Page 1

RSFieldbus and the

1757-FFLD Linking

Device

1757-FFLD

Programming Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (Publication SGI-1.1 available from your local

Rockwell Automation sales office or online at

http://www.rockwellautomation.com/literature) describes some important

differences between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular

installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety

considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can

cause an explosion in a hazardous environment, which may lead

to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application

and understanding of the product.

Identifies information about practices or circumstances that can

lead to personal injury or death, property damage, or economic

loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequence

Labels may be located on or inside the equipment (for example,

drive or motor) to alert people that dangerous voltage may be

present.

Labels may be located on or inside the equipment (for example,

drive or motor) to alert people that surfaces may be dangerous

temperatures.

Page 3

Preface

This programmig manual describes how to use the 1757-FFLD linking device

along with RSFieldbus in applications with the F

network. This document provides technical, network setup and configuration

information with guidelines on application function block use. In addition, this

manual offers references to third party device configuration guidelines for the

Foundation Fieldbus and the linking device. For more information about using

Rockwell Automation products with F

OUNDATION Fieldbus, see Fieldbus

Solutions for Rockwell Automation’s Integrated Architecture, publication

1757-UM006.

RSFieldbus is for use with Microsoft Windows 2000 or XP Professional. This

manual assumes that you are already familiar with navigating and running

applications in a Microsoft Windows 2000 or XP Professional environment.

OUNDATION Fieldbus

Conventions Used in This Manual

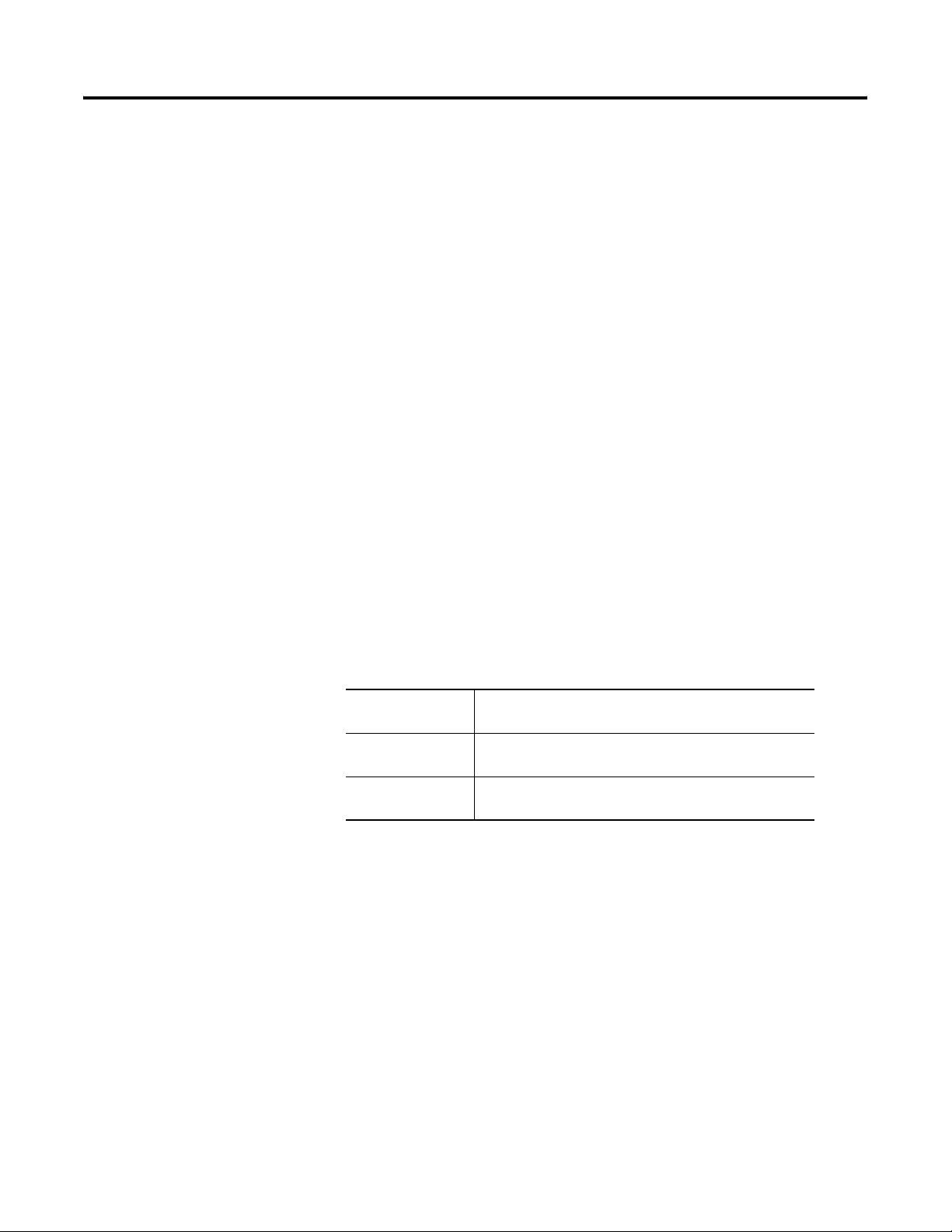

Convention Meaning Example

click Click left mouse button once. (Assumes cursor is

positioned on object or selection.)

double-click Click left mouse button twice in quick succession.

(Assumes cursor is positioned on object or selection.)

right-click Click right mouse button once. (Assumes cursor is

positioned on object or selection.)

drag and drop Click and hold the left mouse button on an object, move

the cursor to where you want to move the object, and

release the mouse button.

select Click to highlight a menu item or list choice. Select H1-1 from the drop-down list.

check/uncheck Click to activate/deactivate a checkbox. Check the Do not show this dialog again

⇒

expand Click the + to the left of a given item /folder to show its

Shows nested menu selections as menu name followed

by menu selection.

contents.

This manual uses the following conventions:

Click Browse.

Double-click the H1 icon.

Right-click the Fieldbus Networks icon.

Drag and drop the desired block into the

Strategy window.

checkbox.

Click File ⇒ Page Setup ⇒ Options.

In the H1-1 window, expand the FFLD.

<Enter> Keys to be pressed are shown in angle brackets. Press <Enter>.

>PID Example< Data to be typed at a prompt or in an entry field. Enter >PID Example< for the name.

3 Publication 1757-PM002A-EN-E - June 2006

Page 4

Preface 4

Related Documentation

For information on the Rockwell Software products found in this manual,

refer to the following publications:

• RSFieldbus Installation Guide, publication RSFBUS-IN001

• RSFieldbus User Manual, publication RSFBUS-UM001

• RSView Supervisory Edition User’s Guide, publication

VIEWSE-UM003C

These FOUNDATION Fieldbus Specification documents contain information

that you may find helpful as you read this manual:

• System Architecture, publication FF-800

• Technical Overview, publication FD-043

• Application Guide 31.25 kbit/s Wiring and Installation, publication

AG-140

• System Engineering Guidelines, publication AG-181

These documents can be purchased from the Fieldbus Foundation as part of

the H1 Communications and User Layer Technical Specification.

For more information go to

http://www.fieldbus.org/ProductsAndServices/FFProductCatalog/

and look under Final Specifications.

Publication 1757-PM002A-EN-E - June 2006

Page 5

System Requirements

Chapter

1

In This Chapter

Purpose of this Chapter

Foundation Fieldbus Description

For See Page

Purpose of this Chapter 1-1

Foundation Fieldbus Description 1-2

Hardware Requirements 1-4

Software Requirements 1-12

Additional Resources 1-12

This chapter describes the components of a typical fieldbus system, including

the Rockwell Automation Linking Device, 1757-FFLD.

Refer to the Glossary for further explanation of fieldbus terms and concepts.

If you already have a basic understanding of fieldbus concepts, skip to Chapter

2,

Setting Up A System, or if you want to start using RSFieldbus for

applications immediately, skip to Chapter 4, Applications.

The term fieldbus refers to an all-digital, two-way communication system that

connects control systems to instrumentation.

The Fieldbus Foundation is an organization that developed a fieldbus network

standard based on the work and principles of the ISA and IEC. The goal of the

Fieldbus Foundation is to provide multi-vendor interoperable process control

using a single robust industrial network based on standards and other proven

technologies.

FOUNDATION Fieldbus, the communications network created by the Fieldbus

Foundation, is a protocol designed for robust, distributed control of process

control applications. Devices that you connect within a F

Fieldbus network are used for sophisticated, highly distributed Process

Control. F

integrated into Rockwell Automation’s Integrated Architecture through the

linking device.

1 Publication 1757-PM002A-EN-E - June 2006

OUNDATION Fieldbus is an enabling technology that has been

OUNDATION

Page 6

1-2 System Requirements

Hardware Requirements

To build a simple fieldbus system, you need:

• Power supply

• Power conditioner

• Fieldbus cable

• Field devices

• Connector blocks

• Ter minal blocks

• Ter minators

• 1757- FFLD linking device

• Personal computer

Power Supply

The following power supplies are available according to the referenced

Fieldbus Foundation Physical Layer Profile Specification:

Type 131 Non-I.S. Power supply intended for feeding and I.S. barrier. Output

voltage depends on barrier rating.

Type 132 Non-I.S. Power supply not intended for feeding and I.S. barrier.

Output voltage is 32 VDC Max.

Type 133 I.S. Power supply; complies with recommended I.S.

parameters

You can configure power supplies to provide dual redundancy as long as they

meet the IEC/ISA Physical Layer Standards requirements. It is not acceptable

for example, to merely parallel two power supplies.

A typical power supply for a small network is a SOLA SDN 5-24-100. 5A, 24

VDC output, 110 AC input. For more specifications on power supplies, see the

Power Considerations section on page 2-2.

Power Conditioner

Publication 1757-PM002A-EN-E - June 2006

A power supply impedance matching network is required for Fieldbus use.

This is referred to as a power conditioner. A power conditioner is a

Page 7

System Requirements 1-3

resistive/inductive network that is either external or built into the fieldbus

power supply.

Fieldbus Cable

The preferred fieldbus cable is specified in the IEC/ISA Physical Layer

Standard, Clause 22.7.2 for conformance testing. It is referred to as type “A”

fieldbus cable. This cable will probably be used in new installations.

Other types of cable can also be used. The alternate preferred fieldbus cable is

a multiple, twisted pair cable with an overall shield. It is referred to as Type

“B” cable. Less preferable types of cable include single or multiple twisted pair

cable without any shield, referred to as Type “C” cable, and multiple conductor

cable without twisted pairs, but with overall shield, referred to as Type “D”

cable.

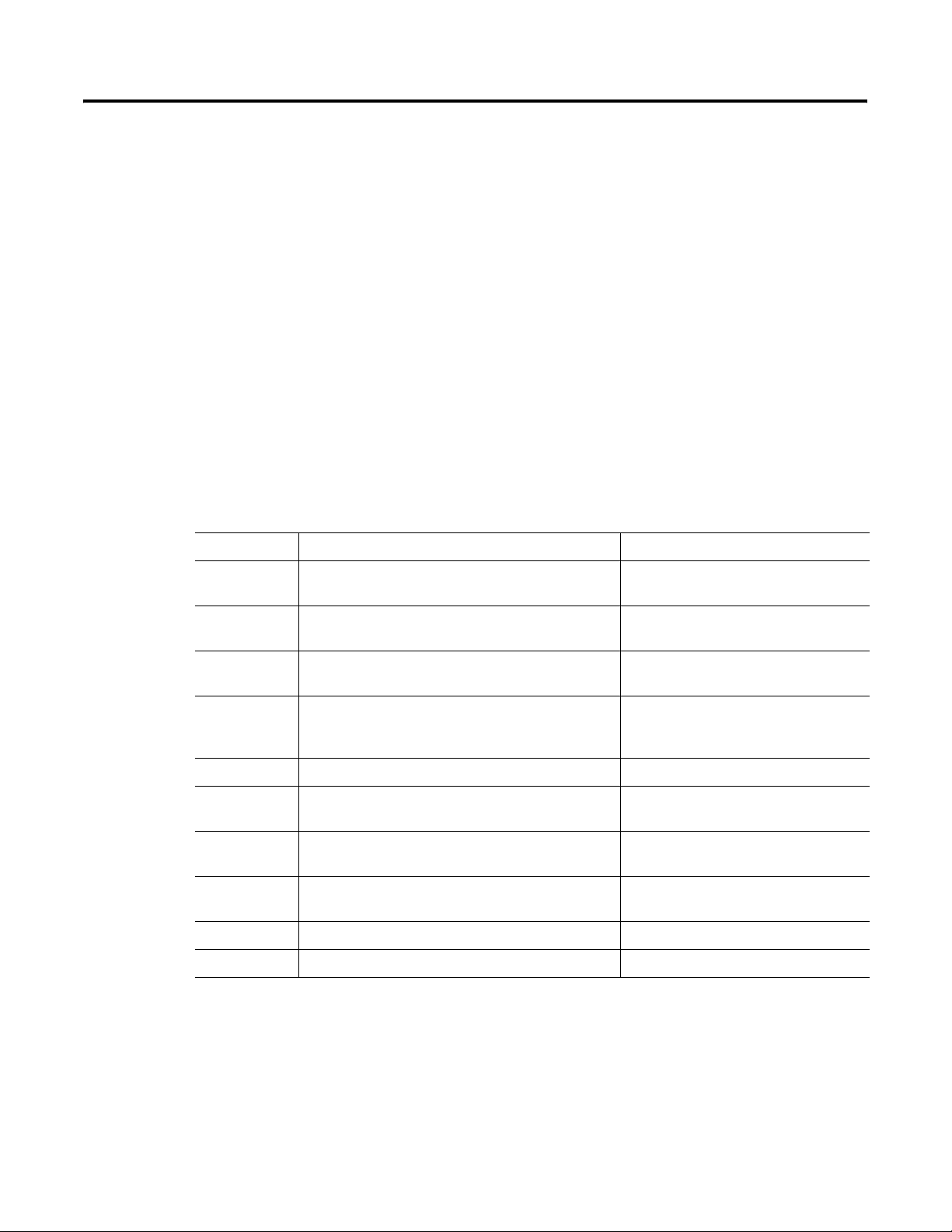

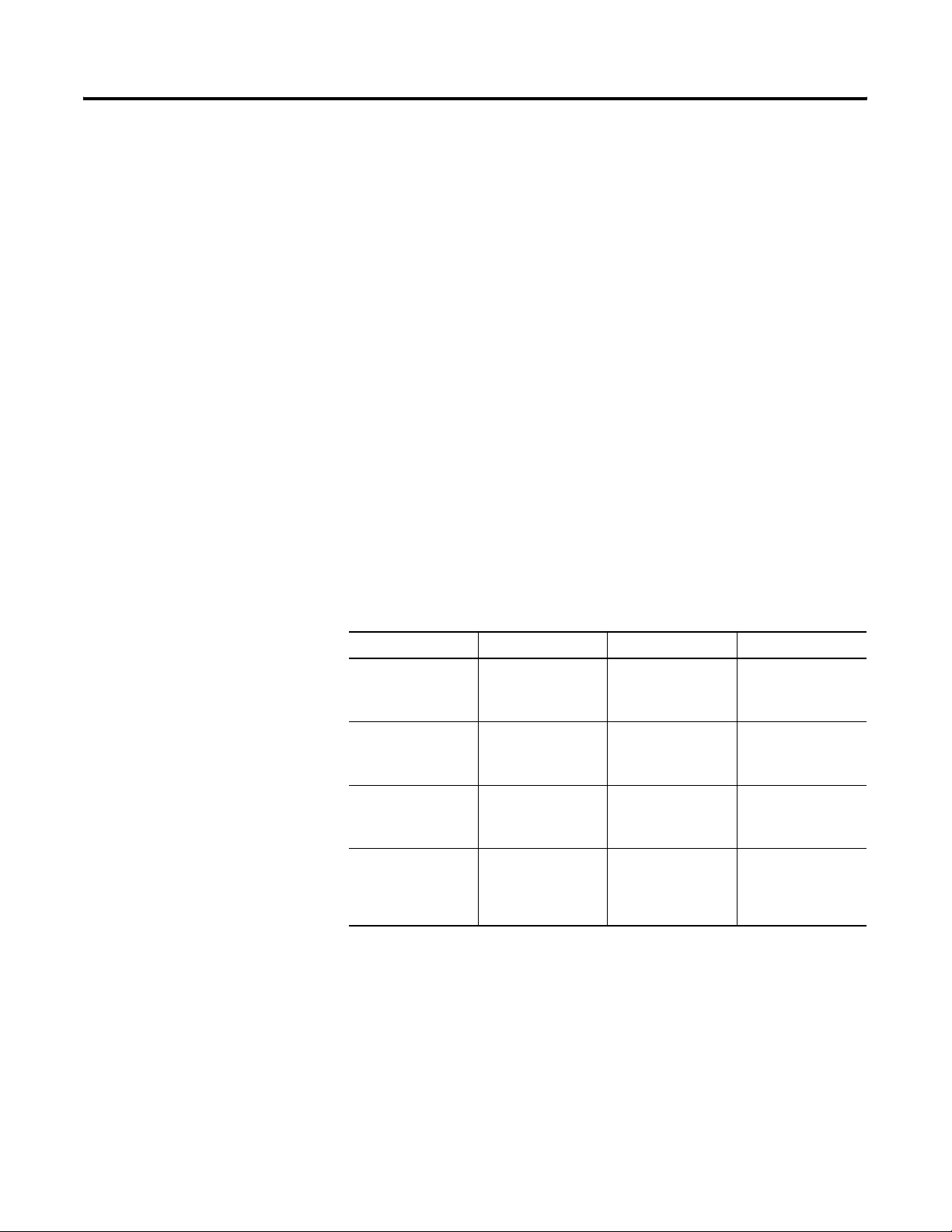

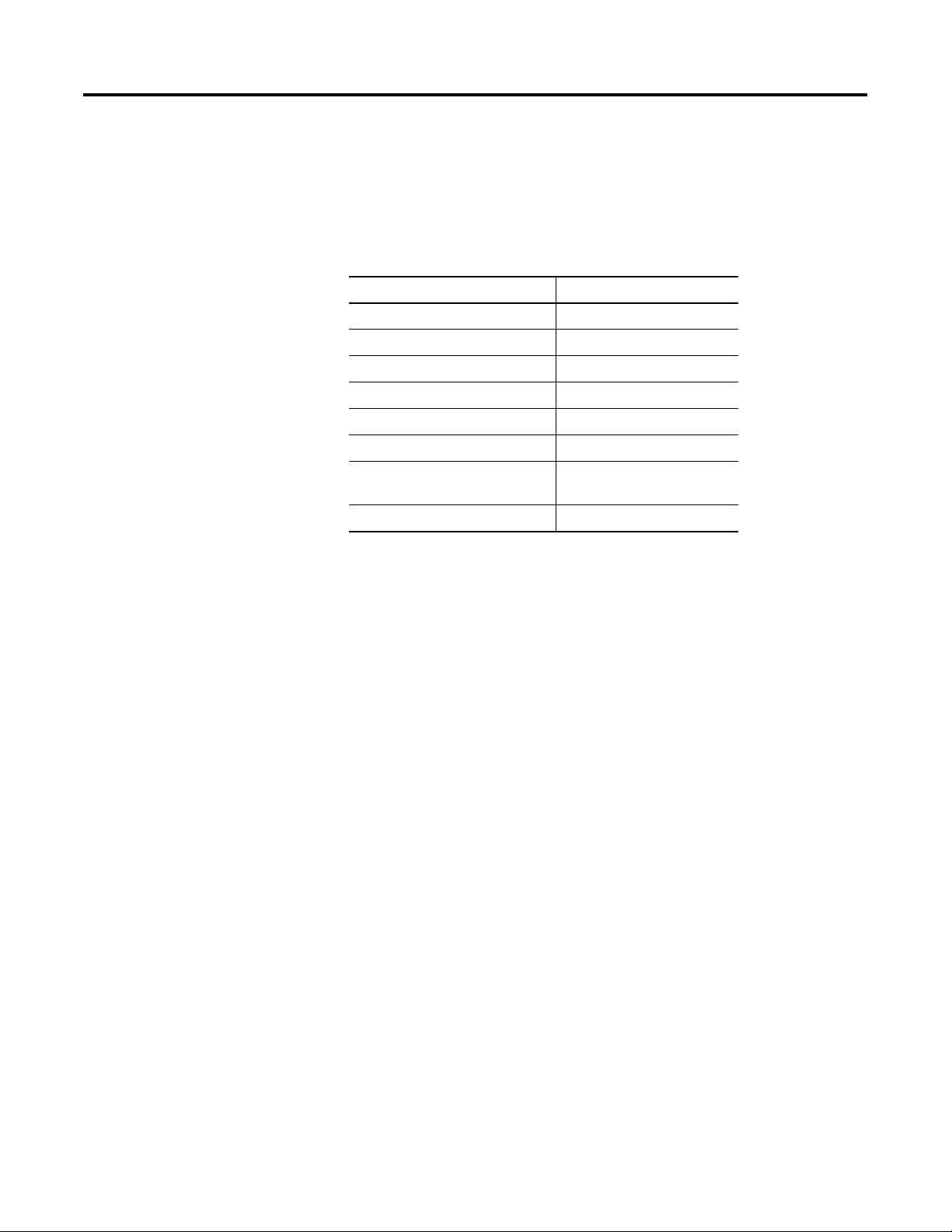

The following table contains the types of cable identified by the IEC/ISA

Physical Layer Standard and their maximum length values. For information

about spur wire length, see the

page 2-9.

Spur Wire Length Calculations section on

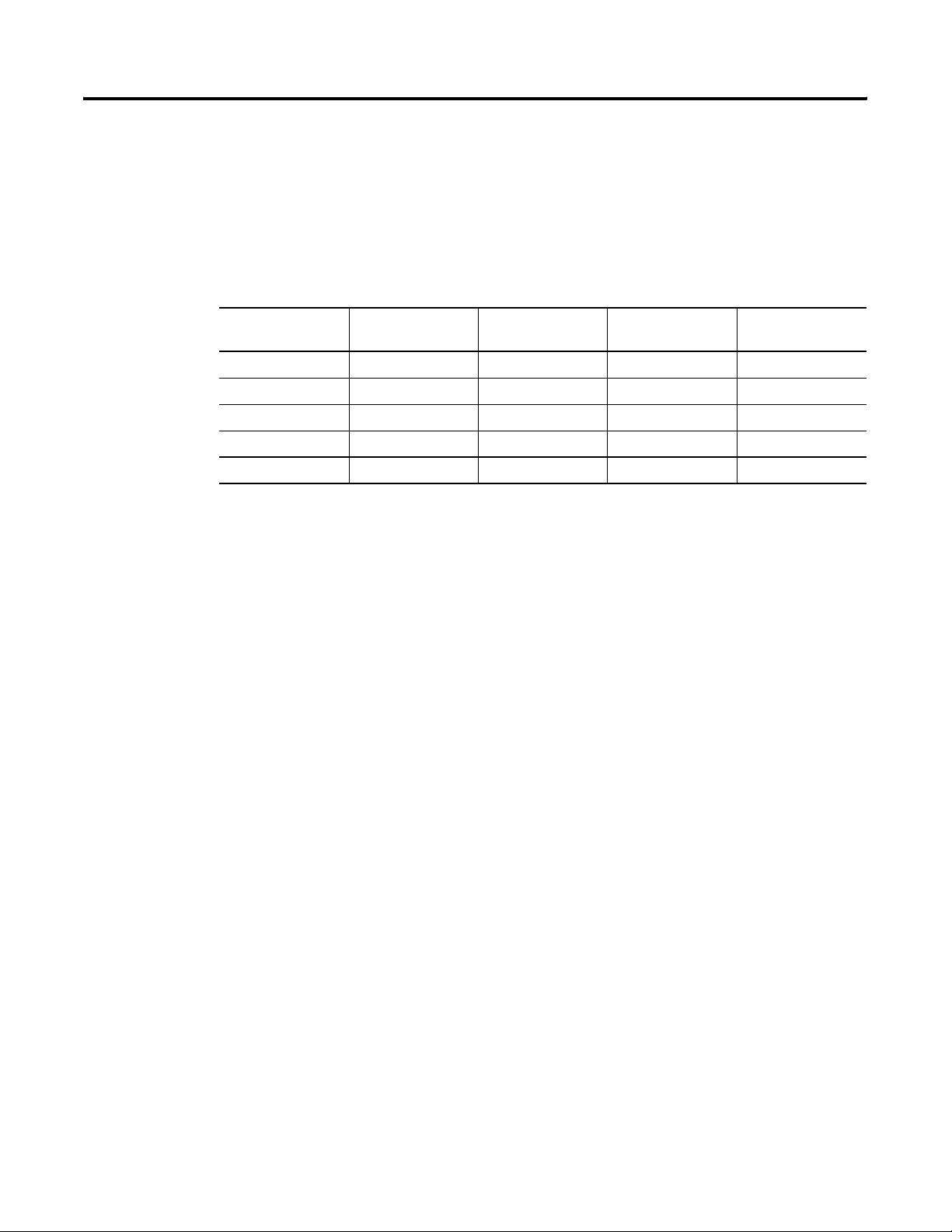

Ty pe Cable Description Size Maximum Length

Type A Shielded, twisted

pair

Type B Multi-twisted pair

with shield

Type C Multi-twisted pair

without shield

Type D Multi-core, without

twisted pairs and

having an overall

shield

#22 AWG

(.8 mm2)

#22 AWG

(.32 mm2)

#26 AWG

(.13 mm2)

#16 AWG

(1.25 mm2)

1900 m

(6232 ft.)

1200 m

(3936 ft.)

400 m

(1312 ft.)

200 m

(656 ft.)

Devices

Fieldbus links smart field devices with automation systems. The devices

generally used in fieldbus networks are type 113 (bus powered) or type 114

(separate power). Examples of these devices are the Rosemount 3051S

pressure Transmitter and the Micro Motion 2700 Flowmeter.

Publication 1757-PM002A-EN-E - June 2006

Page 8

1-4 System Requirements

Connector Blocks

Connector blocks are optional coupling devices. They can be used to connect

wire to a fieldbus device, or to another section of wire (e.g. at a junction block).

Connector blocks are useful for installations where devices may be periodically

disconnected or moved.

Standard fieldbus connectors are specified in Annex B of the ISA Physical

Layer Standard and Annex A of the IEC Physical Layer Standard.

1757-FFLD Linking Device

The 1757-FFLD, also referred to as the linking device, bridges both

F

OUNDATION Fieldbus™ HSE and Ethernet/IP networks to FOUNDATION

fieldbus H1 device networks. Bridging these networks facilitates information

flow between a Logix system’s control layers.

Terminal Blocks

Terminal blocks typically provide multiple bus connections, so a device can be

wired to any set of bus terminals. They can be the same terminal blocks as

used for 4-20 mA.

Terminators

A terminator is an impedance matching module used at or near each end of a

transmission line. Terminators prevent distortion and signal loss, and are

typically purchased and installed as preassembled, sealed modules. Each

terminator has a value of 50 ohms.

ATTENTION

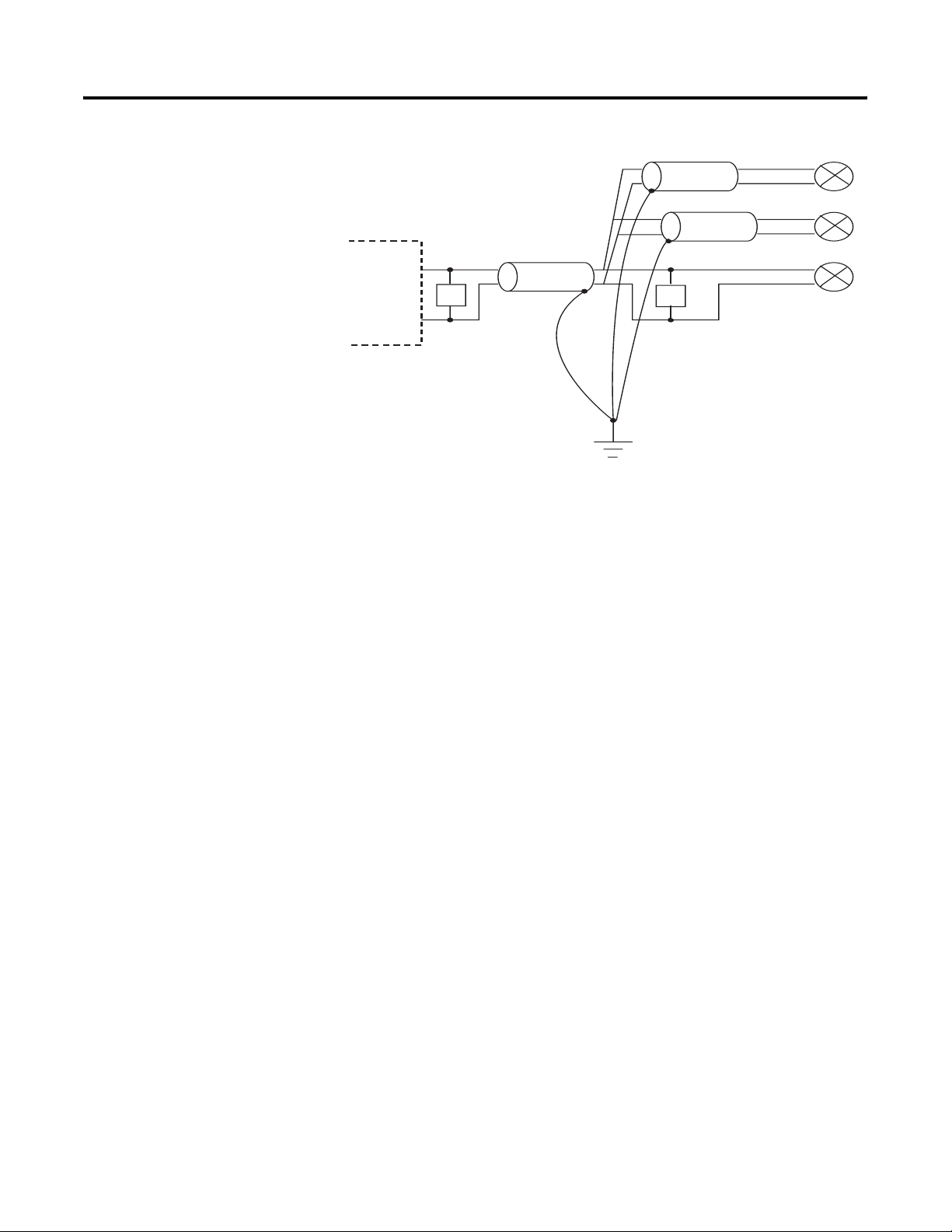

A trunk is the longest cable path between any two devices on the network. All

connections to the trunk are called spurs. Place the terminators at the ends of

You can use a maximum of two terminators per bus

segment.

Publication 1757-PM002A-EN-E - June 2006

Page 9

System Requirements 1-5

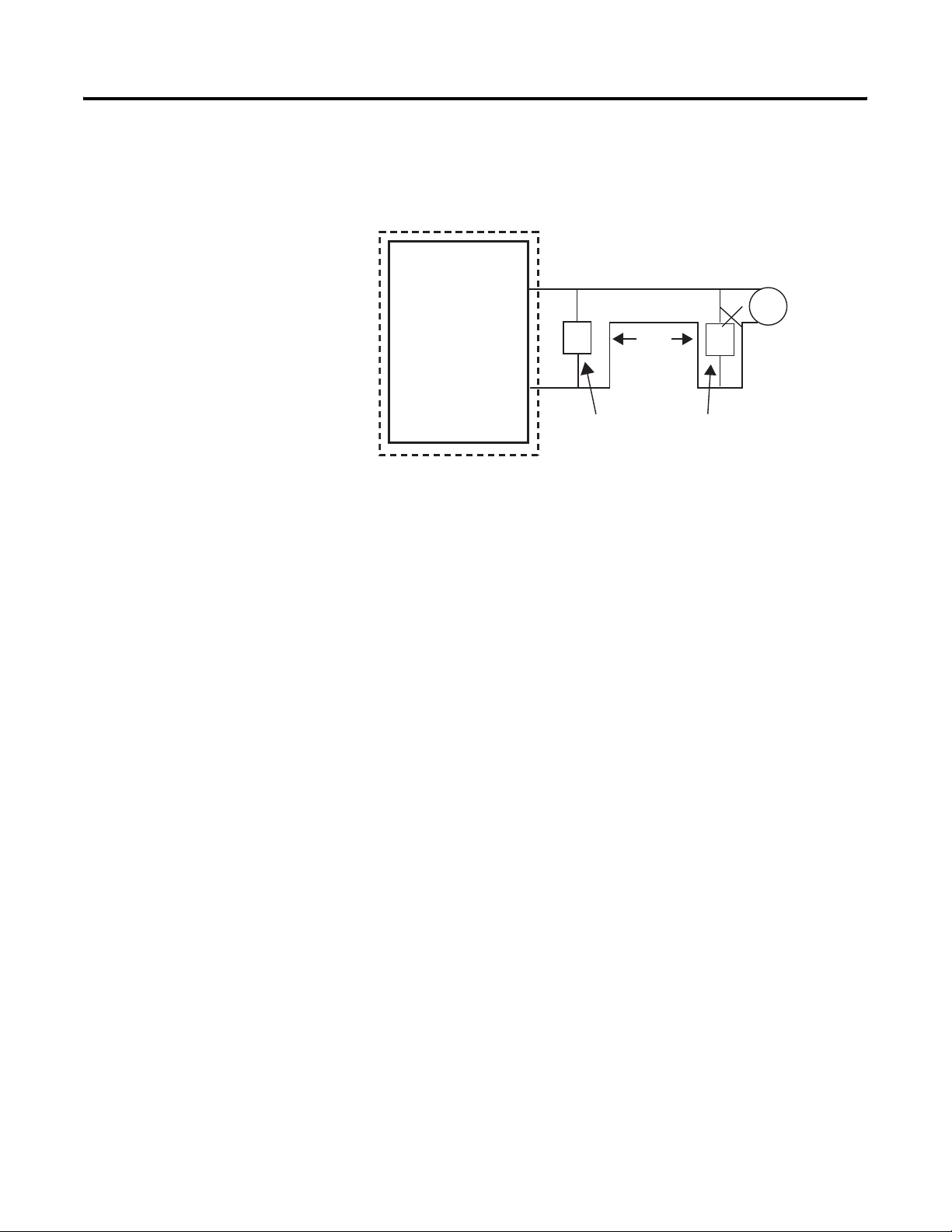

the trunk. The following illustration shows a sSimple Fieldbus network with

terminators

FFI

Trunk

Software Requirements

FFLD

Wire Pair

T

Terminator Terminator

Signals

T

Fieldbus

Digital

Field

Device

Personal Computer

You need a computer to run RSFieldbus software.

RSFieldbus and RSLogix 5000 software for are required. As an option, you can

use RSView Supervisory Edition software for specific applications.

Additional Resources

There are a number of resources available should you encounter difficulties

with your fieldbus application.

Publication 1757-PM002A-EN-E - June 2006

Page 10

1-6 System Requirements

Web Sites

• Rockwell Automation

– External:

http://domino.automation.rockwell.com/applications/gs/region/gt

swebst.nsf/pages/Process_Solutions_Home

– Internal:

http://rain.ra.rockwell.com (select Process Solutions

from the A-Z menu)

• FOUNDATION Fieldbus:

http://www.fieldbus.org/

• Tech Support:

– For Knowledge-base information, go to the Tech support Web site:

http://support.rockwellautomation.com/ (select Knowledge

Bases)

– For telephone support call: 440-646-5800

Documents

For a list of additional support documentation that may be useful in

conjunction with this manual, see the

page P-2.

Related Documentation section on

Publication 1757-PM002A-EN-E - June 2006

Page 11

Set Up A System

Chapter

2

In This Chapter

Purpose of this Chapter

For See Page

Purpose of this Chapter 2-1

Hardware Requirements 2-2

Software Requirements 2-5

Set Up A System 2-6

Physical Media 2-7

Network Basics 2-20

Things to Consider When Setting

Up a System

Additional Resources 2-27

This chapter describes the components of a typical fieldbus system and how to

set up and prepare your system for operation.

Refer to the Glossary for further explanation of fieldbus terms and concepts.

If you want to start using RSFieldbus for applications immediately, skip to

Chapter 4,

Applications.

2-27

1 Publication 1757-PM002A-EN-E - June 2006

Page 12

2-2 Set Up A System

Hardware Requirements

To build a simple fieldbus system, you need:

• Power supply

• Power conditioner

• Fieldbus cable

• Field devices

• Connector blocks

• Ter minal blocks

• Ter minators

• 1757- FFLD linking device

• Personal computer

Power Supply

The following power supplies are available according to the referenced

Fieldbus Foundation Physical Layer Profile Specification:

Type 131 Non-I.S. Power supply intended for feeding and I.S. barrier. Output

voltage depends on barrier rating.

Type 132 Non-I.S. Power supply not intended for feeding and I.S. barrier.

Output voltage is 32 VDC Max.

Type 133 I.S. Power supply; complies with recommended I.S.

parameters

You can configure power supplies to provide dual redundancy as long as they

meet the IEC/ISA Physical Layer Standards requirements. It is not acceptable

for example, to merely parallel two power supplies.

A typical power supply for a small network is a SOLA SDN 5-24-100. 5A, 24

VDC output, 110 AC input. For more specifications on power supplies, see the

Power Considerations section on page 2-2.

Power Conditioner

Publication 1757-PM002A-EN-E - June 2006

A power supply impedance matching network is required for Fieldbus use.

This is referred to as a power conditioner. A power conditioner is a

Page 13

Set Up A System 2-3

resistive/inductive network that is either external or built into the fieldbus

power supply.

Fieldbus Cable

The preferred fieldbus cable is specified in the IEC/ISA Physical Layer

Standard, Clause 22.7.2 for conformance testing. It is referred to as type “A”

fieldbus cable. This cable will probably be used in new installations.

Other types of cable can also be used. The alternate preferred fieldbus cable is

a multiple, twisted pair cable with an overall shield. It is referred to as Type

“B” cable. Less preferable types of cable include single or multiple twisted pair

cable without any shield, referred to as Type “C” cable, and multiple conductor

cable without twisted pairs, but with overall shield, referred to as Type “D”

cable.

The following table contains the types of cable identified by the IEC/ISA

Physical Layer Standard and their maximum length values. For information

about spur wire length, see the

page 2-9.

Spur Wire Length Calculations section on

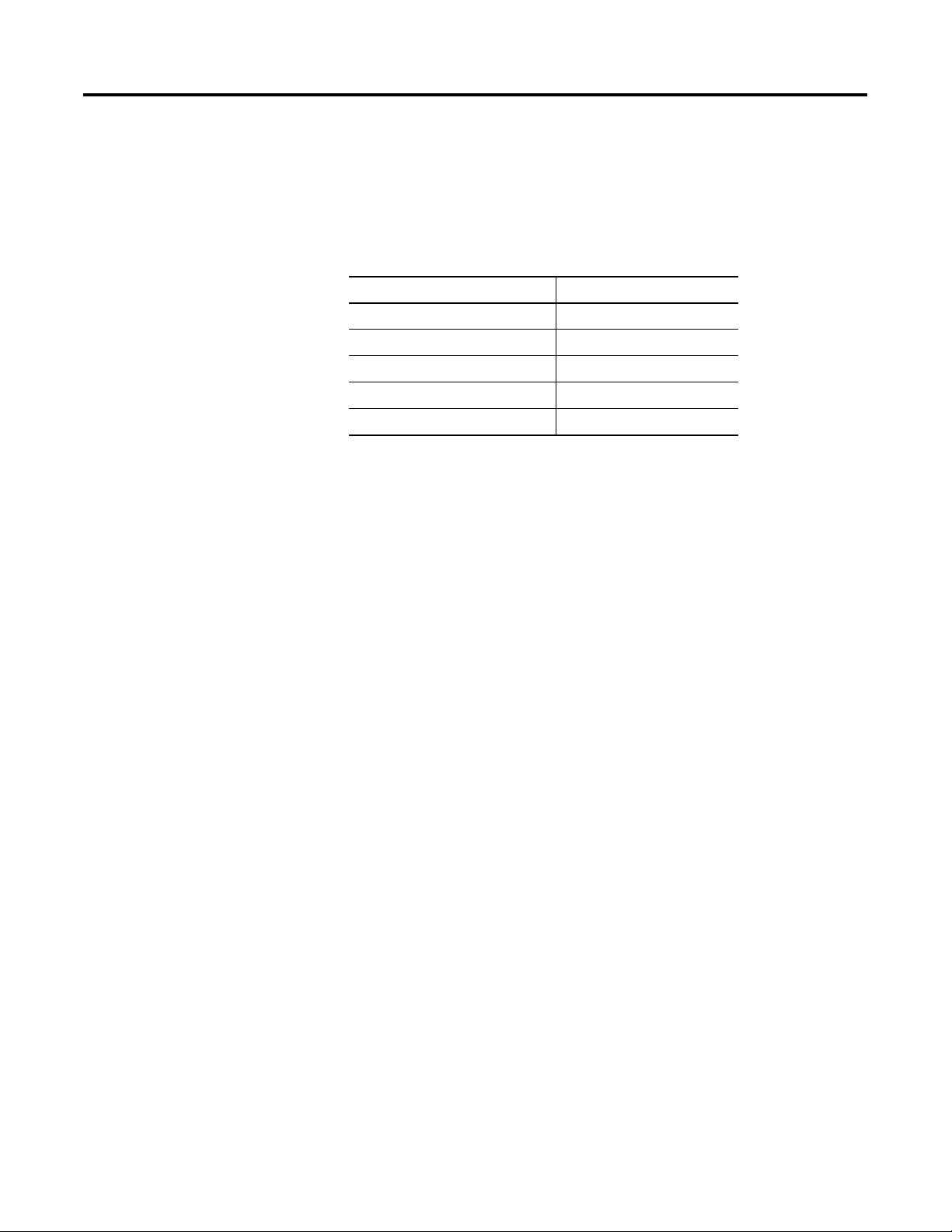

Ty pe Cable Description Size Maximum Length

Type A Shielded, twisted

pair

Type B Multi-twisted pair

with shield

Type C Multi-twisted pair

without shield

Type D Multi-core, without

twisted pairs and

having an overall

shield

#22 AWG

(.8 mm2)

#22 AWG

(.32 mm2)

#26 AWG

(.13 mm2)

#16 AWG

(1.25 mm2)

1900 m

(6232 ft.)

1200 m

(3936 ft.)

400 m

(1312 ft.)

200 m

(656 ft.)

Devices

Fieldbus links smart field devices with automation systems. The devices

generally used in fieldbus networks are type 113 (bus powered) or type 114

(separate power). Examples of these devices are the Rosemount 3051S

pressure Transmitter and the Micro Motion 2700 Flowmeter.

Publication 1757-PM002A-EN-E - June 2006

Page 14

2-4 Set Up A System

Connector Blocks

Connector blocks are optional coupling devices. They can be used to connect

wire to a fieldbus device, or to another section of wire (e.g. at a junction block).

Connector blocks are useful for installations where devices may be periodically

disconnected or moved.

Standard fieldbus connectors are specified in Annex B of the ISA Physical

Layer Standard and Annex A of the IEC Physical Layer Standard.

1757-FFLD Linking Device

The 1757-FFLD, also referred to as the linking device, bridges both

F

OUNDATION Fieldbus™ HSE and Ethernet/IP networks to FOUNDATION

fieldbus H1 device networks. Bridging these networks facilitates information

flow between a Logix system’s control layers.

Terminal Blocks

Terminal blocks typically provide multiple bus connections, so a device can be

wired to any set of bus terminals. They can be the same terminal blocks as

used for 4-20 mA.

Terminators

A terminator is an impedance matching module used at or near each end of a

transmission line. Terminators prevent distortion and signal loss, and are

typically purchased and installed as preassembled, sealed modules. Each

terminator has a value of 50 ohms.

ATTENTION

A trunk is the longest cable path between any two devices on the network. All

connections to the trunk are called spurs. Place the terminators at the ends of

You can use a maximum of two terminators per bus

segment.

Publication 1757-PM002A-EN-E - June 2006

Page 15

Set Up A System 2-5

the trunk. The following illustration shows a sSimple Fieldbus network with

terminators

FFI

Trunk

Software Requirements

FFLD

Wire Pair

T

Terminator Terminator

Signals

T

Fieldbus

Digital

Field

Device

Personal Computer

You need a computer to run RSFieldbus software.

RSFieldbus and RSLogix 5000 software for are required. As an option, you can

use RSView Supervisory Edition software for specific applications.

Publication 1757-PM002A-EN-E - June 2006

Page 16

2-6 Set Up A System

Set Up A System

When setting up a fieldbus system, you must first install and configure your

software and all fieldbus devices.

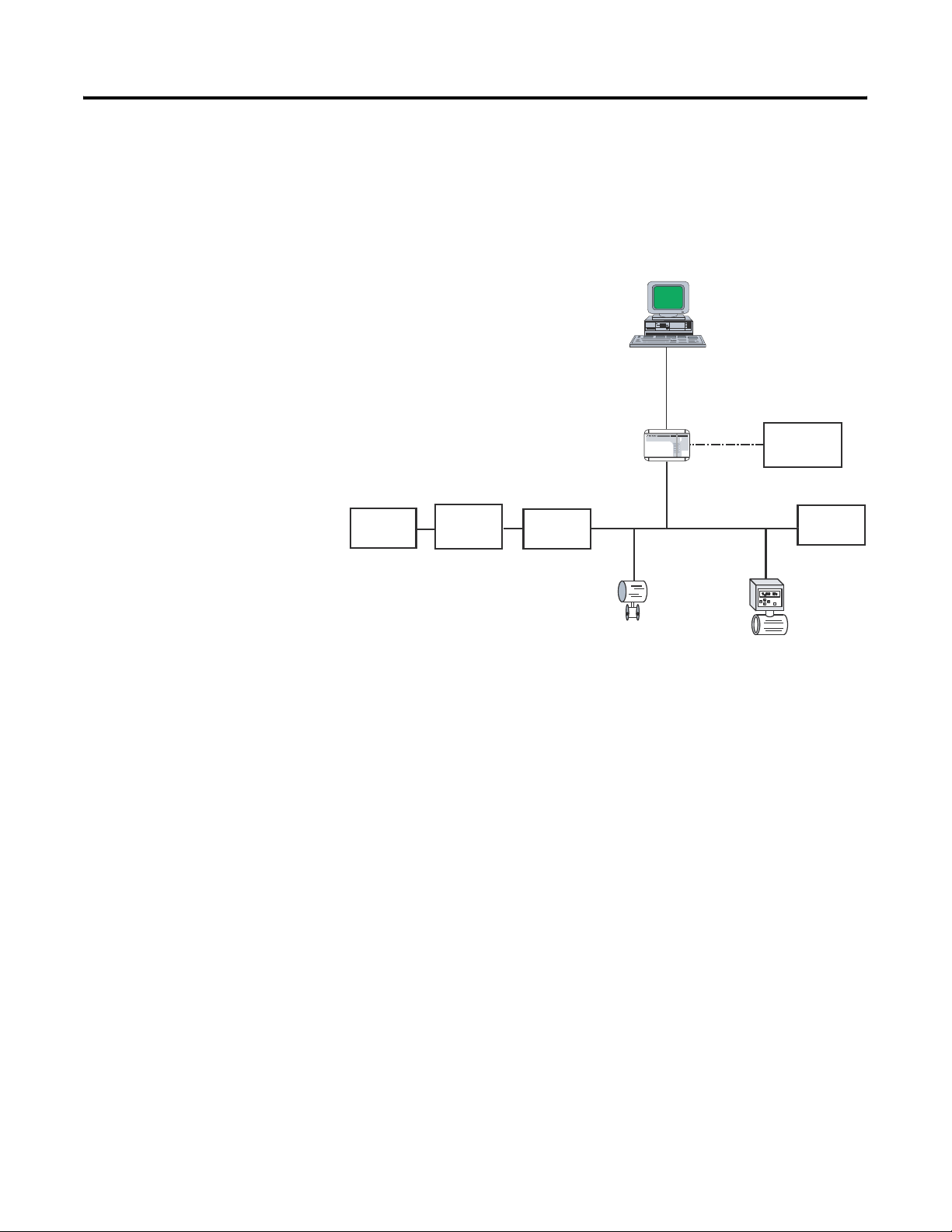

The following figure is a simplified diagram of a fieldbus system using

RSFieldbus.

Figure 2.1 Simplified Fieldbus Network HSE

RSFieldbus

HSE Network

FOUNDATION Fieldbus

H1

H1-1

H1

H1-2

FOUNDATIO N Fieldbus

H1

H1-3

Linking Device

H1

H1-4

STATUS

WDOG

BATT

NS 1

MODE

H1 Network

Field

Device

24V dc

Power Supply

Network

Terminator

Field

Device

Power

Supply

Power

Conditioner

Linking

Device

Network

Terminator

Note the relation of the HSE and H1 levels in the system.

Publication 1757-PM002A-EN-E - June 2006

Page 17

Set Up A System 2-7

Physical Media

Power Considerations

Fieldbus devices may be either powered from the segment (bus) or locally

powered, depending on the design. If at all possible, field devices should be

bus powered.

Power Supplies

Power supplies shall comply with IEC 61158-2 criteria and performance

requirements, with preferential consideration given to the low-power signal

option. We recommend using one power supply dedicated to the linking device

and any additional supplies dedicated toward the field devices.

Rockwell Automation manufactures a DIN rail mountable 1794-PS3 supply

that is Class 1, DIV2 compliant. It will supply +24VDC at 3 Amps.

Power Conditioning

If an ordinary power supply were used to power the fieldbus, the power supply

would absorb signals on the cable because it would try and maintain a constant

voltage level. For this reason, an ordinary power supply must be conditioned

for fieldbus use.

DC Power Supply

Putting an inductor between the power supply and the fieldbus wiring is a way

to isolate the fieldbus signal from the low impedance of the bulk supply. The

inductor lets in the DC power on the wiring, but it prevents signals from going

into the power supply.

One fieldbus power supply conditioner is required for each fieldbus network

segment (

Power conditioners should be redundant units that provide flawless transfer

from one unit to another. Primary and secondary sources should be

physically separated, not sharing a common backplane or AC source. Be

aware that power conditioners have limits on how much current they can

source.

Figure 2.2).

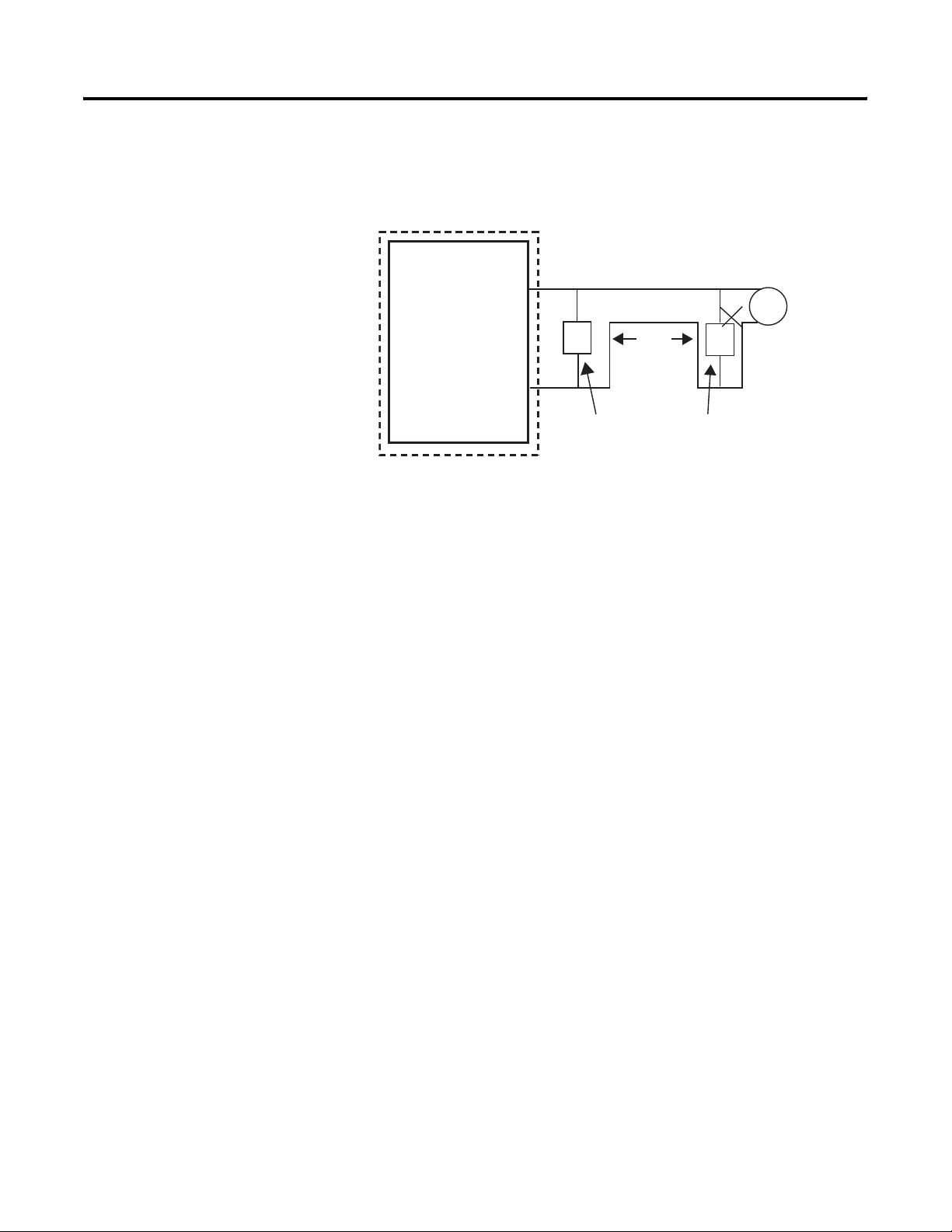

Figure 2.2 Power Supply With One Power Conditioner

Conditioner H1 Fieldbus

Publication 1757-PM002A-EN-E - June 2006

Page 18

2-8 Set Up A System

Additionally, power conditioners may have an internal terminator which

should be considered when placing terminators on the network.

Signal Wire Polarity

The combination signal/power wires have a plus (+) and minus (-) polarity

associated to the power conditioner outputs, which must be wired to the

appropriate terminals on the devices. Some devices are polarity insensitive,

meaning they still work if you connect the positive wire to the negative

terminal, and vice-versa.

Grounding

Follow all international, national and local codes for grounding and bonding

equipment. Above all, follow the manufacturer’s instructions and

recommendations for each device installed in a plant.

IMPORTANT

Signal wiring of the fieldbus segment cannot be grounded.

Grounding out one of the signal wires will shut down an

entire fieldbus network.

To prevent ground loops, a Fieldbus segment should only be grounded at one

point. This is usually done by grounding the cable shield at the control room

end of the segment.

Each process installation has a different requirement for grounding. Be sure

that the shield is electrically isolated from the transmitter housing and other

grounded fixtures.

Limiting Factors

Bus powered devices usually require 10-30ma of current and between 9-32

volts. The number of bus powered (two-wire) devices on a segment is limited

by the following factors:

• Output voltage of the fieldbus power supply

• Current consumption of each device

Publication 1757-PM002A-EN-E - June 2006

• Location of the device on the network/segment

• Location of the fieldbus power supply

• Resistance of each section of cable

• Minimum operating voltage of each device

Page 19

Set Up A System 2-9

• Additional current consumption due to one spur short-circuit fault

(10ma)

The length of a fieldbus wiring system and the number of devices on a

network/segment are limited by the power distribution, attenuation, and signal

distortion. Refer to ISA 50.02 for the limitations on cable length.

Fieldbus Network Topologies

A network topology refers to the shape and design of a fieldbus network.

There are basically three types of network topologies supported: tree; bus with

spurs; and daisy chain. The daisy chain network, however, is not

recommended.

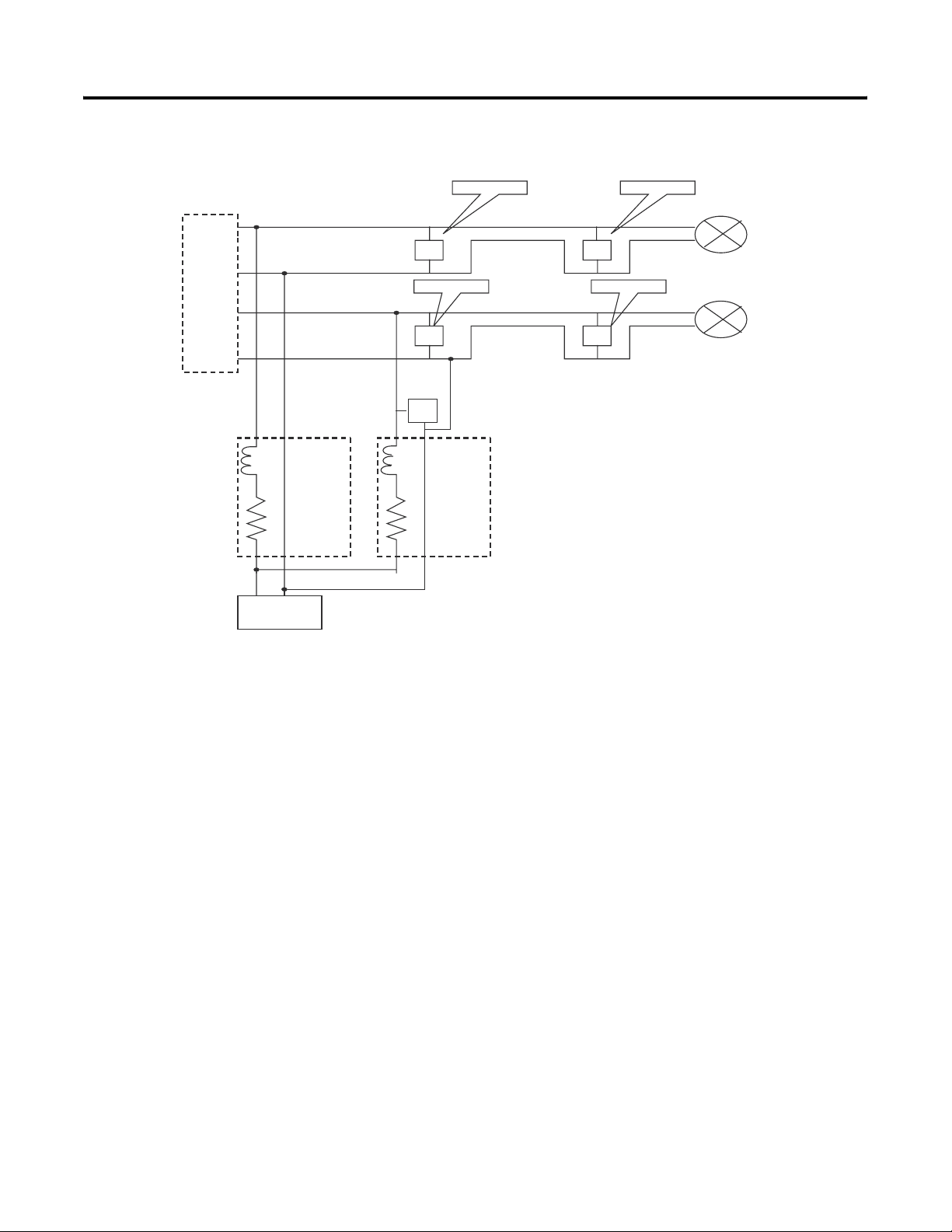

The two port linking device shown below in Figure 2.3 is an example of a

simple fieldbus network on each H1 port. Notice that there are two

terminators and one power conditioner per fieldbus segment. The terminators

should be placed at the ends of the trunk.

IMPORTANT

You can use a maximum of two terminators per bus

segment.

Publication 1757-PM002A-EN-E - June 2006

Page 20

2-10 Set Up A System

Figure 2.3 Rockwell linking device with a Simple Two-Port

Fieldbus Network

Terminator Terminator

Wire Pair

TwoPort

Linking

Device

Power

Conditioner

Power Supply

TT

Fieldbus Device

Terminator Terminator

Wire Pair

TT

Fieldbus Device

T

Power

Conditioner

Tree Topology - Chicken Foot

This topology consists of a single fieldbus segment connected to a common

junction box to form a network. A tree topology is practical if the devices on

the same segment are well separated but in the general area of the junction

box. It allows maximum flexibility when configuring and assigning devices to

networks/segments, and it is the preferred topology for reuse of existing

wiring.

(1)

Figure 2.4 is an example of a junction box at the end of a trunk. Remember

that a trunk is the longest cable path between any two devices on the network.

Since it is at the end of the trunk, the terminator within the junction box is

activated. The spurs that are shown on the bottom of the junction box must be

taken into consideration using the maximum spur length table (

Table 2.1 on

page 13).

(1)

FF Engineering Guide (6.1.2)

Publication 1757-PM002A-EN-E - June 2006

Page 21

Figure 2.4 Tree Topology (Chicken Foot)

Junction Box

Set Up A System 2-11

1 Linking

ce

T

Tru nk

Note: The ìTî is for Terminator.

T

Publication 1757-PM002A-EN-E - June 2006

Page 22

2-12 Set Up A System

Figure 2.5 and Figure 2.6 are examples of chicken foot topologies using

Relcom Blocks.

Figure 2.5 Tree Topology (Chicken Foot) Using Relcom Blocks

Isolated

Terminator

Block

Expansion

Block

To H1 Linking

Device

TT

Trunk

Power

Conditioner

D/1 D/3D/2 D/4 D/5 D/6 D/7

Figure 2.6 Relcom Blocks in a Chicken Foot or Star Fieldbus

Topology

Bus With Spurs Topology

This topology consists of fieldbus devices that are connected to a multi-drop

bus segment through a length of cable called a spur. A bus with spurs topology

is technically acceptable but not generally a good economic choice.

Figure 2.7 below is an example of a bus with spurs topology. Since it is at the

end of the trunk, the junction box on the right has its internal terminator

enabled.

Publication 1757-PM002A-EN-E - June 2006

ng

e

T

Figure 2.7 Pepperl + Fuchs F4-JB-I1.CGS FieldConnex

Junction Boxes

Junction Box

Junction Box Junction Box

Page 23

Spur Wire Length Calculations

Spur lengths can vary from 1 meter to 200 meters. If you have a choice about

spur length, the general rule is that the shorter the spur, the better. A spur less

than 1 meter is considered a splice.

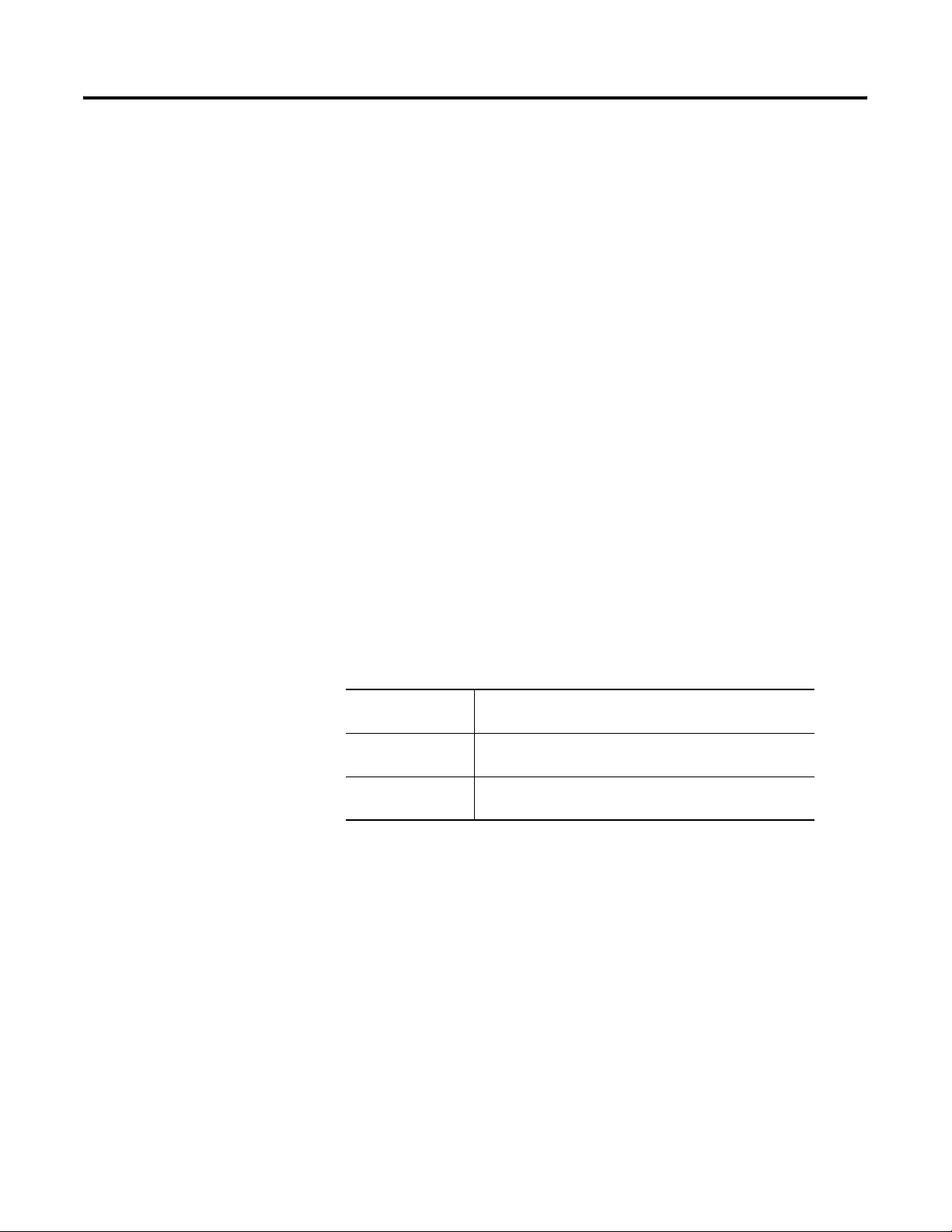

lengths for devices.

Table 2.1 Recommended Maximum Spur Length Table m(ft)

Set Up A System 2-13

Table 2.1 below lists recommended spur

Total Devices 1 Device per Spur 2 Devices Per

Spur

25-32 1(3) 1(3) 1(3) 1(3)

19-24 30 (98) 1(3) 1(3) 1(3)

15-18 60 (197) 30 (98) 1(3) 1(3)

13-14 90 (295) 60 (197) 30 (98) 1(3)

1-12 120 (394) 90 (295) 60 (197) 30 (98)

Note: These lengths are recommended, not required

3 Devices per

Spur

4 Devices per

Spur

Shielding

For optimal performance, fieldbus cables should be shielded. Common

multi-conductor (multi-core) “instrument” cable can be used. It has one or

more twisted pairs, an overall metallized shield, and a shield wire.

The instrument shield should be terminated at the host (power conditioner)

end of the network in a marshalling cabinet and should not be connected to

ground at any other place. If a multiple home run cable goes to a fieldbus

junction box, do not attach the cable shield wires from different networks

together. This creates ground loops and noise on the network. The most

common problems with fieldbus networks are usually due to noise, which can

occur if you have the wrong wiring, improper grounding, and/or bad

connections.

A cable signal encountering a discontinuity, such as a wire open or short,

produces a reflection. The reflection is a form of noise that distorts the

original signal. A terminator is used at the ends of a fieldbus cable to prevent a

reflection.

Publication 1757-PM002A-EN-E - June 2006

Page 24

2-14 Set Up A System

F

F

F

Figure 2.8 Proper Shielding for a Tree Network

FFLD

T

T

All Shields

Tied Here

Signal Quality

When a fieldbus network’s signal quality is poor, it can cause intermittent loss

of communication to devices, unreasonably long downloads, and lost data. The

following components are critical to achieving good signal quality:

• Shielded two wire cable, preferably specifically designed for fieldbus.

The type of cable will determine overall length of the trunks and drops.

Publication 1757-PM002A-EN-E - June 2006

• Terminators. Terminators reduce noise on segments caused by signal

reflections at the end of an open cable. One terminator on each end of

the H1 trunk is needed for proper performance.

• Power conditioners are mandatory between a supply and the H1 trunk,

which can deliver 9-32 V DC consistently out of the conditioner when

under the appropriate load from the cable resistance and while powering

the devices. One power supply, or redundant power supplies designed

for fieldbus, can be used.

• In areas vulnerable to lightning, lightning arresters should be installed.

The four issues above along with proper shielding and grounding will ensure

proper signal qualities.

Page 25

Set Up A System 2-15

Protocol Analysis

There are a number of ways in which you can verify that the network you have

set up will perform properly. A protocol analyzer is a tool that allows you to

test for the content of the message sent, what the messages mean, and what

sequence the fieldbus devices talk to each other. It should be noted, however,

that a protocol analyzer is an advanced tool with a complex range of functions.

Publication 1757-PM002A-EN-E - June 2006

Page 26

2-16 Set Up A System

Fieldbus Network Testers

Other testers are used to monitor and characterize network signals. The

Relcom Fieldbus Network Monitor (FBT-3) can be used to examine the

(1)

operation of a live fieldbus network, without interfering with its operation.

The FBT-3 will verify the DC voltage on the network and check how noisy the

network is. It can also be used to measure peak noise levels, framing errors, the

number of transmitters on the wire, and what the signal level of the weakest

field transmitter is. In addition, with the FBT-3 you can see the total number of

devices up and running, and what devices are left on the network. The FBT-3

can be purchased from Relcom (

www.relcominc.com).

Publication 1757-PM002A-EN-E - June 2006

(1)

FBT-3 Manual

Page 27

Set Up A System 2-17

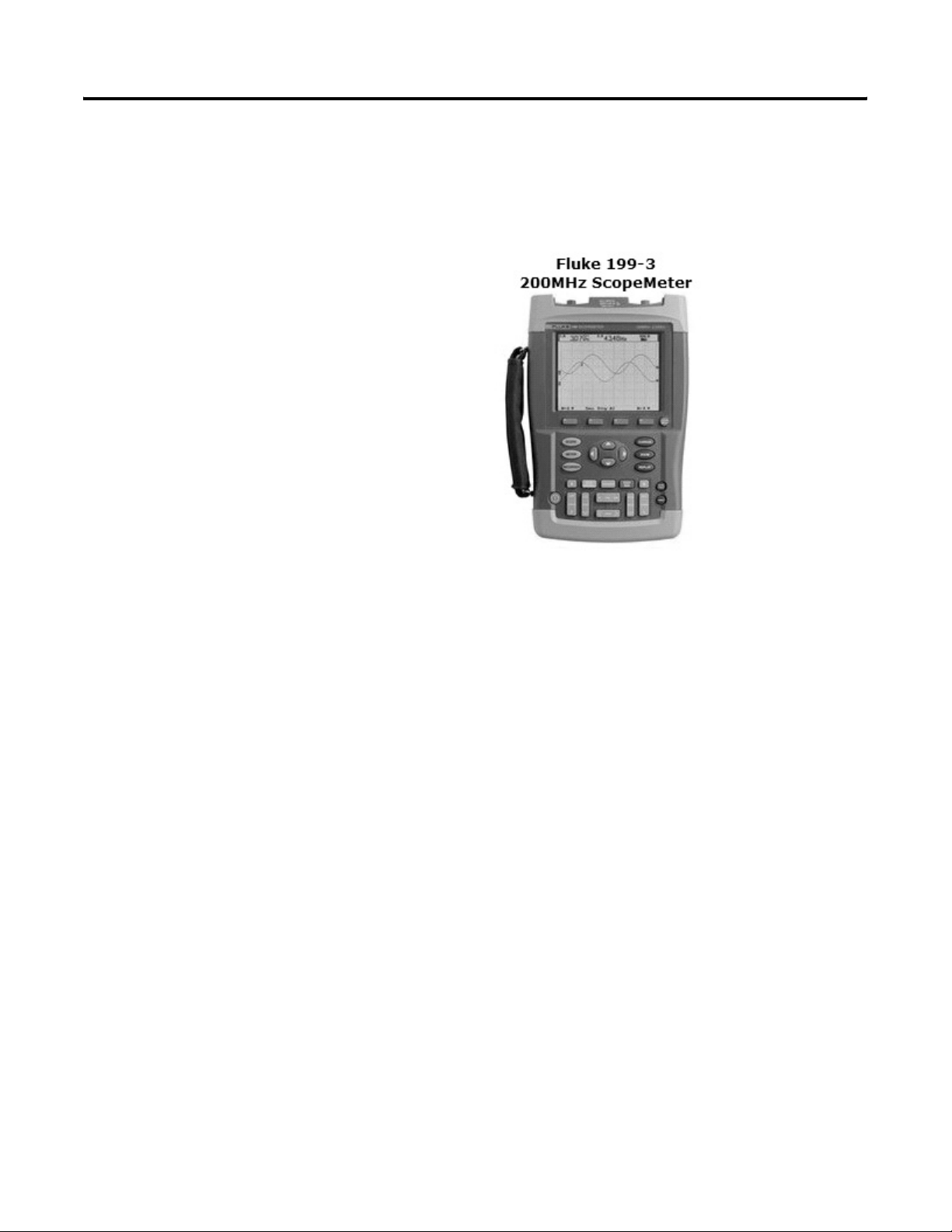

Another way of testing the signal quality of a network is to use an oscilloscope.

We recommend a hand-held battery-operated unit because of its small size and

ease of use. The Fluke 199-3 ScopeMeter is one such scope.

Figure 2.9 Fluke 199-3 200MHz ScopeMeter

Other scopes that can be used include the TPI-E1505, the Extech-381275

(

www.professionalequipment.com), and the Techtronix THS700 Series

(www.tek.com).

Signal Analysis

Oscilloscopes, whether portable or stationary, from 50MHz to 1GHz, can be

used to capture and examine the waveform. The power supply waveform

should be a +/- 0.75 VDC to +/- 1.00 VDC square wave riding on the 9 V

DC to 32 V DC steady power supply with < 0.10 V DC ripple. The sharper

the rising and falling edges of the waveform, the better the data transfer. The

physical media of a system will determine what shape the waveform takes.

The signal is a current modulated ±10mA signal on a 50 test load. This

generates a 1.0 Vpp signal. A valid signal can range from 150mVpp up to

1.0Vpp and noise must not exceed 75mvpp (

Figure 2.10).

Publication 1757-PM002A-EN-E - June 2006

Page 28

2-18 Set Up A System

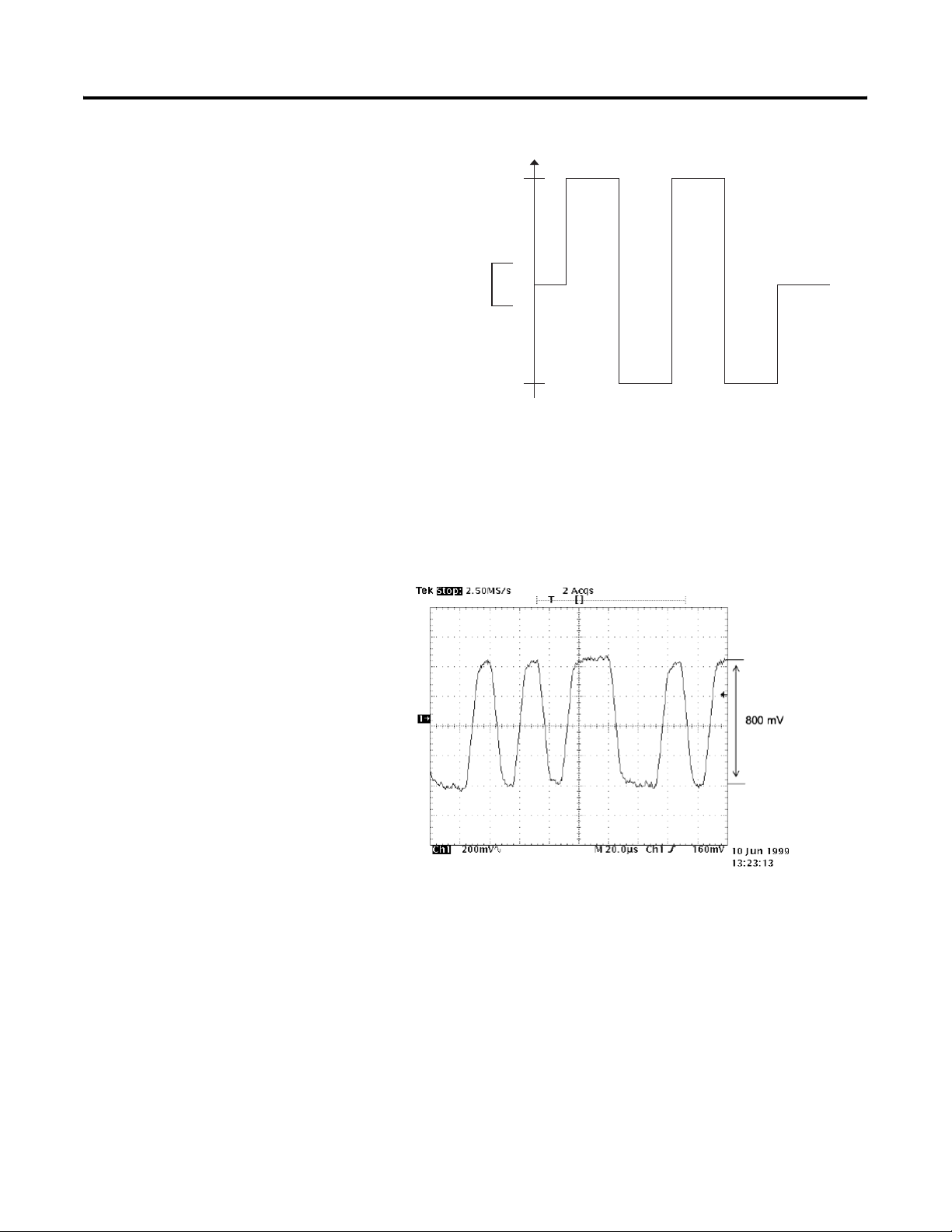

Figure 2.10 An Ideal Fieldbus Communications Signal

75-500 mv

Max Noise

75 mv (pk-pk)

75-500 mv

Good Network Scope Display

In order to analyze a fieldbus network signal, you must know what constitutes

a good signal versus a bad one.

consisting of two terminators.

Figure 2.11 represents a normal signal

Figure 2.11 Good Network Signal

(1)

Publication 1757-PM002A-EN-E - June 2006

(1)

FF Engineering Guide (11.4.3)

Page 29

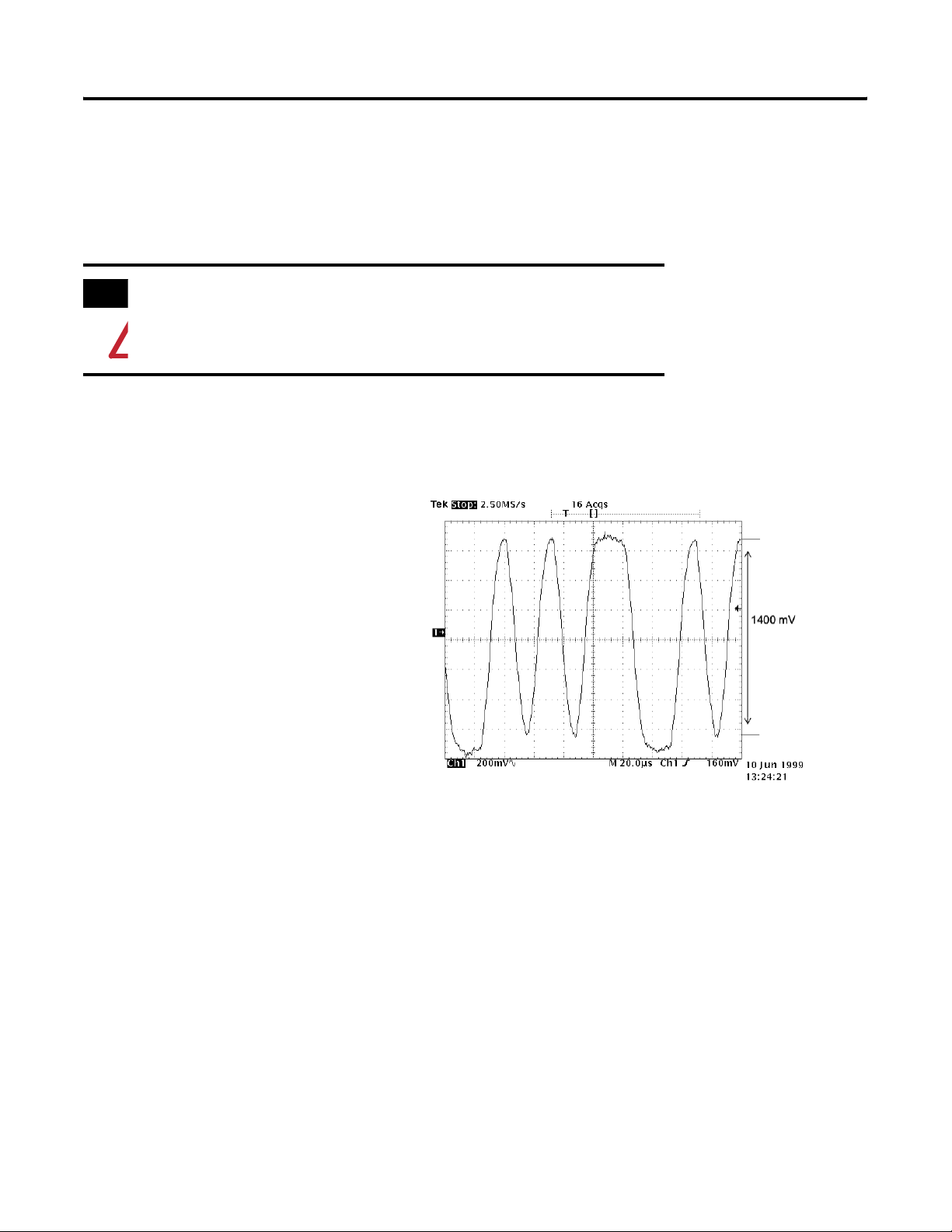

Bad Network Scope Display

R

Bad network signals can inhibit the performance of your network. A common

reason for bad signals is the addition of one or more unnecessary terminators

in a network.

Remember, there can be only two terminators per bus segment.

WA

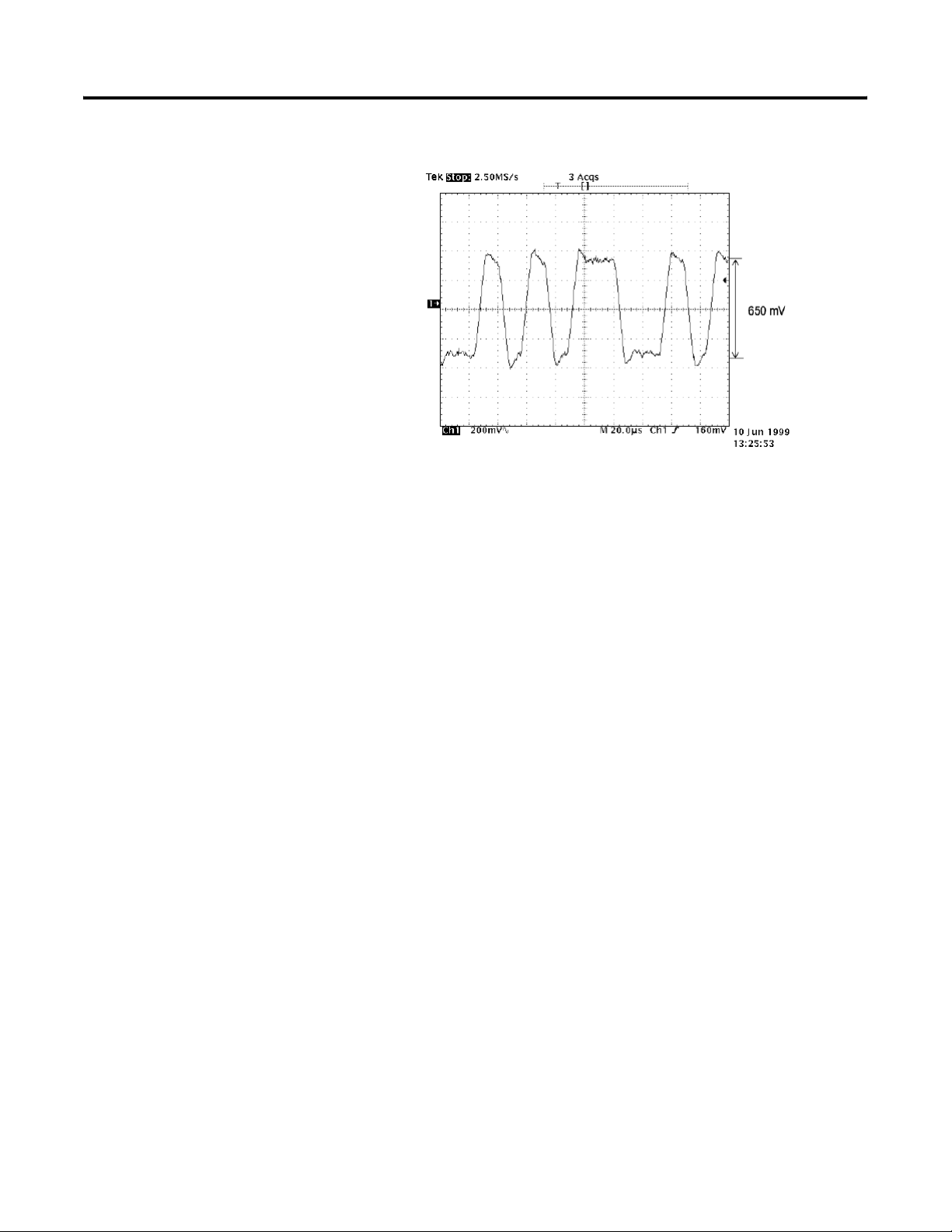

Figure 2.12 shows a bad signal due to only one terminator in a system, while

Figure 2.13 shows a bad signal due to one extra terminator (3 total).

Set Up A System 2-19

Figure 2.12 Bad Network Signal Due to One Terminator

(1)

(1)

11.4.3 FF Engineering Guide

Publication 1757-PM002A-EN-E - June 2006

Page 30

2-20 Set Up A System

Network Basics

Figure 2.13 Bad Network Signal Due to Three Terminators

When using the linking device, there are two networks that must be

considered: the HSE network and the H1 network.

(1)

HSE

HSE stands for High Speed Ethernet. HSE is the Fieldbus Foundation's

backbone network running Ethernet and IP. An HSE field device is a fieldbus

device connected directly to a High Speed Ethernet (HSE) fieldbus. Typical

HSE field devices include HSE linking devices, HSE field devices running

function blocks (FBs), and host computers.

IP Addresses

Every device that communicates over the Internet is assigned an IP address

that uniquely identifies the device and distinguishes it from other devices on

the Internet. An IP address consists of 32 bits, often shown as 4 octets of

numbers from 0-255 represented in decimal form instead of binary form.

For example, the IP address 168.212.226.204 in binary form is

10101000.11010100.11100010.11001100.

It is easier to remember decimals as opposed to binary numbers, so we use

decimals to represent the IP addresses when describing them. However, the

(1)

Additional material for ëPhysical Mediaí section taken from FF Engineering

Guidelines, Relcom's Fieldbus Wiring and Test Solutions Guide

(WWW.Relcominc.com), and Foundation Fieldbus Project Implementation

Considerations (Power point Slide by John Yingst at Honeywell)

Publication 1757-PM002A-EN-E - June 2006

Page 31

Set Up A System 2-21

binary number is important because it will determine which class of network

the IP address belongs to.

An IP address consists of two parts, one identifying the network and one

identifying the node, or host. The class of the address determines which part

belongs to the network address and which part belongs to the node address.

All nodes on a given network share the same network prefix, but must have a

unique host number.

Class A Network: Binary addresses start with 0, therefore the decimal

number can be anywhere from 1 to 126. The first 8 bits (the first octet)

identify the network and the remaining 24 bits indicate the host within

the network.

An example of a Class A IP address is 102.168.212.226, where "102"

identifies the network and "168.212.226" identifies the host on that

network.

Class B Network: Binary addresses start with 10, therefore the decimal

number can be anywhere from 128 to 191. (The number 127 is reserved

for loopback and is used for internal testing on the local machine.) The

first 16 bits (the first two octets) identify the network and the remaining

16 bits indicate the host within the network.

An example of a Class B IP address is 168.212.226.204, where "168.212"

identifies the network and "226.204" identifies the host on that network.

Class C Network: Binary addresses start with 110, therefore the

decimal number can be anywhere from 192 to 223. The first 24 bits (the

first three octets) identify the network and the remaining 8 bits indicate

the host within the network.

An example of a Class C IP address is 200.168.212.226, where

"200.168.212" identifies the network and "226" identifies the host on

that network.

Class D Network: Binary addresses start with 1110, therefore the

decimal number can be anywhere from 224 to 239.

Class D networks are used to support multicasting.

Class E Network: Binary addresses start with 1111, therefore the

decimal number can be anywhere from 240 to 255.

Class E networks are used for experimentation. They have never been

documented or utilized in a standard way

.

Publication 1757-PM002A-EN-E - June 2006

Page 32

2-22 Set Up A System

T

Default Configuration

The default configuration of the linking device is to use DHCP and a BootP

server.

The Dynamic Host Configuration Protocol (DHCP) is an Internet protocol for

automating the configuration of computers that use TCP/IP. DHCP can be

used to automatically assign IP addresses, to deliver TCP/IP stack

configuration parameters such as the subnet mask and default router, and to

provide other configuration information

The Rockwell BOOTP/DHCP Server (BOOTP) is a standalone program that

combines the functionality of standard BOOTP software with DHCP

software. The linking device is shipped with BOOTP enabled.

See the linking device Installation Guide for the

DHCP/BootP procedure.

(1)

.

Set PC to Correct Subnet

The linking device and the PC Host must be on the same sub-net.

If the PC and the linking device are not on the same subnet, a switch is needed

to connect the two. Putting them on the same subnet saves this added step.

For example, if the linking device IP address is 192.168.164.99, the PC Host

must be 192.168.164.xxx, where xxx is between 1 and 255.

Use RSLinx To Find the IP Address of the linking device

RSLinx is a complete 32-bit product family that links Allen-Bradley networks

and devices to Microsoft Windows applications. These range from device

programming and configuration applications to HMI applications, such as

RSView32, to your own data acquisition applications using Microsoft Office,

Web pages, or Visual Basic. RSLinx also incorporates advanced data

optimization techniques and contains a set of diagnostics. RSLinx is an OPC

Data Access Compliant Server and a DDE server.

To find the IP address of an linking device that is on the same sub-net as the

PC Host using RSLinx:

(2)

Publication 1757-PM002A-EN-E - June 2006

1. Select Start ⇒ Programs ⇒ Rockwell Software ⇒ RSLinx ⇒

RSLinx.

The RSLinx window opens.

(1)

dhcp.org

(2)

RSLinx help file

Page 33

Set Up A System 2-23

2. In the RSLinx window, select Communications from the drop-down

list and Configure Drivers from the menu.

3. Select Ethernet IP Driver from the drop-down menu

4. Click Add New.

5. Click OK (to use the default driver name).

Publication 1757-PM002A-EN-E - June 2006

Page 34

2-24 Set Up A System

6. Click OK to use the default configuration settings as shown.

The AB-ETHIP-1 Driver should show “Running.”.

7. Close the configuration window.

8. Select Communications from the drop-down list and RSWho from

the menu.

9. Expand the AB-EtherIP-1 driver to see the devices on the network.

In this case, there are two linking devices.

Publication 1757-PM002A-EN-E - June 2006

What Do I Do If There’s No DHCP?

A possible cause for the lack of a DHCP is a binding socket error, in which

another application is already using the DHCP server.

Page 35

Set Up A System 2-25

However, it is still best to call RA Tech Support (see page 1-6) if this situation

occurs, and for other problems concerning DHCP.

H1

H1 Fieldbus is a digital, serial, multidrop data bus for communication with

industrial devices or systems. The Physical Layer provides for transparent

transmission of data between Data Link Layer entities across physical

connections.

The Physical Layer receives data from the Data Link Layer, adds preamble and

delimiters, provides encoding and transmits the resulting physical signals to the

wire medium. Signals are then received at one or more other devices and

decoded and stripped of preamble and delimiters before being passed to the

Data Link Layer of the receiving device(s).

Figure ?.?? shows a physical realization of a simple H1 network using Relcom

physical media. Please note that the RelCom FCS-PCT2 incorporates two (2)

terminators. The power supply may be any good 24 VDC supply that meets

the current requirements for the number of devices. Additional FCS-Es could

be added if more devices are added to the network.

Device Addressing

When installing instruments for the first time, it is recommended that each

instrument be installed one at a time and that you address the instruments in

succession (one after the other). Because like instruments have the same H1

foundation fieldbus address from the factory, you will only be able to see one

device. This condition will disable the installer from knowing which device he

is actually programming in the plant.

Also, the installer must decide which address to start with for each H1 node.

Currently, the linking device (address 10) addresses devices consecutively

starting at 18. Other Rockwell Interfaces, like the CN2FF (address 16), starts

numbering at 17. The FIM starts numbering at address 18.

Number of Devices per H1 Segment

The specified number of devices per H1 is 32. However, it should be noted

that most manufacturers would agree that the actual maximum limit to the

number of devices on the H1 is approximately 16. This is due to voltage drop

and the physical media that the system uses.

Rockwell Automation feels that the H1’s design is optimized by having 6 to 8

devices per H1 network. This optimized limit is mainly due to physical media,

the time required for each device to communicate, the extra bandwidth

Publication 1757-PM002A-EN-E - June 2006

Page 36

2-26 Set Up A System

required to configure the H1 network, and the ability for the network to

perform necessary housekeeping.

IMPORTANT

Intrinsic safety barriers cause the maximum device number

per H1 to change to 4 to 6 devices, depending on the

power consumption of the devices installed and the

manufacturers’ specifications for both the barrier and the

transmitter.

Scheduling

Scheduling is done automatically.

The linking device is the LAS when active and running, but each H1 should

have at least one Link Master capable device within its network so it can

become the backup Link Master/LAS if the linking device is reset or fails to

keep the H1 network running.

Getting Devices in the Live List

After the device is connected to an active H1 network, the status of the device

in the H1 Live List should be monitored. Instructions for viewing the LiveList

can be found in the RSFieldbus User Manual. In addition, the manual explains

what to do if the device does not show up in the Live List correctly. For

additional troubleshooting tips involving the Live List, see page

5-5.

Publication 1757-PM002A-EN-E - June 2006

Device Tags

(1)

Device tags are names that you assign to devices. A device tag is assigned to

the device when it is commissioned and (for most device states) retains the tag

in its memory when it is disconnected. The network address is the current

address that the fieldbus is using for the device.

The Fieldbus Foundation uses node addresses in the range 0-255. Each vendor

allocates the node numbers in a way that is somewhat unique. They all have

reserved low numbers for overhead and host interfaces, and a group above

that for live field devices, and some higher numbers for spares.

Addresses used by FF are in accordance with the following ranges:

• 0-15 are reserved.

• 16-247 are available for permanent devices. Some host systems may

further subdivide this range. This range is typically shortened for

efficiency.

(1)

FF Engineering Guide (8.2.1)

Page 37

Set Up A System 2-27

• 248-251 are available for devices with no permanent address such as

new devices or decommissioned devices.

• 252-255 are available for temporary devices, such as handhelds.

Naming Conventions for Devices

Each FOUNDATION fieldbus device must have a unique physical device tag.

The device tag shall be used for the device diagnostic alarm faceplate.

Every FOUNDATION fieldbus has a 32-byte unique identifier, which is a

hardware address very similar to MAC addressing and consists of the

following:

• 6-byte manufacturer code

• 4-byte device type code

• 22-byte serial number

Things to Consider When Setting Up a System

These identifiers uniquely distinguish the device from all others in the world.

The manufacturer code is universally administered by the Fieldbus

Foundation, which eliminates the potential for duplication. The device

manufacturer assigns the device type code and sequential number. When

devices are shipped or configured as spares, this is the default device tag. The

FOUNDATION fieldbus device tag shall match the instrument tag Indicated

on P&ID.

• For greater reliability, at least one Link Master capable device should be

installed on each H1 network as a backup LAS. Please design for this.

• Redundant transmitters should be installed in separate H1 networks,

preferably in separate linking devices.

• Each H1 should have a seperate power supply and conditioner.

• Each linking device should have a separate power supply.

• Factory Acceptance Tests (FATs) can be completed on a fieldbus system

to verify graphics, database, power, communications, and other system

integration features and functions. For more information on FATs, see

the System Engineering Guidelines, publication AG-181

Additional Resources

There are a number of resources available should you encounter difficulties

with your fieldbus application.

Publication 1757-PM002A-EN-E - June 2006

Page 38

2-28 Set Up A System

Web Sites

• Rockwell Automation

– External:

http://domino.automation.rockwell.com/applications/gs/region/gt

swebst.nsf/pages/Process_Solutions_Home

– Internal:

http://rain.ra.rockwell.com (select Process Solutions

from the A-Z menu)

• FOUNDATION Fieldbus:

http://www.fieldbus.org/

• Tech Support:

– For Knowledge-base information, go to the Tech support Web site:

http://support.rockwellautomation.com/ (select Knowledge

Bases)

– For telephone support call: 440-646-5800

Documents

For a list of additional support documentation that may be useful in

conjunction with this manual, see the

page P-2.

Related Documentation section on

Publication 1757-PM002A-EN-E - June 2006

Page 39

Basic Function Blocks

Chapter

3

In This Chapter

Purpose of this Chapter

Basic Function Blocks

For See Page

Purpose of this Chapter 3-1

Basic Function Blocks 3-1

Put Blocks in Auto 3-2

Block Errors 3-4

Naming Conventions 3-4

Differences Between

Configuration and Calibration

Initial Configuration: Virtual

Communication Relationships

This chapter deals with the basic usage of function blocks within transmitters

and the minimum configuration needed to make these transmitters active.

Basic function blocks are needed to make a transmitter functional and readable

within RSFieldbus. These blocks are the Resource Block (RES), Transducer

Block (XDCR), Analog Input Block (AI), Analog Output Block (AO), Digital

Input Block (DI), and Digital Output Block (DO).

3-5

3-6

Not all transmitters have these function blocks, but the majority of them do.

Resource Block

The Resource Block is the base block needed in all transmitters before the

transmitter can become active. It holds data specific to the transmitter.

The important parameter within the RES is the MODE_BLK. Putting this

parameter to AUTO allows the function block to be active upon download.

1 Publication 1757-PM002A-EN-E - June 2006

Page 40

3-2 Basic Function Blocks

Transducer Block

The Transducer Block acts as the connection between the physical world of

wires and circuit boards to the electronic world of RSFieldbus. The XDCR

allows the I/O blocks to access data on the wire and bring it into RSFieldbus

to be used for control loops.

The important parameters within the XDCR are MODE_BLK and

TERMINAL_NUMBER. Putting the MODE_BLK to AUTO allows the

function block to be active upon download.

TERMINAL_NUMBER reflects the physical wiring on a transmitter. Some

transmitters have multiple inputs or outputs, so the parameter links the

function block to the actual physical wires that have been landed on that

terminal.

Input/Output Blocks

The I/O Blocks take the data retrieved from the transducer links and makes it

available to RSFieldbus for use.

The important parameters within the I/O blocks are the MODE_BLK and

CHANNEL. Putting the MODE_BLK to AUTO allows the function block

to be active upon download.

CHANNEL is the I/O block equivalent of the XDCR’s

TERMINAL_NUMBER. When the CHANNEL parameter is equal to the

TERMINAL_NUMBER, data will flow from the physical transmitter wires to

the I/O blocks and from the I/O blocks to the transmitter wires, eventually

then to the device.

There are several things to keep in mind with regards to function block use.

The sheer volume of individual transmitters available makes listing them all

virtually impossible. The function blocks discussed here will allow a user to put

a device on the wire, access it through RSFieldbus, and retrieve data. The

actual use of these and all functions blocks are based on the individual vendor.

For answers to more specific questions, refer to your vendor’s manual in

regards to how best to use these and any other functions blocks.

Put Blocks in Auto

Publication 1757-PM002A-EN-E - June 2006

There are a few blocks that need some additional work in order to get them to

go into Auto. The Analog Output, Digital Output, APID, Splitter, and

Setpoint Generator all have an IMAN status in the MODE_BLK parameter.

This status is in response to the parameter BKCAL_ (OUT/IN) being used. It

has to do with the handshaking between two blocks that need to be connected

before the IMAN can be cleared.

Page 41

Basic Function Blocks 3-3

To look at how to clear IMAN from individual blocks, refer to the Function

Block Manual, page 1-14.

Publication 1757-PM002A-EN-E - June 2006

Page 42

3-4 Basic Function Blocks

Block Errors

Naming Conventions

The BLOCK_ERR parameter gives a non-specific reason for the block being

in error. The most common errors have to do with a block being Out Of

Service. There are various other block-specific reasons for certain blocks to be

in error, including ranges being required and logical parameters needing to be

set.

To find a specific error given by the BLOCK_ERR parameter, reference the

function block in the Function Block Manual, or your specific vendor’s

manual.

When discussing naming conventions, the standard for the facility takes

precedence. However, when naming devices on your H1, one should try to

incorporate either the device type (temperature transmitter, pressure

transmitter) or the serial number of the device within the name.

Publication 1757-PM002A-EN-E - June 2006

When a device first comes up on the live list and makes the connection to

RSFieldbus, the ID field contains Device Description (DD) information. The

specific serial number that is sought is in the last 4 numbers of the string.

These numbers are the unique serial number for that device. It is this number

that we recommend be incorporated with the tag name somewhere.

Page 43

Basic Function Blocks 3-5

s

Differences Between Configuration and Calibration

Definition of Calibration

Calibration is the process of adjusting certain device parameters in order that

the physical quantities measured meet an established standard for accuracy.

Calibration Parameters in the Transducer Block

Transducer Blocks are used to configure devices. Transducer Blocks decouple

Function Blocks from the local input/output functions required to read

sensors and command output hardware. They contain information such as

calibration data and sensor type. Calibration parameters are located in the

Transducer Function Block because the Transducer Function Block is the

interface between the physical measuring unit (I/O Subsystem) and the other

function blocks.

Definition of Configuration?

Configuration is the process of setting parameters in function blocks so that

information processed from the I/O Subsystem in the Transducer Block is

made available to other function blocks.

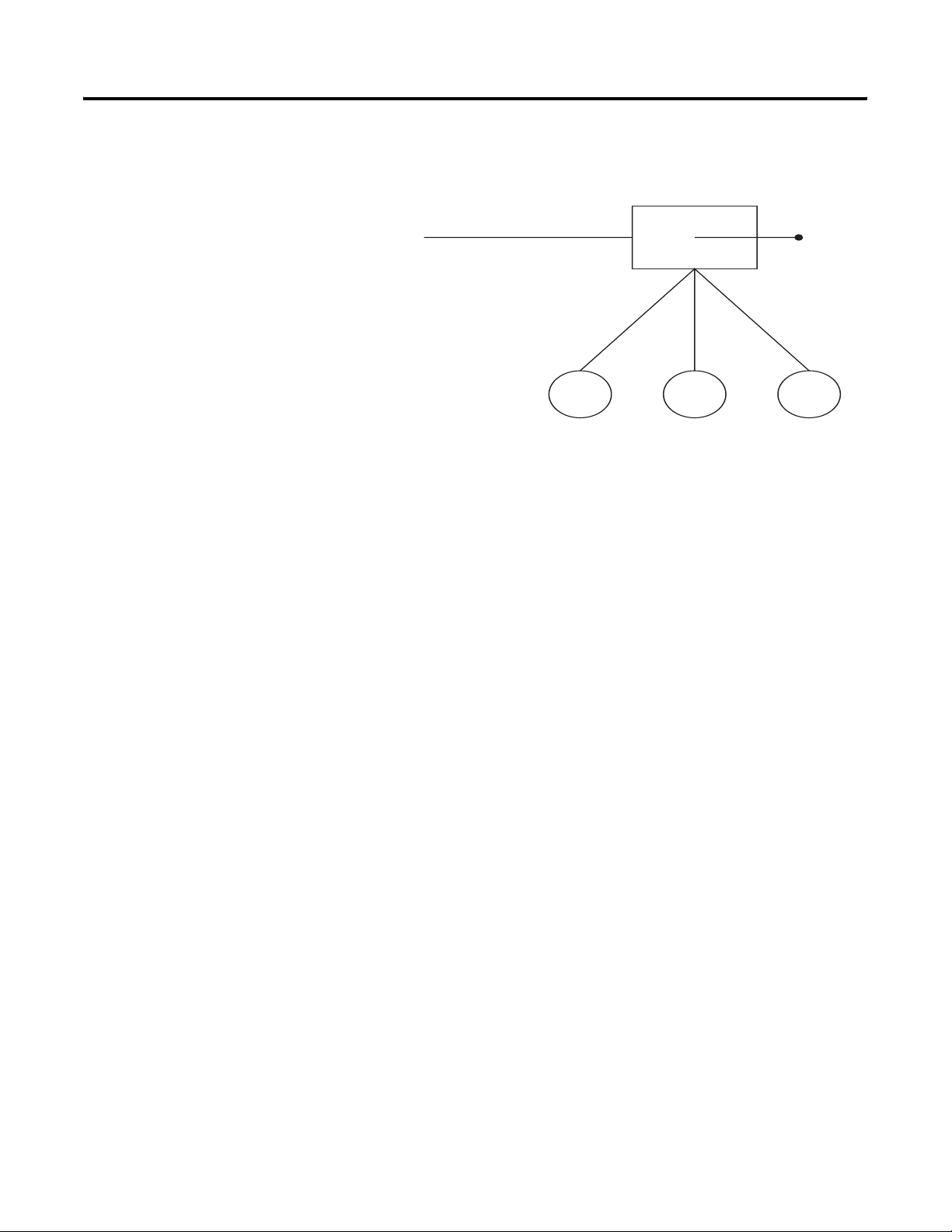

Relationship of the Transducer to Other Input Function Blocks

/O

ubsystem

Input

Transducer

Block

Manufacturer

Specific

Channel

Input Snap of

Transducer

Block

Outputs

Block

Algorithm

Output

Parameter

Publication 1757-PM002A-EN-E - June 2006

Page 44

3-6 Basic Function Blocks

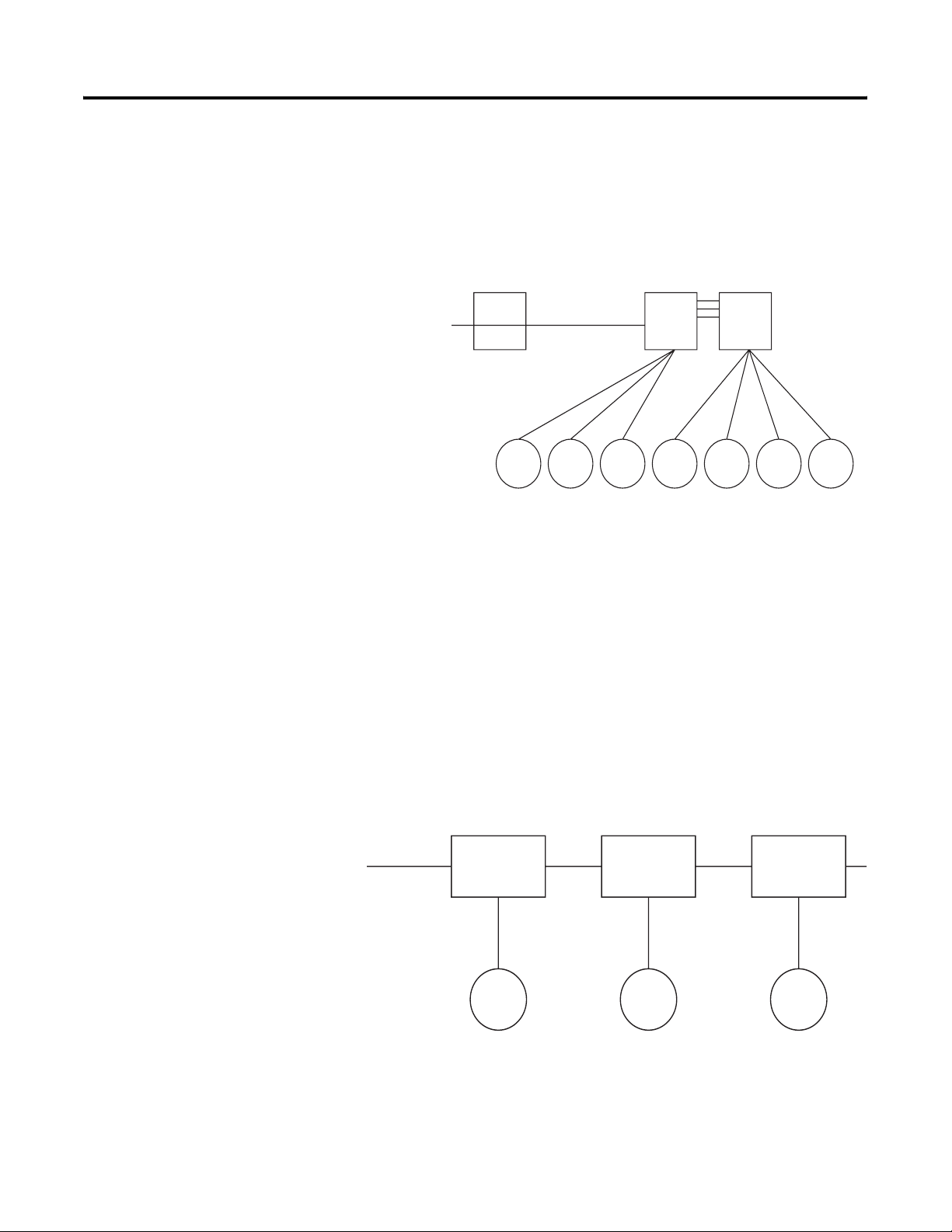

m

Relationship of Output Function Blocks to the Transducer

ut

ameters

Block

Algorithm

Output Snap

of Transducer

Block

Inputs

Channel

Output

Transducer

Block

Manufacturer

Specific

I/O

Subsyste

Initial Configuration: Virtual Communication Relationships

Virtual Communication Relationships (VCRs) are communication links on an

H1 network. A total of 128 VCR’s are possible within the linking device, and

these VCRs are restricted to 32 per H1 channel. This is further restricted to 16

VCRs going to the Control Logix processor from H1 devices and publishers,

and 16 VCRs coming from the Control Logix processor to H1 devices and

subscribers.

These restrictions limit the number of inputs and outputs within an H1 line.

However, there is no restriction on the type of signals. They can all be analog,

all discrete, or a mix of the two. The only restriction is the 16 publisher and 16

subscriber limits.

If the VCR limit is exceeded, a download will still be permitted, although when

the download reaches the 17

16 VCR’s will still be in place, but the 17

th

VCR, a “download failure” will occur. The first

th

will not exist.

VCR Classes

The Foundation Fieldbus specification Fieldbus Access Sublayer (FF-875-1.4)

defines three classes of Virtual Communication Relationships that are possible

for communications with an H1 field device. These classes are:

Publication 1757-PM002A-EN-E - June 2006

• BNU: Buffered Network-Scheduled Unidirectional

• QUU: Queued User-triggered Unidirectional

Page 45

Basic Function Blocks 3-7

• QUB: Queued User-triggered Bidirectional

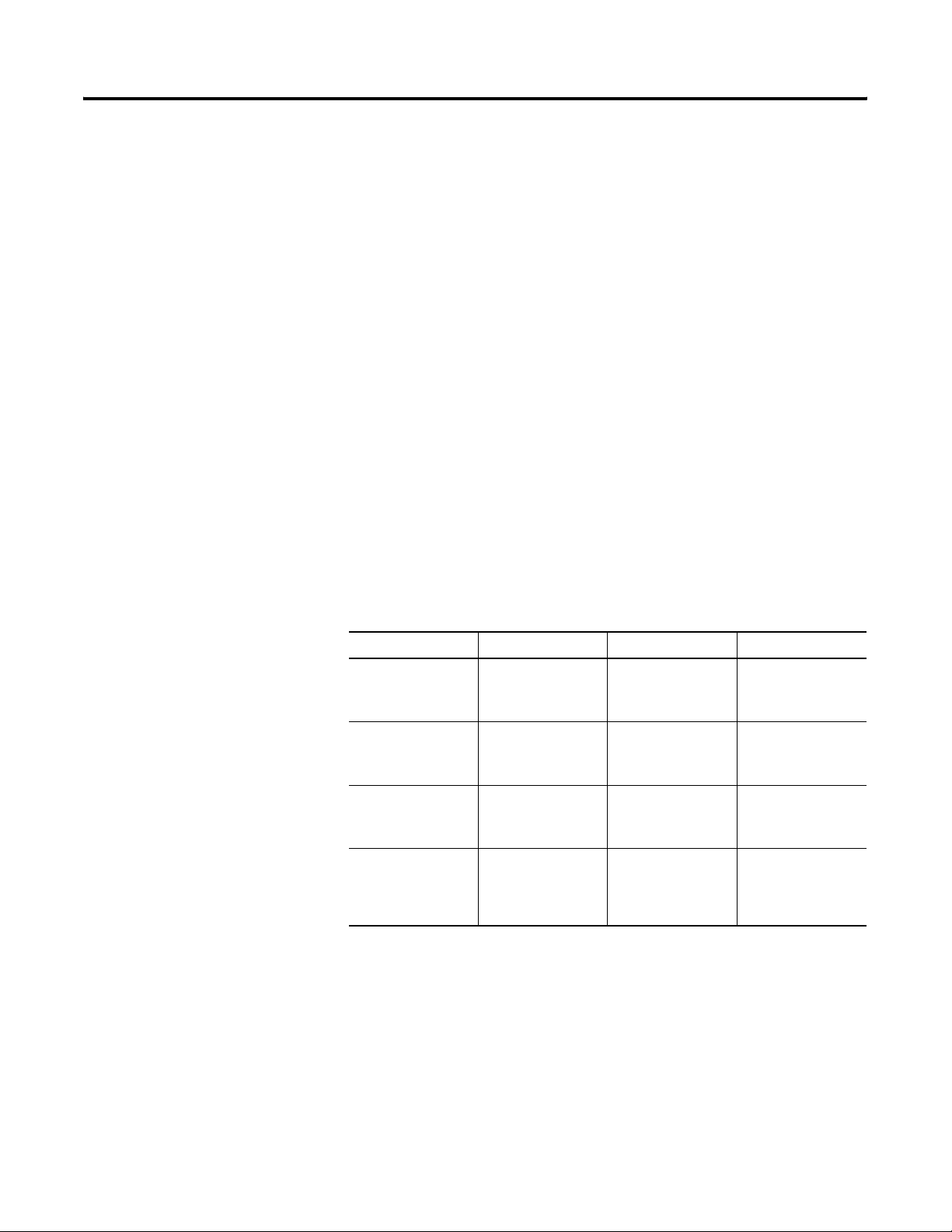

Table 3.1 : VCR Classes

BNU QUU QUB

Permitted Roles Publisher, Subscriber Source, Sink Client, Server, Peer

Conveyance Paths 1 1 2

Conveyance Policy Buffered Queued Queued

Transmission Policy Network Scheduled User Triggered User Triggered

The quantity of each class of VCR that is available for configuration and

communication is device dependent. The quantities are specified in the DD

files, which are provided with each device. An example of the quantities

defined in a DD file, specifically the *.cff file, is shown below.

// From VcrListCharacterisitcs

MaxEntries = 44

NumPermanentEntries = 44

DynamicsSupportedFlag = FALSE //Rev 1.5

StatisticsSupported = 0x0 //Rev 1.5

MaximumNumberOfClientVcrs = 0

MaximumNumberOfServerVcrs = 5

MaximumNumberOfSourceVcrs = 8

MaximumNumberOfSinkVcrs = 0

MaximumNumberOfPublisherVcrs = 19

MaximumNumberOfSubscriberVcrs = 12

As can be seen, the quantities are broken into sub-categories depending on

usage. The above example states that the device can have more publisher BNU

than subscriber BNU. Additionally, the device has no client QUB VCR, but it

has the ability to serve 8 server QUB VCR. Currently, these limits manifest

themselves in either download or communication errors when they are

exceeded.

There is also a nuance to the quantities that need to be emphasized with regard

to linking devices. The 1757-FFLD *.cff file is used below as an example.

// From VcrListCharacterisitcs

MaxEntries = 44

NumPermanentEntries = 44

DynamicsSupportedFlag = FALSE //Rev 1.5

StatisticsSupported = 0x0 //Rev 1.5

MaximumNumberOfClientVcrs = 0

Publication 1757-PM002A-EN-E - June 2006

Page 46

3-8 Basic Function Blocks

MaximumNumberOfServerVcrs = 5

MaximumNumberOfSourceVcrs = 8

MaximumNumberOfSinkVcrs = 0

MaximumNumberOfPublisherVcrs = 64

MaximumNumberOfSubscriberVcrs = 64

The user would be under the impression that there are 64 publishers and 64

subscribers available. This is both correct and incorrect at the same time. The

user can correctly use the total quantity, but it must be evenly distributed

among the four H1 channels that the linking device uses. In other words, each

channel owns 16 publishers and 16 subscribers. The 16 publishers and 16

subscribers are dedicated to each channel; they cannot be shared if not used by

one particular channel.

BNU Class

The BNU class is defined as scheduled. It occurs on a synchronous basis

within the macrocycle schedule. During the scheduled portion of Foundation

Fieldbus communications, when the devices receive the Compel Data token,

this is the class of communication that occurs. The BNU VCR is part of the

function block strategy that transfers data from one function block to another.

This class can be further defined as the link between function blocks. More

specifically, the BNU VCR is the unique link between function blocks in

different devices. Links between function blocks within a device do not use a

BNU VCR. Also, links that are used multiple times, or fanned out, between the

same devices are not considered unique.

The BNU VCR is also defined as to whether it is a publisher or a subscriber.

Therefore, the use of a VCR relative to a device is very important. The

connection of the link from one function block to another in a different device

will be counted based on its point of origin. The originating device will

consume a publisher VCR, whereas the receiving device will consume a

subscriber VCR.

Examples of the BNU VCR counting are provided to emphasize the above

statements:

1. Linking Device: 1 Subscriber

Device 1: 1 Publisher

Publication 1757-PM002A-EN-E - June 2006

Page 47

VCRs: 2 total; 1 Publisher, 1 Subscriber

Basic Function Blocks 3-9

FB 1

2. Linking Device: 1 Subscriber

Device 1: 1 Publisher

VCRs: 2 total; 1 Publisher, 1 Subscriber

FB 1

3. Linking Device: 2 Subscribers

LGX

LGX

Device 1: 2 Publishers

VCRs: 4 total; 2 Publishers, 2 Subscribers

FB 1

FB 2

4. Linking Device: 2 Subscribers

Device 1: 1 Publisher

LGX

Publication 1757-PM002A-EN-E - June 2006

Page 48

3-10 Basic Function Blocks

Device 2: 1 Publisher

VCRs: 2 total; 2 Publisher, 2 Subscriber

Device 1

FB 1

Device 2

LGX

FB 2

5. Linking Device: 1 Subscriber

Device 1: 1 Publisher (Internal Links use link objects rather than VCRs)

VCRs: 2 total; 1 Publisher, 1 Subscriber

Device 1

FB 1

LGX

Publication 1757-PM002A-EN-E - June 2006

FB 2

6. Linking Device: 1 Publisher

Device 1: 1 Subscriber

Page 49

Basic Function Blocks 3-11

VCRs: 2 total; 1 Publisher, 1 Subscriber

Device 1

FB 1

LGX

FB 2

7. Linking Device: 2 Publishers (assuming two links are different LGX

outputs)

Device 1: 2 Subscribers

VCRs: 2 total; 1 Publisher, 1 Subscriber

LGX

8. Linking Device: 1 Publisher

Device 1: 1 Subscriber

Device 1

FB 1

Device 2

FB 2

Publication 1757-PM002A-EN-E - June 2006

Page 50

3-12 Basic Function Blocks

VCRs: 2 total; 1 Publisher, 1 Subscriber

Device 1

FB 1

LGX

FB 2

9. Linking Device: 1 Publisher & 1 Subscriber

Device 1: 1 Publisher & 1 Subscriber

VCRs: 4 total; 2 Publisher, 2 Subscriber

FB 1

10. Linking Device: 1 Publisher & 1 Subscriber

Device 1: 1 Publisher & 1 Subscriber

VCRs: 4 total; 2 Publisher, 2 Subscriber

LGX

LGX

Device 1

FB 1

FB 2

Publication 1757-PM002A-EN-E - June 2006

Page 51

11. Linking Device: 2 Publishers & 1 Subscriber

Device 1: 1 Publisher & 2 Subscribers

VCRs: 6 total; 3 Publisher, 3 Subscriber

LGX

Basic Function Blocks 3-13

Device 1

FB 1

FB 2

12. Linking Device: 2 Publishers & 2 Subscribers

Device 1: 2 Publishers & 2 Subscribers

VCRs: 8 total; 4 Publisher, 4 Subscriber

FB 1

FB 2

13. Linking Device: 2 Publishers & 2 Subscribers

Device 1: 1 Publisher & 1 Subscriber

LGX

Device 2: 1 Publisher & 1 Subscriber

Publication 1757-PM002A-EN-E - June 2006

Page 52

3-14 Basic Function Blocks

VCRs: 8 total; 4 Publisher, 4 Subscriber

Device 1

FB 1

Device 2

FB 2

14. Linking Device: 2 Publishers & 2 Subscribers

Device 1: 1 Publisher

Device 2: 1 Publisher

Device 3: 1 Subscriber

Device 4: 1 Subscriber

VCRs: 8 total; 4 Publisher, 4 Subscriber

Device 1

LGX

Device 3

Publication 1757-PM002A-EN-E - June 2006

FB 1

Device 2

LGX

FB 2

15. Linking Device: 2 Subscribers & 1 Publisher

Device 1: 1 Subscriber & 2 Publishers

FB 3

Device 4

FB 4

Page 53

VCRs: 6 total; 3 Publisher, 3 Subscriber

Device 1

Basic Function Blocks 3-15

FB 1

LGX

QUU and QUB VCR Classes

The QUU and QUB VCR classes are defined as user triggered. During the

unscheduled portion of Foundation Fieldbus communications, these are the

class of communication that occur when the available time is sensed by the

devices. QUU and QUB communications take place when the Link Active

Scheduler passes the token to the devices, allowing them to communicate.

The QUU class can be defined as the reporting link with function blocks.

Specifically, the QUU VCR is used to report contained parameter values in

function blocks such as alarms and change of state. HMI information such as

alarm conditions and device calibration data uses this type of configuration

with an existing strategy.

The QUB class can be defined as the command link with function blocks.

More specifically, the QUB VCR is used to change contained parameter values

in function blocks such as MODE or Set Point. HMI interaction via a

faceplate or a configuration tool uses this type of communication with an

existing strategy.

Since the QUU and QUB VCR use the asynchronous portion of the

macrocycle, enough time must be made available. The focus during

configuration is to make the macrocycle as small as possible to allow function

block execution to occur quickly. Minimizing the asynchronous portion of the

macrocycle will adversely affect QUU and QUB VCR from taking place, since

that time must also be used for housekeeping activities such as probe nodes.

If there is an expectation of increased communication with devices, either

from a control or HMI monitoring standpoint, then the macrocycle should be

increased. This is to be done with the understanding that the function block

cycle time will be increased as a consequence. Therefore, judicious choice of

macrocycle times must be exercised to allow effective QUU and QUB

communications.

Publication 1757-PM002A-EN-E - June 2006

Page 54

3-16 Basic Function Blocks

Publication 1757-PM002A-EN-E - June 2006

Page 55

Applications

Chapter

4

In This Chapter

RSFieldbus PID With ControlLogix Application Example

For See Page

RSFieldbus PID With ControlLogix Application Example 4-1

Device Replacement 4-40

PID Guide 4-43

This example shows you how to incorporate the following devices into a

project with a ControlLogix controller:

• Rockwell Automation 1757-FFLD linking device

• Smar FI 302

• Smar LD 292

1 Publication 1757-PM002A-EN-E - June 2006

Page 56

4-2 Applications

This strategy will use the Fieldbus devices as I/O and the ControlLogix

controller as the PID controller.

ControlLogix

SP

P-10

PIC

1-10

PV

OP

Steam Drum

PT

1-11

P-9

E-2

OUT= 904.98608

LD292 AI

IN_0 = 904.98608

Create A New RSFieldbus Project

Open a Project

P-8

FFLD LGX

IN_1 = 23

Steam

V-3

OUT_0 = 23

FI302 AO

CAS_IN = 23

BKCAL_OUT = 23

Publication 1757-PM002A-EN-E - June 2006

1. Select Start ⇒ Programs ⇒ Rockwell Software ⇒ RSFieldbus ⇒

RSFieldbus.

The Licensing System Information window shows how many Blocks are

licensed on your system.

Page 57

Applications 4-3

2. Click OK.

The RSFieldbus window opens.

3. Click , and select Project.

4. Enter >PID < for the name and click Save.

Save your project often to prevent loss of time and work.

The Project window opens.

Define the Server

This step defines the OPC Server and where it is located.

1. In the Project window, right-click the Fieldbus Networks icon and select

Communication Settings.

The Communication Settings window opens.

2. Verify that the settings are the same as the window above, and click OK.

Create a New HSE Network

1. In the Project window, right-click the Fieldbus Networks icon and select

New Fieldbus.

The New Fieldbus window opens.

2. Select HSE for the Type of Fieldbus.

3. Enter a tag for the Fieldbus and click OK.

Publication 1757-PM002A-EN-E - June 2006

Page 58

4-4 Applications

Tags cannot include a “.” (period). If a separator is needed, we suggest

using an “_” (underscore).

The HSE is added to the Project.

Define the HSE Host

This step defines your PC as the HSE Host.

1. In the Project window, right-click the HSE and select Expand.

The HSE window opens.

2. In the HSE window, right-click the HSE and select New Bridge.

The New Bridge window opens.

3. Select the following settings: give the New Bridge the Device Tag of

HOST.

Publication 1757-PM002A-EN-E - June 2006

Page 59

Applications 4-5

4. Click OK.

The HSE Host is added to the HSE.

Change Device Class to Link Master

1. Right-click the HSE Host and select Attributes.

The Bridge attributes window opens.

2. Select Link Master for the BOF Class, verify that Root Bridge is

selected, and click OK.

By selecting the HSE Host as the Link Master, it becomes the Primary

Link Master. Therefore, all other field devices can not be configured as

the Primary Link Master.

Create a New 1757-FFLD - Bridge

1. Right-click the HSE and select New Bridge.

The New Bridge window opens.

2. Select the following settings for the 1757-FFLD (linking device). Give

the New Bridge the Device Tag of FFLD

Publication 1757-PM002A-EN-E - June 2006

Page 60

4-6 Applications

The Upstream Port must be 5 for the linking device to connect to the HSE

Host. Ports 1–4 are reserved for H1 ports.

3. Click OK.

The linking device is added to HSE.

Change the Root Bridge

1. Right-click the linking device and select Attributes.

2. Select Bridge for the BOF class and click OK.

3. Close the HSE window.

The Project window reflects your additions.

Create a New Fieldbus - H 1

1. In the Project window, right-click the linking device icon and select New

Fieldbus.

The New Fieldbus window opens.

Publication 1757-PM002A-EN-E - June 2006

2. Select H1 for the Type of Fieldbus.

Page 61

Applications 4-7

3. Enter >H1-1< for the Tag.

The linking device has 2 or 4 H1 ports. We recommend that you name them

accordingly. For example, H1-1 indicates that this is the first H1 port..

4. Select the Upstream Port to which you are connected.

The linking device does not support redundancy yet, do not select "Is

Redundant".

5. Click OK.

The Fieldbus (H1-1) is added to the Project.

Add Devices

1. In the Project window, right-click the H1 and select Expand.

The H1-1 (Fieldbus) window opens.

2. In the H1-1 window, right-click the H1 and select New Device.

Publication 1757-PM002A-EN-E - June 2006

Page 62

4-8 Applications

3. Select the following settings for the Smar FI 302 and click OK.

IMPORTANT

The Device Rev, DD Rev and CF Rev values in this window

default to the latest version in the Device Support files. If

your devices do not match these values, change them

accordingly.

If you do not correctly match your devices to their version

values, you will have to delete the devices and recreate them.

Publication 1757-PM002A-EN-E - June 2006

Page 63

Applications 4-9

4. Repeat steps 1 and 2, substituting LD 292 for the Device Type and

>LD292< for the Device Tag.

The Devices are added to the H1.

Configure Communication Settings

Initialize Communications and Associate the Linking Device

Before continuing, click Window ⇒ Tile to make all windows visible at the

same time.

Publication 1757-PM002A-EN-E - June 2006

Page 64

4-10 Applications

1. Click the On Line button .

The Initialize Communication animation begins.

During this time, all Bridges and Fieldbus are identified.

A red x appears next to the H1, FFLD and Device icons. This indicates

that they need to be associated with the actual hardware.

There is an order of precedence in associating devices. The bridges on

the HSE network need to be associated prior to the devices on the H1

network, since the linking device is the link between the H1 and the PC.

Publication 1757-PM002A-EN-E - June 2006

Page 65

Applications 4-11

2. In the HSE window, right-click the HOST icon and select Attributes.

Using the drop-down menu for the Device Id, select the following

setting

.

This selection is not available until the communications are on line.

3. Click OK.

4. In the HSE window, right-click the linking device and select Attributes.

Using the drop-down menu for the Device Id, select the following

setting:

Publication 1757-PM002A-EN-E - June 2006

Page 66

4-12 Applications

5. Click OK.

Note that the red x next to each device in the HSE window has

disappeared once the association has been made. This indicates that

communication with the linking device is established

Check the Live List

This step involves verifying that you are connected to the proper devices.

1. To view the Live List for the HSE, right-click the desired HSE and

select Live List.

The HSE Live List opens, showing all the bridges connected to your PC.

Devices that are ghosted in the HSE Live List have not yet established a

connection to RSFieldbus through the HSE Server.

2. Right-click H1-1 network and select Live List.

The H1-1 Live List opens, showing all of the devices connected through

your linking device. Devices that are ghosted in the H1-1 Live List have

not yet established a connection to RSFieldbus through the HSE Server

and linking device. Prior to continuation, the device must not be in a

ghosted state in the live list.

Associate Devices

1. Once all the devices have become solid on the H1-1 live list, select the

H1-1 Fieldbus window.

Publication 1757-PM002A-EN-E - June 2006

2. In the HSE window, right-click the FI302 and select Attributes.

3. In the Device Attributes window, select your FI302 from the Device Id

drop-down list and click OK.

Page 67

Applications 4-13

Note that the Device ID is specific to the device based on type and

serial number.

The red x on the FI302 disappears. This indicates that communication

with the Device is established.