Page 1

Installation Instructions

Analog Encoder (AE) Servo Module

(Catalog Number 1756-M02AE)

The Analog Encoder (AE) Servo Module mounts in a ControlLogix™ chassis

and uses a removable terminal block (RTB) to connect all field-side wiring.

Before you install your module you should have:

• installed and grounded a 1756 chassis and power supply.

• ordered and received an RTB and its components for your

application.

page:

Preventing Electrostatic Discharge 2

Removing and Inserting Under Power (RIUP) 3

Understanding Compliance to the European Union Directive 3

Determining the Power Requirements 4

Identifying Module Components 4

Installing the Module 6

Keying the Removable Terminal Block 8

Wiring a Removable Terminal Block 10

Wiring Examples 13

Assembling the Removable Terminal Block and Housing 22

Installing the Removable Terminal Block onto the Module 23

Checking the LED Indicators 24

Removing the Removable Terminal Block from the Module 29

Removing the Module from the Chassis 31

Module Specifications 32

Installation Environment 34

Publication 1756-IN047D-EN-P - March 2001

Page 2

2 Analog Encoder (AE) Servo Module

WARNING

!

Preventing Electrostatic Discharge

Electrostatic discharge can damage the servo board if

you touch the circuitry or connector pins without taking

precautions. Follow these guidelines when you handle

the servo board:

• Touch a grounded object to discharge potential

static.

• Wear an approved grounding wrist strap.

• Do not touch the connector or connector pins on

the servo board.

• Do not touch circuit components inside the servo

board.

• If available, use a static-safe work station.

Publication 1756-IN047D-EN-P - March 2001

Page 3

Analog Encoder (AE) Servo Module 3

WARNING

!

Removing and Inserting Under Power (RIUP)

This module is designed so you can remove and insert it

under backplane power and field-side power. When you

remove or insert a module while field-side power is

applied, you can cause an electrical arc. An electrical arc

can cause personal injury or property damage because it

can:

• Send an erroneous signal to your system field

devices causing unintended machine motion or loss

of process control.

• Cause an explosion in a hazardous environment.

Repeated electrical arcing causes excessive wear to

contacts on both the module and its mating connector.

Worn contacts can create electrical resistance. For

additional information on RIUP, please contact your

local Allen-Bradley sales representative.

Understanding Compliance to the European Union Directive

If this product bears the CE marking, it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in whole

or in part, documented in a technical construction file:

• EN 50081-2EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 50082-2EMC - Generic Immunity Standard, Part 2 - Industrial

Environment

This product is intended for use in an industrial environment.

Publication 1756-IN047D-EN-P - March 2001

Page 4

4 Analog Encoder (AE) Servo Module

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers,

Part 2 - Equipment Requirements and Test.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines publication

1770-4.1

• Automation Systems Catalog, publication B111

This equipment is classified as open equipment and must be installed

(mounted) in an enclosure during operation as a means of providing safety

protection.

Determining the Power Requirements

This module receives power from the 1756 chassis power supply and requires

two sources of power: 700mA at 5V and 2.5 mA at 24V from the backplane.

Add this current to the requirements of all other modules in this chassis to

prevent overloading the backplane power supply.

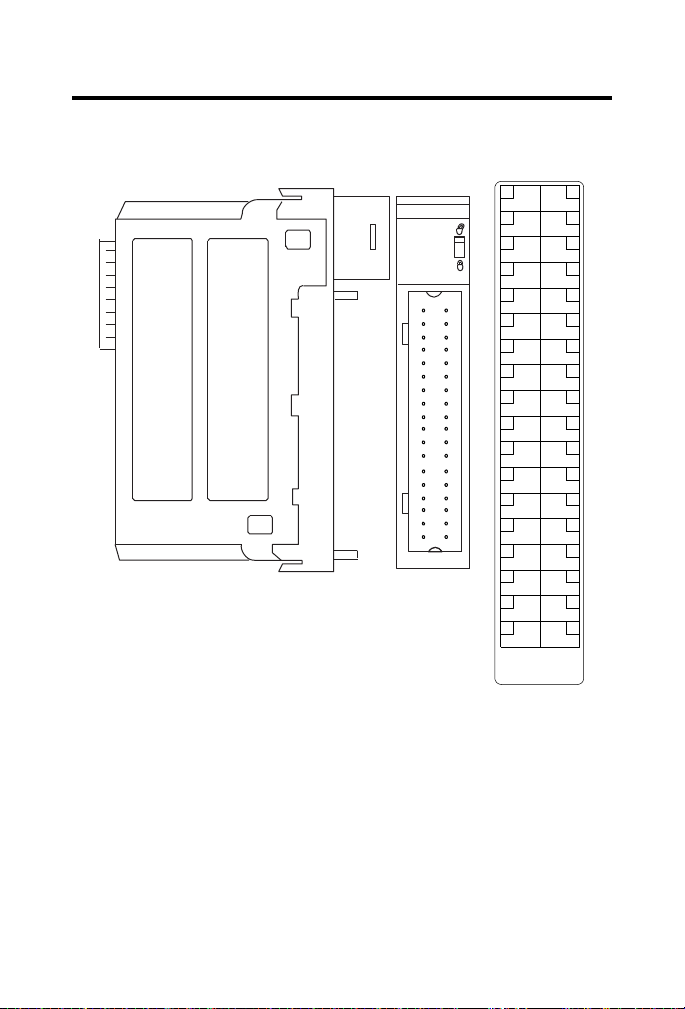

Identifying Module Components

You received two components with your order:

• 1756-M02AE module

• RTB door label

Publication 1756-IN047D-EN-P - March 2001

Page 5

Figure 1 1756-M02AE Module

Side view

2 Axis Servo

Front view

1756-M02AE module

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

+OUT-0

-OUT-0

+ENABLE-0

-ENABLE-0

DRVFLT-0

CHASSIS

IN_COM

HOME-0

REG24V-0

REG5V-0

+OK

CHASSIS

+CHA-0

-CHA-0

+CHB-0

-CHB-0

+CHZ-0

-CHZ-0

+OUT-1

-OUT-1

+ENABLE-1

-ENABLE-1

DRVFLT-1

CHASSIS

IN_COM

HOME-1

REG24V-1

REG5V-1

-OK

CHASSIS

+CHA-1

-CHA-1

+CHB-1

-CHB-1

+CHZ-1

-CHZ-1

1756-MO2AE

2 AXIS

ENCODER/ANALOG

SERVO

RTB door label

Analog Encoder (AE) Servo Module 5

If you did not receive these components, contact your local Allen-Bradley

representative.

Removable Terminal Block and Housing

A separately-ordered RTB connects field-side wiring to the module. You

cannot use your module without an RTB and its components.

Use one of the following RTBs with your module:

Publication 1756-IN047D-EN-P - March 2001

Page 6

6 Analog Encoder (AE) Servo Module

WARNING

!

• 1756-TBCH 36-position cage clamp RTB

• 1756-TBS6H 36-position spring clamp RTB

You received the following components with your RTB:

• 1756-TBH standard-depth RTB housing

• wedge-shaped keying tabs and U-shaped keying bands

• RTB door label

Installing the Module

When you remove or insert an RTB with field-side

power applied, unintended machine motion or loss of

process control can occur. Exercise extreme caution

when power is applied. Failure to observe this caution

can cause personal injury.

To install the AE module:

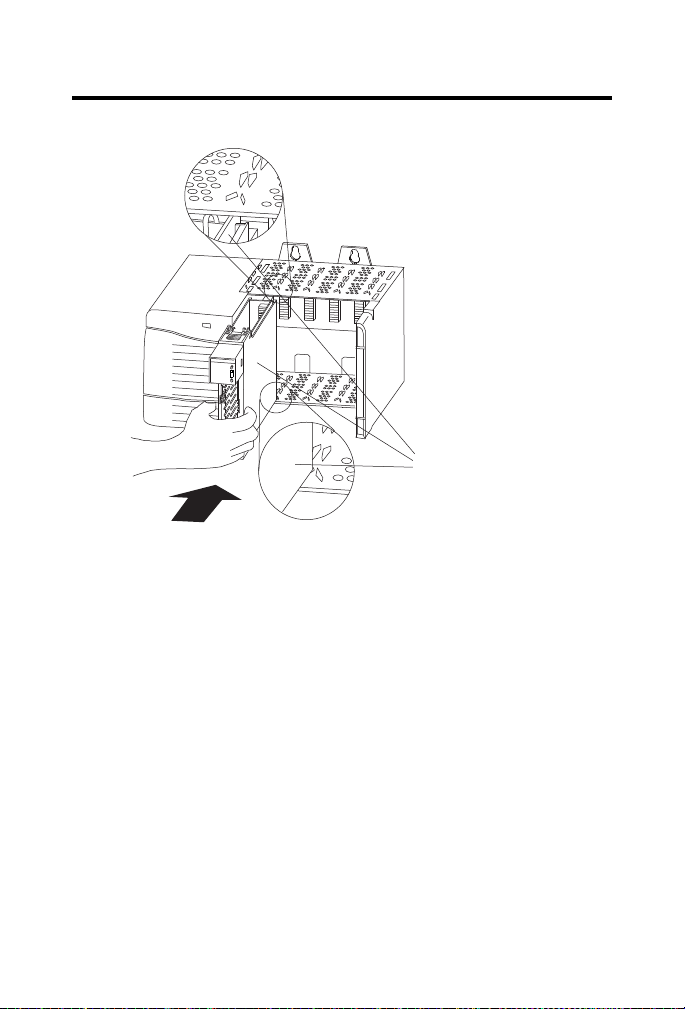

1. Align the module circuit board with the top and bottom chassis

guides.

Publication 1756-IN047D-EN-P - March 2001

Page 7

Analog Encoder (AE) Servo Module 7

P

O

W

E

R

Printed circuit board

Figure 2 Circuit Board Alignment

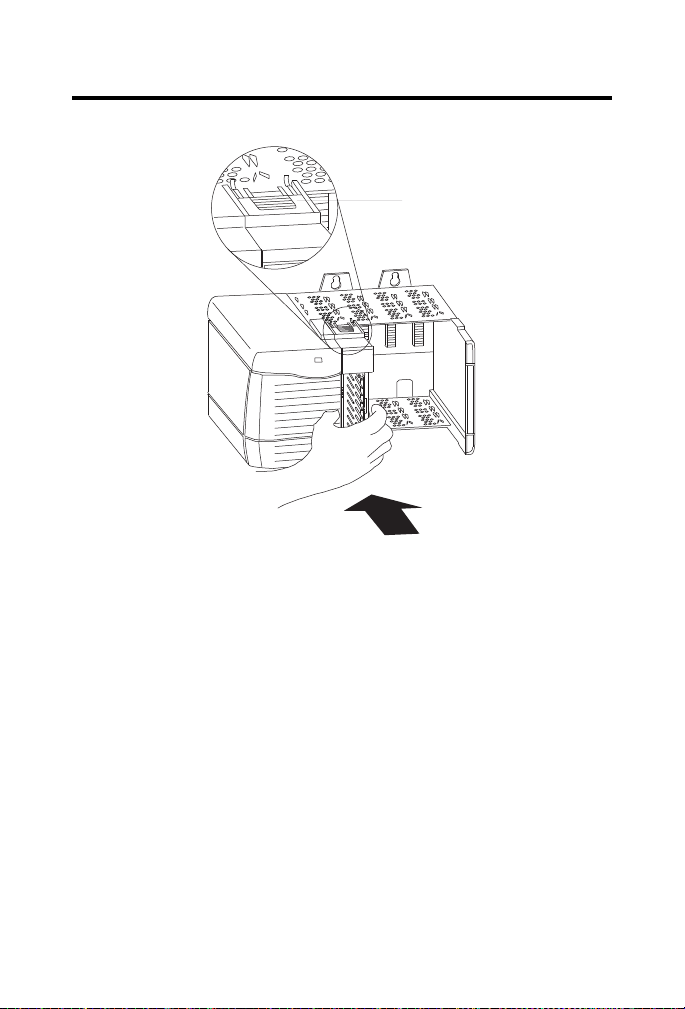

2. Push evenly and firmly to seat the module in the chassis. It is seated

when the top and bottom locking tabs have snapped into place.

Publication 1756-IN047D-EN-P - March 2001

Page 8

8 Analog Encoder (AE) Servo Module

P

O

W

E

R

Locking

tab

Figure 3 Module Locking Tabs

Note: The 1756 chassis provides grounding for your module.

Keying the Removable Terminal Block

To identify the RTB that belongs with each module, you can use a module

keying pattern. First, you can create a unique keying pattern for your module

using the U-shaped keying bands that you received with your RTB. Then you

can use the keying tabs to key the RTB with the same pattern as the module.

To prevent confusion, use a unique keying pattern to each module.

To key the module:

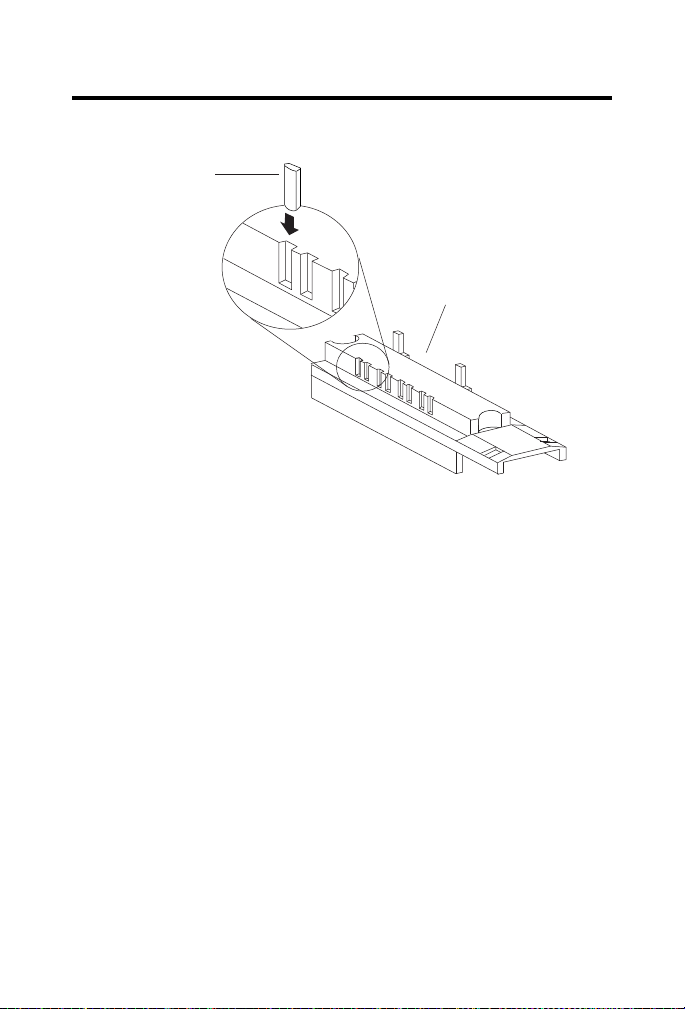

1. Insert the U-shaped keying band with the longer side near the

terminals.

Publication 1756-IN047D-EN-P - March 2001

Page 9

Analog Encoder (AE) Servo Module 9

P

OWER

U-shaped

keying band

Figure 4 Keying Band

2. Push the keying band onto the module until it snaps into place.

To key your removable terminal block:

1. With the rounded edge first, insert the wedge-shaped keying tab on

the RTB.

Note: Insert the wedge-shaped keying tabs in positions that

correspond to unkeyed positions on the module

Publication 1756-IN047D-EN-P - March 2001

Page 10

10 Analog Encoder (AE) Servo Module

Wedge-shaped

keying tab

Bottom of RTB

Figure 5 Keying Tab.

2. Push the keying tab onto the RTB until it stops.

Note: To use the RTB in future module applications, you can reposition

the keying tabs on the RTB.

Wiring a Removable Terminal Block

There are two types of RTBs:

This section describes how to wire each type of RTB and shows wiring

examples for the AE module.

Wire the RTB before installing it onto the module. Use a 1/8 inch (3.2mm)

maximum flat-bladed screwdriver.

Publication 1756-IN047D-EN-P - March 2001

• spring clamp

• cage clamp

Page 11

Analog Encoder (AE) Servo Module 11

Strain Relief Area

Wiring a Spring Clamp RTB

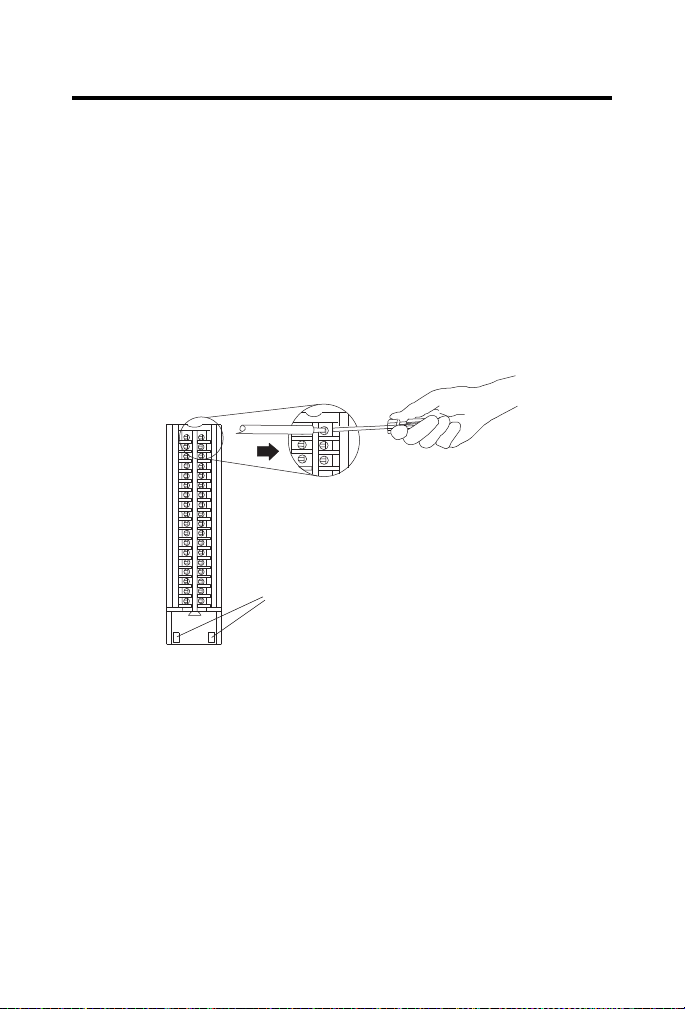

To wire a spring clamp RTB:

1. Strip a maximum of 7/16 inch (11mm) of insulation from the end of

your wire.

2. Insert the screwdriver into the outer hole of the RTB.

3. Insert the wire into the open terminal and remove the screwdriver.

Figure 6 Strain Relief Area

4. After you complete field-side wiring, secure the wires in the strain

relief area with a cable-tie.

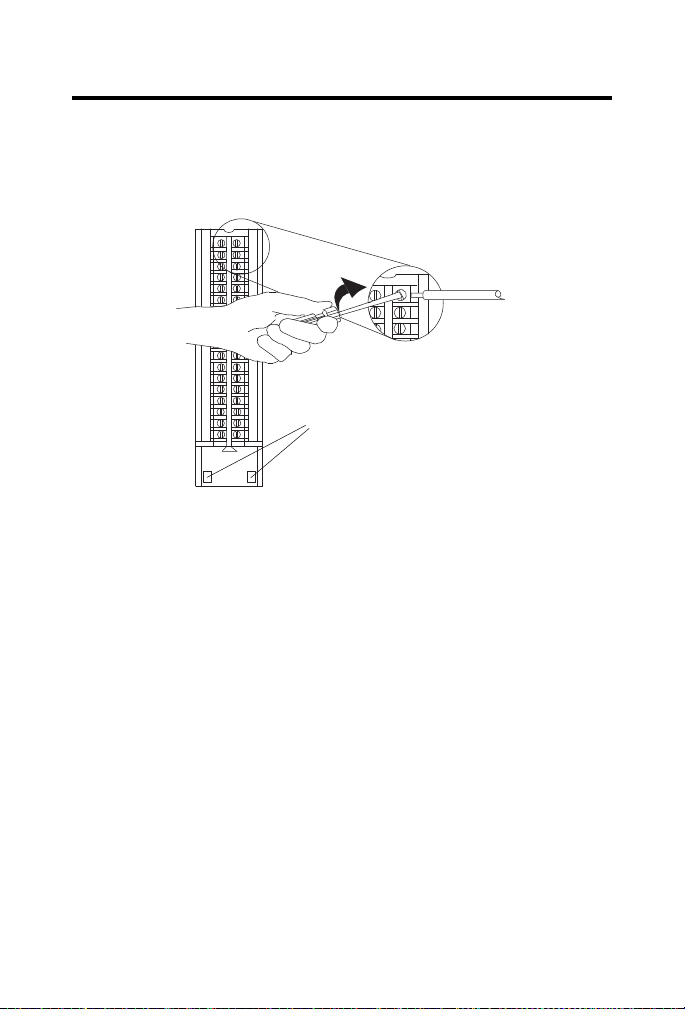

Wiring a Cage Clamp RTB

To wire a cage clamp RTB:

1. Strip 5/16 - 3/8 inch (8 - 9.5mm) of insulation from the end of your

wire.

2. Insert the screwdriver into the open terminal.

Publication 1756-IN047D-EN-P - March 2001

Page 12

12 Analog Encoder (AE) Servo Module

Strain Relief Area

3. Turn the screw clockwise to close the terminal on the wire. Use

5 lb-in. (0.5 Nm) maximum torque

Figure 7 Closing Wire Terminal.

4. After you complete field-side wiring, secure the wires in the strain

relief area with a cable-tie.

Publication 1756-IN047D-EN-P - March 2001

Page 13

General Cable

C0720

To servo drive

To servo drive

To home

limit switch

To registration

sensor

To encoder

To E-stop relay coil

General Cable

C0720

General Cable

C0720

General Cable

C0720

General Cable

C0722

General Cable

C0721

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

+OUT-0

-OUT-0

+ENABLE-0

-ENABLE-0

DRVFLT-0

CHASSIS

IN_COM

HOME-0

REG24V-0

REG5V-0

+OK

CHASSIS

+CHA-0

-CHA-0

+CHB-0

-CHB-0

+CHZ-0

-CHZ-0

-OK

+OUT-1

-OUT-1

+ENABLE-1

-ENABLE-1

DRVFLT-1

CHASSIS

IN_COM

HOME-1

REG24V-1

REG5V-1

CHASSIS

+CHA-1

-CHA-1

+CHB-1

-CHB-1

+CHZ-1

-CHZ-1

Analog Encoder (AE) Servo Module 13

Wiring Examples

Figure 8 Wiring to a servo module RTB

Note: This is a general wiring example illustrating Axis 1 wiring only.

Other configurations are possible with Axis 0 wiring identical to Axis 1.

Publication 1756-IN047D-EN-P - March 2001

Page 14

14 Analog Encoder (AE) Servo Module

5V DC

Field Power

Supply

+5V DC

+5 COM

RED

BLK

To fault

string

OK

RED

BLK

WHT

BLK

RED

BLK

WHT

BLK

RED

BLK

GRN

BLK

+OUT 0

-OUT 0

+ENABLE 0

-ENABLE 0

DRVFLT 0

CHASSIS

IN_COM

HOME 0

REG24V 0

REG5V 0

+OK

CHASSIS

+CHA 0

-CHA 0

+CHB 0

-CHB 0

+CHZ 0

-CHZ 0

+OUT 1

-OUT 1

+ENABLE 1

-ENABLE 1

DRVFLT 1

CHASSIS

IN_COM

HOME 1

REG24V 1

REG5V 1

-OK

CHASSIS

+CHA 1

-CHA 1

+CHB 1

-CHB 1

+CHZ 1

-CHZ 1

Servo Module RTB

1394CCAExx

24V DC

Field Power

Supply

1394 Servo Drive

1394CCAExx

WHT

BLK

RED

BLK

+ENABLE 1

-ENABLE 1

DRVFLT 1

IN_COM

TB2 7

TB2 19

TB2 18

W2

W1

TB2 15

24V DC

24V COM

24V DC

24V COM

24V ENABLE COM

A1 ENABLE

DROK

DROK

AQB1

A

RED OK+

BLK OK-

1756-M02AE

Axis 1

ENA/DR OK 1

ENC. PWR -1

A

Figure 9 Wiring to a 1394 Servo Drive (in Torque Mode only)

Note: The wiring diagram illustrates Axis 1 wiring only. Other

configurations are possible.

Note: The 1394CCAExx cable is wired to connect to torque command

reference input pins.

Note: An external +5V power supply is required to power the encoder

driver circuit of the 1394 servo drive. Because this connection is shared by all

four axis encoder driver circuits, only one connection is needed to the +5V

field supply.

Note: The xx in the cable number is the length of the cable. Options are

5, 10, 25, and 50 feet.

Publication 1756-IN047D-EN-P - March 2001

Page 15

Analog Encoder (AE) Servo Module 15

Individually Jacketed Pairs

7

1216

ENABLE/DRIVE FAULT - AXIS 0

5.0 in.

1.0 in.

5V ENC PWR - AXIS 0

M02AE - OK

AXIS 0

1394-CFLAE

1756-M02AE

3.0 in.

Figure 10 The 1394-CFLAExx Cable Wiring Diagram

Note: The 1394-CFLAE cable is available in 1, 3, 8, and 15 meter lengths.

Publication 1756-IN047D-EN-P - March 2001

Page 16

16 Analog Encoder (AE) Servo Module

3

9

+5V

+5VCOM

4

10

5

11

6

12

CHANNEL A HIGH

CHANNEL A LOW

CHANNEL B HIGH

CHANNEL B LOW

CHANNEL Z HIGH

CHANNEL Z LOW

VREF+

TREF+

VREFTREF-

1

2

7

8

(DROK-0)

(24V EN COM)

(24V)

(AX_-ENABLE)

TO SYSTEM

FAULT STRING

RED 22GA

BLACK 22GA

DRAIN

ORANGE 22GA

WHT/ORG 22GA

YELLOW 22GA

WHT/YEL 22GA

GREEN 22GA

WHT/GRN 22GA

DRAIN

BLUE 22GA

WHT/BLU 22GA

DRAIN

VIOLET 22GA

WHT/VIO 22GA

GRAY 22GA

WHT/GRY 22GA

DRAIN

RED 22GA

BLACK 22GA

DRAIN

Figure 11 Pinouts for the 1394-CFLAE

Publication 1756-IN047D-EN-P - March 2001

Page 17

Analog Encoder (AE) Servo Module 17

24 VDC

Field Power Supply

24VDC

READY+

24VCOM

COMMAND+

COMMAND-

ENABLE

READY-

AOUT+

AOUTBOUT+

BOUTIOUT+

IOUT-

24VDC

24VCOM

24 VDC

24 VCOM

+OUT

-OUT

+ENABLE

-ENABLE

DRVFLT

IN_COM

+CHA

-CHA

+CHB

-CHB

+CHZ

-CHZ

J1-5

J1-26

J1-24

J1-6

J1-13

J1-22

J1-23

J1-20

J1-25

J1-7

J1-8

J1-9

J1-10

J1-11

J1-12

General Cable

C0720

General Cable

C0721

General Cable

C0722

From

1756-M02AE

From

1756-M02AE

From

1756-M02AE

J1 to 50-pin

Terminal Block

(Kit P/N 9109-1391)

Ultra 100 Series

Digital Servo Drive

Interface

Cable

P/N 9109-1369-003

J1

Figure 12 Wiring to an Ultra 100 Series Drive

Note: This is a general wiring example only. Other configurations are

possible. For more information, refer to the Ultra 100 Series Installation Manual,

publication number 1398-5.2.

Publication 1756-IN047D-EN-P - March 2001

Page 18

18 Analog Encoder (AE) Servo Module

J1 to 50-pin

Terminal Block

(Kit P/N 9109-1391)

24VDC

READY+

24VCOM

COMMAND+

COMMAND-

ENABLE

READY-

AOUT+

AOUTBOUT+

BOUTIOUT+

IOUT-

+OUT

-OUT

+ENABLE

-ENABLE

DRVFLT

IN_COM

+CHA

-CHA

+CHB

-CHB

+CHZ

-CHZ

J1-5

J1-24

J1-6 or 13

J1-22

J1-23

J1-20

J1-25

J1-7

J1-8

J1-9

J1-10

J1-11

J1-12

General Cable

C0720

General Cable

C0721

General Cable

C0722

From

1756-M02AE

From

1756-M02AE

From

1756-M02AE

Ultra 200 Series

Digital Servo Drive

Interface

Cable

P/N 9109-1369-003

J1

24V

BRAKE

RESET

Individually Jacketed pairs

1398-CFLAE

J1

1.0 in.

5.0 in.

Figure 13 Wiring to an Ultra 200 Series Drive

Note: This is a general wiring example only. Other configurations are

possible. For more information, refer to the Ultra 200 Series Installation Manual,

publication number 1398-5.0.

Figure 14 1398-CFLAExx Cable Diagram

Note: The 1398-CFLAE Cable is available in 10, 25, and 50 foot lengths.

Publication 1756-IN047D-EN-P - March 2001

Page 19

Analog Encoder (AE) Servo Module 19

WHT/ORG 22GA

WHT/YEL 22GA

DRAIN

TAN 28GA

DRAIN

WHT/RED 22GA

WHT/BLK 22GA

DRAIN

WHT/GRN 22GA

WHT/BLU 22GA

DRAIN

BROWN 28GA

RED 28GA

ORANGE 28GA

YELLOW 28GA

DRAIN

GREEN 28GA

BLUE 28GA

VIOLET 28GA

GRAY 28GA

WHITE 28GA

BLACK 28G

DRAIN

49

50

21

5

6

22

23

26

24

20

25

13

7

8

9

10

11

12

BRAKE +

BRAKE -

RESET

24VDC

24VCOM

COMMAND +

COMMAND -

24VDC

READY +

ENABLE

READY 24VCOM

AOUT +

AOUT BOUT +

BOUT IOUT +

IOUT -

Wires

Terminated

with

Ferrules

Wires

Stripped

Back

.25 in.

Figure 15 Pinouts for1398-CFLAExx Cable

Publication 1756-IN047D-EN-P - March 2001

Page 20

20 Analog Encoder (AE) Servo Module

24 VDC

Field Power

Supply

REG24V

IN_COM

General Cable

C0720

From

1756-M02AE

+-

24 Volt

Sourcing Type

Registration

Sensor

Supply

Output

Common

5 VDC

Field Power

Supply

REG5V

IN_COM

General Cable

C0720

From

1756-M02AE

+-

5 Volt

Sourcing Type

Registration

Sensor

Supply

Output

Common

Wiring Registration Sensors

The registration inputs to the servo module can support 24V or 5V

registration sensors. These inputs must be wired to receive source current

from the sensor. Only use sourcing type registration sensors. Current sinking

sensor configurations are not allowed because the registration input common

(IN_COM) is shared with the other 24V servo module inputs.

Figure 16 24V Registration Sensor

Figure 17 5V Registration Sensor

Publication 1756-IN047D-EN-P - March 2001

Page 21

Analog Encoder (AE) Servo Module 21

24 VDC

Field Power

Supply

HOME

IN_COM

General Cable

C0720

From 1756-M02AE

+-

Wiring the Home Limit Switch Input

The home limit switch inputs to the servo module are designed for 24V

nominal operation. These inputs should be wired for current sourcing

operation.

Figure 18 Home Limit Switch

Wiring the OK Contacts

A set of isolated solid-state OK relay contacts is provided for optional

interface to an E-stop string, which controls power to the associated drives.

The OK contacts are rated for pilot duty and can drive an external 24V relay

(for example, Allen-Bradley 700-HA32Z24) whose contacts can be

incorporated into the E-Stop string as shown below.

Publication 1756-IN047D-EN-P - March 2001

Page 22

22 Analog Encoder (AE) Servo Module

IMPORTANT

24 VDC

Field Power

Supply

+OK

-OK

General Cable

C0720

From 1756-M02AE

+-

OK Relay

OK Relay

Contacts

Start

CR1

Stop

CR1

CR1

M1

+

-

24 VDC

Field Power

Supply

To User's circuitry

+OK -OK

Figure 19 OK Relay Pilot Duty Application Wiring

When the OK Relay is loaded with an inductive load,

use a counter-EMF suppression diode across the load.

The maximum rating of the OK relay contacts must not

exceed 60V DC.

Assembling the Removable Terminal Block and Housing

To assemble the removable terminal block and housing:

Publication 1756-IN047D-EN-P - March 2001

1. Align the grooves at the bottom of each side of the housing with the

side edges of the RTB.

2. Slide the RTB into the housing until it snaps into place

Page 23

Analog Encoder (AE) Servo Module 23

WARNING

!

WARNING

!

Groove

Side edge of RTB

Strain relief area

Groove

Side edge of RTB

1756-TBCH RTB shown for reference

Figure 20 RTB and Housing.

Installing the Removable Terminal Block onto the Module

A shock hazard exists. If the RTB is installed onto the

module while the field-side power is applied, the RTB is

electrically live. Do not touch the RTB terminals. Failure

to observe this caution can cause personal injury.

When you connect or disconnect the RTB with field

side power applied, an electrical arc can occur. This

could cause an explosion in hazardous location

installations. Be sure that all sources of power are

removed or the area is nonhazardous before proceeding.

Before installing the RTB, make certain:

Publication 1756-IN047D-EN-P - March 2001

Page 24

24 Analog Encoder (AE) Servo Module

P

O

W

E

R

Top

guide

Bottom

guide

Left side

guides

• field-side wiring of the RTB has been completed.

• the RTB housing is snapped into place on the RTB.

• the RTB housing door is closed.

• the locking tab at the top of the module is unlocked.

To install the removable terminal block onto the module:

1. Align the top, bottom, and left side guides of the RTB with the guides

on the module.

Figure 21 Aligning RTB

2. Press quickly and evenly to seat the RTB on the module until the

latches snap into place.

3. Slide the locking tab down to lock the RTB onto the module.

Publication 1756-IN047D-EN-P - March 2001

Page 25

Analog Encoder (AE) Servo Module 25

P

OW

E

R

Locking

tab

Figure 22 Locking Tabs

Checking the LED Indicators

The module provides bi-colored LED indicators to show individual drive and

feedback status for both axes and a single bi-colored LED for module OK.

Publication 1756-IN047D-EN-P - March 2001

Page 26

26 Analog Encoder (AE) Servo Module

CH 0 CH 1

FDBK

DRIVE

OK

2 AXIS SERVO

FDBK

DRIVE

Figure 23 1756-M02AE Module LEDs

During power up, the module completes an indicator test. The OK indicator

turns red for 1 second and then turns to flashing green if the module passes

all its self tests.

This completes the installation of the module.

Understanding Module Status Using the OK Indicator

If the OK LED

displays:

Off The module is not operating. • Apply chassis power.

Then the module status

is:

Take this action:

• Verify the module is completely

inserted into the chassis and

backplane.

Flashing green

light

The module has passed

internal diagnostics, but it is

not communicating axis

data over the backplane.

• None, if you have not

configured the module.

• If you have configured the

module, check the slot number

in the 1756-M02AE Properties

dialog box.

Publication 1756-IN047D-EN-P - March 2001

Page 27

Analog Encoder (AE) Servo Module 27

If the OK LED

displays:

Steady green

light

Flashing red

light

Solid red light • A potential

Then the module status

is:

• Axis data is being

exchanged with

the module.

• The module us in

the normal

operating state.

• A major

recoverable failure

has occurred.

• A communication

fault, timer fault,

or NVS update is

in progress.

• The OK contact

has opened.

nonrecoverable

fault has occurred.

• The OK contact

has opened.

Take this action:

None. The module is ready for action.

If an NVS update is in progress,

complete the NVS update.

If an NVS update is not in progress:

• Check the Servo Fault word for

the source of the error.

• Clear the servo fault condition

using the Motion Axis Fault

Reset instruction.

• Resume normal operation.

• If the flashing persists,

reconfigure the module.

• Reboot the module.

• If the solid red persists, replace

the module.

Understanding Module Status Using the FDBK Indicator

If the FDBK

LED displays:

Off The axis is not used. • None, if you are not using this

Flashing green

light

Then the module status

is:

The axis is in the normal

servo loop inactive state.

Take this action:

axis.

• If you are using this axis, make

sure the module is configured

and an axis tag has been

associated with the module.

None. The servo axis state can be

changed by executing motion

instructions.

Publication 1756-IN047D-EN-P - March 2001

Page 28

28 Analog Encoder (AE) Servo Module

If the FDBK

LED displays:

Steady green

light

Flashing red

light

Solid red light An axis encoder feedback

Then the module status

is:

The axis is in the normal

servo loop active state.

The axis servo loop error

tolerance has been

exceeded.

fault has occurred.

Take this action:

None. The servo can may be changed by

executing motion instructions.

• Correct the source of the

problem.

• Clear the servo fault condition

using the Motion Axis Fault

Reset instruction.

• Resume normal operation.

• Correct the source of the

problem by checking the

encoder and power

connections.

• Clear the servo fault condition

using the Motion Axis Fault

Reset instruction.

• Resume normal operation.

Understanding Module Status Using the DRIVE Indicator

If the DRIVE

LED displays:

Off • The axis is not

Flashing green

light

Then the module status

is:

used.

• The axis is a

position-only axis

type.

The axis drive is in the

normal disabled state.

Take this action:

• None, if the axis is not used or

is a position-only type.

• Otherwise, make sure the

module is configured, an axis

tag has been associated with

the module, and the axis type is

servo.

None. The servo axis state can be

changed by executing motion

instructions.

Publication 1756-IN047D-EN-P - March 2001

Page 29

Analog Encoder (AE) Servo Module 29

WARNING

!

If the DRIVE

LED displays:

Steady green

light

Flashing red

light

Solid red light The axis drive is faulted. • Check the drive status.

Then the module status

is:

The axis drive is in the

normal enabled state.

The axis drive output is in

the shutdown state.

Take this action:

None. The servo axis state can be

changed by executing motion

instructions.

• Check for faults that may have

generated this state.

• Execute the Shutdown Reset

motion instruction.

• Resume normal operation.

• Clear the Drive Fault condition

at the drive.

• Clear the servo fault condition

using the Motion Axis Fault

Reset instruction.

• Resume normal operation.

• Check the configuration for the

Drive Fault.

- If configured to be normally

open and there is no voltage,

this is the normal condition.

- If configured to be normally

closed and 24V is applied,

this is the normal condition.

Removing the Removable Terminal Block from the Module

A shock hazard exists. If the RTB is removed from the

module while the field-side power is applied, the module

is electrically live. Do not touch the RTBs terminals.

Failure to observe this caution can cause personal injury.

Publication 1756-IN047D-EN-P - March 2001

Page 30

30 Analog Encoder (AE) Servo Module

WARNING

!

P

OW

E

R

P

U

L

L

H

E

R

E

D

A

N

G

E

R

P

U

L

L

H

E

R

E

D

A

N

G

E

R

When you connect or disconnect the RTB with field

side power applied, an electrical arc can occur. This

could cause an explosion in hazardous location

installations. Be sure that all sources of power are

removed or the area is nonhazardous before proceeding.

You must remove the RTB before you can remove the module.

To remove the RTB from the module:

1. Unlock the locking tab at the top of the module.

2. Open the RTB door using the bottom tab.

3. Hold the spot marked PULL HERE and pull the RTB toward you and

off the module.

Figure 24 Removing RTB

Publication 1756-IN047D-EN-P - March 2001

Page 31

Analog Encoder (AE) Servo Module 31

PO

W

ER

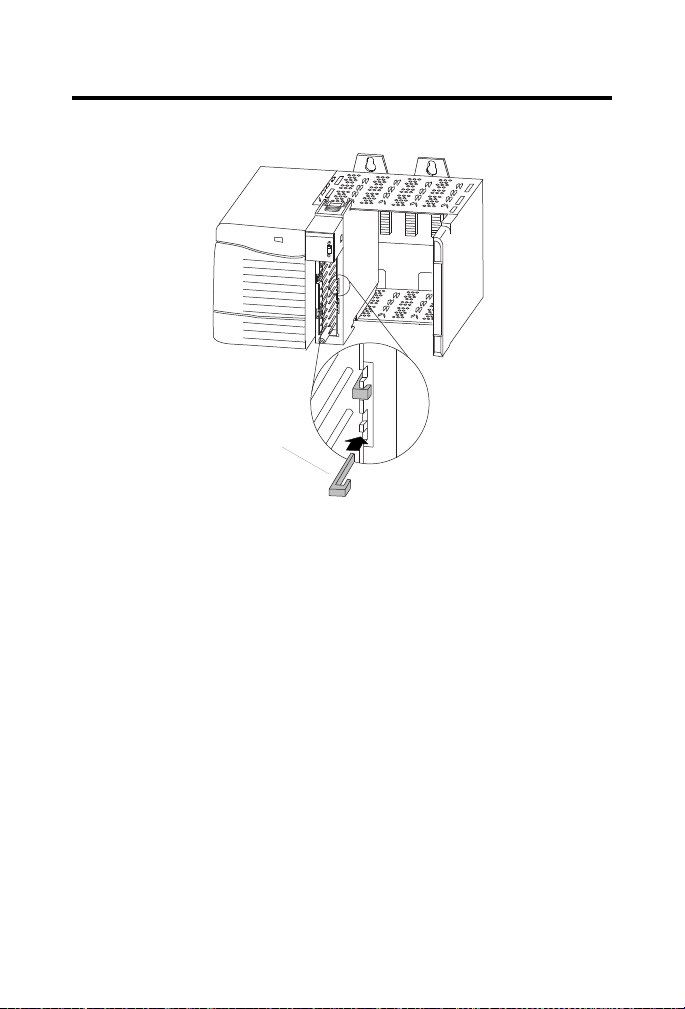

Removing the Module from the Chassis

To remove the module from the chassis:

1. If the RTB is on the module, unlock the RTB and remove it. For

more information, refer to Removing the Removable Terminal Block from the

Module.

2. Push in and hold the top and bottom locking tabs on the module.

Figure 25 Hold Locking Tabs

3. Pull the module out of the chassis.

Publication 1756-IN047D-EN-P - March 2001

Page 32

32 Analog Encoder (AE) Servo Module

PO

WE

R

Figure 26 Pulling Module Out

Module Specifications

Number of axes 2 axes maximum

Servo loop

Typ e

Gain resolution

Absolute position range

Rate

Module location 1756 ControlLogix chassis

Module keying Electronic

Power dissipation 5.5W maximum

Backplane current 5.1V dc @ 700 mA and 24V dc @ 2.5 mA

Encoder input

Typ e

Mode

Rate

Electrical interface

Voltage range

On state

Off state

Input impedance

Nested PI digital position and velocity servo

32-bit floating point

±1,000,000,000 encoder counts

5 kHz

Incremental AB quadrature with marker

4X quadrature

4 MHz counts per second maximum

Optically isolated 5V differential

3.4V to 5.0V

0V to 1.8V

531 Ohms differential

Publication 1756-IN047D-EN-P - March 2001

Page 33

Analog Encoder (AE) Servo Module 33

Registration inputs

Typ e

24V input voltage

Maximum

Minimum on

Maximum off

5V input voltage

Maximum

Minimum on

Maximum off

Input impedance

24V input

5V input

Response time

(position latched)

All other inputs

Typ e

Input voltage

Maximum

Minimum on

Maximum off

Input impedance

Servo output

Typ e

Isolation

Voltage range

Voltage resolution

Load

Maximum offset

Gain error

Optically isolated, current sinking input

+24V dc nominal

26.4V

18.5V

3.5V

+5V dc nominal

5.5V

3.7V

1.5V

9.5 kOhms

1.2 kOhms

1µs

Optically isolated, current sinking input

+24V dc nominal

26.4V

17.0V

8.5V

7.5 kOhms

Analog voltage

200 kOhms

±10V

16 bits

5.6 kOhms resistive minimum

25 mV

±4%

All other outputs

Typ e

Operating voltage

Maximum

Operating current

Solid-state isolated relay contacts

+24V dc nominal (Class 2 source)

26.4V

75 mA

RTB keying User-defined

Field wiring arm

36-position RTB (1756-TBCH or -TBS6H)

RTB screw torque (cage clamp) 5 lb-in. (0.5 Nm) maximum

Conductors

Wire size

Category

22 AWG to 14 AWG copper

3/64 inch (1.2 mm) insulation maximum

2,3

1

Screwdriver blade width for RTB 1/8 inch (3.2 mm) maximum

1

1

Publication 1756-IN047D-EN-P - March 2001

Page 34

34 Analog Encoder (AE) Servo Module

N223

Environmental conditions

Operating temperature

Storage temperature

Relative humidity

Agency Certifications

When product is marked

1) Maximum wire size will require the extended depth RTB housing (1756-TBE).

2) Use this conductor category information for planning conductor routing as described in the system

level installation manual.

3) Refer to Industrial Automation Wiring and Grounding Guidelines, publication number 1770-4.1.

0 to 60ºC (32 to 140ºF)

-40 to 85ºC (-40 to 185ºF)

5 to 95% noncondensing

Listed Industrial Control Equipment

Certified Process Control Equipment

Certified Class I, Division 2, Group A, B, C, D

Marked for applicable directives

Marked for all applicable acts

Installation Environment

This product must be mounted within a suitable system enclosure to prevent

personal injury resulting from accessibility to live parts. The interior of this

enclosure must be accessible only by the use of a tool.

This industrial control equipment is intended to operate in a Pollution Degree

2 environment, in overvoltage category II applications, (as defined in IEC

publication 664A) at altitudes up to 2000 meters without derating.

The following information applies when operating this equipment in hazardous locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suitable for use in Class I

Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous

locations only. Each product is supplied with markings on the rating

nameplate indicating the hazardous location temperature code. When

combining products within a system, the most adverse temperature code

(lowest “T” number) may be used to help determine the overall temperature

Publication 1756-IN047D-EN-P - March 2001

Page 35

Analog Encoder (AE) Servo Module 35

WARNING

!

code of the system. Combinations of equipment in your system are subject to

investigation by the local Authority Having Jurisdiction at the time of

installation.

EXPLOSION HAZARD –

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is

known to be nonhazardous. Secure any external

connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or

other means provided with this product.

• Substitution of components may impair suitability

for Class I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement

en environnements dangereux:

Les produits marqués «CL I, DIV 2, GP A, B, C, D» ne conviennent qu’à une

utilisation en environnements de Classe I Division 2 Groupes A, B, C, D

dangereux et non dangereux. Chaque produit est livré avec des marquages sur

sa plaque d’identification qui indiquent le code de température pour les

environnements dangereux. Lorsque plusieurs produits sont combinés dans

un système, le code de température le plus défavorable (code de température

le plus faible) peut être utilisé pour déterminer le code de température global

du système. Les combinaisons d’équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de l’installation.

Publication 1756-IN047D-EN-P - March 2001

Page 36

36 Analog Encoder (AE) Servo Module

Informations sur l’utilisation de cet équipement

en environnements dangereux:

RISQUE D’EXPLOSION –

• Couper le courant ou s’assurer que l’environnement

est classé non dangereux avant de débrancher

l'équipement.

• Couper le courant ou s'assurer que l’environnement

est classé non dangereux avant de débrancher les

connecteurs. Fixer tous les connecteurs externes

reliés à cet équipement à l'aide de vis, loquets

coulissants, connecteurs filetés ou autres moyens

fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe 1, Division 2.

• S’assurer que l’environnement est classé non

dangereux avant de changer les piles.

Publication 1756-IN047D-EN-P - March 2001

Page 37

NOTES:

Analog Encoder (AE) Servo Module 37

Publication 1756-IN047D-EN-P - March 2001

Page 38

38 Analog Encoder (AE) Servo Module

NOTES:

Publication 1756-IN047D-EN-P - March 2001

Page 39

NOTES:

Analog Encoder (AE) Servo Module 39

Publication 1756-IN047D-EN-P - March 2001

Page 40

ControlLogix is a trademark of Allen-Bradley Company, Inc., a Rockwell

International company.

Publication 1756-IN047D-EN-P - March 2001 PN957536-48

Supersedes Publication 1 756-IN047C-EN-P - November 2000 © 2001 Rockwell International Corporation. Printed in USA

Loading...

Loading...