Page 1

Allen-Bradley

Dataliner DL40 Plus

Offline Programming

User

Software

(Cat. No.2706-LSW)

Manual

Page 2

Important User

Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

death, property damage or economic loss.

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

PLC and PLC–5 are registered trademarks of Allen–Bradley Co.

SLC is a trademark ofAllen–Bradley Co.

Windows, MS–DOS, and Windows NT are a trademarks of Microsoft Corporation.

Page 3

Using this Manual

Overview of the DL40 Plus

Installing the Software

Preface

What You Need to Know P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents of this Manual P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions Used P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Available Configurations 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Support 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Features 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Modes 1–1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Messages 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Support for Remote I/O 1–13. . . . . . . . . . . . . . . . . . . . . . . . .

Available Catalog Numbers 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Personal Computer Requirements 2–1. . . . . . . . . . . . . . . . . . . . . . . . .

Package Contents 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installed Files 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Requirements 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Management 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Installation (without PassThrough) 2–4. . . . . . . . . . . . . . . . . . . .

Software Installation for DH+ PLC PassThrough 2–5. . . . . . . . . . . . . . .

Software Installation for Ethernet PLC PassThrough 2–1 1. . . . . . . . . . . .

Starting the Program 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Establishing Initial Non–networked Communications 2–13. . . . . . . . . . . .

Publication 2706-6.2

Page 4

Table of Contentstoc–ii

Navigating the Software

Offline Operating Modes

Chapter 3

Starting the Software 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Title Screen and Main Menu 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Help 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Menu 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Control Keys 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shortcut Keys 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exiting the Software 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Develop Menu 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File Selection Screen 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create New File Window 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Path Directory Window 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Develop Screen 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Messages Menu 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit Message Screen 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Text Window 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Create New Message Screen 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copy Messages Screen 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete Message Screen 4–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Renumber Messages Screen 4–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Text Search Screen 4–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modify Message Attributes Screen 4–24. . . . . . . . . . . . . . . . . . . . . . . .

Message Attribute Default Screen 4–32. . . . . . . . . . . . . . . . . . . . . . . . .

Options Menu 4–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ports Menu 4–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verify Menu 4–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Menu 4–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading/Uploading Message Files

Publication 2706-6.2

Chapter 5

Transfer Menu 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading a File using RS-232 or RS-485 5–3. . . . . . . . . . . . . . . . .

Uploading a File using RS-232 or RS-485 5–6. . . . . . . . . . . . . . . . . . .

Downloading a File using Remote I/O (PassThrough) 5–8. . . . . . . . . . .

Uploading a File using Remote I/O (PassThrough) 5–10. . . . . . . . . . . . .

Creating a New Communications File 5–12. . . . . . . . . . . . . . . . . . . . . .

Modifying an Existing Communications File 5–16. . . . . . . . . . . . . . . . . .

Sending the Time and Date Using RS-232 or RS–485 5–17. . . . . . . . . .

Writing a File to Tape 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading a File from Tape 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents toc–iii

Getting Reports

Managing Message Files

Chapter 6

Reports Menu 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select File Submenu 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Ports Submenu 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Print Job 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7

Files Menu 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Select Files Menu 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File Selections/File Picks Window 7–4. . . . . . . . . . . . . . . . . . . . . . . . .

Copy File(s) 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delete File(s) 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rename File(s) 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Convert DL20 File(s) 7–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A – Message Display Worksheets

Appendix B – Cables

Appendix C – ASCII Character Sets

Appendix D – PLC-5 Data Pass-Through

Index

Publication 2706-6.2

Page 6

Contents of this Manual

Using this Manual

This preface provides an overview of the Dataliner DL40 Plus

Offline Programming Software. The topics it covers include:

• What you need to know

• Contents of the manual

• Conventions used throughout the manual

• Related publications

What You Need to Know

No special knowledge is required to read this manual or use the

DL40 Plus Offline Programming Software (Catalog No. 2706-LSW).

However, you should be familiar with the operation of the DL40

Plus and how it will be integrated into your control system before

trying to use the Offline Programming Software.

This manual describes how to install and use the DL40 Plus Offline

Programming Software. The manual is organized as follows:

Chapter Title Purpose

1 Overview of the DL40 Plus Provides an overview of the DL40 Plus

2 Installing the Software Describes how to install the DL40 Plus

3 Navigating the Software Provides a description of the menus

4 Creating Message Files Describes how to create and manage

5 Downloading/Uploading

Message Files

6 Getting Reports Describes the contents and use of the

7 Managing Message Files Describes the contents and use of the

Appendix A Message Display

Worksheets

Appendix B Cables Cable pinout diagrams

Appendix C ASCII Character Sets Summary of ASCII characters and their

Appendix D PLC-5 Pass-Through Provides an application example of using

Message Display.

Offline Programming Software.

along with instructions for setting up and

exiting the software.

message application files.

Describes the contents and use of the

Transfer menu.

Reports menu.

Files menu.

Convenient forms for recording message

contents.

keyboard codes.

PLC-5 data Pass-Through.

Publication 2706-6.2

Page 7

Using this ManualP–2

Conventions Used

Related Publications

The following conventions are used in this manual:

• All menus and screens reproduced in this manual approximate

what you see when using the software.

• A symbol or word in brackets represents a single key that you

press. These include keys such as [A] or [Del]. Since the

Dataliner can be programmed with a variety of keyboards or

terminals, the printing on your keyboard may be different from

the symbol or word indicated in brackets.

• This manual uses ↵ to specify the carriage return function of a

keyboard. On your keyboard this may correspond to an

[ENTER], ↵ , or [Rtrn] key.

• The up caret, ^, is the symbol for a control character. For

example:

computers this character is entered by pressing [Ctrl] and [W]

simultaneously.

^W is the symbol for a Control W character. On most

• In the following chapters, we refer to the Dataliner DL40 Plus

Message Display as the DL40.

Other publications to which you may want to refer include:

• Dataliner DL40 Plus Message Display User Manual,

(Publication 2706-6.1)

• Dataliner DL40 Plus Message Displays Release Note (provided

with DL40 Plus display) is helpful if you are replacing an existing

DL40 display with a DL40 Plus display.

Publication 2706-6.2

Page 8

Overview of the DL40 Plus

Chapter Objectives

Available Configurations

This chapter describes key features and capabilities of the DL40

Plus. Understanding the capabilities allows you to use the Offline

Programming Software more effectively. For more information,

refer to the DL40 Plus user manual (Publication 2706-6.1).

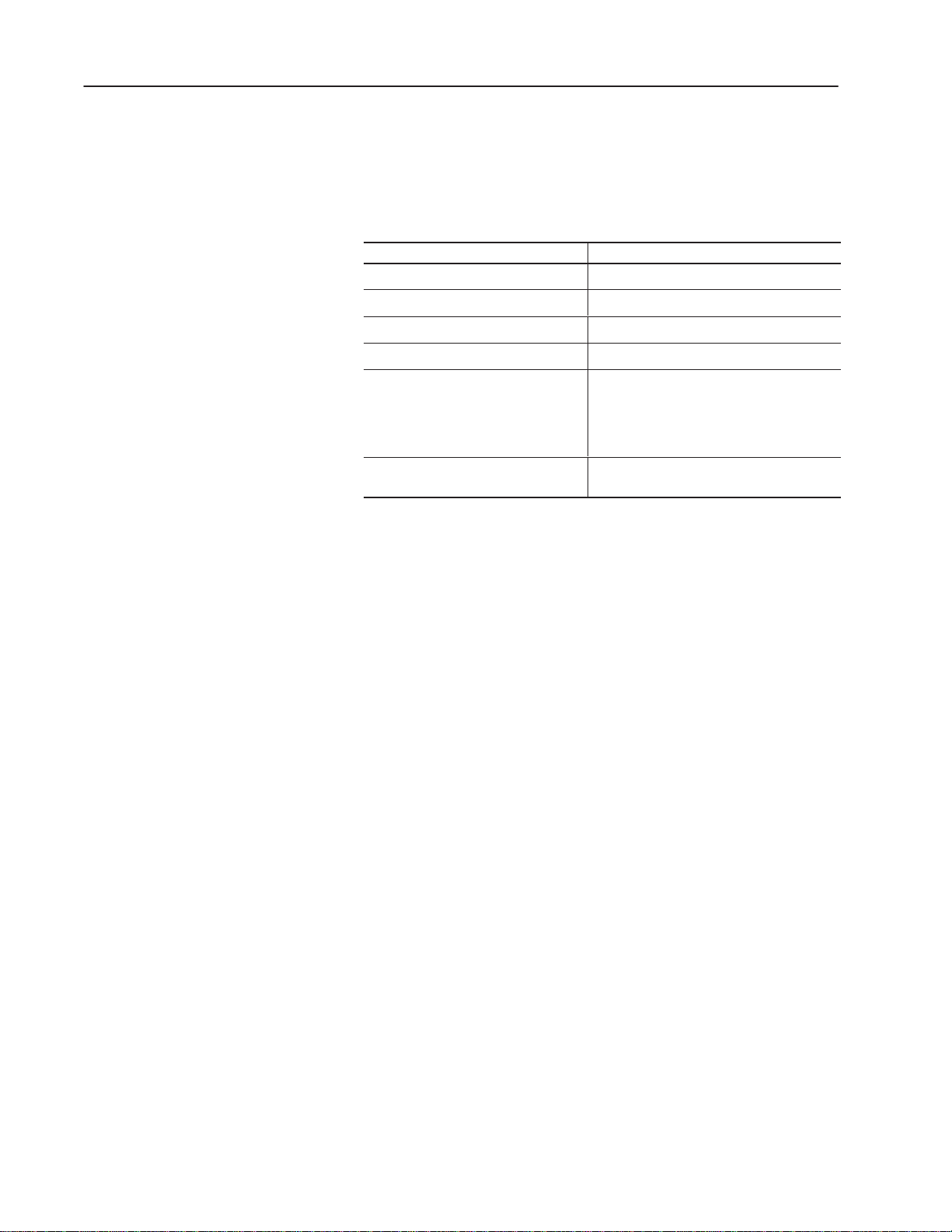

Section Page

Available Configurations 1–1

Message Support 1–3

Programming Features 1–4

Operating Modes 1–11

Special Messages 1–12

Controller Support for Remote I/O 1–13

Available Catalog Numbers 1–15

The DL40 Plus is available in a 2- or 4-line configuration (capable of

displaying 20 characters per line) with either Remote I/O or Parallel

port communication options.

Remote I/O Version

The Remote I/O version enables two-way communications with the

Allen-Bradley family of PLCs and SLCs. A remote I/O version of

the DL40 Plus can appear to the PLC or SLC as any size I/O rack

1

1

(

/

/2, 3/4, or full).

4,

Parallel Port Version

The Parallel Port version receives message number triggers, slave

addresses, and variable data from a PLC or SLC output module via

16 data lines and 4 strobe lines (indicating the type of data).

Page 9

1–2 Overview of the DL40 Plus

ConfigurationsDescription

Plus Port

line Programmin

1

line Programmin

R

line Programmin

R

line Programmin

R

line Programmin

R

line Programmin

R

line Programmin

R

line Programmin

R

lave Communications

R

lave Communications

R

line Programmin

R

line Programmin

R

ssa

rin

R

ssa

rin

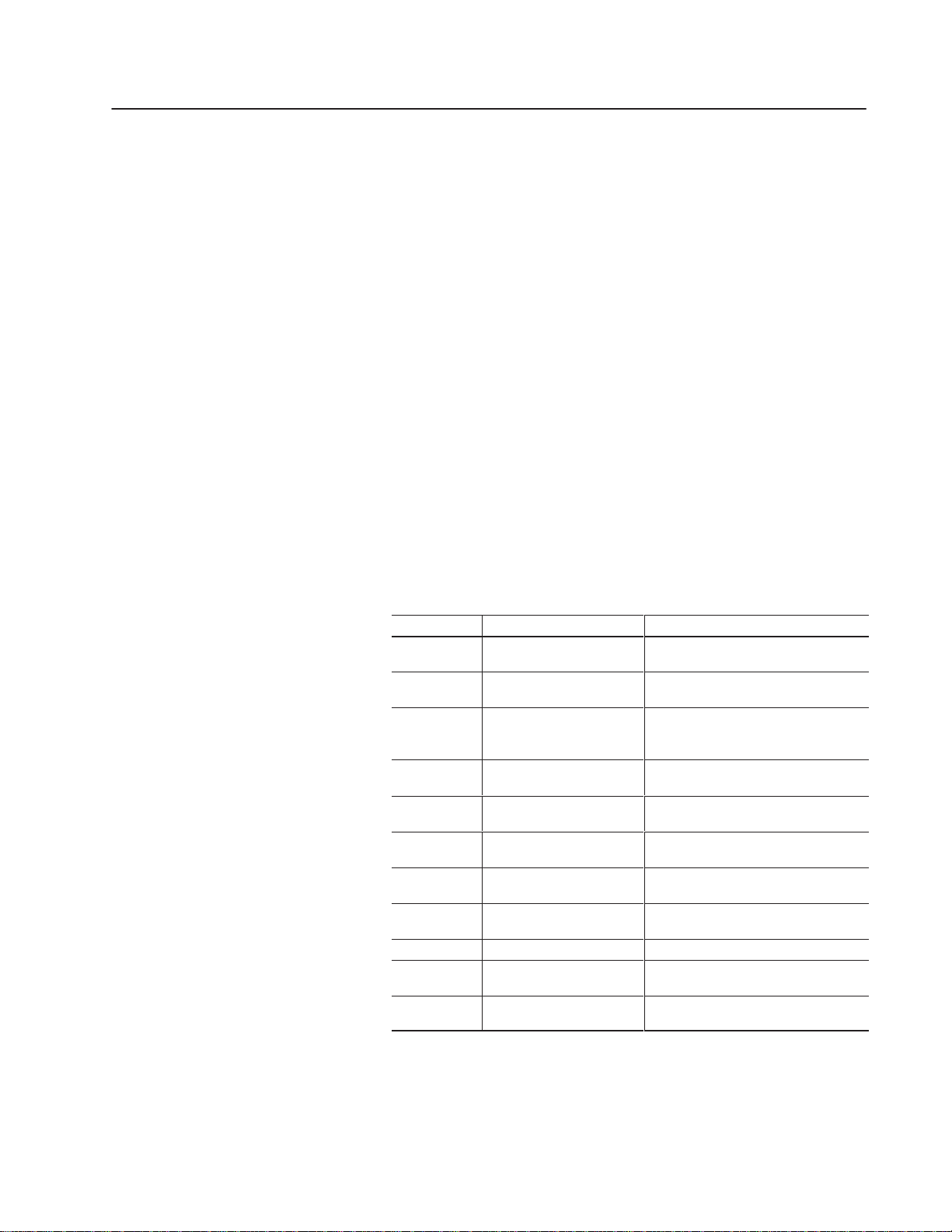

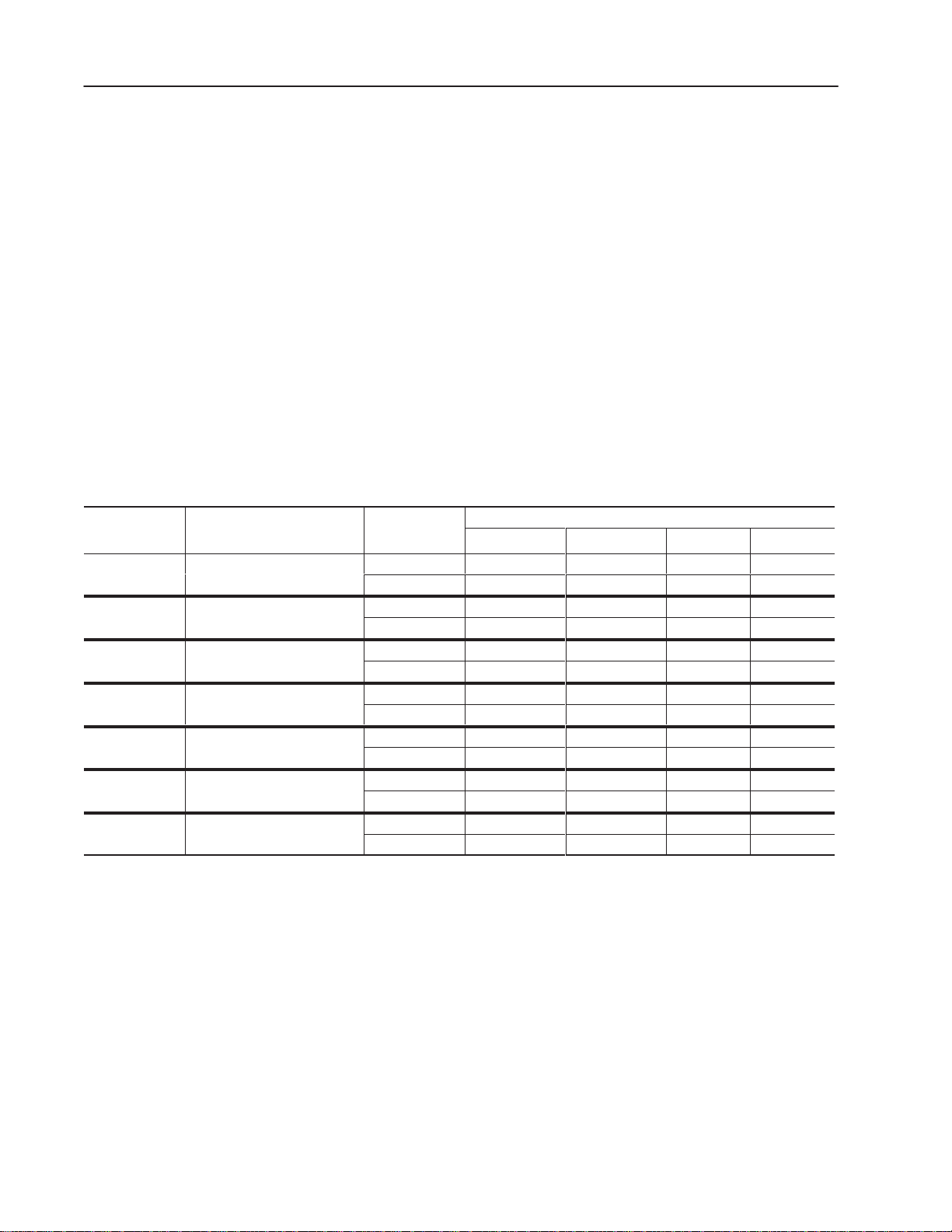

RS-485/RS-232 Communications

Both the Remote I/O and Parallel Port versions have RS-485 and

RS-232 ports. You can configure these ports for Programmer, DL

Slave or Open Protocol communications (see table below). Port

settings are modified through the Ports menu in the Offline

Programming software or the Onboard Editor. You select a

communication option under the Port Use submenu.

The RS-232 port always communicates with the Offline

Programming Software regardless of the configured mode. Open

Protocol or DL Slave operation can occur on either the RS-232 or

RS-485 port.

If the RS-485 port is configured for Open protocol or DL Slave

operation, you cannot configure the RS-232 port for the same

protocol. Instead, an information message reports an invalid port

configuration (Incompatible Port Usage).

DL40

Off

Off

and Serial Printing

S-232 Off

2

3

4

5

6

7

S-232 Off

and RS-485 Message Triggering

S-232 Off

S-232 Off

RS-485 Slave Communications

S-485 Off

S-485 Off

RS-232 Message Triggering

S-485 S

S-485 S

RS-232 Message Triggering

S-485 Off

S-485 Off

RS-232 Slave Communications

S-485 Me

S-485 Me

RS-232 Slave Communications

ge Trigge

ge Trigge

g

g

g

g

g

g

g

g

g

g

g

g

RS–485

RS–232

RS–485

RS–232

RS–485

RS–232

RS–485

RS–232

RS–485

RS–232

RS–485

RS–232

RS–485

RS–232

Programmer Open Protocol Slave Printing

√

√ √

√ √

√ √

√

√

Communication/Printing Options

√

√

√

√

√

√

√

√

Note: Open protocol is a serial ASCII based format for triggering

messages stored in the DL40 Plus displays. Open protocol supports

message triggers with or without variable data over the RS-232 or

RS-485 serial ports.

Publication 2706-6.2

Page 10

1–3Overview of the DL40 Plus

Message Support

The DL40 Plus stores messages of varying length. Each message is

identified by a unique message number from 1 to 9999. Messages

are placed in an internal memory queue when triggered by a

command from your control system. They are then run according to

attributes selected in the DL40 Plus.

The DL40 Plus can display a wide variety of characters and symbols,

including:

• Uppercase letters

• Lowercase letters

• Punctuation

• Special characters from the English extended ASCII character set

• English character set (default)

• International character set ISO 8859–1

• Cyrillic character set (Russian)

Note: English characters are also available with both the

International an Cyrillic character sets.

A person with normal vision can easily read the display from a

distance of up to 25 feet.

Publication 2706-6.2

Page 11

1–4 Overview of the DL40 Plus

Programming Features

The DL40 Plus is a versatile status, prompt and diagnostic display

tool, equipped with a full range of high-end programming and

performance features.

DL40 Plus Capabilities

Supports offline programming software Yes Yes

PLC-5 Remote I/O PassThrough via DH+ Yes No

PLC-5E Remote I/O PassThrough via Ethernet Yes No

International and Cyrillic character sets Yes Yes

Onboard editing with PC keyboard Yes Yes

Send ASCII data to a PLC via a Remote I/O link Yes No

Send ASCII data to a device via an RS-485 link Yes Yes

Communicates with any programmable controller No Yes

Customizable historical events stack Yes Yes

Real-time clock operations Yes Yes

RS-232 and RS-485 ports Yes Yes

Debug Mode No Yes

Support for auxiliary devices such as slave displays

and printers

Background messages Yes Yes

Remote I/O

Version

Yes Yes

Parallel Port

Version

Hidden messages Yes Yes

Embedded variables Yes Yes

Data mode selection Yes Yes

Message chaining Yes Yes

Adjustable parameters for serial communications Yes Yes

Adjustable display brightness Yes Yes

Publication 2706-6.2

Page 12

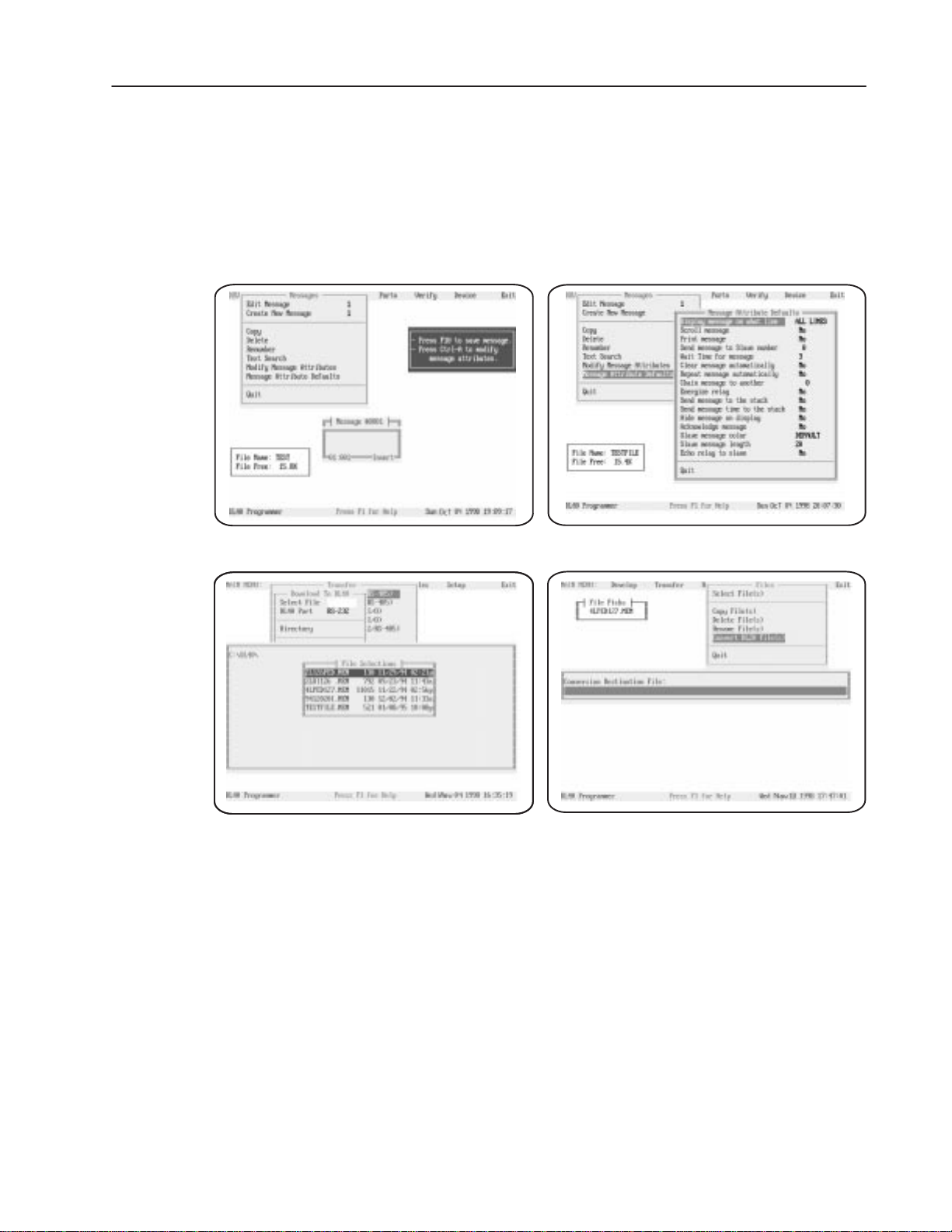

Offline Programming Software

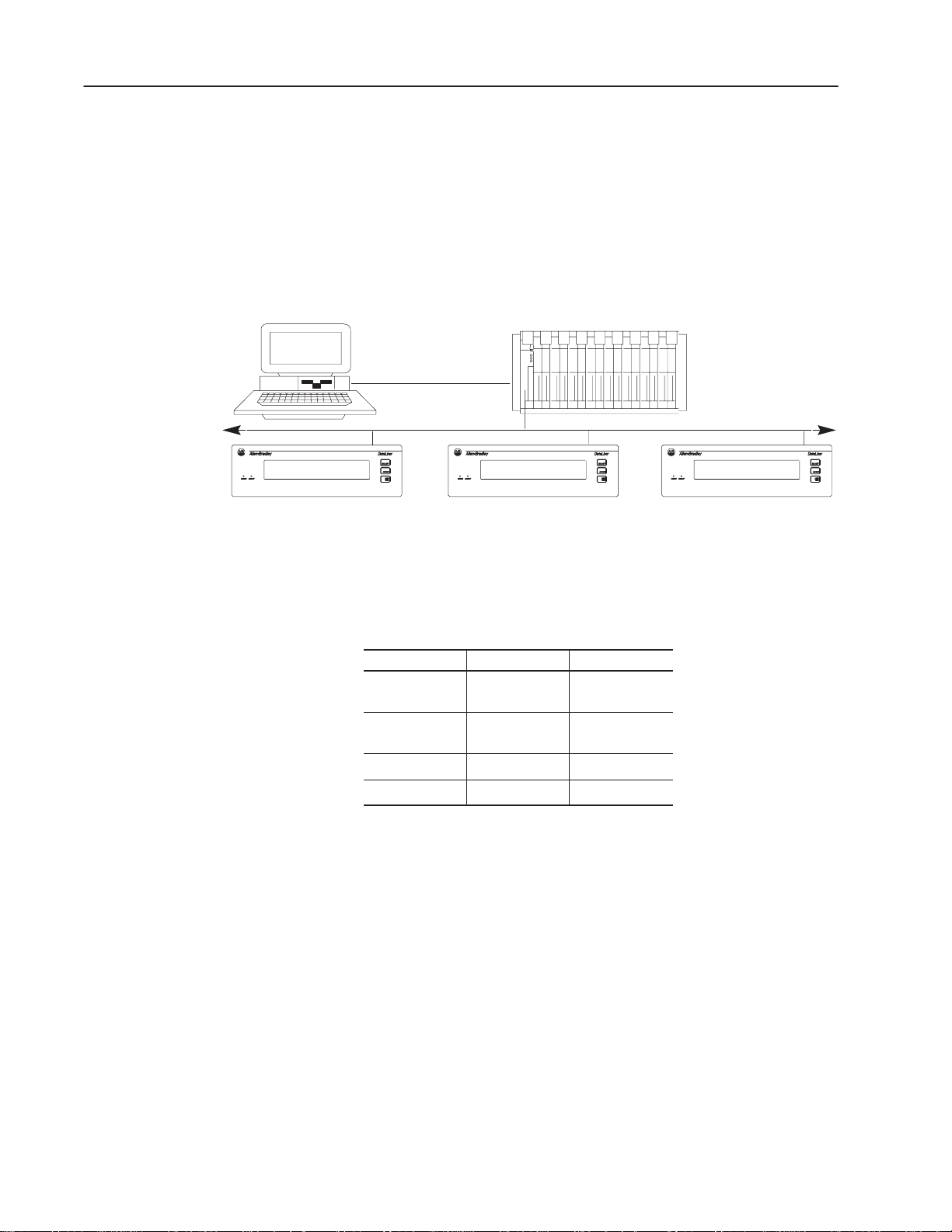

Create and edit application files using the Offline Programming

Software (Catalog No. 2706-LSW) on a personal computer. With

interactive menus you can quickly create messages, set message

attributes, and download messages to one or more DL40 Plus

displays.

1–5Overview of the DL40 Plus

Create Message editing screen Set Message Attributes window

Download Message Files screen

Convert DL20 files for use with a DL40 Plus

The offline programming cable (Catalog No. 2706-NC13) provides a

direct connection between a personal computer running the Offline

Programming Software and a DL40 Plus. This 3-meter cable has a

9-pin, D-shell connector on each end.

Publication 2706-6.2

Page 13

1–6 Overview of the DL40 Plus

International and Cyrillic Character Sets

The local language character sets let you create and display messages

in other languages such as French, German, Italian, and Spanish with

the Offline Programming Software with:

• English (default)

• International character set ISO 8859–1

• Cyrillic (Russian)

English characters are also available with both the International and

Cyrillic character sets.

Onboard Editor

With the Onboard Editor you can create or edit messages, select

message attributes, and set options and variable formats using a

standard IBM PC keyboard. The Keyboard port is located on the rear

panel of the DL40 Plus.

Send ASCII Data to a PLC via Remote I/O Link

Using Remote I/O communications, you can send ASCII data to a

PLC. Attach an IBM compatible keyboard to the DL40 Plus and you

can enter part numbers, badge numbers, passwords, and similar

information as required. The DL40 Plus processes and displays the

information, and then sends it to the controller.

You can establish similar communications over an RS-232 or

RS-485 link.

Communicate with any Programmable Controller

(Parallel Port Version)

The DL40 Plus accepts information from any programmable

controller over a total of 20 input lines (16 data and 4 strobe lines).

Parallel Port versions of the DL40 Plus have an isolated 12 VDC

supply output that can be used to power outputs that pull data and

strobe lines high.

Publication 2706-6.2

Backup Operations

Archive DL40 Plus application files in the Offline Programming

Software (Catalog No. 2706-LSW) by uploading or downloading

files between a computer and DL40 Plus displays.

Page 14

1–7Overview of the DL40 Plus

Historical Events Stack

The Historical Events Stack records the occurrence and sequence of

some or all messages and logs variable data values that have been

triggered and/or displayed. The 16K bytes of stack memory holds

about 1,000 events. You can view information in chronological order

or by frequency of occurrence, or print the record.

Clock Operations

A real-time battery-backed clock keeps accurate time even when

power is removed from the unit. The DL40 Plus can display the

current time and/or date in either AM/PM or 24-hour military

format.

Note: The date function is year 2000 compliant.

Date and time information can be displayed as part of any triggered

message, and passed on to a PLC. You can also date- or time-stamp

events as they are recorded in the Historical Events Stack.

Set the DL40 Plus internal clock using the front panel menus, a

keyboard connected to the Onboard Editor, a PLC/SLC, or the

Offline Programming Software.

RS-232 and RS-485 Ports

The DL40 Plus has both an RS-232 and RS-485 port.

Use the RS-232 port to:

• upload or download message files from a computer

• trigger messages via Open protocol (ASCII triggering)

• send messages to a single slave message display

• print messages and/or the contents of the Historical Event Stack

Use the RS-485 port to:

• multi-drop upload or download message files from a computer

• trigger messages via Open protocol (ASCII triggering)

• send messages to one or more slave message displays

• input ASCII data via bar code

Publication 2706-6.2

Page 15

1–8 Overview of the DL40 Plus

Keyboard Port

Use the Keyboard port on the DL40 Plus to:

• edit options, messages, communication port settings

• input ASCII data to a host controller, PLC, or computer

• trigger messages using Open protocol (ASCII triggering)

Debug Mode (Parallel Port Version)

Use Debug mode to display the binary status (1 or 0 value) of the

data lines and the state of the strobe lines. This mode is useful for

checking the output of a programmable controller.

Auxiliary Devices

Connect a variety of useful auxiliary devices to the DL40 Plus

display.

Slave Displays

Address up to 126 DL40 Plus or DL50 slave displays over an

RS-485 network at distances up to 4,000 feet (1200 m) from the

originating DL40 Plus. You can also control the annunciation relay

on remote DL40 Plus or DL50 Series slave displays. By assigning a

specific address to each slave display, you can control which slaves

receive and display a given message.

Printers

Connect a serial printer to print the Historical Events Stack or a

listing of the internal application file. The time and date a message

was triggered can be included on the stack printout. You can also set

message attributes such as sending triggered messages to a printer

through the RS-232 port.

Alarms

The alarm relay activates or deactivates an external remote alarm or

warning light. Individual message attributes can be set to energize or

de-energize the alarm relay contacts on DL40 Plus or slave displays.

ATTENTION: Use the DL40 Plus alarm relay for

annunciation purposes only. Do not use the alarm relay

!

for control applications.

Publication 2706-6.2

Page 16

1–9Overview of the DL40 Plus

Background Messages

Specify a background message that will display whenever the DL40

Plus has no other triggered messages in the queue.

Hidden Messages

Hidden messages do not appear on the DL40 Plus display or have

any affect on what is being displayed. Hidden messages can be sent

to a slave display, printed, or stored on the Historical Events Stack.

Embedded Variables

Messages can contain variable data. Variable values are received

when the message is triggered. Incoming variable data can be binary,

BCD (binary coded decimal), and/or ASCII. You can also embed

time and date information in a message from the battery-backed

real-time clock of the DL40 Plus.

Data Mode Selection

When using the DL40 Plus with Remote I/O or parallel input for

communication, you can select two data modes:

• Binary

• Binary Coded Decimal (BCD) either signed or unsigned

Within any application, triggers and variable data can be in either

form. For example, message triggers can be in a binary format, while

variable data can be BCD.

Note: When using serial RS-232 or RS-485 communications, all

data is in ASCII character format.

Message Chaining

Chain messages together for display in sequence. Only the first

message in the chain is triggered from the host controller. Then each

message in the chain can trigger the next until the complete sequence

has run.

Publication 2706-6.2

Page 17

1–10 Overview of the DL40 Plus

Adjustable Parameters for Serial Communications

With the DL40 Plus, you can configure RS-232 or RS-485 port

parameters as needed for compatibility with PLCs/SLCs, printers,

slave displays, or control computers.

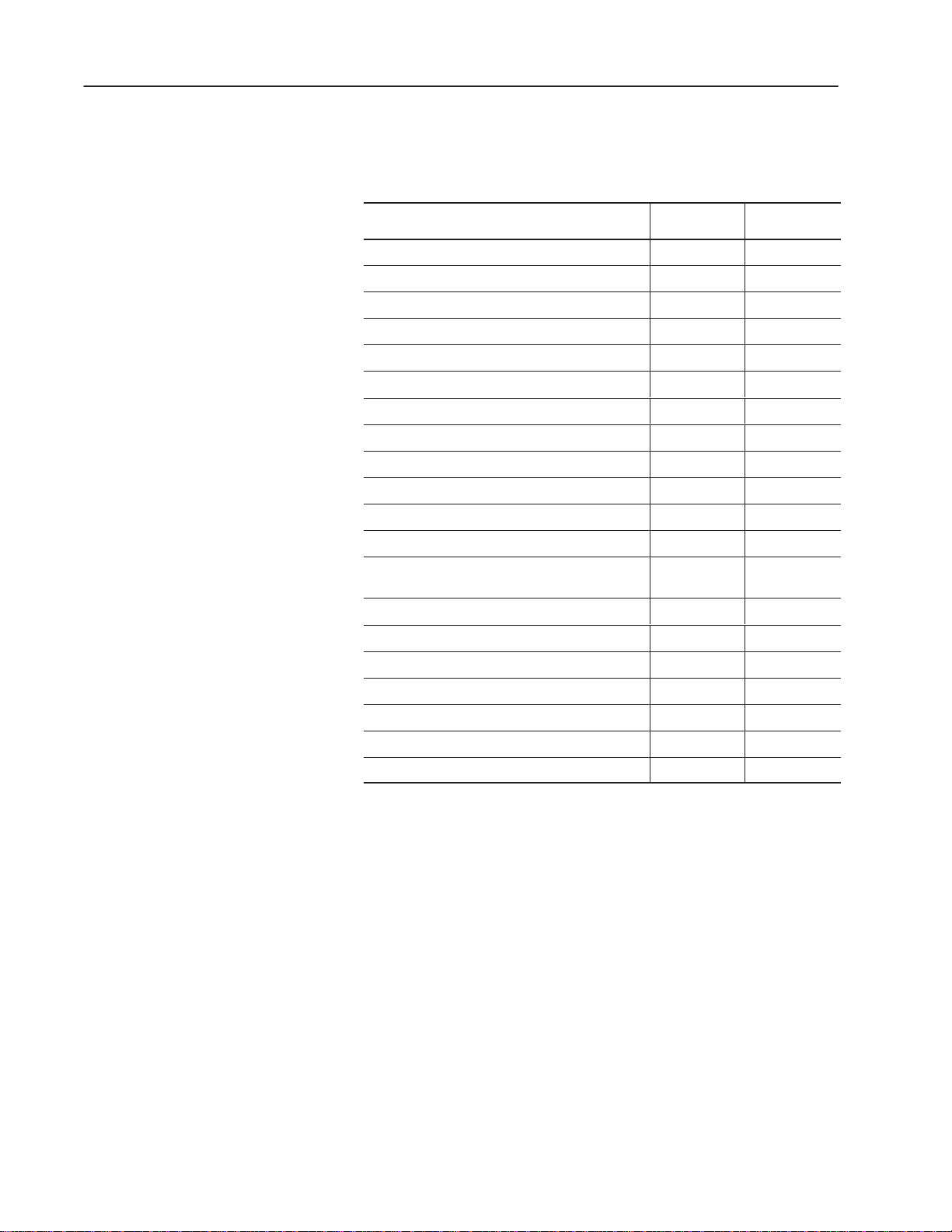

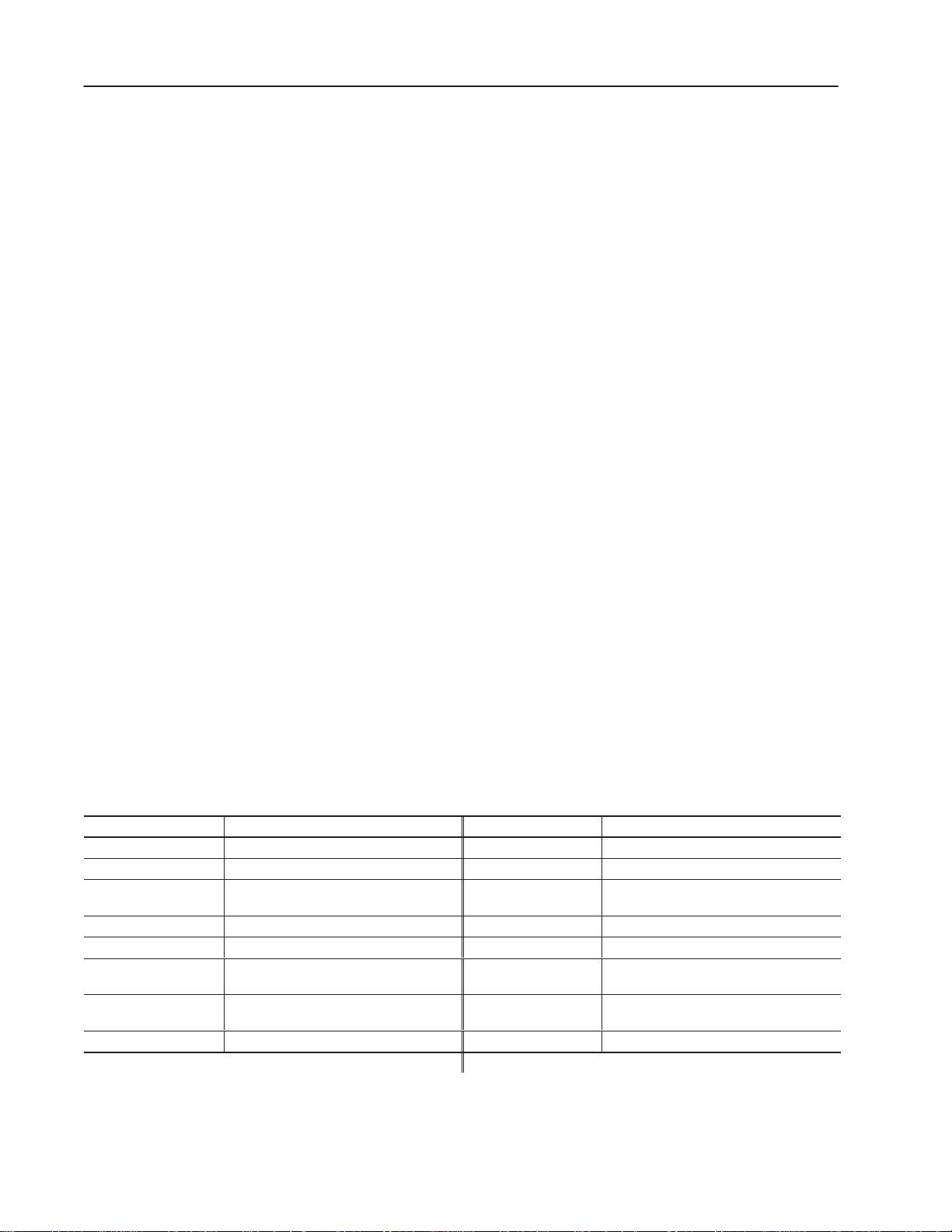

Serial Communication Parameters Settings

Baud Rate 300, 1200, 2400, 4800, 9600, 19200

Parity Odd, Even, No Parity

Handshake Software, Hardware, None

Data Bits per Character 7 or 8

0 to 255

Null Count

Page With

Allows you send a string of nulls to the printer

between characters. Useful with slow printers

that drop characters because they can’t keep

up with normal DL40 Plus output.

20 –132 characters

Useful for narrow width printer devices.

Publication 2706-6.2

Page 18

1–11Overview of the DL40 Plus

Operating Modes

The DL40 Plus has a number of operating modes. Each mode

provides tools to perform a different set of functions. The following

sections provide a brief overview of the operating modes.

Run Mode

Run mode is the normal operating mode for the DL40 Plus. In Run

mode, messages are triggered for display on the DL40 Plus and slave

message displays (if desired).

The Remote I/O version of the DL40 Plus comes up in Run mode

after a reset. The Parallel port version also comes up in Run mode,

except when the Run Mode/Debug DIP switch is set to Debug on the

DL40 Plus.

The Remote I/O version of the DL40 Plus has 4 Run modes.

• Message/Variable/Slave Mode triggers a message with variables

containing up to 20 ASCII or 40 BCD characters in any

combination as long as the total does not exceed 10 words. This

mode allows you to override the slave address attribute.

• Message/Variable Mode is similar to the Message/Variable/Slave

mode but you cannot override the slave address attribute.

• Message List Mode triggers a message list of up to 20 messages

in round robin order.

• Bit Trigger Mode triggers a priority message and up to 496

messages in priority and/or round robin order.

The Parallel port version of the DL40 Plus has 2 Run modes.

• Message/Variable/Slave Mode triggers a message with variables

containing up to 20 ASCII or 40 BCD characters in any

combination as long as the total does not exceed 10 words.

• Message List Mode triggers a message list of up to 20 messages

in round robin order.

To select Run mode, use the Onboard Editor or the Offline

Programming Software.

Publication 2706-6.2

Page 19

1–12 Overview of the DL40 Plus

Serial Triggering (RS–232/RS–485)

Both the Remote I/O and the Parallel port versions of the DL40 Plus

support serial triggering. The RS-232, RS-485, or Keyboard port

can control message triggering and variable data communications.

Serial triggering uses Open protocol, which communicates using

ASCII characters in a serial data stream.

Open protocol is available in the following run modes:

• Message/variable/slave mode

• Message/variable

• Message list

Offline Modes

The DL40 Plus offers the following offline operating modes:

• Help mode

• Historical Recall mode

• Remote Program mode (for Offline Programming Software)

• RS-232/RS-485 Port Configuration mode

• Clock mode

• Print mode

• Debug mode (on Parallel port versions only)

Special Messages

Special messages let you monitor and control certain functions of the

DL40 Plus without leaving Run Mode. Special messages normally

occupy message numbers 901 through 916. You can move special

messages to message numbers 1 to 16, or disable them with the

Offline Programming Software or Onboard Editor.

Message Number Content Message Number Content

901 (or 01) Terminate Message – Clear Display 909 (or 09) Clear Historical Events Stack

902 (or 02) Clear Queue 910 (or 10) Set Interactive Clock

903 (or 03)

904 (or 04) Reset Unit 912 (or 12)

905 (or 05) Test Display 913 (or 13)

906 (or 06)

907 (or 07)

908 (or 08) View Historical Events Stack 916 (or 16) Set Display Intensity

➀

Remote I/O versions only

Terminate Message – Clear Display and

Queue

Print Historical Events Stack –

Chronological Order

Print Historical Events Stack – Frequency

of Occurrence

911 (or 11) Set Clock with Variable Data

Send Time to PLC

Send Date to PLC

914 (or 14) View Display Parameters

915 (or 15)

Stop Special Messages/Resume Run

Mode

➀

➀

Publication 2706-6.2

Page 20

1–13Overview of the DL40 Plus

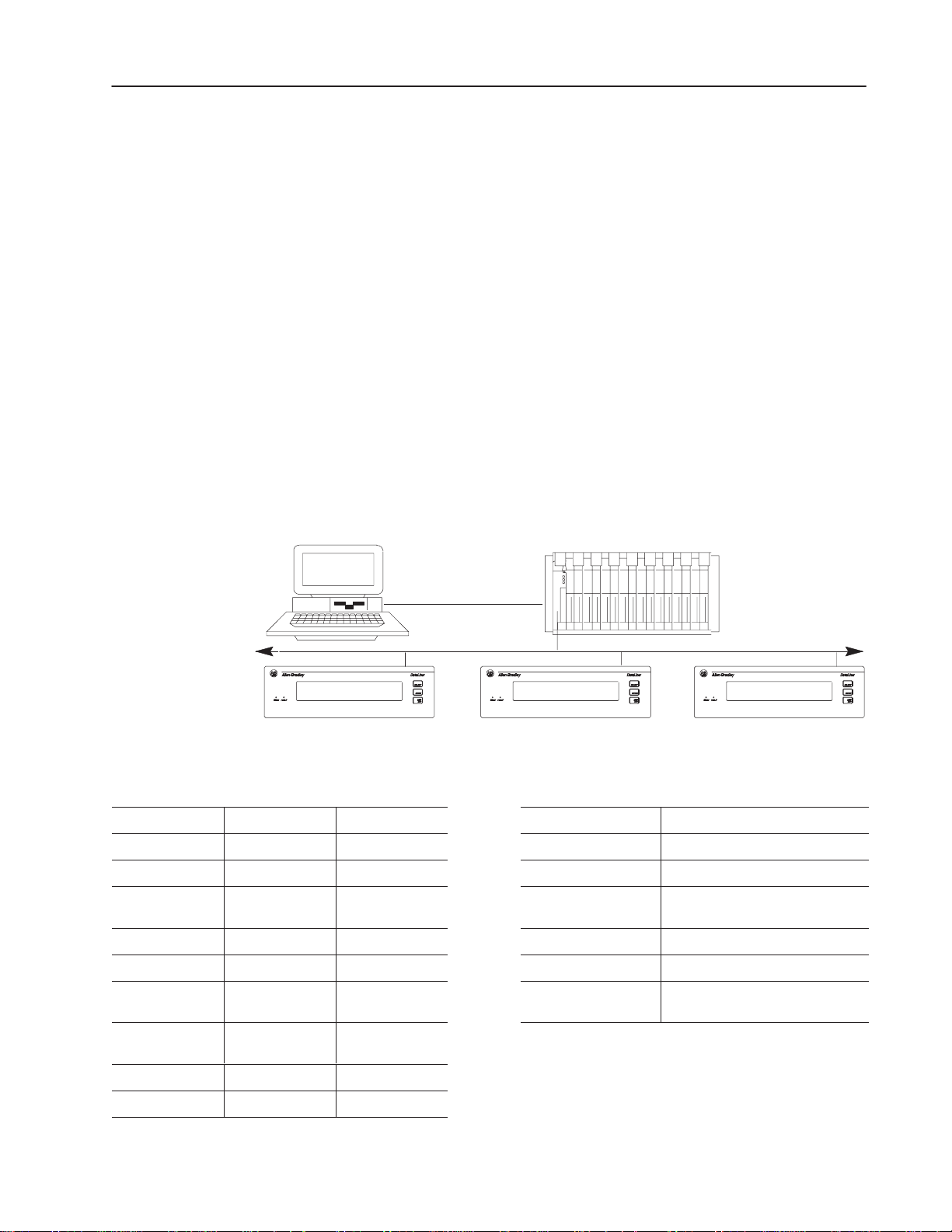

Controller Support for Remote I/O

Computer

The following PLCs and SLCs support Remote I/O communications

with the DL40 Plus.

• PLC-5/11, 5/15

➀

, 5/20, 5/25, 5/30, 5/40, 5/60, 5/80, 5/250

• PLC-2, PLC-5/10, 5/12 with Catalog Number 1771-SN Scanner

• SLC-5/02, 5/03, 5/04 with Catalog Number 1747-SN Scanner

➀

If you are using a PLC-5/15 with partial rack addressing and block transfers, you must use Series

B, Rev. J or later.

➁

Block Transfer requires a Series B or later Scanner.

➁

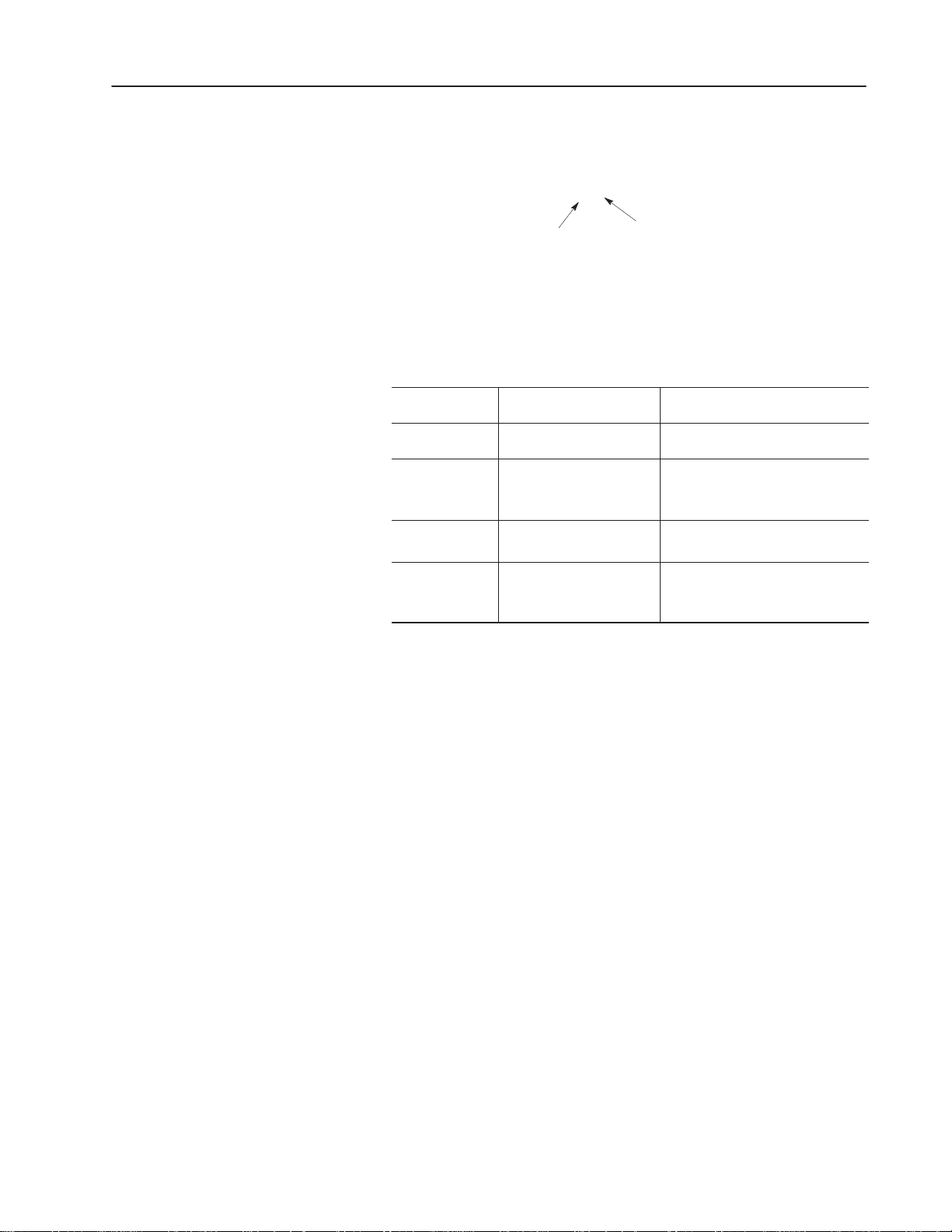

PassThrough Support over a DH+ Link

PLC-5 Remote I/O PassThrough lets you upload and download

message files between a computer and a DL40 Plus connected by

Remote I/O to a PLC on the DH+ link. Refer to Appendix D for an

example application. Separate wiring from the computer to the

DL40 Plus is not required. For a list of supported controllers, see

table below. Refer to Appendix D for additional instructions.

DH+ Network

Remote I/O LinkRemote I/O Link

DL40 Plus

PLCs supporting PassThrough over a DH+ link

PLC Types

PLC-5/11 All All 1784-KT

PLC-5/15 B N or later 1784-KTX

PLC 5/20 All All 1784-KL

PLC 5/25 A J or later 1784-KT2 Interface module for IBM PS2

PLC 5/30 A B or later 1770-KF2 Serial to DH+ interface module

PLC 5/40

PLC 5/60

PLC 5/80 All All

Series Revision Catalog No. Description

A

B

A

B

E or later 1784-PCMK PCMCIA interface board

B or later

DL40 Plus DL40 Plus

Computer interface boards for PassThrough

1

/2-slot interface board

1

/2-slot interface board

Interface board for Allen-Bradley

1784-T45 or -T47

PLC 5/250 All All

Publication 2706-6.2

Page 21

1–14 Overview of the DL40 Plus

Computer

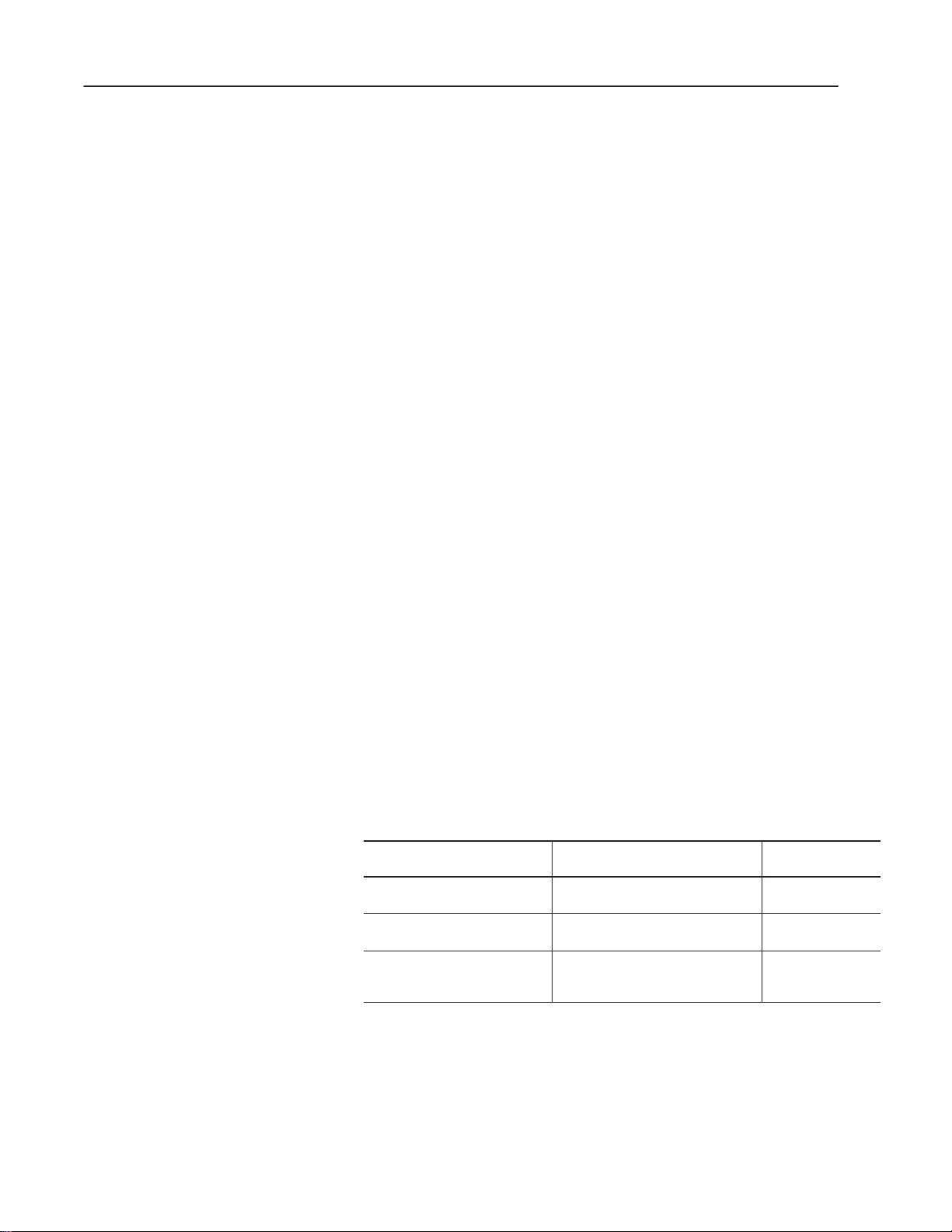

PassThrough Support over an Ethernet Link

PLC-5E Remote I/O PassThrough lets you upload and download

message files between a computer and a DL40 Plus connected by

Remote I/O to a PLC on the Ethernet link. Refer to Appendix E for

an application example. Separate wiring from the computer to the

DL40 Plus is not required. For a list of supported controllers, see

table below.

Ethernet Network

Remote I/O LinkRemote I/O Link

DL40 Plus

DL40 Plus DL40 Plus

The following table lists the Allen-Bradley PLCs that support

PassThrough file transfers with the DL40 Plus message display over

an Ethernet link as of this printing.

PLC Types Series Revision

PLC 5/40E

PLC 5/60E

PLC 5/80E All All

PLC 5/250 All All

A

B

A

B

E or later

B or later

Use one of the Allen-Bradley Ethernet computer interface boards (or

its equivalent) for PassThrough file transfers.

• Catalog Number 6628-A5: Ethernet adapter module for IBM PC

compatible computers

• Catalog Number 6628-A7: Ethernet adapter module for IBM

MicroChannel bus compatible computers

Publication 2706-6.2

Page 22

1–15Overview of the DL40 Plus

Available Catalog Numbers

DL40 Plus displays are available with 128K bytes of memory in

either 2- or 4-line versions with two communication options.

2706–LV2R

Display Type:

2 – Two–line

4 – Four–line

The table below shows the standard catalog numbers for the DL40

Plus and how they equate to previous versions of the DL40 displays.

DL40 Plus

Catalog Number

2706–LV2P Two–line display, AC supply

2706–LV4P Four–line display, AC supply

2706–LV2R Two–line display, AC supply

2706–LV4R Four–line display, AC supply

Description

with parallel port

with parallel port

with remote I/O

with remote I/O

Communication Options:

R – RIO

P – Parallel Port

S – Slave

Equivalent Catalog Numbers for

Previous Versions of the DL40

2706–E23J16, 2706–E23C16

2706–E23J32, 2706–E23C32

2706–E43J32, 2706–E43C32

2706–E43J64, 2706–E43C64

2706–E43J128, 2706–E43C128

2706–E23J16B1, E23C16B1

2706–E23J32B1, 2706–E23C32B1

2706–E43J32B1, 2706–E43C32B1

2706–E43J64B1, 2706–E43C64B1

2706–E43J128B1, 2706–E43C128B1

Publication 2706-6.2

Page 23

Installing the Software

Chapter Objectives

Personal Computer Requirements

This chapter describes how to install the DL40 Offline Programming

Software on your computer. It also explains the basic steps required

to configure your system for use with PassThrough on systems

equipped with an Allen-Bradley PLC capable of Remote I/O

PassThrough file transfers.

Section Page

Personal Computer Requirements 2–1

Package Contents 2–1

Installed Files 2–2

Memory Requirements 2–2

Memory Management 2–3

Installation 2–3

Basic Installation (without PassThrough file transfers) 2–4

Installing Software for DH+ PLC PassThrough 2–5

Installing Software for Ethernet PLC PassThrough 2–11

Starting the Program 2–13

Establishing Initial Non–network Communications 2–13

The minimum equipment required to install and run the Offline

Programming Software consists of an IBM compatible personal

computer (PC) with:

Package Contents

• a 386 (or higher) processor

• 640K RAM

• one 3

1

/2 inch micro diskette drive

• a hard disk with at least 1 Megabyte of available space

• one open serial port (COM1 or COM2)

• one open printer port (LPT1, LPT2, LPT3, LPT4, COM1, or

COM2) for printing messages

• a printer

In addition to this manual, the Offline Programming Software

package consists of three disks and a number of documents.

They include:

• DL40 Plus Offline Programmer

• DL40 Plus PASSTHROUGH Drivers

• DL40 Plus INTERCHANGE Software

Publication 2706-6.2

Page 24

2–2 Installing the Software

Installed Files

Memory Requirements

After installing the software, your computer will contain a

DL40.EXE as well as a PS.HLP file containing online help. If you

install the PassThrough capability, you will also have the

PassThrough files and their companion TSR (Terminate and Stay

Resident) server files.

Important: For the Offline Programming Software to operate

without generating warning messages about memory limitations,

your computer needs a minimum available memory of 570K RAM.

Editing a 128K message file requires the full 570K. Smaller

message files require less computer memory.

With DOS versions prior to 5.0, use the CHKDSK↵ command at

the DOS prompt to determine the available conventional RAM on

your system. The available conventional RAM will be reported in

bytes. Your system must have 583,680 or more free bytes RAM to

run the Offline Programming Software and edit large application

files.

With DOS versions 5.0 or higher, use CHKDSK ↵ or the MEM↵

command to accomplish the same task. (The MEM ↵ commands

reports more quickly and in greater detail than does CHKDSK ↵ .)

The value reported for free conventional memory must be at least

570K.

The following table provides RAM recommendations for creating

and editing message files and requirements for using PassThrough.

If your computer has less than the required bytes free, reduce the

number of memory resident programs (communications programs,

mouse drivers, etc.) your computer is running. For additional

information on increasing the amount of available memory, refer to

the configuration section of your computer’s DOS manual.

PC memory requirements for typical activities

Function

Create and edit message files

PLC–5 PassThrough w/DH+

PLC–5 PassThrough w/Ethernet

For a

DL40 Plus, 128Kbyte

message memory

PLC–5 with a DH+

Communications Interface Card

PLC–5 with an Ethernet

Communications Interface Card &

FTP’s PC/TCP Software

CHKDSK

bytes free

580,000 bytes

(recommended)

515,000 bytes

(required)

515,000 bytes

(required)

Publication 2706-6.2

Page 25

2–3Installing the Software

Memory Management

Your computer system configuration at startup can affect the amount

of RAM available for use by the Offline Programming Software.

DOS offers a number of options that can help increase the amount of

RAM available to programs.

With DOS versions 5.0 or earlier you can maximize available RAM

by editing your CONFIG.SYS file. Your CONFIG.SYS should

contain text lines similar the following:

DOS=HIGH, UMB

DEVICE=C:\DOS\HIMEM.SYS

BUFFERS=10

FILES=10

STACKS=9,128

In the example above, the BUFFERS, FILES, and STACKS values

are set to low values to conserve RAM for program operation.

Important: The line DOS=HIGH,UMB should be used only with

DOS versions 5.0 or higher.

DOS version 6.0 introduced the MEMMAKER command, which

automates memory management and can often free large amounts of

RAM. DOS 6.0 and higher versions also allow you to create multiple

configuration files from which to choose at startup. This feature can

prove useful on PCs used for programming the DL40 as well as other

activities.

Installation

Refer to your DOS user manuals for information on creating and

editing CONFIG.SYS files, techniques for optimizing memory, and

using multiple configuration files on a single PC.

The Offline Programming Software can be installed and run in any

of three distinct environments:

• without PassThrough file transfers

• with PassThrough file transfers over a DH+ link

• with PassThrough file transfers over an Ethernet link

Installation of the basic Offline Programming Software is the same

for all three environments. You will have to perform additional steps

to install PassThrough capability on either a DH+ or Ethernet link.

Publication 2706-6.2

Page 26

2–4 Installing the Software

Basic Installation (without PassThrough)

Use the following procedure to install the basic Offline Programming

Software files on an IBM PC. Note that prompts appearing here

represent a typical PC. The prompts you see on your computer may

vary slightly from those shown here.

Note: Do not automatically install all of the program disks. First

determine the type of installation you require and install just the

programs required.

1. If running in a Windows environment, restart your computer in

DOS mode. Windows NT users need to restart their computers

with a Windows 95 or less operating system.

2. Start your computer and log on to the hard disk (normally you

will see the DOS prompt C:>).

Note: Depending on your installation, your DOS prompt may be

different.

3. Insert the DL40 Offline Programmer disk into the micro drive.

Most often this will be the A: drive.

4. At the DOS prompt (C:>), type:

A:INSTALL↵

5. Follow the onscreen installation prompts until installation is

complete and the C:> prompt reappears. Note: If the Offline

Programming Software program is already on disk, you will be

able to overwrite the program during installation.

6. The installation procedure automatically creates a default

sub–directory which contains the Offline Programming Software

program. By default that directory is DL40. Change to that

directory by typing:

CD\DL40↵

Publication 2706-6.2

Page 27

2–5Installing the Software

Software Installation for DH+ PLC PassThrough

If you are using a DH+ link and want to enable PLC PassThrough

file transfers, you must perform the following additional steps after

completing the basic installation described above.

The following paragraphs outline only the most essential information

required to install and use PassThrough file transfers on a DH+ link.

Refer to the instructions that came with your DH+ add-in board.

Install and Configure Your DH+ Communication Interface Card

Install and configure your DH+ communication interface card. Refer

to the instructions that came with the card for information on how to

install and configure it. Currently the following DH+ cards are

supported by the Offline Programming Software:

– 1784-PCMK – 1784-KL

– 1770-KF2 – 1784-KT

– 1784-KT2 – 1784-KTX

Important: Be sure to record the IRQ and Card address for each

interface card. You will need to know them later in the

configuration process.

Install the Offline Programming Software

Perform the basic installation procedure described earlier in this

chapter to install the Offline Programming Software on your

personal computer.

Publication 2706-6.2

Page 28

2–6 Installing the Software

Install and Configure INTERCHANGE

Your Offline Programming Software package contains a runtime

version of Allen-Bradley’s INTERCHANGE software and a number

of other files. You must install this package to perform

PassThroughs over a DH+ network device.

INTERCHANGE software is an Application-Programming Interface

(API) that provides a host computer running the MS-DOS operating

system with a library of executable commands. INTERCHANGE

software lets multiple applications share a single common interface

module to communicate with various devices on DH+ and/or

DH-485 networks. Use the following procedure for installation:

1. Insert the INTERCHANGE disk into your 3

1

/2 inch drive.

2. Start the automated installation procedure by typing:

A:INSTALL↵

This program copies all required INTERCHANGE files to the

directory \ABIC\BIN on your hard disk. Those files include the

executable INTERCHANGE servers listed below:

DTL_KT.EXE – CFG_DF1.EXE

–

– DTL_DF1.EXE – RNASTR.EXE

– CFG_KT.EXE – RNA.EXE

Important The next part of the installation and configuration

process depends on how you use your PC. If you use your PC for

other activities in addition to offline programming, then you

should create a new batch file as described in step 3. If you use

your computer solely for the Offline Programming Software, then

modify your AUTOEXEC.BAT file as described in step 4 below.

3. If you use your PC for other activities in addition to offline

programming, then create a new batch file containing the

INTERCHANGE server files listed above. You can name the file

anything you want, but it must end with the extension .BAT.

Assume you call the file ABICRUN.BAT, and your hard drive is

drive C:

Publication 2706-6.2

a. Create the file with any ASCII text editor. If you use the DOS

text editor, type:

EDIT C:\ABICRUN.BAT↵

b. Type in the names of the INTERCHANGE server files.

Put each file name on its own line followed by a hard return:

DTL_KT.EXE

DTL_DF1.EXE

CFG_KT.EXE

CFG_DF1.EXE

RNASTR.EXE

RNA.EXE

Page 29

2–7Installing the Software

c. Save the file. If you are using the DOS text editor, type:

[ALT]FXY

d. Skip step 4 and go on to step 5.

4. If you use your PC solely for the Offline Programming Software,

you need not create a new batch file. Instead, you should modify

your AUTOEXEC.BAT file to load the INTERCHANGE server

files whenever you start your system.

a. Open the AUTOEXEC.BAT file with any ASCII text editor. If

you use the DOS text editor, type:

EDIT C:\AUTOEXEC.BAT↵

Your AUTOEXEC.BAT file contents will appear in the editing

window.

b. Move the cursor to the end of the file.

c. Type in the names of the INTERCHANGE server files. Put

each file name on its own line followed by a hard return:

DTL_KT.EXE

DTL_DF1.EXE

CFG_KT.EXE

CFG_DF1.EXE

RNASTR.EXE

RNA.EXE

Do not close the file at this time.

5. If your AUTOEXEC.BAT is not open in your ASCII text editor,

then open it now. If you use the DOS text editor, type:

EDIT C:\AUTOEXEC.BAT↵

Your AUTOEXEC.BAT file contents will appear in the editing

window.

6. Locate the line in your AUTOEXEC.BAT file that begins with

the word PATH. This is your system’s “Path Statement”, which

tells DOS where to look for executable files when no specific

path is otherwise specified.

7. Move to the end of the Path line and insert the complete name for

the directory in which the INTERCHANGE server files were

stored. In a standard installation they are located in

C:\ABIC\BIN. When you have finished editing it, your Path

Statement will look like this:

PATH=C:\DOS;C:\APP1;C\APP2;C:\ABIC\BIN

Publication 2706-6.2

Page 30

2–8 Installing the Software

Create CFG_KT.INI File

INTERCHANGE needs to know exactly what hardware you are

using, and how it is configured. This information is provided by a

configuration file (CFG_KT.INI) modified to match your own

installation.

1. Edit the file with any ASCII text editor. If you use the DOS text

editor, type:

EDIT C:\ABIC\BIN\CFG_KT.INI↵

The CFG.INI file that installs with INTERCHANGE includes

configurations for numerous cards. Lines preceded by a

semicolon (;) have been commented out. To activate your

interface card, edit and uncomment the appropriate options by

removing the semicolon at the beginning of the line.

If you are using a card other than the 1770-KF2 go to step 2

below. If you are using the 1770-KF2 communications interface

card, skip step 2 and go directly to step 3.

2. If you are using a card other than the 1770-KF2, the contents of

the CFG_KT.INI file should be similar to the format shown in the

sample file below. This sample is for a 1784-KT board:

[DTL_KT.Options] ①

PATH=C:\ABIC\BIN ②

③

[DTL_KT.1] ④

DEVICE=KT ⑤

MEMORY=C800 ⑥

PROTOCOL=DHPLUS ⑦

IRQ=5 ⑧

STATION=77 ⑨

NAME=DTL_KT 1 ⑩

In this file:

① This line identifies the file and prefaces a section of the file used to record

information common to all the communications interface cards on your system.

② PATH line that designates the directory where the INTERCHANGE server

programs are located. This will be the same value for all interface cards on your

system.

③ Blank line to separate sections and improve readability.

④ This line identifies the general class of hardware device (in this case a KT

device) and a logical pushwheel identifier of 1. Note: The DL40 Offline

Programming Software assumes that pushwheel 1 is used. Only use pushwheel

1 when communicating with the DL40 Offline Programming Software.

⑤ DEVICE line that specifies the exact communication interface card used.

Acceptable values include KT, KTX, KL, KT2, or PCMK.

⑥ MEMORY line that matches the dip switch settings on the interface card.

⑦ PROTOCOL line that identifies the protocol in use.

⑧ IRQ line that matches the dip switch settings on the interface card.

⑨ STATION line designates the octal station address on the communications link.

⑩ NAME is a unique string you define to specify to this configuration.

Publication 2706-6.2

Page 31

2–9Installing the Software

Models for other interface cards appear below. Note that some of

the values in these files vary depending on the installation.

1784-KT2

[DTL_KT.Options]

PATH=C:\ABIC\BIN

[DTL_KT.1]

DEVICE=KT2

MEMORY=C400

PROTOCOL=DHPLUS

IRQ=5

STATION=77

NAME=DTL_KT2

1784-KL

[DTL_KT.Options]

PATH=C:\ABIC\BIN

[DTL_KT.1]

DEVICE=KL

MEMORY=E000

PROTOCOL=DHPLUS

IRQ=2

STATION=77

NAME=DTL_KL 1

1784-KTX

1784-PCMK

[DTL_KT.Options]

PATH=C:\ABIC\BIN

[DTL_KT.1]

DEVICE=KTX

MEMORY=D400

PROTOCOL=DHPLUS

IRQ=10

STATION=77

NAME=DTL_KTX1

[DTL_KT.Options]

PATH=C:\ABIC\BIN

[DTL_KT.1]

DEVICE=PCMK

MEMORY=CF00

PROTOCOL=DHPLUS

IRQ=7

STATION=77

NAME=DTL_PCMK

Publication 2706-6.2

Page 32

2–10 Installing the Software

3. If you are using the 1770-KF2 communications interface card, the

contents of the CFG_KT.INI file should be similar to the format:

[DTL_KT.Options]

PATH=C:\ABIC\BIN

[DTL_DF1.1]

DEVICE=DF1

BAUD=9600

IRQ=4

COM_PORT=2

NAME=DTL_DF1

ERROR=1 ①

PARITY=0 ②

DUPLEX=1 ③

① 0=BCC,1=CRC

② 0=No Parity, 1=Even Parity

③ 0=Half Duplex, 1=Full Duplex

4. Save the file. If you are using the DOS text editor, type:

[ALT]FXY

Publication 2706-6.2

Page 33

2–11Installing the Software

Installing the Software for Ethernet PLC PassThrough

If you are using an Ethernet link and want to enable PLC

PassThrough file transfers, you must first modify your

CONFIG.SYS and AUTOEXEC.BAT files, and install and configure

the following products on your computer:

• Allen-Bradley Ethernet communications interface card (Cat. Nos.

6628-A5 or -A7) or equivalent

• FTP’s PC/TCP Software for DOS/Windows (FTP Cat. No.

PC-210)

Install Ethernet Card

Follow the instructions that came with your Allen-Bradley Ethernet

communications interface card to install and configure it on your

personal computer.

Install the PC/TCP Software

Follow the instructions that came with FTP’s PC/TCP Software to

install it on your personal computer.

Install the Offline Programming Software

Perform the basic installation procedure described earlier in this

chapter to install the Offline Programming Software on your

personal computer.

Modify CONFIG.SYS & AUTOEXEC.BAT Files

The following steps show a sample network setup. Consult with

your network administrator to determine if this setup applies in your

environment.

1. Change to the directory containing the PC/TCP drivers. Type:

CD \PCTCP↵

2. At the C:\PCTCP> prompt, type:

RENAME FTP22DOS.INI PROTOCOL.INI

3. Open the CONFIG.SYS file with any ASCII text editor. If you

use the DOS text editor, type:

EDIT C:\CONFIG.SYS↵

Your CONFIG.SYS file contents will appear in the editing

window.

4. Move the cursor to the end of the file.

Publication 2706-6.2

Page 34

2–12 Installing the Software

5. Assuming you have installed the Ethernet Board drivers in the

directory C:\PCTCP (the default), be sure the following lines

appear in your CONFIG.SYS file.

DEVICE=C:\PCTCP\PROTMAN.DOS /I:C:\PCTCP

DEVICE=C:\PCTCP\SMC8000.DOS

DEVICE=C:\PCTCP\DIS_PKT.GUP

6. Save the file. If you are using the DOS text editor, type:

[ALT]FXY

7. Open the AUTOEXEC.BAT file with any ASCII text editor. If

you use the DOS text editor, type:

EDIT C:\AUTOEXEC.BAT↵

Your AUTOEXEC.BAT file contents appears in the editing

window.

8. Move the cursor to the end of the file.

9. The following lines should appear in the AUTOEXEC.BAT file.

If they are not there, add them now.

SET PCTCP=C:\PCTCP\PCTCP.INI

C:\PCTCP\NETBIND.COM

C:\PCTCP\ETHDRV.EXE

For additional information regarding installation of your PC/TCP

software, refer to the section on installing an NDIS driver in the

PC/TCP Software Installation Guide.

Restart Your PC

When installation is complete, remove the installation diskette from

1

/2 inch micro drive and store all installation software in a safe

the 3

place. Finally, restart your PC to activate your changes to the

CONFIG.SYS and AUTOEXEC.BAT files.

Configure Your PLC

Use Allen-Bradley’s 6200 Series PLC-5 programming software or

the EIBOOT utility to set the PLC’s IP address. Refer to the

documentation that came with your PLC for additional configuration

information.

Publication 2706-6.2

Page 35

2–13Installing the Software

Starting the Program

Establishing Initial

Non–networked

Communications

If you have installed the Offline Programming Software without

PassThrough processing, your computer will return to the DOS

prompt, C:\DL40>. If you have installed PassThrough processing,

your computer returns to the directory it displayed when you began

the PassThrough processing installation.

If you do not return to the C:\DL40> directory, change directories by

typing:

CD C:\DL40↵

You may then start the the Offline Programming Software program

by typing:

DL40↵

The communication port settings on your computer and the DL40

must be the same in order to communicate.

• the port usage on the RS-485 port must be set to PRGMR to

perform message file transfers via the RS-485 port.

• the DL40 RS-232 port will always communicate with the DL40

Offline Programming Software regardless of the port

configuration.

• set your computer’s serial communication port to the following:

– baud rate 9600

– data bits 8

– parity none

– handshaking none

• Use the [SELECT] and [ENTER] push buttons on the front panel

of the DL40 to select SET RS232PORT?– PGMR/PRNTER

SETUP or SET RS-485 PORT?–PRGMR and set the parameters

to match the setting of your computer’s serial communication

port.

Note: Select Enable DIP switch (SW2-9) must be ON.

• You can also change the settings of the DL40’s serial ports with

the [CTRL][R] command using the DL40’s Onboard Editor and

an IBM compatible keyboard connected to the rear keyboard port

of the DL40 display.

Publication 2706-6.2

Page 36

Navigating the Software

Chapter Objectives

Starting the Software

This chapter provides a basic understanding of how to move around

in the DL40 Offline Programming Software. The information in this

chapter will help you:

• start the program

• move around within the program

• exit the program

This chapter contains the following topics:

Topic Page

Starting the Software 3–1

Title Screen and Main Menu 3–2

Getting Help 3–3

Setup Menu 3–4

Menu Control Keys 3–6

Shortcut Keys 3–6

Exiting the Software 3–7

After you have installed and set up the Offline Programming

Software on your computer, you can run the program at any time.

The most basic way to do so is to:

1. Start your computer.

2. Make sure you are logged on to the C: drive by typing:

C:↵

3. Go to the directory C:\DL40 by typing:

CD C:\DL40↵

4. Start the program by typing:

DL40↵

Publication 2706-6.2

Page 37

3–2 Navigating the Software

Title Screen & Main Menu Bar

The program opens with the Title screen shown below. The screen

identifies the product, and indicates the revision number and date of

the software. Close this screen and open the Main Menu screen by

pressing any key.

Opening title screen

Main Menu screen

Menu Title

Cursor

Menu Bar

Menu Item

Date & Time

Publication 2706-6.2

Page 38

3–3Navigating the Software

Getting Help

The Offline Programming Software offers context-sensitive online

Help at any time. To use Help:

• press [F1] to access a Help screen offering information about the

highlighted menu item.

• press [F1] again to replace the current Help screen with the Menu

Key Control Help screen.

• press [ESC] to close the Menu Key Control Help screen and

return to the context-sensitive Help screen

• press [ESC] to close the context-sensitive Help screen and return

to the Main screen

Sample Help Screen

Use the [ ] and [ ] keys

to scroll through the help text.

Publication 2706-6.2

Page 39

3–4 Navigating the Software

Setup Menu

Use the Setup menu to match the software to your color or

monochrome monitor, and to set the date and time. Access the Setup

menu by using the right and left arrow keys to move to Setup and

pressing [

Setup Menu

↵], or by pressing [S] at the Main menu.

Configuring the Program to Match Your Monitor

The Offline Programming Software supports both color and

monochrome displays. To change the display type, move the cursor

to Setup on the Main menu and press [↵ ]. Select Colors, and then

select either Color or Monochrome. Select Yes to confirm your

choice, then press [↵]. A message appears in the center of the screen

to indicate that the software is saving your selection to its setup file.

Press [Q] or [ESC] repeatedly to return to the Main menu.

Setup→Colors Screen

Publication 2706-6.2

Page 40

3–5Navigating the Software

Setting Time & Date

You can set the time and date by selecting Setup→Time & Date or by

pressing [S][T] from the the Main menu bar. The Date & Time

window appear showing the current date and time setting of the

personal computer. The cursor will highlight Time when the window

first opens. Press [↵] and input the desired time using military style

(24-hour) format. Press [↵] to record your changes and move the

cursor to Date. Press [↵] and input the desired date. Press [↵] to

record your changes and move the cursor to Quit.

Setup→Time & Date Screen

Publication 2706-6.2

Page 41

3–6 Navigating the Software

Menu Control Keys

Use the following keys to navigate through the Offline Programming

Software menus. These keys have the same effect wherever they are

used in the software. Individual screens may use additional

keystroke commands. These additional commands are described

immediately below the sample screens that appear throughout this

manual.

Help. Pressing F1 when Help is open will open the Menu Key

Control help screen

Toggle Help screen between partial and full screen view.

Return to the previous menu.

Select highlighted menu item.

↵

Highlight previous menu item.

↑

Highlight next menu item

↓

→

Move the cursor to the right

Shortcut Keys

←

Move the cursor to the left

Highlight first menu item.

Highlight last menu item.

You can also select most menu items by typing their initial letter.

For example, to exit the program you can type [E][Y]. [E] is the

initial letter in the Exit Main menu item, and [Y] is the initial letter

of the Yes Exit menu item.

Publication 2706-6.2

Page 42

3–7Navigating the Software

Exiting the Software

You can exit the Offline Programming Software at any time by

repeatedly pressing [ESC] until the Exit Confirmation menu appears.

Press [↵] to confirm your intention to exit the program.

Exiting the Offline Programming Software

You can also exit the program by typing the shortcut keys [E][Y]

from the Main menu.

Publication 2706-6.2

Page 43

Creating Message Files

This chapter describes the functions available to you from the

Develop menu. As its name implies, the options available from this

menu provide the tools needed to create and manage your application

files for the DL40 message display. This chapter contains the

following topics:

Page

Develop Menu 4–2

File Selection Screen 4–4

Create New File Window 4–5

Data Path Directory Window 4–6

Develop Screen 4–7

Messages Menu 4–8

Edit Message Screen 4–9

Message Text Window 4–10

Create New Message Screen 4–16

Copy Messages Screen 4–17

Delete Message Screen 4–19

Renumber Messages Screen 4–20

Text Search Screen 4–22

Modify Message Attributes Screen 4–24

Message Attribute Default Screen 4–32

Options Menu 4–34

Ports Menu 4–36

Verify Menu 4–39

Device Menu 4–44

Publication 2706-6.2

Page 44

4–2 Creating Message Files

Develop Menu

To open the Develop menu, use the right and left arrow keys to

highlight Develop on the Main menu bar, then press [↵ ].

Develop Menu

Special keys

You may use the following special keys on the Develop menu.

↓ ↑

↵

Move the cursor to the desired function

Move the cursor directly to the first menu item (Select)

Move the cursor directly to the last menu item (Quit)

Selects the item highlighted by the cursor

Closes the Develop menu and returns cursor to Main menu

Get Online Help

Publication 2706-6.2

Page 45

4–3Creating Message Files

Notes

From the Develop menu you can choose from the following:

• Select File to modify an existing data file.

• Create New File to create a new data file.

• Directory to specify a data path

The Offline Programming Software supports both color and

monochrome monitors. Make sure your monitor type matches the

type selected in the Setup menu. Refer to Chapter 3 for instructions

on changing your monitor type.

You cannot Select a file unless that file is located on the current DOS

path. If necessary, use the Directory menu item to change

directories. The window that opens when you pick DevelopSelect

File shows the current directory in the upper left.

Publication 2706-6.2

Page 46

4–4 Creating Message Files

File Selections Screen

When Select File is selected, a window appears with the default path

in the upper left corner and a list of the files found in that path.

If you want to edit files under a different path, press [ESC], highlight

Directory, and press [↵ ]. You can then edit the program’s data path

in the window show below.

File Selections screen showing typical application file list

Path

Time file was created

or last edited

Date file was created

or last edited

File length in bytes

Special Keys

Use the following special keys on the File Selections screen.

↓ ↑

Move the cursor to the desired file

Move the cursor directly to the first file

Move the cursor directly to the last file

Selects the item highlighted by the cursor (Opens Develop Screen)

↵

Returns to the top level of the Develop menu

Get Online Help

Notes

Use the arrow keys to move to the file you want to edit and press

[↵ ]. If the name of the file you want to edit does not appear here,

you may be using the wrong data path. Change the data path by

backing up and selecting Directory on the Develop menu.

Publication 2706-6.2

Page 47

4–5Creating Message Files

Create New File Window

When Create New File is selected on the Develop menu, a window

opens in which you can enter a new file name. Type in the file name

and press [↵ ]. You can type a drive and directory path as well if you

do not want to store the file on the current data path.

Create New File Window

If the default path is to be used, enter only the file

name. If a path other than the default path is to be

used, enter the path in the form: Drive:\Directory\File.

Flashing cursor

Special keys

You may use the following special keys on this window.

← →

Moves the cursor forward or backward through the file name to

allow editing

Accepts the file name (and path, if applicable).

↵

Opens Develop Screen

Returns to the top level of the Develop menu

Get Online Help

Notes

When creating a new file you will be asked to specify a path and

filename in the format:

Drive:\Directory\File

If you do not specify a path, then the currently active path will be

used.

When you press [↵ ] to accept the file name in the Create a New File

window, the Device menu opens.

Publication 2706-6.2

Page 48

4–6 Creating Message Files

Data Path Directory Window

Change data path directories by selecting Develop→Directory from

the Main menu bar. When you enter a complete directory path in the

Directory window the Offline Programming Software will use that

path as a default for all file activities. Override the Directory setting

by typing another complete data path when naming files.

Data Path Directory window

Special Keys

Use the following special keys on this window.

← →

Moves the cursor forward or backward through the data path

description to allow editing

Accepts the data path directory you have entered in the window

↵

Returns to the top level of the Develop menu

Get Online Help

Notes

When creating a new data path, specify the path in the format:

Drive:\Directory1\Directory2\Directory3

You can change the selected data path directory at any time the

Message menu is displayed. The change becomes effective

immediately.

Publication 2706-6.2

Page 49

4–7Creating Message Files

Develop Screen Menu

Editing an existing file and creating a new file use the same screen.

After entering the name and data path of a file to create or change,

the screen shown below appears. Notice that the Main Menu bar has

been replaced by a the Develop Menu bar. Use this menu bar as you

would use the Main menu bar.

Develop Screen menu after selecting or creating a file

Remaining (free) memory

Special Keys

Use the following special keys on this menu.

← →

or

Moves the cursor to the desired function

Moves the cursor directly to the desired

function: Messages, Options, Ports,

Verify, or Exit.

Moves cursor directly to the first function

(Messages)

Moves cursor directly to the last function

(Exit)

Selects the function highlighted by the cursor

↵

Get Online Help

Notes

The Messages, Options, Ports, Verify, and Device branch menus

control every aspect of your message file. Work through each of

these menus in turn to avoid omissions and mistakes.

Specify a selection for every item on the Develop menu bar branch

menus. If you have not edited every selection, a System Attribute

Warning message appears when you save the file.

Publication 2706-6.2

Page 50

4–8 Creating Message Files

Messages Menu

Use the selections on the Messages menu to create, edit, and control

the display format of messages intended for display on the DL40.

Messages menu

Special keys

Use the following special keys on this menu.

↓ ↑

↵

Moves the cursor to the desired function

Moves the cursor directly to the first menu item

Moves the cursor directly to the last menu item (Quit)

Selects the item highlighted by the cursor

Closes the Develop menu and returns cursor to Main menu

Get Online Help

Publication 2706-6.2

Page 51

4–9Creating Message Files

Edit Message Screen

After you have selected Edit Message, the Message Selections

window shown below opens. Select the message you want to edit,

then press [↵ ] to open the Message Text window

Message Selections after selecting Edit Message

Special keys

You may use the following special keys on this window.

↑ ↓

↵

Moves the cursor to the desired message.

Moves cursor directly to the first message.

Moves cursor directly to the last message.

Selects the message highlighted by the cursor and

opens the Message text window.

Closes the window and returns to the Messages menu.

Get Online Help.

Publication 2706-6.2

Page 52

4–10 Creating Message Files

Message Text Window

After you have selected a message from the Message Selections

window by highlighting it and pressing [↵ ], a window opens

showing the text of the selected message. In this window you can

edit the message as required.

Note that the Message Text window also appears when you select

Create New Message from the Messages menu as described on

page 4–8.

Message Text window

Message Text

Messages can contain up to

20 characters (including

spaces) per line.

Insert or Overstrike Mode

Column cursor is currently in

Row cursor is currently in. Note that the cursor row

does not necessarily correspond to the display line on

the DL40 if Line Usage is other than All Lines.

Publication 2706-6.2

Page 53

Special Keys and Editing Rules

You may use the following keys to move through and edit your

message text.

Moves the cursor up or down one line at a time

↑

4–11Creating Message Files

Any alphabetic or numeric key

V F W X T Y

plus

← →

or

or

ALT

or

Moves the cursor right or left without changing the underlying text

Moves cursor directly to the beginning or end of the message

Moves cursor exactly 1 display window forward or backward through the

message (except when Scroll attribute is set as described on page 4–26

Toggles between insert and overstrike. If there is a character at the position

of the cursor, then the insert mode inserts a character immediately to the

left of the cursor. In overstrike mode the character at the cursor position is

replaced by any new character you type.

Deletes the character to the left of the cursor

Deletes the character at the cursor position

Inserts a return to start a new line

↵

Press the [ALT] key while entering a number from the numeric keypad

inserts an ASCII or Extended ASCII character. See Appendix A.

Inserts that character at the position of the cursor.

Add or modify variables (see below)

B

E

N

F10

Lets you set Message Attributes for only the message being created or

A

edited.

Start and end marker for blinking characters. Must be used in pairs.

The text between the markers will blink on the message display.

Erases message text, but leaves message number intact.

You will be asked to confirm this action before it takes effect.

Centers or un-centers the active message in the Edit Message window.

Returns to Messages menu. Note that the Abort Message Edit confirmation

window appears if you have changed the message in any way.

The window asks if you want to discard your changes.

Get Online Help

Toggles size of Message Text window between 40 and 200 characters

Saves changes and returns to the Messages menu

Publication 2706-6.2

Page 54

4–12 Creating Message Files

More About Variables

You can send variables to the DL40 from a PLC or via the Parallel

Input Port. Variables can be sent to message only in the

Message/Variable/Slave or Message/Variable Run Modes. Insert

variables using the [CTRL] key in combination with a letter.

Commands to add or modify variables include:

Command Function

[CTRL][V] Insert a BCD or binary variable

[CTRL][F] Change the formatting parameters of a variable

[CTRL]W] Insert ASCII or BCD variable data

[CTRL][X] Insert request for ASCII input data

[CTRL][T] Insert the system time into a message

[CTRL][Y] Insert the system date into a message

The number of variables you can insert in any one message depends

upon your hardware and the selected Run Mode.

Insert Formatted Variable With [CTRL][V]

Use [CTRL][V] to insert a BCD or binary variable into a message.

Specify the variable type.

When you press [CTRL][V], the software will ask you to enter 3

parameters:

Parameter Acceptable values

Variable Size 1 to 7 (including decimal point)

Decimal Point Position

(number of placed after the

decimal point)

Suppress Zeroes

(appearing in front of the

first significant digit)

0 to 6 (the maximum value is one less

than the variable size selected above)

Yes or No

The variable symbol _________ appears in the message at the

variable’s location.

The difference between a formatted variable entered with

[CTRL][V] and an unformatted variable entered with [CTRL][W] is

the flexibility to modify the parameters shown above.

Publication 2706-6.2

Note that neither AutoRun Messages or Background Messages

support inserted variable data.

Page 55

4–13Creating Message Files

Change Formatted Variable With [CTRL][F]

Use [CTRL][F] to change the formatting parameters of a variable.

Place the cursor under the symbol for the variable you want to

change, then press [CTRL][F]. The software will ask you to modify

any one or more of the 3 formatting parameters:

Parameter Acceptable values

Variable Size 1 to 7 (including decimal point)

Decimal Point Position

(number of placed after the

decimal point)

Suppress Zeroes

(appearing in front of the

first significant digit)