Page 1

NeXUS Module

1756-CLX/C

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication, those

responsible for the application and use of these products must satisfy themselves that all

necessary steps have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws, regulations, codes

and standards. In no event will Allen-Bradley be responsible or liable for indirect or

consequential damage resulting from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples shown in this publication

are intended solely for purposes of example. Since there are many variables and

requirements associated with any particular installation, Allen-Bradley does not assume

responsibility or liability (to include intellectual property liability) for actual use based

upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and

Maintenance of Solid-State Control (available from your local Allen-Bradley office),

describes some important differences between solid-state equipment and

electromechanical devices that should be taken into consideration when applying products

such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without

written permission of Rockwell Automation, is prohibited.

Throughout this publication, notes may be used to make you aware of safety

considerations. The following annotations and their accompanying statements help you to

identify a potential hazard, avoid a potential hazard, and recognize the consequences of a

potential hazard:

ATTENTION

IMPORTANT

Identifies information about practices or circumstances that can

lead to personal injury or death, property damage, or economic

loss.

Identifies information that is critical for successful application

and understanding of the product.

Page 3

ATTENTION

Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial

environment, in overvoltage Category II applications (as defined in

IEC publication 60664-1), at altitudes up to 2000 meters without

derating.

This equipment is supplied as "open type" equipment. It must be

mounted within an enclosure that is suitably designed for those specific

environmental conditions that will be present and appropriately

designed to prevent personal injury resulting from accessibility to live

parts. The interior of the enclosure must be accessible only by the use

of a tool. Subsequent sections of this publication may contain

additional information regarding specific enclosure type ratings that

are required to comply with certain product safety certifications.

See NEMA Standards publication 250 and IEC publication 60529, as

applicable, for explanations of the degrees of protection provided by

different types of enclosure. Also, see the appropriate sections in this

publication, as well as the Allen-Bradley publication 1770-4.1

("Industrial Automation Wiring and Grounding Guidelines"), for

additional installation requirements pertaining to this equipment.

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with over 75 sales/support

offices, 512 authorized distributors and 260 authorized systems integrators located

throughout the United States alone, as well as Rockwell Automation representatives in

every major country in the world.

IMPORTANT

The 1756-CLX/C module is supported only by Rockwell Automation

Japan. Refer to Technical Product Assistance on page 4 for contact

information.

Product Support

Contact your Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Page 4

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance, please review the

troubleshooting information first. If the problem persists, contact a Rockwell Automation

representative at the following location:

Rockwell Automation Japan Co., Ltd.

Tokyo Headquarters

Shinkawa Sanko Building

8F/9F, 1-3-17, Shinkawa,

Chuo-ku, Tokyo 104-0033

Tokyo

Japan

Telephone: 81-3-3206-2781

Fax: 81-3-3206-2788

Page 5

Preface

What This Preface Contains

This preface describes how to use this manual. The following table describes what this

preface contains and where to find it.

For information about this topic: See page:

Who Should Use This Manual P-1

Purpose of This Manual P-1

What This Manual Contains P-2

Common Techniques Used in This Manual P-3

Related Documentation P-3

Who Should Use This Manual

You must be able to program and operate an Allen-Bradley ControlLogix™ Logix

controller and ControlLogix I/O modules to efficiently use your 1756-CLX/C module.

We assume that you know how to do this in this manual. If you do not, refer to the list of

Related Documentation on page P-3 of this preface before you attempt to use this module.

Purpose of This Manual

This manual describes how to install, configure, and troubleshoot your 1756-CLX/C

module.

Publication 1756-UM524B-EN-P - December 2008

Page 6

P-2 Preface

s

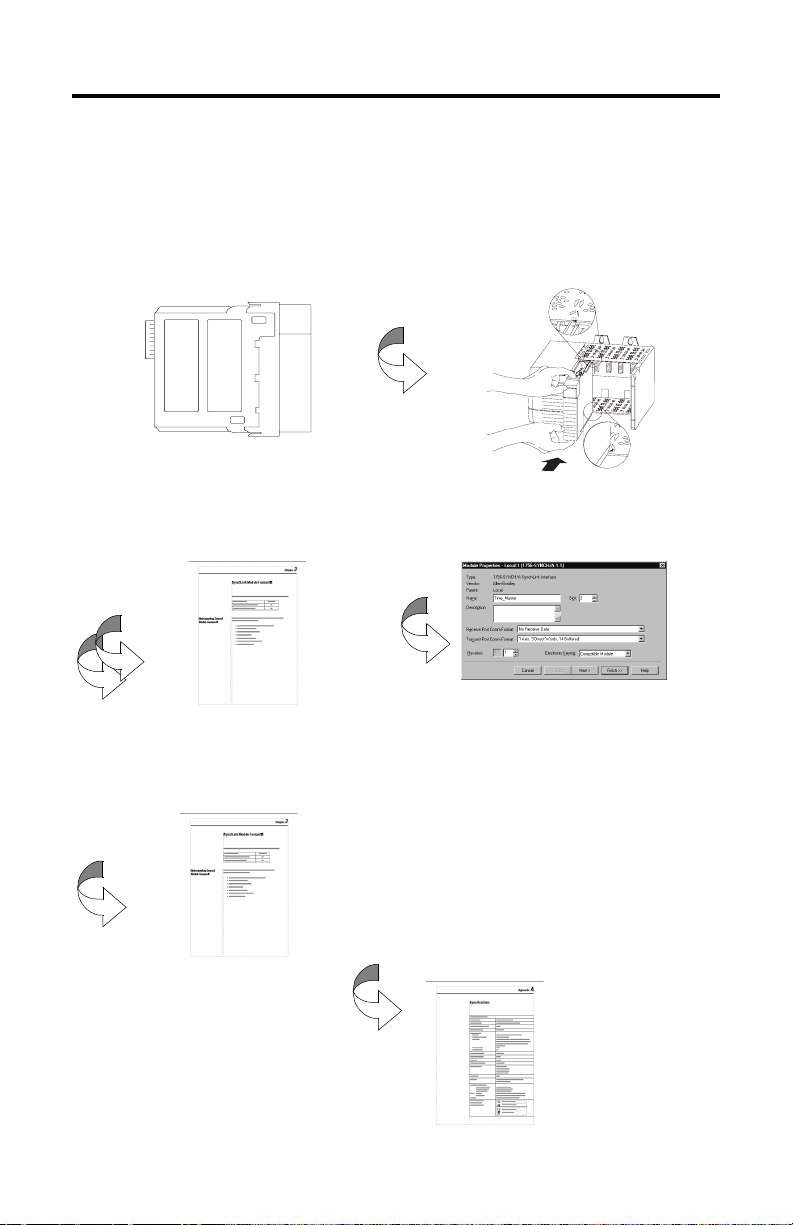

What This Manual Contains

This user manual contains the following sections:

Chapter 1 - About the 1756-CLX/C Module

Description of the 1756-CLX/C module

Chapter 3 - About the NeXUS Network

Overview of the NeXUS network and functions

supported by the 1756-CLX/C module

Chapter 5 - Status Indicators and

Troubleshooting

Description of how to troubleshoot the

1756-CLX/C module

Chapter 2 - Install the 1756-CLX/C Module

Description of how to install the 1756-CLX/C

module and connect the Ethernet cable

Chapter 4 - Configure the 1756-CLX/C Module

Description of how to configure the 1756-CLX/C

module with RSLogix 5000

Appendix A - Specifications

Listing of the 1756-CLX/C module specifications

Appendix B - Appendix B - Factory-set Jumpers

Description of all factory-set jumper positions

Appendix C - 1756-CLX/C Web Interface

Describes how to access and use web-based

information about the 1756-CLX/C module

Appendix D - 1756-CLX/C Module Backplane

Communication Tag List

Complete list of backplane (API) communication tag

Appendix E - 1756-CLX/C Module Tag List

Complete list of the input and output data tags

Glossary - Definitions of terms used in this manual

Publication 1756-UM524B-EN-P - December 2008

Page 7

Common Techniques Used in This Manual

The following conventions are used throughout this manual:

• Bulleted lists provide information, not procedural steps

• Numbered lists provide sequential steps

• Screen captures are pictures of the software’s actual screens

• The names of screen buttons and fields are often in bold in

the text of a procedure

Preface P-3

TIP

This symbol identifies helpful information.

Related Documentation

The following table lists related ControlLogix documentation:

Table A Related Documentation

Catalog number: Document title: Pub. number:

1756-A4, -A7, -A10,

-A13, -A17

1756-PA72, -PB72 ControlLogix Power Supply Installation Instructions 1756-IN078B

1756-PA75, -PB75 ControlLogix Power Supply Installation Instructions 1756-IN596A

1756-Series ControlLogix Module Installation Instructions

1756-Series ControlLogix System User Manual 1756-UM001

TIP

ControlLogix Chassis Installation Instructions 1756-IN080C

(Each module has separate installation document.)

Multiple 1756-IN numbers

Many of the above publications are available online from the

Automation Bookstore (www.theautomationbookstore.com).

TIP

Rockwell Software products are provided with extensive tutorials and

online help. We recommend that you use the tutorials and help menus

to learn about these products.

For more information about Rockwell Software products, visit the

Rockwell Software internet site (www.software.rockwell.com).

Publication 1756-UM524B-EN-P - December 2008

Page 8

P-4 Preface

Notes:

Publication 1756-UM524B-EN-P - December 2008

Page 9

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Product Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Preface

What This Preface Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

What This Manual Contains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Common Techniques Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Chapter 1

About the 1756-CLX/C Module

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

About the 1756-CLX/C Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Some Points to Remember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

About the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Hardware/Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Preventing Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Removal and Insertion Under Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1756-CLX/C Module Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Configuration Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Process Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Chapter 2

Install the 1756-CLX/C Module

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Identify Module Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

About the Jumpers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Install and Connect the Chassis and Power Supply . . . . . . . . . . . . . . . . . . . . . 2-2

Determine Module Slot Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Install the Module in the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Apply Power to the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Removal and Insertion under Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Publication 1756-UM524B-EN-P - December 2008

Page 10

TOC-ii Table of Contents

Make the Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Wire the Ethernet Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Plug in the Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Remove or Replace the Module (When Applicable) . . . . . . . . . . . . . . . . . . . . 2-5

Check Power Supply and Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Chapter 3

About the NeXUS Network

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Protocol Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Supported Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Network Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Supported ADP Message Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Configuration Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Gateways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Subnet Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

For More Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Chapter 4

Configure the 1756-CLX/C Module

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Configure Your 1756-CLX/C Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Configuration Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Overview of the Configuration Process . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Create a New Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

View and Change Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Configure the Module IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Chapter 5

Status Indicators and Troubleshooting

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Use the LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Use the Communications Port Status Indicators . . . . . . . . . . . . . . . . . . . . . . . 5-3

Use the Alpha-numeric Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Publication 1756-UM524B-EN-P - December 2008

Page 11

Table of Contents TOC-iii

Appendix A

Specifications

Appendix B

Factory-set Jumpers

Appendix C

1756-CLX/C Web Interface

User Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Appendix D

1756-CLX/C Module Backplane Communication Tag List

About the Nexus Communication Flags (NX20 – NX91) . . . . . . . . . . . . . . . D-2

Boot /Reboot 1756-CLX/C Module Procedure. . . . . . . . . . . . . . . . . . . . D-2

1756-CLX/C Module Configuration Check Procedure . . . . . . . . . . . . . D-4

1756-CLX/C System Error Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

1756-CLX/C Module Sending Procedure . . . . . . . . . . . . . . . . . . . . . . . . D-6

1756-CLX/C Module Receiving Procedure . . . . . . . . . . . . . . . . . . . . . . D-7

Appendix E

1756-CLX/C Module Tag List

Glossary

Index

Publication 1756-UM524B-EN-P - December 2008

Page 12

TOC-iv Table of Contents

Publication 1756-UM524B-EN-P - December 2008

Page 13

Chapter

1

About the 1756-CLX/C Module

What This Chapter Contains

This chapter provides an overview of the 1756-CLX/C module, its primary features, what

it does, and how to use it. You will need to understand the concepts discussed in this

chapter in order to configure your module and use it in a control system. The following

table lists where to find specific information in this chapter..

For information about this topic: See page:

About the 1756-CLX/C Module 1-1

Module Features 1-2

Some Points to Remember 1-3

About the Battery 1-4

Hardware/Software Compatibility 1-4

Preventing Electrostatic Discharge 1-5

Removal and Insertion Under Power 1-5

1756-CLX/C Module Architecture 1-6

Configuration Overview 1-6

Process Overview 1-7

About the 1756-CLX/C Module

The 1756-CLX/C Interface Module communicates over a plant-floor local area network

known as NeXUS. The network is based on the Autonomous Decentralized Protocol

(ADP).

The latest copy of the following ADP specification is available at

http://www.mstc.or.jp/jop/misc/spec-e.html:

Manufacturing Science and Technology Center, Japan FA Open Systems

Promotion Group, Distributed Manufacturing Architecture Committee,

“Specifications for Autonomous Decentralized Protocol”, R. 3.0, MSTC/JOP

(September 30, 1999).

Publication 1756-UM524B-EN-P - December 2008

Page 14

1-2 About the 1756-CLX/C Module

The module mounts into a ControlLogix chassis. It communicates with Logix controllers

across the ControlLogix chassis backplane. The module connects to the NeXUS network

via an Ethernet cable.

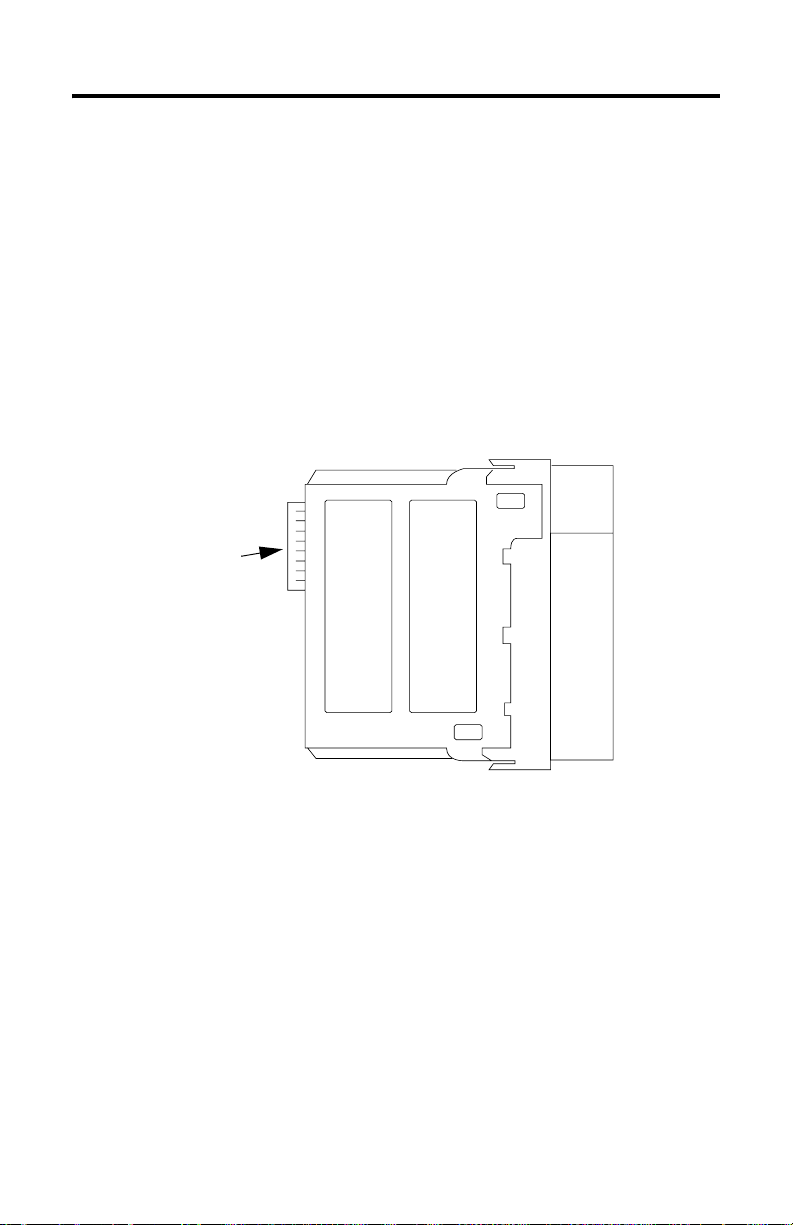

Module Features

1756-CLX/C module features include:

• NeXUS (ADP) messaging encapsulated within standard UDP/IP protocol

• interfacing via Ethernet media

• communication to and from ControlLogix controllers in the same chassis

• battery backed-up SRAM

Backplane connector

(interface to the

ControlLogix backplane)

Publication 1756-UM524B-EN-P - December 2008

Page 15

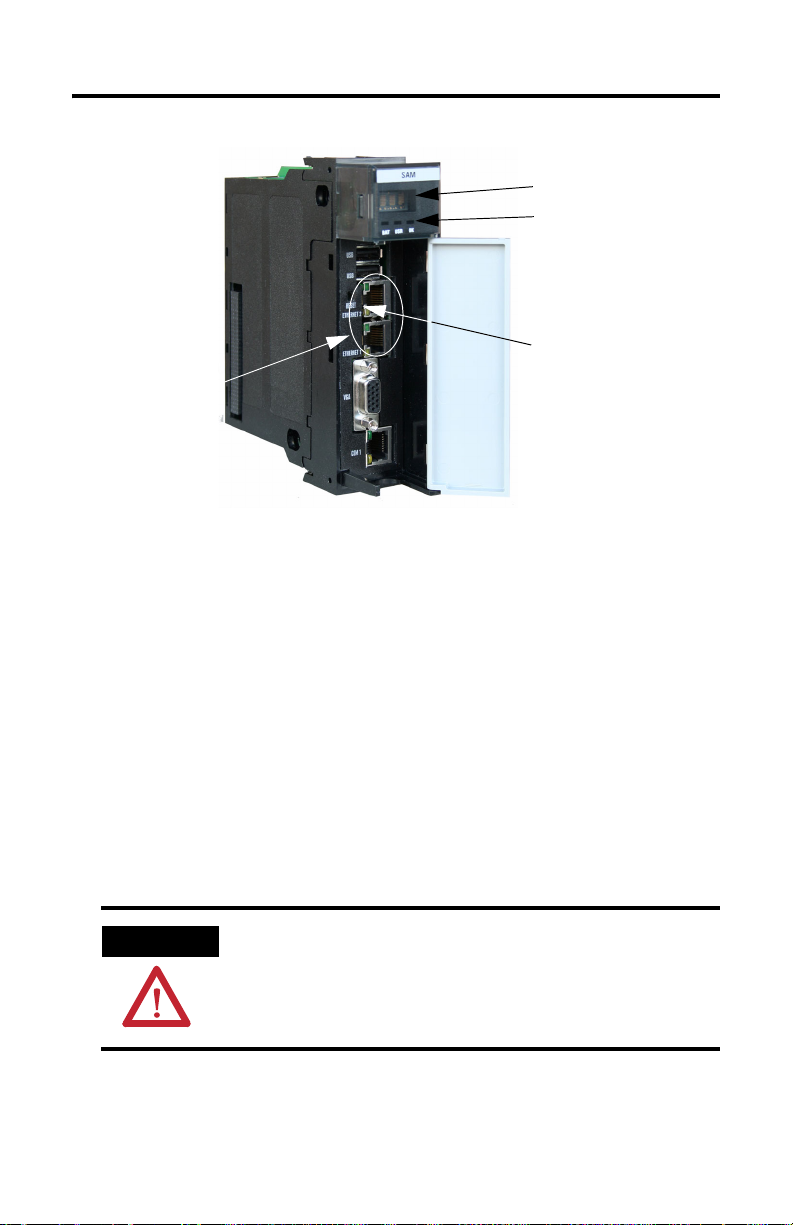

About the 1756-CLX/C Module 1-3

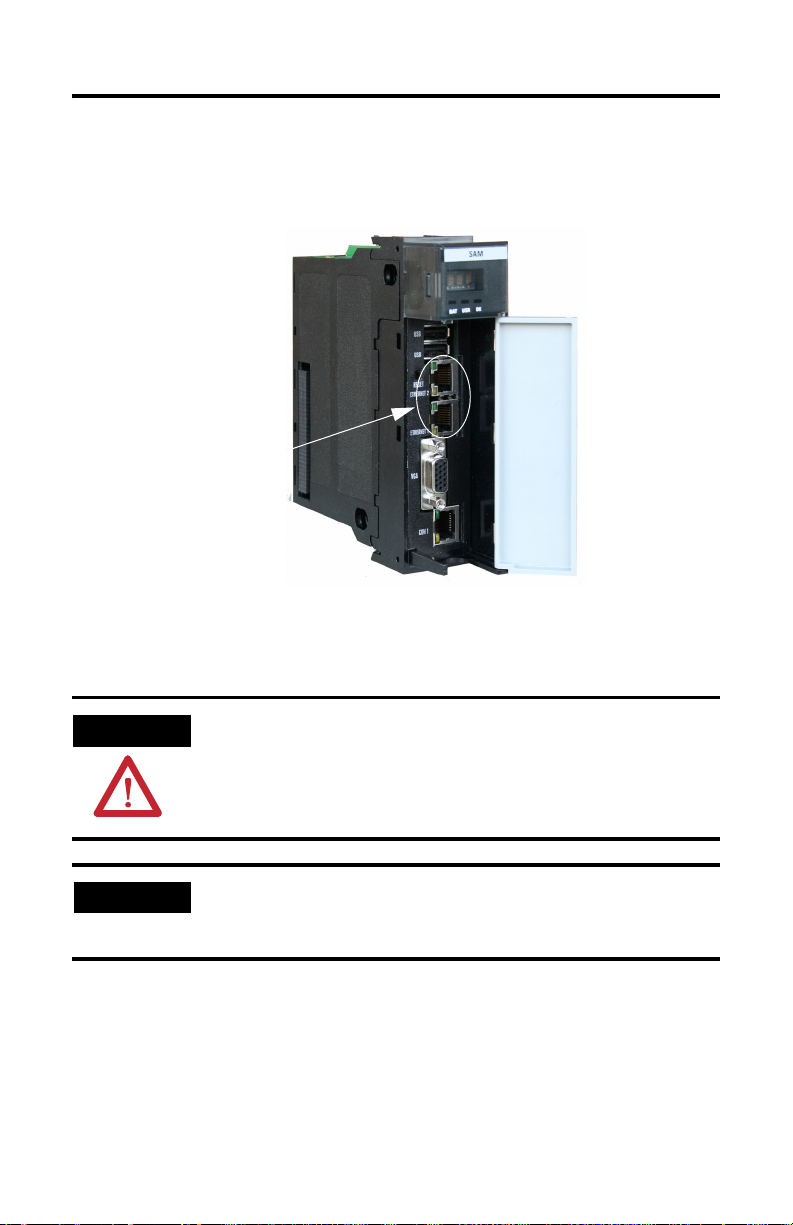

Alpha-numeric display

Status indicators

Ethernet port with

status indicators

Reset Switch

view; actual switch is

(schematic

inside module)

Some Points to Remember

Remember the following points about the 1756-CLX/C module:

• the module is not supported by RSLinx or RSNetworx software

• the module does not support bridging between NeXUS and ControlNet, DeviceNet,

EtherNet/IP, or any other network

• the module does not support bridging between NeXUS sub-nets (i.e., bridging

between 1756-CLX/C modules located in the same chassis)

• the maximum NeXUS (ADP) message size is 1024 bytes

• data rate is 10Mb/sec.; maximum data rate is 100Mb/sec.

• minimum module data transfer rate is 10 packets/sec.

• the module supports a maximum of 32 TCDs

• one Logix controller can own only one 1756-CLX/C module

ATTENTION

Use only the Ethernet connector on the module. Do not use other

connectors.

Publication 1756-UM524B-EN-P - December 2008

Page 16

1-4 About the 1756-CLX/C Module

About the Battery

The 1756-CLX/C module uses a rechargeable lithium vanadium pentoxide battery, which,

when fully charged, provides backup power for the SRAM memory for approximately 21

days. The module must be powered for approximately 20 hours before the battery

becomes fully charged. The battery is not accessible, and should last for the life of the

module.

ATTENTION

The lithium battery is not user-replaceable. Do not attempt to access or

replace it. Lithium batteries can be hazardous to humans and the

environment, and should always be handled and disposed of properly.

Hardware/Software Compatibility

The 1756-CLX/C module is compatible with the following firmware versions and

software releases. Contact Rockwell Automation if you need software or firmware

upgrades to use this equipment.

Product Firmware version/software release

ControlLogix Controller 7.09 or higher

RSLogix5000 Software 7.02 or higher

Publication 1756-UM524B-EN-P - December 2008

Page 17

About the 1756-CLX/C Module 1-5

Preventing Electrostatic Discharge

This module is sensitive to electrostatic discharge.

ATTENTION

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause

internal damage and affect normal operation. Follow these guidelines

when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wrist strap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in appropriate static-safe

packaging.

Removal and Insertion Under Power

ATTENTION

We do not recommend that you install or remove the module under

power.

Publication 1756-UM524B-EN-P - December 2008

Page 18

1-6 About the 1756-CLX/C Module

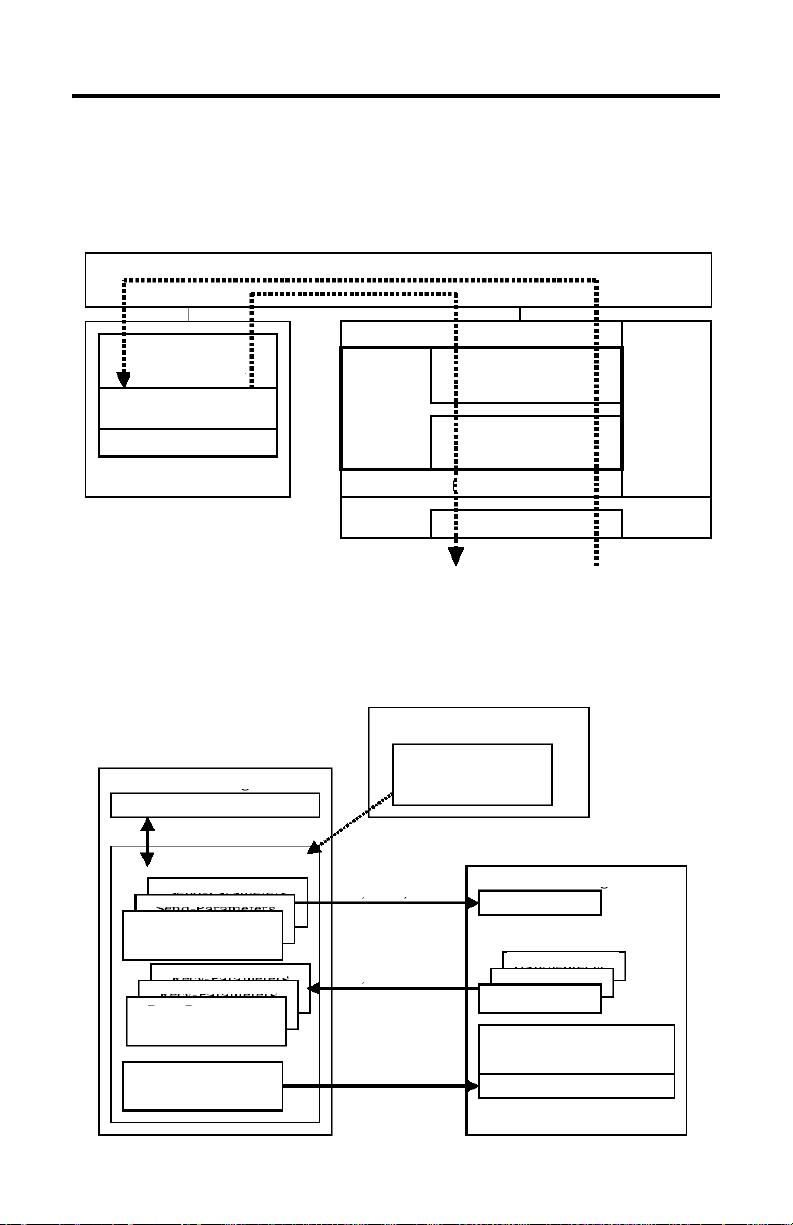

1756-CLX/C Module Architecture

The figure below shows how the various components of a system using the 1756-CLX/C

module interact.

Backplane

Backplane

communication

Application (ladder)

Tags (data)

Logix5000 Controller

1756-CLX/C API

1756-CLX/C

module

1756-CLX/C Dlink

Backplane

communication

1756-CLX/C

message handling

SMG/BS

Ethernet port

Configuration Overview

The figure below shows an overview of the configuration process.

Development PC

Setup

(DF, TCD)

IP Address

Data field

ControlLogix tools

Created at sending

Handle (send)

Created at startup

Handle (receive)

Data field (local only) and

multi-cast groups

IP Address and mask

Logix5000 Controller

Application ladder

Ta gs

Send parameters

(DF, MCG, TCD)

Receive parameters

(DF, TCD)

Parameters

(Node, TCP/IP)

(DF, MCG, TCD)

1756-CLX/C

module

Windows

NT 4.0

(UDP/IP)

Publication 1756-UM524B-EN-P - December 2008

Page 19

About the 1756-CLX/C Module 1-7

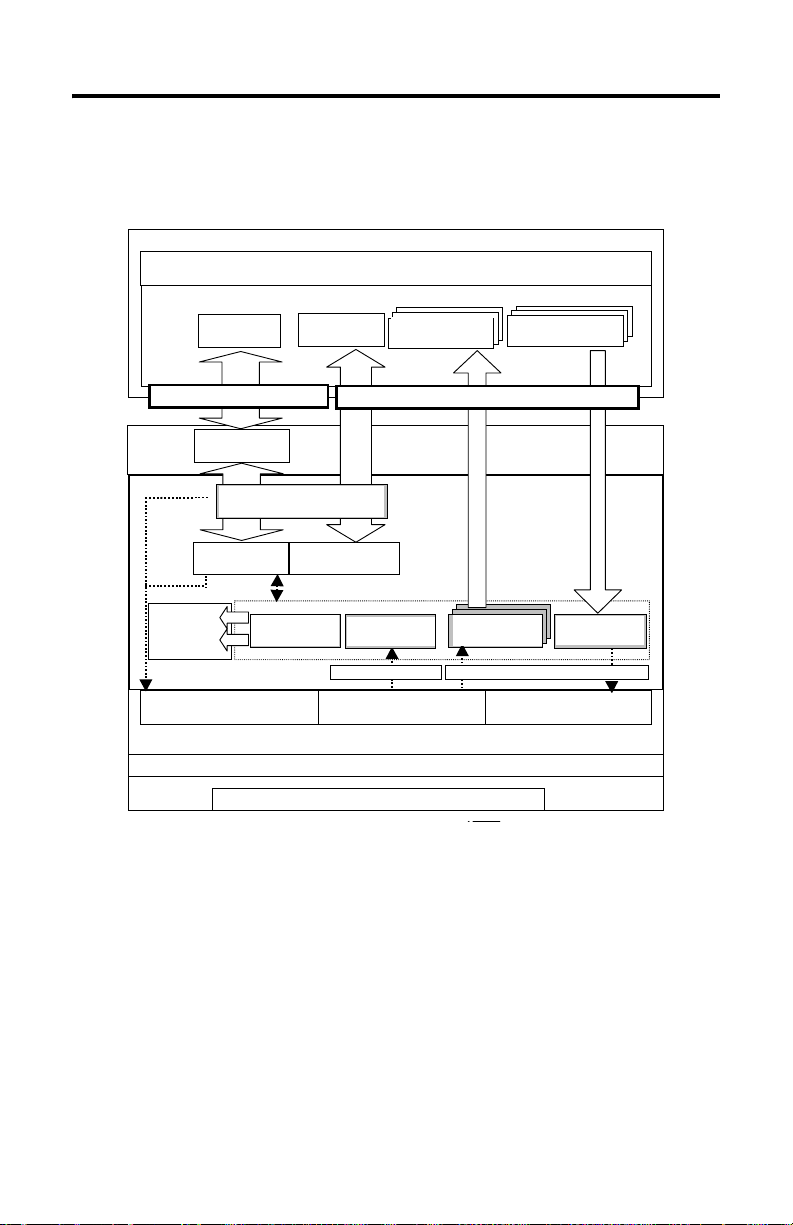

Process Overview

The figure below shows the flow of data to and from the 1756-CLX/C module.

Control Logix

ControlLogix

Application ladder

Application (Ladder)

Tags

System Status

System status

(NX20 - NX51)

NX20

NX51

System

System config.

Configuration

(NX00 - NX07)

07

NX00

TAGs

Recv-Parameters

Recv. parameters and

and data NX90,91

data (NX90 and NX91)

Send-Parameters

Send parameters and

and data NX80

data (NX90 and NX91)

Connected Data Transfer

Connected data transfer

System status

System Status

NX51

NX20

(NX20 - NX51)

1756-CLX/C module

NX/SAM

Shared

Shared

memory

System Status

Memory

System status

NX20

NX51

(NX20 - NX51)

LED segment

LED

display

Segment

Display

Functions to Start/Stop

Functions to

NX Dlink

start/stop NX Dlink

(nx_sam_mon.exe)

Unconnected Data Transfer

Management process

Management Process

(nx_sam_man.exe)

(nx_sam_man.exe)

Monitor Process

Monitor process

(nx_sam_mon.exe)

System Configuration

System config. (NX00

NX Dlink daemons and library

Windows NT 4.0 with SP6a (UDP/IP)

Windo ws NT4.0 with SP6a (UDP/IP)

NX00

07

- NX07)

System Transaction

Sys. transact. recv.

Recv Process

(nx_sam_mon.exe)

(nx_sam_srecv .exe)

System Transaction Transaction Data

System transaction Transaction data

Functions to receive

Functions

to receive

NX Dlink daemons and library

Ethernet port

Ethernet Port

Unconnected data transfer

Recv- Process

Receive process

(nx_sam_recv.exe)

(nx_sam_recv.exe)

Functions to send

Functions

Send -Process

Send process

(nx_sam_send.exe)

(nx_sam_send.exe)

to send

1756-CLX/C module

56SAM

Publication 1756-UM524B-EN-P - December 2008

Page 20

1-8 About the 1756-CLX/C Module

Notes:

Publication 1756-UM524B-EN-P - December 2008

Page 21

Chapter

Install the 1756-CLX/C Module

What This Chapter Contains

This chapter describes how to install the 1756-CLX/C module into a ControlLogix

chassis.

For information about this topic See page

Identify Module Components 2-1

Install and Connect the Chassis and Power Supply 2-2

Determine Module Slot Location 2-2

Install the Module in the Chassis 2-3

Apply Power to the Module 2-3

Removal and Insertion under Power 2-4

Make the Ethernet Connection 2-4

Remove or Replace the Module (When Applicable) 2-5

Check Power Supply and Module Status 2-6

2

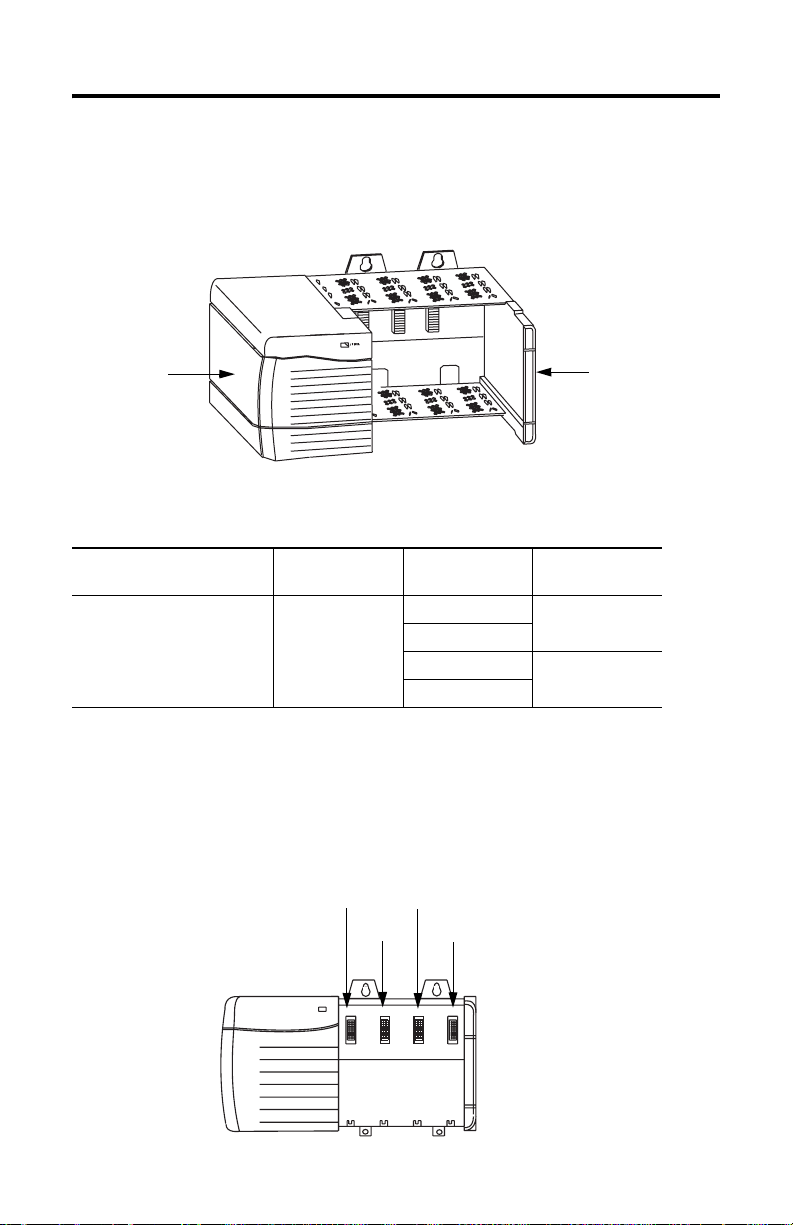

Identify Module Components

Refer to Module Features on page 1-2 for an illustration that will help you identify the

module components.

About the Jumpers

ATTENTION

All jumpers on the 1756-CLX/C module are factory-set and should not

be changed. If you change a jumper by mistake, refer to Appendix B of

this manual to reset it to the proper position.

Publication 1756-UM524B-EN-P - December 2008

Page 22

2-2 Install the 1756-CLX/C Module

Install and Connect the Chassis and Power Supply

Before you install the module, you must install and connect a ControlLogix chassis and

power supply.

Power Supply

20805-M

1756-A4 Chassis

For information on installing these products, refer to the publications listed in the

following table.

Chassis

Typ e

Series B: 1756-A4, -A7, -A10,

-A13, -A17

Chassis

Installation

Pub. No.

1756-IN08C

Power

Supply

1756-PA72/B Pub. No.

1756-PB72/B

1756-PA75/A Pub. No.

1756-PB75/A

Power Supply

Installation

1756-IN078B

1756-IN596A

Determine Module Slot Location

You can install the module in any slot in the ControlLogix chassis.The figure below shows

chassis slot numbering in a 4-slot chassis. Slot 0 is the first slot and is always the left-most

slot in the rack (the first slot to the right of the power supply).

Slot 0

Power Supply

Slot 1

Slot 2

Slot 3

Publication 1756-UM524B-EN-P - December 2008

Chassis

Page 23

Install the 1756-CLX/C Module 2-3

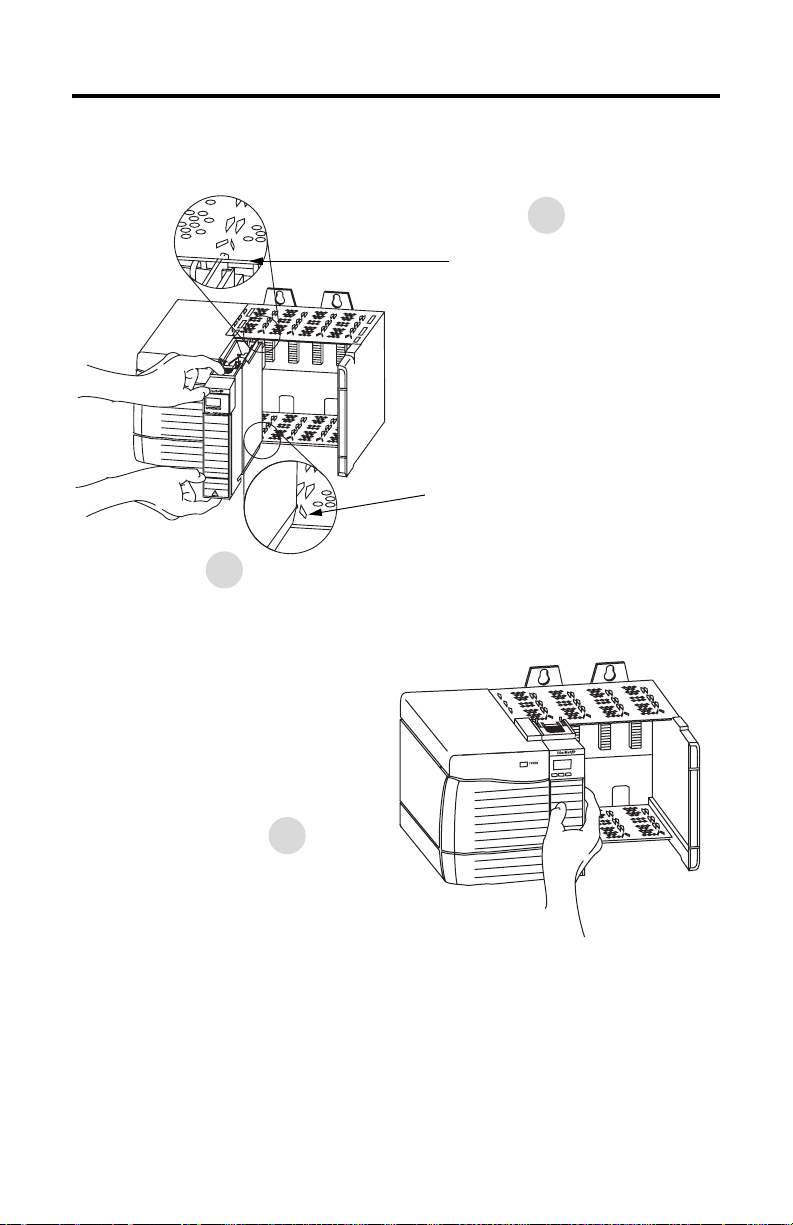

Install the Module in the Chassis

1

Align the circuit board with top and

bottom guides in the chassis.

Circuit Board

31275-M

2

Slide the module into the chassis. Make sure the module backplane connector properly

connects to the chassis backplane. Check that the holding clips on the top and bottom of the

module are securely in the locking holes of the rack.

3

The module is properly installed when

it is flush with the power supply or other

installed modules.

31276-M

Apply Power to the Module

Turn ON power. The 1756-CLX/C module performs a self-test. If the module is operating

properly, the OK LED turns GREEN.

Publication 1756-UM524B-EN-P - December 2008

Page 24

2-4 Install the 1756-CLX/C Module

Removal and Insertion under Power

WARNING

We do not recommend that you install or remove the module under

power.

Make the Ethernet Connection

Wire the Ethernet Connector

The 1756-CLX/C module has an Ethernet port you will use to connect to the NeXUS

network. Use an RJ45 connector to connect to the Ethernet network. Wire the appropriate

connector as shown below:

1 ------ TD+

2 ------ TD3 ------ RD+

4 ------ NC

5 ------ NC

6 ------ RD7 ------ NC

8 ------ NC

For detailed connnection information, refer to the EtherNet/IP Media Planning and

Installation Guide, publication ENET-IN001A-EN-P.

8

1

RJ 45

Publication 1756-UM524B-EN-P - December 2008

Page 25

Install the 1756-CLX/C Module 2-5

Plug in the Connector

Plug the Ethernet connector into the port.

Ethernet port

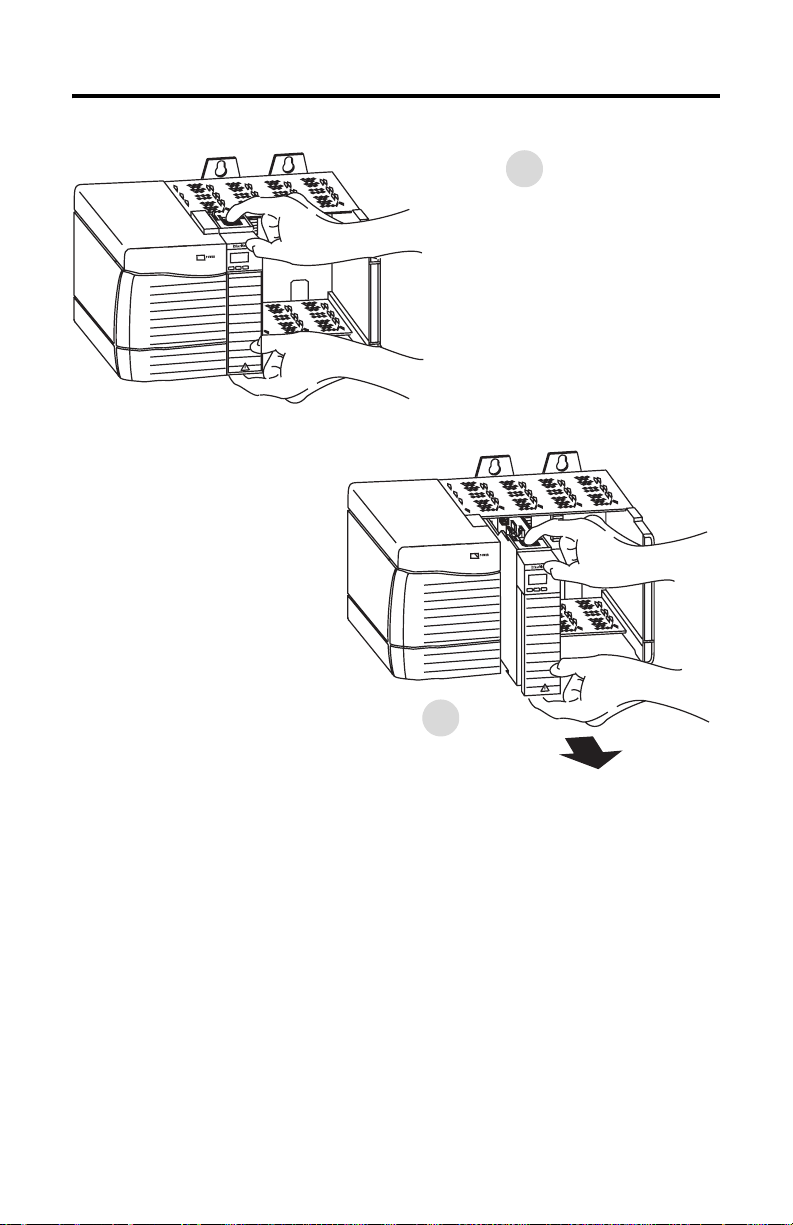

Remove or Replace the Module (When Applicable)

ATTENTION

IMPORTANT

Before you remove the module, you must disconnect the Ethernet

cable.

If you are replacing an existing module with an identical one, and you

want to resume identical system operation, you must install the new

module in the same slot.

Publication 1756-UM524B-EN-P - December 2008

Page 26

2-6 Install the 1756-CLX/C Module

1

Push on upper and lower module tabs to

disengage them.

31277-M

2

Slide module out of chassis.

31278-M

Check Power Supply and Module Status

Refer to chapter 5 to use the status indicators to determine that the 1756-CLX/C module is

operating correctly.

Publication 1756-UM524B-EN-P - December 2008

Page 27

Chapter

About the NeXUS Network

What This Chapter Contains

This chapter provides a brief overview of the NeXUS network. The following table

describes what this chapter contains and where to find it.

For information about this topic: See page:

Protocol Structure 3-1

Supported Services 3-2

Network Organization 3-3

Supported ADP Message Types 3-4

Configuration Requirements 3-4

For More Information 3-8

3

Protocol Structure

The NeXUS network is a TCP/IP over Ethernet type LAN with a manufacturing message

transfer protocol, known as NeXUS, on top, as shown in the table below. This protocol is

known as the Autonomous Decentralized Protocol, or ADP.

Publication 1756-UM524B-EN-P - December 2008

Page 28

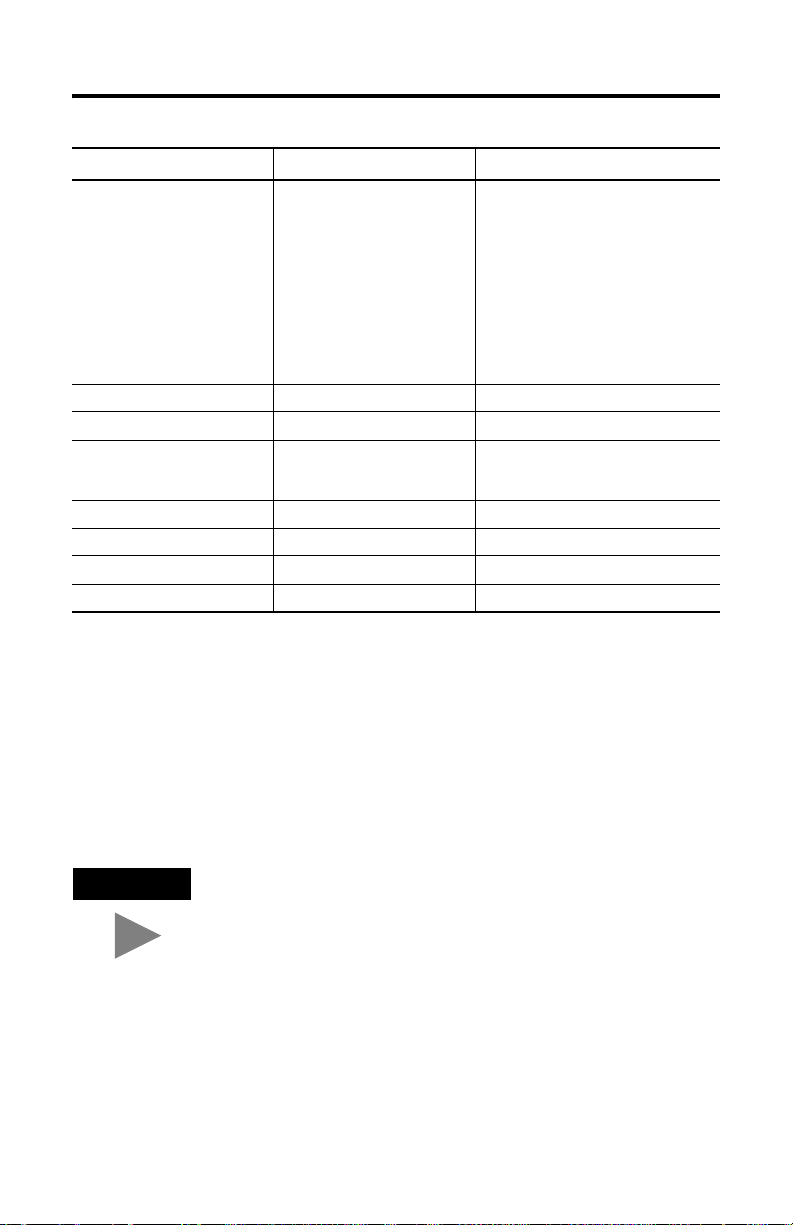

3-2 About the NeXUS Network

OSI Layer NeXUS Network Protocol Comments

Layer 7 - Application NEXUS or ADP See the latest copy of the following

Layer 6 - Presentation Not implemented

Layer 5 - Session Not implemented

Layer 4 - Transport UDP and TCP Most ADP messages are transferred

Layer 3 - Network IP

Layer 2 - Data Link IEEE/802.3 - Ethernet

Layer 1 - Physical IEEE/802.3 - Ethernet

Physical Medium IEEE/802.3 - Ethernet

ADP specification, available at

http://www.mstc.or.jp/jop/misc/spec-e

.html:

Manufacturing Science and

Technology Center, Japan FA Open

Systems Promotion Group,

Distributed Manufacturing

Architecture Committee,

“Specifications for Autonomous

Decentralized Protocol”, R. 3.0,

MSTC/JOP (September 30, 1999).

using the UDP protocol; some are

transferred using the TCP protocol

Supported Services

The ADP protocol provides to application programs 2 means of message transmission:

peer-to-peer and multicast. Because the peer-to-peer message transfer requires a

connection-oriented service as an underlayer, it uses the TCP protocol.

Since multicast transmission is connectionless, multicast messages are sent and received

using the UDP protocol. As with any connectionless service, delivery and sequence of

messages is not guaranteed. Nor is there a flow control mechanism.

TIP

Publication 1756-UM524B-EN-P - December 2008

The 1756-CLX/C module supports multicast transmission services

only.

Page 29

About the NeXUS Network 3-3

Network Organization

Looking from the top down, a NeXUS network is viewed as a system of islands called

domains, interconnected via a wide area network. Each domain is uniquely identified by a

domain number (DMN), which ranges from 1 to 64. The domain number must be provided

in all ADP PDU headers. DMN 0 is reserved for the domain considered within the scope

of the ADP specification.

A domain is divided into data fields. A data field is an area within which a group of logical

nodes communicates with each other via multicast or peer-to-peer messages. A domain is

uniquely identified by a data field number (DFN) which ranges from 1 through 255 and

must be provided in all ADP PDU headers. One data field is configured per network or

sub-network address of the IP address.

Only nodes belonging to the same data field can communicate with each other. A node can

belong to more than one data field. Relative to a node, a data field can be local or remote

(for example, connected to the node via a router). Only local data fields are considered

within the scope of the ADP specification.

To support multicast communication, nodes within a data field are organized into

multicast groups. A node can be a member of more than one multicast group. A multicast

group is uniquely identified as a multicast group number, or MGN, which ranges from 1 to

255. The MGN must be provided in all multicast ADP PDU headers.

Each NeXUS node, also called a logical node, is uniquely identified by a logical node

number, or LNN, which ranges from 1 to 4095. The LNN must be provided in all ADP

PDU headers.

The user normally assigns and manages DFNs, LNNs, and MGNs. DMN, DFN, and LNN

form the source address (SA). DMN, DFN, and MGN form the destination address (DA)

of an ADP PDU header.

Publication 1756-UM524B-EN-P - December 2008

Page 30

3-4 About the NeXUS Network

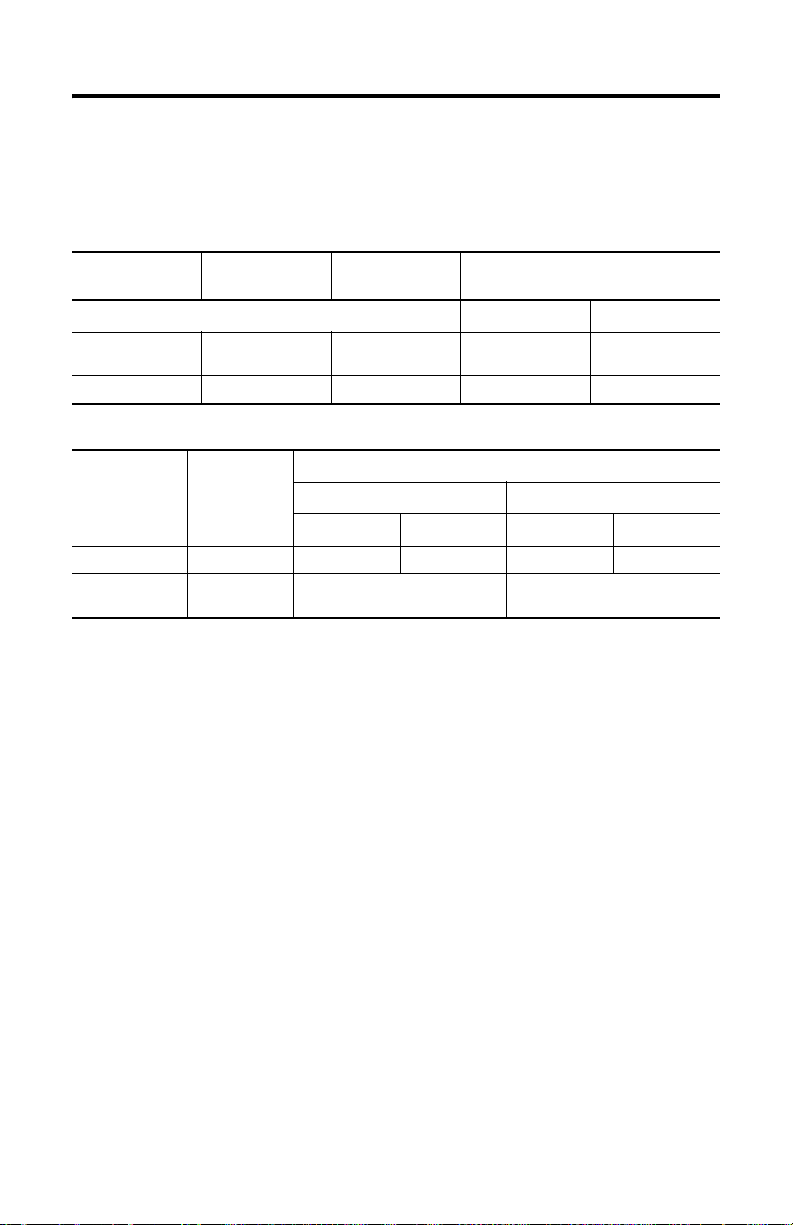

Supported ADP Message Types

The 1756-CLX/C module supports the following communication features referenced in

the ADP specification:

Communication

Feature

Multicast

communication

Alive signal Base-1 4.2 Supported Not supported

Communication

Feature

Test support 4.5 Supported Supported Supported Not supported

Maximum

message length

Class Clause (in ADP

Base-1 4.1 Supported Supported

Clause (in ADP

specification)

- (MTU-92) bytes (MTU-92) bytes

specification)

Requirements for Conformance

Multicast Alive signal

Transmission Reception Transmission Reception

Requirements for Conformance

Transmission Reception

Configuration Requirements

Before you can use your 1756-CLX/C module, you must configure its IP address,

gateway, and subnet mask by specifying parameters NX00 through NX02 on the

Logix5000 controller. Refer to Appendices D and E of this manual for definitions of these

parameters.

IP Address

The IP address identifies each node on the TCP/IP network (or system of connected

networks). Each TCP/IP node on a network must have a unique IP address.

The IP address is 32 bits long and is composed of a net ID, host ID, and/or a multicast ID.

Each network can be a Class A, B, C, or D format. The class of the network determines

how an IP address is formatted.

Publication 1756-UM524B-EN-P - December 2008

Page 31

About the NeXUS Network 3-5

16

16

16

16

24

host ID

24

host ID

24

host ID

24

host ID

Class A

Class B

Class C

Class D

1

0

1

0

1

1

0

1

111

Network ID

Network ID

0

0

0

1

0

1

0

8

8

8

Network ID

Multicast ID

Each node on the same physical network must have an IP address of the same class and

must have the same nework or multicast ID. Each node on the same network must have a

different host ID, giving it a unique IP address.

IP addresses are written as four decimal integers (0-255), separated by periods, where each

integer gives the value of one byte of the IP address.

EXAMPLE

For example, the 32-bit IP address:

10000010 00000000 00000000 00000001 is written as 130.0.0.1.

You can distinguish the class of an IP address from the first integer in its dotted-decimal

IP address as follows:

Range of first integer Class

0 -127 A

128 -191 B

192 - 223 C

224 - 239 D

240 - 255 Experimental

31

31

31

31

TIP

Contact your network administrator or the Network Information Center

for a unique fixed IP address to assign to your module.

For more information on Internet addressing, see Comer, Douglas E; Internetworking with

TCP-IP, Volume 1: Protocols and Architecture; Englewood Cliffs, N.J.: Prentice-Hall,

1990.

Publication 1756-UM524B-EN-P - December 2008

Page 32

3-6 About the NeXUS Network

Gateways

A gateway connects individual physical networks into a system of networks. When a node

needs to communicate with a node on another network, a gateway transfers the data

between the two networks. The following figure shows gateway G connecting Network 1

with Network 2.

A

128.1.0.1

Network 1

128.1.0.2

G

B

128.2.0.1 128.2.0.2

C

128.2.0.3

Network 2

When host B with IP address 128.2.0.1 communicates with host C, it knows from C’s IP

address that C is on the same network. In an Ethernet environment, B can then resolve C’s

IP address to a MAC address and communicate with C directly.

When host B communicates with host A, it knows from A’s IP address that A is on another

network (the net IDs are different). In order to send data to A, B must have the IP address

of the gateway connecting the two networks. In this example, the gateway’s IP address on

Network 2 is 128.2.0.3.

The gateway has two IP addresses (128.1.0.2 and 128.2.0.3). The first must be used by

hosts on Network 1 and the second must be used by hosts on Network 2. To be usable, a

host’s gateway must be addressed using a net ID matching its own.

Publication 1756-UM524B-EN-P - December 2008

Page 33

About the NeXUS Network 3-7

Subnet Mask

Subnet addressing is an extension of the IP address scheme that allows a site to use a

single net ID for multiple physical networks. Routing outside of the site continues by

dividing the IP address into a net ID and a host ID via the class. Inside a site, the subnet

mask is used to redivide the IP address into a custom net ID portion and host ID portion.

Take Network 2 (a Class B network) in the previous example and add another physical

network. Selecting the following subnet mask would add two additional net ID bits

allowing for four physical networks:

EXAMPLE

Two bits of the Class B host ID have been used to extend the net ID. Each unique

combination of bits in the part of the host ID where subnet mask bits are 1 specifies a

different physical network.

The new configuration is:

11111111 11111111 11000000 00000000 = 255.255.192.0

A

128.1.0.1

Network 1

128.1.0.2

G

B

128.2.64.1 128.2.64.2

C

128.2.64.3

Network 2.1

G2

D

128.2.128.1 128.2.128.2

E

128.2.128.3

Network 2.2

A second network with Hosts D and E has been added. Gateway G2 connects Network 2.1

with Network 2.2. Hosts D and E will use Gateway G2 to communicate with hosts not on

Network 2.2. Hosts B and C will use Gateway G to communicate with hosts not on

Network 2.1. When B is communicating with D, G (the configured Gateway for B) will

route the data from B to D through G2.

Publication 1756-UM524B-EN-P - December 2008

Page 34

3-8 About the NeXUS Network

For More Information

For more information about Ethernet, refer to the following publications:

Publication data ISBN

Internetworking with TCP/IP

Vol. 1, 2nd ed.

by Douglas E. Comer

The Ethernet Management Guide –

Keeping The Link

An Introduction to TCP/IP ISBN 3-540-96651-X

Computer Networks

by Andrew S. Tanenbaum

ISBN 0-13-216987-8

ISBN 0-07-046320-4

ISBN 0-13-162959-X

Publication 1756-UM524B-EN-P - December 2008

Page 35

Chapter

4

Configure the 1756-CLX/C Module

What This Chapter Contains

This chapter describes why you must configure your 1756-CLX/C module and how to

configure it for use in the ControlLogix system.

For information about this topic See page:

Configure Your 1756-CLX/C Module 4-1

Create a New Module 4-2

View and Change Module Tags 4-5

Configure the Module IP Address 4-6

Configure Your 1756-CLX/C Module

You must configure your module upon installation. The module will not work until it has

been configured.

Configuration Software

Use RSLogix 5000 software to set configuration for your 1756-CLX/C module. You have

the option of accepting default configuration for your module or writing configuration

specific to your application.

Both options are explained in detail, including views of software screens, in this chapter.

Publication 1756-UM524B-EN-P - December 2008

Page 36

4-2 Configure the 1756-CLX/C Module

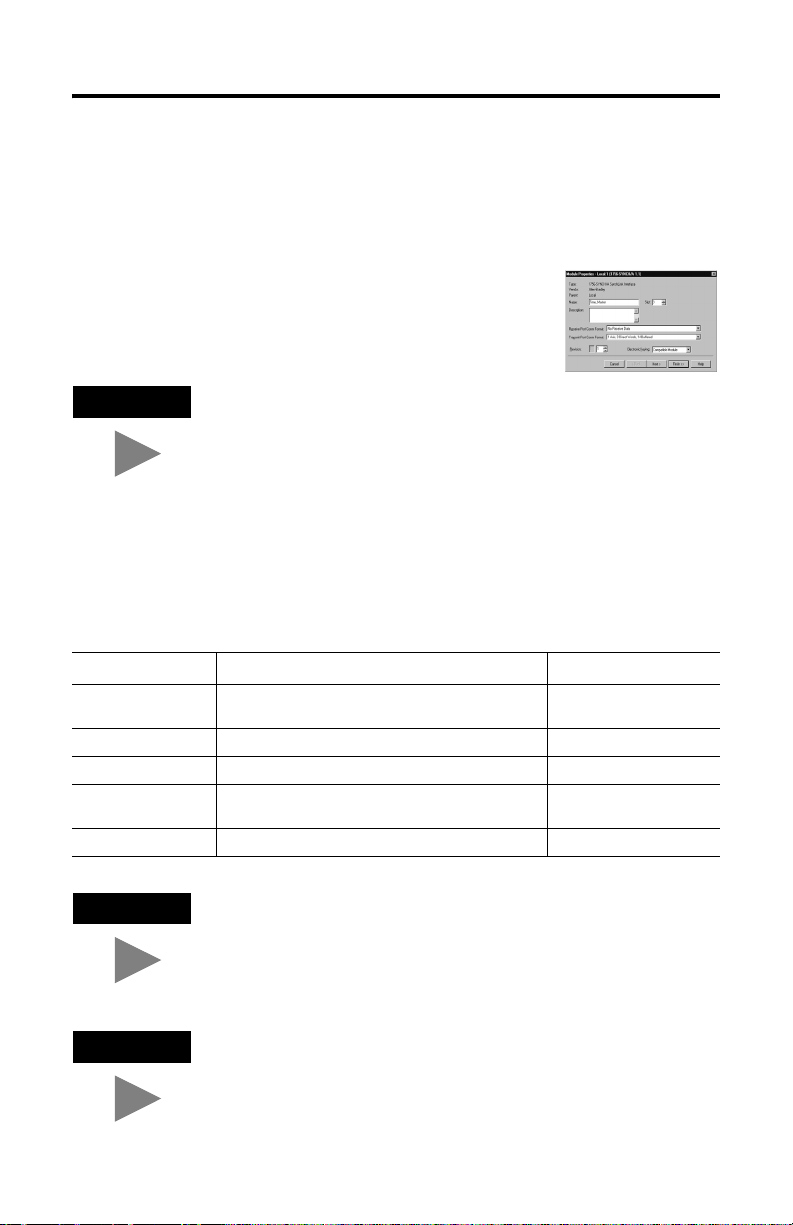

Overview of the Configuration Process

When you use the RSLogix 5000 software to configure a 1756-CLX/C module, you must

perform the following steps:

1. Create a new module.

2. Accept the default configuration or change it to specific configuration for the

module.

3. Edit configuration for a module when changes are needed.

4. Configure the module’s IP address.

Create a New Module

After you have started RSLogix 5000 and created a controller, you must create a new

module. The wizard allows you to create a new module and write configuration. You can

use default configuration or write specific configuration for your application.

IMPORTANT

Publication 1756-UM524B-EN-P - December 2008

You must be offline when you create a new module

If you are not offline, use this

pull-down menu to go offline

Page 37

Configure the 1756-CLX/C Module 4-3

When you are offline, you must select a new module.

1. Select I/O Configuration.

2. Click on the right mouse

button to display the menu.

3. Select New Module

A screen appears with a list of possible new modules for your application. Select a module

from the list.

Click OK. The new module creation wizard appears. Enter information as follows:

in this field enter

Name an optional name

Description an optional description

Input

Assembly Instance 1

Size 4

Output

Assembly Instance 2

Size 5

Configuration

Assembly Instance 4

Size 0

Publication 1756-UM524B-EN-P - December 2008

Page 38

4-4 Configure the 1756-CLX/C Module

After you name the page, this screen appears

Inhibit the connection to

the module here

If you want a Major

Fault on the Controller

to occur if there is

connection failure with

the I/O module, click

here

This Fault box is empty when you are

offline. If a fault occurs while the

module is online, the type of fault will

be displayed here

Click here to move to the next page

Adjust the Requested

Packet Interval here.

The default RPI is 5ms.

This screen is used

during online

monitoring but not initial

configuration

Click here to move to the next page

Publication 1756-UM524B-EN-P - December 2008

Page 39

Configure the 1756-CLX/C Module 4-5

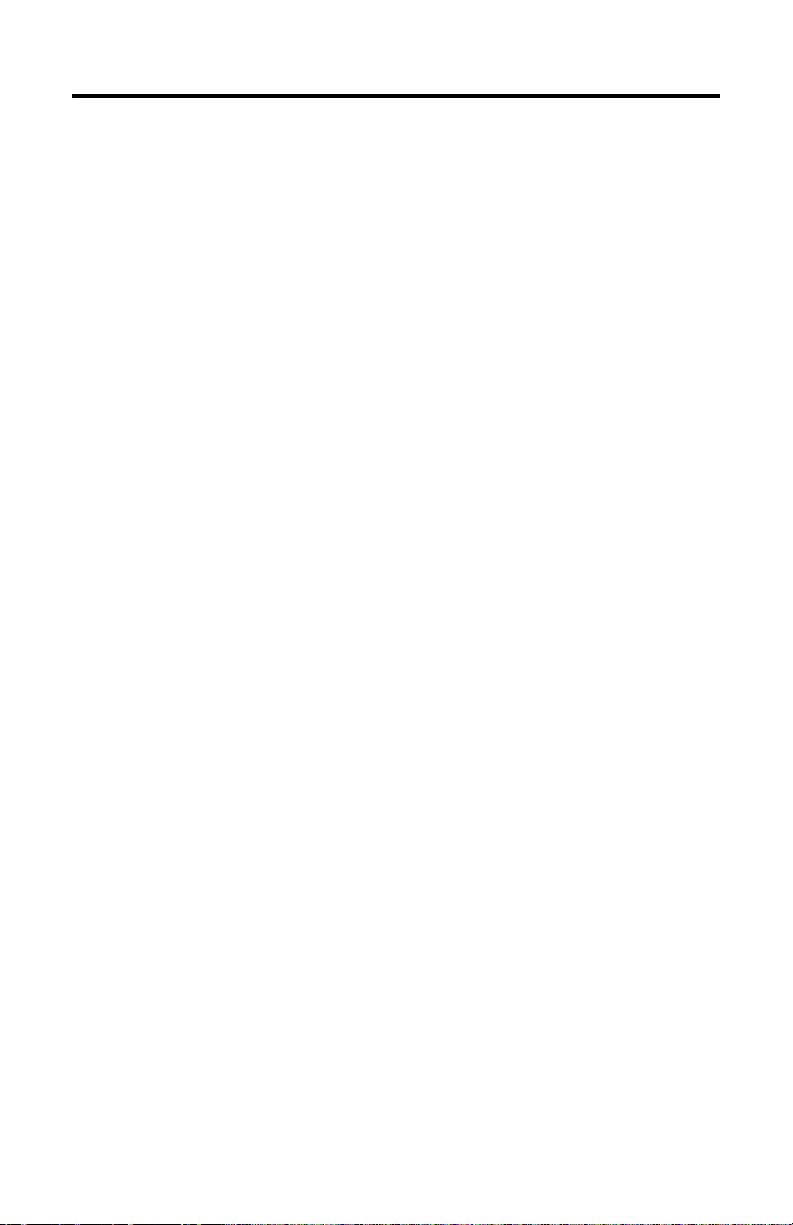

View and Change Module Tags

When you create a module, a set of tags are created by the ControlLogix system that can

be viewed in the Tag Editor of RSLogix 5000. Each configurable feature on your module

has a distinct tag that can be used in the processor’s ladder logic.

You can access a module’s tags through RSLogix 5000 as shown below.

1. Select Controller Tags.

2. Click on the right mouse

button to display the menu.

3. Select Monitor Tags.

You can view the tags from here

Click on the slot number of

the module you want to see

Because the process of viewing and changing a module’s configuration tags is broader in

scope than can be addressed in this chapter, refer to Appendix D for more information and

sample tag collections.

Publication 1756-UM524B-EN-P - December 2008

Page 40

4-6 Configure the 1756-CLX/C Module

Configure the Module IP Address

Before you can use your 1756-CLX/C module, you must configure its IP address,

gateway, and subnet mask by specifying parameters NX00 through NX02 on the

Logix5000 controller. Refer to Appendices D and E of this manual for definitions of these

parameters.

Publication 1756-UM524B-EN-P - December 2008

Page 41

Chapter

5

Status Indicators and

Troubleshooting

What This Chapter Contains

This chapter shows you the status indicators on the 1756-CLX/C module, and provides

basic troubleshooting procedures.

Alpha-numeric display

LED status indicators

Communication port

status indicators

For information about this topic See page

Use the LED Status Indicators 5-2

Use the Communications Port Status Indicators 5-3

Use the Alpha-numeric Display 5-3

Publication 1756-UM524B-EN-P - December 2008

Page 42

5-2 Status Indicators and Troubleshooting

Use the LED Status Indicators

The 1756-CLX/C module has the following LED status indicators. Use these indicators to

troubleshoot module status.:

Table 5.A LED Status Indicators

This LED When Means So you should

BAT (RED) ON The battery is low. Replace the module.

USR

(GREEN)

OK

(STATUS)

The battery is charging. The BAT

LED turns OFF within a few

minutes after power is applied.

OFF The Battery is charged.

The module is not powered up.

ON/OFF Data is being sent or received

OFF No data is being sent or received

GREEN The module is operating

RED The module has experienced an

OFF The module is not powered up. Apply power to the module.

over the NeXUS port.

over the NeXUS port.

The module is not powered up.

correctly.

error.

Wait for the battery to finish

charging.

Do nothing. The module is ready

for use.

Apply power to the module.

Do nothing. The module is

operating correctly.

Check the Communication port

LEDs. If:

•

LEDs are working properly,

restart the module

•

LEDs are not working

properly, follow the

instructions in

page 5-3

•

the problem persists, replace

the module

Apply power to the module.

Do nothing. The module is ready

for use.

Restart the module. If the

problem persists, replace the

module.

Ta bl e 5.B on

Publication 1756-UM524B-EN-P - December 2008

Page 43

Status Indicators and Troubleshooting 5-3

Use the Communications Port Status Indicators

The 1756-CLX/C module has the following communications port status indicators. Use

these indicators to troubleshoot module communication:

Table 5.B Communication Port Status Indicators

This LED When operating like this, means So you should

10/100 (GREEN)

(Top LED)

ACTIVE (YELLOW)

(Bottom LED)

•

This LED will be ON if 100BASE-TX

link is detected and OFF if a

10BASE-T link is detected. If the link

fails while in Auto-negotiation, this

LED will keep the last valid link state.

If the 100BASE-TX link is forced, this

LED will be ON, regardless of the

link status.

•

This LED will be OFF if the

10BASE-T link is forced, regardless

of the link status.

This LED is OFF until a valid link has

been detected. After a valid link has

been detected, the LED will remain ON,

blinking ON and OFF when network

activity is detected.

Do nothing. The module is operating

correctly.

If this link is not valid (LED is OFF),

do the following:

•

Check the Ethernet cable.

Replace if necessary

•

Check the Communications port

on the device connected to the

module

•

If the problem persists, replace the

module.

Use the Alpha-numeric Display

The 1756-CLX/C module has a 4-character alpha-numeric display on the front panel. Use

this display to check system health..

Table 5.C Alpha-numeric Display Indicators

This message on

the alpha-numeric

display

RUN Enabled Running No Do nothing.

ERR Enabled Running Ye s See Table 5.D for error

STOP Disabled N/A N/A Restart the module. If

No activity Disabled N/A N/A Restart the module. If

means that

1756-CLX/C

software is

and NX Dlink

software is

Publication 1756-UM524B-EN-P - December 2008

and an

error is

present

So you should

codes.

problem persists,

replace the module.

problem persists,

replace the module.

Page 44

5-4 Status Indicators and Troubleshooting

Table 5.D Firmware error codes

Error type Error

contents

Configu-

Configuration

ration Error

Error

System

NX DLINK is

Online

inactive

Error

Data Buffer

Overflowed

Data Buffer

Upper Limit

Data Buffer

Lower Limit

Receive Limit

Over

of Data Handle

MC Receive

Number

has missed

CPU Temp Over

Limit

CPU Temp

Upper Limit

Send/

CPU Temp

Receive

Lower Limit

Error

Send Error

Receive Error

Module

stopped

Alpha-

NX46_

NX60_

numeric

System

display

error

ERR ON Error_

ERR ON 0x11008000 E 0x11008000 N/A N/A NXDlink Majo r Fault

RUN OFF N/A W 0x11008001 N/A N/A NXDlink Warn ing

RUN OFF N/A E 0x11008002 N/A N/A NXDlink Minor Fault

RUN OFF N/A I 0x11008003 N/A N/A NXDlink Informa-

RUN OFF N/A W 0x12008004 N/A N/A N/A Wa rnin g

RUN OFF N/A I 0x11008004 N/A N/A NXDlink Informa-

RUN OFF N/A W 0x4e000001 N/A N/A NX SAM Wa rnin g

RUN OFF N/A E 0x4e000002 N/A N/A NX SAM Minor Fault

RUN OFF N/A I 0x4e000003 N/A N/A NX SAM Informa-

RUN OFF N/A N/A N/A See Table 5.F NXDlink Individ-

STOP OFF N/ A N/A N/A N/A N/A N/A

NX63_

System

status

error code

level

N/A N/A N/A N/A NX SAM See

Code

NX64_

NX61_

VX62_

Event

Status

code

Send

error code

Receive

error code

log

source

User

action

Table 5.E

tion

tion

tion

ual error for

each handle.

See

Table 5.F.

Table 5.E Module error codes

No. Error code Decription User action

1 0x00000001 Incorrect Data Setting for

NX00_Node_Name_param

2 0x00000002 Incorrect Data Setting for

3 0x00000003 Incorrect Data Setting for

NX01_IP_Address_Param

NX02_Subnet_Mask_Param

4 0x00000004 Incorrect Data Setting for

NX03_Node_Param[0] “Logical

Node Number”

5 0x00000005 Incorrect Data Setting for

NX03_Node_Param[1] “Local Data

Field Number”

Publication 1756-UM524B-EN-P - December 2008

Correct the Data Setting for

NX00_Node_Name_param

Correct the Data Setting for

NX01_IP_Address_Param

Correct the Data Setting for

NX02_Subnet_Mask_Param

Correct the Data Setting for

NX03_Node_Param[0]

Correct the Data Setting for

NX03_Node_Param[1]

Page 45

Status Indicators and Troubleshooting 5-5

Table 5.E Module error codes

No. Error code Decription User action

6 0x00000006 Incorrect Data Setting for

7 0x00000007 Incorrect Data Setting for

8 0x00000008 Incorrect Data Setting for

9 0x00000009 Incorrect Data Setting for

10 0x0000000a Incorrect Data Setting for

11 0x00000010 Multicast_Group_Number is out of

12 0x00000011 Online Port Number is out of range

13 0x00000012 Test Port Number is out of range

14 0x00000013 S/R OK Flag Value is out of range

15 0x00000014 Multicast_Group_Number is

16 0x00000015 Port Number is overlapped Correct the Port Number for

17 0x00000090 Low Limit Value is out of range for

18 0x00000091 High Limit Value is out of range for

19 0x0000FFFF System has corrupted during the

NX03_Node_Param[2] “Node

Mode at start up”

NX03_Node_Param[4] “Message

Send Port Number”

NX03_Node_Param[5] “Node Alive

Receive Port Number”

NX03_Node_Param[6] “Node Alive

Interval”

NX03_Node_Param[7] “Node Alive

Count”

range for

NX06_Multicast_Group_Param

for NX06_Multicast_Group_Param

for NX06_Multicast_Group_Param

for NX06_Multicast_Group_Param

overlapped for

NX06_Multicast_Group_Param

NX07_Overflow_Param[0] “Low

Limit”

NX07_Overflow_Param[1] “High

Limit”

NX Dlink Initialization

Correct the Data Setting for

NX03_Node_Param[2]

Correct the Data Setting for

NX03_Node_Param[4]

Correct the Data Setting for

NX03_Node_Param[5]

Correct the Data Setting for

NX03_Node_Param[6]

Correct the Data Setting for

NX03_Node_Param[7]

Correct the Data Number for

Entry0~7

Multicast_Group_Number

Correct the Data Number for

Entry0~7 Online Port Number

Correct the Data Number for

Entry0~7 Test Port Number

Correct the Data Value for

Entry0~7 S/R OK FlagValue

Correct the Data Number for

Entry0~7

Multicast_Group_Number

Entry0~7and also check the value

for NX03_Node_Param[4] and

NX03_Node_Param[5]

Correct the Data Setting for

NX07_Overflow_Param[0]

Correct the Data Setting for

NX07_Overflow_Param[1]

Refer to Appendix C, Web Page

Diagnostics

Publication 1756-UM524B-EN-P - December 2008

Page 46

5-6 Status Indicators and Troubleshooting

Table 5.F Send/receive error codes

No. Error code Description User action

1 0x00000000 Data was sent or received properly N/A

2 0x81000005 Multicast_Group_Number is not

3 0x81000006 TCD Number is not specified or out

4 0x82000011 TCD Number is overlapped Correct the TCD Number of the

5 0x84000002 Error has occurred when creating

6 0x84000003 Error has occurred when attaching

specified or out of range

of range

the socket or during the socket

communication

the common memory

Correct the the

Multicast_Group_Number of the

related Handle

Correct the TCD Number of the

related Handle

related Handle

Consult Rockwell Automation

technical support

Consult Rockwell Automation

technical support

Publication 1756-UM524B-EN-P - December 2008

Page 47

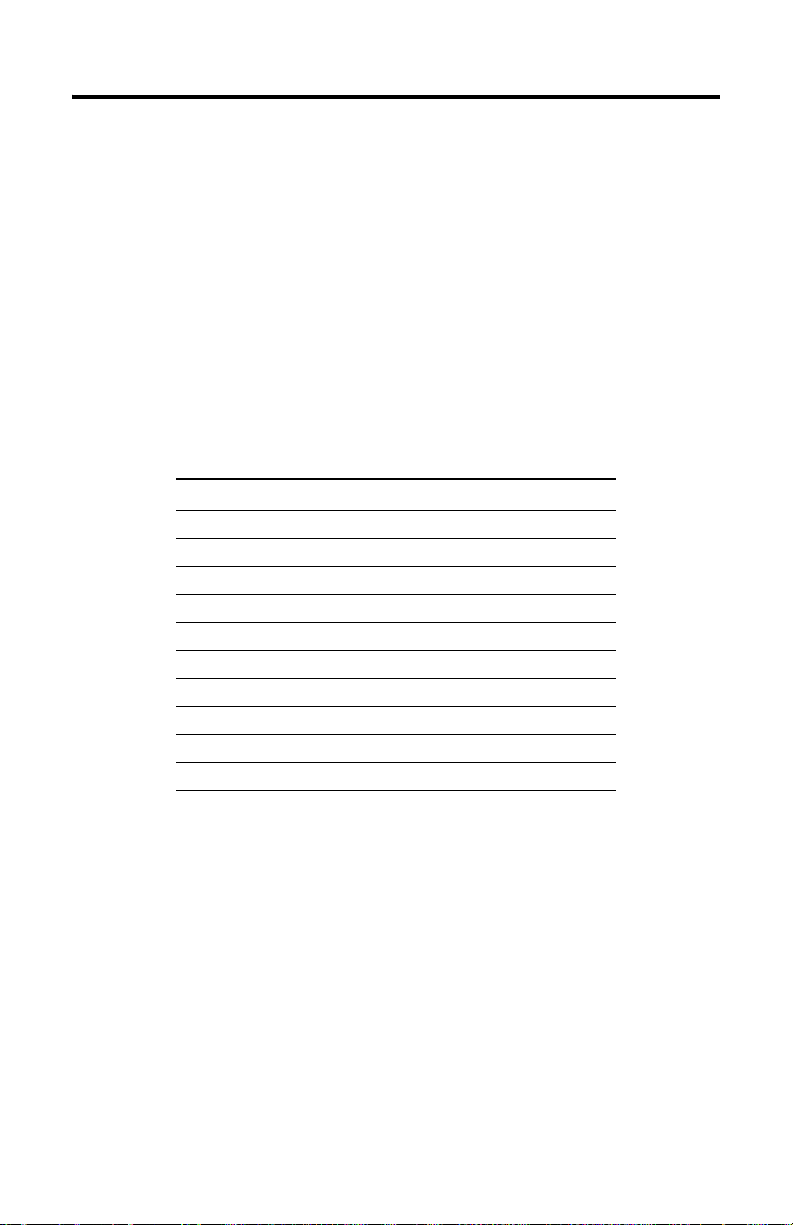

Appendix

Specifications

Module Location 1756 ControlLogix chassis

Maximum Backplane Current 1A @ 5V dc

Maximum Power Dissipation 5W

Communication Ports Ethernet 10/100T IEEE 802.3

Battery Rechargeable Lithium Vanadium Pentoxide

Temperature Operating: 0 to 60 ° C

Form Factor Single Slot ControlLogix Module

Certifications

Storage: 0 to 80 ° C

UL Recognized Industrial Control

Component (pending)

CUL (pending)

Marked for all applicable directives

A

Publication 1756-UM524B-EN-P - December 2008

Page 48

A-2 Specifications

Notes:

Publication 1756-UM524B-EN-P - December 2008

Page 49

Appendix

B

Factory-set Jumpers

Jumpers on the 1756-CLX/C module are factory-set. If you change the jumper settings by

mistake, follow this procedure to reset them.

ATTENTION

Do not change the jumper positions. If you change a jumper position

by mistake, you must re-set it to the position shown below.

Publication 1756-UM524B-EN-P - December 2008

Page 50

B-2 Factory-set Jumpers

32-bit (shown)

16-bit (shown)

1756-CLX/C CON FIGURATION

JUMPER SETTINGS

Front of module

Publication 1756-UM524B-EN-P - December 2008

Page 51

Appendix

C

1756-CLX/C Web Interface

The 1756-CLX/C module’s web page offers extensive internal and network diagnostics.

To view the web pages, enter the module’s IP address into your web browser. You can

access the following web pages.

For information about this topic: See page:

User Screens C-1

User Screens

Figure C.1 Title screen

Publication 1756-UM524B-EN-P - December 2008

Page 52

C-2 1756-CLX/C Web Interface

Figure C.2 Data Field Status screen

Publication 1756-UM524B-EN-P - December 2008

Page 53

Figure C.3 Multicast group statistics screen

1756-CLX/C Web Interface C-3

TIP

You can also access this screen by typing nxstat -m in a DOS window.

Publication 1756-UM524B-EN-P - December 2008

Page 54

C-4 1756-CLX/C Web Interface

Figure C.4 Transaction Statistics screen

TIP

You can also access this screen by typing nxstat -t in a DOS window.

Publication 1756-UM524B-EN-P - December 2008

Page 55

Figure C.5 Buffer Usage statiscs screen

1756-CLX/C Web Interface C-5

TIP

You can also access this screen by typing nxstat -b in a DOS window.

Publication 1756-UM524B-EN-P - December 2008

Page 56

C-6 1756-CLX/C Web Interface

Figure C.6 Handle Status and Statistics screen

TIP

You can also access this screen by typing nxstat -h or nxhdl in a DOS

window.

Publication 1756-UM524B-EN-P - December 2008

Page 57

Figure C.7 Event Log screen

1756-CLX/C Web Interface C-7

Publication 1756-UM524B-EN-P - December 2008

Page 58

C-8 1756-CLX/C Web Interface

Figure C.8 Technical Support Information screen

You can access this screen, type in the required information, then send this screen to

Technical Support.

Figure C.9 Clear Statistics screen

Publication 1756-UM524B-EN-P - December 2008

Page 59

Appendix

D

1756-CLX/C Module Backplane

Communication Tag List

The 1756-CLX/C module tags NX00 through NX91 are used for backplane (API)

communication, and should be defined in your ladder logic exactly as listed in Table D-A

in this Appendix. Refer to Appendix F for information on copying the tags and ladder

logic files from the .acd file supplied with the 1756-CLX/C module.

For information about this topic: See page:

About the Nexus Communication Flags (NX20 – NX91) D-2

ATTENTION

Failure to properly define the module tags NX00 through NX91 may

result in unpredictable module operation.

Publication 1756-UM524B-EN-P - December 2008

Page 60

D-2 1756-CLX/C Module Backplane Communication Tag List

G

X

About the Nexus Communication Flags (NX20 – NX91)

Boot /Reboot 1756-CLX/C Module Procedure

The following tags are applied for this sequence. Refer the timing chart for more details.

• NX20_Module_Enable

• NX40_Module_Enabled

• NX47_Module_Ready

• NX48_Module_Enable_Ack

Figure D.1 Boot and Parameter Configuration Timing Chart

Power on

1756-CLX/C

NX47_Module_

Ready

(BOOL)

(S/W of 56NE

RUN/PROG

Mode

S:FS (Fi rst Scan

Flag)

NX20_Module

_Enable

(BOOL)

NX48_Module_

Enable_Ack

(BOOL)

NX40_Module_

Enabled

(BOOL)

Change Par ameter

NX

OS SMG/BS

NX

)

Management

Process

PRO

NX

Confi gurati on

Check

RUN

OFF

NX Dlink

Initialization

NX

Initialization

ON

Configuration

Check

OFF

NX Dlink

InitializationNXInitialization

ON

Publication 1756-UM524B-EN-P - December 2008

Page 61

1756-CLX/C Module Backplane Communication Tag List D-3

G

F

W

NOFF

NOFF

Figure D.2 Operating System Reboot Timing Chart

Change Paramet er

(Node Name or IP addr ess)

Power o n

1756-CLX/C

ON

NX47_Module_

Ready

(BOOL)

56NEX S

RUN/PROG

Mode

S:FS ( First Sc an

Flag)

NX20_Module

_Enable

(BOOL)

NX48_Module_

Enable_Ack

(BOOL)

NX40_Module_

Enabled

(BOOL)

ON

OS Reboot SMG/BS NX

NX

Configuration

Check

PRO

RU

ON

OF

Management

Proce ss

NX

Configuration

Check

NX Dlin k

Initialization

NX

Initialization

O

Publication 1756-UM524B-EN-P - December 2008

Page 62

D-4 1756-CLX/C Module Backplane Communication Tag List

1756-CLX/C Module Configuration Check Procedure

The following tags are applied for this sequence. Refer the timing chart for more details.

• NX20_Module_Enable

• NX40_Module_Enabled

• NX48_Module_Enable_Ack

• NX46_System_Error

• NX60_System_Error_Code

Figure D.3 1756-CLX/C Configuration Check Timing Chart

CLX

Ta gs

1756-CLX/C

(1) Sets NX00-07 Tags for Parameter

Ladder

NX20_Module_Enable

(BOOL)

NX48_Module_

Enable_Ack

(BOOL)

NX40_Module_Enabled

(BOOL)

NX46_System_Error

(BOOL)

NX60_System_Error

Code(DI NT)

NX

Management

Process

(2) Set s NX20_Module_E nable

(3) Cl ears NX20_Modul e_Enable

(1) Set s NX48_Modul e_Enable_Ack

(2) Clears NX40_Module_Enabled

(3) Sets if NX Dlink configuration is in failure

If success NX60_System_Err or_Code

Clear, N X46_Syst em_Err or OFF

If failure NX60_System_Error_Code Set,

NX46_System_Error ON

Publication 1756-UM524B-EN-P - December 2008

Page 63

1756-CLX/C Module Backplane Communication Tag List D-5

1756-CLX/C System Error Procedure

The following tags are applied for this sequence. Refer the timing chart for more details.

• NX63_Status_Leve

• NX64_Status_Code

Figure D.4 1756-CLX/C System Error Timing Chart

NX63_Status_Level

(DINT)

NX64_Status_Code

(DI NT)

1756- CLX/C

NX

Mon i t o r

Process

(1) Sets NX63_Status_Level

(2) Sets NX64_Status_Code

(3) Displ ays t he Segment Dis play

Publication 1756-UM524B-EN-P - December 2008

Page 64

D-6 1756-CLX/C Module Backplane Communication Tag List

1756-CLX/C Module Sending Procedure

The following tags are applied for this sequence. Refer the timing chart for more details.

• NX30_Send_Request

• NX50_Send_Done

• NX61_Send_Error_Code

Figure D.5 1756-CLX/C Module Sending Procedure Timing Chart

Ladder

CLX

Tag s

1756-CLX/C

NX

Send-Process

Request Sending.

(1) Sets Send_D ata and Data Buffer

Size NX80 tags

(2) Sets N X30_Send_Request

NX30_Send_Request

(BOOL)

NX50_Send_Done

(BOOL)

NX61_Send_Error_Code

(DINT[32])

(1) Sends the data

(2) Sets NX61_S end_Error_Code

(3) Sets NX50_S end_Done

(1) Checks NX61_Send_Error_Code has not set Error

(2) Clears NX30_Send_Requ est.

0 if success, Error code if f ailure

(1) Clears NX61_ Send_Error_Code

(2) Clears NX50_ Send_Done

Publication 1756-UM524B-EN-P - December 2008

Page 65

1756-CLX/C Module Backplane Communication Tag List D-7

1756-CLX/C Module Receiving Procedure

The following tags are applied for this sequence. Refer the timing chart for more details.

• NX31_Receive_Done

• NX51_Receive_Request

• NX62_Receive_Error_Code

Figure D.6 1756-CLX/C Module Receiving Procedure Timing Chart

(1) Check NX62 _Receive_Error_C ode has

Ladder

CLX

Ta gs

1756-CLX/C

NX

Recv-Process

(xx:00-3 1)

NX31_Receive_Done

(BOOL)

NX51_Receive_

Request

(BOOL)

NX62_Receive_

Error_Code

(DINT[32])

(1) Receiving data

(2) If success

Sets NX91_Recei ve_Data_xx

Sets NX90_Rec eived_Data_size[ xx]

(3)Sets NX6 2_Receive_Error _Code

(4)Sets NX31_Receive_Request

not set Error, and read data from

NX91_Receive_D ata_xx( the si ze is set to

NX90_Received_D ata_size[xx] )

(2) NX31_Recei ve_Done ON

0 if success, Error code if failure

(xx:00-31)

(1) Clears NX62_Receive_Err or_Code

(2) Clears NX51_Receive_Request

Clears

NX31_Receive_D one

Publication 1756-UM524B-EN-P - December 2008

Page 66

D-8 1756-CLX/C Module Backplane Communication Tag List

Table D.A Module Backplane Communication Tag List

Tag N ame Data

NX00_Node_Name-Param SINT[10] Parameters for Node_Name - - -

NX00_Node_Name_Param[0] SINT 1st character of Node Name 5

NX00_Node_Name_Param[1] SINT 2nd character of Node Name 6

NX00_Node_Name_Param[2] SINT 3rd character of Node Name N

NX00_Node_Name_Param[3] SINT 4th character of Node Name E

NX00_Node_Name_Param[4] SINT 5th character of Node Name X

NX00_Node_Name_Param[5] SINT 6th character of Node Name (null)

NX00_Node_Name_Param[6] SINT 7th character of Node Name (null)

NX00_Node_Name_Param[7] SINT 8th character of Node Name (null)

NX00_Node_Name_Param[8] SINT 9th character of Node Name (null)

NX00_Node_Name_Param[9] SINT 10th character of Node Name (null)

NX01_IP_Address_Param INT[4] Parameters for IP_Address - - -

NX01_IP_Address_Param[0] INT 1st character of IP Address 192

NX01_IP_Address_Param[1] INT 2nd character of IP Address 168

NX01_IP_Address_Param[2] INT 3rd character of IP Address 0

NX01_IP_Address_Param[3] INT 4th character of IP Address 1

NX02_Subnet_Mask_Param INT[4] Parameters for Subnet_Address - - -

NX02_Subnet_Mask_Param[0] INT 1st character of Subnet Mask 255

NX02_Subnet_Mask_Param[1] INT 2nd character of Subnet Mask 255

NX02_Subnet_Mask_Param[2] INT 3rd character of Subnet Mask 255

NX02_Subnet_Mask_Param[3] INT 4th character of Subnet Mask 0

NX03_Node_Param DINT[16] Parameters related to Node - - -

NX03_Node_Param[0] DINT Logical Node Number <1 to 4095> 1

NX03_Node_Param[1] DINT Local Data Field Number <1 to 255> 1

NX03_Node_Param[2] DINT Node Mode at Startup

NX03_Node_Param[3] DINT Reserved 0

NX03_Node_Param[4] DINT Message Send Port Number

NX03_Node_Param[5] DINT Node Alive Receive Port Number

NX03_Node_Param[6] DINT Node Alive Interval <1 - 3600> 20

NX03_Node_Param[7] DINT Node Alive Count <2 - 100> 4

NX03_Node_Param[8] DINT Reserved 0

NX03_Node_Param[9] DINT Reserved 0

Typ e

Description Initial

<0 - 65535 >

<1 - 65534 >

Value

10000

10001

Publication 1756-UM524B-EN-P - December 2008

Page 67

1756-CLX/C Module Backplane Communication Tag List D-9

Table D.A Module Backplane Communication Tag List

Tag Name Data

NX03_Node_Param[10] DINT Reserved 0

NX03_Node_Param[11] DINT Reserved 0

NX03_Node_Param[12] DINT Reserved 0

NX03_Node_Param[13] DINT Reserved 0

NX03_Node_Param[14] DINT Reserved 0

NX03_Node_Param[15] DINT Reserved 0

NX04_Send_Handle_Param DINT[192] Parameters related to Send_Handle - - -

NX04_Send_Handle_Param[0] DINT Send 0 ; Reserved 0

NX04_Send_Handle_Param[1] DINT Send 0 ; Transaction Code

NX04_Send_Handle_Param[2] DINT Send 0 ; Multicast Group Number

NX04_Send_Handle_Param[3] DINT Send 0 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[4] DINT Send 0 ; Reserved 0

NX04_Send_Handle_Param[5] DINT Send 0 ; Reserved 0

NX04_Send_Handle_Param[6] DINT Send 1 ; Reserved 0

NX04_Send_Handle_Param[7] DINT Send 1 ; Transaction Code

NX04_Send_Handle_Param[8] DINT Send 1 ; Multicast Group Number

NX04_Send_Handle_Param[9] DINT Send 1 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[10] DINT Send 1 ; Reserved 0

NX04_Send_Handle_Param[11] DINT Send 1 ; Reserved 0

NX04_Send_Handle_Param[12] DINT Send 2 ; Reserved 0

NX04_Send_Handle_Param[13] DINT Send 2 ; Transaction Code

NX04_Send_Handle_Param[14] DINT Send 2 ; Multicast Group Number

NX04_Send_Handle_Param[15] DINT Send 2 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[16] DINT Send 2 ; Reserved 0

NX04_Send_Handle_Param[17] DINT Send 2 ; Reserved 0

NX04_Send_Handle_Param[18] DINT Send 3 ; Reserved 0

NX04_Send_Handle_Param[19] DINT Send 3 ; Transaction Code

NX04_Send_Handle_Param[20] DINT Send 3 ; Multicast Group Number

Typ e

Description Initial

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

Value

0

0

0

0

0

0

0

0

Publication 1756-UM524B-EN-P - December 2008

Page 68

D-10 1756-CLX/C Module Backplane Communication Tag List

Table D.A Module Backplane Communication Tag List

Tag Name Data

NX04_Send_Handle_Param[21] DINT Send 3 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[22] DINT Send 3 ; Reserved 0

NX04_Send_Handle_Param[23] DINT Send 3 ; Reserved 0

NX04_Send_Handle_Param[24] DINT Send 4 ; Reserved 0

NX04_Send_Handle_Param[25] DINT Send 4 ; Transaction Code

NX04_Send_Handle_Param[26] DINT Send 4 ; Multicast Group Number

NX04_Send_Handle_Param[27] DINT Send 4 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[28] DINT Send 4 ; Reserved 0

NX04_Send_Handle_Param[29] DINT Send 4 ; Reserved 0

NX04_Send_Handle_Param[30] DINT Send 5 ; Reserved 0

NX04_Send_Handle_Param[31] DINT Send 5 ; Transaction Code

NX04_Send_Handle_Param[32] DINT Send 5 ; Multicast Group Number

NX04_Send_Handle_Param[33] DINT Send 5 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[34] DINT Send 5 ; Reserved 0

NX04_Send_Handle_Param[35] DINT Send 5 ; Reserved 0

NX04_Send_Handle_Param[36] DINT Send 6 ; Reserved 0

NX04_Send_Handle_Param[37] DINT Send 6 ; Transaction Code

NX04_Send_Handle_Param[38] DINT Send 6 ; Multicast Group Number

NX04_Send_Handle_Param[39] DINT Send 6 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[40] DINT Send 6 ; Reserved 0

NX04_Send_Handle_Param[41] DINT Send 6 ; Reserved 0

NX04_Send_Handle_Param[42] DINT Send 7 ; Reserved 0

NX04_Send_Handle_Param[43] DINT Send 7 ; Transaction Code

NX04_Send_Handle_Param[44] DINT Send 7 ; Multicast Group Number

NX04_Send_Handle_Param[45] DINT Send 7 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[46] DINT Send 7 ; Reserved 0

NX04_Send_Handle_Param[47] DINT Send 7 ; Reserved 0

NX04_Send_Handle_Param[48] DINT Send 8 ; Reserved 0

Typ e

Description Initial

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

Value

0

0

0

0

0

0

0

0

Publication 1756-UM524B-EN-P - December 2008

Page 69

1756-CLX/C Module Backplane Communication Tag List D-11

Table D.A Module Backplane Communication Tag List

Tag Name Data

NX04_Send_Handle_Param[49] DINT Send 8 ; Transaction Code

NX04_Send_Handle_Param[50] DINT Send 8 ; Multicast Group Number

NX04_Send_Handle_Param[51] DINT Send 8 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[52] DINT Send 8 ; Reserved 0

NX04_Send_Handle_Param[53] DINT Send 8 ; Reserved 0

NX04_Send_Handle_Param[54] DINT Send 9 ; Reserved 0

NX04_Send_Handle_Param[55] DINT Send 9 ; Transaction Code

NX04_Send_Handle_Param[56] DINT Send 9 ; Multicast Group Number

NX04_Send_Handle_Param[57] DINT Send 9 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[58] DINT Send 9 ; Reserved 0

NX04_Send_Handle_Param[59] DINT Send 9 ; Reserved 0

NX04_Send_Handle_Param[60] DINT Send 10 ; Reserved 0

NX04_Send_Handle_Param[61] DINT Send 10 ; Transaction Code

NX04_Send_Handle_Param[62] DINT Send 10 ; Multicast Group Number

NX04_Send_Handle_Param[63] DINT Send 10 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[64] DINT Send 10 ; Reserved 0

NX04_Send_Handle_Param[65] DINT Send 10 ; Reserved 0

NX04_Send_Handle_Param[66] DINT Send 11 ; Reserved 0

NX04_Send_Handle_Param[67] DINT Send 11 ; Transaction Code

NX04_Send_Handle_Param[68] DINT Send 11 ; Multicast Group Number <1

NX04_Send_Handle_Param[69] DINT Send 11 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[70] DINT Send 11 ; Reserved 0

NX04_Send_Handle_Param[71] DINT Send 11 ; Reserved 0

NX04_Send_Handle_Param[72] DINT Send 12 ; Reserved 0

NX04_Send_Handle_Param[73] DINT Send 12 ; Transaction Code <1 to

NX04_Send_Handle_Param[74] DINT Send 12 ; Multicast Group Number <1

NX04_Send_Handle_Param[75] DINT Send 12 ; Data Size <0 to 1024> 1024

Typ e

Description Initial

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

to 255>

59999> <0=Not used>

to 255>

Value

0

0

0

0

0

0

0

0

0

0

Publication 1756-UM524B-EN-P - December 2008

Page 70

D-12 1756-CLX/C Module Backplane Communication Tag List

Table D.A Module Backplane Communication Tag List

Tag Name Data

NX04_Send_Handle_Param[76] DINT Send 12 ; Reserved 0

NX04_Send_Handle_Param[77] DINT Send 12 ; Reserved 0

NX04_Send_Handle_Param[78] DINT Send 13 ; Reserved 0

NX04_Send_Handle_Param[79] DINT Send 13 ; Transaction Code

NX04_Send_Handle_Param[80] DINT Send 13 ; Multicast Group Number

NX04_Send_Handle_Param[81] DINT Send 13 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[82] DINT Send 13 ; Reserved 0

NX04_Send_Handle_Param[83] DINT Send 13 ; Reserved 0

NX04_Send_Handle_Param[84] DINT Send 14 ; Reserved 0

NX04_Send_Handle_Param[85] DINT Send 14 ; Transaction Code

NX04_Send_Handle_Param[86] DINT Send 14 ; Multicast Group Number

NX04_Send_Handle_Param[87] DINT Send 14 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[88] DINT Send 14 ; Reserved 0

NX04_Send_Handle_Param[89] DINT Send 14 ; Reserved 0

NX04_Send_Handle_Param[90] DINT Send 15 ; Reserved 0

NX04_Send_Handle_Param[91] DINT Send 15 ; Transaction Code <1 to

NX04_Send_Handle_Param[92] DINT Send 15 ; Multicast Group Number

NX04_Send_Handle_Param[93] DINT Send 15 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[94] DINT Send 15 ; Reserved 0

NX04_Send_Handle_Param[95] DINT Send 15 ; Reserved 0

NX04_Send_Handle_Param[96] DINT Send 16 ; Reserved 0

NX04_Send_Handle_Param[97] DINT Send 16 ; Transaction Code

NX04_Send_Handle_Param[98] DINT Send 16 ; Multicast Group Number

NX04_Send_Handle_Param[99] DINT Send 16 ; Data Size <0 to 1024> 1024

NX04_Send_Handle_Param[100] DINT Send 16 ; Reserved 0

NX04_Send_Handle_Param[101] DINT Send 16 ; Reserved 0

NX04_Send_Handle_Param[102] DINT Send 17 ; Reserved 0

NX04_Send_Handle_Param[103] DINT Send 17 ; Transaction Code

Typ e

Description Initial

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

<1 to 255>

<1 to 59999> <0=Not used>

Value

0

0

0

0

0

0

0

0

0

Publication 1756-UM524B-EN-P - December 2008

Page 71