Samsung DV393GTPAWR, DV365GTBGWR, DV365GTBGSF User Manual 2

CLOTHES DRYER

Technical Information

IMPORTANT SAFETY NOTICE – “For Technicians only” This service data sheet is intended for use by persons having electrical, electronic, and mechanical experience and knowledge at a level generally considered acceptable in the appliance repair trade. Any attempt to repair a major appliance may result in personal injury and property damage. The manufacturer or seller cannot be responsible, nor assume any liability for injury or damage of any kind arising from the use of this data sheet.

•Due to possibility of personal injury or property damage, always contact an authorized technician for servicing or repair of this unit.

•Refer to Service Manual (DV405, DV398, DV395, DV393, DV231, DV365) for detailed installation, operating, testing, troubleshooting, and disassembly instructions.

CAUTION

CAUTION

All safety information must be followed as provided in Service Manual of DV405, DV398, DV395, DV393, DV231, DV365.

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

Code No. : DC68-02365H-03_EN

1

(Technical)DV405-02365H-03_EN_130221.indd 1 |

|

|

2013-02-21 5:31:59 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

ERROR ITEMS AND DIAGNOSTIC CODES

An occurrence of an Error will make a sound of error melody for 5sec and continuously show one of the Error Displays from the following errors.

Error Display |

Trigger |

Action Taken |

|

|

|

Check for: |

|

tE |

The Termistor resistance is |

- Clogged lint screen. |

|

very low or high. |

- Restricted vent system. |

||

|

|||

|

|

- Check Thermistor resistance. |

|

|

|

|

|

|

Invalid heating Temp in |

Check for: |

|

HE |

- Restricted vent system. |

||

running the dryer |

|||

|

- Check Thermistor resistance. |

||

|

|

||

|

|

|

|

|

|

Check for: |

|

dE |

Running the dryer with door |

- Close the door, and run the dryer. |

|

open |

- Loose or open wire terminals in |

||

|

|||

|

|

Door Sense circuit. |

|

|

|

|

|

|

Invalid door state for more |

Check for: |

|

dF |

- Loose or open wire terminals in |

||

than 256 milliseconds |

|||

|

Door Sense circuit. |

||

|

|

||

|

|

|

|

|

Invalid state of key circuit |

Check for: |

|

bE2 |

- Display PCB key circuit short or |

||

short for 30 secs |

|||

|

not. |

||

|

|

||

|

|

|

|

|

|

Check for: |

|

|

Invalid power source |

- Not using regular power source |

|

FE |

frequency |

||

Frequency |

|||

|

- Invalid power frequency sense |

||

|

|

||

|

|

circuit |

|

|

|

|

|

|

Electronic Control Problem |

Check for: |

|

2E |

- Check PCB and Wire harness. |

||

(Over Voltage Error) |

|||

|

- Check Power supply. |

||

|

|

||

|

|

|

|

|

Electronic Control Problem |

Check for: |

|

AE |

- Check PCB and Wire harness. |

||

(Communication Error) |

|||

|

- Replace PCB. |

||

|

|

||

|

|

|

|

Et |

Invalid state of Eeprom |

Check for : |

|

communication |

- PCB with Eeprom circuit. |

||

|

|||

|

|

|

2

(Technical)DV405-02365H-03_EN_130221.indd 2 |

|

|

2013-02-21 5:31:59 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

TEST MODE

Service Mode (DV405, DV398, DV395, DV393 only)

How to enter:

-To enter Service Mode , press Mixed Load Bell + Temp. Keys 3 seconds in normal mode until it sends out a beeping sound.

-If pressing Mixed Load Bell + Temp. Keys in Service mode , it will return Normal mode.

-Even though entering Service mode, the operating cycle will not be influenced.

DR Ready Modem Wire Test(DV431AS* only)

How to enter:

-After entering Service Mode, press the Wrinkle Prevent button to start the Wire Test.

-During the test, “----” is displayed.

-If the test result is normal after the test, “SG” is displayed.

-If a problem occurs, the “AE3” error code is displayed.

Touch Sensor Data Display Mode

Definition of Touch Sensor Data Display Mode:

-This mode is default mode of entering service mode.

How to enter:

-With Power On pressing Mixed Load Bell +Temp(DV405, DV398, DV395, DV393) or Wrinkle Prevent + Temp(DV231, DV365) for 3 seconds.

-This action will put the dryer into sensor bar touch data mode

-Dryer will display Sensor Bar data.

Cycle Count Mode

Definition of Cycle Count Mode:

-This mode is to bring up the total number of cycles that User have carried out.

How to enter:

-Press the Mixed Load Bell(DV405, DV398, DV395, DV393) orTime(DV231,DV365) key in Service Mode.

Software Revision Mode

Definition of Software Revision Mode:

- It is to retrieve its software version

How to enter:

At Service Mode, press Temp until it sends out a beeping sound

ex) In case of “U1 05”, U1 means major version “U1”, 05 means minor version “05”.

-If press Temp key In Software Version Mode, it will return Service Mode.

3

(Technical)DV405-02365H-03_EN_130221.indd 3 |

|

|

2013-02-21 5:31:59 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

Continuous Run Mode

Power On state |

|

Mixed Load Bell +Dry Level(DV405, DV398, DV395, DV393) |

|

Continuous Run Mode |

(Normal user mode) |

|

or Wrinkle Prevent + Time(DV231, DV365) 7 SEC |

|

|

|

|

|

||

|

|

|

|

|

How to enter:

-Press Mixed Load Bell +Dry Level(DV405, DV398, DV395, DV393) or Wrinkle Prevent + Time(DV231, DV365) for 7 sec during Power On State (normal user mode).

-Once in Continuous Run Mode, display “cc” for 1 sec and finished cycle count for 1 sec and the remaining time for 1 sec in turns.

-The previous cycle will restart during Continuous Run Mode until the mode is deactivated.

-During Continuous Run Mode, press Mixed Load Bell +Dry Level(DV405, DV398, DV395, DV393) or Wrinkle Prevent + Time(DV231, DV365) for 7 seconds to go back to normal user mode.

Data Display Mode (DV405, DV398, DV395, DV393 only)

How to Enter:

-With Power On, press AdjustUp Key + AdjsutDown Key for 7 seconds until it sends out a beeping sound .

-If not pressed any keys for 5 minutes, it will be set back from Data Display Mode

-If pressing AdjustUp Key in this mode, Display Mode will be incresed.

-If pressing AdjustDown Key in this mode, Display Mode will be decresed.

Definition of Data Display Mode:

-Display Mode 1 : Air Temperature data

-Display Mode 2 : Average Touch Sensor data for 1 minute

-Display Mode 3 : Average Temperature data for 1 minute

-Display Mode 4 : Vent sensor temperature data (*DV398 Only)

4

(Technical)DV405-02365H-03_EN_130221.indd 4 |

|

|

2013-02-21 5:32:00 |

|

|

||

|

|

|

|

ALIGNMENT AND ADJUSTMENTS

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

TROUBLE DIAGNOSIS

-As the micom dry machine is configured of the complicate structure, there might be the service call.

Below information is prepared for exact trouble diagnosis and suitable repair guide.

Caution for the Repair and Replacement

Please follow below instruction for the trouble diagnosis and parts replacement.

1)As some electronic components are damaged by the charged static electricity from the resin part of dryer or the human body, prepare the human body earth or remove the potential differ ence of the human body and dryer by contacting the power supply plug when the work contacting to PCB is executed.

2)As the P.C.B assembly is designed for no trouble, do not replace the P.C.B assembly by the wrong diagnosis and follow the procedure of the trouble diagnosis when the micom is not operated normally.

5

(Technical)DV405-02365H-03_EN_130221.indd 5 |

|

|

2013-02-21 5:32:00 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

No |

Problem |

What To Do |

||

|

|

|

||

|

|

• All wires are hooked up to their corresponding terminals. |

||

|

|

• Dryer is plugged in. |

||

|

|

• Blown fuse or circuit breaker. |

||

|

|

• Door switch functional...door closed. Check for error code 3 (See |

||

|

|

|

Table for codedefinition). |

|

1 Will Not Start or Run |

• |

Start/Pause rotary selector dial functional. |

||

|

|

• |

Control Board operational. |

|

|

|

• Belt off or broken and Belt Cut-off Switch operates. |

||

|

|

• |

Drive motor functional. |

|

|

|

• Check motor winding resistance: 2.88ohms between pin #3 and |

||

|

|

|

4, 3.5ohms between pin #4 and 5. |

|

|

Motor runs/ tumbler |

• Belt off or broken/damaged. |

||

2 |

• |

Idler tension spring too weak or stretched. |

||

will not turn |

||||

|

• Idler pulley jammed or stuck. |

|||

|

|

|||

|

|

|

||

|

|

• Lint buildup around drive motor. |

||

3 |

Runs a few minutes |

• |

Low voltage present. |

|

and then stops |

• |

Blower impeller blocked in blower housing. |

||

|

||||

|

|

• Drive motor - start switch contacts stuck closed. |

||

|

|

|

|

|

|

|

- |

Is the belt connected well? |

|

|

Blows fuses or trips |

- |

Is the winding of the motor continuous? |

|

4 |

|

(Rotor winding, stator winding, generator) |

||

circuit breaker |

- |

Is the motor protector normal? |

||

|

||||

|

|

• If above points are not found, the PCB assembly is out of order. |

||

|

|

|

Replace it. |

|

|

|

|

||

|

|

• During ignition the dryer will draw X amps. With the burner ON, |

||

|

|

|

the dryer will draw X amps. If the dryer is drawing amperages |

|

|

Blows fuses or trips |

|

above this, then the house wiring, fuse box or circuit breaker is |

|

5 |

circuit breaker (Gas |

• |

suspected to be at fault. |

|

|

Model) |

Igniter harness loose and shorted to base. |

||

|

|

• Incorrect wiring or wire shorted to ground. |

||

|

|

• Drive motor winding shorting to ground. |

||

|

|

|

Open heating element. |

||||||

|

|

Will not heat (motor |

• Hi-Limit trips easily or is open. |

||||||

6 |

• |

Regulating thermostat trips easily or is open. |

|||||||

runs) |

|||||||||

|

|

• |

Membrane switch open. |

||||||

|

|

|

|||||||

|

|

|

• |

Check Thermistor. |

|

||||

|

|

Will Not Dry Gas |

When the dryer is operated on a heat setting, the igniter should be |

||||||

|

|

energized and burner shall fire within 45 seconds at 120 VAC. The |

|||||||

|

7 Model Poor Gas |

||||||||

|

failure of a component in this system will usually be indicated by one |

||||||||

|

|

Ignition |

|||||||

|

|

of three symptoms: |

|||||||

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

|||

(Technical)DV405-02365H-03_EN_130221.indd |

6 |

|

|

|

2013-02-21 5:32:00 |

||||

|

|

|

|||||||

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

TROUBLE SHOOTING

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

No |

Problem |

What To Do |

||

|

|

|

||

|

|

If the igniter does not heat up, remove power and using an |

||

|

|

ohmmeter, check the following: |

||

|

|

• |

Open flame sensor |

|

8 |

The igniter does not |

• |

Open igniter |

|

glow |

• |

Shorted booster coil |

||

|

||||

|

|

• |

Open wiring |

|

|

|

• Bad motor switch ( Neutral supply) |

||

|

|

• No power from control ( L1 supply) |

||

|

|

If the igniter heats up but the main burner flame is not ignited, |

||

|

|

remove power and using an ohmmeter, check the following: |

||

9 |

Igniter glows - No gas |

• |

Open secondary coil |

|

ignition |

• |

Open holding coil |

||

|

||||

|

|

• |

Open wire harness |

|

|

|

• Stuck flame sensor (Stuck closed) |

||

|

|

If a normal ignition takes place and after a short while the flame goes |

||

|

|

out, check for the following: |

||

|

The gas is ignited but |

• |

Radiant sensor contacts opening prematurely. |

|

10 |

the flame goes out |

• |

Weak gas valve coil may open when stressed by higher Temps. |

|

|

|

• Weak Hi-Limit |

||

|

|

• |

Poor venting |

|

|

|

• |

Bad drum seals |

|

|

|

• Lint filter is not clean. |

||

|

|

• |

Restriction in exhaust. |

|

|

|

• Outside exhaust hood damper door stuck closed. |

||

|

Improper drying |

• |

Exhaust too long, too many elbows, flex ductwork installed. |

|

11 |

clothes wrinkled |

• |

Poor intake air available for the dryer. |

|

Rough texture long |

• |

Incorrect tumbler speed. Tumbler belt slipping. |

||

|

dry time |

• |

Blower impeller bound; check for foreign material in blower area. |

|

|

|

• |

Customer overloading dryer. |

|

|

|

• Check clothing labels for fabric content and cycle selected. |

||

|

|

• Clothes too wet due to insufficient spin out by washer. |

||

|

|

• Thumping Check for loose tumbler baffle, rear tumbler roller(s) |

||

|

|

|

worn or misaligned, out-of-round tumbler or high weld seam on |

|

|

|

|

tumbler. |

|

|

|

• Ticking Check for loose wire harness or object caught in blower |

||

12 |

Noisy and/Or |

• |

wheel area. |

|

Vibration |

Scraping Check for front or rear bulkhead felt seal out of |

|||

|

|

|

position or worn tumbler front bearings. |

|

|

|

• Roaring Check for blower wheel rubbing on blower housing or |

||

|

|

|

bad motor bearings. |

|

|

|

• Popping or squealing sound. Check for a sticky or frayed belt. |

||

|

|

|

|

|

|

|

|

7 |

|

(Technical)DV405-02365H-03_EN_130221.indd 7 |

|

|

2013-02-21 5:32:00 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

COMPONENT TESTING PROCEDURES

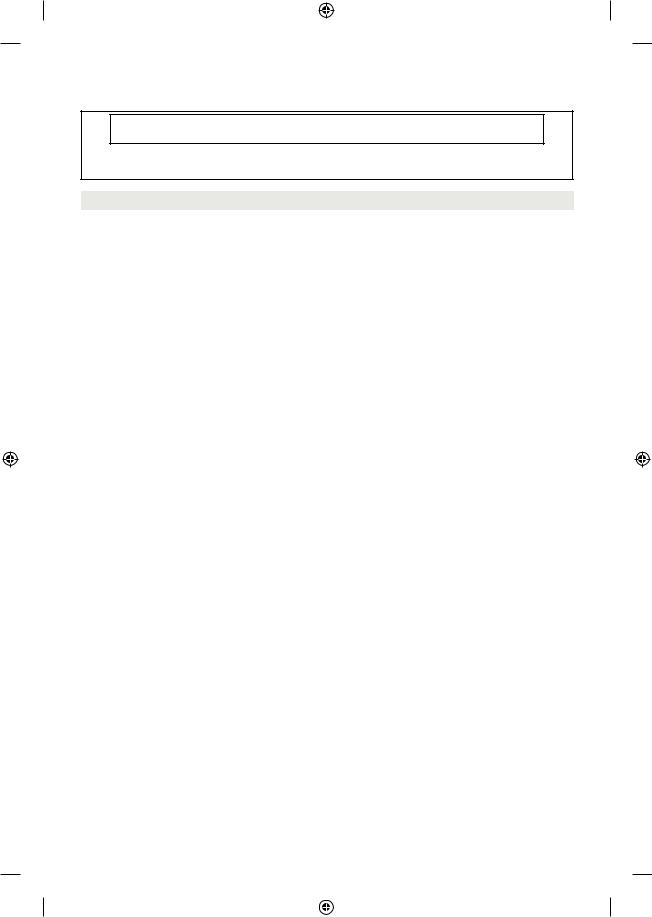

Component Electrical Testing (with ohmmeter) |

Belt Cut-off S/W |

|

|

Thermistor resistance 10K Ω @ 25°C 77°F |

- Lever open: Resistance value < 1Ω |

|

Thermostat 1 resistance < 1Ω |

- Lever push: Resistance value : ∞ Ω |

|

||

Thermostat 3 resistance < 1Ω |

Lamp resistance 80~100 Ω (Violet & gray) |

- If resistance is infinity, replace thermostat 3. |

Thermostat 2 resistance < 1Ω

-If resistance is infinity, replace thermostat 2.

Heater resistance 10 Ω

-If resistance is infinity, replace Heater.

Thermostat |

3 |

Thermostat 2 |

Heater |

|

160 °C, 25A |

|

127/99 °C, 25A |

240V/5300W |

|

thermal cut-off |

Hi-limit |

|||

|

||||

Measure resistance of the following terminal

1)Door switch : off

Terminal : “COM” - “NC” (1-3) < 1Ω

Terminal : “COM” - “NO” (1-2) : ∞ Ω

2)Door switch : On

Terminal : “COM” - “NC” (1-3) : ∞ Ω

Terminal : “COM” - “NO” (1-2) < 1Ω

Motor (Electronic & GAS)

Contacts

Function 1M 2M 3M 5M 6M

Start

Run

= Contact closed

Centrifugal Switch (Motor)

2.88Ω between Pin# 3 and 4

3.5Ω between Pin# 4 and 5

8

(Technical)DV405-02365H-03_EN_130221.indd 8 |

|

|

2013-02-21 5:32:01 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

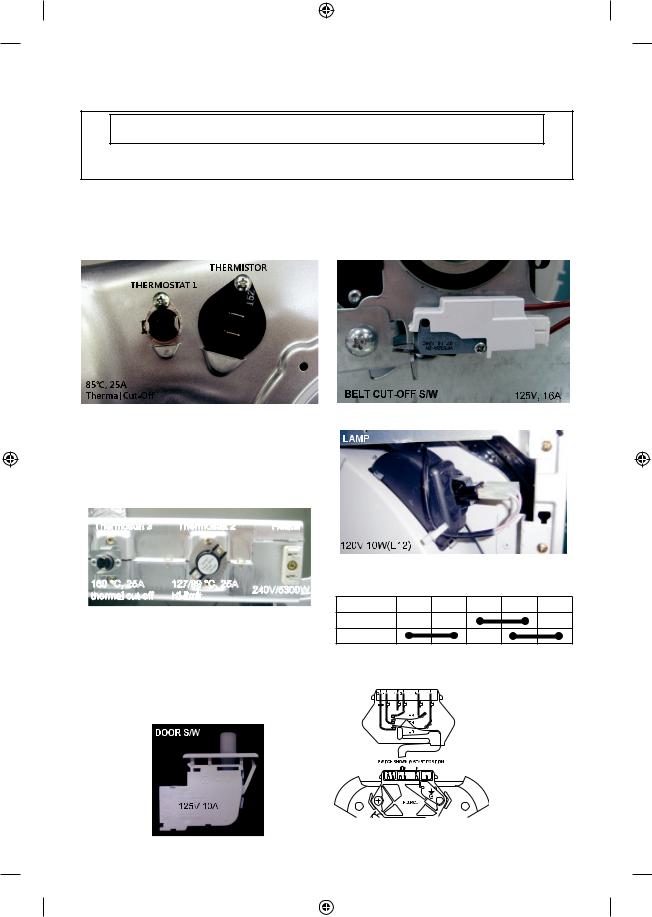

THERMISTOR

238.23Ω @ 25 °C 77

GAS MODEL

Radiant Sensor(10RS) |

Gas Valve(25M01A) |

Resistance value < 1 Ω |

Valve 1-2 : Resistance value 1.2K Ω |

If resistance is infinite, replace Radiant sensor |

Valve 1-3 : Resistance value 0.5K Ω |

|

Valve 4-5 : Resistance value 1.2K Ω |

|

If resistance is infinity, replace Valve |

Igniter(101D)

Resistance value 40~400 Ω

If resistance is infinite, replace Igniter Thermostat (60T21 Hi-Limit)230F-50F Resistance value < 1 Ω

If resistance is infinity, replace Thermostat

9

(Technical)DV405-02365H-03_EN_130221.indd 9 |

|

|

2013-02-21 5:32:02 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

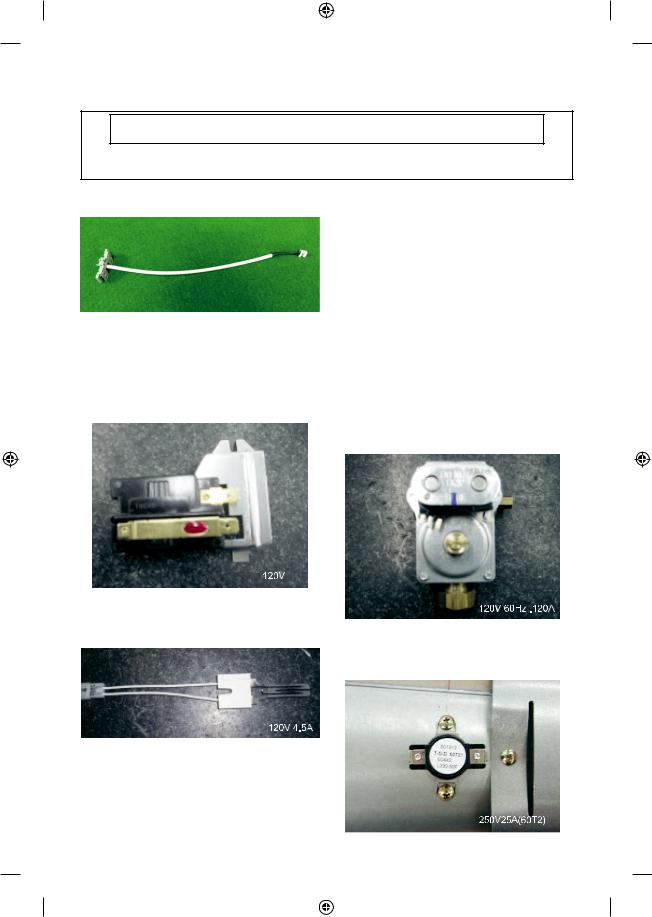

Sensor Bars & temperature sensor check

Sensor Bars - Disconnect harness and test Pink wire Pin 4 to

Orange wire Pin 5.

Approx ∞ Ω without laundry

Approx 190Ω ± 10% with wet clothes

Cycling Thermistor - Disconnect harness and test Blue wire

Pin 3 to Red wire Pin 6.

Approx 10 KΩ at 25 °C/77 °F

Sensor Bars & temperature sensor check (DV398 only)

Sensor Bars - Disconnect harness and test Pink wire Pin 4 to Orange wire Pin 5.

Approx ∞ Ω without laundry

Approx 190Ω ± 10% with wet clothes

Cycling Thermistor1 - Disconnect harness and test Blue wire Pin 3 to Red wire Pin 6.

Approx 10 KΩ at 25 °C / 77 °F

Cycling Thermistor2 - Disconnect harness and test Yellow wire Pin 2 to White wire Pin 7.

Approx 238.231 KΩ at 25 °C / 77 °F 10

(Technical)DV405-02365H-03_EN_130221.indd 10 |

|

|

2013-02-21 5:32:03 |

|

|

||

|

|

|

|

TROUBLE SHOOTING

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

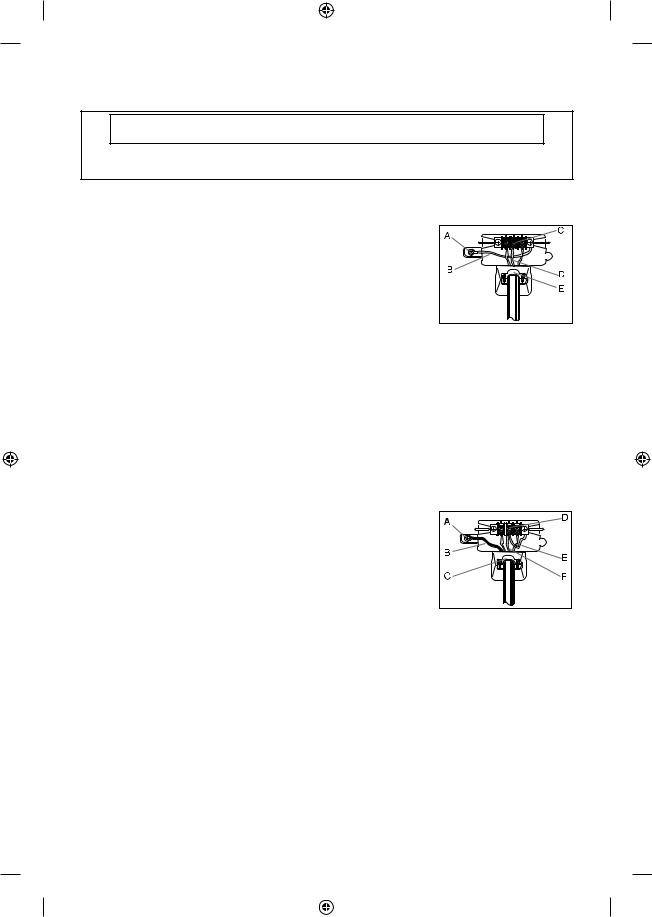

3-WIRE system connections

A. External ground connector

B. Neutral grounding wire (green/yellow)

C. Center silver-colored terminal block screw D. Neutral wire (white or center wire)

E. ¾” (1.9 cm) UL-listed strain relief

1.Loosen or remove the center terminal block screw.

2.Connect the neutral wire (white or center wire) of the power cord to the center, silver-colored terminal screw of the terminal block. Tighten screw.

3.Connect the other wires to outer terminal block screws. Tighten screws.

4.Tighten the strain relief screws.

5.Insert the tab of the terminal block cover into your Dryer’s rear panel slot. Secure the cover with a hold-down screw.

If converting from a 4-wire electrical system to a 3-wire, the ground strap must be reconnected to the terminal block support to ground the Dryer frame to the neutral conductor.

4-WIRE system connections

A. External ground connector

B. Green or bare copper wire of power cord C. ¾” (1.9 cm) UL-listed strain relief

D. Center silver-colored terminal block screw E. Neutral Grounding wire (green/yellow)

F.Neutral wire (white or center wire)

1.Remove the External ground connector screw.

2.Connect the ground wire (green or unwrapped) of the power cord to the external ground connector screw. If you want to connect B(Green or bare copper wire of power cord) to the Neutral Post without assembling with A(cabinet ground), call the service technician.

3.Loosen or remove the center terminal block screw.

4.Connect the neutral wire (white or center wire) of the power cord and the appliance ground wire (green with yellow stripes) under the central screw of the terminal block.

5.Connect the other wires to the outer terminal block screws. Tighten screws.

6.Tighten the strain relief screws.

7.Insert the tab of the terminal block cover into your Dryer’s rear panel slot. Secure the cover with a hold-down screw.

11

(Technical)DV405-02365H-03_EN_130221.indd 11 |

|

|

2013-02-21 5:32:03 |

|

|

||

|

|

|

|

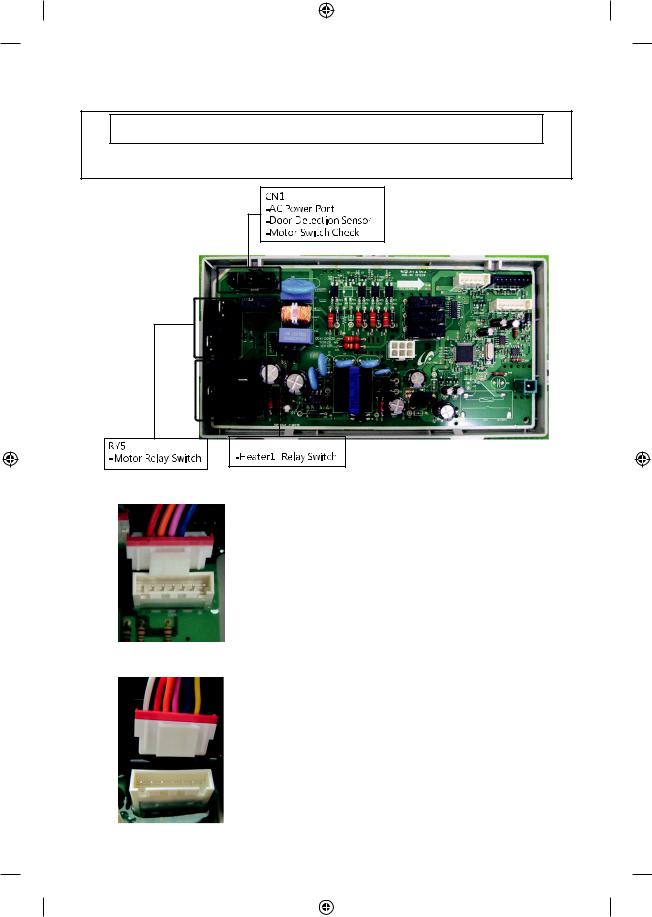

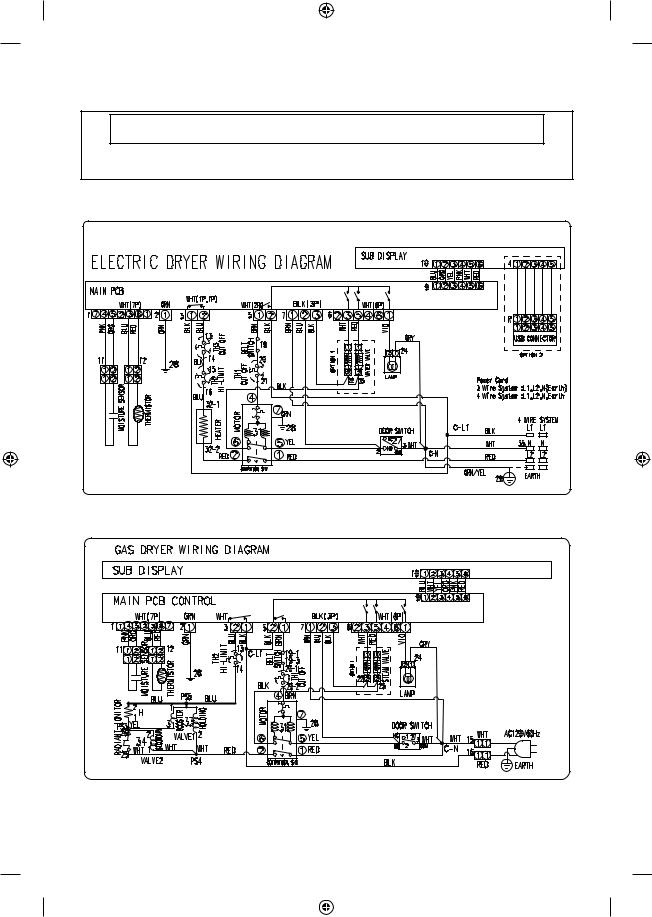

WIRING DIAGRAM

WARNING

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless testing requires power.

WIRING DIAGRAM

OPTION 1 : Steam Models Only, OPTION 3 : DR READY Models Only

12

(Technical)DV405-02365H-03_EN_130221.indd 12 |

|

|

2013-02-21 5:32:03 |

|

|

||

|

|

|

|

Loading...

Loading...