Page 1

ControlLogix

SynchLink Module

1756-SYNCH

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may

be present.

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be

dangerous temperatures.

Page 3

Summary of Changes

Introduction

New and Revised Information

This release of this publication contains updated information. Change

bars, as shown in the right margin of this page, designate locations in

the publication that contain changed information.

Table Summary of Changes.1 lists the new and revised information included in

this publication.

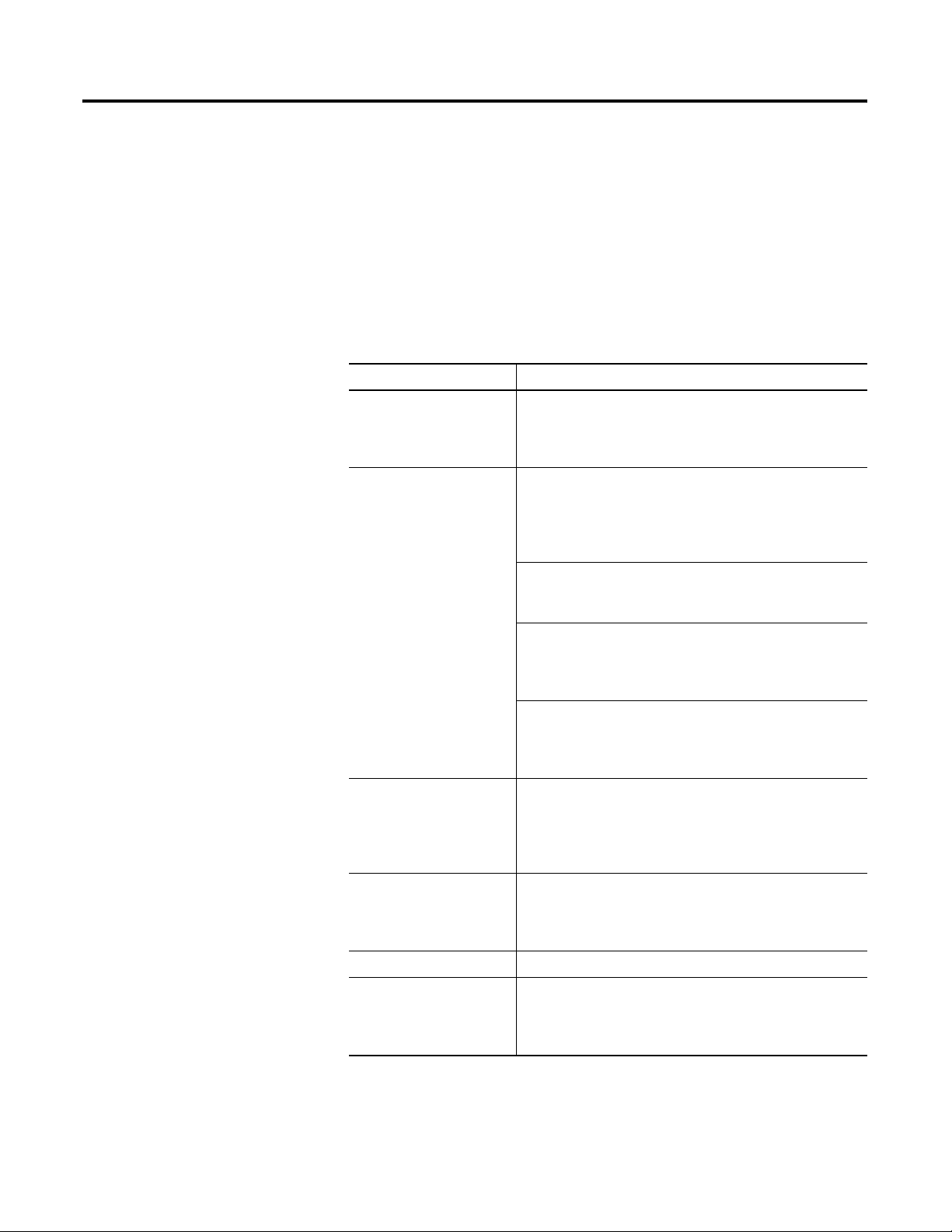

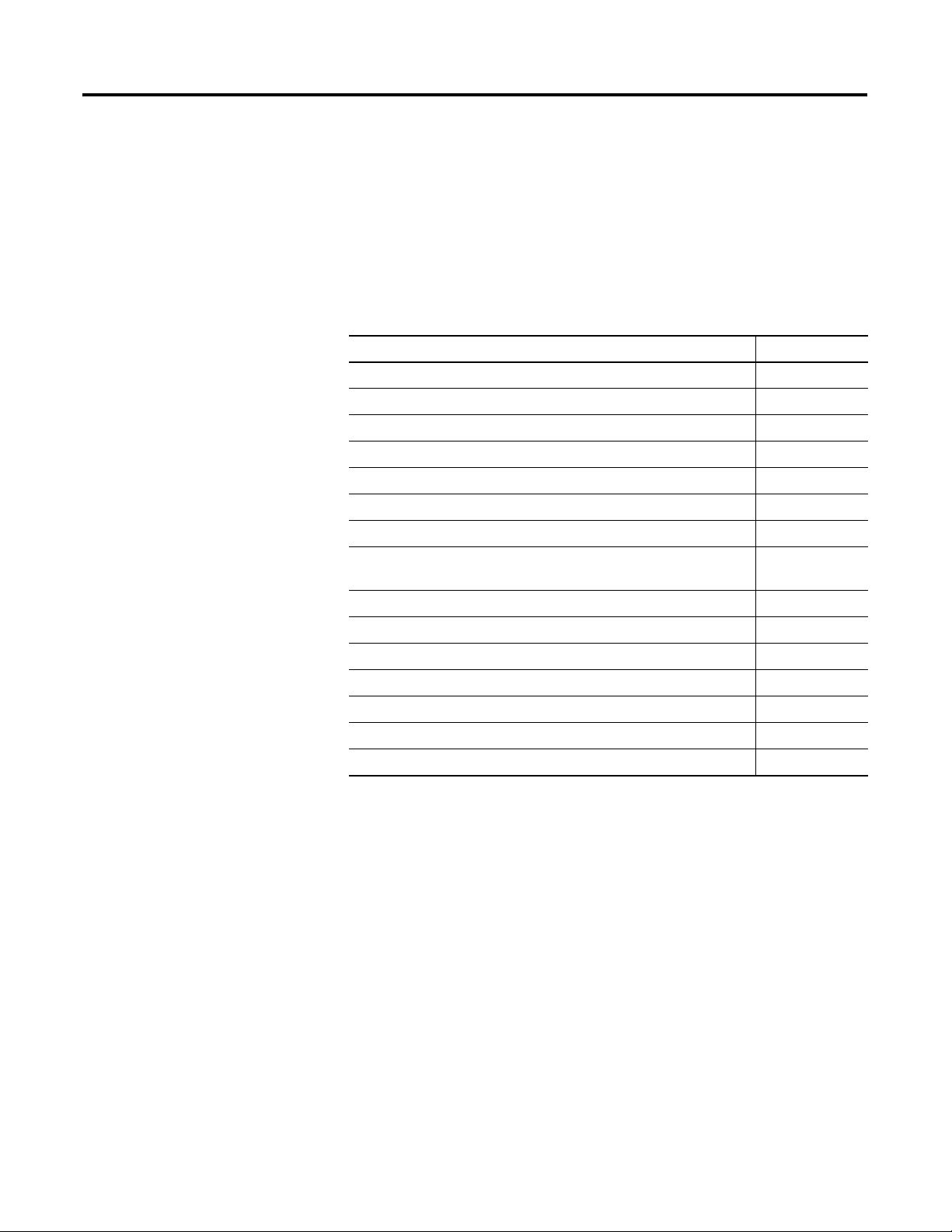

Table Summary of Changes.1

In this section: This information was changed or added:

Chapter 2 The brief description of Configuring Time Mastership

Functionality was changed to reflect changes on the module.

For more information, see page 2-5.

Chapter 3 For 1756-SYNCH modules using firmware revision 2.18 or

greater, the module can now use its last configuration when

its connection to the owner-controller closes.

For more information, see page 3-5.

The electronic keying description has been revised.

For more information, see page 3-11.

The Multiplier description has been revised to describe how

the module may truncate values beyond the decimal point.

For more information, see page 3-17.

The CST and SynchLink Mastership description has

changed significantly.

For more information, see page 3-18.

Chapter 5 New configuration screens are included to reflect the

1756-SYNCH module’s new role in Coordinated System Time

(CST) Mastership.

For more information, see page 5-7.

Chapter 6 The behavior of the 1756-SYNCH module’s status indicators

has changed slightly.

For more information, see page 6-2.

Appendix A Updated specifications are available.

Appendix E A full description of the 1756-SYNCH module’s newly

incorporated Configuration Data Tags is available.

For more information, see page E-3.

Other changes have been made throughout this manual and, although

not significant enough to warrant mention in the table above, they are

marked by change bars.

1 Publication 1756-UM521C-EN-P - July 2004

Page 4

Summary of Changes 2

Publication 1756-UM521C-EN-P - July 2004

Page 5

Preface

About This Preface

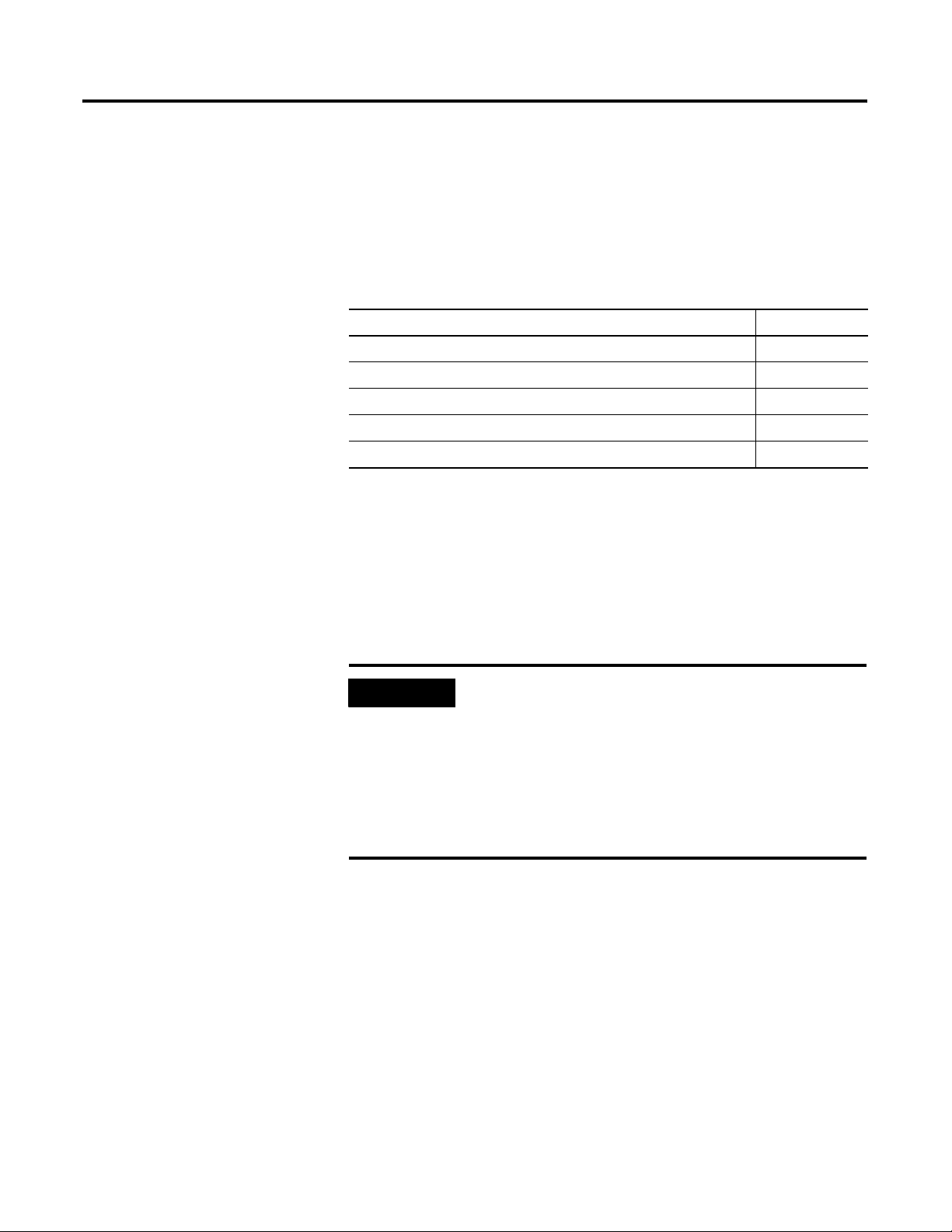

This preface describes how to use this manual. The following table

describes what this preface contains and its location.

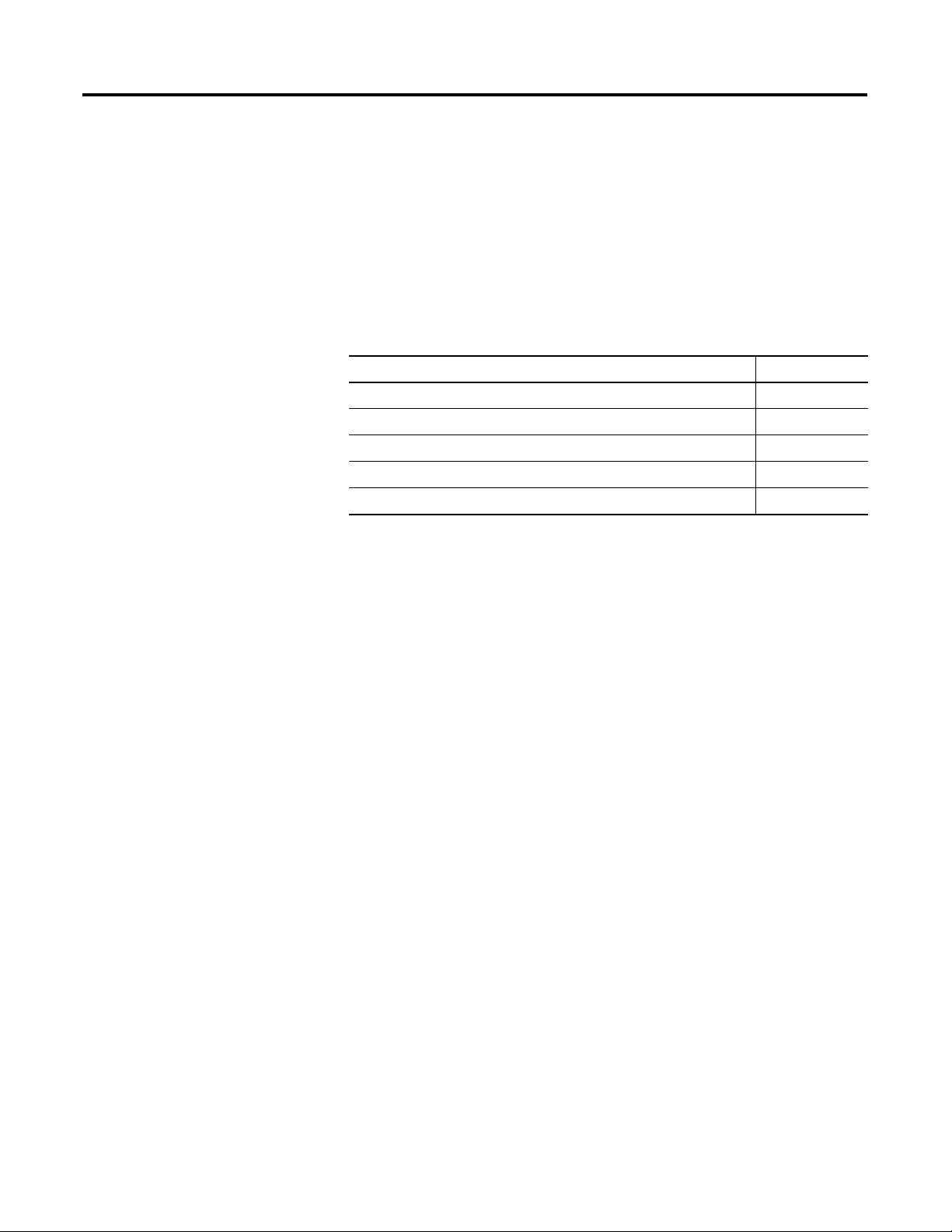

Table Preface.1

For information about: See page:

Who Should Use This Manual Preface-1

Purpose of This Manual Preface-1

Using the Latest Module Firmware Preface-2

What This Manual Contains Preface-4

Related Products and Documentation Preface-5

Who Should Use This Manual

Purpose of This Manual

You must be able to program and operate an Allen-Bradley

ControlLogix™ controller and ControlLogix I/O modules to efficiently

use your SynchLink™ module.

We assume that you know how to do this in this manual. If you do

not, refer to Related Documentation, before you attempt to use this module.

IMPORTANT

This manual describes how to install, configure, and troubleshoot

your ControlLogix SynchLink module.

SynchLink should be used in conjunction with a

standard control network, such as ControlNet or

Ethernet. A standard network is used for general

control interlocking and transfer of diagnostic data

across the system.

SynchLink does not function as a standard control

network (e.g. it broadcasts data in a unidirectional

manner).

1 Publication 1756-UM521C-EN-P - July 2004

Page 6

Preface 2

Using the Latest Module Firmware

This manual describes changes to the 1756-SYNCH module when the

module uses firmware revision 2.18. Some of the features described in

this publication may not be available on modules using previous

firmware revisions.

We recommend that you upgrade your 1756-SYNCH module to

firmware revision 2.18 or greater when possible to use fully the

module’s functionality.

FLASH Upgrade the Module’s Firmware Revision

To update a 1756-SYNCH module’s firmware of a controller, first

install a firmware upgrade kit.

• An upgrade kit ships on a supplemental CD along with RSLogix

5000 software.

• To download an upgrade kit:

1. Go to www.ab.com.

2. Choose Product Support.

3. Choose Firmware Updates.

Update the Module

1. Connect the 1756-SYNCH module to the same network as

your workstation.

2. Start ControlFLASH software.

3. Choose N

4. Select the 1756-SYNCH catalog number and choose N

ext >.

ext >.

Publication 1756-UM521C-EN-P - July 2004

Page 7

5. Expand the network until you see the module. If the required

network is not shown, first configure a driver for the network in

RSLinx software.

6. Select the controller and choose OK.

7. Select the revision level to which you want to update the

1756-SYNCH module and choose N

ext >.

Preface 3

IMPORTANT

If the Revision list is empty, download a new

upgrade kit. Some older upgrade kits do not work

with new modules.

8. To start the update of the module, choose Finish and then Ye s.

After the module is updated, the status box displays

Update complete.

9. Choose OK.

10. To close ControlFLASH software, choose Cancel and then Yes

Publication 1756-UM521C-EN-P - July 2004

Page 8

Preface 4

What This Manual Contains

This user manual contains the following sections:

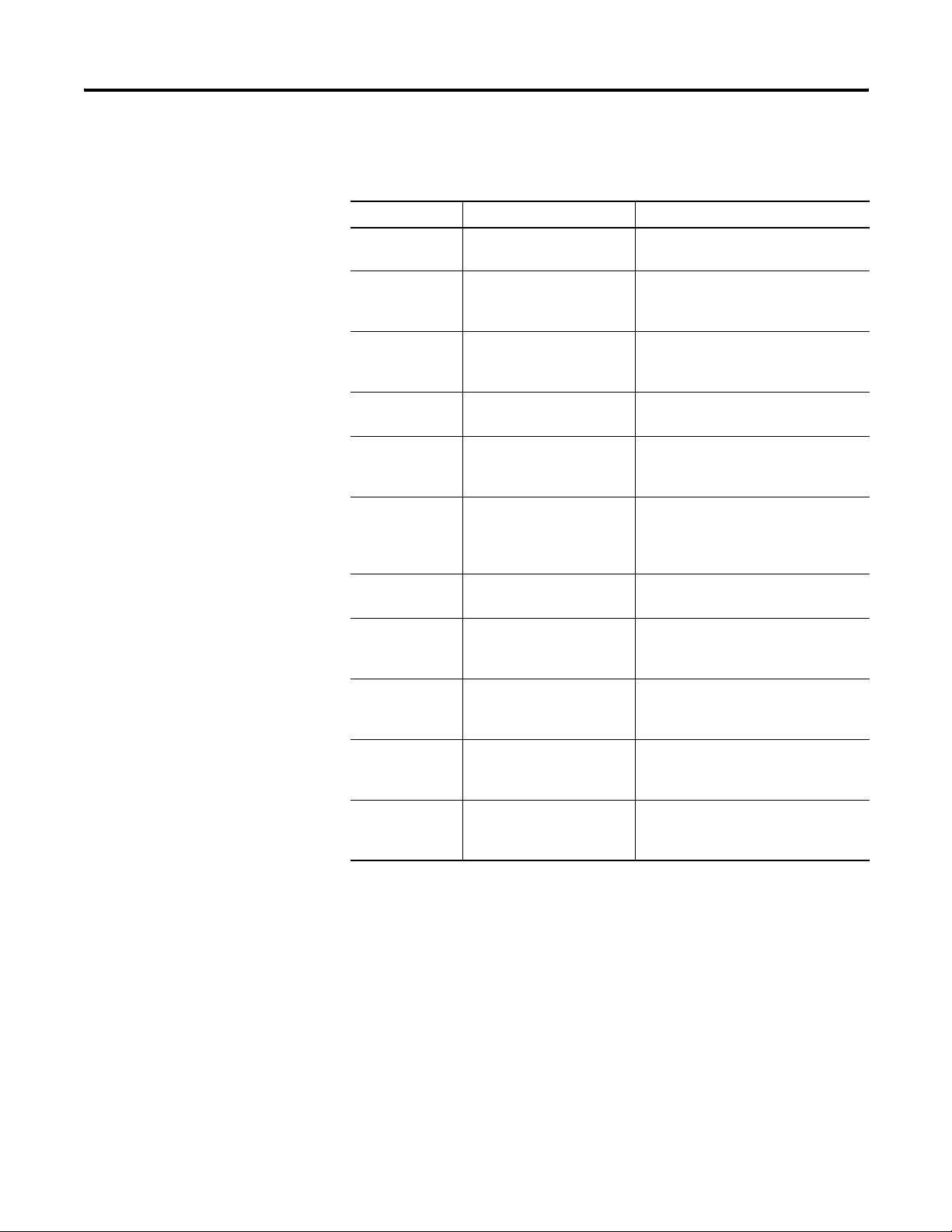

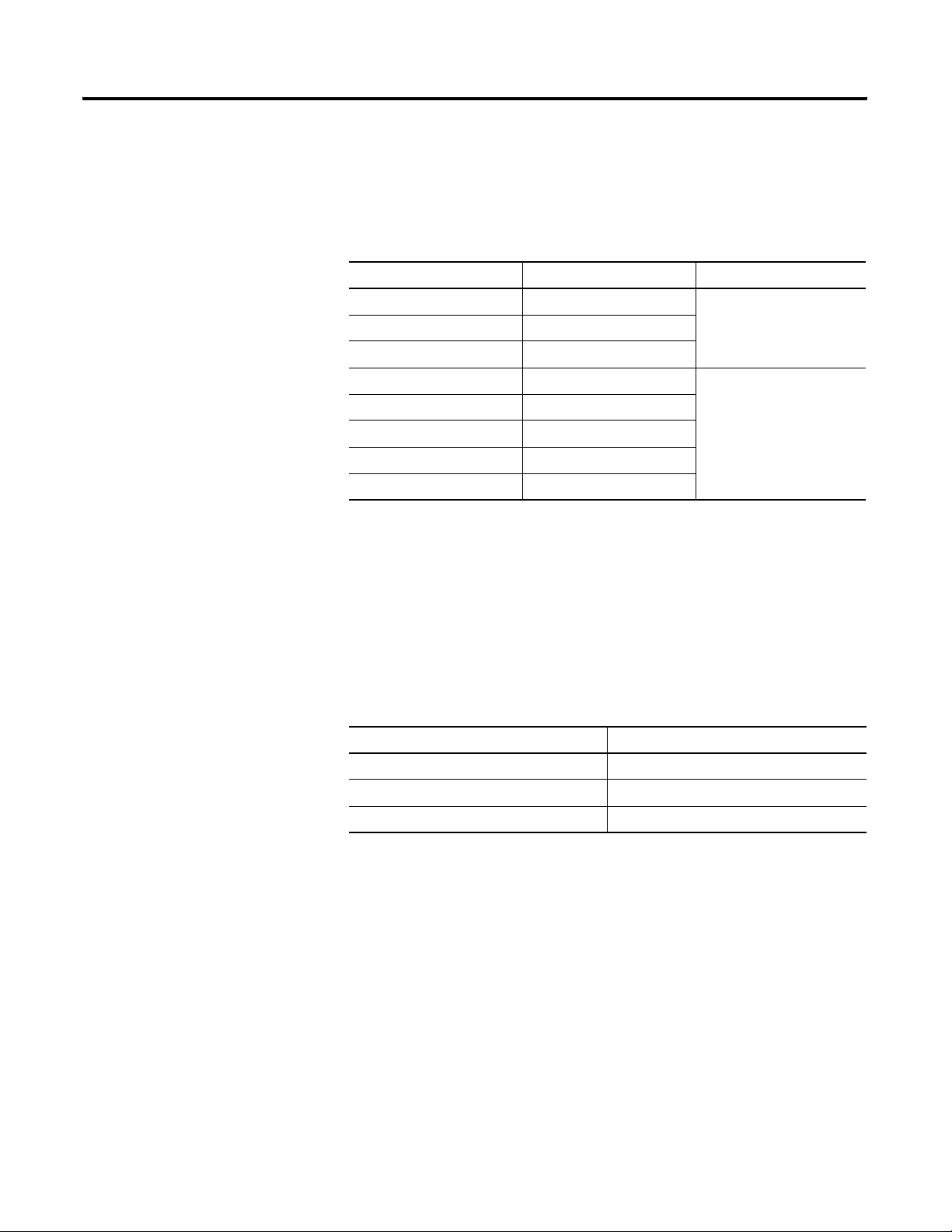

Table Preface.2

Section: Title: Description:

Chapter 1 What is the 1756-SYNCH

module?

Chapter 2 Time Synchronization in the

ControlLogix System

Chapter 3 SynchLink Module Features Listing and description of the

Chapter 4 Installing the SynchLink

Module

Chapter 5 Configuring the SynchLink

Module

Chapter 6 Troubleshooting the

SynchLink Module

Appendix A Specifications Listing of the ControlLogix SynchLink

Overview of the ControlLogix SynchLink

module

Description of how the ControlLogix

SynchLink module fits in the

ControlLogix system

ControlLogix SynchLink module’s

features

Description of how to install the

ControlLogix SynchLink module

Description of how to use RSLogix 5000

to configure the ControlLogix

SynchLink module

Description of how to use module

indicators and RSLogix 5000 to

diagnose and correct problems with the

ControlLogix SynchLink module

module’s specifications

Appendix B Configuring the Star

Configuration

Appendix C Configuring the Daisy Chain

Configuration

Appendix D Configuring the Ring

Configuration

Appendix E Software Configuration Tags Description of the module-defined data

Description of how to set up a star

configuration with the ControlLogix

SynchLink module

Description of how to set up a daisy

chain configuration with the

ControlLogix SynchLink module

Description of how to set up a ring

configuration with the ControlLogix

SynchLink module

types and tags created in RSLogix 5000

for the ControlLogix SynchLink module

Publication 1756-UM521C-EN-P - July 2004

Page 9

Preface 5

Related Products and Documentation

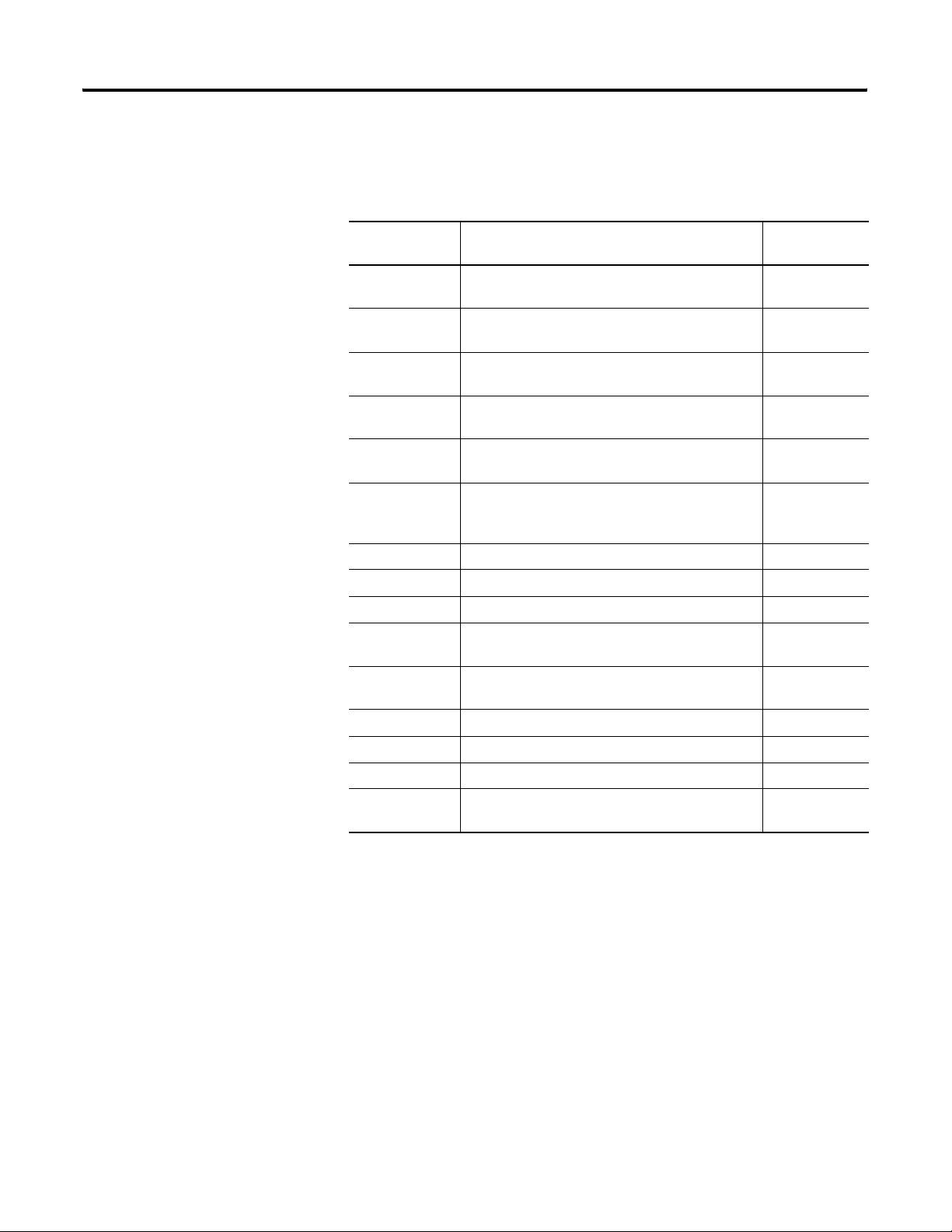

The following table lists related ControlLogix products and

documentation:

Table Preface.3 Related Documentation

Catalog

number:

1756-SYNCH ControlLogix SynchLink Module Installation

1756-A4, -A7,

-A10, -A13, -A17

1756-PA72,

-PB72

1756-PA75,

-PB75

1756-PA75R,

-PB75R

1756-Series ControlLogix Module Installation Instructions

1756-Series ControlLogix System User Manual 1756-UM001

Multiple numbers SynchLink Design Guide 1756-TD008

1751-SLBA SynchLink Base Block Installation Instructions 1751-IN001

Document title: Publication

number:

1756-IN575

Instructions

ControlLogix Chassis Installation Instructions 1756-IN080

ControlLogix Power Supply Installation Instructions 1756-5.67

ControlLogix Power Supply Installation Instructions 1756-5.78

ControlLogix Redundant Power Supply Installation

Instructions

(Each module has separate installation document.)

1756-IN573

Multiple

1756-IN

numbers

1751-SL4SP SynchLink 4-port Splitter Block Installation

Instructions

1751-SLBP SynchLink Bypass Switch Block Installation

Instructions

1756-DM ControlLogix Drive Module Installation Instructions 1756-IN577

1756-DM ControlLogix Drive Module User Manual 1756-UM522

PowerFlex 700S User Manual 20D-UM001

1756-IB16ISOE,

-IH16ISOE

ControlLogix Sequence of Events Module User

Manual

1751-IN002

1751-IN003

1756-UM528

For more information on these products, contact your local Rockwell

Automation distributor or sales office. The documentation listed in

Table Preface.3 is available at:

• http://www.ab.com/manuals

• http://www.theautomationbookstore.com

Publication 1756-UM521C-EN-P - July 2004

Page 10

Preface 6

Notes:

Publication 1756-UM521C-EN-P - July 2004

Page 11

What is the 1756-SYNCH module?

Time Synchronization in the

ControlLogix System

Table of Contents

Chapter 1

What is the ControlLogix SynchLink Module?. . . . . . . . . . . . . . . . . . 1-1

What Data Does the SynchLink Module Transfer?. . . . . . . . . . . 1-1

Why Synchronize Time Between Chassis? . . . . . . . . . . . . . . . . . . 1-2

What Are Some of the Features Available On the

ControlLogix SynchLink Module? . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Connecting a SynchLink Module to a SynchLink System . . . . . . . . . 1-3

Physical Features of the ControlLogix SynchLink Module . . . . . 1-4

Using Module Identification and Status Information. . . . . . . . . . . . . 1-5

Preventing Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Removal and Insertion Under Power . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2

Using the Coordinated System Time (CST) . . . . . . . . . . . . . . . . . . . . 2-2

Time Synchronization in a Distributed Control System . . . . . . . . . . 2-2

Time Synchronization in the SynchLink System . . . . . . . . . . . . . . . . 2-2

SynchLink Node Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

How Do the CST Clock and SynchLink Node Clock

Work Together? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Configuring Time Mastership Functionality. . . . . . . . . . . . . . . . . . . . 2-5

What are the SynchLink Configurations? . . . . . . . . . . . . . . . . . . . . . . 2-6

Star Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Daisy Chain Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Ring Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Cable Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Chapter 3

SynchLink Module Features

1 Publication 1756-UM521C-EN-P - July 2004

Module Features That Cannot Be Configured . . . . . . . . . . . . . . . . . . 3-2

Removal and Insertion Under Power (RIUP) . . . . . . . . . . . . . . . 3-2

Module Fault Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Full RSLogix 5000 Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Status Indicator (LED) Information. . . . . . . . . . . . . . . . . . . . . . . 3-4

Class I Division 2 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Agency Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Use Last Configuration When Connection Closes . . . . . . . . . . . 3-5

Module Features That Can Be Configured. . . . . . . . . . . . . . . . . . . . . 3-5

Communications Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Electronic Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Requested Packet Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

SynchLink Transmitted Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Transmitted Direct Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

CST and SynchLink Mastership . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Page 12

Table of Contents 2

Installing the SynchLink Module

Configuring the SynchLink Module

Chapter 4

Noting the Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Installing the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Connecting the Fiber Optic Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Removing the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Chapter 5

RSLogix 5000 Configuration Software . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Overview of the Configuration Process . . . . . . . . . . . . . . . . . . . . . . . 5-2

Choose a SynchLink Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Star Configuration.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Daisy Chain Configuration.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Ring Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Creating a New Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Downloading New Configuration Data . . . . . . . . . . . . . . . . . . . . . . . 5-8

Changing Configuration After Module Operation Has Begun . . . . . 5-9

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Troubleshooting the

SynchLink Module

Specifications

Chapter 6

Using the Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Using RSLogix 5000 to Troubleshoot the Module. . . . . . . . . . . . . . . 6-3

Determining Fault Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Using Diagnostic Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Message Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Enter Message Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Appendix A

Publication 1756-UM521C-EN-P - July 2004

Page 13

Configuring the Star Configuration

Configuring the Daisy Chain

Configuration

Configuring the Ring Configuration

Software Configuration Tags

Glossary

Index

Table of Contents 3

Appendix B

Using Remote Axis Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Configure Time Master Chassis - Master Node. . . . . . . . . . . . . . B-2

Configure Time Slave Chassis - End Node . . . . . . . . . . . . . . . . . B-8

Configure Time Slave Chassis - End Node . . . . . . . . . . . . . . . . B-13

Appendix C

Configure Time Master Chassis - Master Node. . . . . . . . . . . . . . C-2

Configure Time Slave Chassis - Center Node . . . . . . . . . . . . . . . C-7

Configure Time Slave Chassis - End Node . . . . . . . . . . . . . . . . C-12

Appendix D

Configure Time Master Chassis - Master Node. . . . . . . . . . . . . D-2

Configure Time Slave Chassis - Center Node . . . . . . . . . . . . . . D-7

Configure Time Slave Chassis - End Node . . . . . . . . . . . . . . . D-12

Appendix E

Accessing the Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Configuration Data Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Input Data Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

Output Data Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Installation Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

New Product Satisfaction Return . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Publication 1756-UM521C-EN-P - July 2004

Page 14

Table of Contents 4

Publication 1756-UM521C-EN-P - July 2004

Page 15

Chapter

1

What is the 1756-SYNCH module?

This chapter describes the ControlLogix SynchLink module. It also describes

what you must know and do before using the SynchLink module.

Table 1.1

For information on: See page:

What is the ControlLogix SynchLink Module? 1-1

Connecting a SynchLink Module to a SynchLink System 1-3

Using Module Identification and Status Information 1-5

Preventing Electrostatic Discharge 1-6

Removal and Insertion Under Power 1-6

What is the ControlLogix SynchLink Module?

A ControlLogix SynchLink module, through the use of fiber optic

communication technology, allows you to implement:

• time synchronization

• distributed motion control

• coordinated drive control

based on the ControlLogix and PowerFlex 700S platforms. In distributed

control system, the SynchLink module broadcasts reference data and

synchronizes time from a single ControlLogix chassis to multiple other chassis

at a high speed.

What Data Does the SynchLink Module Transfer?

The SynchLink module transfers multiple types of reference data between

chassis, including:

• Produced axis data for chassis to chassis remote axis control

• High speed drive reference data for chassis to drive control

• General control information that requires transfer at a high speed and in

a synchronized manner

1 Publication 1756-UM521C-EN-P - July 2004

Page 16

1-2 What is the 1756-SYNCH module?

Why Synchronize Time Between Chassis?

In synchronizing time between chassis, the SynchLink module allows you to:

• share motion data from chassis to chassis because a consistent time

reference is available among chassis for interpolation of velocity and

position data.

• timestamp I/O in multiple chassis and have a common time reference

with which to compare the timestamps.

For more information on how the SynchLink module impacts the time

references between ControlLogix chassis, see Chapter 2, Time

Synchronization in the ControlLogix System.

What Are Some of the Features Available On the ControlLogix

SynchLink Module?

The following are some of the features available on the ControlLogix

SynchLink module:

• Support of multiple SynchLink system configurations - Star, daisy chain

and ring

For more information on these functions, see Chapter 2, Time

Synchronization in the ControlLogix System.

For more information on how to configure the module with RSLogix

5000, see Chapter 5, Configuring the SynchLink Module.

• Removal and insertion under power (RIUP) - This system feature allows

you to remove and insert the module while power is applied. For more

information on RIUP, see page 1-6.

• Communication of remote axis data in a timely and

deterministic manner

• Communication of direct and buffered data

• Class I Division 2, UL, CSA, and CE Agency Certification

Publication 1756-UM521C-EN-P - July 2004

Page 17

What is the 1756-SYNCH module? 1-3

Connecting a SynchLink Module to a SynchLink System

ControlLogix SynchLink modules mount in a ControlLogix chassis and

connects to other SynchLink node through a fiber optic cable system.

For more information on the available fiber optic cables, see Table 1.2.

Table 1.2 Fiber Optic Cables Available with the 1756-SYNCH Module

Catalog number: Cable length Cables per box:

1403-CF001 1m (3.28ft) 2

1403-CF003 3m (9.84ft)

1403-CF005 5m (16.4ft)

1403-CF010 10m (32.8ft) 1

1403-CF020 20m (65.6ft)

1403-CF050 50m (164ft)

1403-CF100 100m (328ft)

1403-CF250 250m (820ft)

When you install the SynchLink module in a Star Configuration, you need to

use hubs as well as fiber optic cables. A hub is a combination of one base block

with up to four splitter blocks. A bypass switch block is also available for use in

the daisy chain configuration. For more information on the Star

Configuration, see 2-6.

For more information the hub components available for use with the

SynchLink module, see Table 1.3

Table 1.3 Hub Components Available with the 1756-SYNCH Module

Catalog Number: Hub Type:

1751-SLBA SynchLink Fiber Base Block

1751-SL4SP SynchLink Fiber 4-Port Splitter Block

1751-SLBP SynchLink Fiber Bypass Switch Block

For more information on SynchLink fiber optic cable systems, see The

SynchLink Design Guide, publication 1756-TD008.

Publication 1756-UM521C-EN-P - July 2004

Page 18

1-4 What is the 1756-SYNCH module?

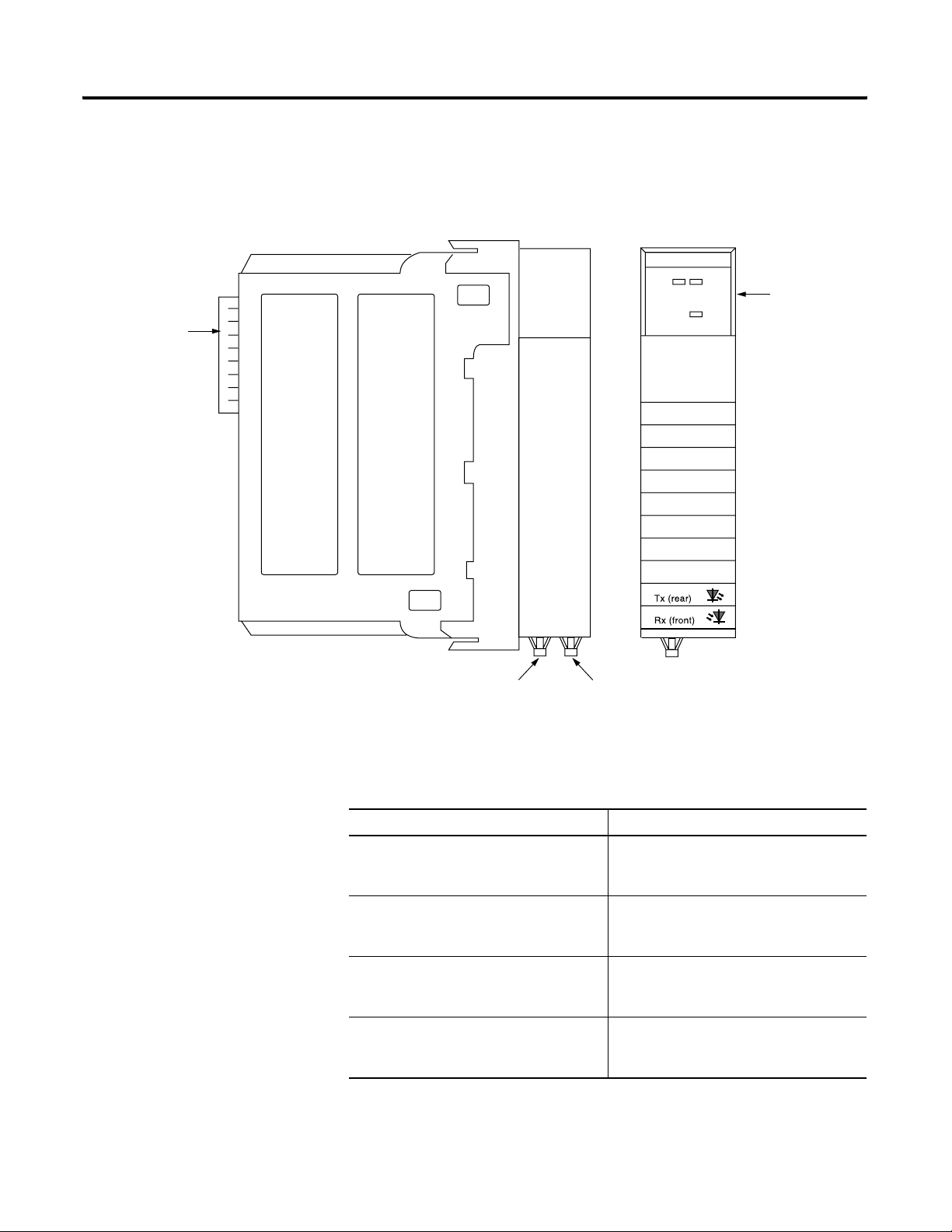

Physical Features of the ControlLogix SynchLink Module

Figure 1.1

Module side view Module front view

Backplane

Connector- Interface

to the ControlLogix

system backplane

Tr an sm it

Fiber Port

Receive

Fiber Port

LINK

COMM

LINK

SYNC

OK

Status

Indicators

42744

Publication 1756-UM521C-EN-P - July 2004

Table 1.4 lists descriptions of the physical features shown in Figure 1.1.

Table 1.4

Physical Feature: Description:

Backplane connector The backplane connector connects the

module to the ControlLogix chassis

backplane.

Status indicators The status indicators display the module’s

communications and SynchLink system

status.

Transmit fiber port The transmit fiber port allows connection

(via fiber optic cables) to other SynchLink

modules so the module can send data.

Receive fiber port The receive fiber port allows connection (via

fiber optic cables) to other SynchLink

modules so the module can receive data.

Page 19

What is the 1756-SYNCH module? 1-5

Using Module Identification and Status Information

Each ControlLogix SynchLink module maintains specific identification

information that separates it from all other modules. This information assists

you in tracking all the components of your system.

For example, you can track module identification information to be aware of

exactly what modules are located in any ControlLogix rack at any time. While

retrieving module identity, you can also retrieve the module’s status.

Each module maintains the following information:

Table 1.5 Module Identification and Status Information

Module Identification: Description:

Product Type Module’s product type, such as Digital I/O or Analog I/O

module

Product Code Module’s catalog number

Major Revision Module’s major revision number

Minor Revision Module’s minor revision number

Status Module’s status. Returns the following information:

• Controller ownership (if any)

• Whether module has been configured

• Device Specific Status, such as:

– Self-Test

– Flash update in progress

– Communications fault

– Not owned (outputs in program mode)

– Internal fault (need flash update)

– Run mode

• Minor recoverable fault

• Minor unrecoverable fault

• Major recoverable fault

• Major unrecoverable fault

Vendor ID Module manufacturer vendor, for example Allen-Bradley

Serial Number Module serial number

Length of ASCII Text String Number of characters in module’s text string

ASCII Text String Module name

IMPORTANT

To retrieve this information, you can use the WHO service

in RSLinx. For more information on how to retrieve

module identification information, see the RSLinx online

help.

Publication 1756-UM521C-EN-P - July 2004

Page 20

1-6 What is the 1756-SYNCH module?

Preventing Electrostatic Discharge

Removal and Insertion Under Power

This module is sensitive to electrostatic discharge.

ATTENTION

These modules are designed to be installed or removed while chassis power is

applied.

WARNING

This equipment is sensitive to electrostatic discharge, which

can cause internal damage and affect normal operation.

Follow these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in appropriate

static-safe packaging.

When you insert or remove the module while backplane

power is on, an electrical arc can occur. This could cause an

explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before

proceeding.

Chapter Summary and What’s Next

Repeated electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create electrical

resistance that can affect module operation.

In this chapter, you read about the ControlLogix SynchLink module. For

information about Time Synchronization in the ControlLogix System, see

Chapter 2.

Publication 1756-UM521C-EN-P - July 2004

Page 21

Chapter

Time Synchronization in the

ControlLogix System

This chapter describes how the ControlLogix SynchLink module fits in

the ControlLogix system.

Table 2.1

For information on: See page:

Using the Coordinated System Time (CST) 2-2

Time Synchronization in a Distributed Control System 2-2

Time Synchronization in the SynchLink System 2-2

How Do the CST Clock and SynchLink Node Clock Work Together? 2-5

2

What are the SynchLink Configurations? 2-6

Before you can fully understand how the SynchLink module can be

used in a distributed ControlLogix system, you should understand

how a ControlLogix application works without SynchLink. See the

ControlLogix System User Manual, publication 1756-UM001 for a

detailed description of the ControlLogix system.

IMPORTANT

In RSLogix 5000, v13 or greater, you can use a

1756-SYNCH module in a remote chassis without a

ControlLogix controller and still provide a CST value

for the chassis. I/O modules (e.g., 1756-IH16ISOE)

can use the CST value when generating timestamps.

For SynchLink systems that use RSLogix 5000, v12 or

earlier, you cannot use a 1756-SYNCH module to

synchronize I/O timestamps in a remote chassis

without first installing a ControlLogix controller in

that chassis.

1 Publication 1756-UM521C-EN-P - July 2004

Page 22

2-2 Time Synchronization in the ControlLogix System

Using the Coordinated System Time (CST)

Time Synchronization in a Distributed Control System

The Coordinated System Time (CST) is the clocking mechanism used

to achieve time synchronization in a ControlLogix chassis. The

ControlLogix Coordinated System Time (CST) clock is a 64-bit clock

on the backplane of the ControlLogix chassis. It has a 1μS resolution

and is used as the main time reference for all modules plugged into a

chassis backplane.

For more information on how the ControlLogix CST affects the

operation of other ControlLogix products, see the ControlLogix System

User Manual, publication 1756-UM001.

The same CST mechanism described above is also used to

synchronize ControlLogix chassis in a distributed control system. In

such a system, SynchLink transfers the CST value from the CST Master

chassis to CST Slave chassis.

Each chassis must be equipped with a SynchLink module and,

depending on what version of RSLogix 5000 the system is using, each

chassis may or may not require that a controller reside in remote

chassis. This distributed control system is identified as a SynchLink

system.

Time Synchronization in the SynchLink System

The 1756-SYNCH module provides synchronization of CSTs between

ControlLogix chassis provides with no more than +/-5µs drift

between chassis.

Time synchronization within a SynchLink system is required to:

• transfer a CST value from the CST Master chassis to CST Slave

chassis.

• transfer motion and drive control data.

• support time synchronization between ControlLogix chassis and

non-ControlLogix products (e.g. PowerFlex 700S products).

The SynchLink Node Clock is integral to all devices that contain the

SynchLink circuitry. It is the clocking mechanism on the fiber optic

side of the SynchLink system. This clock has a resolution of 1μS.

During system configuration, you establish one SynchLink node clock

as the master system clock on the SynchLink fiber. By design, the

ControlLogix chassis that is configured as the SynchLink master also

acts as the CST master of the system. In this manner, one SynchLink

node acts as a Time Master for the entire system. This chapter gives

more detail on how this functionality is accomplished.

Publication 1756-UM521C-EN-P - July 2004

Page 23

Time Synchronization in the ControlLogix System 2-3

Multiple Rockwell Automation products can be synchronized with

SynchLink. In addition to the SynchLink module, the PowerFlex 700S

and the 1756-DMxxx series products (both used for drive control) also

use SynchLink to achieve drive to drive synchronization. While all of

these products maintain interoperability, not all SynchLink features are

incorporated into every product that uses SynchLink; the 1756-SYNCH

module, however, uses all of the SynchLink features.

SynchLink Node Clock

The SynchLink node clock is integral to the SynchLink circuit design.

Any product incorporating SynchLink incorporates the SynchLink

node clock as a base-line requirement. The SynchLink node clock has

a 1μS resolution and is synchronized from node to node when the

SynchLink system is configured.

SynchLink uses a Time Master-Slave mechanism to achieve time

synchronization. During system configuration, you configure one

SynchLink node as the Time Master and all other nodes as Time

Slaves. The SynchLink node that is configured as Time Master

becomes the system clock for the entire SynchLink system. As such,

the SynchLink Time Master broadcasts its time reference to the

SynchLink Time Slaves which adjust their node clocks to be in phase

with the master clock.

Because SynchLink is a unidirectional, broadcasting mechanism, the

master is always placed at the beginning of SynchLink systems using

the star or daisy chain configurations.

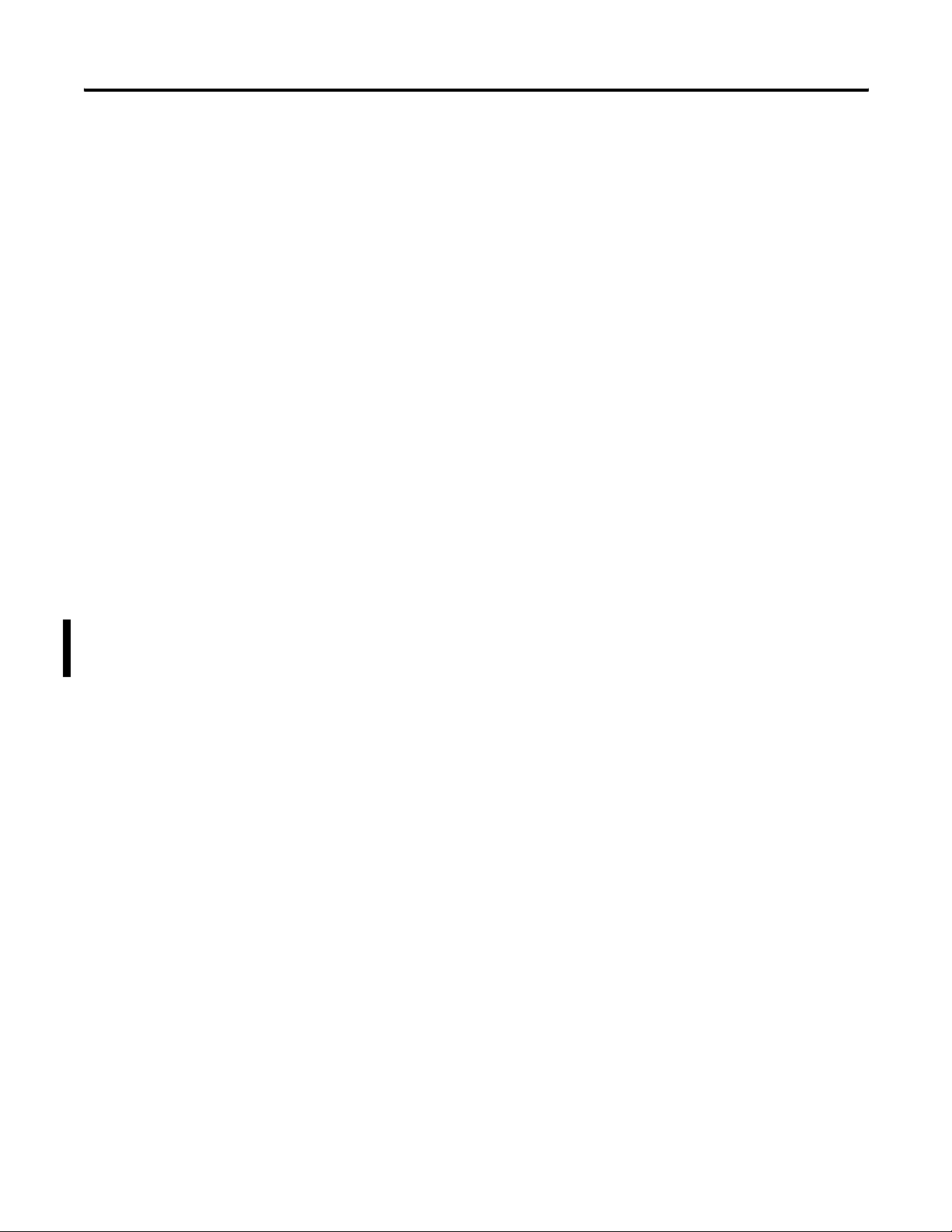

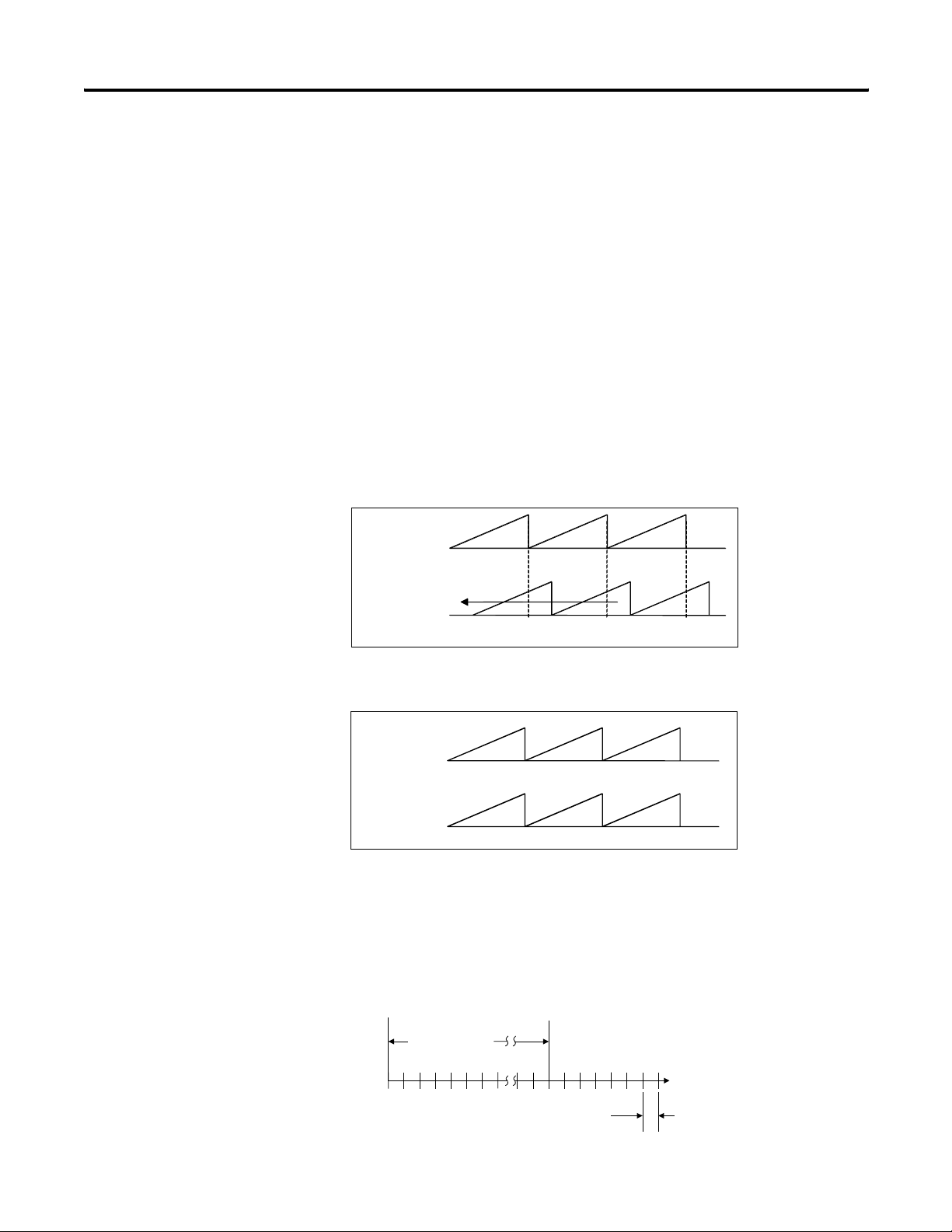

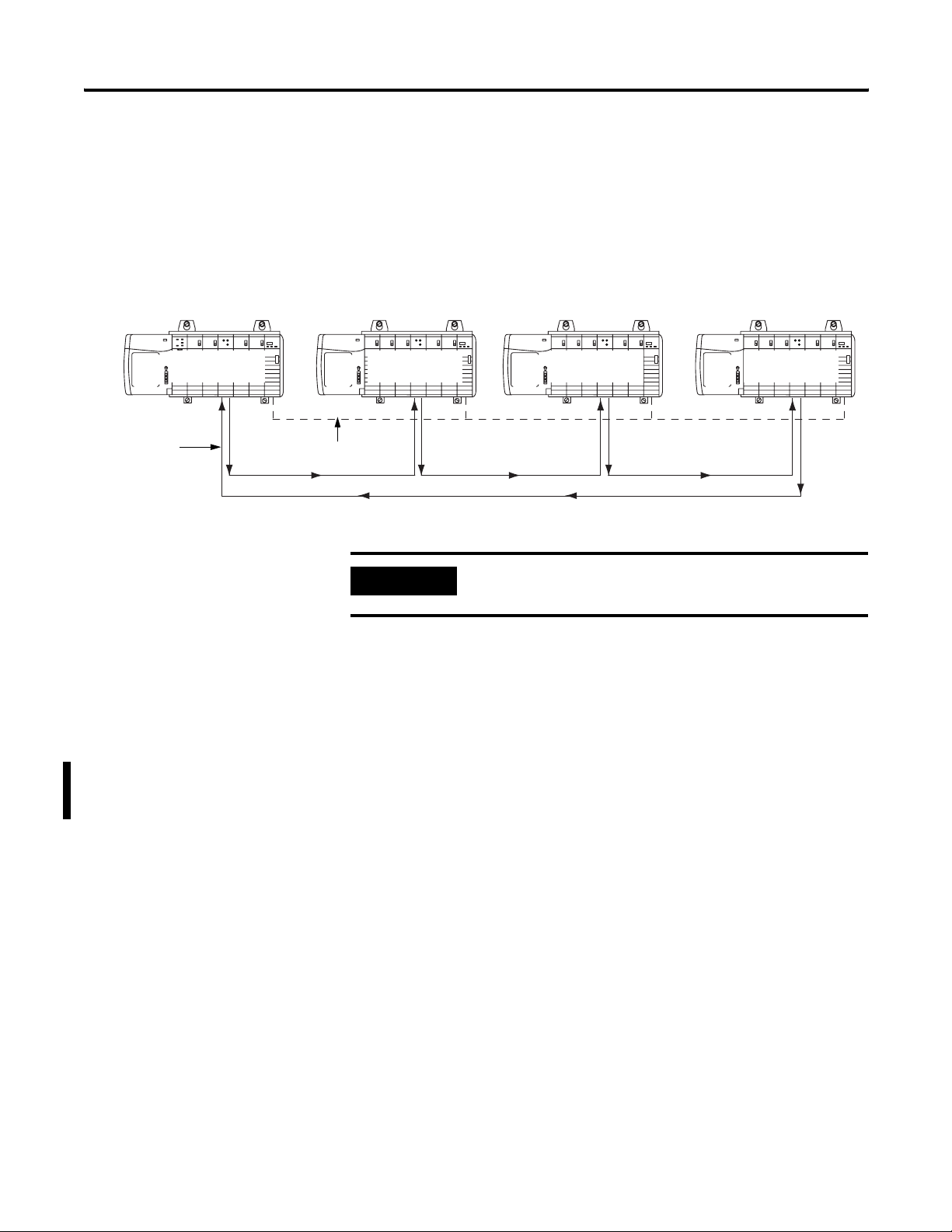

Figure 2.1

Star Configuration

SynchLink

Time Master

S.L.N.C.

Hub

S.L.N.C. S.L.N.C. S.L.N.C. S.L.N.C.

SynchLink

Time Slave

SynchLink

Time Slave

SynchLink

Time Slave

SynchLink

Time Slave

S.L.N.C. = SynchLink Node Clock

42980

Daisy Chain Configuration

S.L.N.C. S.L.N.C. S.L.N.C.

SynchLink

Time Master

SynchLink

Time Slave

SynchLink

Time Slave

42981

Publication 1756-UM521C-EN-P - July 2004

Page 24

2-4 Time Synchronization in the ControlLogix System

System Synchronization

When a SynchLink system is initialized, the individual SynchLink

nodes power-up at separate times and the individual SynchLink node

clocks begin to count at arbitrary points in time. When this occurs, the

system is not yet synchronized. As the master node clock counts, it

reaches a point where it rolls over and goes back to zero.

When the rollover occurs, the SynchLink Time Master transmits a

beacon signal to the SynchLink Time Slaves; the beacon is included in

the control field of the transmitted message. When the SynchLink

Time Slave receives the first message with the beacon signal, it begins

to adjust the 1μs time base of its node clock to synchronize with the

master clock. This process can be gradual or immediate, depending

on the product implementation.

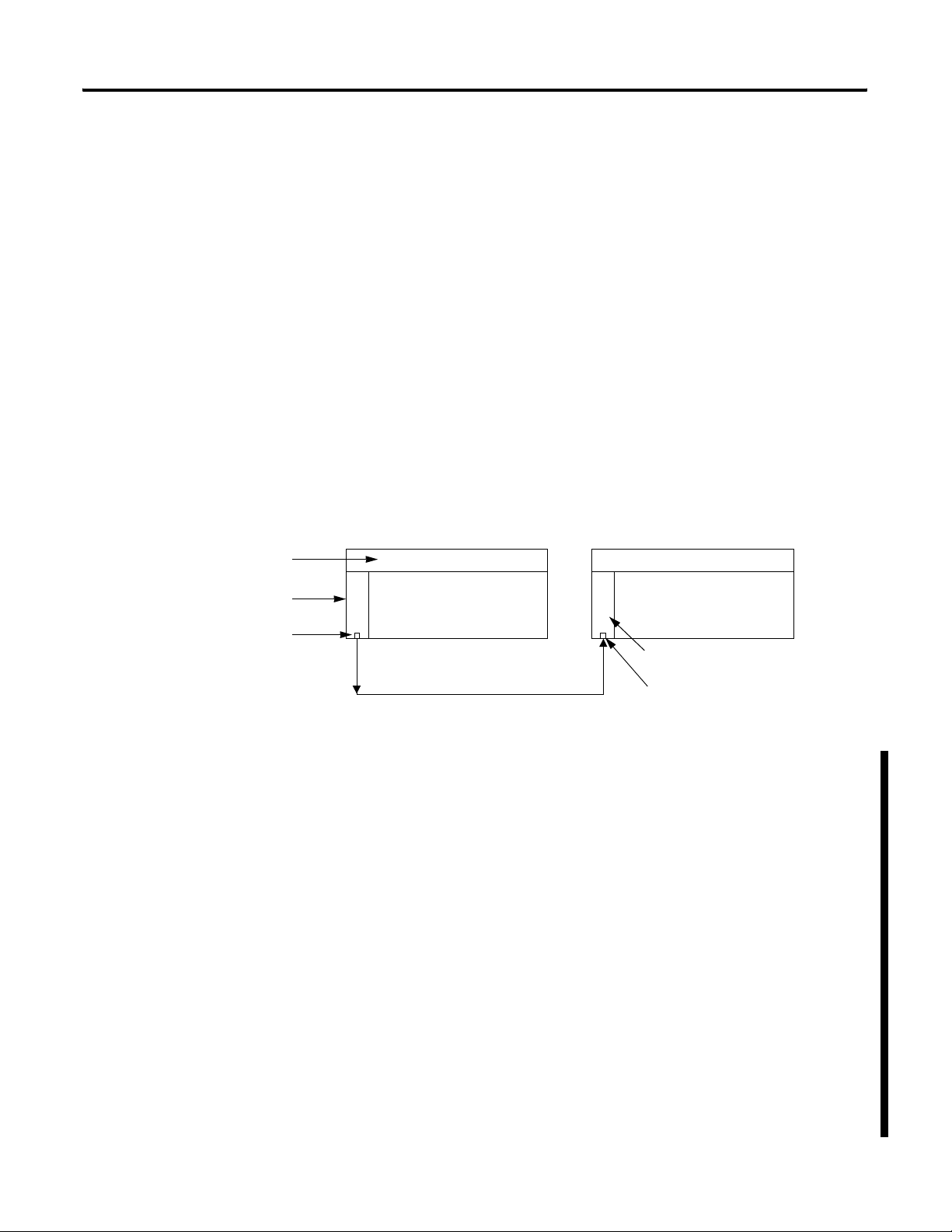

Figure 2.2

Initial Start-Up

Master

Time adjustment

Slave

Beacon Beacon Beacon

Synchronized Operation

Master

Slave

42982

42983

After a SynchLink Time Slave is synchronized with the Time Master,

each SynchLink frame that is transmitted serves as a 50μS “tick” (or

mark) used for the periodic adjustment of its clock’s 1μS time base.

This process provides highly accurate results.

Figure 2.3

Publication 1756-UM521C-EN-P - July 2004

Beacon signal

synchronizes

SynchLink node

clocks

SynchLink 50 microsecond message frame

serves as a “tick” to keep clocks synchronized

42984

Page 25

Time Synchronization in the ControlLogix System 2-5

How Do the CST Clock and SynchLink Node Clock Work Together?

64-bit clock

As stated earlier, the ControlLogix Coordinated System Time clock

(CST) is a 64-bit clock on the ControlLogix backplane. It is used as the

main time reference for all modules plugged into a ControlLogix

chassis. The SynchLink node clock is used to establish the time

reference on the SynchLink fiber.

Figure 2.4 illustrates how the SynchLink node clock and the CST time

reference are coordinated in a system. In this example, the SynchLink modules

in chassis A & B synchronize the CST clock in chassis B with the CST

reference in chassis A.

Chassis A is the Time Master for the system. When the SynchLink

module strobes the beacon signal onto the fiber optic link, it also

transmits the CST time reference value that tells the downstream node

what time it is as the beacon occurs. The downstream chassis receives

the CST time reference and synchronizes its time with the CST

reference value on the beacon signal.

Figure 2.4

Chassis A Chassis B

Coordinated System Time Coordinated System Time

1756-SYNCH

SynchLink Node Clock

Configuring Time Mastership Functionality

1756-SYNCH

Clock

SynchLink beacon over the fiber optic link

You must configure each 1756-SYNCH module’s role in Coordinated

System Time (CST) Mastership. For any SynchLink system, there can

only be one SynchLink CST Time Master for the system; the Time

Master can be a 1756-SYNCH module or a ControlLogix controller. All

other devices connected to the SynchLink must be configured as Time

Slaves. However, the 1756-SYNCH modules that are Time Slaves are

Chassis CST Masters that receive the SynchLink time from the fiber

optic cable and relay it to all devices in their local chassis.

For example, the 1756-SYNCH modules in Figure 2.4 can be configured as

follows:

• 1756-SYNCH in Chassis A - MUST be SynchLink CST Master;

CAN also be Chassis CST Master

• 1756-SYNCH in Chassis B - MUST be Chassis CST Master;

CANNOT be SynchLink CST Master

For a full explanation on how to configure CST and SynchLink Mastership,

see page 3-18.

Publication 1756-UM521C-EN-P - July 2004

Page 26

2-6 Time Synchronization in the ControlLogix System

What are the SynchLink Configurations?

SynchLink communications are a unidirectional data transfer from one

SynchLink node to another. Each configuration starts with a single

Master Node. The SynchLink network can be configured in the

following ways.

• Star Configuration

• Daisy Chain Configuration

• Ring Configuration

Do not mix the configurations (i.e. begin in the star configuration and

change to the daisy chain configuration). Examples of these

configurations are shown in the following sections.

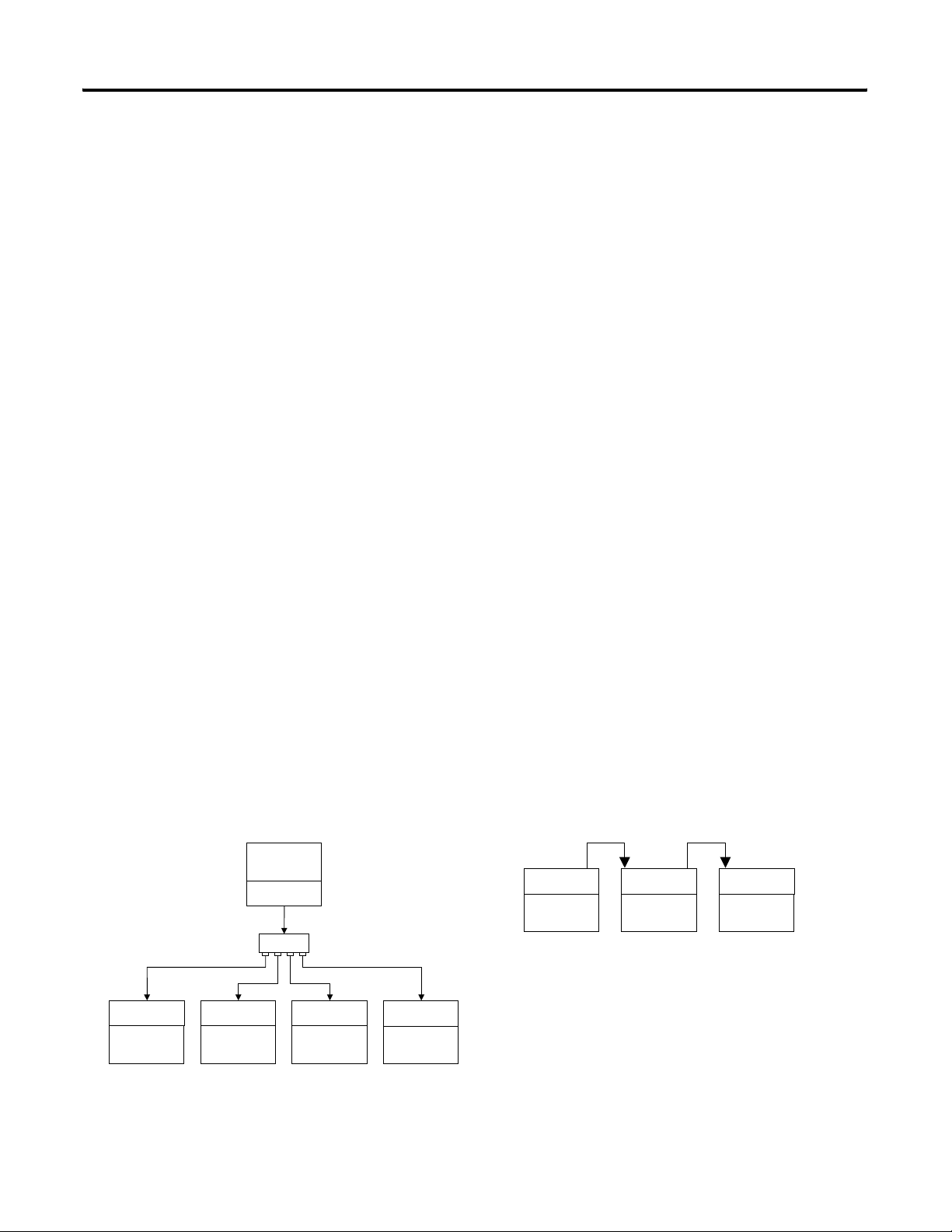

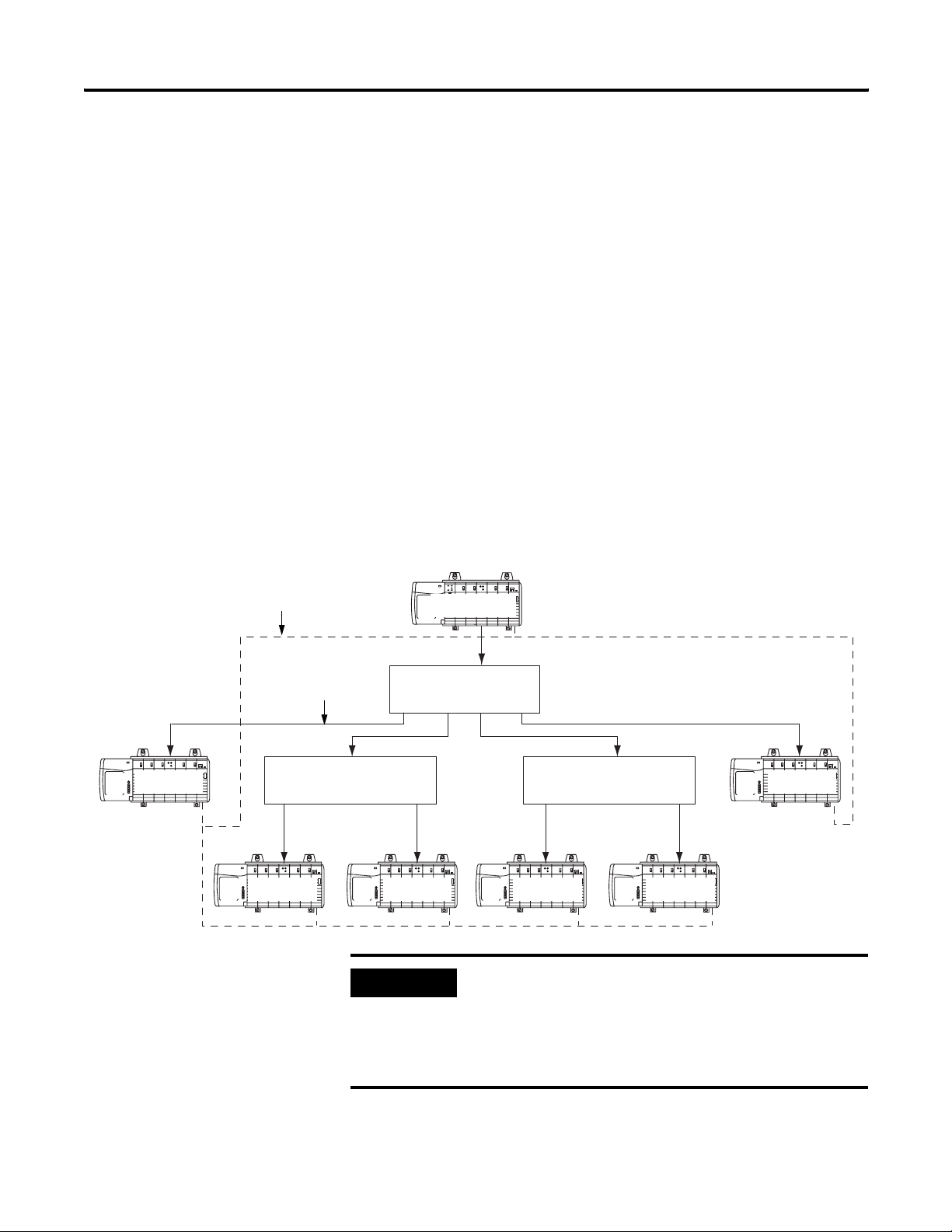

Star Configuration

The star configuration transfers data from a Master Node through

Hubs to End Nodes.

Figure 2.5

ControlNet

SynchLink

End Node End Node

End Node End NodeEnd NodeEnd Node

Hub Hub

IMPORTANT

Master Node

Hub

The star configuration supports 2 layers of hubs with

up to 16 end nodes connected to each hub.

A maximum of 257 SynchLink modules (including

the Master Node) can be connected in the star

configuration.

42747

Publication 1756-UM521C-EN-P - July 2004

For an example of how to configure a Star configuration, see Appendix B.

Page 27

Time Synchronization in the ControlLogix System 2-7

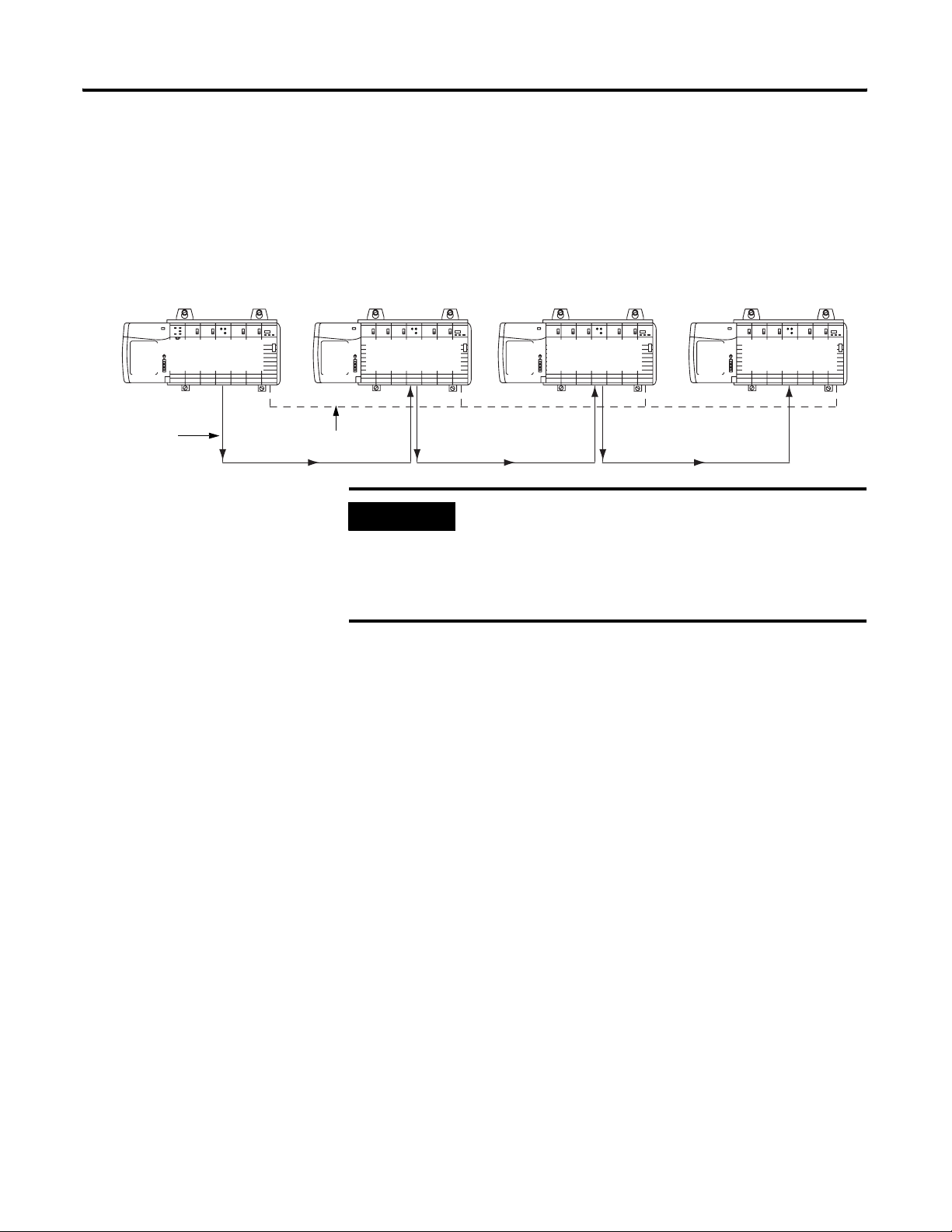

Daisy Chain Configuration

In the daisy chain configuration, the SynchLink network starts at the

Master Node and ends at an End Node. You can include Center Nodes

(shown in Figure ) in the configuration as needed.

Figure 2.6

Master Node Center Node Center Node End Node

ControlNetSynchLink

42746

IMPORTANT

In the daisy chain configuration, you can use a

maximum of 10 nodes, including the master and

end nodes.

Also, the only difference between Center and End

Nodes is their physical location.

In the daisy chain configuration the time synchronization process is

more complicated than in the star. It’s based on the following rules.

• Each node enables its transmitter right after it has received the

first message from the upstream node.

• Each node can generate and transmit the beacon signal

regardless of whether it has received one or not.

• Each node is a Time Slave of its upstream node and will attempt

to synchronize with it.

The SynchLink Time Master node must be set as the SynchLink Time

Master. Its node clock is the SynchLink system clock. After power-up,

the Master node begins to transmit a message every 50μS. As soon as

the node connected to it receives the first of these messages, it begins

to send messages to its downstream node. Eventually, all center nodes

are transmitting messages.

As soon as a node receives the first message with the beacon signal, it

starts to synchronize its node clock with the upstream node clock. The

node connected to the Master, is the first to synchronize its clock with

the SynchLink system clock. This process then propagates down the

daisy chain until all nodes are synchronized with the Master.

For an example of how to configure a Daisy Chain configuration, see

Appendix C.

Publication 1756-UM521C-EN-P - July 2004

Page 28

2-8 Time Synchronization in the ControlLogix System

Ring Configuration

The ring configuration is a permutation of the daisy chain

configuration. In the ring chain configuration, the SynchLink network

starts and ends at the Master Node. You can include Center Nodes

(shown in Figure ) in the configuration as needed.

Master Node Center Node Center Node Center Node

ControlNetSynchLink

42748

Chapter Summary and What’s Next

IMPORTANT

For an example of how to configure a Ring configuration, see Appendix D.

In the ring chain configuration, you can use a

maximum of 10 nodes.

Cable Usage

You must use fiber optic cable to connect SynchLink modules in all

configurations. For more information on SynchLink fiber components,

see Table 1.2 and Table 1.3 on page 1-3.

For more information on choosing the correct cable lengths for your

application, see the SynchLink Design Guide, publication 1756-TD008.

In this chapter, you learned how the ControlLogix SynchLink module

fits into the ControlLogix system. For more information on SynchLink

Module Features, see Chapter 3.

Publication 1756-UM521C-EN-P - July 2004

Page 29

Chapter

SynchLink Module Features

This chapter describes the ControlLogix SynchLink module features.

Table 3.1

For information on: See page:

Module Features That Cannot Be Configured 3-2

Removal and Insertion Under Power (RIUP) 3-2

Module Fault Reporting 3-3

Full RSLogix 5000 Support 3-3

Status Indicator (LED) Information 3-4

Class I Division 2 Certification 3-4

Agency Certification 3-4

Use Last Configuration When Connection to Owner-Controller

Closes - For Module’s Using Firmware Revision 2.18 or Greater

Module Features That Can Be Configured 3-5

Communications Format 3-6

3-5

3

Electronic Keying 3-11

Requested Packet Interval 3-13

SynchLink Transmitted Axes 3-15

Transmitted Direct Words 3-16

CST and SynchLink Mastership 3-18

Configurable module features are features (e.g. Communications

Format) that can be configured to work differently in various

SynchLink applications.

1 Publication 1756-UM521C-EN-P - July 2004

Page 30

3-2 SynchLink Module Features

Module Features That Cannot Be Configured

These general module features (e.g. Removal and Insertion Under

Power) are supported on the module regardless of configuration and

application. The following general module features are available with

the ControlLogix SynchLink module:

• Removal and Insertion Under Power (RIUP)

• Module Fault Reporting

• Full RSLogix 5000 Support

• Status Indicator (LED) Information

• Class I Division 2 Certification

• Agency Certification

• Use Last Configuration When Connection to Owner-Controller Closes

- For Module’s Using Firmware Revision 2.18 or Greater

Removal and Insertion Under Power (RIUP)

All ControlLogix SynchLink modules may be removed and inserted

from the chassis while power is applied. This feature allows greater

availability of the overall control system because, while the module is

being removed or inserted, there is no additional disruption to the rest

of the controlled process.

Although there is no disruption to other devices when the SynchLink

module is removed and inserted from the chassis while power is

applied, the removal and insertion will break communications

between SynchLink modules and will impact the performance of the

SynchLink system.

Removing and reinserting the SynchLink module under power also

impacts overall system performance and operation because the

ControlLogix chassis are no longer synchronized. Depending on the

application, removing and reinserting the SynchLink module under

power may cause significant changes to an application, including the

possibility of a system E-Stop (emergency stop).

Because of its impact on other chassis, the removal of a SynchLink

module while under power may cause personal injury or property

damage.

WARNING

When you insert or remove the module while

backplane power is on, an electrical arc can occur.

This could cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

Publication 1756-UM521C-EN-P - July 2004

Page 31

SynchLink Module Features 3-3

Repeated electrical arcing causes excessive wear to contacts on both

the module and its mating connector. Worn contacts may create

electrical resistance that can affect module operation.

Module Fault Reporting

ControlLogix SynchLink modules provide both hardware and software

indication when a module fault has occurred. Each module’s LED fault

indicator and RSLogix 5000 will graphically display this fault and

include a fault message describing the nature of the fault.

This feature allows you to determine how your module has been

affected and what action should be taken to resume normal operation.

Full RSLogix 5000 Support

RSLogix 5000 uses a custom, easily understood interface to write

configuration. All module features are enabled or disabled through the

I/O configuration portion of the software.

You can also use the software to interrogate any module in the system

to retrieve

• serial number

• revision information

• catalog number

• vendor identification

• error/fault information

By eliminating such tasks as setting hardware switches and jumpers,

the software makes module configuration easier and more reliable.

Publication 1756-UM521C-EN-P - July 2004

Page 32

3-4 SynchLink Module Features

Status Indicator (LED) Information

The ControlLogix SynchLink module has status indicators (LED) on

the front of the module that allow you to check the module health

and operational status.

With the LED indicators, you can check:

• SynchLink and ControlLogix backplane status

• Module health status

For examples of LED indicators, see page 6-1.

Class I Division 2 Certification

The ControlLogix SynchLink module is certified for use in

nonhazardous locations as well as Class I, Division 2 hazardous

Locations containing gas groups A, B, C, and D. This equipment may

be used as a component of a control system which is certified to

operate in hazardous locations.

WARNING

When you insert or remove the module while

backplane power is on, an electrical arc can occur.

This could cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

Agency Certification

When the SynchLink module is marked appropriately, the following

agency certifications apply:

• UL Listed Industrial Control Equipment

• CSA Certified Process Control Equipment

• CSA Certified for Class I, Division 2 Hazardous Locations

Publication 1756-UM521C-EN-P - July 2004

Page 33

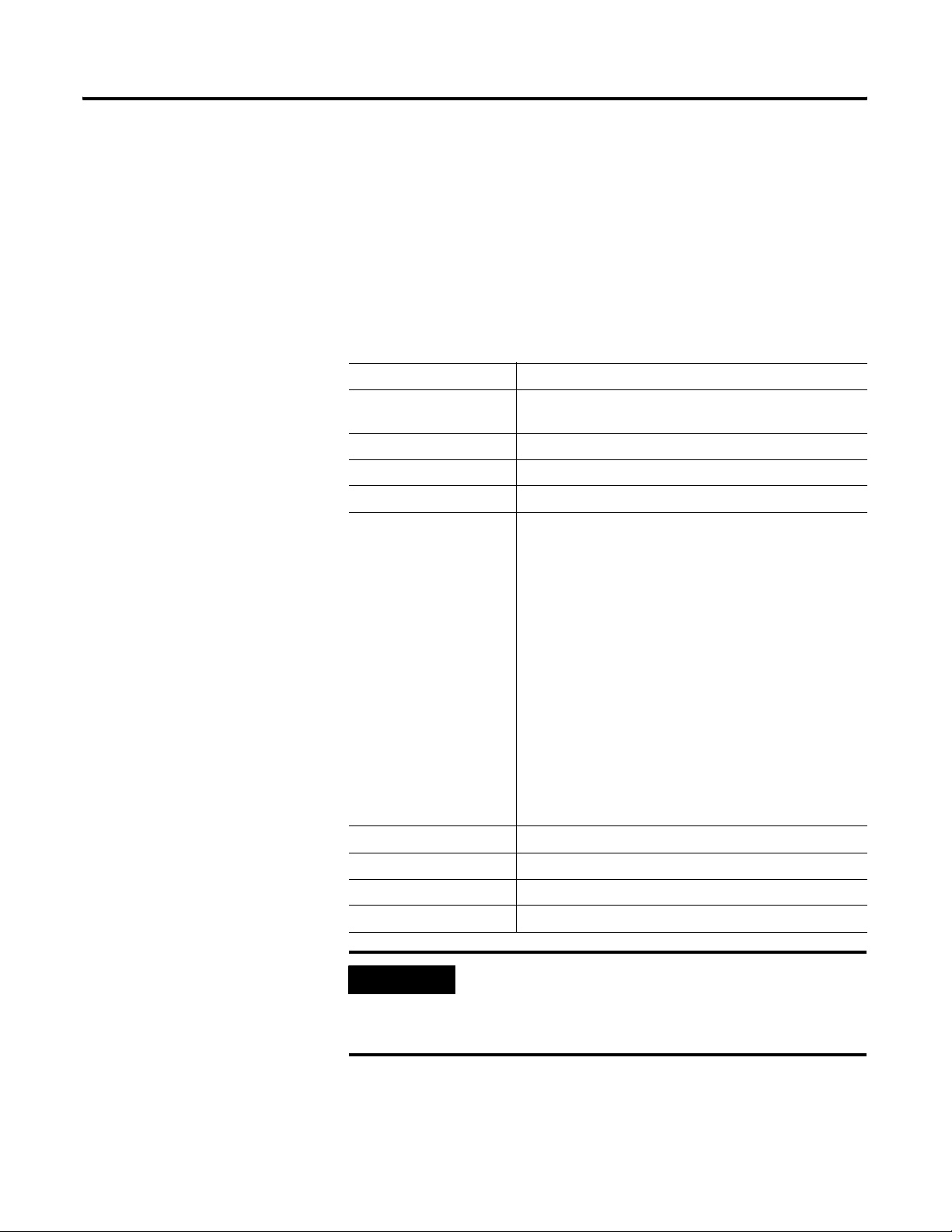

Table 3.2

SynchLink Module Features 3-5

Use Last Configuration When Connection to Owner-Controller

Closes - For Module’s Using Firmware Revision 2.18 or Greater

With firmware revision 2.18 or greater, the 1756-SYNCH module can

continue to operate, using its last configuration, when the module’s

connection to the owner-controller closes.

If the 1756-SYNCH module is used in

this scenario:

• The 1756-SYNCH module is located

in a chassis with two ControlLogix

controllers.

• The 1756-SYNCH module is the time

master for the local chassis.

• One of the ControlLogix controllers is

the 1756-SYNCH module’s

owner-controller.

• The other ControlLogix controller is

controlling motion based on the CST

set by the 1756-SYNCH module.

Module Features That Can Be Configured

and the owner-controller closes its

connection to the 1756-SYNCH module,

such as for one of the following reasons:

• The controller is downloading a new

project.

• The controller is saving its NVS.

• The controller is restoring its NVS.

• The controller is updating the module’s

firmware.

• The controller is removed from

the chassis.

The 1756-SYNCH behaves as follows:

The module continues to act as time

master for the local chassis, operating as

directed by its most recent configuration.

The 1756-SYNCH module’s behavior only

changes if the owner-controller reopens

the connection to the module and

reconfigures the module.

The following SynchLink module features are configurable via

RSLogix 5000:

• Communications Format

• Electronic Keying

• Requested Packet Interval

• SynchLink Transmitted Axes

• Transmitted Direct Words

• CST and SynchLink Mastership

Each of these features is described in this section, including

information on which RSLogix 5000 configuration screen should be

used to configure the feature. For an overview of the entire

configuration process, see Chapter 5, Configuring the SynchLink Module.

Communications Format

The communications format defines the connection between the

owner-controller and the module (i.e. determines what type of data is

Publication 1756-UM521C-EN-P - July 2004

Page 34

3-6 SynchLink Module Features

transferred between them). The SynchLink module can receive and

transmit data and, therefore, uses a Receive Port Communications

Format and Transmit Port Communications Format.

SynchLink messages are structured as six 32-bit words; the words are

divided into three types as described in Table 3.3:

Table 3.3

Word Type: Description:

Direct Data delivered in a single message. A SynchLink message can contain

a maximum of four direct data words; each word is 32 bits in length.

Direct data can be automatically forwarded to the next node in the

daisy chain and ring configurations.

Buffered Data that exceeds the four word limit of a direct data transfer.

Buffered data is appropriately segmented at the transmitting module

and reassembled at the receiving module. Buffered data cannot be

automatically forwarded to the next node in the daisy chain and ring

configurations.

Axis data Motion data used by the motion planner in the controller. The

1756-SYNCH module can consume an Axis tag from a controller and

pass it over SynchLink. A controller in another chassis can then

consume axis tags passed over SynchLink from the 1756-SYNCH

module in that chassis. This data is not automatically forwarded in

daisy chain or ring configurations.

The Communications Formats available on the 1756-SYNCH module

use various combinations of the words described in Table 3.3. The following

choices are available:

• 1 Axis, 3 Direct Words, 14 Buffered

• 2 Axis

• 2 Axis, 3 Direct Words

• 2 Direct Words, 18 Buffered

• 4 Direct Words, 18 Buffered

• 4 Direct Words, 8 Buffered

• No Receive Data - Available on the Receive Port only

• Listen Only, No Transmit Data - Available on the Transmit

Port only

• No Transmit Data - Available on the Transmit Port only

Publication 1756-UM521C-EN-P - July 2004

Page 35

SynchLink Module Features 3-7

Multiple Port Communications Formats in Single Module

You must set a communications format for receiving data (Receive Port

Communications Format) and transmitting data (Transmit Port

Communications Format) in each SynchLink module. The following

requirements apply to communication format choices:

• If a SynchLink module does not receive data (e.g. a SynchLink

Time Master in a star or daisy chain configuration), you must

choose the No Receive Data Receive Port communication format.

• If a SynchLink module does not transmit data (e.g. an end

node), you must choose the No Transmit Data Transmit Port

communications format.

• The receive communication format for any SynchLink module

that receives data must match the transmit communications

format of the upstream node in the system. For example, if the

Time Master SynchLink module uses a 2 Axis Transmit Port

communication format, the SynchLink module physically

connected to the Time Master must use a 2 Axis Receive Port

communications format.

• If a SynchLink module is used to provide CST signals to remote

I/O chassis, you can choose any communication format except

No Receive Data, Listen Only or No Transmit Data. CST signals

are used in the remote chassis to synchronize I/O timestamps. In

this case, the data words transmitted over SynchLink are

not used.

IMPORTANT

The receive and transmit on the same module do not

have to match.

Also, once the module is created, you cannot change

the communications format. You must delete and

recreate the module.

Publication 1756-UM521C-EN-P - July 2004

Page 36

3-8 SynchLink Module Features

Module-Defined Data Tags

When you create a module, RSLogix 5000 creates module-defined data

types and tags. These tags allow you to access the Configuration,

Input and Output Data of the module via the controller’s ladder logic.

The types of tags created vary, depending on which communications

format you choose when creating a module. There are three types

of tags:

• Configuration Data Tags

• Input Data Tags

• Output Data Tags

For a complete listing of all the module-defined data tags available on

your SynchLink module, see Appendix E.

Internal Scan on SynchLink Module

Every 500μS, the SynchLink module scans its internal hardware and

captures a “snapshot” of the data there. This data is then sent to the

local owner-controller at the Change of State (COS) instance,

independent of the requested packet interval (RPI) rate. But,

depending on the communications formats chosen during module

configuration, data types are transmitted between SynchLink nodes

(via the fiber optic cable) at various rates and may be transmitted

multiple times between the 500μS snapshots.

IMPORTANT

The transfer rate times listed in Table 3.4 and Table 3.5

only represent the rate at which data is passed between

SynchLink modules over the fiber optic cable.

Although the data is passed over the fiber optic cable

at various rates, according to the communications

format choices, the owner-controllers in each local

chassis only receive the data after the local

SynchLink module’s internal scan every 500μS.

Publication 1756-UM521C-EN-P - July 2004

Page 37

SynchLink Module Features 3-9

The SynchLink module updates its receive and transmit buffers once

every 500μS. Because direct data can be passed through from node to

node once every 50μS, up to 10 nodes can be updated with direct

data in a single 500μS SynchLink scan. Pass-through functionality only

applies to direct data in a daisy chain configuration, though; axis data

and buffered data cannot be passed through. Instead, these data types

require the intervention of the local controller to move data along. For

this reason, it is not recommended that a daisy chain configuration

be used when distributing axis data among multiple axis in a

distributed control system.

For more information on the available Receive Port and Transmit Port

communication formats, see Table 3.4.

Table 3.4 SynchLink Module Receive Communications Formats

Receive Port Communications Format

1 Axis, 3 Direct Words, 14 Buffered Axis Data - Updated every 500μS

2 Axis Axis Data - Updated every 250μS

2 Axis, 3 Direct Words Axis Data - Updated every 500μS

2 Direct Words, 18 Buffered Direct Data - Updated every 50μS

4 Direct Words, 18 Buffered Direct Data - Updated every 50μS

4 Direct Words, 8 Buffered Direct Data - Updated every 50μS

No Receive Data No data updated in this format

Transfer Rate (across the fiber optic

cable) for Each Data Type:

Direct Data - Updated every 50μS

Buffered Data - Updated every 500μS

Direct Data - Updated every 50μS

Buffered Data - Updated every 250μS

Buffered Data - Updated every 500μS

Buffered Data - Updated every 250μS

Publication 1756-UM521C-EN-P - July 2004

Page 38

3-10 SynchLink Module Features

Table 3.5 SynchLink Module Transmit Communications Formats

Transmit Port Communications Format

Transfer Rate (across the fiber optic

cable) for Each Data Type:

1 Axis, 3 Direct Words, 14 Buffered Axis Data - Updated every 500μS

Direct Data - Updated every 50μS

Buffered Data - Updated every 500μS

2 Axis Axis Data - Updated every 250μS

2 Axis, 3 Direct Words Axis Data - Updated every 500μS

Direct Data - Updated every 50μS

2 Direct Words, 18 Buffered Direct Data - Updated every 50μS

Buffered Data - Updated every 250μS

4 Direct Words, 18 Buffered Direct Data - Updated every 50μS

Buffered Data - Updated every 500μS

4 Direct Words, 8 Buffered Direct Data - Updated every 50μS

Buffered Data - Updated every 250μS

Listen Only, No Transmit Data No data updated in this format

No Transmit Data No data updated in this format

The Communications Format feature is configured on the following screen.

Communications Formats

Publication 1756-UM521C-EN-P - July 2004

Page 39

SynchLink Module Features 3-11

Electronic Keying

Instead of plastic mechanical backplane keys, electronic keying allows

the ControlLogix system to control what modules belong in the

various slots of a configured system.

During module configuration, you must choose one of the following

keying options for your 1756-SYNCH module:

• Exact Match

• Compatible Match

• Disable Keying

When the controller attempts to connect to and configure a

1756-SYNCH module (e.g. after program download), the module

compares the following parameters before allowing the connection

and configuration to be accepted:

• Vendor

• Product Type

• Catalog Number

• Major Revision - Change that affects the module’s function or

RSLogix 5000 interface

• Minor Revision - Change that does not affects the module’s

function or RSLogix 5000 interface (e.g. bug fixes)

The comparison is made between the keying information present in

the SynchLink module and the keying information in the controller’s

program. This feature can prevent the inadvertent operation of a

control system with the wrong module in the wrong slot. For

example, if you select Exact Match and a module with revision 2.10 is

placed in a location configured for a module with revision 2.18, the

controller does not make a connection to the new module because of

the mismatched revisions.

Publication 1756-UM521C-EN-P - July 2004

Page 40

3-12 SynchLink Module Features

Table 3.6 describes the keying options available with your 1756-SYNCH

module.

Table 3.6

Keying option: Definiton:

Exact Match All of the parameters listed above must match or the inserted module will reject a connection to the controller.

Compatible Match The Compatible Match mode allows a 1756-SYNCH module to determine whether it can emulate the module

defined in the configuration sent from the controller.

With 1756-SYNCH modules, the module can emulate older revisions. The module will accept the configuration

if the configuration’s major.minor revision is less than or equal to the physical module’s revision.

For example, if the configuration contains a major.minor revision of 2.10, the module inserted into the slot

must have a firmware revision of 2.10 or higher for a connection to be made. When a module is inserted with

a major.minor revision that is less than the revision for which the slot is configured (i.e. the module has a

revison of 1.17 and the slot is configured for a module with revision 2.18), no connection is made between the

controller and the I/O module.

TIP

We recommend using Compatible Match whenever possible. Remember, though, with

major revision changes, the module only works to the level of the configuration.

If a slot is configured for a module with major.minor revision of 1.17 and you insert a

module with a major.minor revision of 2.10, the module works at the 1.17 level, with

respect to module functions that are related to RSLogix 5000 such as interface changes.

However, bug fixes that are affected by the module’s firmware, would work at the 2.10

revision level.

If possible, we suggest you make sure configuration is updated to match the revision

levels of all I/O modules. Failure to do so may not prevent the application from working

but may defeat the purpose of upgrading your modules’ revision levels.

Disable Keying The inserted module attempts to accept a connection to the controller regardless of its type.

ATTENTION

If keying is disabled, a controller makes a connection with most modules of the same type as that used in the

slot configuration. Even if keying is disabled, a controller will not establish a connection if the slot is

configured for one module type (e.g. input module) and a module of another type (e.g. output module) is

inserted in the slot.

Be extremely cautious when using the disable keying option; if used incorrectly, this

option can lead to personal injury or death, property damage or economic loss.

Publication 1756-UM521C-EN-P - July 2004

Page 41

SynchLink Module Features 3-13

The Electronic Keying feature is configured on the following screen.

Electronic Keying

Requested Packet Interval

The Requested Packet Interval (RPI) is a configurable parameter that

defines when the module multicasts its data onto the local chassis

backplane. In the SynchLink module, though, the RPI’s role is dictated

by the data the SynchLink transfers.

Axis Data

The RPI does not have an effect on produced or consumed axis data.

In a distributed motion control application, the coarse planner update

establishes the timing of the axis data updates from the producing

controller to the consuming 1756-SYNCH module in the master

chassis. Likewise, in the slave chassis, the RPI parameter does not

affect the delivery of the axis data to the consuming processor. This

data is produced at the coarse update rate established in the master

chassis.

Publication 1756-UM521C-EN-P - July 2004

Page 42

3-14 SynchLink Module Features

Buffered, Direct and Diagnostic Data - RPI Effect on Input Data (to the

controller)

The RPI is one of two mechanisms available through the 1756-SYNCH

module to update the module’s input data onto the backplane. Input

data is transferred from the SynchLink module to its owner-controller

at the rate defined in the RPI.

In addition to the RPI, Change of State (COS) functionality also causes

the module to produce its data to the consuming controller whenever

the values of the data changes. The RPI timer is asynchronous to the

COS functionality. Both cause the module to produce data when

triggered.

Buffered, Direct and Diagnostic Data - RPI Effect on Output Data (from the

controller)

As a producing controller writes data to the 1756-SYNCH module, the

output data is placed in a local buffer until the next RPI reset occurs.

When the RPI timer expires, the output data is moved from the

controller’s local buffer to the 1756-SYNCH module.

Requested Packet Interval

The RPI timer is asynchronous to the program execution. Therefore, a

worst case update to the SynchLink module can be calculated by

adding the program execution time to the RPI timer setting, as

configured by the user.

The SynchLink module minimum RPI = 2.0mS. The RPI is configured

on the following screen:

Publication 1756-UM521C-EN-P - July 2004

Page 43

SynchLink Module Features 3-15

SynchLink Transmitted Axes

Most applications using the ControlLogix SynchLink module use it for

Remote Axis Control. You can use the SynchLink module to produce

axes from a master chassis and broadcast the data to other chassis.

The module can produce and consume two axes (i.e. Axis 0 & Axis 1).

Slave chassis consume the broadcast axis data and redistribute it to

their local motion planners (i.e. the Logix controller in their local

chassis). The controller in the slave chassis must be configured to

consume axis data from the local SynchLink module. With this

configuration, you can control multiple axes synchronously

throughout the system.

The SynchLink Transmitted Axes are configured on the following

screen:

Transmitted Axes

For an example configuration that uses Remote Axis Data, see Appendix B,

Configuring the Star Configuration.

IMPORTANT

This manual assumes you know how to set-up axis

data tags for the data the controller in the Time

Master chassis produces; this manual does not intend

to explain how to plan the motion portion of your

application as that is a controller function.

If you do not know how to set-up remote axis data

tags and account for them in the motion portion of

your application, see the ControlLogix Motion

Module Setup & Configuration User Manual,

publication 1756-UM006.

Publication 1756-UM521C-EN-P - July 2004

Page 44

3-16 SynchLink Module Features

Transmitted Direct Words

The SynchLink module can transmit data from the following direct

word sources:

• Output Direct Words (0-3)

• Received Direct Words (0-3)

• Multiplier

In initial configuration, you can choose the Transmitted Direct Words,

but you must use ladder logic to move data to those locations in data

type tags. For more information on the data tags, see Appendix E.

Direct Words

Direct words are data delivered in a single message. These can be

read from the module input tags (i.e. Local.x.I.DirectData[x]) and sent

from the module output tags (i.e. Local.x.O.DirectData[x]). A

SynchLink message can contain a maximum of four direct data words;

each word is 32 bits in length. Direct data can be automatically

forwarded to the next node in the daisy chain or ring configuration.

Multiplier

The Multiplier multiplies one Direct Word on the receive port by the

value in the local tag "Local:x:O.Multiplier" before transmitting it out

the transmit port. This is useful when your application requires fine

adjustments to the direct word between SynchLink nodes.

EXAMPLE

Although you can configure the multiplier for any of the Direct Words,

it can only be used with one Direct Word at a time.

If the Direct Word 0 passes process status on and the

local controller in the downstream chassis identifies

a change in the process, you can use the multiplier

to change the value of the direct word before

passing it on to the next processor.

Publication 1756-UM521C-EN-P - July 2004

Page 45

SynchLink Module Features 3-17

The multiplier can only transmit the same word it received (i.e. this

feature does not allow your module to receive direct word 0 and

transmit it as direct word 1). The multiplier output is limited to 16 bits;

any value generated by the multipler larger than 65535 is truncated to

16 bits, and a multiplier overflow error (described below) is reported

by the Synchlink module. Make sure any data that is passed onto the

Output word is less than 65535 else you receive incorrect output data.

IMPORTANT

The Multiplier on Transmitted Direct Words truncates

values after the decimal point and can give

misleading results under some circumstances. For

example, using a multiplier of 0.95 with a value of 20

yields a result of 18 instead of the expected 19. The

reason for this error is that 0.95 is represented by a

floating point value (~0.949999). The result of

18.9998 is truncated to 18 instead of rounded to 19.

We recommend you verify your results when using

the multiplier function.

Mutiplier Overflow

The Multiplier Overflow bit is a data tag (Local.x.I.SynchLinkMultiplier

Overflow) that exceeds the maximum multiplier value of 65535. This value is

reported back to you through the input data tags.

IMPORTANT

If you want to pass a Multiplier Overflow value

(received from an upstream node) to a third node

downstream but not locally change the direct word

data transmitted to the downstream node, you must

use a Multiplier value = 1.

Transmitted Direct Words

The Transmitted Direct Words are configured on the following screen:

Publication 1756-UM521C-EN-P - July 2004

Page 46

3-18 SynchLink Module Features

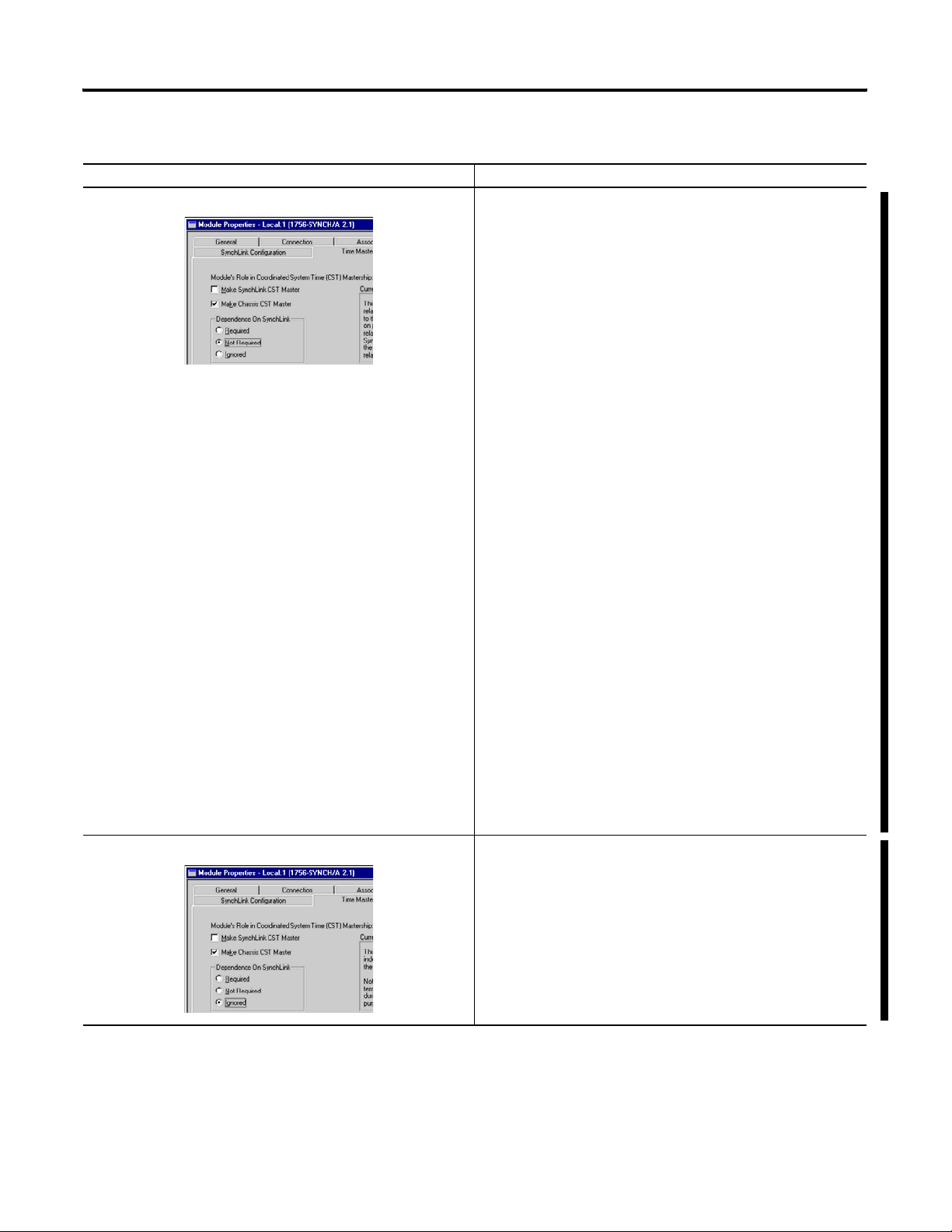

CST and SynchLink Mastership

The SynchLink module can be configured for multiple mastership and

slave roles in respect to the Coordinated System Time and the

SynchLink. Table 3.7 describes the ways you can configure your 1756-SYNCH

module’s role in CST Mastership.

Table 3.7 Possible SynchLink Configurations

This configuration: Means:

Only the Make SynchLink CST Master box is checked.

• This module relays time from the Chassis CST Master to the

SynchLink.

• The SynchLink node clock on this module is the SynchLink

Time Master.

• The chassis where the module resides is the CST Time

Master on SynchLink. Although the chassis establishes the

CST value for the SynchLink, the module is not CST master

of the chassis. In this case, another module (e.g. controller)

sets the CST value for the local chassis.

Both the Make SynchLink CST Master and Make Chassis CST

Master boxes are checked

Only the Make Chassis CST Master box is checked.

Dependence on SynchLink is Required • The module is a Time Slave on SynchLink.

This module is the System Time Master. It sets the CST for its local

chassis and all devices connected to the SynchLink.

In this case, you MUST configure the module for its dependence on

SynchLink. The module is a Time Slave on the SynchLink and

depends on the SynchLink fiber optic cable for CST mastership. The

1756-SYNCH module then relays the time from the cable to the

chassis in which it resides, acting as the Chassis CST master. The

1756-SYNCH module’s behavior varies in this configuration,

according to your configuration choices as described in the

following rows

• The module is the CST Time Master of the local chassis.

• You MUST have selected another module on the fiber optic

cable to be the SynchLink CST Master.

• If communications with the SynchLink CST Master are not

present when the 1756-SYNCH module powers up,

CST-dependent features will not start operating until the

communications to the SynchLink CST Master are restored.

• If communications with the SynchLink CST Master are

broken after operation has begun, the 1756-SYNCH module

stops relaying time to this chassis, and there will be no CST

signal in the chassis.

Publication 1756-UM521C-EN-P - July 2004

Page 47

Table 3.7 Possible SynchLink Configurations

This configuration: Means:

Dependence on SynchLink is Not Required • The module is a Time Slave on SynchLink.

SynchLink Module Features 3-19

• The module is the CST Time Master of the local chassis.

• You MUST have selected another module on the fiber optic

cable to be the SynchLink CST Master.

• If your 1756-SYNCH module uses firmware revision 2.18

or greater and communications with the SynchLink CST

Master are not present at power-up, the module

automatically becomes the Time Master of its local chassis.

If a Time Slave 1756-SYNCH module becomes the Chassis

CST Master without the SynchLink CST master, then the

slave chassis is running unsynchronized motion.

Unsynchronized motion may be acceptable when

troubleshooting or performing machine maintenance. When

synchronized motion is required the application logic in the

slave chassis must check the proper status bit in the slave

1756-SYNCH module.

• If your 1756-SYNCH module uses firmware revision 2.10

or earlier and communications with the SynchLink CST

Master are not present at power-up, CST-dependent

features will not start operating until the communications to

the SynchLink CST Master are restored.

• If communications with the SynchLink CST Master are

broken after operation has begun, the module continues to

relay time and acts as Chassis CST Master. In this case, the

chassis is running unsynchronized motion that you must

account for in your application’s logic.

Dependence on SynchLink is Ignored

IMPORTANT: If your 1756-SYNCH is running unsynchronized

motion (i.e. because the connection to a SynchLink CST Master

either broke or never existed), when communications are resumed

with the Master over the fiber optic cable, you must do the

following to become synchronized with the CST Master:

• Stop all motion connected to this chassis.

• Reset the 1756-SYNCH module via application ladder logic

or RSLogix 5000.

• The module is a Time Slave on SynchLink.

• The module is the CST Time Master of the local chassis.

• You MUST have selected another module on the backplane

to be the SynchLink CST Master.

• The module acts as an unsynchronized Chassis CST Master.

In this case, the module ignores the SynchLink CST Master

at all times, including module power-up.

This option is expected to be a temporary mode of

operation.

For more information on configuring your SynchLink modules, see Chapter 5.

Publication 1756-UM521C-EN-P - July 2004

Page 48

3-20 SynchLink Module Features

Chapter Summary and What’s Next