Page 1

Powerlogic

Easergy P5

Catalog 2020

Network protection relays

www.se.com/easergy

Page 2

Note: Electrical power systems are dangerous, protection relays are defined and governed

by international standards such as IEC 60255 “Measuring relays and protective equipment”

and IEEE C37.97 “Protective relay applications to power systems buses”. Never attempt to

install or operate protection relays or associated equipment without the necessary

qualifications, training and tools. Exposure to electrical arc-flash incidents can be life

threatening, no situation can ever be deemed fully safe. Standards such as NFPA 70E define

important risk categorization and such standards identify both distance from, and energy of

the arc incident to be important factors. In order to reduce the risk category and improve

safety during arc-flash incidents, functionality is available in Easergy P5 protection relays to:

i) to operate electrical panel from a safer distance via wireless communication, and ii) arcflash protection functionality to detect and limit the arc energy by tripping the connected

circuit breaker faster than in a conventional protection scheme.

Page 3

PM107471

General Contents

Easergy P5

Range description

Product description

Digital experience

Additional modules and accessories

5

48

76

82

Services

Ordering

96

102

schneider-electric.com | 3Easergy P5 Catalog

Page 4

Easergy P5

Range description

schneider-electric.com4 | Easergy P5 Catalog

Page 5

Easergy P5

Range description

Overview

Selection guide

10

11

Selection guide by functionality 12

Selection guide by application 14

Feeder / Incomer application 14

Motor application 15

Transformer application 16

Arc-flash application 18

Capacitor application 19

Functions and description

Communication

Examples of architectures 42

Redundancy protocols 43

Time synchronization 44

20

42

Data exchanged 45

Cybersecurity

Cybersecurity - Basic level 46

Cybersecurity - Advanced level 47

46

schneider-electric.com | 5Easergy P5 Catalog

Page 6

The Easergy P5 at a glance

The Easergy P5 is a protection relay for demanding medium-voltage applications. It offers users industry-leading

dedicated protection relay functionality to reduce risks, improve reliability, all with advanced connectivity. Additionally, it

can be used with a range of digital tools that make everyday operations simpler for users. The Easergy P5 is part of the

PowerLogic range of power monitoring and control solutions and has been built on more than 100 years of experience

in protection relays, including Sepam, MiCOM, and Vamp ranges, renowned for their reliability and performance.

Industry-leading protection functions

Built-in arc-flash protection function (optional)

Nearby control with a mobile application

Latest cybersecurity built in, with IEC 62443 standard compliance and Achilles certification

Best-in-class reliability

Withdrawable design for quicker maintenance

Backup memory function enabling industry-leading 10 minute recovery time!

Condition monitoring for reduced risk of power outages and maximized equipment life

Extended equipment lifetime when used with EcoStruxure Asset Advisor

Maximized everyday simplicity

Easier operation with digital tools including the EcoStruxure Power Device app

Powerful communication with plug and play ports and seven protocols supported

Scalable hardware making it easy to upgrade as your applications evolve

schneider-electric.com6 | Easergy P5 Catalog

6

Page 7

Enjoy a package of sought-after

features in one device

The Easergy P5 presents a major step forward for protection relays,

bringing a number of best-in-class features together in one device.

Built-in arc-flash protection functions

Arc-flashes will always exist when switching or during unexpected conditions.

The protection function detects if an arc-flash exists, and take action within

milliseconds to isolate the connected circuit breaker, meaning that

arc-flash energy should not grow and cause unexpected outages or risks.

Advanced cybersecurity

IEC 62443 compliant, the Easergy P5 has been designed with an optional

cybersecurity package. This means reduced exposure to cyber threats

and improved operational security. By default, the Easergy P5 includes

important features such as password management, port hardening, and

secured communication compliant to the latest international standards.

Intuitive withdrawable design

With a handle built in as part of the design, the P5 can be quickly

disconnected or exchanged to speed up maintenance. Wiring, data,

communication, and settings (including backup) can be stored with the

panel and will be there when the relay is reconnected.

Improved recovery time

When maintenance or testing is required, Easergy P5 helps dramatically decrease your outage recovery time. The backup

memory can automatically restore settings, you can continue your operations in as little as 10 minutes.*

*Result of mean time to repair (MTTR) calculation conducted by Schneider Electric

Greater connectivity

The protection relay features seven communication protocols. This includes compliance with IEC 61850 Edition 1 and Edition

2, Modbus (serial/TCP), IEC 60870-5-103, IEC 60870-5-101, Ethernet/IP, and DNP3 (serial/TCP). Easergy P5 can support up

to 3 Ethernet protocols simultaneously, including offering dual redundancy with PRP/HSR and RSTP protocols. Moreover, all

communication modules can be added at any time, including on-site, during the product life cycle to allow you to upgrade

your device in line with future network evolutions.

schneider-electric.com | 7Easergy P5 Catalog

7

Page 8

Make everyday operations

easier with digital tools

The Easergy P5’s industry leading protection features are complemented by a comprehensive set of tools

available on mobile devices such as smartphones or tablets, and desktop computers. This means you get

simpler installation, configuration, and maintenance, enabling you to save time and money. Nearby control

and monitoring allows users to fully operate the device via wireless communication, from a safer distance.

Digital tools for the Easergy P5 include:

EcoStruxure Power Build – Medium Voltage online ordering tool enables quicker and easier ordering

eSetup Easergy Pro software with virtual injection testing

Embedded web server, allowing easy and fast setting changes from a web browser

EcoStruxure™ Power Device app for simpler and safer operation and maintenance

mySchneider app, a simple way to access support and product data by flashing the QR code

on the device

As an EcoStruxure-ready solution, the Easergy P5’s digital benefits can be taken even further with best-in-class

monitoring of substation equipment health. For example, when paired with EcoStruxure Asset Advisor, users

get data for predictive maintenance, which helps them reduce OpEx, speed up processes,

and boost efficiency.

schneider-electric.com8 | Easergy P5 Catalog

Page 9

Take Easergy P5 further with

Connected Products

Edge Control

Apps, Analytics & Services

End to End

Cybersecurity

Cloud and/or

On

Premise

Infrastructure

Building

Data Center

Industry

EcoStruxure

TM

EcoStruxure, Schneider Electric’s IoT-enabled, open and interoperable

architecture and platform, brings together Connected Products, Edge

Control, and Apps, Analytics & Services. EcoStruxure connected products

deliver enhanced value around safety, reliability, efficiency, sustainability,

and connectivity.

EcoStruxure ready

450 000

EcoStruxure systems deployed since

2007 with the support of our 9,000

system integrators

Efficient asset management

Boost your efficiency and

reduce downtime using

predictive maintenance tools

EcoStruxure™ Architecture

24/7 connectivity

Make better informed decisions

with real-time data that’s

available everywhere, anytime

Enhanced safety

Advanced features designed-in

based on well-known designs,

experience and technology

EcoStruxure

Power

schneider-electric.com | 9Easergy P5 Catalog

EcoStruxure

Building

EcoStruxure

IT

EcoStruxure

Machine

EcoStruxure

Plant

EcoStruxure

Grid

9

Page 10

Easergy P5

Overview

Range description

Easergy P5 protection relay is based on proven technology concepts and developed in close cooperation with customers,

so it’s built to meet your toughest demands:

• Modular design that allows user-defined conventional protection and arc-flash protection solutions.

• Compatible with conventional CTs/VTs or low power instrument transformers LPCT/LPVT compliant to IEC 61869-10 and IEC 61869-11

standards.

• Embeds latest cybersecurity functionality to help prevent intentional mis-use and cyber-threats.

• Fast replacement with enhanced safety thanks to withdrawability and back-up memory that automatically restore parameters without using

any configuration tools.

Easergy products are designed to be user friendly, a feature that is proven in our customer reports day after day. You’ll

benet from features that include:

• A complete set of protection functions, related to the application.

• Arc-flash detection in Easergy P5x30 models.

• Dedicated circuit breaker control with single-line diagram, push buttons, programmable function keys, LEDs, and customizable alarms.

• Multilingual HMI for customized messaging.

• Settings tool relay management software for setting parameters, configuring, and network fault simulation.

• Both serial and Ethernet communication, including redundancy.

• IEC 61850 standard Edition1 & Edition 2.

Easergy P5 is available in two sizes

to best t your needs:

PM107437

Easergy P5x20 Easergy P5x30

PM107451

Range overview

DM107110

P5G30

Generator

P5U20

Universal

P5T32

Transformer

dierential

T U L L

Easergy P5 digital protection relays are designed for power distribution

networks in:

• Utilities - Energy distribution

• Critical buildings and Industry:

– Data Center

– Healthcare

– Transportation

– Industrial buildings

P5L30 P5F30

FeederDirectional & Line dierential

P5U20

Universal

• Large industrial processes:

– Oil and Gas

– Mining

– Mineral and Metals

– Water

P5V20

Voltage/Frequency

P5M30

Motor

V

F

U

G

G

T U L L

U

G

U

U

U

M

schneider-electric.com10 | Easergy P5 Catalog

M

M

Page 11

Easergy P5

Range description

Easergy P5 contains two main devices, each

with specific functions to address your needs

in a one-box design, regardless of application.

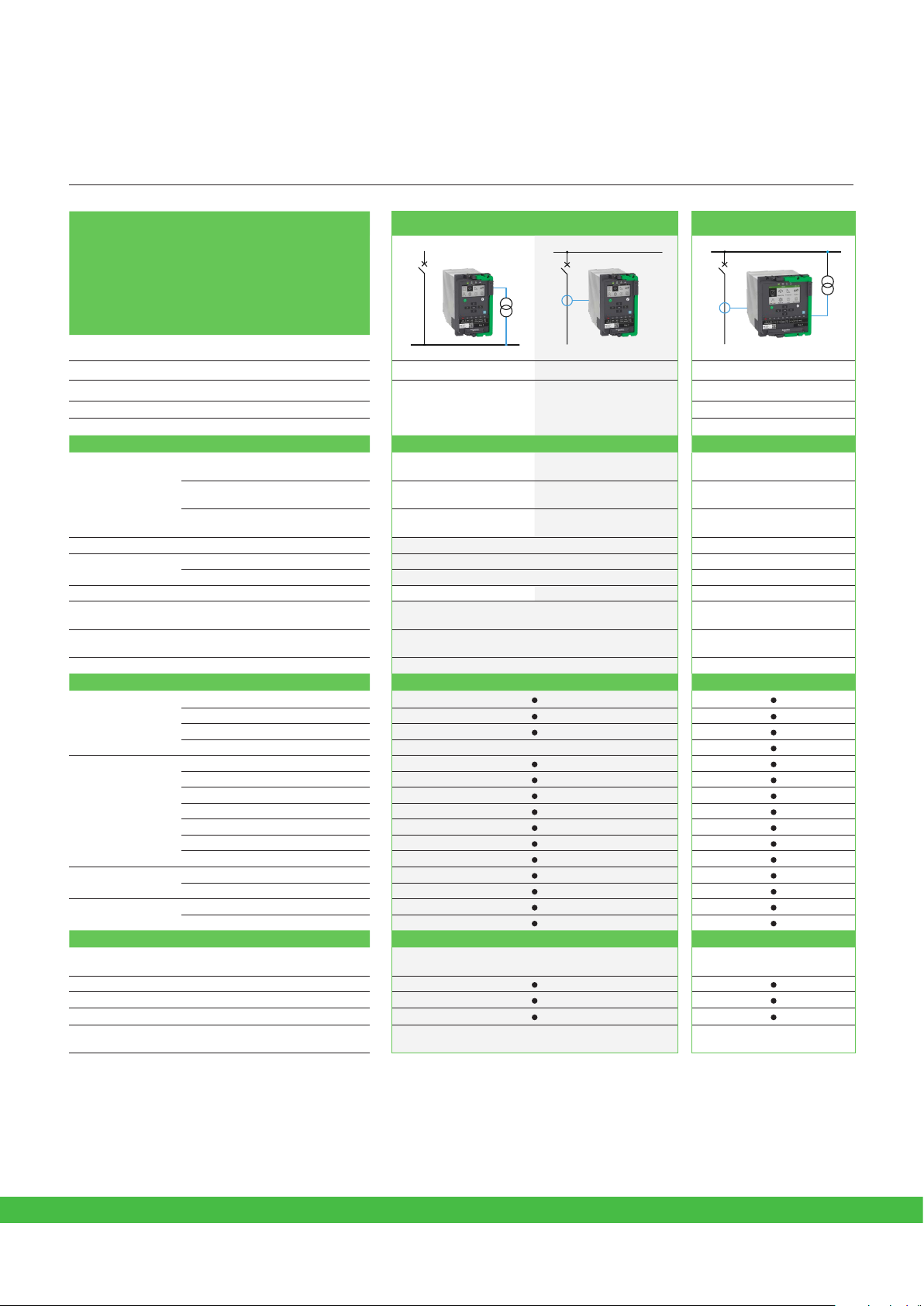

Selection guide

Easergy P5x20 Easergy P5x30

DM107111

DM107112

DM107113

Voltage

Feeder

Transformer

Motor

P5V20 -

P5U20

-

with directional in

LPCT/LPVT version

P5F30 with directional

P5M30 with directional

-

-

Characteristics

Phase current -

Measuring inputs

Arc-flash sensor inputs - 0 to 6 point sensors

Digital

Temperature sensor input - 0 to 16 (external modules) 0 to 16 (external modules)

Front ports

Power supply 24-250 VDC ; 100-230 VAC

Ambient temperature, in service -40 to 70°C (-40 to 158°F) -40 to 70°C (-40 to 158°F)

Residual current -

Voltage VT (x4) LPVT (x4)

Inputs 4 to 16 4 to 40

Outputs 3 to 8 + Watchdog (WD) 3 to 18 + Watchdog (WD)

1 USB for configuration

1 USB for USB key

1/5A CT (x3)

or LPCT (x3)

1/5A CT & 1A CT

or CSH core balance CT

(1)

(1)

1/5A CT (x3)

or LPCT (x3)

1/5A CT & 1A CT

or CSH core balance CT

VT (x4)

or LPVT (x4)

1 USB for configuration

1 USB for USB key

24 - 48 VDC or

48-250 VDC ; 100-230 VAC

Communication

(2)

+ Backup memory

(3)

(4)

Hardware modules

Protocols

Redundancy

protocols

Time synchronization

Extension

Serial

Ethernet

2nd Ethernet IEC 61850 Ed.1 & Ed.2

IEC 60870-5-103 & 101

DNP3 Ethernet

DNP3 serial

Modbus Ethernet

Modbus serial

EtherNet IP

RSTP

PRP / HSR

Pulse, IRIG-B

SNTP, PTP IEEE 1588 v2

Others

Control

Logic (Matrix + Logic Equations)

Cybersecurity

Draw-out device (withdrawability)

Hardware dimensions (H/W/D)

6 controlled + 2 monitored objects

Mimic

102 / 176 / 219 mm

4.01 / 6.93 / 8.62 in

6 controlled + 2 monitored

objects Mimic

152 / 176 / 219 mm

6.0 / 6.93 / 8.62 in

(1) In case P5U20 is choosen for cooperation with low power sensors, it contains LPCT (x3) and LPVT (x4) channels

(2) for connection of RTD module and IRIG-B module

(3) IRIG-B module is a separate accessory

(4) PTP IEEE 1588 v2 is availaible with HSR/PRP communication board

schneider-electric.com | 11Easergy P5 Catalog

Page 12

Easergy P5

Selection guide by

Range description

functionality

Protection Functions

Current protection

Phase overcurrent 50/51 OCPTOC - 3 3 3 3

Earth/ground fault overcurrent

Directional phase overcurrent 67 DOCPTOC - - 4 4 4

Directional earth/ground fault

overcurrent

Transient intermittent/ground fault 67NI IOIOPTEF - - - 1 -

Neutral admittance 21YN EFPADM - - - 2 2

Negative sequence overcurrent 46 (I2/I1) NEGPTOC - 1 1 1 1

Current unbalance, Broken conductor 46BC (I2) UIBCPTOC - 1 1 1 -

Breaker failure 50BF CBFPPIOC 1 1 1 1 1

Phase undercurrent 37 UCPTUC - 1 1 - 1

Switch on to fault (SOTF) 50HS - 1 1 1 1

Cold load pickup (CLP or CLPU) - 1 1 1 1

Voltage protection

Undervoltage 27 UVPTUV 3 - 3 3 3

Overvoltage 59 OVPTOV 3 - 3 3 3

Earth/ground fault overvoltage 59N UOPTOV 3 - 3 3 3

Negative sequence overvoltage 47 NEGPTOV 2 - 2 2 2

Frequency protection

Over and/or underfrequency 81 OFUFPTOF 2 - 2 2 2

Underfrequency 81U UFPTUF 2 - 2 2 2

Rate of change of frequency 81R DFDTPFRC 2 - 2 2 -

Thermal protection

Thermal overload 49 THFPTTR - 1 1 1 1

Temperature monitoring 38 RTDGAPC - 16 16 16 16

Power protection

Wattmetric earth/ground fault 32N EFPDOP - - - 2 2

Directional active underpower 32/37N REVPPDOP - - 2 2 2

Rotating machine protection

Frequent start inhibition 66 FSTPMRI - 1 1 - 1

Motor start-up supervision, locked rotor 48/51LR STALPMSS - 1 1 - 1

Positive sequence undervoltage 27P UVPSPTUV 2 - - - 2

Underspeed

Overspeed

Anti-backspin

Line protection

Fault locator 21FL FLRFLO/SCRFLO - - - 1 -

Auto-Recloser 79 ARRREC - 1 1 1 -

Transformer protection

Magnetizing inrush detection 68H2 HAR2PTOC - 1 1 1 1

Fifth harmonic detection 68H5 HAR5PTOC - 1 1 1 1

Capacitor protection

Capacitor bank unbalance 51C - 2 - 2 -

Capacitor overvoltage 59C - 1 - 1 -

Other protection

Arc-flash detection 50ARC ARCMPIOC - - - 8 8

Programmable stages 99 PSGAPC 8 8 8 8 8

Programmable curves 3 3 3 3 3

Control, monitoring, supervision

Synchronization check 25 RSYN 1 - - 1 -

Lockout relay 86 1 1 1 1 1

CT supervision 60 CTSGGIO - 1 1 1 1

VT supervision 60 VTSGGIO 1 - 1 1 1

Setting groups 4 4 4 4 4

(1) Number of stages depends on the number of residual current inputs. (2) Function available if 12 DI / 4 DO board is present

(2)

(2)

(2)

(1)

ANSI

code

50N/51N EFPTOC - 5 / 8 3 5 / 8 5 / 8

67N DEFPTOC - - 3 3 3

14 M OTPZSU - 2 2 - 2

12 M OTPOVS - 2 2 - 2

ABS MABSPMSS - 1 1 - 1

IEC 61850

Logical Node

P5V20 P5U20

P5U20

LPCT/LPVT

P5F30 P5M30

schneider-electric.com12 | Easergy P5 Catalog

Page 13

Easergy P5

Selection guide by

Range description

functionality

Control functions P5V20 P5U20

Control with Mobile application

Switchgear control and monitoring 6 6 6 6 6

Switchgear monitoring only 2 2 2 2 2

Programmable switchgear interlocking

Local control on single-line diagram

Local switchgear control with OPEN/CLOSE keys

Local/remote function

Function keys 1 1 1 7 7

Custom logic (equations)

Measurement functions P5V20 P5U20

RMS current values

RMS voltage values

RMS active, reactive and apparent power

Frequency

Fundamental frequency current values

Fundamental frequency voltage values

Fundamental frequency active, reactive and apparent power values

Power factor

Motor speed detection

Energy values: active and reactive

Demand values: phase currents

Demand values: active, reactive, apparent power and power factor

Maximum demand values: phase currents

Minimum and maximum demand values: RMS phase currents

Minimum and maximum demand values:

active, reactive, apparent power and power factor

Maximum demand values over the last 31 days and 12 months:

active, reactive, apparent power

Minimum demand values over the last 31 days and 12 months:

active, reactive power

Maximum and minimum values: currents

Maximum and minimum values: voltages

Maximum and minimum: frequency

Maximum and minimum:

active, reactive, apparent power and power factor

Harmonic values of phase current and THD

Harmonic values of voltage and THD

Voltage sags and swells

(1)

P5U20

LPCT/LPVT

P5U20

LPCT/LPVT

P5F30 P5M30

P5F30 P5M30

Logs and records P5V20 P5U20

Sequence of event record

Disturbance record

Tripping context record

Relay maintenance data log

Security data log

Monitoring functions ANSI code P5V20 P5U20

Trip circuit supervision 74 1 1 1 1 1

Circuit breaker monitoring 1 1 1 1 1

Relay monitoring

(1) Function available if 12DI / 4DO board is present

schneider-electric.com | 13Easergy P5 Catalog

P5U20

LPCT/LPVT

P5U20

LPCT/LPVT

P5F30 P5M30

P5F30 P5M30

Page 14

Easergy P5

Selection guide by application

Range description

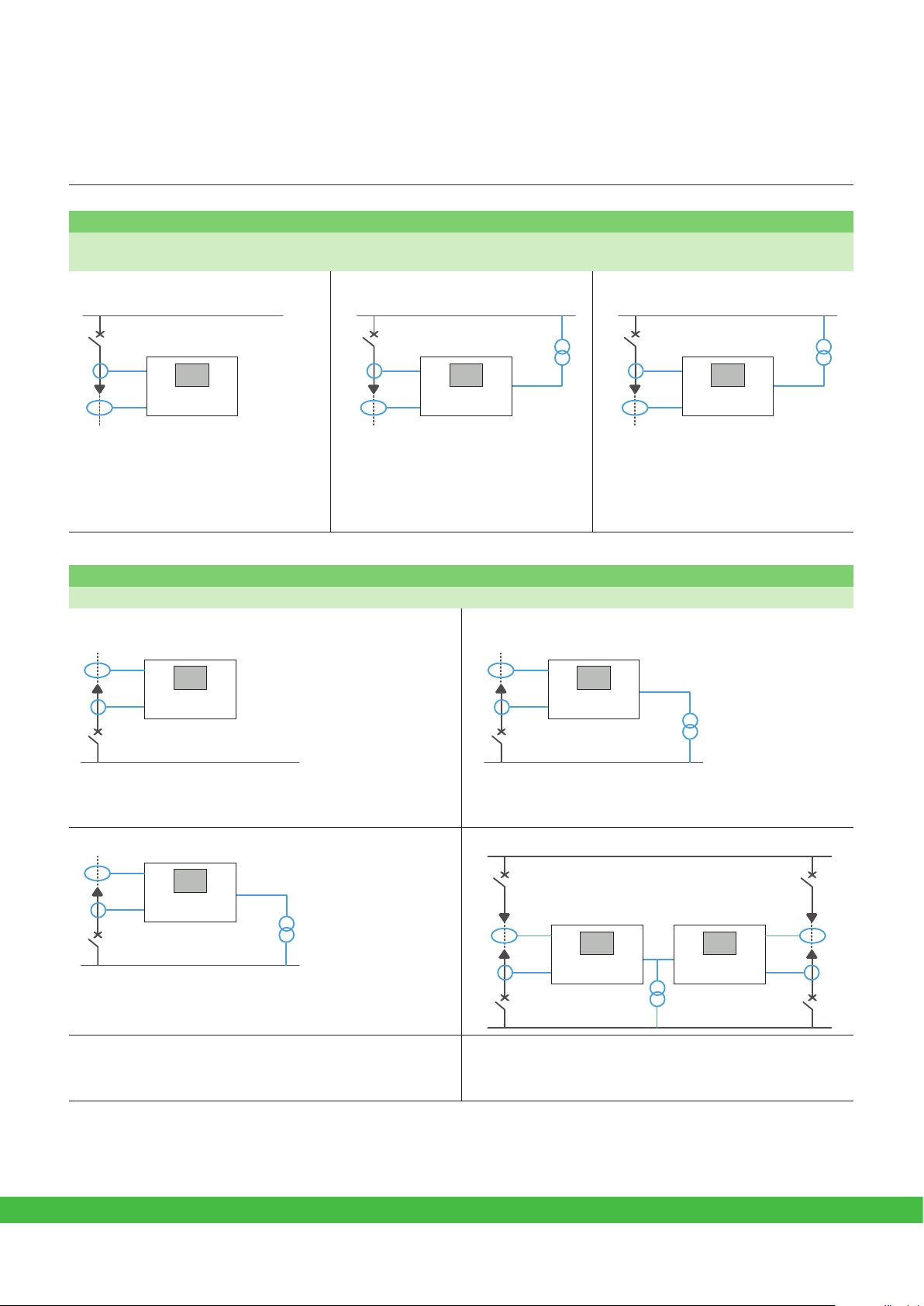

Feeder / Incomer application

Outgoing protection

• Feeder overcurrent protection

• Feeder overload protection

Feeder protection Overhead line protection Protection of feeders with metering

DM107117

P5U20 P5F30

• Feeder earth/ground fault overcurrent • Directional phase and earth/ground fault

DM107118

overcurrent

• Recloser

P5F30

DM107119

P5F30

• Power and energy measurement

• Min and max demand values over the last

31 days and 12 months

• Fault locator

Incomer protection

• Busbar overcurrent protection

Incomer protection without voltage monitoring Incomer protection with voltage and frequency monitoring

DM107120

P5U20 P5F30

DM107121

P5F30

• Earth/ground fault overcurrent • Under/over voltage

• Frequency, rate of change of frequency

Incomer protection with power quality monitoring Parallel incomer protection

DM107122

P5F30

DM107123

P5F30 P5F30

• Voltage and frequency min and max values

• Voltage harmonic values and THD

• Voltage sags and swells

• Directional phase overcurrent

• Directional earth/ground fault overcurrent

schneider-electric.com14 | Easergy P5 Catalog

Page 15

Easergy P5

Selection guide by application

Range description

Feeder / Incomer and Motor applications

Feeder / Incomer application

Voltage monitoring

• Under/over voltage protection

• Earth/ground fault overvoltage

• Under/over frequency protection

DM107124

P5V20

• Load-shedding-specific function: rate of change of frequency

Motor application

Motor protection

• Motor overcurrent and earth/ground fault overcurrent

• Thermal overload

• Motor start-up supervision

• Motor restart inhibition

Motor protection without voltage monitoring Motor protection with voltage monitoring

DM107125

P5U20 P5M30

RTD module

MET148-2

• Temperature measurement (stator, bearings) • Undervoltage protection

DM107126

RTD module

MET148-2

P5M30

schneider-electric.com | 15Easergy P5 Catalog

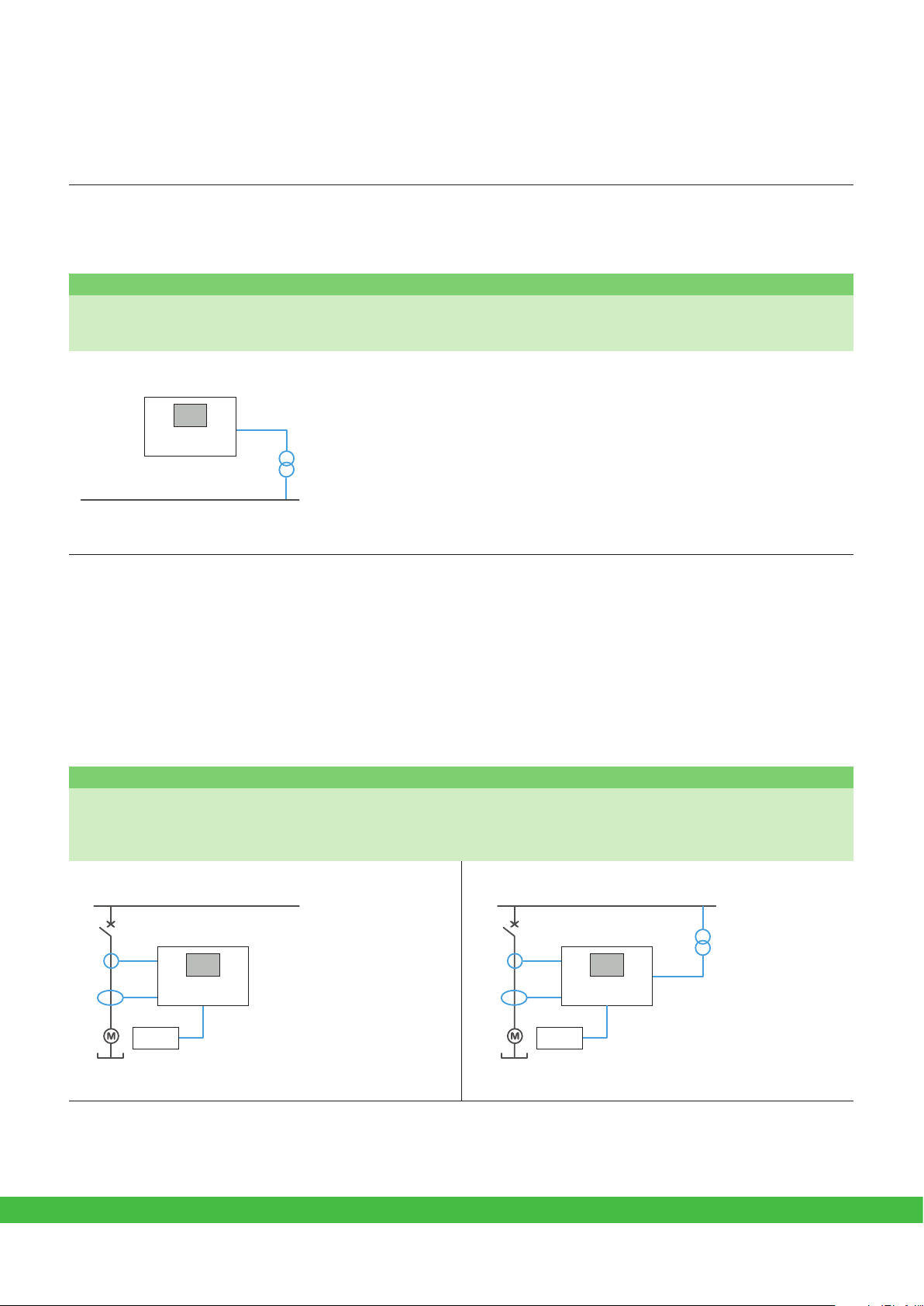

Page 16

Easergy P5

Selection guide by application

Range description

Transformer application

Transformer feeder protection

• Transformer overcurrent and earth/ground fault overcurrent protection

• Thermal overload protection

• External trip from thermostat/Buchholz

Transformer feeder protection without voltage monitoring Transformer feeder protection with voltage monitoring

DM107127

P5U20 P5F30

26

63

RTD module

MET148-2

DM107128

49T

P5F30

26

63

• Temperature measurement (ambient, oil) • Over and undervoltage protection

Transformer feeder protection with additional current measurement

DM107129

49T

P5F30

26

63

DM107130

49T

P5F30

26

63

• Tank earth/ground leakage protection • Earth/ground fault overcurrent on the secondary side

schneider-electric.com16 | Easergy P5 Catalog

Page 17

Easergy P5

Selection guide by application

Range description

Transformer incomer protection

• Busbar overcurrent protection

• Inter-trip from primary circuit breaker protection

Transformer incomer protection without voltage monitoring Transformer feeder protection with

DM107131

P5U20 P5F30

• Transformer earth/ground fault overcurrent • Earth/ground overcurrent for transformer

Transformer application

DM107132

P5U20 P5F30

and back-up protection

voltage monitoring

DM107133

P5U30

P5F30

• Over and undervoltage protection

• Power and energy measurement

• Min and max demand values over the last

31 days and 12 months

Parallel transformer incomer protection

DM107134

P5F30 P5F30

• Directional phase overcurrent

schneider-electric.com | 17Easergy P5 Catalog

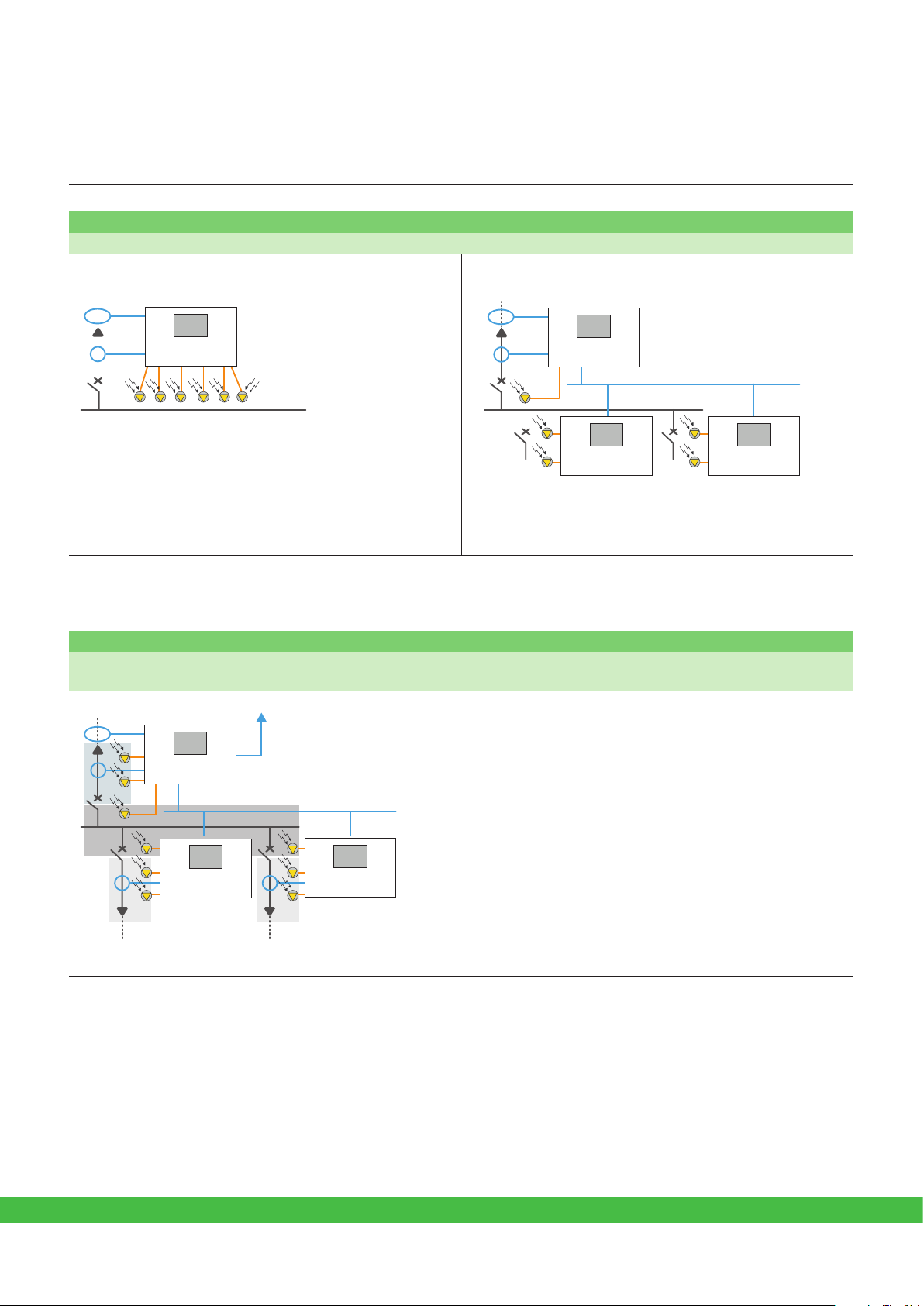

Page 18

Easergy P5

Selection guide by application

Range description

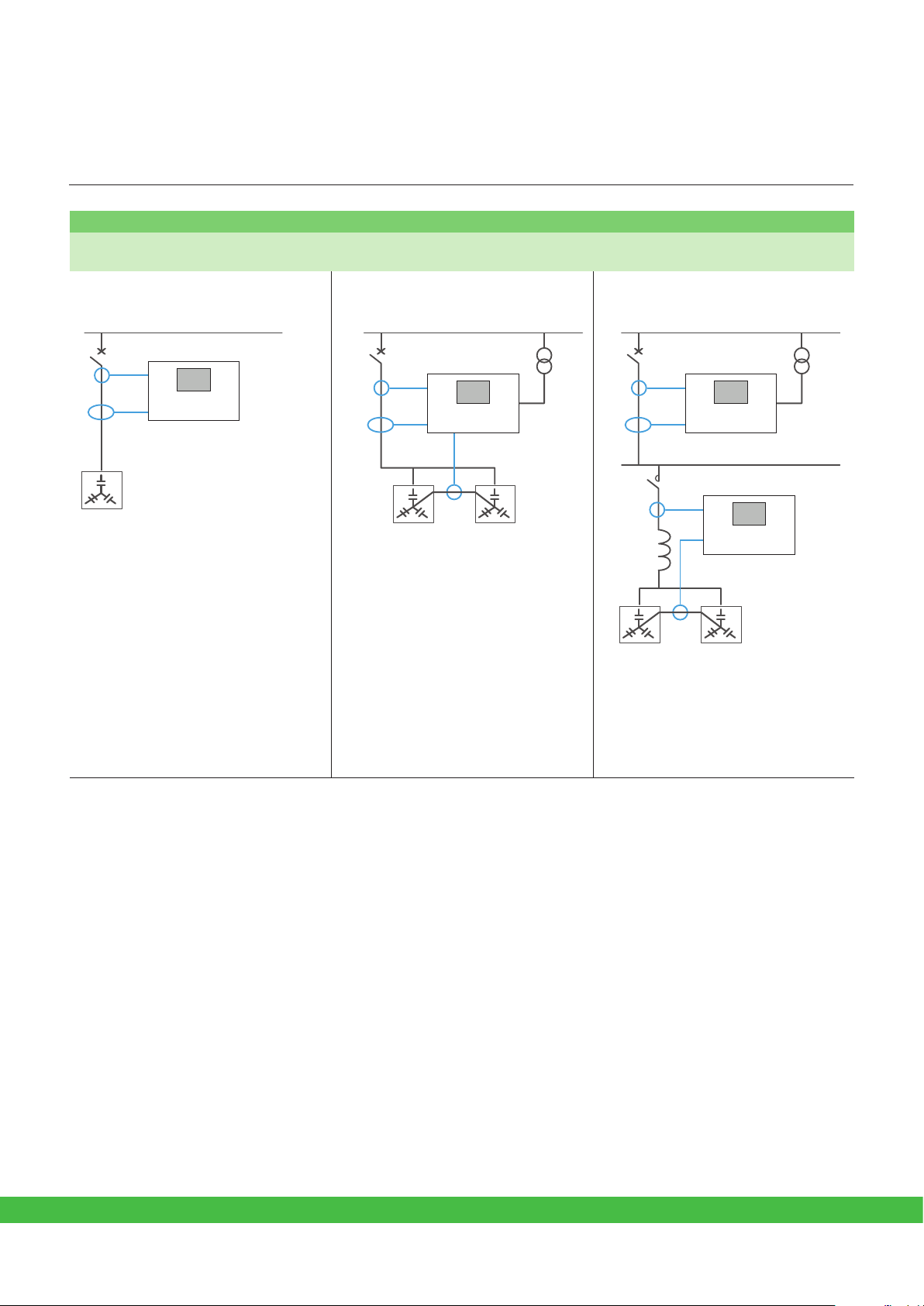

Arc-ash application

Busbar arc-flash protection

• Arc-flash protection, activated by overcurrent and light signals, or light signals alone

Centralized busbar arc-flash protection De-centralized busbar arc-flash protection

DM107114

P5F30

DM107115

P5F30

• Up to 6 light point sensors to monitor the busbar • Up to 6 light point sensors in each relay

• Transmission of light detection signals via digital I/O or

IEC 61850 GOOSE messages

P5F30P5F30

Zone arc-flash protection

• Up to 8 arc-flash protection stages in each device (P5x30)

• Transmission of signals via digital I/O or IEC 61850 GOOSE messages

In this application example, the arc-flash sensor for zone 3.1

is connected to Device 1. If the arc-flash sensor detects light

and simultaneously Device 3 detects and sends an overcurrent

condition, the zone 3.1 is isolated by the outgoing feeder breaker.

The arc-flash sensor for zone 3.2 is connected to Device 2 and

operates the same way.

The arc-flash sensors for zone 2 are connected to Device 1, 2,

or 3. If a sensor detects a flash in zone 3, the light-only signal is

DM107116

Zone 2

Zone 1

DEVICE 3

P5F30

Zone 1

light detection signal

transferred to Device 3, which then trips the main circuit breaker.

DEVICE 1

Zone 3.1 Zone 3.2

P5F30 P5F30

DEVICE 2

An eventual arc-flash fault in zone 1 does not necessarily activate

the current element in Device 3. However, arc-flash detection can be

achieved by using the light-only principle. If an arc-flash occurs in

the cable termination of zone 1, an inter-trip signal is sent by Device

3 to the upstream circuit breaker.

schneider-electric.com18 | Easergy P5 Catalog

Page 19

Easergy P5

Selection guide by application

Range description

Capacitor bank protection

• Overcurrent and earth/ground fault protection

• Overload protection

Capacitor bank protection without

voltage monitoring

DM107135

P5U20 P5F30

Capacitor application

Capacitor bank protection with voltage

monitoring

DM107136

P5F30

Protection of harmonic filters

DM107137

P5F30

P5U20

• Capacitor overvoltage protection, based on

current measurement and harmonics

• Current harmonic values and THD

• Capacitor bank unbalance

• Overvoltage

• Current and voltage harmonic values

and THD

• Overvoltage

• Capacitor bank unbalance

• Capacitor overvoltage protection, based

on current measurement and harmonics

• Current harmonic values and THD

schneider-electric.com | 19Easergy P5 Catalog

Page 20

Easergy P5

Range description

Motor overspeed - ANSI 12

The function is based on the direct measurement of motor speed. The overspeed protection function detects

racing when the motor is driven by the load, or a loss of synchronization for synchronous motors, or for process

monitoring. This function picks up if the speed measured exceeds the speed setting and it will trip after a

definite time delay.

• Two stages of overspeed protection with definite time delay

• The function is available when a 12 DI / 4 DO board is present and the motor speed detection function is

enabled.

Functions Settings

Motor speed setting range 10 – 160% Ωn

Definite time delay 1 s to 300 s

Motor underspeed - ANSI 14

Functions and description

The function is based on the direct measurement of motor speed. The underspeed protection function can

detect the slow-down of motor speed after motor starting, possibly resulting from mechanical overloads or

locked rotor. This protection is active after the motor speed has successfully achieved the speed setting. The

function picks up if the speed measured drops below the speed setting after having first exceeded the set point

by 5%. Under-speed protection is blocked when the motor speed drops below 5% of rated motor speed to avoid

unwanted tripping when the motor is switched off.

• Two stages of underspeed protection with definite time delay

• The function is available when a 12 DI / 4 DO board is present and the motor speed detection function is

enabled.

Functions Settings

Motor speed setting range 10 – 100% Ωn

Definite time delay 1 s to 300 s

Motor anti-backspin (ABS)

For a motor with high inertia, once the CB/Contactor supplying power to the motor is switched off, the rotor may

continue to turn for a considerable length of time. In that case, the motor terminal voltage is out of phase and

the motor re-starting operation may result in catastrophic failure. In some other applications for example when a

motor is on a down-hole pump, after the motor stops, the liquid may fall back down the pipe and spin the rotor

backwards. It would be very undesirable to start the motor at this time. In these circumstances the anti-backspin

function is used to detect when the rotor has completely stopped, to allow re-starting of the motor.

• One stage of anti-backspin protection with definite time delay

• This function is availaible when Motor Status function is enabled

• 3 different criteria for rotor stop detection

• Depending on criteria selected, a 12 DI / 4 DO board and the motor speed detection function may be

required.

Functions Settings

Rotor stop detection mode Zero speed, Zero speed switch, Motor stopped

Definite time delay 1 s to 7 200 s

schneider-electric.com20 | Easergy P5 Catalog

Page 21

Easergy P5

Functions and description

Range description

Fault locator - ANSI 21FL

The function can be used to locate a short-circuit fault and an earth/ground fault in radially operated networks.

The fault location is given as reactance (Ohms) and as distance in kilometers or miles. The fault value can then

be exported, for example, with an event to a Distribution Management System (DMS). The system can then

locate the fault. If a DMS is not available, the distance to the fault is displayed as kilometers and as a reactance

value.

Functions Settings

Pick-up 0.10 to 5.00 In

Line reactance 0.010 to 10.000Ohm/km

Earth/ground factor 0.000 to 10.000

Earth/ground factor angle

-60° to +60°

Neutral admittance - ANSI 21YN

The neutral admittance protection function can be applied in high resistance earthed, unearthed or

compensated power systems to detect earth fault with increased sensitivity. The neutral admittance Yn is

calculated based on the zero-sequence current I0 and the zero-sequence voltage U0.

• Two independent stages with definite time delay.

• Each stage settable for over-admittance or over-conductance or over-susceptance.

• Four setting groups.

Functions Settings

Pick-up for Yn

Pick-up for Gn

Pick-up for Bn

Directional mode Non-directional, Forward, Reverse

Operation delay 0.05 to 300 s

Reset time 0 to 100 s

(1)

SOL

operation Disable/Enable

(1)

SOL

operation delay 0.05 to 300 s

1% - 200% In/Un for current measured with very sensitive earth/ground fault CT

5% - 1000% In/Un for current measured by standard earth/ground fault CTs

5% - 1000% In/Un for current measured by standard earth/ground fault CTs

1% - 100% In/Un for current measured with very sensitive earth/ground fault CT

5% - 500% In/Un for current measured by standard earth/ground fault CTs

25% - 2500% In/Un for current measured by CSH and for calculated Io

1% - 100% In/Un for current measured with very sensitive earth/ground fault CT

5% - 500% In/Un for current measured by standard earth/ground fault CTs

25% - 2500% In/Un for current measured by CSH and for calculated Io

(1) SOL = Selective Overcurrent Logic

schneider-electric.com | 21Easergy P5 Catalog

Page 22

Easergy P5

Range description

Synchro-check - ANSI 25

This function checks the phase to phase voltages on both sides of a circuit breaker (CB) and allows CB closing

when the voltage phase angle, magnitude, frequency differences are all within permitted limits.

• Seven operation modes of no-voltage conditions are provided (dead line, dead bus).

• Synchronous mode is provided, where the frequency difference is less than 0.3 Hz.

• Asynchronous mode is provided, where CB close time is compensated.

• Independent settings for voltage phase angle, magnitude, frequency differences.

• Four setting groups.

Functions Settings

Synchronization mode Off, Asynchronous, Synchronous

Voltage check mode DD, DL, LD, DD/DL, DD/LD, DL/LD, DD/DL/LD

Circuit breaker close time 0.04 to 0.6 s

Dead line voltage setting limit 1% to 120% Un

Active line voltage setting limit 1% to 130% Un

Frequency difference 0.01 to 1.0 Hz

Voltage difference 1% to 60% Un

Phase angle difference 2º to 90º

Request timeout 0.1 to 600 s

Functions and description

(1)

(1) D = no-voltage condition, L = voltage condition

Under voltage - ANSI 27

This function is applied to detect abnormal system voltage decreases, to trigger automatic load shedding,

voltage source transfer, or trip out motor loads to avoid motor stall. This protection works with the minimum phase

to phase voltage.

• Three independent stages with definite time are provided.

• Low voltage self-blocking operates when the maximum phase to phase voltage is less than 10%Un.

• Four setting groups for each stage.

Functions Settings

Pick-up 20 to 120%Un

Hysteresis 0.1 to 20%

Delay type 0.03 to 300s

Adjustable reset 0.3 to 300s

schneider-electric.com22 | Easergy P5 Catalog

Page 23

Easergy P5

Functions and description

Range description

Positive sequence under voltage - ANSI 27P

This function is applied to detect insufficient or unbalanced system voltages and detect reverse rotation.

• Two independent stages with define time are provided.

• Low voltage self-blocking will operate when the maximum phase to phase voltage is less than 10% Un.

Functions Settings

Pick-up 20 % to 120%Un

Time delay 0.08 to 300.00s

Low voltage self-blocking 2 % to 100%Un

Directional active underpower - ANSI 32/37P

This function can be used as underpower protection (e.g. loss of load of a motor) or as reverse power protection

(e.g. power generation by a motor if supply is disconnected). It starts if measured active power drops below the

set threshold and operates with definite time delay.

• Two independent stages with definite time delay are provided

• Undervoltage blocking if the maximum phase to phase voltage is less than 5% Un.

• Four setting groups for each stage.

Functions Settings

Pick-up -200 % to 200 % Sn

Time delay 0.3 to 300.0 s

(1)

with Sn = √3 Un In

schneider-electric.com | 23Easergy P5 Catalog

Page 24

Easergy P5

Functions and description

Range description

Wattmetric earth/ground fault - ANSI 32N

This function detects single phase to earth/ground faults in Petersen coil compensated power systems. It

operates on active residual power. Using memory mode also allows operation on intermittent earth/ground faults.

• Neutral displacement voltage U0> element to enable function.

• Settable forward/reverse direction.

• Operating characteristic with settable minimum active power and sector angles.

• Dedicated blocking input.

• Dedicated input to bypass operate time delay.

• Four setting groups for each stage.

Functions Settings

Direction mode Reverse, forward

Setting range

Time delay 0.05 to 300.00s

U0> 2 % to 80 % Un

Sector angle 0° - 90°

Memory mode None, voltage, time, voltage+time

Memory hold time 0.05 to 10.00s

Memory operating time 0.00 to 100.00s

(1)

SOL

operation

(1)

SOL

operation delay 0.05 to 300.00s

0.1 % to 20 % Sn

Active, inactive

Phase undercurrent - ANSI 37

This function is typically used to detect defects in motor drives based on loss of load detection due to a

significant drop of current. It measures the fundamental component of the phase currents.

• One stage with definite time delay is provided.

• Low-current blocking if maximum current is less than 15% In.

• Four setting groups for each stage.

Functions Settings

Pick-up 20 % to 70 %

Time delay 0.3 s to 300 s

(1) SOL = Selective Overcurrent Logic

schneider-electric.com24 | Easergy P5 Catalog

Page 25

Easergy P5

Functions and description

Range description

Temperature monitoring - ANSI 38

This function is used to detect abnormal heat rise by directly measuring the temperature inside equipment

(transformer, motors, generators, …) with RTD thermal sensors such as Pt100, Ni100 or Ni120.

• Two independent set points: alarm and tripping for each RTD sensor.

• Inbuilt RTD supervision (shorting, open loop).

Functions Settings

Pick-up 0 to 180°C (32 at 356°F)

Time delay 0.3 to 600.0 s

Negative sequence overcurrent - ANSI 46

This function provides greater sensitivity to detect phase to phase faults at the end of long lines or behind

transformers. It can also be used for machine protection (against temperature rise caused by unbalanced power

supplies, phase inversion, or loss of phase).

• One stage with definite time or inverse time delay

• Four setting groups.

Functions Settings

Pick-up 0.02 to 5.00In

Definite time delay

Inverse time delay curves

Inverse time coefficient

0.07 to 300.00s

IEC: NI, VI, EI, LTI

IEEE: VI, EI, LTI, LTEI, LTVI, MI, STI, STEI

IEEE2: NI, VI, EI, MI

Others: RI, RXIDG

Programmable: 3 curves with 16 setting points

0.05 to 20.00 for IEC curves and others (RI)

0.5 to 20.0 for IEEE, IEEE2 curves and others (RXIDG)

schneider-electric.com | 25Easergy P5 Catalog

Page 26

Easergy P5

Functions and description

Range description

Unbalanced overcurrent, broken conductor - ANSI 46BC

This function is applied to detect broken conductor conditions, based on the ratio between the negative

sequence current and positive sequence current.

• One stage with definite time delay is provided.

• This function is not available in 2CT mode.

• Four setting groups.

Functions Settings

Pick-up 2 to 70%

Time delay

0.07 s to 300s

Negative sequence overvoltage - ANSI 47

Protection of a rotating machine from being energized with a reverse voltage sequence or prevention of

overheating of the motor due to a broken conductor condition. It monitors the voltage phase sequence

detecting a reverse rotation or voltage unbalance due to a missing (asymmetrical) phase. The detection of these

conditions can then be used to trip the machine to prevent damage to both motor and any mechanically coupled

processes.

• Two independent stages with definite or inverse time delay.

• When the VT connection is configured to LL/LLy the function is automatically disabled.

• Four setting groups for each stage.

Functions Settings

Pickup value 1% Un - 100% Un

Delay type Definite time (DT), inverse time (INV)

Operation delay 0.08 s to 300 s

Reset time 0.03 s to 300 s

schneider-electric.com26 | Easergy P5 Catalog

Page 27

Easergy P5

Functions and description

Range description

Motor start-up supervision - ANSI 48

Protection of motors against overheating caused by excessive start time due to heavy motor load or too low

voltage.

• Motor start detection is based on circuit breaker (CB) position and current.

• Operation with definite time delay or inverse time delay.

Functions Settings

Motor start detection current 1.3 to 10.0In

Motor start detection mode CB position, current, CB position and current

Delay type Definite time (DT), inverse time (INV)

Motor start time 1 s to 300.0s

Thermal overload protection for feeders - ANSI 49F

This function is applied to detect conditions where thermal damage may be caused by overloads on cables. The

thermal capacity is calculated by the thermal replica according to IEC60255-149. The equivalent current for the

thermal replica is the maximum RMS current of 3 phases.

• Independent settable alarm stage and trip stage are provided.

• Current based setting mode and temperature based setting mode are provided.

• Temperature sensor can be applied for ambient temperature based mode.

• A digital input can be applied to inhibit the thermal overload protection

• Four setting groups are provided.

Functions Settings

Basic current setting

k factor 0.10 to 1.50

Heating time constant 1.0 min to 1000 min

Thermal alarm value 50 % to 100 %

Reserve time thermal alarm 1.0 min to 1000 min

Temperature based mode Current, Ambient

Nominal ambient temperature

Max object temperature -40 ºC to 300 ºC

Alarm object temperature 0 ºC to 300 ºC

Min object temperature -40 ºC to 300 ºC

Default object temperature -40 ºC to 300 ºC

Thermal level initiation 0 to 90%

0.10 In to 4.00 In

-40 ºC to 300 ºC

schneider-electric.com | 27Easergy P5 Catalog

Page 28

Easergy P5

Functions and description

Range description

Thermal overload protection for motor - ANSI 49M

This function is applied to detect conditions where thermal damage may be caused by overloads on motors or

cables. The thermal capacity is calculated by the thermal replica according to IEC 60255-149. The equivalent

current for the thermal replica considers the maximum RMS current of 3 phases and the negative phase

sequence current with a settable weighting coefficient.

• Independent settable alarm stage and trip stage are provided.

• Current based setting mode and temperature based setting mode are provided.

• Temperature sensor can be applied for ambient temperature based mode.

• A digital input can be applied to inhibit the thermal overload protection

• Four setting groups.

Functions Settings

Basic current setting 0.1 In to 4.0 In

k factor

Heating time constant

Time constant for motor start 1.0 min to 1000 min

Cooling time constant 1.0 min to 1000 min

Thermal alarm value 50% to 100%

Reserve time thermal alarm 1.0 min to 1000 min

Temperature based mode Current, Ambient temperature

Nominal ambient temperature -40 ºC to 300 ºC

Max object temperature -40 ºC to 300 ºC

Alarm object temperature 0 ºC to 300 ºC

Min object temperature -40 ºC to 300 ºC

Default object temperature -40 ºC to 300 ºC

Thermal level initiation 0 to 90%

Unbalance factor 0 to 10

1.0 to 1.5

1.0 min to 1000 min

schneider-electric.com28 | Easergy P5 Catalog

Page 29

Easergy P5

Range description

Arc-flash - ANSI 50ARC

This function is used to detect and minimize the effects of an internal arcing fault, commonly by tripping the CB

faster than conventional protection to mitigate the fault.

• Eight independent arc-flash stages.

• GOOSE communication to share informations between two Easergy P5 relays.

• Three to six arc-flash sensors available.

• Trip in 4 ms maximum if light detection only.

• Trip in 15 ms maximum if light detection and overcurrent conditions detected with GOOSE communication

between two Easergy P5 relays.

Functions Settings

Arc-flash stage 1 to 8 On, Off

Detection mode

Pick-up phase current 0.50 to 8.00 In

Pick-up ground/earth current 0.10 to 5.00

Trip delay

Hold time 20 ms to 2500 ms

Functions and description

Light, light + current

0 ms to 255 ms

Breaker failure - ANSI 50BF

The circuit breaker failure function (CBF) can be used to operate any upstream circuit breaker (CB) if the

programmed output signals, to the main breaker, have not disappeared within a given time after the initial

command.

• Two circuit breaker controls are available.

Functions Settings

Phase current pick-up 0.02 to 4.00 In

Earth/ground current pick-up

Very sensitive earth/ground current

pick-up

Time delay 0.02 s to 50.00s

0.02 to 4.00 Ino with 1/5 A standard CT

0.05 to 4.00 Ino with CSH core balance CT

0.002 to 4.000 Ino

schneider-electric.com | 29Easergy P5 Catalog

Page 30

Easergy P5

Functions and description

Range description

Switch onto fault (SOTF) - ANSI 50HS

This function is applied to provide fast tripping based on instantaneous overcurrent protection, when the CB is

closed onto a faulted line.

• One stage instantaneous overcurrent is provided.

• CB open/dead line detection is based on a low current threshold 0.02 In or digital input.

• SOTF active duration after CB closure is settable.

Functions Settings

Pick-up 1.0 to 40.0In

Dead line detection delay

SOTF active time 0.1 to 60.0s

0 to 60.0s

Cold Load Pick-up (CLP)

This function helps avoid unwanted tripping of overcurrent protecton elements (50/51, 50N/51N, 50G/51G and

67) during energisation after long periods of outage. Depending on installation characteristics such operations

can generate inrush currents that can exceed the pick-up level of protection. These inrush currents may be

caused by:

• • Magnetizing currents of power transformers.Magnetizing currents of power transformers.

• • Motor starting currents.Motor starting currents.

• • Simultaneous re-energization of the entire facility load (air conditioning, heating...).Simultaneous re-energization of the entire facility load (air conditioning, heating...).

In principle the protection settings should be defined in order to avoid tripping on such inrush currents. In principle the protection settings should be defined in order to avoid tripping on such inrush currents.

However if the settings result in insufficient sensitivity levels or too long delays, the CLP function can be used to However if the settings result in insufficient sensitivity levels or too long delays, the CLP function can be used to

temporarily increase or inhibit thresholds after re-energization.temporarily increase or inhibit thresholds after re-energization.

Functions Settings

Pick-up

Definite time delay

Inverse time delay curves

Inverse time coefficient(k )

0.02to 20.0In

0.03 to 300.00s

IEC, IEEE, IEEE2, Others, 3 programmable curves

0.05 to 20.00 for IEC curves and others (RI)

0.5 to 20.0 for IEEE, IEEE2 curves and others (RXIDG)

schneider-electric.com30 | Easergy P5 Catalog

Page 31

Easergy P5

Functions and description

Range description

Phase overcurrent - ANSI 50/51

These functions are used to detect short circuit faults and heavy overloads. The overcurrent function measures

the fundamental frequency components (1st harmonic) of the phase currents. The protection is sensitive to the

highest of the three phase currents. Whenever this value exceeds the user’s start setting of a particular stage, a

start signal is issued. If the fault situation remains present longer than the operation delay setting, a trip signal is

issued.

• Two stages ((I> and I>>) with definite time or inverse time delay.

• One stage (I>>>) with definite time delay and a maximum starting time of 20 ms (P5x30).

• Cold load pick-up function.

• Four setting groups for each stage.

Functions Settings

I> 0.05 to 20.00 In

Definite time

(DT) pick-up

Inverse time

(IDMT) pick-up

Definite time delay 0.03 to 300.00 s

Inverse time delay curves

Inverse time coefficient(k)

Reset time 0.03 to 100.00 s

I>>

I>>>

I> 0.05 to 5.00 In

I>> 0.10 to 5.00 In

0.10 to 20.00 In

0.10 to 40.00 In

IEC : NI, VI, EI, LTI

IEEE : VI, EI, LTI, LTEI, LTVI, MI, STI, STEI, others

IEEE2 : NI, VI, EI, MI

Others : RI, RXIDG

Programmable : 3 curves with 16 setting points

0.05 to 20.00 for IEC curves and others (RI)

0.5 to 20.0 for IEEE, IEEE2 curves and others (RXIDG)

schneider-electric.com | 31Easergy P5 Catalog

Page 32

Easergy P5

Functions and description

Range description

Earth/ground fault overcurrent - ANSI 50N/51N and ANSI 50G/51G

Earth/ground fault protection (ANSI 50N/51N) is based on the measured residual current from a 1A/5A standard

CT or CSH core balance CT. Alternatively, it can also apply the calculated residual current.

Sensitive earth/ground fault protection (ANSI 50G/51G) is based on measured residual current with very

sensitive 1 A standard CT.

• ANSI 50N/51N - Two stages with definite and inverse time delay and three stages with definite time delay.

• ANSI 50G/51G - Two stages with definite and inverse time delay and one stage with definite time delay.

• Cold load pick-up.

• Selective overcurrent logic settable for the first four stages.

• Four setting groups for each stage.

Functions Settings

Io (ANSI 50N/51N)

Io’ (ANSI 50G/51G)

Io>, Io’>,

Io>>, Io’>>

Definite time

(DT) pick-up

Inverse time

(IDMT) pick-up

Definite time delay 0.03 to 300s

Inverse time delay curves

Inverse time coefficient(k)

Reset time

Io>>>, Io’>>>,

Io>>>>

Io>>>>> 0.05 to 10.00 Ino

Io>, Io’>,

Io>>, Io’>>

Measured with 1 A/5 A CT

Measured with 1 CSH core balance CT

Calculated with the sum of the 3 phase currents

Measured with 1 A CT

CT CSH core balance CT Calculated earth/ground fault

0.02 to 10.00 Ino 0.05 to 10.00 Ino 0.05 to 20.00 In

0.02 to 20.00 Ino 0.05 to 20.00 Ino 0.05 to 20.00 In

- -

0.02 to 5.00 Ino 0.05 to 5.00 Ino 0.05 to 5.00 In

IEC: NI, VI, EI, LTI

IEEE: VI, EI, LTI, LTEI, LTVI, MI, STI, STEI

IEEE2: NI, VI, EI, MI

Others: RI, RXIDG

Programmable : 3 curves with 16 setting points

0.05 to 20.00 for IEC curves and others (RI)

0.5 to 20.0 for IEEE, IEEE2 curves and others (RXIDG)

0.03 to 100s

schneider-electric.com32 | Easergy P5 Catalog

Page 33

Easergy P5

Functions and description

Range description

Capacitor bank unbalance - ANSI 51C

This function is used in double-wye-connected capacitor banks. The unbalance current is measured with a

dedicated current transformer (i.e. 5A/5A) between two starpoints of the bank.

• Two stages with definite time delay.

• Unbalance current measured with standard earth/ground fault CT or CSH core balance CT.

• Four setting groups for each stage.

Functions Settings

Pick-up

Time delay 0.03 to 300 s

0.02 to 10.00 Ino for standard CT

0.05 to 10.00 Ino for CSH core balance CT

Locked rotor - ANSI 51LR

Protection of motors against overheating caused by motor rotor jam due to heavy motor load or a mechanical

failure after the normal start.

• Operation with definite time delay or inverse time delay.

• Automatically blocked when the motor is starting.

Functions Settings

Pick-up 10 to 100.0%IStart

Time delay 1 to 300.0s

Time delay type

Overvoltage - ANSI 59

This function is applied to detect an abnormal higher system voltage or to check sufficient voltage for voltage

source transfer. This protection works with the maximum phase to phase voltage.

• Three independent stages with definite time delay are provided.

• Four setting groups for each stage.

Functions Settings

Pick-up 50 to 150%Un

Hysteresis 0.1 to 20%

Trip 0.04 to 300s

Hold 0.03 to 300s

Definite time (DT), Inverse time (INV)

schneider-electric.com | 33Easergy P5 Catalog

Page 34

Easergy P5

Functions and description

Range description

Capacitor overvoltage - ANSI 59C

This function calculates the voltages of a three-phase Y-connected capacitor bank using the measured currents

of the capacitors. No voltage measurements are needed.

Especially used in filter applications, harmonics are present, which depending on phase angles, can increase

the peak voltage. This protection function calculates the worst-case overvoltage in per-unit values using Equation

7.10 according to IEC 60871-1 standard. Harmonics up to 15th are taken into account.

• Three independent stages with define time.

• Four setting groups.

Functions Settings

Pick-up setting UC> 0.10 to 2.50UCLN

Time delay 1.0 to 30.0s

Rated L-N voltage UCLN 100 to 260000V

Capacitance per phase

1.00 to 650.00μF

Neutral voltage displacement - ANSI 59N

This function is used for general earth/ground fault detection and for backup protection (unselective). It

measures the fundamental component of the neutral displacement voltage.

• 3 stages with DT operating time

• Attenuation of the third harmonic by more than 60 dB

• Faster high-set stage U0>>>.

• 4 setting groups for each stage.

Function Settings

Pick-up 2 to 120% Uno

Time delay 0.04 s to 300.00s

Motor restart inhibition - ANSI 66

This function prevents too frequent motor starts. Every motor has a restriction on the number of starts within

a defined period to avoid thermal overload, mainly inside the rotor. A settable time interval between two

consecutive starts is also necessary to allow the motor to cool down following the previous start.

• Settable number of starts per hour.

• Settable minimum time between consecutive starts.

Functions Settings

Time from motor start 0min, 120min

Maximum hot starts / hour 1 to 20

Maximum cold starts / hour 1 to 20

Minimum time between starts 0.0 min to 100.0min

schneider-electric.com34 | Easergy P5 Catalog

Page 35

Easergy P5

Functions and description

Range description

Directional phase overcurrent - ANSI 67

This function provides directional short circuit protection.

• Four independent stages with definite time delay (DT), two of them with inverse time delay (IDMT).

• Settable directionality

• Directional voltage memory with fixed duration of 3.2 s.

• Cold Load Pickup (CLP).

• Four setting groups for each stage.

Functions Settings

Direction mode

Definite time

(DT) pick-up

Inverse time

(IDMT) pick-up

Definite time delay 0.03 to 300.00 s

Inverse time delay curves

Inverse time coefficient(k)

Reset time 0.03 s to 100.00 s

Angle offset

I>

I>> 0.10 to 20.00 In

I>>> 0.10 to 40.00 In

I> 0.05 to 5.00 In

I>> 0.10 to 5.00 In

Directional

Non directional

Directional + Backup

0.05 to 20.00 In

IEC: NI, VI, EI, LTI

IEEE: VI, EI, LTI, LTEI, LTVI, MI, STI, STEI, others

IEEE2: NI, VI, EI, MI

Other : RI, RXIDG

Programmable: 3 curves with 16 setting points

0.05 to 20.00 for IEC curves and others (RI)

0.5 to 20.0 for IEEE, IEEE2 curves and others (RXIDG)

-180° to +179°

schneider-electric.com | 35Easergy P5 Catalog

Page 36

Easergy P5

Functions and description

Range description

Directional earth/ground fault overcurrent - ANSI 67N

This function provides selective and sensitive earth/ground fault protection for various network earthing systems

of power neworks.

• Residual current and voltage can be either measured or internally calculated based on phase currents and

voltages.

• Three independent stages with definite time and inverse time delay.

• Directional voltage memorywith fixed duration of 3.2 s.

• Settable directionality.

• Four setting groups for each stage.

Functions Settings

Io - Measured with 1 A/5 A CT

Io / Io’

Definite time (DT) pick-up 0.02 to 10.00 Ino 0.05 to 10.00 Ino 0.05 to 20.00 In 0.002 to 1.00 Ino

Inverse time (IDMT) pick-up 0.02 to 5.00 Ino 0.05 to 5.00 Ino 0.05 to 5.00 In 0.002 to 1.00 Ino

Definite time delay 0.03 to 300s

Inverse time delay curves

Inverse time oefficient(k)

Residual voltage Uo 1 to 50% Uno

Directional mode Resistive, capacitive, sector, non directional

Offset angle -180° to +179°

Io - Measured with 1 CSH core balance CTIo -

Io - Calculated with the sum of the 3 phase currents

Io’ - Measured with 1 A CT

Standard CT

IEC: NI, VI, EI, LTI

IEEE: VI, EI, LTI, LTEI, LTVI, MI, STI, STEI

IEEE2: NI, VI, EI, MI

Others: RI, RXIDG

Programmable: 3 curves with 16 setting points

0.05 to 20.00 for IEC curves and others (RI)

0.5 to 20.0 for IEEE, IEEE2 curves and others (RXIDG)

TCSH core

balance CT

Calculated

earth/ground fault

Very sensitive CT

schneider-electric.com36 | Easergy P5 Catalog

Page 37

Easergy P5

Functions and description

Range description

Transient intermittent earth/ground fault - ANSI 67NI

This function detects short transient intermittent phase to earth/ground faults in compensated networks, which

cannot be correctly recognized by steady-state directional earth/ground fault functions using the fundamental

frequency components only.

• Neutral displacement voltage U0> element to enable function.

• Settable forward/reverse direction.

• Dedicated blocking input to coordinate with AR.

• Four setting groups.

Functions Settings

Io Io measured with standard earth/ground fault CT or CSH core balance CT

Io’ Io’ measured with very sensitive earth/ground fault CT

Direction mode

Minimum of number of peaks 1 to 20

U0> setting

Time delay

Memory hold time 0,01 to 300.00s

Reset time 0.06 to 300.00s

Reverse, Forward

1 to 60% Uno

0.02 to 300.00s

2nd harmonic (H2) detection - ANSI 68H2

This function detects inrush current flows that occur when transformers or machines are energized. It may be

used to stabilize protection functions (e.g. phase overcurrent, earth/ground fault overcurrent, …) or even to issue

a trip if the inrush condition persists too long.

• Based on proven I2/I1 measurement.

• Measurement per phase.

Functions Settings

Pick-up 10 to 100%

Time delay 0.03 to 300.00s

5th harmonic (H5) detection - ANSI 68H5

This function detects 5th harmonic current flows that occur during overexcitation of transformers. It may be used

to stabilize protection functions or even to trip if the condition persists too long.

• Based on proven I5/I1 measurement.

• Measurement per phase.

Functions Settings

Pick-up 10 to 100%

Time delay 0.03 to 300.00s

schneider-electric.com | 37Easergy P5 Catalog

Page 38

Easergy P5

Functions and description

Range description

Auto-recloser function - ANSI 79

The auto-recloser (AR) function can be used in feeder protection relays to help protect an overhead line. It limits

the interruption of service in case of transient or semi-permanent faults that affect overhead lines. The function

uses the object control function to control the CB open/close sequence. All other object control methods are in

simultaneous use, including object failure monitoring. If the circuit breaker (CB) control fails or another function

controls the CB, the AR sequence stops.

• One to four autorecloser shots.

• Control of one or two circuit breakers.

• Control via binary or virtual inputs (IEC 61850).

Functions Settings

Enable Auto-Recloser

Breaker 1 object

Breaker 2 object

Auto CB selection On; Off

Input for CB selection

Reclaim time 0.02 to 3000.00s

Block by external synchro. check digital input (DI), virtual input (VI), virtual output (VO) or function key

Shot specific reclaim time On; Off

Settings per shot

Additional setting 1st shot 0.02 to 300.00s (start delay)

On; Off

with digital input (DI), virtual input (VI), virtual output (VO) or function key

Object 1 to Object 6

Object 1 to Object 6

digital input (DI), virtual input (VI), virtual output (VO) or function key

0.01 to 1200.00s (dead time)

0.02 to 300.00s (discrimination time)

Under and Over frequency - ANSI 81

Frequency deviations result from an imbalance between power generation and power loads. The over/under

frequency protection function is used for load shedding, loss of power system detection, load restoration and as

a backup protection for overspeeding in generators.

• Two independent stages with definite time delay are provided.

• The function is activated with a settable voltage threshold.

• Automatically inhibited if the maximum phase to phase voltage goes below the setting threshold.

• Four setting groups for each stage.

Functions Settings

Trip condition Under, over

Pick-up 40 to 70Hz

Time delay 0.1 s to 300s

Low voltage blocking 30 to 100%Un

schneider-electric.com38 | Easergy P5 Catalog

Page 39

Easergy P5

Functions and description

Range description

Rate of change of frequency - ANSI 81R

This function (ROCOF) is appliced to detect the rate of change of system frequency, for fast load shedding or

fast disconnection of islanded generators under loss of main condition.

• Two independent stages with definite time delay.

• Direction of the frequency change is settable.

• Automatically inhibited if the maximum phase to phase voltage goes below the setting threshold.

• Four setting groups for each stage.

Functions Settings

Direction of change Negative, Positive, Either

Pick-up 0.1 to 10Hz/s

Time delay 0.05 to 10s

Low voltage blocking 30 to 100%Un

Under frequency - ANSI 81U

This function is applied to detect an abnormally low system frequency, to trigger load shedding, or indicate the

loss of main grid.

• Four independent stages with definite time delay are provided.

• Automatically inhibited if the maximum phase to phase voltage goes below the setting threshold.

• Four setting groups for each stage.

Functions Settings

Pick-up 40 to 64Hz

Time delay 0.1 s to 300s

Low voltage blocking 30 to 100%Un

schneider-electric.com | 39Easergy P5 Catalog

Page 40

Easergy P5

Functions and description

Range description

Lockout - ANSI 86

The lockout feature, also called latching, ensures that a manual intervention is required to reset all alarm or

tripping conditions, for example to enable CB re-closing. It can be programmed in the output matrix setting view.

Any protection stage start or trip, digital input, logic output, alarm and GOOSE signal connected to the following

outputs can be latched when required:

• Output contacts.

• LEDs on the local panel.

• Virtual outputs.

Programmable stages - ANSI 99

For special applications the user can build their own detection stages by selecting the supervised signal and the

comparison mode. This allows the user to trigger an event from a selection of signals and select the type, level

and timing to suit the application.

• Eight independent stages with definite time delay.

• Priority selection for fast operation needs.

• Multiple coupling and comparison conditions.

• Four setting groups for each stage.

Functions Settings

Phase currents and earth/ground currents,

Simple or composed voltages,

Coupling

Trip conditions Under, over, dif ference, absolute difference

Time delay 0,08 to 300 s

Cuurent and voltage distortion values,

Direct current or voltage,

Inverse current or voltage,

Phase and earth/ground effective current

schneider-electric.com40 | Easergy P5 Catalog

Page 41

Easergy P5

Functions and description

Range description

Selective Overcurrent Logic (SOL)

The Selective Overcurrent Logic (SOL) function, can considerably reduce the tripping time of the circuit breakers

closest to the source, compared to pure time discrimination, and may be used for logic discrimination in closed

ring networks also using directional protection. SOL function is applied to the phase overcurrent, directional

phase overcurrent, earth/ground fault overcurrent (except stage 5), very sensitive earth/ground fault overcurrent

protection elements, with definite time and inverse time delays.

The selective overcurrent logic allows:

• To send a blocking signal when a fault is detected by overcurrent or earth/ground fault protection elements

(ANSI 50/51, 50N/51N, 50G/51G, 67, 32N).

• To receive a blocking signal that inhibits the protection elements.

Functions Settings

Definite time delay 0.03 to 300s

Inverse time delay curves IEC, IEEE, IEEE2, others, three programmable curves

Inverse time delay coefficient

0.05 to 20.00 for IEC curves and others (RI)

0.5 to 20.0 for IEEE, IEEE2 curves and others (RXIDG)

Circuit Breaker (CB) monitoring

Periodic maintenance of circuit breakers is necessary to ensure that the trip circuit and mechanism operate

correctly and that the interrupting capability has not deteriorated due to previous fault interruptions. The Easergy

P5 protection relay records various statistics related to each circuit breaker operation, allowing an accurate

assessment of the circuit breaker condition. Statistics are recorded to allow evaluation of both the electrical wear

of the breaker contacts and the mechanical wear of the breaker mechanism.

Following counters are provided:

• Number of all circuit breaker operations.

• Number of circuit breaker operations triggered by protection functions e.g. faults.

• Cumulative broken current.

• Circuit breaker operating times.

• Charging times.

• Number of rack-in and rack-out operations.

This feature, when paired with EcoStruxure Asset Advisor brings a proactive maintenance approach to electrical

distribution critical assets, combining newest technologies with Schneider Electric’s expertise and services.

EcoStruxure Asset Advisor offers the ability to anticipate and address issues before they become critical

incidents, mitigating safety risks, avoiding unplanned downtime, operational losses and expensive maintenance

interventions.

schneider-electric.com | 41Easergy P5 Catalog

Page 42

Easergy P5

Communication

Range description

HMI/

SCADA

DM107138

Serial

link

DM107139

Daisy chain

HMI/

SCADA

Examples of architectures

Connection to SCADA using serial line

This architecture allows you to connect HMI/SCADA to a set of Easergy P5

protection relays using a multi-drop serial communication link with master-slave

communication.

Available protocols:

• Modbus RTU

• IEC 60870-5-101

Time synchronization protocol:

• IRIG-B

• Minute pulse

• IEC 60870-5-103

• DNP3

Connection to SCADA using Ethernet

This architecture allows you to connect a set of Easergy P5 protection relays

directly to an Ethernet network.

Available protocols:

• IEC 61850 Edition 1 and Edition 2

• DNP3

• EtherNet/IP

• Modbus TCP/IP

Ethernet

switch

DM107140

SubNetwork

Panel

HMI

Ethernet

GOOSE

messages

Ethernet

switch

Ethernet

switch

Ethernet

Network

GOOSE

messages

Easergy

Pro

Note: It is possible to mix IEC 61850 protocol with other communication or

redundancy protocols from Easergy P5 on the same Ethernet network. This allows

you to use GOOSE messages between relays together with another protocol for

communication to SCADA. It is also possible to connect to two different control

systems, using the same Ethernet communication port and IEC 61850 protocol for

one network, and any available protocol for the second network.

Equipped with two Ethernet modules, Easergy P5x30 can handle 3 Ethernet

protocols simultaneously with a single IP or 3 different IP adresses. Optionally,

Easergy P5x30 offers a capability of dual redundancy providing PRP/HSR protocol

for one system and a separate RSTP protocol for another system or engineering

channel.

Easergy P5 protection relay handles the IEC 61850 station bus, in compliance with

IEC 61850-6, 7-1, 7-2, 7-3, 7-4 and 8-1 Edition 1 or Edition 2 standards, according

to the configuration.

Other available Ethernet protocols:

• FTP for file transfer

• SNTP for time synchronization

• PTP for precise time synchrionisation according to IEEE 1588v2 standard

• HTTPs for web server (setting changes)

Switchboard internal network

This architecture allows fast GOOSE communication between Easergy protection

relays in the same switchboard, this avoiding costly wiring. Typical uses are logic

discrimination, load shedding, etc.

In addition, a panel HMI featuring a web browser can be used to monitor and

control the entire switchboard.

A spare connection on the panel Ethernet switch can also be provided for

connecting the eSetup Easergy Pro setting and configuration tool.

On Easergy P5x30 models, two independent Ethernet communication modules are

available. This allows implementation of the switchboard internal network and the

communication to SCADA on two separate Ethernet networks.

schneider-electric.com42 | Easergy P5 Catalog

Page 43

Easergy P5

Communication

Range description

DM107141

Ethernet

switch

Ethernet

switch

HMI/

SCADA

Ethernet

switch

Ethernet

switch

Redundancy protocols

RSTP (Rapid Spanning Tree Protocol)

The principle of RSTP is to virtually remove all links that are not necessary at a

given time, changing the meshed topology into a tree topology.

The main advantage of RSTP is that it is widespread and works on any network

topology. On the other hand, RSTP takes milliseconds or seconds to reconfigure the

network in case of network interruption.

With Easergy P5, the typical reconfiguration time for a loop of 10 relays is 0,050s.

HMI/

DM107142

Network A

Network

DM107143

Easergy P5 Easergy P5 Easergy P5

SCADA

Ethernet

switch

Network B

PRP (Parallel Redundancy Protocol)

The principle of PRP is to transmit frames in parallel on two independent network

infrastructures: A and B.

The receiving device is in charge of removing the redundant frame, if it has already

been received.

PRP protocol provides an instantaneous recovery time in case of failure, since no

re-transmission of the message is needed.

HSR (High-availability Seamless Redundancy)

HSR is similar to PRP but only works on a ring architecture.

Frames are transmitted on the ring in both directions and the receiving device

eliminates redundant frames.

HSR protocol provides an instantaneous recovery time and is an alternative to PRP

when network topology is restricted to a ring.

Both PRP and HSR protocols are listed in IEC 62439-3 as part of IEC 61850

standard. They both provide standardized, interoperable and high performance

redundant Ethernet solutions.

schneider-electric.com | 43Easergy P5 Catalog

Page 44

Easergy P5

Communication

Range description

Easergy P5 protection relays

offer following solutions for time

synchronization:

Communication protocol, Minute Pulse,

IRIG-B, SNTP and PTP.

IRIG-B Master

DM107460

Switch

Ethernet IED Serial IED

IRIG-B

Cabling

Separate

from

Data Network

Time synchronization

In modern protective schemes it is required to synchronize the internal realtime clock of the relay, so that events from different relays can be placed in

chronological order.

This can be done using the communication interfaces connected to the substation

control system or via dedicated time synchronization options provided by Easergy

P5 relays: minute pulse, IRIG-B time code and SNTP or PTP IEEE 1588v2 over

Ethernet networks.

Minute pulses

The clock can be synchronized by reading minute pulses from digital inputs, virtual

inputs or virtual outputs. The sync source is selected with the SyncDI setting.

When a rising edge is detected from the selected input, the system clock is

adjusted to the nearest minute.

IRIG-B

Inter-Range Instrumentation Group time code B (IRIG-B) is a standard format for

transferring timing information. IRIG-B time synchronization standard is based on a

frame of 100 data bits sent every second to the device.

This time synchronization standard is supported in Easergy P5 by the IRIG-B

module connected to the optional extension module of the relay.

The module provides both a modulated and an unmodulated input and can

automatically detect which input type is used. The time synchronization accuracy in

Easergy P5 with this mode is less than 5 ms. For more information, see the IRIG-B

module details so page 89.

DM107461

GPS clock as SNTP master

DM107462

PTP Grandmaster

HMI/

SCADA

Ethernet

switch

SNTP Protection Relays

HMI/

SCADA

Transparent Clock

(PTP Ethernet switch)

PTP Protection Relays

Substation HMI

with SCADA gateway

Substation HMI

with SCADA gateway

SNTP

Simple Network Time Protocol (SNTP) is a less complex implementation of Network

Time Protocol (NTP), using the same protocol but without requiring the storage of

state over extended periods of time. SNTP is used to synchronize the clocks of

computer systems over packet switched, variable-latency data networks.

A jitter buffer is used to reduce the effects of variable latency introduced by

queuing in packet switched networks, ensuring a continuous data stream over the

network.

The Easergy P5 protection relay receives the synchronization from the SNTP/NTP

server. The time synchronization accuracy in this mode is less than 5 ms.

PTP

Precision Time Protocol according to IEEE 1588-2008 (v2) standard. The

PTP implementation in Easergy P5 protection relay is compliant to IEC618509-3 standard. This protocol enables precise synchronization of clocks in

measurement and control systems implemented with technologies such as network

communication, local computing, and distributed objects.

The protocol is applicable to systems communicating via Ethernet. Systemwide

synchronization accuracy and precision in the sub-microsecond range are

supported with minimal network and local clock computing resources. The time

synchronization accuracy in Easergy P5 with this mode is less than 1 ms.

schneider-electric.com44 | Easergy P5 Catalog

Page 45

Easergy P5

Communication

Range description

Data exchanged

Data exchanged with SCADA

Ports Ethernet Serial or Ethernet Serial

Protocol

Real time data

Measurement -

Alarms and status -

Controls -

Time-stamped events -

Historical data

Disturbance records

Sequence of event record files - - - - -

Setting management

Setting group change -

Settings - - - -

IEC 61850 Ethernet/IP FTP DNP3 Modbus

- -

-

IEC 60870-

5-103

IEC 60870-

5-101

-

-

Data exchanged according to IEC 61850

The Methodology described in the IEC 61850-6 standard can be applied with

Easergy P5 protection relays, in order to build a protection and control system

based on this standard.

.icd file

For each model of Easergy P5 relay, the IED capability file can be downloaded

from the Schneider Electric website.

.scd file

The system description file generated by the system configurator can be

processed by eSetup Easergy Pro and the relevant system settings integrated in

the Easergy P5 configuration.

DM107144

Safe Repository and

Schneider Electric website

.icd file

System

configurator

.iid file.scd file

eSetup

Easergy Pro

.iid file

When the configuration of an Easergy P5 protection relay is completed or

modified, eSetup Easergy Pro can generate an Instantiated IED Description file to

be used by the system configurator to update the system description.

schneider-electric.com | 45Easergy P5 Catalog

Page 46

Easergy P5

Cybersecurity

Range description

Cybersecurity features implemented in

Easergy P5 help to mitigate cyber threats.

Easergy P5 can be ordered, either with:

- Cybersecurity basic level or