max 230 V AC

Comm

}

}

~ 0

G G0 C1C2 X1 M X2 X3 M X4

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

K1 K1C K2 K2C K3 K3C K4 K4C K5 K5C

5 Relay output

Indicators (green)

DO

2 3 4 5 1 2 3 4

TAC Xenta 422

ON

AUTO

OFF

DI

4 DI Indicators:

⇑ red

⇓ green

Fig. 3.4: TAC Xenta 421/422 terminals and TAC Xenta 422 relay output switches and Indicators

Table 3.2: TAC Xenta 421/422 summary

Type No. TAC Menta Block type Terminal ref. Ind./Override (422)

Digital inputs 4 DI - Digital input or

X1 - X4

red or green / -

Relay outputs /

Digital outputs

CNT - Pulse counter

5 DO - Digital output or

DOPU - Dig. pulse output

X1 - X4

K1 - K5

K1 - K5

red or green / -

a

green

/ ON-AUTO-OFF

a

green

/ ON-AUTO-OFF

a. Note! The five output indicators always show the AUTO output status, irrespective of

the output override switch position (ON-AUTO-OFF).

20 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 21

TAC Xenta, TAC Xenta® 400 I/O Modules 3 Technical Description

Technical data TAC Xenta 421 and 422

Supply voltage (G, G0) .................................24 V AC ±20%, 50/60 Hz

or..........................................................................19–40 V DC

Power consumption.................................................................max. 2 W

Transformer sizing .........................................................................5 VA

Digital inputs (X1–X4):

Quantity..........................................................................................4

Voltage across open contact..............................................33 V DC

Current through closed contact ...............................................4 mA

Pulse input duration (TAC Menta CNT block)..............min. 20 ms

Digital outputs (K1–K5):

Quantity..........................................................................................5

Control voltage, relay output

...............................protected by a max. 10 A fuse, 230 V AC

Control current...................................................................max 2 A

Pulse length (TAC Menta DOPU block) .........................min. 0.5 s

LED digital input status indicators (TAC Xenta 422 only):

Quantity..........................................................................................4

Color.................................red or green, selected with a DIP switch

Manual override for digital outputs (TAC Xenta 422 only):

Quantity..........................................................................................5

Switch positions.................................................. ON, AUTO, OFF

Indicators for Auto output status.................................. green LEDs

Ambient temperature TAC Xenta 421XT and 422XT:

Storage and Operation...........–20 °C to +70 °C (–4 °F to +158 °F)

Humidity ........................................max. 90 % RH non condensing

TAC AB, Dec 2004 21 (48)

0-004-7771-3 (EN)

Page 22

3 Technical Description TAC Xenta, TAC Xenta® 400 I/O Modules

3.4 TAC Xenta 421A/422A Universal Input and Digital Output module

The modules have four universal inputs and five digital outputs. The

universal inputs can be used as analog inputs, digital inputs or pulse

counters.

The TAC Xenta 422A is also equipped with LED status indicators for

each universal input (when used as digital in puts) and man ual override

switches for the digital outputs. The LED colors, red or green, and the

polarity (lit when contact is open or closed) can be selected individually

by altering the parameter settings in TAC Menta.

Terminals (421A, 422A) and Switches/Indicators (422A)

24 V AC

(21.6−40 V DC)

Comm

}

}

~ 0

G G0 C1C2 U1 M U2 U3 M U4

max 230 V AC

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

K1 K1C K2 K2C K3 K3C K4 K4C K5 K5C

5 Relay output

Indicators (green)

DO

2 3 4 5 1 2 3 4

TAC Xenta 422A

ON

AUTO

OFF

DI

4 DI Indicators:

red/green

Fig. 3.5: TAC Xenta 421A/422A terminals and TAC Xenta 422A relay output switches and Indicators

Table 3.3: TAC Xenta 421A/422A summary

Type No. TAC Menta Block type Terminal ref. Ind./Override (422A)

Universal

inputs

4 AI - Analog input or

DI - Digital input or

CNT - Pulse counter

Relay outputs /

Digital outputs

a. Note! The five output indicators always show the AUTO output status, irrespective of

th

e output override switch position (ON-AUTO-OFF).

5 DO - Digital output or

DOPU - Dig. pulse output

U1 - U4

U1 - U4

U1 - U4

K1 - K5

K1 - K5

red or green / -

a

green

/ ON-AUTO-OFF

a

green

/ ON-AUTO-OFF

These modules can also be used as certified LONMARK® devices. The

configuration and use of SNVTs are explained in th e 0FL-4181 Configuration Instruction.

22 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 23

TAC Xenta, TAC Xenta® 400 I/O Modules 3 Technical Description

Technical data TAC Xenta 421A and 422A

Supply voltage (G, G0) .................................24 V AC ±20%, 50/60 Hz

or...................................................................... 21.6–40 V DC

Power consumption.................................................................max. 4 W

Transformer sizing .........................................................................8 VA

Universal inputs (U1–U4):

Quantity..........................................................................................4

A/D-resolution ......................................................................12 bits

–as Digital Inputs;

Voltage across open contact..............................................20 V DC

Current through closed contact ...............................................3 mA

Pulse input duration (TAC Menta CNT block)..............min. 20 ms

–as Thermistor Inputs;

TAC thermistor sensor........................ 1800 ohms at 25 °C (77 °F)

Supply voltage.....................................................................1 V DC

or (individually selectable)

TAC thermistor .....................................10 kohms at 25 °C (77 °F)

Supply voltage.....................................................................5 V DC

Measuring range.................. –50 °C to +150 °C (–58 °F to 302 °F)

Inaccuracy:

–50 °C to –30 °C (–58 °F to –22 °F)...........................................±1.5 °C (±2.7 °F)

–30 °C to 0 °C (–22 °F to +32 °F) ..............................................±0.5 °C (±0.9 °F)

±0 °C to +50 °C (+32 °F to +122 °F).......................................... ±0.2 °C (±0.4 °F)

+50 °C to +100 °C (122 °F to 212 °F)........................................ ±0.5 °C (±0.9 °F)

+100 °C to +150 °C (212 °F to 302 °F)...................................... ±1.5 °C (±2.7 °F)

–as Current Inputs;

Input signal (terminals U–M; over-current protected)......0–20 mA

Input resistance .................................................... ............... 47 ohm

Inaccuracy within..........................± (0.03 mA + 0.4 % of reading)

–as Voltage Inputs;

Input signal....................................................................0–10 V DC

Input resistance ............................................................. >100 kohm

Inaccuracy within...............................± (7 mV + 0.2 % of reading)

LED digital input status indicators (TAC Xenta 422A only):

Quantity..........................................................................................4

Color................................ red or green, selected using TAC Menta

Polarity.........non-inverted or inverted, selected using TAC Menta

Digital outputs (K1–K5):

Quantity..........................................................................................5

Control voltage, relay outputs......................... max. 2A, 250 V AC

Control current, to be protected by a max. 10 A fuse,

................max 2 A (greater current allowed for short periods)

Pulse length .....................................................................min. 0.5 s

Manual override for digital outputs (TAC Xenta 422A only):

Quantity..........................................................................................5

Switch positions.................................................. ON, AUTO, OFF

Indicators for Auto output status.................................. green LEDs

TAC AB, Dec 2004 23 (48)

0-004-7771-3 (EN)

Page 24

3 Technical Description TAC Xenta, TAC Xenta® 400 I/O Modules

3.5 TAC Xenta 451/452 Analog Input and Output module

The modules have four universal inputs, four thermistor inputs and two

analog outputs. The universal inputs can be used as analog inputs, digital inputs or pulse counters.

The TAC Xenta 452 is also equipped with LED status indicators, one

for each universal input, when used as a digital input, and manual override controls for the analog output values. The LED input status colors,

red or green, can be selected individually by setting switches under the

front cover.

Terminals (451, 452) and Controls/Indicators (452)

24 V AC/DC

Comm

}

}

~ 0

UI

G G0 C1C2 U1 M U2 U3 M U4

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

Y1 M Y2 B1 M B2 B3 M B4

AO

Thermistor inputs

2 Analog outputs:

Override controls

TAC Xenta 452

AO

MAN 1

MAN 2

0 - 10V

AUTO

AUTO

0 - 10V

DI

1 2 3 4

4 DI Indicators:

⇑ red

⇓ green

Fig. 3.6: TAC Xenta 451/452 terminals and TAC Xenta 452 Analog output override controls and Indicators

Table 3.4: TAC Xenta 451/452 summary

Type No. TAC Menta Block type Terminal ref. Ind./Override (452)

Thermistor inputs 4 AI - Analog input B1 - B4 -

Universal inputs 4 AI - Analog input or

DI - Digital input or

CNT - Pulse counter

U1 - U4

U1 - U4

U1 - U4

red or green / -

-

-

Analog outputs 2 AO - Analog output Y1 - Y2 - / Man-Auto

24 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 25

TAC Xenta, TAC Xenta® 400 I/O Modules 3 Technical Description

Technical data TAC Xenta 451 and 452

Supply voltage (G, G0) .................................24 V AC ±20%, 50/60 Hz

or..........................................................................19–40 V DC

Power consumption.................................................................max. 2 W

Transformer sizing .........................................................................4 VA

Universal inputs (U1–U4):

Quantity..........................................................................................4

A/D-resolution ......................................................................12 bits

–as Digital Inputs;

Voltage across open contact..................................... max. 28 V DC

Current through closed contact ...............................................4 mA

Pulse input duration (TAC Menta CNT block)..............min. 80 ms

–as Thermistor Inputs;

Supply voltage..................................................................0.6 V DC

TAC thermistor sensor........................ 1800 ohms at 25 °C (77 °F)

–as Voltage Inputs;

Input signal....................................................................0–10 V DC

Input resistance .................................................... ..........100 kohms

accuracy ..................................................... ........... 1% of full scale

LED digital input status indicators (TAC Xenta 452 only):

Quantity..........................................................................................4

Color.................................red or green, selected with a DIP switch

Thermistor inputs (B1–B4):

Quantity..........................................................................................4

A/D-resolution ......................................................................12 bits

TAC thermistor sensor........................ 1800 ohms at 25 °C (77 °F)

Measuring range.................. –50 °C to +150 °C (–58 °F to 302 °F)

Accuracy:

–50 °C to –30 °C (–58 °F to –22 °F)...................... ±4 °C (±7.2 °F)

–30 °C to –10 °C (–22 °F to +14 °F) ..................... ±2 °C (±3.6 °F)

–10 °C to +10 °C (+14 °F to +50 °F)..................... ±1 °C (±1.8 °F)

+10 °C to +30 °C (50 °F to 86 °F)...................... ±0.5 °C (±0.9 °F)

+30 °C to +60 °C (86 °F to 140 °F)....................... ±1 °C (±1.8 °F)

+60 °C to +120 °C (140 °F to 248 °F)................... ±2 °C (±3.6 °F)

+120 °C to +150 °C (248 °F to 302 °F).................±4 °C (±7.2 °F)

Analog outputs (Y1–Y2):

Quantity..........................................................................................2

D/A-resolution ......................................................................12 bits

Control voltage..............................................................0–10 V DC

Control current, short-circuit proof................................max. 2 mA

Deviation max ±1%

Manual control of the analog outputs (TAC Xenta 452 only):

Quantity..........................................................................................2

Switch positions........................................................MAN, AUTO

Control voltage..............................................................0–10 V DC

TAC AB, Dec 2004 25 (48)

0-004-7771-3 (EN)

Page 26

3 Technical Description TAC Xenta, TAC Xenta® 400 I/O Modules

3.6 TAC Xenta 451A/452A Universal Input and Analog Output module

The modules have eight universal inputs and two analog outputs. The

universal inputs can be used as analog inputs, digital inputs or pulse

counters.

The TAC Xenta 452A is also equipped with LED status indicators for

each universal input (when used as a digital input) and manual override

controls for the analog output values. The LED input status colors, red

or green, and the polarity (lit when contact is open or closed) can be

selected individually by altering the parameter settings in TAC Menta.

Terminals (451A, 452A) and Controls/Indicators (452A)

24 V AC

(21.6−40 V DC)

Comm

}

}

~ 0

UI

G G0 C1C2 U1 M U2 U3 M U4

TAC Xenta 452A

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

Y1 M Y2 U5 M U6 U7 M U8

AO

UI

20 V DC

2 Analog outputs:

Override controls

AO DI

MAN 1

MAN 2

0-10V 0-10V

AUTO

AUTO

8 DI Indicators:

76543218

red/green

Fig. 3.7: TAC Xenta 451A/452A terminals and TAC Xenta 452A Analog output override controls and

Indicators

Table 3.5: TAC Xenta 451A/452A summary

Type No. TAC Menta Block type Terminal ref.

Universal inputs 8 AI - Analog input or

DI - Digital input or

CNT - Pulse counter

U1 - U8

U1 - U8

U1 - U8

Ind./Override

(452A)

-

red or green / -

-

Analog outputs 2 AO - Analog output Y1 - Y2 - / Man-Auto

These modules can also be used as certified LONMARK® devices. The

configuration and use of SNVTs are explained in th e 0FL-4182 Configuration Instruction.

26 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 27

TAC Xenta, TAC Xenta® 400 I/O Modules 3 Technical Description

Technical data TAC Xenta 451A and 452A

Supply voltage (G, G0) .................................24 V AC ±20%, 50/60 Hz

or...................................................................... 21.6–40 V DC

Power consumption..................................................................max. 3W

Transformer sizing .........................................................................6 VA

Universal inputs (U1–U8):

Quantity..........................................................................................8

A/D-resolution ......................................................................12 bits

–as Digital Inputs;

Voltage across open contact..............................................20 V DC

Current through closed contact ...............................................3 mA

Pulse input duration (TAC Menta CNT block)..............min. 80 ms

–as Thermistor Inputs;

TAC thermistor sensor........................ 1800 ohms at 25 °C (77 °F)

Supply voltage.....................................................................1 V DC

or (individually selectable)

TAC thermistor ....................................10 kohms at 25 °C (77 °F)

Supply voltage.....................................................................5 V DC

Measuring range.................. –50 °C to +150 °C (–58 °F to 302 °F)

Inaccuracy:

–50 °C to –30 °C (–58 °F to –22 °F)...........................................±1.5 °C (±2.7 °F)

–30 °C to 0 °C (–22 °F to +32 °F) ..............................................±0.5 °C (±0.9 °F)

±0 °C to +50 °C (+32 °F to +122 °F).......................................... ±0.2 °C (±0.4 °F)

+50 °C to +100 °C (122 °F to 212 °F)........................................ ±0.5 °C (±0.9 °F)

+100 °C to +150 °C (212 °F to 302 °F).....................................±1.5 °C (±2.7 °F))

–as Current Inputs;

Input signal (terminals U–M; over-current protected)......0–20 mA

Input resistance .................................................... ............... 47 ohm

Inaccuracy within................................± (7 mV +0.4 % of reading)

Power supply for one 2-wire 4–20 mA transmitter.....20 V DC/25 mA

–as Voltage Inputs;

Input signal....................................................................0–10 V DC

Input resistance ............................................................. >100 kohm

Inaccuracy within................................± (7 mV +0.2 % of reading)

LED digital input status indicators (TAC Xenta 452A only):

Quantity..........................................................................................8

Color................................ red or green, selected using TAC Menta

Polarity.........non-inverted or inverted, selected using TAC Menta

Analog outputs (Y1–Y2):

Quantity..........................................................................................2

D/A-resolution ........................................................................8 bits

Control voltage..............................................................0–10 V DC

Control current, short-circuit proof................................max. 2 mA

Deviation..........................................................................max ±1%

TAC AB, Dec 2004 27 (48)

0-004-7771-3 (EN)

Page 28

3 Technical Description TAC Xenta, TAC Xenta® 400 I/O Modules

Manual override for analog outputs (TAC Xenta 452A only):

Quantity.........................................................................................2

Switch positions ........................................................MAN, AUTO

Potentiometer range....................................................0–10.5 V DC

28 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 29

TAC Xenta, TAC Xenta® 400 I/O Modules 3 Technical Description

3.7 TAC Xenta 471 Analog Input module

The module has eight universal analog inputs (U). The analog inputs

can independently be used for current input or as voltage inputs. The

current inputs use either the internal power (24V DC) or the external

power (M).

Terminals on 471

24 V AC

(19-40 V DC)

Comm

}

}

~ 0

G G0 C1C2 U1 M U2 U3

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

M U4 U5 M U6 U7 M U8

24 V DC

24 V DC

24 V DC

24 V DC

Green LED

Fig. 3.8: The TAC Xenta 471 terminal

Table 3.6: TAC Xenta 471 summary

Type No. TAC Menta Block type Terminal ref. Override

Universal inputs 8 AI - Analog inputs U1 - U8 (n.a.)

Technical data TAC Xenta 471

Supply voltage (G, G0) .................................24 V AC ±20%, 50/60 Hz

or..........................................................................19–40 V DC

Power consumption...............................................................max. 10 W

Transformer sizing .......................................................................10 VA

Universal inputs (U1–U8):

Quantity..........................................................................................8

A/D-resolution ......................................................................12 bits

– as current input with an external power supply;

Input signal (terminals U–M)........................................ 0/4–20 mA

Input resistance .................................................... ..............20 ohms

accuracy ................................................................ within 0.02 mA

– as current input with an internal power supply;

Input signal (terminals 24 V DC–U).................................4–20 mA

Input resistance .................................................... ..............20 ohms

TAC AB, Dec 2004 29 (48)

0-004-7771-3 (EN)

Page 30

3 Technical Description TAC Xenta, TAC Xenta® 400 I/O Modules

accuracy..................................................................within 0.02 mA

Voltage .....................................................................24 V DC ±2 V

Current limit, total value .............................................200 ±20 mA

– as Voltage input;

Input signal (terminals U–M).............................0–1, 0/2–10 V DC

Input resistance...............................................................100 kohms

accuracy.....................................................................within 0.01 V

Resetting default values

If you press the Service Pin for seven seconds during the first minute

following a restart, the parameters of the module will automatically be

reset to the factory default settings. A restart occurs following power on.

The green LED on the front will light continuously during activation

(about 7 seconds) and when the reset is completed, it will flash rapidly

(off-line indication).

• The parameters of the I/O module are now reset:

• Domain table index 0: ID len = 1, ID = 11

, Subnet = 1, Node = 1

hex

and Clone Domain = 0 (internal parameter making the unit silent,

until its correct address has been set by the system).

• Domain table index 1: Unused.

• Address table index 0: Domain = 0, Node = 0, Rpt Tmr = 16,

Retries = 0, Rcv Tmr = 128, Tx Tmr = 16, Subnet = 0.

• Address table index 1: Unused.

• Non_Group_Receive_Timer = 768 ms.

• Node Mode: Unconfig.

• Network Management Authentication = Off

• Pre-emption Timeout = Forever

• The inputs will be configured as voltage inputs.

30 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 31

TAC Xenta, TAC Xenta® 400 I/O Modules 3 Technical Description

3.8 TAC Xenta 491/492 Analog Output module

The modules have eight analog outputs.

The TAC Xenta 492 also has switches for manually controlling the ana-

log outputs.

Terminals (491, 492) and switches (492)

24 V AC

(19-40 V DC)

Fig. 3.9: TAC Xenta 491/492 terminals and manual control of the TAC Xenta 492

Comm

}

}

~ 0

AO

G G0 C1C2 Y1 M Y2 M Y3 M

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

Y4 M Y5 M Y6 M Y7 M Y8 M

AO

Green LED

8 Analog outputs:

Manual control

8 AO

MAN 1

MAN 2

0-10V

AUTO

AUTO

TAC Xenta 492

MAN 5

MAN 6

0-10V

AUTO

AUTO

0-10V

0-10V

MAN 3

AUTO

MAN 7

AUTO

0-10V

0-10V

MAN 4

AUTO

MAN 8

AUTO

0-10V

0-10V

Table 3.7: TAC Xenta 491/492 summary

Type No. TAC Menta Block type Terminal ref. Override (492)

Analog outputs 8 AO - Analog outputs Y1 -Y8 - / Man-Auto

Technical data TAC Xenta 491 and 492

Supply voltage (G, G0) .................................24 V AC ±20%, 50/60 Hz

or..........................................................................19–40 V DC

Power consumption.................................................................max. 2 W

Transformer sizing .........................................................................3 VA

Analog outputs (Y1–Y8):

Quantity..........................................................................................8

D/A-resolution ......................................................................12 bits

Control voltage..............................................................0–10 V DC

Control current, short-circuit proof................................max. 2 mA

Deviation ......................................................................... max ±1%

Manual control of the analog outputs (TAC Xenta 492 only):

Quantity..........................................................................................8

Switch positions........................................................MAN, AUTO

Control interval ....................................................................0–10 V

TAC AB, Dec 2004 31 (48)

0-004-7771-3 (EN)

Page 32

3 Technical Description TAC Xenta, TAC Xenta® 400 I/O Modules

Resetting default values

If you press the Service Pin for seven seconds during the first minute

following a restart, the parameters of the module will automatically be

reset to the factory default settings. A restart occurs following power on.

The green LED on the front will light continuously during activation

(about 7 seconds) and when the reset is completed, it will flash rapidly

(off-line indication).

The parameters of the I/O module are now reset:

• Domain table index 0: ID len = 1, ID = 11

, Subnet = 1, Node = 1

hex

and Clone Domain = 0 (internal parameter making the unit silent,

until its correct address has been set by the system).

• Domain table index 1: Unused.

• Address table index 0: Domain = 0, Node = 0, Rpt Tmr = 16,

Retries = 0, Rcv Tmr = 128, Tx Tmr = 16, Subnet = 0.

• Address table index 1: Unused.

• Non_Group_Receive_Timer = 768 ms.

• Node Mode: Unconfig.

• Network Management Authentication = Off

• Pre-emption Timeout = Forever

• The start values of the analog outputs will be reset.

32 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 33

TAC Xenta, TAC Xenta® 400 I/O Modules 4 Installation

4 Installation

4.1 Mounting

The TAC Xenta controllers and I/O modules are designed for mounting

on a DIN rail inside a cabinet. They can also be mounted directly on a

wall. In such cases, a wide range of standard enclosures are available

which meet DIN 43 880, with different enclosure ratings.

The enclosure mainly consists of a terminal part containing screw terminals, as well as an electronics part, where the printed circuit boards

are situated. The enclosure is designed so that electrical installation can

be carried out using the screw terminals of the terminal part, when

mounted on a DIN rail or wall.

Fig. 4.1: The terminal part and the electronics part of the TAC Xenta I/O module

90

180

Ø 4.

0

110

48 ± 0.5

16.1

TAC Xenta 300

148 ± 2.0

174 + 0.4 to an I/O module

4

Ø

110

48 ± 0. 5

10,1

2 3 4 5 6 7 8 10

12 13 14 15 16 17 18 20

70 ± 2.0

90 + 0.4 to the next 400 module

Fig. 4.2: Mounting distances for TAC Xenta controllers and one or more I/O modules

TAC AB, Dec 2004 33 (48)

0-004-7771-3 (EN)

Page 34

4 Installation TAC Xenta, TAC Xenta® 400 I/O Modules

4.2 Electrical installation

4.2.1 General considerations

Installation is normally treated as category CAT III (IEC 664), which in

principle means permanent connection to a 230 V AC mains supply. For

the Xenta 400, this is only applicable to the relay outputs of the I/O

modules.

All equipment connected to the TAC Xenta units must comply with the

following standards:

• EN 60 742 (or other relevant safety standard; for example ETL

listing UL 3111-1, first version and CAN/CSA C22.2 No. 1010.1-

92) for the device(s) that provide an ELV-type power supply (normally 24 V AC) to the controller and other connected equipment.

• EN 61 010 or IEC 950 (or other relevant safety standard) for computers, modems and other equipment powered by a 230 V mains

supply.

If equipment using a 230 V mains supply is connected to a relay output

terminal of the I/O modules, low-voltage equipment connected to the

other relay terminals of the controller must provide at least basic insulation to all touchable parts.

We strongly recommend that switches are installed to make it possible

to separate external equipment when the relay output terminals control

equipment using a 230 V mains supply.

4.2.2 Input/Output Circuit Principles

The input/output circuit principles and key values are shown below.

Current Input 0-20 mA

Table 4.1:

Unit Ri ohm

Xenta 420A 47

Xenta 450A 47

Xenta 470 20

Fig. 4.3: Current Input - internal resistance

34 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 35

TAC Xenta, TAC Xenta® 400 I/O Modules 4 Installation

Voltage Input 0-10 V

Table 4.2:

Unit Ri ohm

Xenta 420A >100k

Xenta 450 100k

Xenta 450A >100k

Xenta 470 >100k

Fig. 4.4: Voltage Input - internal resistance

Digital Input

Table 4.3:

Unit

Xenta 410 33 6.6k 14

Xenta 420 33 6.6k 14

Xenta 420A 20 6.8k 10

Xenta 450 28 6.6k 14

Xenta 450A 20 6.8k 10

Fig. 4.5: Digital Input - voltage and resistance values

Note

When connected to this input, a pulse generator must use an npn-type

output transistor.

Us

V

Rs

ohm

Ut

V

TAC AB, Dec 2004 35 (48)

0-004-7771-3 (EN)

Page 36

4 Installation TAC Xenta, TAC Xenta® 400 I/O Modules

Thermistor Input 1.8 kohm @25 °C

Table 4.4:

Unit

Ub

V

Rb

ohm

Char

Xenta 420A 1 1.5k a*

Xenta 450 0.85 1.22k b*

Xenta 450A 1 1.5k a*

* Thermistor curves are shown below

Fig. 4.6: Thermistor Input 1.8 kohm - voltage and resistance values

Fig. 4.7: Thermistor curve type a- Xenta 420A and 450A

Fig. 4.8: Thermistor curve type b - Xenta 450

36 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 37

TAC Xenta, TAC Xenta® 400 I/O Modules 4 Installation

Thermistor Input 10 kohm @25 °C

Table 4.5:

Unit

Ub

V

Rb

ohm

Xenta 420A 10 6.8k c*

Xenta 450A 10 6.8k c*

* Thermistor curve is shown below

Fig. 4.9: Thermistor Input 10 kohm - voltage and resistance values

Fig. 4.10: Thermistor curve type c - Xenta 420A and 450A

Char

Analog Output

Table 4.6:

Unit Ro ohm

Xenta 450 47

Xenta 450A 22

Xenta 490 44

Fig. 4.11: Analog Output - resistance value

Relay Output

Fig. 4.12: Relay Output - Normally open

TAC AB, Dec 2004 37 (48)

0-004-7771-3 (EN)

Page 38

4 Installation TAC Xenta, TAC Xenta® 400 I/O Modules

4.2.3 Terminals and units

• Mount the terminal part on a DIN rail.

• Connect the cables to the correct terminals, see the figure below.

• Put the electronics part of the module on the terminal part.

24 V AC

Comm

(19-40 V DC)

Fig. 4.13: The terminal blocks of a TAC Xenta 400

}

}

~ 0

G G0 C1C2

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

38 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 39

TAC Xenta, TAC Xenta® 400 I/O Modules 4 Installation

Connections

When cabinet mounting is used, jumpers may be used between M (measurement neutral) terminal pairs, as shown in the figure below and on

the next page. All G0 points must be connected to protective ground.

min 1.5 mm2, max 2 m

Insulated

signal

ground rail

230

VAC

N

Cabinet

ground

rail

TAC Xenta 451/452 I/O module

G G0 U1 M U2 Y1 M Y2 B1 M B2 M

G

G0

Cabinet

terminals

G G0 M S

M S

0 - 10

V

G G0 M

G G0 MX X1

X

1 2

2 1 2

1

U3

R

PU

G1 G G0

R =500

Ω

Measuring

device

0–10 V

Measuring

device (with

its own trafo)

Actuator Actuator with

differential input (FORTA)

Thermistor

(2 sensors)

Measuring

device, twowire 4–20 mA

Fig. 4.14: Basic circuit diagram for cabinet connections of TAC Xenta 451/452 I/O modules

A corresponding diagram for the TAC Xenta 471 is shown on the next

page.

TAC AB, Dec 2004 39 (48)

0-004-7771-3 (EN)

Page 40

4 Installation TAC Xenta, TAC Xenta® 400 I/O Modules

min 1.5 mm2, max 2 m

TAC Xenta 471 I/O module

G G0 U1 M U2 U3 M U4 U5 U6 24VDC M U7

Insulated

signal

ground rail

230

G

VAC

G0

N

Cabinet

ground

rail

Cabinet

terminals

Isolated

converter

G G0 M S

0 - 10

V

Measuring

device

M S

V

0 - 10

Measuring

device (with

its own trafo)

G G0 M S

0(4) - 20 mA

Measuring

device

M S

0(4) - 20 mA

Measuring

device (with

its own trafo)

Out 24

VDC

4-20 mA

Out 24

VDC

4-20 mA

Two Measuring devices

(2-wire)

Fig. 4.15: Basic circuit diagram for cabinet connections of TAC Xenta 471 I/O module

When connecting G0 to ground, each TAC Xenta unit must have its

own connection to the ground rail, i.e. jumpers cannot be used for the

G0 terminals. Please refer to the figure on the next page.

Several units may share the same ground rail, but every unit with measuring inputs and/or analog outputs must have all its ground connections

with the same ground rail.

In other words, a discontinuation in the ground rail must not split a controller or separate it from the connected units.

M

S

Frequency converter

(Signal ground

connected to

protective ground)

40 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 41

TAC Xenta, TAC Xenta® 400 I/O Modules 4 Installation

Incoming cables for TAC Xenta 1 Incoming cables for TAC Xenta 2

TR

G0

2

Insulated signal ground rail

TAC Xenta 1

G0

PU

G0

Insulated signal ground rail

TAC Xenta 2

G0

min 1.5 mm

Cabinet

ground

rail

Fig. 4.16: Connections between insulated signal ground rails and the cabinet ground rail

When a Wall Module (ZS101–105) is connected to TAC Xenta 400 I/O

modules, the following terminals can be used (term. B2: v 3.0 or later).

min 1.5 mm2, max 2 m

TAC Xenta 42x

X1 M K1 KC1 G G0

Insulated

signal

ground rail

230

VAC

TAC Xenta 45x

G G0 C2 C1 M B1 B2

G

PU

G0

G0

N

Cabinet

ground

rail

Cabinet

terminals

ZS 101-105

F0 F1 F2 F3G0 G C2 C1 1 2 3 4 5 6 7 8

2

1

3

0

470 Ω

10 kΩ

(24 V AC)

Fig. 4.17: Basic circuit diagram for connecting Wall Module ZS 101–105 to TAC Xenta 400 I/O modules

TAC AB, Dec 2004 41 (48)

0-004-7771-3 (EN)

Page 42

4 Installation TAC Xenta, TAC Xenta® 400 I/O Modules

4.2.4 Cables

Power and Communication

G and G0 (Power supply):

G, min. cross-sectional area ...........................0.75 mm² (19 AWG)

G0 to TAC Xenta, min. cross-sectional area....1.5 mm² (16 AWG)

C1 and C2 (Network):

The TP/FT-10 system allows the user to wire the control devices

with virtually no topology restrictions.

Min. cross-sectional area................................0.65 mm² (22 AWG)

The max. wire length in one segment depends on the type of wire

and the topology, see the table below.

The wires are not polarity sensitive, but must be a twisted-pair.

For more details, please refer to the ”TAC Xenta Network guide”.

One of the following cable types must be used:

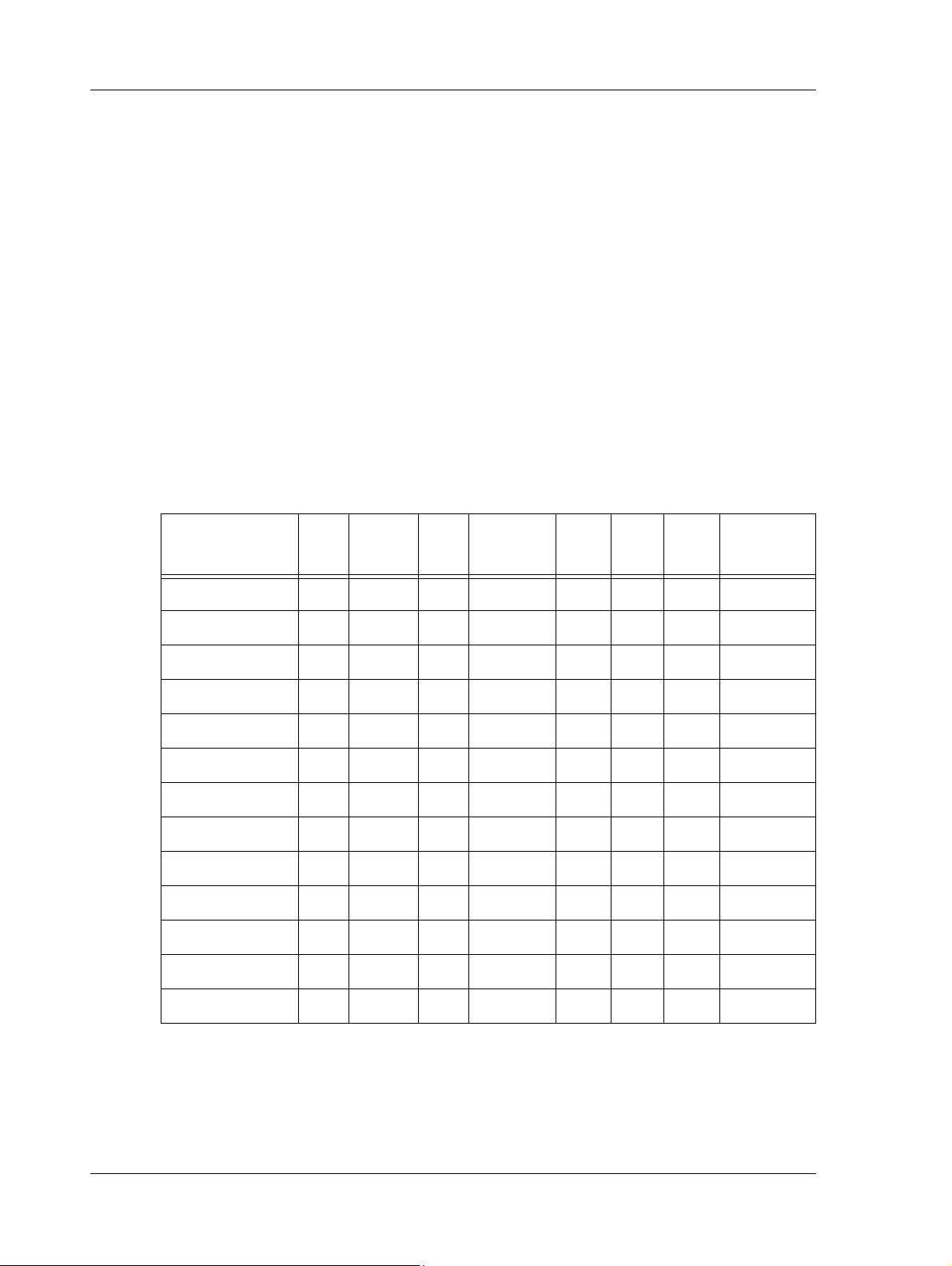

Table 4.7: Recommended TP/FT-10 communication cables

Cable

Belden 85102, single

twisted pair

Belden 8471, single

twisted pair

UL Level IV 22A WG,

twisted pair

Connect-Air 22AWG,

1 or 2 pairs

Siemens J-Y(st)Y

2x2x0.8 4-wire helical

twist, solid, shielded

TIA568A Cat. 5

24AWG, twisted pair

Max. bus length,

doubly terminated

bus topology

m (ft.)

2700 (9000)

2700 (9000)

1400 (4600)

1400 (4600)

900 (3000)

900 (3000)

Max. node-to-node

distance, single

terminated free

topology

m (ft.)

500 (1600)

400 (1300)

400 (1300)

400 (1300)

320 (1000)

250 (820)

Max. total wire

length single

terminated free

topology

m (ft.)

500 (1600)

500 (1600)

500 (1600)

500 (1600)

500 (1600)

450 (1500)

If a shielded communication cable is us ed, the shield must be grounded

at one point only.

Redundant wires (second pair of Siemens J-Y(st)Y) are cut at the end of

the shield.

42 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 43

TAC Xenta, TAC Xenta® 400 I/O Modules 4 Installation

Communication cable,

unshielded

Terminals for

incoming cables

C1 C2

TAC Xenta 1

C1 C2

TAC Xenta 2

Separate

junction

Communication cable,

unshielded

470 kΩ

¼ W

C1 C2

TAC Xenta 1

C1 C2

TAC Xenta 2

Terminals for

incoming cables

Shield is grounded

at one point only

Fig. 4.18: Connecting the communication cable

TAC Xenta 400 input/output cable requirements

Terminals type X:

Min. cross-sectional area................................0.25 mm² (22 AWG)

Max. cable length.................................................... 200 m (660 ft.)

Terminals type U, connected as

a) digital inputs,

b) measurement devices using voltage signals that are not

powered via the same transformer as the I/O module or

c) measurement devices using current signal

Min. cross-sectional area................................0.25 mm² (22 AWG)

Max. cable length.................................................... 200 m (660 ft.)

Terminals type U, connecting measurement devices, using voltage

signals that are powered via the same transformer as the

I/O module:

Min. cross-sectional area................................0.75 mm² (19 AWG)

Max. cable length........................................................ 20 m (66 ft.)

TAC AB, Dec 2004 43 (48)

0-004-7771-3 (EN)

Page 44

4 Installation TAC Xenta, TAC Xenta® 400 I/O Modules

Terminals type B or U, as thermistor inputs:

Min. cross-sectional area................................0.75 mm² (19 AWG)

Max. cable length,

up to 75 °C (167 °F), cross-sectional area 0.75 mm² (19 AWG)

............................................................................75 m (250 ft.)

up to 75 °C (167 °F), cross-sectional area 1.5 mm² (16 AWG)

..........................................................................150 m (500 ft.)

up to 150 °C (302 °F), cross-sectional area 1.5 mm² (16 AWG)

............................................................................75 m (250 ft.)

Terminals type K (relay outputs):

Cross-sectional area.......................0.75 – 1.5 mm² (19 – 16 AWG)

Max. cable length ....................................................200 m (660 ft.)

Terminals type Y (for actuators powered via

the same transformer as the I/O module):

Min. cross-sectional area................................0.75 mm² (16 AWG)

Max. cable length

1

.....................................................20 m (66 ft.)

Terminals type Y (for actuators power supplied via

their own transformer, external or internal;

or when the outputs have isolated converters):

Min. cross-sectional area................................0.25 mm² (22 AWG)

Max. cable length ....................................................200 m (660 ft.)

1

Some actuators allow greater cable lengths, for example:

EM52 0.5 mm² (20 AWG) 80 m (260 ft.)..three wires

EM15LBB 0.75 mm² (19 AWG) 80 m (260 ft.)..three wires

EM42 0.75 mm² (19 AWG) 80 m (260 ft.)..four wires

TAC Forta 0.75 mm² (19 AWG) 80 m (260 ft.)..four wires

TAC Forta 1.5 mm² (16 AWG) 100 m (330 ft.)..three wires(part nos. xxxx-010)

4.3 Commissioning

Commissioning of the I/O modules is normally carried out together with

the TAC Xenta controller units that they belong to.

The procedure is therefore described in the TAC Xenta 280 - 300 - 401

manual.

However, TAC Xenta 421A/422A and 451A/452A can also be used as

certified L

tocol is used, some additional configuration is required. This is

explained in the Configuration instructions

• 0FL-4181 for TAC Xenta 421A/422A and

• 0FL-4182 for TAC Xenta 451A/452A.

ONMARK® devices. When the open LonTalk® (SNVT) pro-

44 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 45

TAC Xenta, TAC Xenta® 400 I/O Modules Index

Index

A

agency compliances 18

Analog Input and Output module 24

Analog Input module 29

Analog Output 37

Analog Output module 31

AO 15

ASIC 9

B

B1 - B4 24

C

C1 and C2 (Network) 42

cabinet mounting 39

cable

input/output, requirements 43

shielded 42

cables 42

commissioning 44

Configuration instructions 44

connections 39

Current Input 0-20 mA 34

D

DI 15

Digital Input 35

Digital Input and Output module 20

Digital Input module 19

DIN rail 33

DIP switch 19

DO 15

Docnet 9

E

external power 29

G

G and G0 (Power supply) 42

ground

communication cable 42

G0 40

measuring inputs 40

, 21, 25

protective 39

rail 40

–41

signal 41

I

I/O configuration 14

I/O expansion modules 13

indication

off-line 30

status 14

indicators

LED 17

input/output circuits 34

installation 33

internal power 29

, 32

J

jumpers

G0 40

M terminals 39

K

K1 - K5 20, 22

L

LonMark® device 44

TAC Xenta 421A/422A 22

TAC Xenta 451A/452A 26

LonTalk® (SNVT) protocol 44

M

manual control

analog outputs 24

digital outputs 20

mounting distances 33

, 26, 31

, 22

N

network 14

P

parameters

default values 30

part

electronics 33

terminal 33

part numbers 18

, 32

TAC AB, Dec 2004 45 (48)

0-004-7771-3 (EN)

Page 46

Index TAC Xenta, TAC Xenta® 400 I/O Modules

polarity

network wires 42

Xenta 422A LED 22

Xenta 452A LED 26

pulse generator 35

R

Relay Output 37

relay output 34

relay outputs 20

reset to default

TAC Xenta 471 30

TAC Xenta 491/492 32

, 22, 34

S

safety 34

service pin 17

SNVT 44

TAC Xenta 421A/422A 22

TAC Xenta 451A/452A 26

standards

compliance with 34

switch

external equipment 34

thermistor inputs 25

TI 15

TP/FT-10

communication cables 42

network 14

, 27

U

U1 - U4 24

U1 - U8 26

UI 15

Universal Input and Analog Output module 26

Universal Input and Digital Output module 22

universal inputs (UI) 14

, 29

V

Voltage Input 0-10 V 35

W

Wall Module 41

X

X1 - X4 20

X1–X10 19

T

TAC Menta 22, 26

TAC Xenta 301/302/401 13

TAC Xenta 400 9

TAC Xenta 400 I/O modules 13

TAC Xenta 411/412 19

TAC Xenta 421/422 20

TAC Xenta 421A/422A 22

TAC Xenta 421XT and 422XT

ambient temperature 21

TAC Xenta 451/452 24

TAC Xenta 451A/452A 26

TAC Xenta 471 29

TAC Xenta 491/492 31

TAC Xenta OP 13

technical data

common 18

TAC Xenta 411 and 412 19

TAC Xenta 421 and 422 21

TAC Xenta 421A and 422A 23

TAC Xenta 451 and 452 25

TAC Xenta 451A and 452A 27

TAC Xenta 471 29

TAC Xenta 491 and 492 31

terminals 17

Thermistor Input

1.8 kohm @25 °C 36

10 kohm @25 °C 37

, 40

, 44

, 39

, 44

Y

Y1 - Y2 24, 26

Y1 -Y8 31

Z

ZS10x Sensors 41

46 (48) TAC AB, Dec 2004

0-004-7771-3 (EN)

Page 47

Page 48

TAC helps people feel and function better, as a direct result of greater indoor climate. This is

made possible by TAC’s concept of Open Systems for Building IT

®

, which utilizes information

technology to provide clients with advantages such as indoor climate optimization, energy

savings, flexibility, security, reduced expenses and user-friendly operation.

Loading...

Loading...