Page 1

Installation Instructions

ControlLogix Chassis and Power Supply

Standard Chassis Catalog Numbers 1756-A4, 1756-A10, 1756-A13, 1756-A17

ControlLogix-XT Chassis Catalog Numbers 1756-A4LXT, 1756-A5XT, 1756-A7XLT, 1756-A7XT

Standard Power Supplies Catalog Numbers 1756-PA72, 1756-PA75, 1756-PB72, 1756-PB75, 1756-PC75, 1756-PH75

ControlLogix-XT Power Supplies Catalog Numbers 1756-PAXT, 1756-PBXT

Redundant Power Supplies Catalog Numbers 1756-PA75R, 1756-PB75R

Redundant Power Supplies Chassis Adapter Catalog Number 1756-PSCA2

ControlLogix-XT Redundant Power Supplies Catalog Numbers 1756-PAXTR, 1756-PBXTR

ControlLogix-XT Redundant Power Supplies Chassis Adapter Catalog Number 1756-PSCA2XT

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, ControlLogix, ControlLogix-XT, and FLEX I/O-XT are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated

Information

The following components were added to these installation instructions.

• ControlLogix-XT Redundant Power Supply (catalog number

1756-PAXTR)

• ControlLogix-XT Redundant Power Supply (catalog number

1756-PBXTR)

• ControlLogix-XT Redundant Power Supply Chassis Adapter (catalog

number 1756-PSCA2XT)

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 5

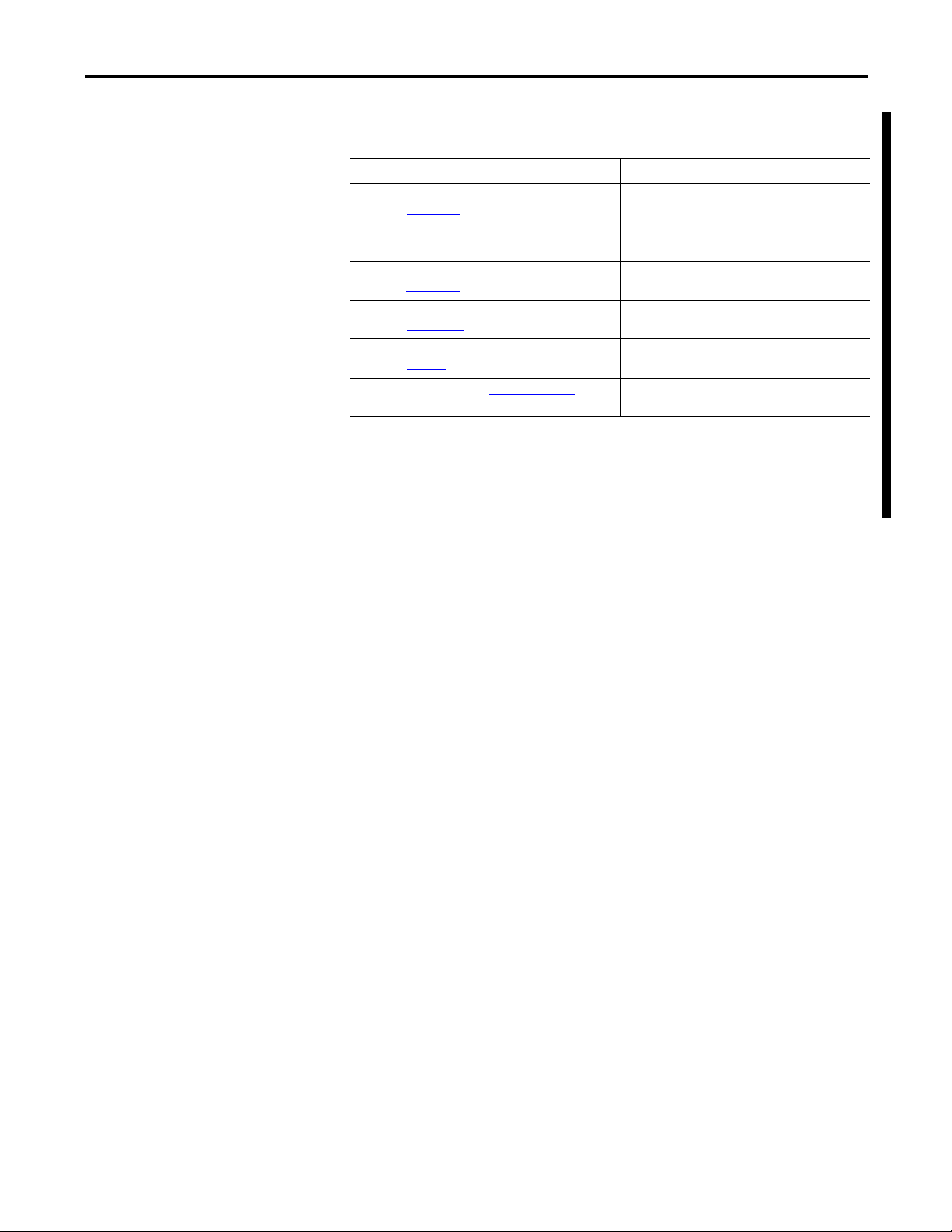

Table of Contents

Preface

Install Chassis and Power Supplies

Standard ControlLogix Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ControlLogix-XT Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Where to Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation Advisories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

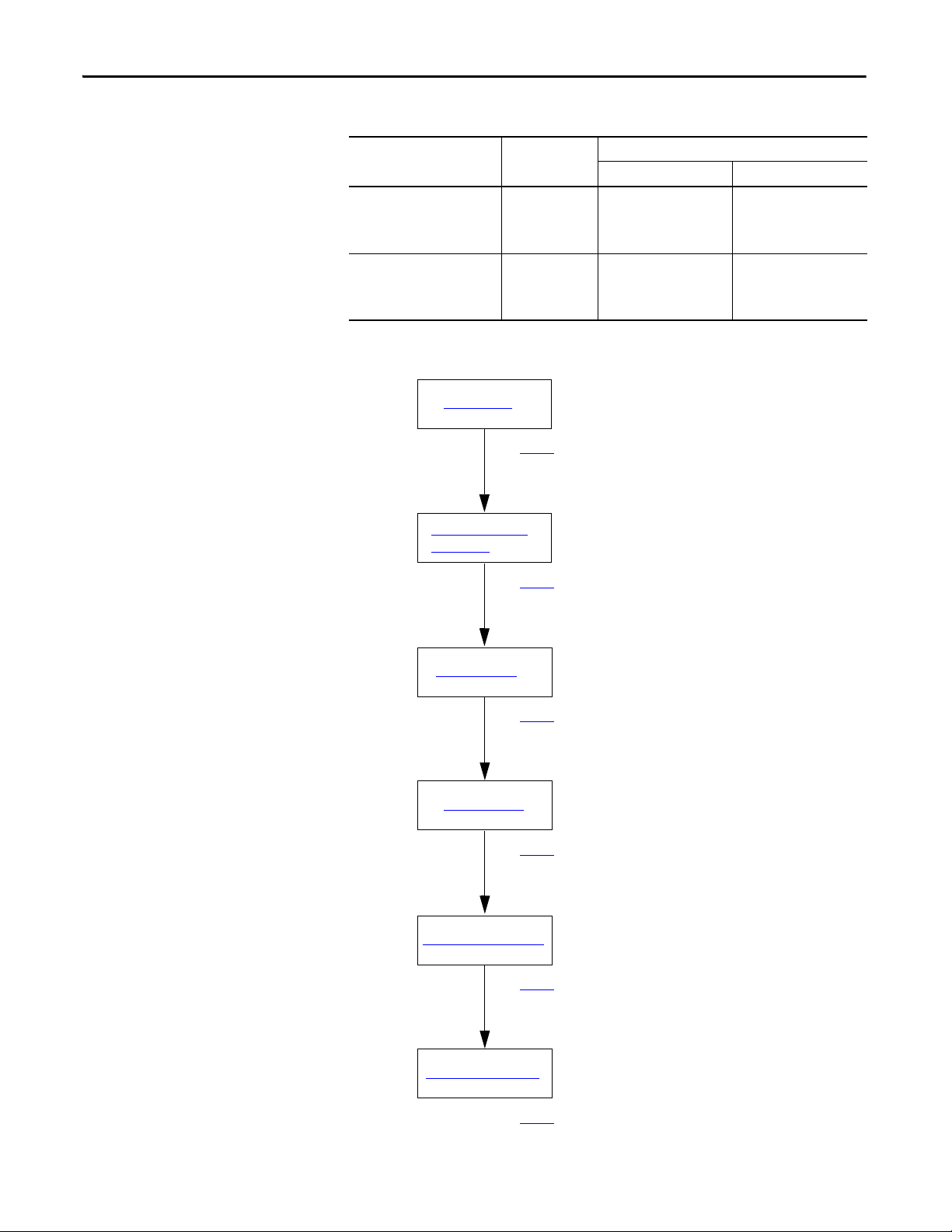

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Plan the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power Supply and Chassis Compatibility . . . . . . . . . . . . . . . . . . . . . . . 15

Minimum Cabinet Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Spacing Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mounting Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Install the Chassis and Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ground the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Install a Central Ground Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Connect the Functional Earth Ground on the Chassis. . . . . . . . . . . 24

Connect the Protective Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connect the Grounding Conductors to the Ground Bus . . . . . . . . 26

Connect Ground Bus to Grounding-electrode System . . . . . . . . . . . 26

Connect the Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remove the Protective Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Apply Power to the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Input Power Requirements and Transformer Sizing. . . . . . . . . . . . . . . . . 29

Troubleshoot the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Install Chassis and Redundant Power

Supplies

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 5

Chapter 2

Redundant Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Components of the Redundant System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Parts Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Follow These Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Plan the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Redundant Power Supply and Chassis Compatibility. . . . . . . . . . . . 35

Spacing Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

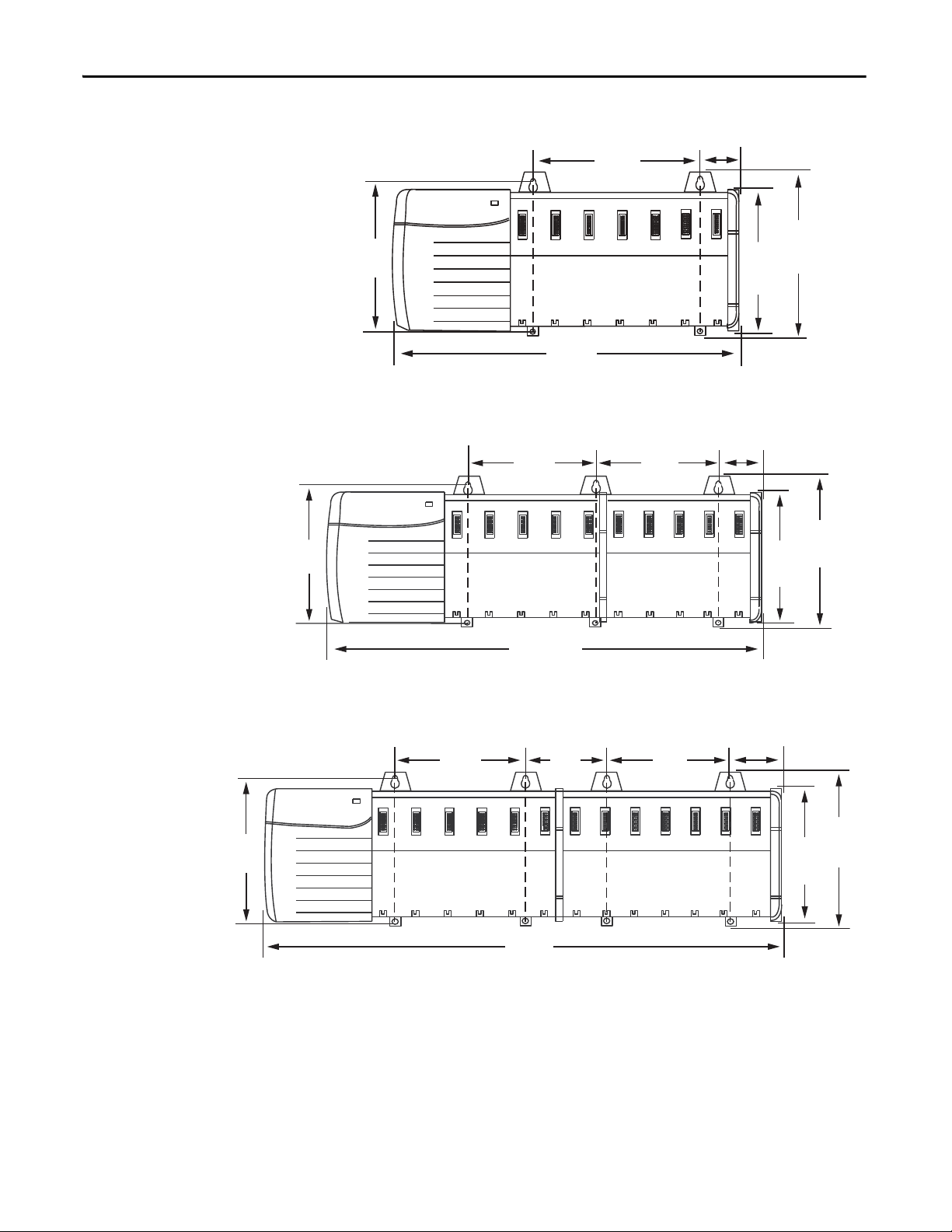

Mounting Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

System Configuration Recommendations . . . . . . . . . . . . . . . . . . . . . . 41

Install the Chassis and Chassis Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Install the Redundant Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Ground the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Install a Central Ground Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Connect the Functional Earth Ground on the Chassis. . . . . . . . . . . 46

Page 6

Table of Contents

Connect the Protective Earth Ground on the Chassis

and Redundant Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connect the Grounding Conductors to the Ground Bus. . . . . . . . . 48

Connect Ground Bus to Grounding-electrode System . . . . . . . . . . . 48

Connect the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Connect the 1756-CPR2 Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Connect Power to the Redundant Power Supply . . . . . . . . . . . . . . . . 49

Connect the Solid-state Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Remove the Protective Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Apply Power to the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Input Power Requirements and Transformer Sizing . . . . . . . . . . . . . . . . . 53

Troubleshoot the Redundant Power Supplies . . . . . . . . . . . . . . . . . . . . . . . 54

Chassis Adapter Status Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Remove or Replace a Redundant Power Supply . . . . . . . . . . . . . . . . . . . . . 55

Remove a Redundant Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Replace a Redundant Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Remove or Replace a Chassis Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Remove a Chassis Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Replace a Chassis Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 7

Preface

Standard ControlLogix Systems

ControlLogix-XT Systems

The ControlLogix system is a modular system that requires a 1756 I/O chassis

that houses various modules. Chassis are available with 4, 7, 10, 13, and 17 slots

for standard applications where temperatures range from 0…60 °C

(32…140 °F). You can place any module into any slot.

The chassis backplane provides the following features:

• A high-speed communication path between modules

• Power distribution to each module housed in the chassis

• Messages passed between multiple controllers housed in the chassis

• Messages passed between and through multiple communication-interface

modules housed on the chassis

The ControlLogix-XT products include power, control, and communication

system components that, when used with FLEX I/O-XT™ products, provide a

complete control system solution that can be used in environments where

temperatures range from -20…70 °C (-4…158 °F). Chassis are available with 4, 5,

and 7 slots.

When used independently, ControlLogix-XT systems can withstand

environments where temperatures range from -25…70 °C (-13…158 °F) for

equipment designated as ‘XT’ and -25…60 °C (-13…140 °F) for equipment

designated ‘LXT’.

These installation instructions describe how to install the following components

of a ControlLogix system:

• Standard ControlLogix chassis

• Standard ControlLogix power supplies

• ControlLogix-XT™ chassis

• ControlLogix-XT power supplies

• ControlLogix redundant power supplies

• ControlLogix chassis adapters

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 7

Page 8

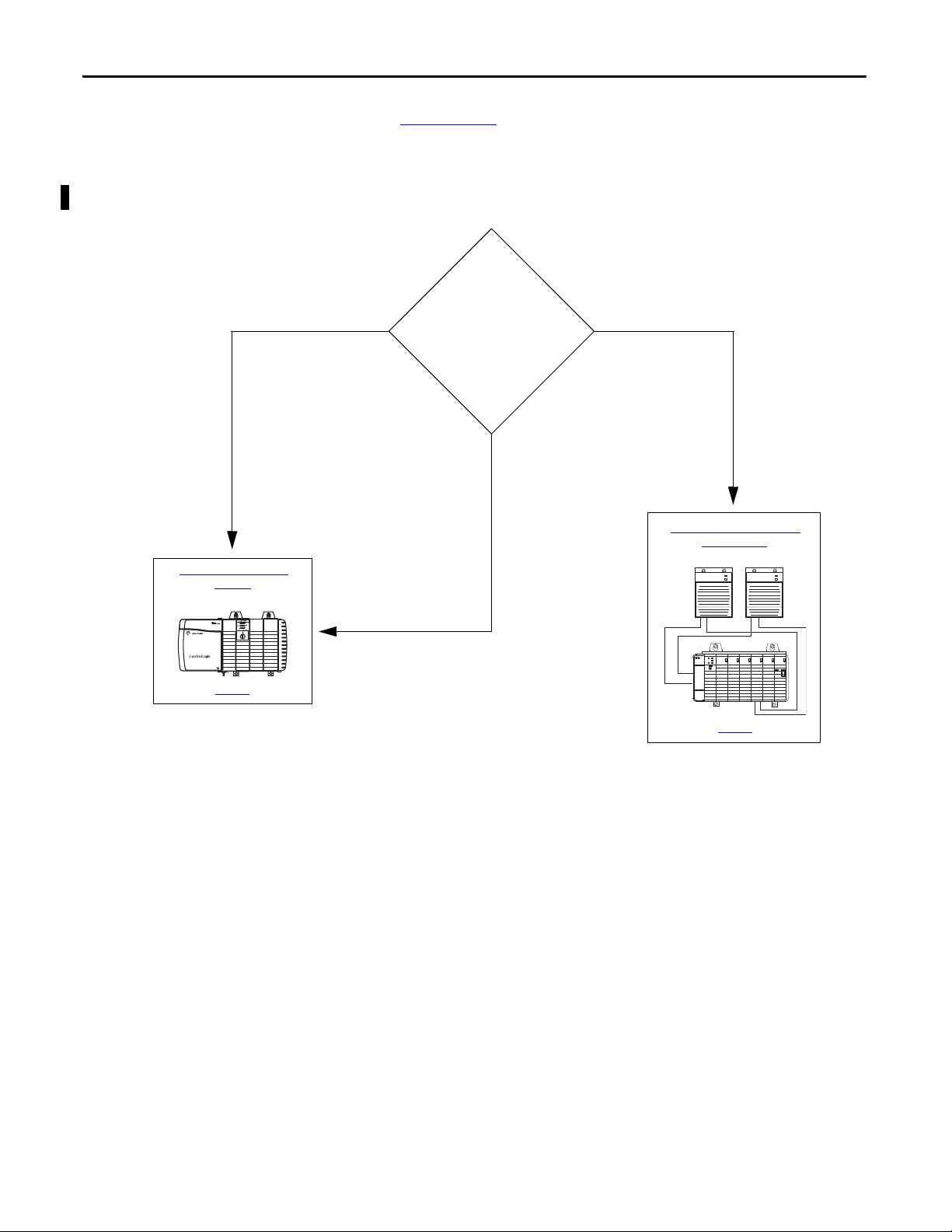

Preface

Are you using a Standard

ControlLog ix,

ControlLogix-XT or

ControlLogix w ith

Redundant Power Supply

System?

Standard

Control Logix

System

ControlLog ix-XT

System

ControlLogix with

Redundant Power

Supply System

Install Chassis and Power

Supplies

Install Chassis and Redundant

Power Sup plies

page 31

page 13

Where to Start

Use the Where to Start chart below to determine the steps to follow.

8 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 9

Installation Advisories

IMPORTANT

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined

in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide adequate protection to radio communication

services in such environments.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application if nonmetallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures

Preface

, for additional installation requirements

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

ControlLogix-XT system components are rated for extreme environmental conditions only when used properly with

other Logix-XT system components. The use of ControlLogix-XT components with standard ControlLogix system

components nullifies extreme-environment ratings.

If a ControlLogix-XT module is used with standard ControlLogix products, the ControlLogix-XT module can withstand only the

environments specified for the standard ControlLogix version of the module. For example, if a 1756-L63XT controller is used in a

standard 1756-A10 chassis, the ControlLogix-XT controller can withstand only the environment specified for the standard

1756-L63 controller.

The ControlLogix-XT system components are designed to meet the same and greater operational and environmental requirements

as traditional ControlLogix products.

When a ControlLogix-XT component is used as a replacement for a traditional ControlLogix component, the functional and

environmental requirements of the traditional ControlLogix component apply, with the exception of the power output ratings.

ATTENTION: If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment

may be impaired.

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 9

Page 10

Preface

European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to

comply with the Essential Health and Safety Requirements relating to the design and construction of Category 3 equipment intended for use in

Zone 2 potentially explosive atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN 60079-0.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

WARNING:

• This equipment shall be mounted in an ATEX-certified enclosure with a minimum ingress protection rating of at least IP54 (as

defined in IEC60529) and used in an environment of not more than Pollution Degree 2 (as defined in IEC 60664-1) when

applied in Zone 2 environments. The enclosure must have a tool-removable cover or door.

• Provision shall be made to prevent the rated voltage from being exceeded by transient disturbances of more than 140% of the

rated voltage when applied in Zone 2 environments.

• This equipment must be used only with ATEX certified Rockwell Automation backplanes.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

North American Hazardous Location Approval

The following information applies when operating this equipment

in hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I

Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous locations

only. Each product is supplied with markings on the rating nameplate

indicating the hazardous location temperature code. When combining

products within a system, the most adverse temperature code (lowest "T"

number) may be used to help determine the overall temperature code of the

system. Combinations of equipment in your system are subject to

investigation by the local Authority Having Jurisdiction at the time of

installation.

WARNING: EXPLOSION HAZARD -

• Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

• Do not disconnec t connections to this equipment unless

power has been removed or the area is known to be

nonhazardous. Secure any external connections that

mate to this equipment by using screws, sliding latches,

threaded connectors, or other means provided with this

product.

• Substitution of components may impair suitability for

Class I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en

environnements dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une

utilisation en environnements de Classe I Division 2 Groupes A, B, C, D

dangereux et non dangereux. Chaque produit est livré avec des marquages

sur sa plaque d'identification qui indiquent le code de température pour les

environnements dangereux. Lorsque plusieurs produits sont combinés dans

un système, le code de température le plus défavorable (code de

température le plus faible) peut être utilisé pour déterminer le code de

température global du système. Les combinaisons d'équipements dans le

système sont sujettes à inspection par les autorités locales qualifiées au

moment de l'installation.

AVERTISSEMENT: RISQUE D’EXPLOSION –

• Couper le courant ou s'assurer que l'environnement est

classé non dangereux avant de débrancher

l'équipement.

• Couper le courant ou s'assurer que l'environnement est

classé non dangereux avant de débrancher les

connecteurs. Fixer tous les connecteurs externes reliés à

cet équipement à l'aide de vis, loquets coulissants,

connecteurs filetés ou autres moyens fournis avec ce

produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non dangereux

avant de changer les piles.

10 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 11

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

ControlLogix Selection Guide,

publication 1756-SG001

ControlLogix Chassis Specifications Technical Data,

publication 1756-TD006

ControlLogix Power Supplies Specifications Technical Data,

publication 1756-TD005

ControlLogix System User Manual,

publication 1756-UM001

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and

Provides overview of the ControlLogix system and its

products.

Provides technical specifications for ControlLogix

chassis.

Provides technical specifications for ControlLogix power

supplies.

Provides information on how to install, configure,

program, and use ControlLogix controllers.

Provides general guidelines for installing a

Rockwell Automati on® industrial system.

other certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 11

Page 12

Preface

12 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 13

Chapter 1

Install Chassis and Power Supplies

This chapter describes how to install standard and ControlLogix-XT versions of

the 1756 chassis with nonredundant power supplies.

Tools Required

Parts Required

When installing either the standard or ControlLogix-XT versions of your 1756

chassis and power supplies, the following items are required:

• 3.18 mm (0.125 in.) slotted screwdriver

• 6.35 mm (0.25 in.) slotted or #2 Phillips screwdriver

• Torque screwdriver

• Needle-nose pliers

• Crimping tool

• Wire-stripping tool

• Drill

Use these tables to determine the parts required to install your chassis. These

parts are not included with the chassis and must be ordered separately.

Table 1 - Parts Required Per Mounting Tab

Tab Position With SEM Screws

Top • 1 Phillips screw

• 1 flat washer

• 1 split-lock washer

Bottom 1 SEM screw • 1 Phillips screw

(1)

Without SEM Screws

N/A

• 1 star washer

(1) Phillips screw with attached star washer.

Table 2 - Total Parts Required Per Chassis

Chassis Number of

1756-A4, 1756-A7,

1756-A4LXT, 1756-A7LXT

1756-A10,

1756-A5XT, 1756-A7XT

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 13

Mounting Tabs

2 top

2 bottom

3 top

3 bottom

Total Parts Required Per Chassis

With SEM Screws Without SEM Screws

• 2 Phillips screws

• 2 flat washers

• 2 split-lock washers

• 2 SEM screws

• 3 Phillips screws

• 3 flat washers

• 3 split-lock washers

• 3 SEM screws

• 4 Phillips screws

• 2 flat washers

• 2 split-lock washers

• 2 star washers

• 6 Phillips screws

• 3 flat washers

• 3 split-lock washers

• 3 star washers

Page 14

Chapter 1 Install Chassis and Power Supplies

Plan the System

page 15

Install the Chassis and

Power Supply

page 21

Ground the Chassis

page 23

Connect the Power

page 27

Remove the Protective Label

page 28

Apply Power to the Chassis

page 28

Table 2 - Total Parts Required Per Chassis

Follow These Steps

Chassis Number of

Mounting Tabs

1756-A13 4 top

4 bottom

1756-A17 5 top

5 bottom

Total Parts Required Per Chassis

With SEM Screws Without SEM Screws

• 4 Phillips screws

• 4 flat washers

• 4 split-lock washers

• 4 SEM screws

• 5 Phillips screws

• 5 flat washers

• 5 split-lock washers

• 5 SEM screws

• 8 Phillips screws

• 4 flat washers

• 4 split-lock washers

• 4 star washers

• 10 Phillips screws

• 5 flat washers

• 5 split-lock washers

• 5 star washers

14 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 15

Install Chassis and Power Supplies Chapter 1

IMPORTANT

Plan the System

Use the following information to assist you in planning your system.

Power Supply and Chassis Compatibility

The chassis series you have determines the power supply you can use. The

following table lists the chassis that can be installed with each power supply.

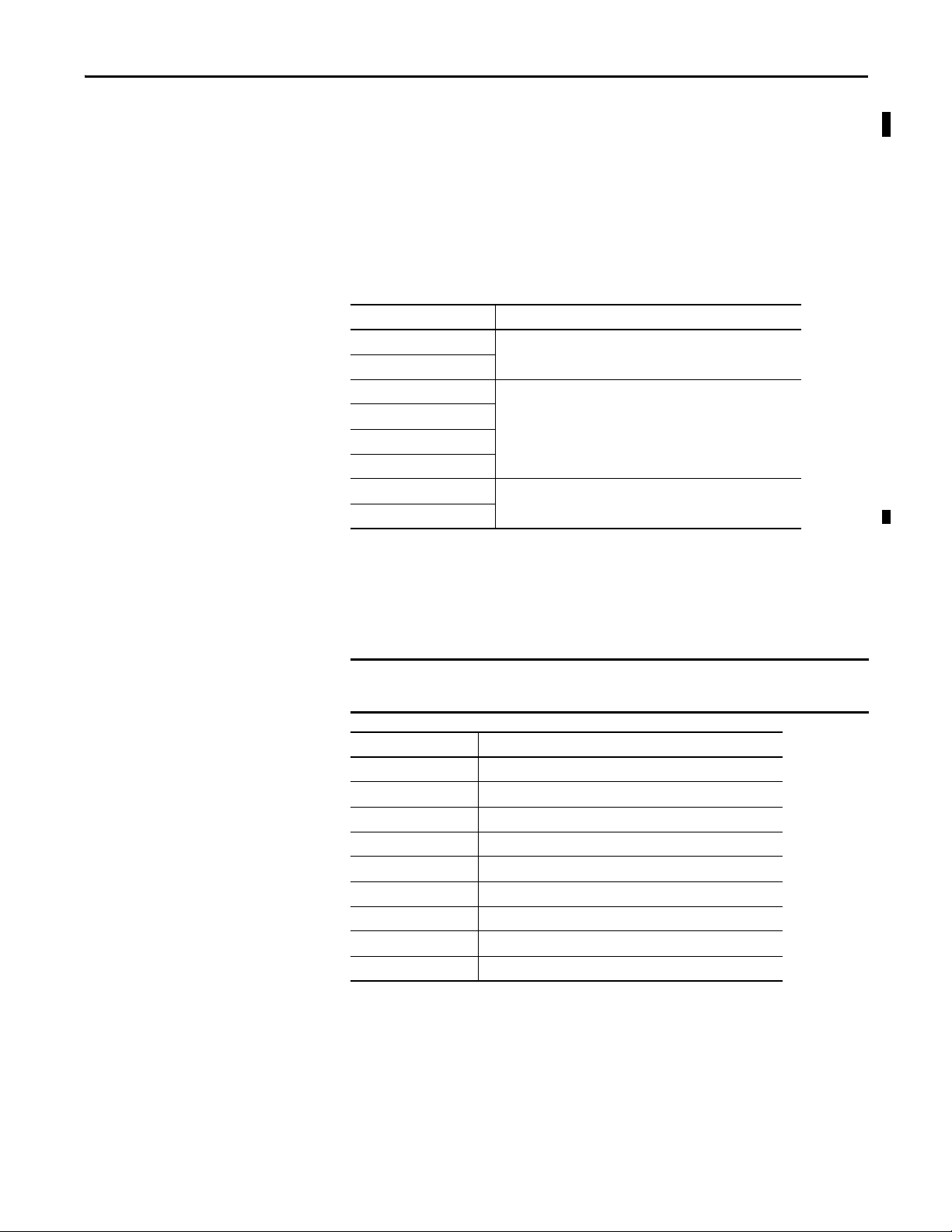

Table 3 - Chassis Compatibility

Power Suppl y Cat. No. Chassis Cat. No.

1756-PA72/C 1756-A4/A, 1756-A7/A, 1756-A10/A, 1756-A13/A, 1756-A17/A,

1756-PB72/C

1756-PA75/B 1756-A4/B, 1756-A7/B, 1756-A10/B, 1756-A13/B, 1756-A17/B

1756-PB75/B

1756-PC75/B

1756-PH75/B

1756-PBXT 1756-A4LXT, 1756-A5XT, 1756-A7LXT, 1756-A7XT

1756-PAXT

1756-A4/B, 1756-A7/B, 1756-A10/B, 1756-A13/B, 1756-A17/B

Minimum Cabinet Size

The following table lists the minimum cabinet size for each ControlLogix chassis.

To meet the UL/CSA standards, the cabinet housing your ControlLogix chassis

cannot be smaller than these minimum cabinet-size requirements.

Chassis Minimum Cabinet Size (H x W x D), approx

1756-A4 50.8 x 50.8 x 20.3 cm (20 x 20 x 8 in.)

1756-A7 50.8 x 60.9 x 20.3 cm (20 x 24 x 8 in.)

1756-A10 50.8 x 76.2 x 20.3 cm (20 x 30 x 8 in.)

1756-A13 60.9 x 76.2 x 20.3 cm (24 x 30 x 8 in.)

1756-A17 76.2 x 91.4 x 20.3 cm (30 x 36 x 8 in.)

1756-A4LXT 50.8 x 50.8 x 20.3 cm (20 x 20 x 8 in.)

1756-A5XT 50.8 x 76.2 x 20.3 cm (20 x 30 x 8 in.)

1756-A7LXT 50.8 x 60.9 x 20.3 cm (20 x 24 x 8 in.)

1756-A7XT 50.8 x 76.2 x 20.3 cm (20 x 30 x 8 in.)

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 15

Page 16

Chapter 1 Install Chassis and Power Supplies

IMPORTANT

W

i

r

e

w

a

y

Wireway

W

i

r

e

w

a

y

45796

15.3 (6.0)

10.2

(4.0)

7.7

(3.0)

5.1 (2.0)

15.3 (6.0)

5.1 (2.0)

15.3 (6.0)

10.2

(4.0)

The 10.2 (4.0)

measurement to the side

of the enclosure can

include the wireway.

Spacing Requirements

Use the following information to plan your installation.

Make sure you meet the minimum spacing requirements specified.

Allow 15.3 cm (6.0 in.) between chassis and a heat source, and allow

5.1 cm (2.0 in.) between a wireway and the top or bottom of a chassis.

Chassis are intended to be mounted only horizontally. Do not mount vertically.

Dimensions are in cm (in.).

16 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Table 4 - Spacing Requirements, Top and Bottom

From a chassis to a Requires this space, min

Cabinet 15.3 cm (6.0 in.)

Chassis or other heat source 15.3 cm (6.0 in.)

Wireway 5.1 cm (2.0 in.)

Table 5 - Spacing Requirements, Sides

From a chassis to a Requires this space, min

Cabinet 10.2 cm (4.0 in.)

Chassis or other heat source 7.7 cm (3.0 in.)

Wireway No minimum spacing required

Page 17

Install Chassis and Power Supplies Chapter 1

1.1

(0.433)

0.55

(0.217)

Top Mounting

Hole Diameter

Bottom Mounting

Hole Diameter

Right-side View of All Standard Chassis

16.9

(6.65)

14.5

(5.71)

0.78

(0.31)

43591

45797

16.9

(6.65)

14.9

(5.87)

45865

Right-side View of All ControlLogix-XT Chassis

7.0

(2.76)

4.71

(1.85)

16.9

(6.65)

26.3

(10.34)

43592

15.8

(6.22)

14.5

(5.70)

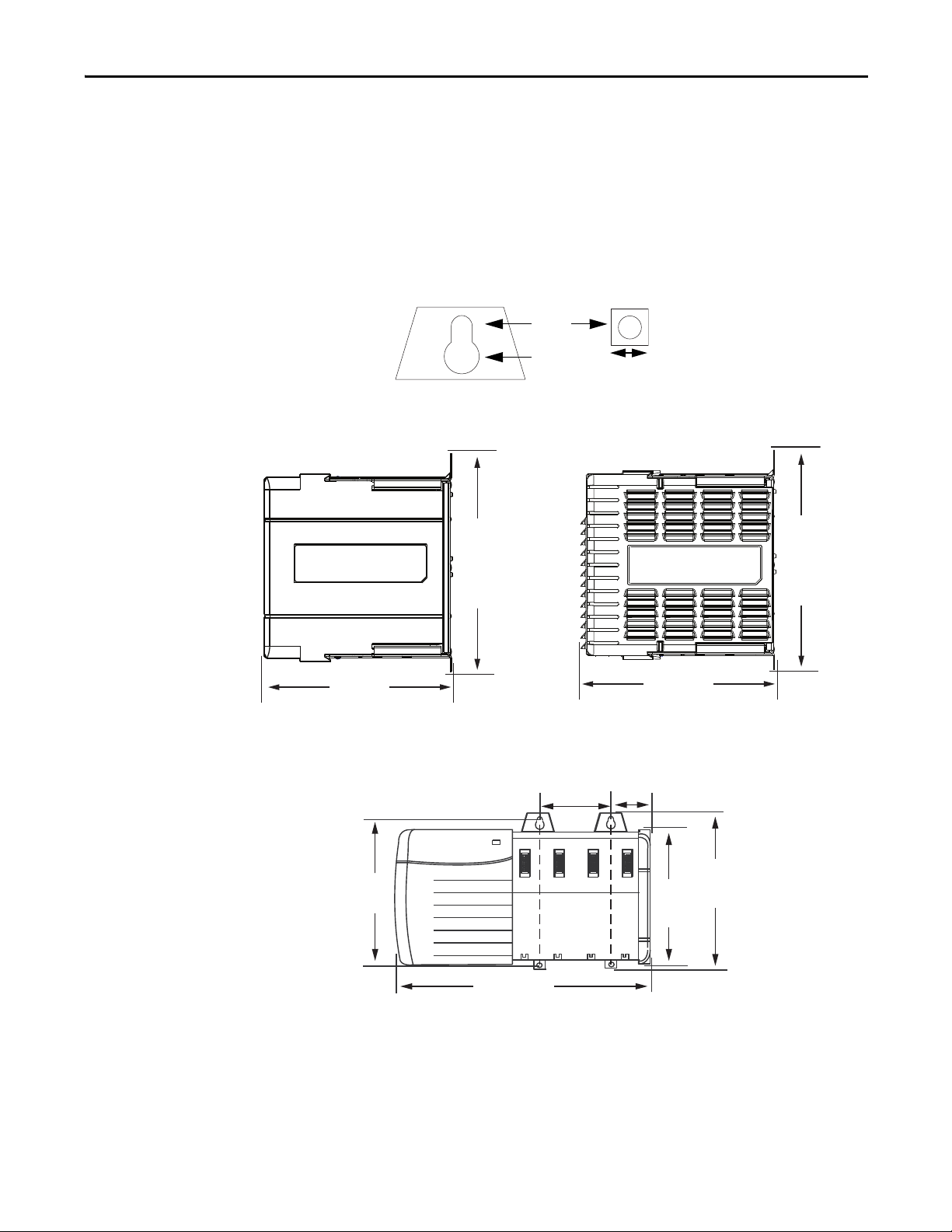

Mounting Dimensions

Use these dimensions to plan your chassis installation.

Dimensions are in cm (in.).

Figure 1 - Chassis Common Dimensions

Figure 2 - 1756-A4 Chassis and Power Supply

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 17

Page 18

Chapter 1 Install Chassis and Power Supplies

17.5

(6.89)

14.5

(5.70)

16.9

(6.65)

36.7

(14.47)

43593

15.8

(6.22)

4.71

(1.85)

14.5

(5.70)

16.9

(6.65)

48.3

(19.02)

43594

15.8

(6.22)

5.7

(2.25)

14.0

(5.51)

14.0

(5.51)

14.5

(5.70)

16.9

(6.65)

58.8

(23.13)

43595

15.8

(6.22)

5.7

(2.25)

14.0

(5.51)

14.0

(5.51)

10.5

(4.13)

Figure 3 - 1756-A7 Chassis and Power Supply

Figure 4 - 1756-A10 Chassis and Power Supply

Figure 5 - 1756-A13 Chassis and Power Supply

18 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 19

Figure 6 - 1756-A17 Chassis and Power Supply

14.5

(5.70)

16.9

(6.65)

73.8

(29.04)

43596

15.8

(6.22)

4.7

(1.85)

14.0

(5.51)

14.0

(5.51)

13.3

(5.22)

13.3

(5.22)

7.0

(2.76)

6.3

(2.48)

16.9

(6.65)

27.8

(10.96)

45798

15.8

(6.22)

14.5

(5.72)

14.5

(5.72)

16.9

(6.65)

49.8

(19.62)

45799

15.8

(6.22)

7.3

(2.87)

14.0

(5.51)

14.0

(5.51)

Figure 7 - 1756-A4LXT Chassis and Power Supply

Install Chassis and Power Supplies Chapter 1

Figure 8 - 1756-A5XT Chassis and Power Supply

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 19

Page 20

Chapter 1 Install Chassis and Power Supplies

17.5

(6.89)

14.5

(5.72)

16.9

(6.65)

38.3

(15.10)

45800

15.8

(6.22)

6.3

(2.48)

14.5

(5.70)

16.9

(6.65)

49.8

(19.62)

45801

15.8

(6.22)

7.3

(2.87)

14.0

(5.51)

14.0

(5.51)

Figure 9 - 1756-A7LXT Chassis and Power Supply

Figure 10 - 1756-A7XT Chassis and Power Supply

20 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 21

Install Chassis and Power Supplies Chapter 1

IMPORTANT

20289-M

Install the Chassis and Power Supply

After planning your system, use these instructions to properly install the standard

or ControlLogix-XT versions of your 1756 chassis and power supplies.

ATT EN TI ON : Do not drill holes above an installed chassis. Metal chips from

drilling can damage the backplane and cause intermittent operation.

Chassis are intended to be mounted only horizontally. Do not mount vertically.

1. Drill holes in the back panel of the enclosure for the chassis mounting tabs.

See the Plan the System on page 15 for assistance in hole placement.

2. Scrape paint off the back panel for an electrical connection between the

chassis and back panel.

3. Hold the chassis in place against the holes.

ATT EN TI ON : If the chassis mounting tabs do not lay flat before the screws are

tightened, use additional washers as shims so the chassis is not warped by

tightening the screws.

Warping a chassis can damage the backplane and cause intermittent operation.

4. Install the hardware for the top mounting tabs and tighten.

See Parts Required

on page 13 for more information.

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 21

Page 22

Chapter 1 Install Chassis and Power Supplies

20290-M

Leave farleft bottom

tab open.

Card Guide

43614

43614

5. Leaving the far-left bottom tab open for functional ground, install the

remaining tab screws.

6. Align the power-supply circuit board with the card guides on the left side

of the chassis and slide the power supply back until it is flush with the front

of the chassis.

7. Tighten the top and bottom screws to fasten the power supply to the

chassis.

22 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 23

Install Chassis and Power Supplies Chapter 1

TIP

Functional Earth Ground, page 24

Protective

Earth Ground,

page 25

Cabinet

To Grounding-electrode System

45805

8.3 mm² (8 AWG) solid or

stranded-copper wire

rated at 90 °C (194 °F) or

greater

2.1 mm² (14 AWG) solid or

stranded-copper wire

rated at 90 °C (194 °F) or

greater

Ground Bus

Ground the Chassis

Complete these steps to properly ground your chassis.

Grounding Step Page

Install a Central Ground Bus 24

Connect the Functional Earth Ground on the Chassis 24

Connect the Protective Earth Ground 25

Connect the Grounding Conductors to the Ground Bus 26

Connect Ground Bus to Grounding-electrode System 26

The following figure shows an example grounding configuration. After you

complete the grounding steps, your system looks similar to this figure.

To minimize the resistance between the chassis and ground connection, keep

wire lengths as short as possible.

Figure 11 - Grounding Configuration Example

Use these guidelines when connecting the grounding:

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 23

• Use a steel enclosure to guard against electromagnetic interference (EMI).

• Install a bonding wire for electrical contact between the enclosure door

and the enclosure; do not rely on the hinge.

• Make sure the enclosure-door viewing window is a laminated screen or a

conductive optical substrate (to block EMI).

Page 24

Chapter 1 Install Chassis and Power Supplies

20291-M

1

3

4

2

Install a Central Ground Bus

Each enclosure must contain a central ground bus. The ground bus is the

common connection for each chassis within the enclosure and the enclosure

itself.

For more information on installing a central ground bus, refer to the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1

.

Connect the Functional Earth Ground on the Chassis

Use 8.3 mm (8 AWG) solid or stranded-copper wire rated at 90 °C (194 °F) or

greater to connect the functional earth ground.

Connect the functional earth ground as shown in Figure 12

Figure 12 - Functional Earth Ground Connection

Item Description

1 Chassis mounting tab

2 Equipment grounding conductor (ground lug with 8.3 mm² [8 AWG] solid or

stranded-copper wire rated at 90 °C [194 °F] or greater)

3 M4 or M5 (#10 or #12) flat or star washer

4 M4 or M5 (#10 or #12) Phillips screw and flat or star washer (or SEM screw)

.

24 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 25

Install Chassis and Power Supplies Chapter 1

+

-

+

-

45802

5

3

4

1

3

2

3

To G rou nd Bu s

IMPORTANT

Connect the Protective Earth Ground

Use 2.1 mm (14 AWG) solid or stranded-copper wire rated at 90 °C (194 °F) or

greater to connect the protective earth ground. Tighten the nuts on the

protective earth ground terminal stud to a torque of 16.27 N•m (12 lb•in).

Connect the functional earth ground as shown in Figure 13

Figure 13 - Protective Earth Ground Connection

.

Some chassis can have a second protective earth-ground terminal stud. If your

application requires the use of a second protective earth-ground terminal stud,

please use the additional protective earth-ground terminal stud to connect the

chassis to the ground bus.

Item Description

1 Protective earth-ground terminal stud

2Star washer

3 Equipment grounding conductor (ground lug with 2.1 mm² [14 AWG] solid or stranded-copper wire rated

4 Nut with captive star washer

5 Wiring terminal block (bottom terminal is protective earth ground)

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 25

at 90 °C [194 °F] or greater)

Page 26

Chapter 1 Install Chassis and Power Supplies

2

3

4

1

5

45803

2

3

1

45803

Connect the Grounding Conductors to the Ground Bus

Connect the equipment grounding conductors (functional and protective

earth ground) directly from each chassis to an individual bolt on the ground bus.

Figure 14 - Ground Bus Connection

Item Description

1 Flat or star washer

2Bolt

3 Equipment grounding conductor (from protective and functional earth ground connections)

4Ground bus

5 Ground bus mounting

Connect Ground Bus to Grounding-electrode System

Use a grounding-electrode conductor to connect the ground bus to the

grounding-electrode system.

At minimum, use 8.3 mm (8 AWG) solid or stranded-copper wire rated at

90 °C (194 °F) or greater for the grounding-electrode conductor to guard against

EMI. The National Electrical Code specifies safety requirements for the

grounding-electrode conductor.

Figure 15 - Grounding-electrode System Connection

Item Description

1 Flat or star washer

26 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

2Bolt

3 Equipment grounding conductor (ground lug with minimum 8.3 mm² [8 AWG] solid or stranded-

copper wire rated at 90 °C [194 °F] or greater)

Page 27

Connect the Power

IMPORTANT

L1

L2

L1

L2

+

-

+

-

AC Power Supplies DC Power Supplies

1

2

3

1

3

2

4

4

45806

45807

Install Chassis and Power Supplies Chapter 1

WARNING: If you connect or disconnect wiring while the field-side power is on,

an electrical arc can occur. This can cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous before

proceeding.

ATT EN TI ON : Do not wire more than 1 conductor on any single terminal.

Use 15 A time-delay type fuse in all ungrounded power connections.

Use 2.5 mm (14 AWG) solid or stranded-copper wire rated at 90 °C (194 °F), or

greater, 1.2 mm (3/64 in.) insulation maximum to connect power. Tighten the

terminals to a torque of 0.8 N•m (7 lb•in).

Connect the power as shown in Figure 16

.

The power supplies’ voltage input connections are auto-sensing.

You do not use a jumper, for example, a 120/240V AC jumper, when

connecting external power to the power supply, as shown in Figure 16

Figure 16 - Power Connection

Item Description, AC Power Supplies Description, DC Power Supplies

1 L1 (high side of line power) DC+ (positive supply)

2 L2 (low side of line power) DC- (negative supply return)

3 This terminal is not used and is capped to prevent use

4 2.5 mm² (14 AWG) 75 °C (167 °F) copper wire with 1.2 mm (3/64-in.) insulation

.

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 27

Page 28

Chapter 1 Install Chassis and Power Supplies

20264b-M

43615

Remove the Protective Label

Apply Power to the Chassis

ATT EN TI ON : Make sure the chassis is mounted and all panel fabrication is

complete before you remove the protective label. This label protects the power

supply from metal shavings falling inside the power supply and damaging it

during operation.

Remove the plastic label from the top of the power supply.

Tur n o n the pow er.

28 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 29

Install Chassis and Power Supplies Chapter 1

75

60

45

30

15

0

0 20 40 60 80 100 120

6

100

75

60

45

30

15

0

0 20 40 60 80 100 120

4

95

75

60

45

30

15

0

0 20 40 60 80 100 120

4

95

42

35

28

21

14

7

0

0 10 20 30 40 50 60 70

64

6

43895

1756-PA72/C, 1756-PA75/B (AC)

1756-PB72/C, 1756-PB75/B (DC)

43896

Real Power (Watts)

Backplane Power

Load (Watts)

Apparent Power (Watts) = Transformer Load (VA) = Real Power (Watts)

Backplane Power

Load (Watts)

Real Power (Watts)

1756-PH75/B, 1756-PC75/B (DC)

43618

Backplane Power

Load (Watts)

Real Power (Watts)

Backplane Power

Load (Watts)

Real Power (Watts)

1756-PBXT (DC)

1756-PAXT (AC)

Backplane Power

Load (Watts)

45808

45809

Real Power (Watts)

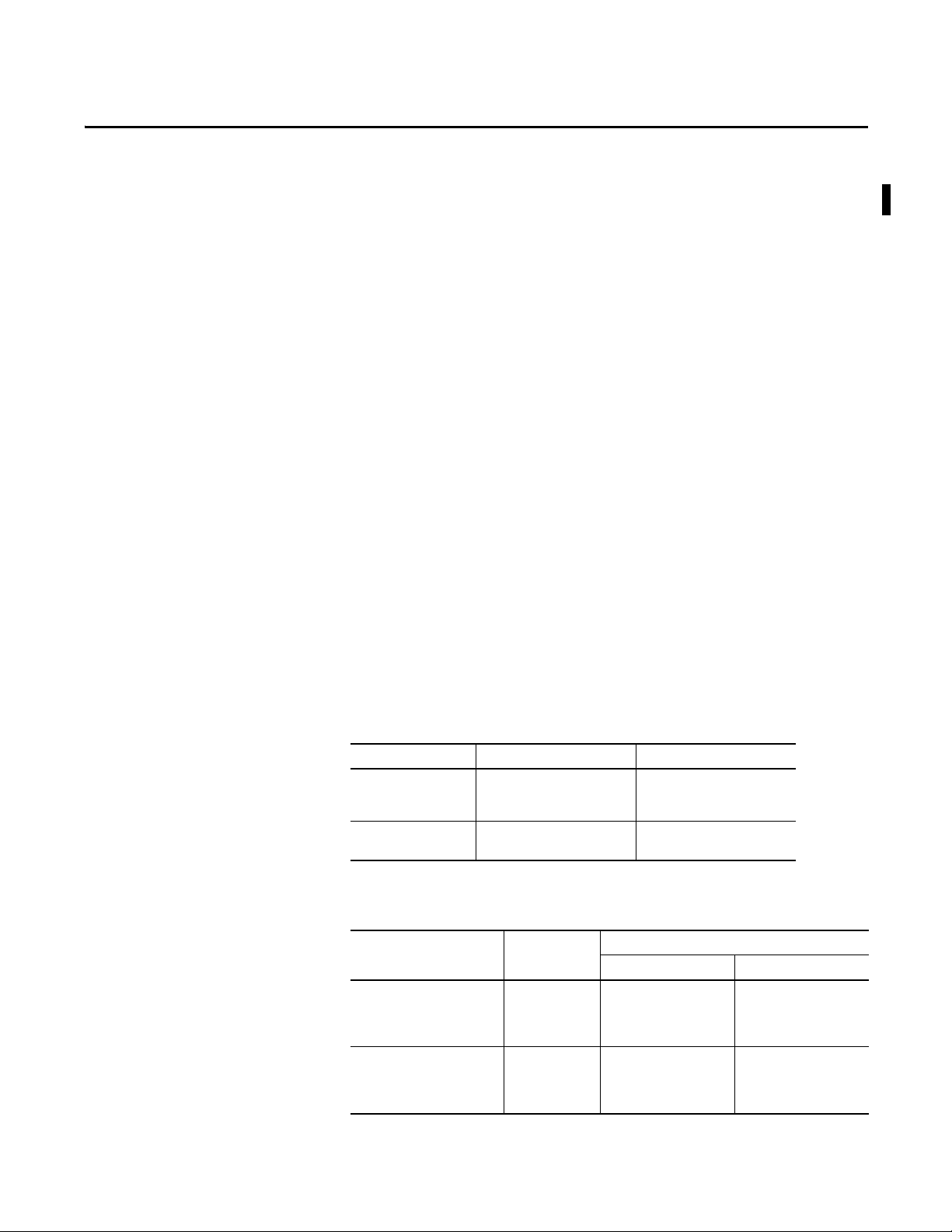

Input Power Requirements and Transformer Sizing

These graphs show the input power requirements for the power supplies, given

the power they are providing to the modules in the chassis.

Follow these steps to determine the power requirements for your chassis.

1. Calculate the Backplane Power Load by adding the power draw (in Watts)

for all of the planned modules.

Refer to the module specification tables in the ControlLogix Selection

Guide, publication 1756-SG001

, for module power draws.

2. Locate the Backplane Power Load on the graph’s vertical (y) axis and

determine the corresponding Real Power (input-power) rating on the

horizontal (x) axis.

The Real Power value is the amount of power consumed by the power

supply.

Figure 17 - Power Supply Power Requirements

54

42

35

28

21

14

7

4

0

0 10 20 30 40 50 60

For more information about calculating the required power for your system, see

the ControlLogix Selection Guide, publication 1756-SG001

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 29

.

Page 30

Chapter 1 Install Chassis and Power Supplies

Status Indicator

45810

Troubleshoot the Power Supply

All ControlLogix power supplies have a green status indicator that remains ON

during normal operation.

If the indicator turns OFF during operation, take these steps to troubleshoot the

power supply.

1. Verify that the line voltage is within the specified range.

2. If the indicator remains OFF, turn off the power.

3. Loosen the screws holding the power supply to the chassis.

See step 7 on page 22

for the location of the screws on the power supply.

4. Slide the power supply out so that the rear connector is disconnected.

5. Turn on th e p ow er.

6. Follow these steps if the indicator does the following:

• Tur ns ON :

a. Verify that the Backplane Power Load of the system is within the

output rating of the power supply.

b. Turn off the power.

c. Reinstall the power supply in the chassis.

d. Turn on the power.

• Remains OFF:

Contact your local Allen-Bradley distributor.

30 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 31

Chapter 2

Install Chassis and Redundant Power Supplies

This chapter describes how to install standard and ControlLogix-XT versions of

the 1756 chassis with redundant power supplies.

Redundant Power Supplies

The redundant power supply system provides additional uptime protection for

chassis used in critical applications. The two remotely-mounted supplies are

designed to share the current required by the chassis and are available in AC

(catalog number 1756-PA75R/A or 1756-PAXTR) and DC (catalog number

1756-PB75R/A or 1756-PBXTR) versions that can be mixed or matched when

used in tandem.

In the event of a failure by one power supply, the remaining supply accommodates

the entire load of the chassis without disruption to chassis activity.

The 1756-PSCA2 chassis adapter is a passive device designed to funnel power

from one or two ControlLogix redundant power supplies to the single power

connector on the ControlLogix chassis (only Series B) backplane.

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 31

Page 32

Chapter 2 Install Chassis and Redundant Power Supplies

42655

2

3

1

4

Components of the Redundant System

The following figure shows the components of a redundant system in a typical

configuration.

Item Description Cat. No.

1 Redundant power supply 1756-PA75R/A and/or 1756-PB75R/A

2 Redundant power supply cable

(Length = 0.91 m [3 ft])

3 Redundant power supply chassis adapter 1756-PSCA2

4 Annunciator wiring

(Maximum length = 10 m [32.8 ft])

(1) Cable bend radius is 12.7 cm (5.0 in.)

(2) Optional user-provided annunciator wiring can be connected to the solid-state relay for status and troubleshooting

purposes. See page 50

(2)

for more information.

(1)

1756-CPR2

User-supplied

32 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 33

Install Chassis and Redundant Power Supplies Chapter 2

Tools Required

Parts Required

When installing your chassis and power supplies, the following items are

required:

• 3.18 mm (0.125 in.) slotted screwdriver

• 6.35 mm (0.25 in.) slotted or #2 Phillips-head screwdriver

• Torque screwdriver

• Needle-nose pliers

• Crimping tool

• Wire-stripping tool

• Drill

Each redundant power supply requires four, #10 Phillips screws for installation.

Eight, #10 Phillips screws are required to install two redundant power supplies.

Use these tables to determine the parts required to install your chassis. These

parts are not included with the chassis and must be ordered separately.

For each mounting tab on the chassis, the following parts are required.

Tab Position With SEM Screws

Top • 1 Phillips screw

• 1 flat washer

• 1 split-lock washer

Bottom 1 SEM screw • 1 Phillips screw

(1)

Without SEM Screws

N/A

• 1 star washer

(1) Phillips screw with attached star washer.

Table 6 - Mounting Tabs per Chassis

Chassis Number of

1756-A4, 1756-A7,

1756-A4LXT, 1756-A7LXT

1756-A10,

1756-A5XT, 1756-A7XT

1756-A13 4 top

1756-A17 5 top

Mounting Tabs

2 top

2 bottom

3 top

3 bottom

4 bottom

5 bottom

Total Parts Required Per Chassis

With SEM Screws Without SEM Screws

• 2 Phillips screws

• 2 flat washers

• 2 split-lock washers

• 2 SEM screws

• 3 Phillips screws

• 3 flat washers

• 3 split-lock washers

• 3 SEM screws

• 4 Phillips screws

• 4 flat washers

• 4 split-lock washers

• 4 SEM screws

• 5 Phillips screws

• 5 flat washers

• 5 split-lock washers

• 5 SEM screws

• 4 Phillips screws

• 2 flat washers

• 2 split-lock washers

• 2 star washers

• 6 Phillips screws

• 3 flat washers

• 3 split-lock washers

• 3 star washers

• 8 Phillips screws

• 4 flat washers

• 4 split-lock washers

• 4 star washers

• 10 Phillips screws

• 5 flat washers

• 5 split-lock washers

• 5 star washers

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 33

Page 34

Chapter 2 Install Chassis and Redundant Power Supplies

Plan the System

page 35

Install the Chassis and

Chassis Adapter

page 42

Ground the Chassis

page 45

Connect the Power

page 49

Remove the Protective Label

page 52

Apply Power to the Chassis

page 52

Install the Redundant

Power Sup plies

page 44

Follow These Steps

34 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 35

Install Chassis and Redundant Power Supplies Chapter 2

IMPORTANT

Plan the System

Use the following information to assist you in planning your system.

Redundant Power Supply and Chassis Compatibility

The redundant power supplies and chassis adapter are compatible with only

standard, Series B, ControlLogix chassis.

Table 7 - Chassis Compatibility

Power Suppl y Cat. No. Chassis Cat. No.

1756-PA75R 1756-A4/B, 1756-A7/B, 1756-A10/B, 1756-A13/B, 1756-A17/B,

1756-PB75R

1756-PAXTR 1756-A4/B, 1756-A7/B, 1756-A10/B, 1756-A13/B, 1756-A17/B,

1756-PBXTR

1756-A4LXT, 1756-A5XT, 1756-A7LXT, 1756-A7XT

1756-A4LXT, 1756-A5XT, 1756-A7LXT, 1756-A7XT

Spacing Requirements

Use the following information to plan your installation.

Make sure you meet the minimum spacing requirements specified:

• 10.2 cm (4.0 in.) between redundant power supplies and cabinet housing

the control system

• 12.7 cm (5.0 in.) below redundant power supply for 1756-CPR2 cable

routing and connection

• 2.55 cm (1.0 in.) between redundant power supplies

• 15.3 cm (6.0 in.) between chassis and heat source

• 5.1 cm (2.0 in.) between wireway and top or bottom of chassis or

redundant power supply

• 12.7 cm (5.0 in.) of clearance next to the chassis adapter for 1756-CPR2

cable routing to conform to cable bend radius

Chassis and redundant power supplies are intended to be mounted only

horizontally. Do not mount vertically.

The 1756-CPR2 cable has a bend radius of 12.7 cm (5.0 in.). The chassis must

have a minimum clearance of 12.7 cm (5.0 in.) on the left side in order to

properly route and connect the 1756-CPR2 cable. The redundant power

supplies must have a minimum clearance of 12.7 cm (5.0 in.) below the supply

to properly route and connect the 1756-CPR2 cable.

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 35

Page 36

Chapter 2 Install Chassis and Redundant Power Supplies

45828 (2)

15.3 (6.0)

10.2

(4.0)

12.7

(5.0)

5.1 (2.0)

5.1 (2.0)

15.3 (6.0)

10.2

(4.0)

10.2

(4.0)

15.3

(6.0)

2.55

(1.0)

12.7

(5.0)

12.7

(5.0)

5.1 (2.0)

12.7 (5.0)

The 10.2 (4.0) measurement

to the side of the enclosure

can include the wireway on

the right side of the chassis.

15.3 (6.0)

15.3 (6.0)

15.3 (6.0)

12.7

(5.0)

12.7

(5.0)

12.7

(5.0)

WIREWAY

WIREWAY

W

I

R

E

W

A

Y

Dimensions are in cm (in.).

Figure 18 - Minimum Spacing Requirements

Table 8 - Spacing Requirements, Top and Bottom

From a To a chassis

Cabinet 15.3 cm (6.0 in.) 10.2 cm (4.0 in.), 12.7 cm (5.0 in.) (only

Chassis or other heat source 15.3 cm (6.0 in.) 15.3 cm (6.0 in.)

Wireway 5.1 cm (2.0 in.) 5.1 cm (2.0 in.), 2.7 cm (5.0 in.) (only

requires this space, mi n

To a redu nda nt po wer s upp ly

requires this space, min

bottom)

bottom)

Table 9 - Spacing Requirements, Sides

From a To a chassis

Cabinet 10.2 cm (4.0 in.), 12.7 cm (5. 0 in.) (only left

requires this space, mi n

side)

To a redu nda nt po wer s upp ly

requires this space, min

10.2 cm (4.0 in.)

36 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 37

Table 9 - Spacing Requirements, Sides

1.1

(0.433)

0.55

(0.217)

Top Moun ting

Hole Diameter

Bottom Mounting

Hole Diameter

17.5

(6.88)

14.4

(5.66)

42668

45829

15.8

(6.22)

7.0

(2.76)

Install Chassis and Redundant Power Supplies Chapter 2

From a To a chassis

requires this space, mi n

Chassis or other heat source 7.7 cm (3.0 in.), 12.7 cm (5.0 in.) (only left

side)

Redundant power supply 7.7 cm (3.0 in.), 12.7 cm (5.0 in.) (only left

side)

Wireway No minimum spacing required, 12.7 cm

(5.0 in.) (only left side)

Mounting Dimensions

Use these dimensions to plan your chassis installation.

Dimensions are in cm (in.).

Figure 19 - Redundant Power Supplies

To a redu nda nt po wer s upp ly

requires this space, min

7.7 cm (3.0 in.)

2.55 cm (1.0 in.)

No minimum spacing required

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 37

Page 38

Chapter 2 Install Chassis and Redundant Power Supplies

1.1

(0.433)

0.55

(0.217)

Top Moun ting

Tab Diameter

Bottom Mounting Tab

Diameter

Right-side View of All Chassis

16.9

(6.65)

14.5

(5.71)

0.78

(0.31)

43591

45797

7.0

(2.76)

4.7

(1.85)

16.9

(6.65)

18.6

(7.32)

45830

15.8

(6.22)

14.5

(5.70)

17.5

(6.89)

14.5

(5.70)

16.9

(6.65)

29.1

(11.46)

45831

15.8

(6.22)

4.7

(1.85)

Figure 20 - Chassis Common Dimensions

Figure 21 - 1756-A4 Chassis and Chassis Adapter

Figure 22 - 1756-A7 Chassis and Chassis Adapter

38 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 39

Figure 23 - 1756-A10 Chassis and Chassis Adapter

14.5

(5.70)

16.9

(6.65)

40.6

(15.98)

45832

15.8

(6.22)

5.71

(2.25)

14.0

(5.51)

14.0

(5.51)

14.5

(5.70)

16.9

(6.65)

51.1

(20.12)

45833

15.8

(6.22)

5.71

(2.25)

14.0

(5.51)

14.0

(5.51)

10.5

(4.13)

14.5

(5.70)

16.9

(6.65)

66.1

(26.02)

45834

15.8

(6.22)

4.7

(1.85)

14.0

(5.51)

14.0

(5.51)

13.3

(5.22)

13.3

(5.22)

Figure 24 - 1756-A13 Chassis and Chassis Adapter

Install Chassis and Redundant Power Supplies Chapter 2

Figure 25 - 1756-A17 Chassis and Chassis Adapter

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 39

Page 40

Chapter 2 Install Chassis and Redundant Power Supplies

6.29

(2.48)

16.9

(6.65)

20.1

(7.91)

15.8

(6.22)

14.5

(5.70)

7.0

(2.76)

45866

14.5

(5.70)

16.9

(6.65)

42.1

(16.57)

15.8

(6.22)

7.3

(2.87)

14.0

(5.51)

14.0

(5.51)

45867

Figure 26 - 1756-A4LXT Chassis and Chassis Adapter

Figure 27 - 1756-A5XT/A7XT Chassis and Chassis Adapter

40 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 41

Install Chassis and Redundant Power Supplies Chapter 2

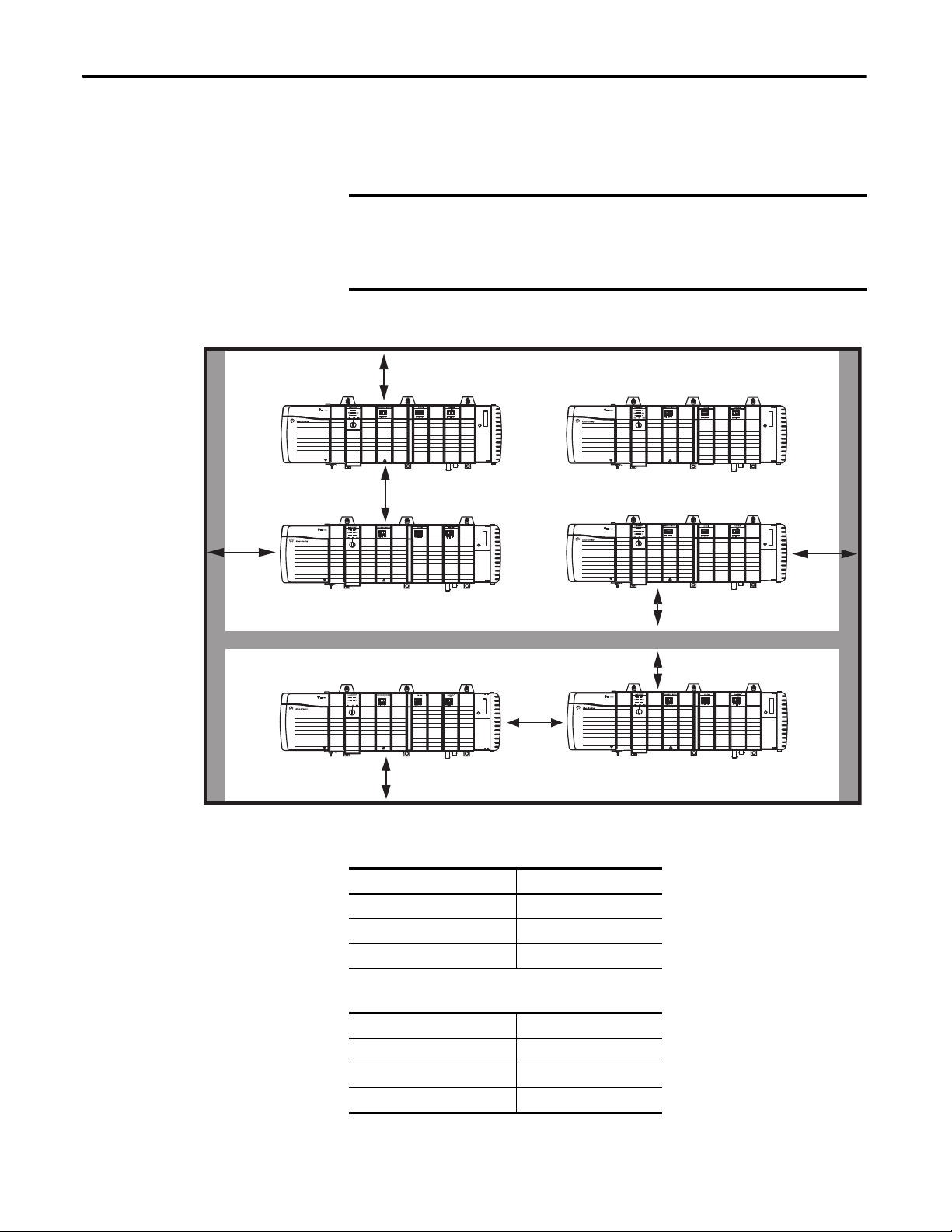

Figure 28 - Recommended Configurations for a System That Uses One Chassis

42655 42657

Figure 29 - Recommended Configurations for a System That Uses Two Chassis

4265542658

System Configuration Recommendations

We recommend you use one of these methods to configure your redundant

power supply system.

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 41

Page 42

Chapter 2 Install Chassis and Redundant Power Supplies

IMPORTANT

20289-M

Install the Chassis and Chassis Adapter

After planning your system, use the instructions below to properly install your

chassis and 1756-PSCA2 chassis adapter.

ATT EN TI ON : Do not drill holes above an installed chassis. Metal chips from

drilling can damage the backplane and cause intermittent operation.

Chassis are intended to be mounted only horizontally. Do not mount vertically.

1. Drill holes in the back panel of the enclosure for the chassis mounting tabs.

See the Spacing Requirements on page 35 for assistance in hole placement.

2. Scrape paint off the back panel for an electrical connection between the

chassis and back panel.

3. Hold the chassis in place against the holes.

ATT EN TI ON : If the chassis mounting tabs do not lay flat before the screws are

tightened, use additional washers as shims so the chassis is not warped by

tightening the screws.

Warping a chassis can damage the backplane and cause intermittent operation.

4. Install the hardware for the top mounting tabs and tighten.

See Parts Required

on page 33 for more information.

42 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 43

Install Chassis and Redundant Power Supplies Chapter 2

20290-M

Leave the farleft bottom

tab open.

Card Guide

45835

5. Leaving the far-left bottom tab open for functional ground, install the

remaining tab screws.

6. Align the 1756-PSCA2 adapter’s circuit board with the card guides on the

left side of the chassis and slide the adapter back until it is flush with the

front of the chassis.

WARNING: If you connect or disconnect the 1756-CPR2 cables while

either backplane power source is on, an electrical arc can occur. This

could cause an explosion in hazardous location installations. Repeated

electrical arcing causes excessive wear to contacts on both the module

and its mating connector. Worn contacts may create electrical

resistance that can affect module operation.

Be sure that power is removed or the area is nonhazardous before

proceeding.

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 43

Page 44

Chapter 2 Install Chassis and Redundant Power Supplies

Install the Redundant Power Supplies

Follow these steps to install your redundant power supplies.

ATT EN TI ON : Do not drill holes for a redundant power supply above installed

equipment. Metal chips from drilling can damage the backplane and cause

intermittent operation.

1. Drill holes in the back panel of the enclosure for the redundant power

supply.

See the Spacing Requirements

2. Insert the #10 Phillips screws into the top mounting holes, but do not

tighten completely.

3. Slide the redundant power supply over the installed screws and tighten the

screws.

4. Insert the bottom screws and tighten them.

5. Repeat these steps for additional power supplies.

on page 35 for assistance in hole placement.

44 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 45

Install Chassis and Redundant Power Supplies Chapter 2

TIP

Functional Earth Ground, page 46

Protective Earth

Ground, page 47

Cabinet

To Grounding-electrode System

45836

Ground Bus

8.3 mm² (8 AWG) solid

or stranded-copper

wire rated at 90 °C

(194 °F) or greater

2.1 mm² (14 AWG) solid

or stranded-copper

wire rated at 90 °C

(194 °F) or greater

Ground the Chassis

Complete these steps to properly ground your system.

Grounding Step Page

Install a Central Ground Bus 46

Connect the Functional Earth Ground on the Chassis 46

Connect the Protective Earth Ground on the Chassis and

Redundant Power Supply

Connect the Grounding Conductors to the Ground Bus 48

Connect Ground Bus to Grounding-electrode System 48

Figure 30

shows an example grounding configuration. After you complete the

47

grounding steps, your system looks similar to this figure.

To minimize the resistance between the chassis and ground connection, keep

wire lengths as short as possible.

Figure 30 - Grounding Configuration Example

Use these guidelines when connecting the grounding:

• Use a steel enclosure to guard against electromagnetic interference (EMI).

• Install a bonding wire for electrical contact between the enclosure door

and the enclosure; do not rely on the hinge.

• Make sure the enclosure-door viewing window is a laminated screen or a

conductive optical substrate (to block EMI).

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 45

Page 46

Chapter 2 Install Chassis and Redundant Power Supplies

20291-M

1

3

4

2

Install a Central Ground Bus

Each enclosure must contain a central ground bus. The ground bus is the

common connection for each chassis within the enclosure and the enclosure

itself.

For more information on installing a central ground bus, refer to the Industrial

Automation Wiring and Grounding Guidelines, publication 1770-4.1

.

Connect the Functional Earth Ground on the Chassis

Use 8.3 mm (8 AWG) solid or stranded-copper wire rated at 90 °C (194 °F) or

greater to connect the functional earth ground.

Connect the functional earth ground as shown in Figure 31

Figure 31 - Functional Earth Ground Connection

Item Description

1 Chassis mounting tab

2 Equipment grounding conductor (ground lug with 8.3 mm² [8 AWG] solid or

stranded-copper wire rated at 90 °C [194 °F] or greater)

3 M4 or M5 (#10 or #12) flat or star washer

4 M4 or M5 (#10 or #12) Phillips screw and flat or star washer (or SEM screw)

.

46 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 47

Install Chassis and Redundant Power Supplies Chapter 2

45837

5

2

4

3a

1

3b

45836

To Ground Bus

To G rou nd Bus

IMPORTANT

Connect the Protective Earth Ground on the Chassis and Redundant Power Supply

Use 2.1 mm (14 AWG) solid or stranded-copper wire rated at 90 °C (194 °F) or

greater to connect the protective earth ground. Tighten the nuts on the

protective earth ground terminal stud to a torque of 16.27 N•m (12 lb•in).

Connect the functional earth ground as shown in Figure 32

Figure 32 - Protective Earth Ground Connection

.

Some chassis can have a second earth ground terminal stud. Either of these

terminal studs can be used to connect the chassis to the ground bus.

Item Description

1Star washer

2 Nut with captive star washer

3a Equipment grounding conductor (ground lug with 2.1 mm² [14 AWG] solid or stranded-

3b Equipment grounding conductor (2.1 mm² [14 AWG] solid or stranded-copper wire rated

4 Protective earth-ground terminal stud

5 Wiring terminal block (bottom terminal is protective earth ground)

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 47

copper wire rated at 90 °C [194 °F] or greater)

at 90 °C [194 °F] or greater)

Page 48

Chapter 2 Install Chassis and Redundant Power Supplies

2

3

4

1

5

45803

2

3

1

45803

Connect the Grounding Conductors to the Ground Bus

Connect the equipment grounding conductors (functional and protective

earth ground) directly from each chassis to an individual bolt on the ground bus.

Figure 33 - Ground Bus Connection

Item Description

1 Flat or star washer

2Bolt

3 Equipment grounding conductor (from protective and functional earth ground connections)

4Ground bus

5 Ground bus mounting

Connect Ground Bus to Grounding-electrode System

Use a grounding-electrode conductor to connect the ground bus to the

grounding-electrode system.

At minimum, use 8.3 mm [8 AWG] solid or stranded-copper wire rated at 90 °C

[194 °F] or greater for the grounding-electrode conductor to guard against EMI.

The National Electrical Code specifies safety requirements for the groundingelectrode conductor.

Figure 34 - Grounding-electrode System Connection

Item Description

1 Flat or star washer

48 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

2Bolt

3 Equipment grounding conductor (ground lug with minimum 8.3 mm² [8 AWG] solid or stranded-

copper wire rated at 90 °C [194 °F] or greater)

Page 49

Install Chassis and Redundant Power Supplies Chapter 2

31176

31174

Connect the Power

Use the information in the following sections to connect the power.

Connect the 1756-CPR2 Cable

Use the 1756-CPR2 cable to connect your redundant power supply to the

1756-PSCA2 chassis adapter.

WARNING: If you connect or disconnect the 1756-CPR2 cables while either

backplane power source is on, an electrical arc can occur. This could cause an

explosion in hazardous location installations. Repeated electrical arcing causes

excessive wear to contacts on both the module and its mating connector. Worn

contacts may create electrical resistance that can affect module operation.

Be sure that power is removed or the area is nonhazardous before proceeding.

1. Connect the male end of the 1756-CPR2 cable to the 1756-PSCA2

chassis adapter.

2. Connect the female end of the 1756-CPR2 cable to the redundant

power supply.

3. Tighten the screws to hold the cable in place.

Make sure you tighten the screws all the way to hold the cable in place for

the life of the product.

4. Repeat these steps with the second redundant power supply.

Connect Power to the Redundant Power Supply

WARNING: If you connect or disconnect wiring while the field-side power is on,

an electrical arc can occur. This can cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous before

proceeding.

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 49

Page 50

Chapter 2 Install Chassis and Redundant Power Supplies

IMPORTANT

1756-PA75R/A (AC) 1756-PB75R/A (DC)

1

3

2

5

45839

4

1

3

2

5

45840

4

ATT EN TI ON : Do not wire more than 1 conductor on any single terminal.

Use 15 A time-delay type fuse in all ungrounded power connections.

Use 2.5 mm (14 AWG) solid or stranded-copper wire rated at 90 °C (194 °F), or

greater, 1.2 mm (3/64 in.) insulation maximum to connect power. Tighten the

terminals to a torque of 0.8 N•m (7 lb•in).

Connect the power as shown in Figure 35

.

The power supplies’ voltage input connections are auto-sensing.

You do not use a jumper, for example, a 120/240V AC jumper, when

connecting external power to the power supply, as shown in Figure 35

Figure 35 - Power Connection

Item Description, 1756-PA75R/A (AC) Description, 1756-PB75R/A (DC)

1 L1 (high side of line power) Not used

2 Not used DC+ (positive supply)

3 L2 (low side of line power) Not used

4 Not used DC- (negative supply return)

5 2.5 mm² (14 AWG) solid or stranded-copper wire rated at 90 °C (194 °F), or greater,

1.2 mm (3/64 in.) insulation max

.

For recommendations on how to route the wiring in your redundant power

supply application, see page 45

.

Connect the Solid-state Relay

A solid-state relay on your redundant power supplies can be connected to any

compatible monitoring or signaling device. This connection indicates if the

supplies are functioning properly.

50 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 51

Install Chassis and Redundant Power Supplies Chapter 2

The redundant power supply and the annunciator

cable that use different input power sources.

Redundant power supply and the annunciator cable

that use the same input power source.

The annunciator wiring must be tucked under the tab at the top of

the plastic barrier and routed separately from the power wires.

1

3

2

5

4

1

4

2

3

Configuration 1

Configurat ion 2

45841

45842

The relays are closed during standard operation. The solid-state relay contacts

open if either of these events occur:

• One or both of the supplies fail.

In this case, the contact opens on the failed supply (or supplies), and the

input module alerts you to the failure through the controller program.

• The connected redundant power supplies are turned OFF.

When you use the solid state relay annunciator function, connect a compatible

source voltage to either contact terminal. Then connect the other terminal to the

monitoring or signaling device.

ATT EN TI ON : Annunciator cable length is less than 10 m (32.8 ft).

The annunciator output is rated for resistive loads. Do not use it to drive the coil of

an electromagnetic relay.

Connect the solid-state relay as shown in Figure 36

.

Figure 36 - Solid-state Relay Connection

Item Description

1Source voltage

2 Annunciator cable to input module

3 0.25…2.5 mm² (22…14 AWG) solid or stranded-copper wire rated at 90 °C (194 °F), or

4 0.25…2.5 mm² (22…14 AWG) solid or stranded-copper wire rated at 90 °C (194 °F), or

5 Plastic barrier

greater, 1.2 mm (3/64 in.) insulation max

greater, 1.2 mm (3/64 in.) insulation max

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 51

Page 52

Chapter 2 Install Chassis and Redundant Power Supplies

42841

43615

Remove the Protective Label

ATT EN TI ON : Make sure the power supply is mounted and all panel fabrication

is complete before you remove the protective label. This label protects the

power supply from metal shavings falling inside the power supply and

damaging it during operation.

Remove the plastic label from the top of the power supply.

Apply Power to the Chassis

Tur n o n the pow er.

52 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 53

Install Chassis and Redundant Power Supplies Chapter 2

0

7

14

21

28

35

42

10 20 30 40 50 60 70 80 0

75

6

0

7

14

21

28

35

42

10 20 30 40 50 60 70 80 0

64

6

75

60

45

30

15

0

0 20 40 60 80 100 120

115

13

75

60

45

30

15

0

0 20 40 60 80 100 120

110

7

43588

1756-PA75R/A (AC)

Backplane Power

Load (Watts)

Real Power (Watts)

Real Power (Watts)

Backplane

Power Load

1756-PB75R/A (DC)

43589

1756-PAXTR (AC)

Backplane Power

Load (Watts)

Real Power (Watts)

Real Power (Watts)

Backplane Power

Load (Watts)

1756-PBXTR (DC)

Apparent Power (Watts) = Transformer Load (VA) = Real Power (Watts)

43897

43898

Input Power Requirements and Transformer Sizing

These graphs show the input power requirements for the power supplies, given

the power they are providing to the modules in the chassis.

Follow these steps to determine the power requirements for your chassis.

1. Calculate the Backplane Power Load by adding the power draw (in Watts)

for all of the planned modules.

Refer to the module specification tables in the ControlLogix Selection

Guide, publication 1756-SG001

, for module power draws.

2. Locate the Backplane Power Load on the graph’s vertical (y) axis and

determine the corresponding Real Power (input-power) rating on the

horizontal (x) axis.

The Real Power value is the amount of power consumed by the power

supply.

Figure 37 - Power Supply Power Requirements

For more information about calculating the required power for your system, see

the ControlLogix Selection Guide, publication 1756-SG001

Rockwell Automation Publication 1756-IN005C-EN-P - March 2014 53

.

Page 54

Chapter 2 Install Chassis and Redundant Power Supplies

Power

Non-red

45843

Troubleshoot the Redundant Power Supplies

The redundant power supplies have a green status indicator for power and an

amber status indicator for non-redundancy.

The following table describes how to use the status indicators to troubleshoot

your redundant power supplies.

Power Indicator Non-red Indicator Description Take This Action

Solid green Off Both power supplies are operating properly. None

Solid green Solid amber This power supply is operating properly, but is the only

power supply providing power to the chassis adapter.

Off Solid amber All possible connections are made, but the power supply is

turned off.

Off Off Any of the following conditions can apply: Take the corresponding action:

The supply is turned OFF. Turn the power supply ON.

Line voltage is not within the specified range. Verify that line power is in the specified range. If the indicators

All connections are made, but input power is not

supplied.

All connections are made, including input power, but the

output cable (1756-CPR2) is not connected.

The power supply is ON but defective. The power supply can need to be replaced.

Check the other power supply.

Turn the power supply ON. If the power supply does not turn ON, follow

these steps.

1. Remove the input power from the power supply

2. Wait 30 seconds

3. Reconnect the input power

4. Turn the power supply ON.

If the power supply still does not turn ON, it can need to be replaced.

remain O FF, cycle power.

Verify that input power is supplied and turn the power supply ON.

Connect the output cable and turn the power supply ON.

Chassis Adapter Status Indicator

The chassis adapter has a green power status indicator. When the status indicator

is solid green, the chassis is receiving power from the redundant power supplies. If

the indicator is off, the chassis is not receiving power from the redundant power

supplies. See the table above to troubleshoot the redundant power supplies.

54 Rockwell Automation Publication 1756-IN005C-EN-P - March 2014

Page 55

Install Chassis and Redundant Power Supplies Chapter 2

IMPORTANT

Remove or Replace a Redundant Power Supply

Use this information to remove or replace a redundant power supply.

WARNING: Remove or replace power supplies only when backplane and power

supply power are removed or the area is known to be nonhazardous. Removal

or replacement of a power supply in a hazardous area can cause an electrical arc

across the contacts if backplane power is still applied.

You can replace one redundant power supply while the other supply is

operating in nonredundant mode without affecting chassis operation.

Remove a Redundant Power Supply

Follow these steps to remove the redundant power supply.

1. Turn the r ed un da nt po we r supp ly OFF.

2. Disconnect the line power source voltage from the redundant power

supply and annunciator.

3. Remove the wiring terminal blocks.

4. Unscrew and disconnect the 1756-CPR2 cable.