Page 1

ControlLogix

Sequence of Events

Module

1756-IB16ISOE (24/48V dc),

1756-IH16ISOE (125V dc)

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we may use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside equipment to alert

people that dangerous voltage may be present.

Labels may be located on or inside equipment to alert

people that surfaces may be dangerous temperatures.

Page 3

Preface

Purpose of This Manual

This manual describes how to use the ControlLogix Sequence of

Events module in your ControlLogix application. With this manual,

you can learn how to install, configure and troubleshoot the module.

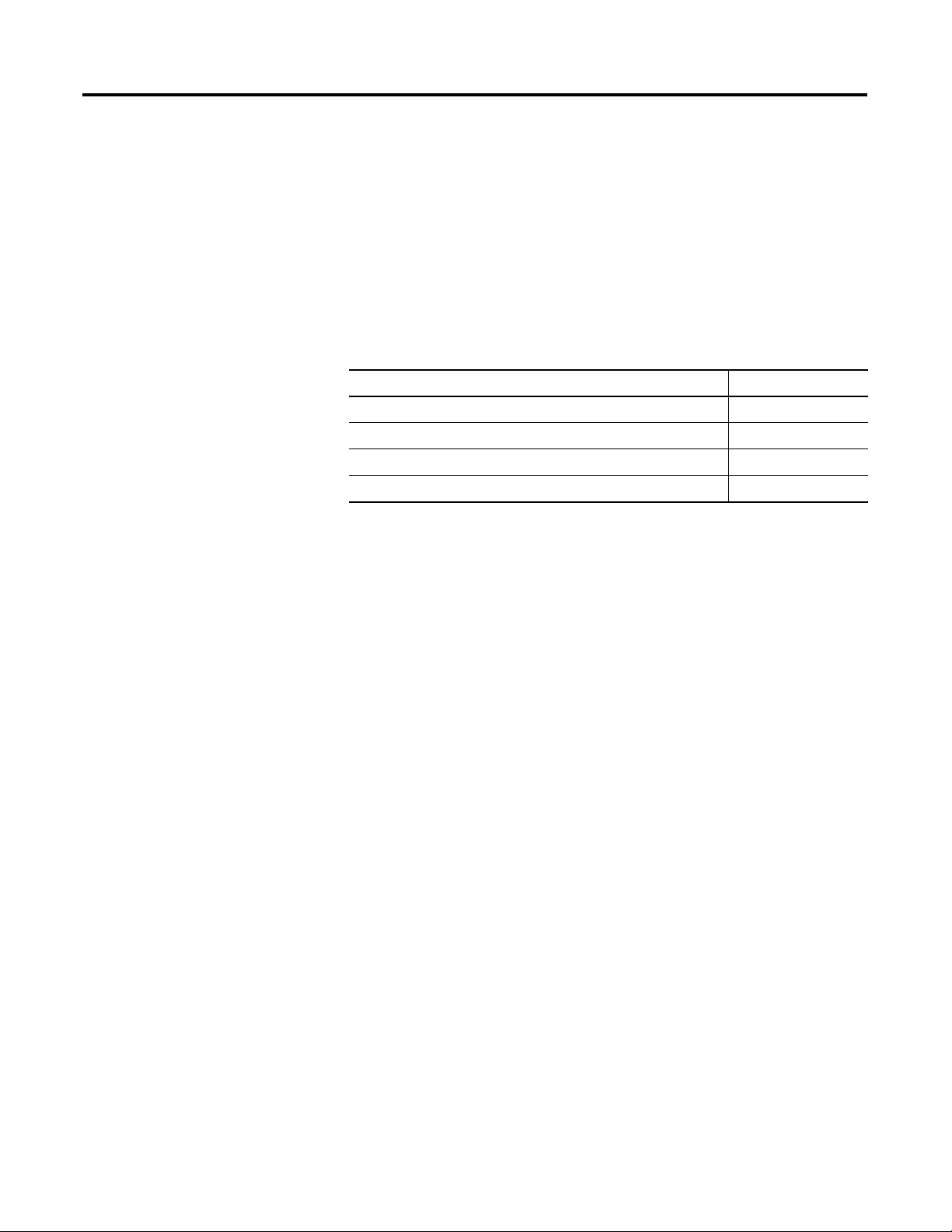

There are two types of ControlLogix Sequence of Events modules, as

described in Table Preface.1:

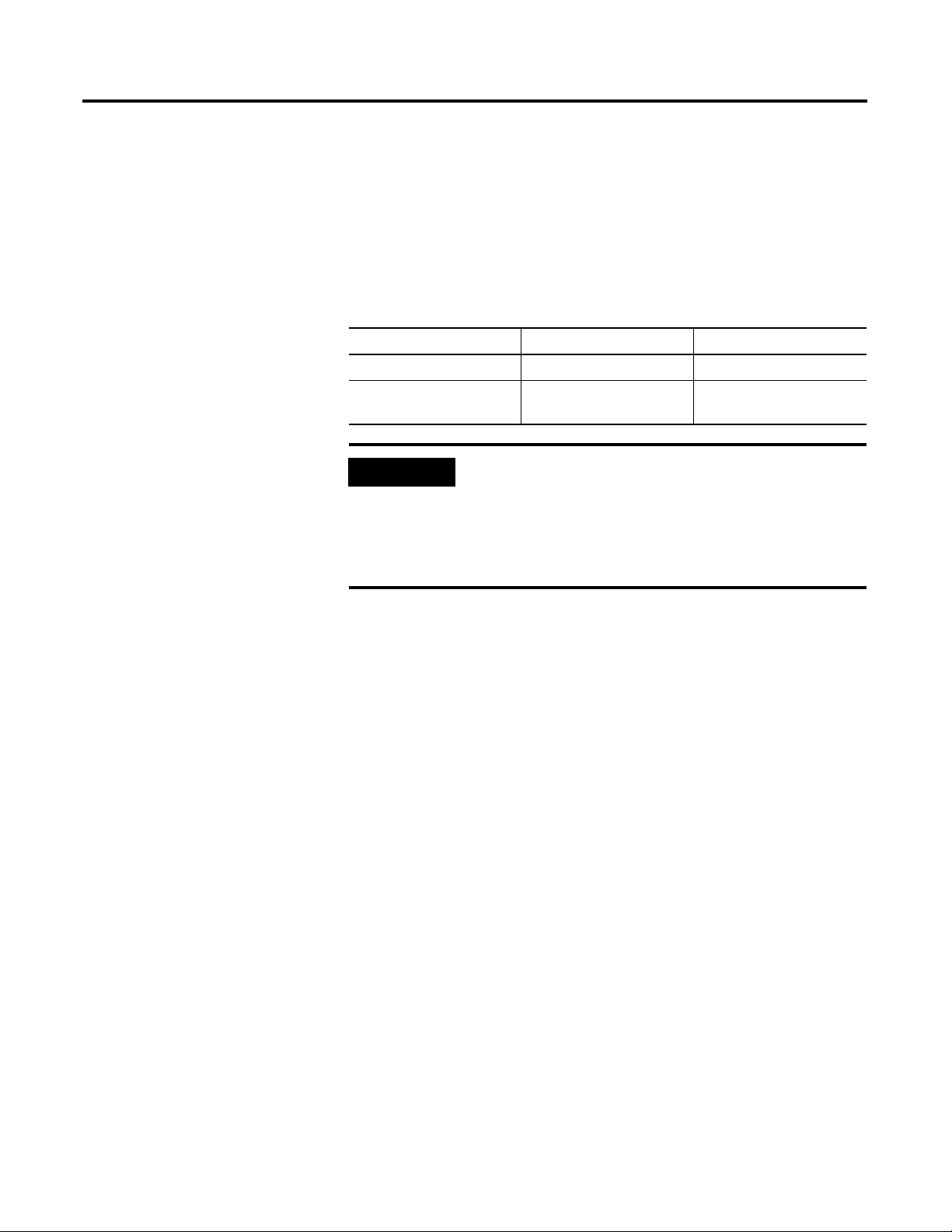

Table Preface.1

Catalog number: Description: Availability date:

1756-IB16ISOE 16-point, 10 - 50V dc module June 2004

1756-IH16ISOE 16-point, 90 - 140V dc

module

IMPORTANT

The two types of Sequence of Events modules have

identical functionality, except for the fact that they

operate at different voltage levels. Throughout this

manual, we use the term Sequence of Events module

generically. When you read the term, it refers to both

types of modules unless specifically noted.

April 2004

Who Should Use This Manual

This manual is intended for individuals who program ControlLogix

control systems, such as:

• software engineers

• control engineers

• application engineers

To most efficiently use the Sequence of Events module, you should be

familiar with:

• ControlLogix™ controllers

• ControlLogix ControlNet™ communication modules

• RSLogix 5000™

• RSNetWorx for ControlNet™

1 Publication 1756-UM528A-EN-P - April 2004

Page 4

Preface 2

What This Manual Contains

Table Preface.2 lists the sections contained in this manual:

Table Preface.2

Section: Title:

Chapter 1 What is the ControlLogix Sequence of Events Module?

Chapter 2 How Does the Sequence of Events Module Operate in a

ControlLogix System?

Chapter 3 Installing the Sequence of Events Module

Chapter 4 Configuring the Sequence of Events Module

Chapter 5 Using the Sequence of Events Module Features

Chapter 6 Using The Sequence of Events Module in CST Per Point Mode

Chapter 7 Using The Sequence of Events Module in FIFO Mode

Chapter 8 Troubleshooting the Sequence of Events Module

Appendix A Specifications and Module Block Diagrams

Appendix B Integrating The HiProm GPS Module (1756HP-GPS) into a

ControlLogix Sequence of Events Module System

Appendix C Using the Sequence of Events Module for Absolute First Fault

Detection

Appendix D Using Module Tags

Appendix E Using Sample RSLogix 5000 Projects with the Sequence of Events

Module

Related Documentation

Table Preface.3 lists related ControlLogix documentation that may

assist you when using the Sequence of Events module.

Table Preface.3 Related Documentation

Catalog

number:

1756-A4, -A7,

-A10, -A13, -A17

1756-PA72/B,

-PB72/B

1756-PA75,

-PB75

1756-PH75 ControlLogix 125V DC (90-143V) Power Supply 1756-IN589

1756-Series ControlLogix Module Installation Instructions

1756-CNB,

-CNBR

1756-Lx ControlLogix System User Manual 1756-UM001

Document title: Publication

number:

ControlLogix Chassis–Series B Installation

Instructions

ControlLogix Power Supply Installation

Instructions

ControlLogix Power Supply Installation

Instructions

(Each module has separate installation

document.)

Using ControlNet Communication Modules in

Logix5000 Control Systems User Manual

1756-IN080

1756-5.67

1756-5.78

Multiple 1756-IN

numbers

CNET-UM001

Publication 1756-UM528A-EN-P - April 2004

Page 5

Preface 3

Preventing Electrostatic Discharge

This module is sensitive to electrostatic discharge.

ATTENTION

This equipment is sensitive to electrostatic discharge,

which can cause internal damage and affect normal

operation. Follow these guidelines when you handle

this equipment:

• Touch a grounded object to discharge potential

static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the

equipment.

• If available, use a static-safe workstation.

When not in use, store the equipment in appropriate

static-safe packaging.

Publication 1756-UM528A-EN-P - April 2004

Page 6

Preface 4

Environment and Enclosure

ATTENTION

This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage

Category II applications (as defined in IEC

publication 60664-1), at altitudes up to 2000 meters

without derating.

This equipment is considered Group 1, Class A

industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions,

there may be potential difficulties ensuring

electromagnetic compatibility in other environments

due to conducted as well as radiated disturbance.

This equipment is supplied as “open type”

equipment. It must be mounted within an enclosure

that is suitably designed for those specific

environmental conditions that will be present and

appropriately designed to prevent personal injury

resulting from accessibility to live parts. The interior

of the enclosure must be accessible only by the use

of a tool. Subsequent sections of this publication

may contain additional information regarding

specific enclosure type ratings that are required to

comply with certain product safety certifications.

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for explanations of

the degrees of protection provided by different types

of enclosure. Also, see the appropriate sections in

this publication, as well as the Allen-Bradley

publication 1770-4.1 (“Industrial Automation Wiring

and Grounding Guidelines”), for additional

installation requirements pertaining to this

equipment.

Publication 1756-UM528A-EN-P - April 2004

Page 7

What is the ControlLogix

Sequence of Events Module?

How Does the Sequence of Events

Module Operate in a ControlLogix

System?

Table of Contents

Chapter 1

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 1-1

What does Sequence of Events Module Do? . . . . . . . . . . . . 1-1

Timestamping Using the Coordinated System Time (CST) 1-1

On-Board Data Storage . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Two Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . 1-3

What Else Does the Sequence of Event Module Do? . . . . . . 1-3

Understanding the Module’s Physical Features . . . . . . . . . . 1-4

Using Module Identification and Status Information . . . . . . 1-5

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 1-6

Chapter 2

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 2-1

Differences Between Sequence of Events Module

and Standard Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Similar Functionality to Standard ControlLogix DC

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Propagating a Signal From Field Device to Backplane . . . . 2-4

Sequence of Events Module in a Local Chassis . . . . . . . . . . 2-6

Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . 2-6

Enable CST Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Sequence of Events Module in a Remote Chassis . . . . . . . . 2-8

Remote Input Module Connected Via ControlNet . . . . . 2-8

Remote Input Modules Connected Via EtherNet/IP . . . . 2-10

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 2-10

Installing the Sequence of

Events Module

Chapter 3

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 3-1

Installing the Sequence of Events Module. . . . . . . . . . . . . . 3-1

Keying the Removable Terminal Block. . . . . . . . . . . . . . . . 3-3

Connecting Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wiring the RTB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Recommendations for Wiring Your RTB . . . . . . . . . . . . 3-5

Wiring the Sequence of Events Module . . . . . . . . . . . . . . . 3-6

Assembling The Removable Terminal Block and

the Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Choosing the Extended-Depth Housing . . . . . . . . . . . . . . . 3-8

Recommendations for Using the

Extended-Depth Housing . . . . . . . . . . . . . . . . . . . . . . . 3-9

Cabinet Size Considerations With the

Extended-Depth Housing . . . . . . . . . . . . . . . . . . . . . . . 3-9

Installing the Removable Terminal Block . . . . . . . . . . . . . . 3-10

Removing the Removable Terminal Block . . . . . . . . . . . . . 3-12

Removing the Module from the Chassis . . . . . . . . . . . . . . . 3-13

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 3-14

1 Publication 1756-UM528A-EN-P - April 2004

Page 8

Table of Contents 2

Configuring the Sequence of

Events Module

Using the Sequence of Events

Module Features

Chapter 4

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 4-1

Configuring Your I/O Module . . . . . . . . . . . . . . . . . . . . . . 4-1

RSLogix 5000 Configuration Software . . . . . . . . . . . . . . 4-1

Overview of the Configuration Process . . . . . . . . . . . . . . . 4-2

Adding a New Module to Your RSLogix 5000 Project . . . . . 4-3

Communications Format. . . . . . . . . . . . . . . . . . . . . . . . 4-5

Electronic Keying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Using the Default Configuration. . . . . . . . . . . . . . . . . . . . . 4-6

Altering the Default Configuration . . . . . . . . . . . . . . . . . . . 4-6

Downloading Configuration. . . . . . . . . . . . . . . . . . . . . . . . 4-7

Editing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Configuring Modules in a Remote Chassis . . . . . . . . . . . . . 4-9

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 4-11

Chapter 5

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 5-1

Determining Module Compatibility . . . . . . . . . . . . . . . . . . 5-2

Module Features That Can Be Configured . . . . . . . . . . . . . 5-3

Two Operational Modes. . . . . . . . . . . . . . . . . . . . . . . . 5-3

Enable CST Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Latch CST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Chatter Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Software Configurable Input Filters. . . . . . . . . . . . . . . . 5-10

Electronic Keying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Module Inhibiting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Other Inherent Module Features . . . . . . . . . . . . . . . . . . . . 5-16

Removal and Insertion Under Power (RIUP) . . . . . . . . . 5-16

Module Fault Reporting . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Fully Software Configurable . . . . . . . . . . . . . . . . . . . . . 5-17

Producer/Consumer Model. . . . . . . . . . . . . . . . . . . . . . 5-17

Status Indicator Information . . . . . . . . . . . . . . . . . . . . . 5-18

Full Class I Division 2 Compliance . . . . . . . . . . . . . . . . 5-19

Agency Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 5-19

Publication 1756-UM528A-EN-P - April 2004

Page 9

Using The Sequence of Events

Module in CST Per Point Mode

Table of Contents 3

Chapter 6

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 6-1

Overview of the Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

How Does the Module Store Timestamp Data in CST

Per Point Mode? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

What Are The Typical Applications Where CST Per Point

Mode is Used?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Configuring the Module for CST Per Point Mode . . . . . . . . 6-4

Choosing a Communications Format. . . . . . . . . . . . . . . 6-5

Using Latch CST in CST Per Point Mode . . . . . . . . . . . . 6-6

Using Enable CST Capture in CST Per Point Mode. . . . . 6-7

Managing the Data in CST Per Point Mode . . . . . . . . . . . . . 6-8

Module Sends Data to the Controller . . . . . . . . . . . . . . 6-8

Copying Relevant Input Data to a Separate

Data Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Acknowledging Latched Timestamp Data . . . . . . . . . . . 6-12

Sorting the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Clearing All Data From the Module’s Buffers At Once. . . . . 6-14

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 6-14

Using The Sequence of Events

Module in FIFO Mode

Chapter 7

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 7-1

Overview of the Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How Does the On-Board Buffer Work in FIFO Mode? . . . . 7-2

What the Typical Applications Where FIFO Mode is Used? . 7-4

Configuring the Module for FIFO Mode . . . . . . . . . . . . . . . 7-4

Choosing a Communications Format. . . . . . . . . . . . . . . 7-5

Using Latch CST in FIFO Mode. . . . . . . . . . . . . . . . . . . 7-6

Using Enable CST Capture in FIFO Mode . . . . . . . . . . . 7-9

Managing the Data in FIFO Mode . . . . . . . . . . . . . . . . . . . 7-10

Retrieving Data in FIFO Mode . . . . . . . . . . . . . . . . . . . 7-10

Producing Current Event Data . . . . . . . . . . . . . . . . . . . 7-14

Copying Relevant Input Data to a Separate

Data Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Acknowledging Latched Timestamp Data . . . . . . . . . . . 7-17

Clearing All Data From the Module’s Buffers At Once. . . . . 7-20

Changing Between Retrieval Methods . . . . . . . . . . . . . . . . 7-20

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 7-20

Publication 1756-UM528A-EN-P - April 2004

Page 10

Table of Contents 4

Troubleshooting the Sequence of

Events Module

Specifications and Module

Block Diagrams

Integrating The HiProm GPS

Module (1756HP-GPS) into a

ControlLogix Sequence of Events

Module System

Chapter 8

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 8-1

Using LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Using RSLogix 5000 To Troubleshoot the Module. . . . . . . . 8-2

Determining Fault Type . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Chapter Summary and What’s Next . . . . . . . . . . . . . . . . . . 8-4

Appendix A

1756-IB16ISOE Specifications. . . . . . . . . . . . . . . . . . . . . . . A-1

1756-IB16ISOE Module Block Diagram . . . . . . . . . . . . . . . A-4

1756-IH16ISOE Specifications . . . . . . . . . . . . . . . . . . . . . . A-5

1756-IH16ISOE Module Block Diagram . . . . . . . . . . . . . . . A-8

Appendix B

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

What is the 1756HP-GPS Module? . . . . . . . . . . . . . . . . . . . B-2

Correlating CST with UCT . . . . . . . . . . . . . . . . . . . . . . B-2

Determining the Absolute First Fault Across Multiple Chassis B-4

How Does the ControlLogix Controller Retrieve

Converted Value from the 1756HP-GPS Module? . . . . . . . . B-6

Converting Timestamps from CST Format to Universal

Coordinated Time Format . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Synchronizing CSTs Across

Multiple Chassis

Using Module Tags

Using Sample RSLogix 5000

Projects with the Sequence of

Events Module

Glossary

Appendix C

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Using a Time Master . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Configuring 1756-SYNCH Modules in RSLogix 5000. . . . C-3

Synchronizing Chassis in ControlLogix Redundancy Systems C-4

Related SynchLink Documentation. . . . . . . . . . . . . . . . . . . C-5

Appendix D

Fault and Status Reporting Between the Module

and Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Module Tag Names and Definitions . . . . . . . . . . . . . . . . . . D-2

Tags Used in CST Point Per Mode . . . . . . . . . . . . . . . . D-2

Tags Used in FIFO Mode . . . . . . . . . . . . . . . . . . . . . . . D-7

Appendix E

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Accessing the Sample Projects . . . . . . . . . . . . . . . . . . . . . . E-2

Index

Publication 1756-UM528A-EN-P - April 2004

Page 11

Chapter

What is the ControlLogix Sequence of

Events Module?

1

What This Chapter Contains

What does Sequence of Events Module Do?

This chapter describes the ControlLogix Sequence of Events module.

Table 1.1

For information on: See page:

What does Sequence of Events Module Do? 1-1

What Else Does the Sequence of Event Module Do? 1-3

Understanding the Module’s Physical Features 1-4

Using Module Identification and Status Information 1-5

The ControlLogix Sequence of Events module is a DC input module

that offers sub-millisecond timestamping on a per point basis in

addition to providing the basic ON/OFF detection as found on other

ControlLogix input modules.

Timestamping is a ControlLogix feature that registers a time reference

to a change in input data. In ControlLogix, the time mechanism used

for timestamping is the Coordinated System Time (CST).

Timestamping Using the Coordinated System Time (CST)

The Coordinated System Time (CST) is a 64-bit, free-running timer

with microsecond (µs) granularity on a ControlLogix backplane. A

time master (either a ControlLogix controller or 1756-SYNCH

module) generates the timer and sets it on the backplane. All other

modules in the chassis have access to the CST and adjust their time

reference based on the backplane time reference.

1 Publication 1756-UM528A-EN-P - April 2004

Page 12

1-2 What is the ControlLogix Sequence of Events Module?

CST cannot easily translate to real-time but serves as a relative time

reference. Each module in a chassis has access to this reference. The

Sequence of Events module grabs the current CST value at the time of

the input state change to timestamp the input data.

You can propagate the same CST value across multiple chassis,

effectively making sure that modules in separate chassis use the same

time reference in all their operations, if necessary.

You can extend a single CST value across multiple chassis that are

physically connected via 1756-SYNCH modules. Additionally, multiple

ControlLogix systems–even those that are geographically separated–

can use the 1756HP-GPS module to share a common real-time

reference. For more information on extending a single CST value

across multiple chassis, see Appendix C.

On-Board Data Storage

Once a CST timestamp is captured for an input transition, the

module’s operational mode impacts how the module functions with

respect to:

• what data is stored on-board

• how much data is stored for each input point

• how the data is sent to the controller

The next section briefly describes the two modes of operation

available with the Sequence of Events module and how they impact

the module’s behavior.

Publication 1756-UM528A-EN-P - April 2004

Page 13

What is the ControlLogix Sequence of Events Module? 1-3

Two Modes of Operation

The Sequence of Events module can operate in either of the modes

described in Table 1.2:

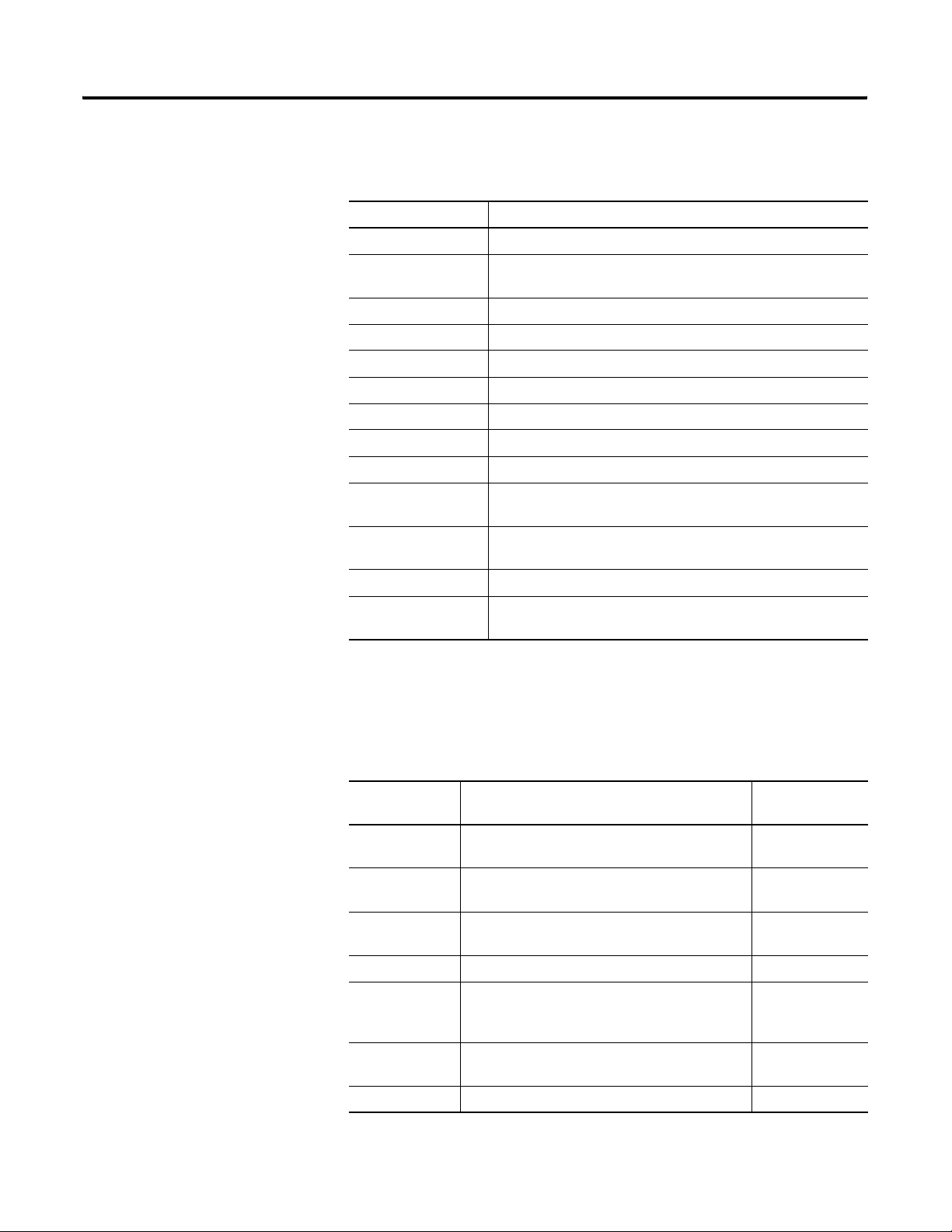

Table 1.2

Operational mode: Description:

CST Per Point Mode The module timestamps up to 2 input transitions per input, one for OFF to ON transitions and another

for ON to OFF transitions.

First In First Out (FIFO) Mode The module timestamps an unlimited number of input transitions, regardless of direction (i.e., either

OFF to ON or ON to OFF) or input (i.e., the same input can transition many times and the module will

timestamp every transition) and stores them in an on-board buffer.

The module is capable of storing the data for up to 160 input transitions in its on-board buffers at a

single time. However, if you retrieve data from the buffers effectively, the module will never miss an

input transition, regardless of how many occur.

You set the module’s operational mode when you choose a

communication format during initial module configuration.

Depending on operational mode, RSLogix 5000 creates different tags

for the Sequence of Events when it is added to a project.

What Else Does the Sequence of Event Module Do?

For more information on each mode, see Chapter 6, Using The

Sequence of Events Module in CST Per Point Mode and Chapter 7,

Using The Sequence of Events Module in FIFO Mode.

The Sequence of Events module offers additional features that are

common to ControlLogix digital input modules, such as:

• Full software configuration via RSLogix 5000

• Removal and insertion under power

• Full Class I Division Compliance

• Agency Certifications (e.g. UL and CSA)

To see a full description of all the features available on your Sequence

of Events module, see Chapter 5, Using the Sequence of Events

Module Features.

Publication 1756-UM528A-EN-P - April 2004

Page 14

1-4 What is the ControlLogix Sequence of Events Module?

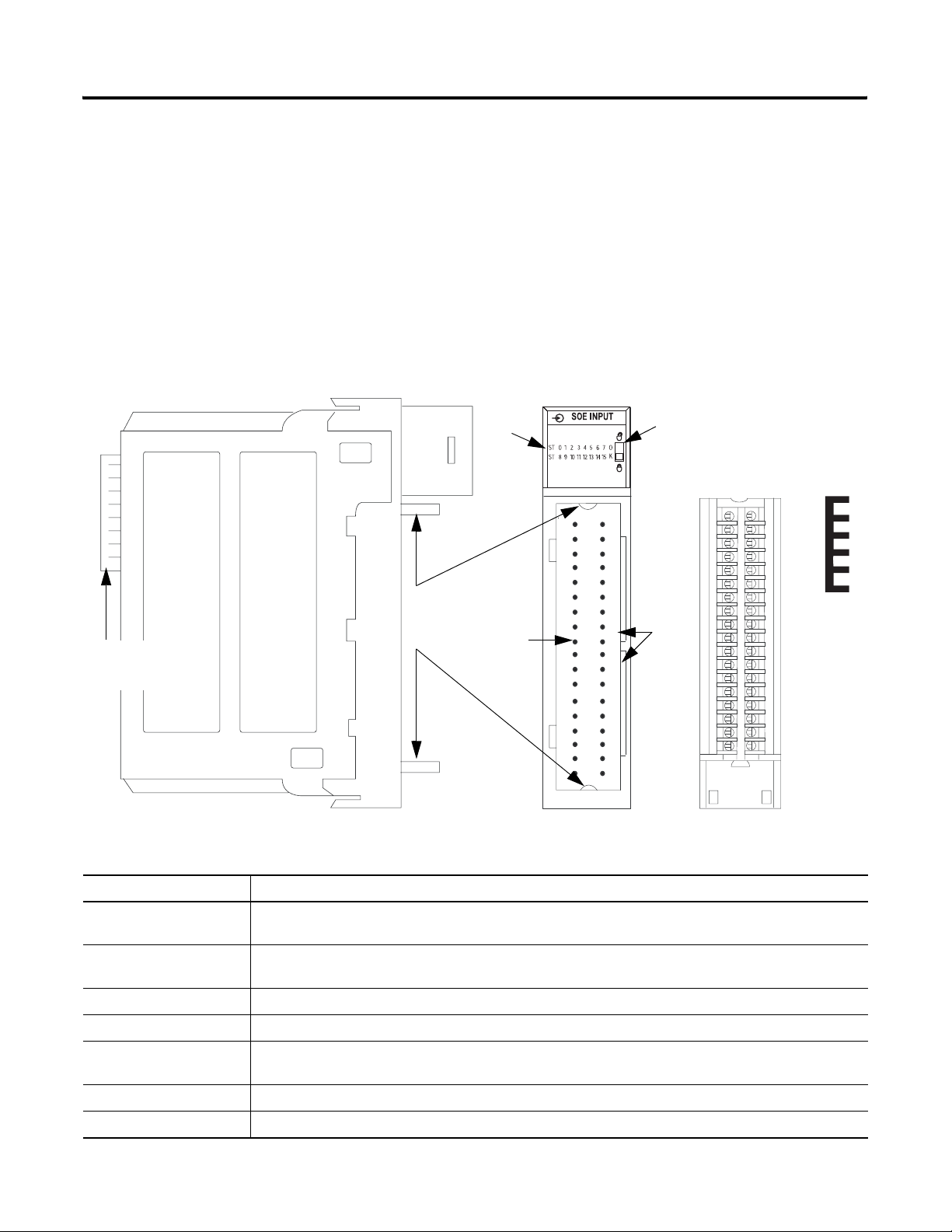

Understanding the Module’s Physical Features

ControlLogix modules mount in a ControlLogix chassis and use a

Removable Terminal Block (RTB), or a Bulletin 1492 Interface Module

cable that connects to an IFM, to connect all field-side wiring. Before

you use your module, you should have already:

• installed and grounded a 1756 chassis and power supply. To

install these products, refer to the publications listed in

Table Preface.3 on page Preface-2.

• ordered and received an RTB or IFM and its components for

your application; neither RTBs nor IFMs are included with your

module purchase.

Figure 1.1

Indicators Locking tab

O

K

Removable terminal

block

Jumper

bar

Top and

ControlLogix

backplane

bottom

guides

Connector

pins

Slots

for

keying

the

RTB

41623

Table 1.3 Physical Features on the ControlLogix Sequence of Events Module

Physical Feature: Description:

Backplane connector The backplane connector interface for the ControlLogix system connects the module to the ControlLogix

backplane.

Connector pins Input/output, power and grounding connections are made to the module through these pins with the use of

an RTB or IFM.

Locking tab The locking tab anchors the RTB or IFM cable on the module, maintaining wiring connections.

Slots for keying Mechanically keys the RTB to prevent inadvertently making the wrong wire connections to your module.

Status indicators Indicators display the status of communication, module health and input/output devices. Use these

indicators to help in troubleshooting.

Top and bottom guides Guides provide assistance in seating the RTB or IFM cable onto the module.

Jumper bar Device you can use to connect multiple points in non-isolated wiring application, as shown on page 3-6.

Publication 1756-UM528A-EN-P - April 2004

Page 15

What is the ControlLogix Sequence of Events Module? 1-5

Using Module Identification and Status Information

Each Sequence of Events module maintains specific identification

information that separates it from all other modules. This information

assists you in tracking all the components of your system. For

example, you can track module identification information to be aware

of exactly what modules are located in any ControlLogix chassis at

any time. While retrieving module identity, you can also retrieve the

module’s status.

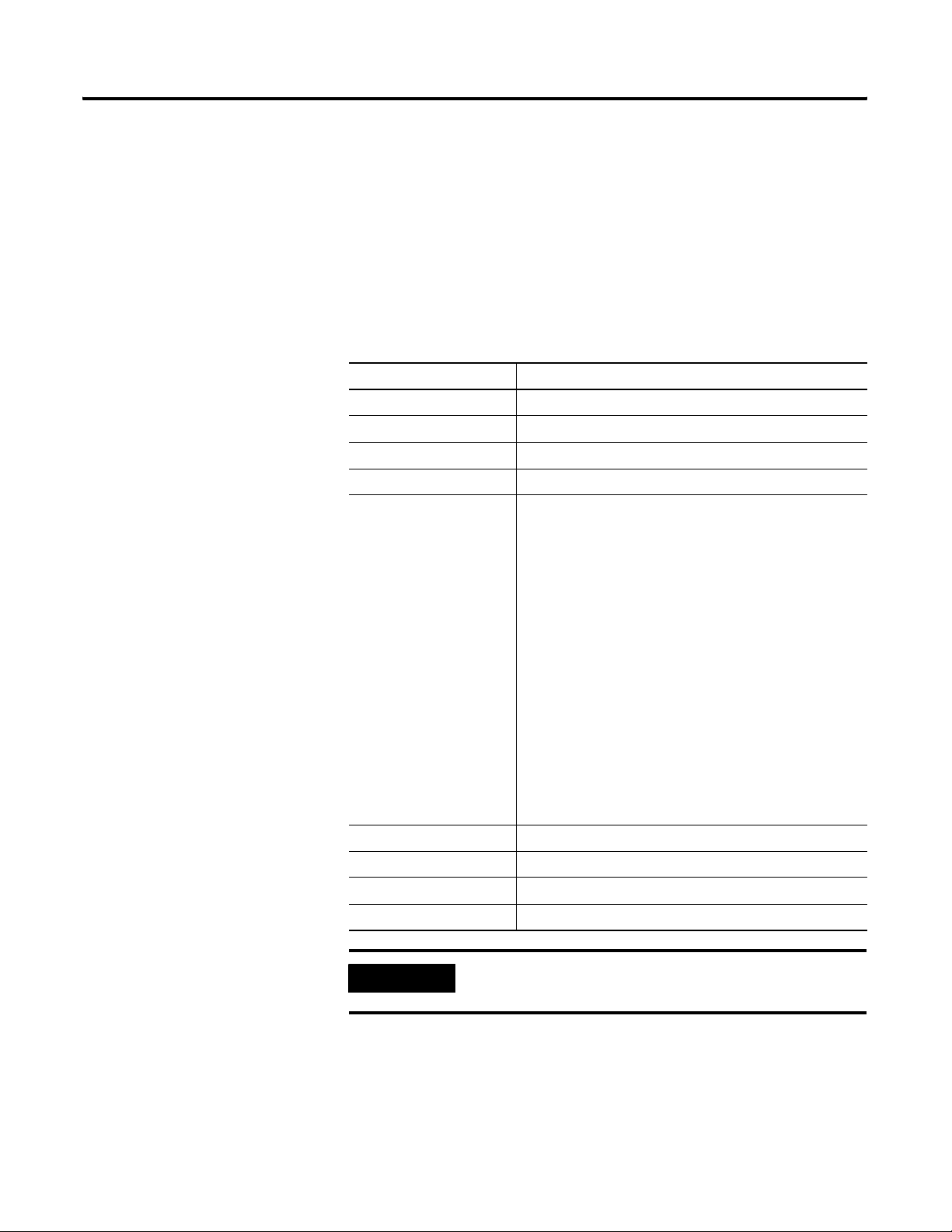

Each module maintains the information listed in Table 1.4:

Table 1.4 Module Identification and Status Information

Module Identification: Description:

Product Type Module’s product type

Product Code Module’s catalog number

Major Revision Module’s major revision number

Minor Revision Module’s minor revision number

Status Module’s status. Returns the following information:

• Controller ownership (if any)

• Whether module has been configured

• Device Specific Status, such as:

• Self-Test

• Flash update in progress

• Communications fault

• Not owned

• Internal fault (need flash update)

• Run mode

• Minor recoverable fault

• Minor unrecoverable fault

• Major recoverable fault

• Major unrecoverable fault

Vendor ID Module manufacturer vendor, for example Allen-Bradley

Serial Number Module serial number

Length of ASCII Text String Number of characters in module’s text string

ASCII Text String Module’s ASCII text string description

IMPORTANT

You must perform a WHO service to retrieve this

information.

Publication 1756-UM528A-EN-P - April 2004

Page 16

1-6 What is the ControlLogix Sequence of Events Module?

Chapter Summary and What’s Next

In this chapter you read about what the ControlLogix Sequence of

Events module is. Chapter 2 explains How Does the Sequence of

Events Module Operate in a ControlLogix System?

Publication 1756-UM528A-EN-P - April 2004

Page 17

Chapter

2

How Does the Sequence of Events Module

Operate in a ControlLogix System?

What This Chapter

This chapter describes how the Sequence of Events module

operates in a ControlLogix system.

Contains

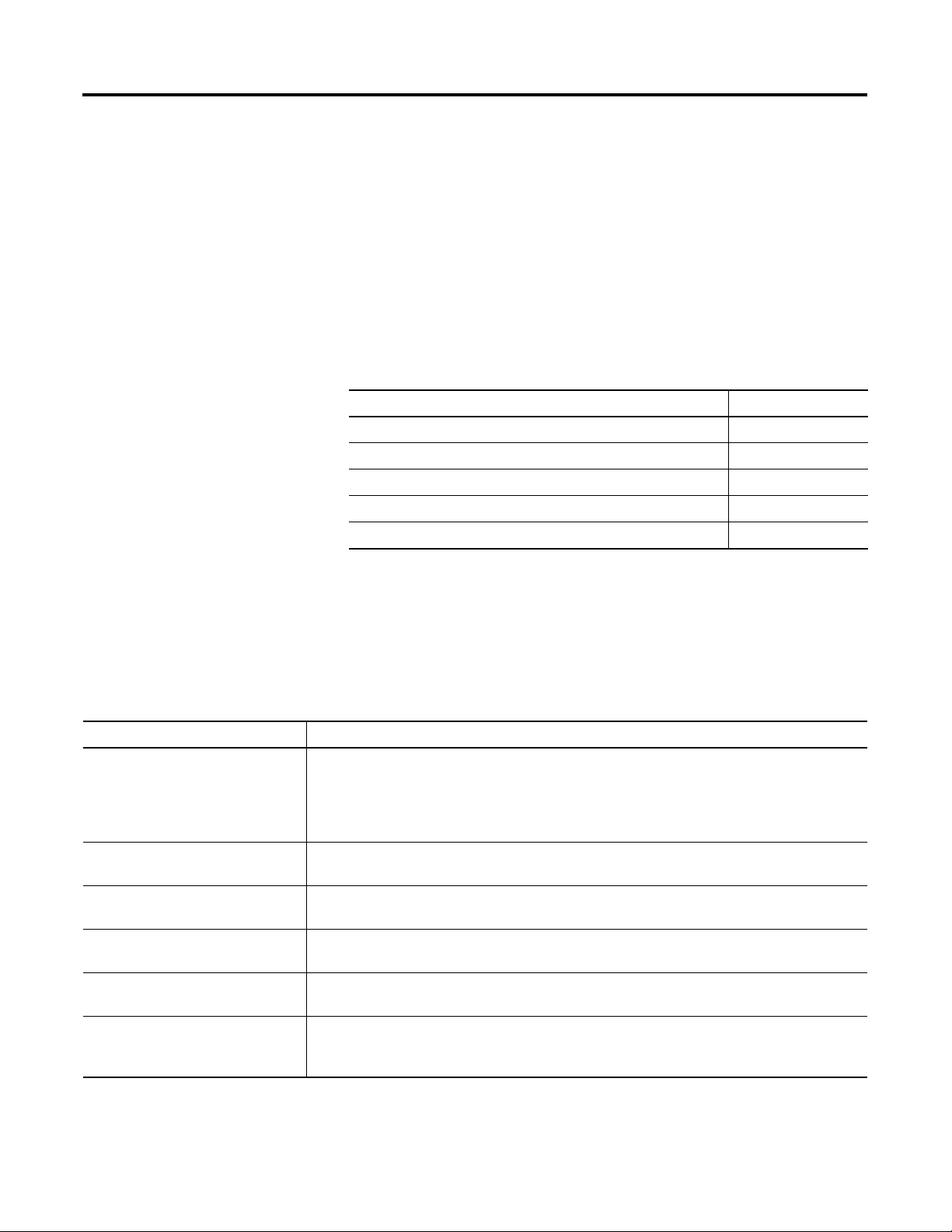

Table 2.1

For information on: See page:

Ownership 2-2

Using RSNetWorx and RSLogix 5000 2-2

Propagating a Signal From Field Device to Backplane 2-4

Sequence of Events Module in a Local Chassis 2-6

Sequence of Events Module in a Remote Chassis 2-8

Differences Between Sequence of Events Module and Standard Digital I/O

Table 2.2

Difference: Description:

Additional data produced for

controller

Only one owner-controller per module While multiple controllers can simultaneously own other digital input modules, the Sequence of

In many aspects, the Sequence of Events module behaves the same as

other ControlLogix digital input modules. However, the module offers

several significant differences from other ControlLogix digital input

modules, including those described in Table 2.2:

The Sequence of Events module produces significantly more data for its owner-controller than

standard ControlLogix digital input modules. While other input modules only produce ON/OFF and

fault status, the Sequence of Events module produces data such as ON/OFF and fault status,

timestamp data, indication of whether new data was produced for specific input points or if

transitions were not timestamped.

Events module only supports a single owner-controller.

Rack-optimized connections not

supported

Change of State (COS) functionality in

Enable CST Capture feature

No listen-only connections Controllers cannot make listen-only connections to the Sequence of Events module. All

Input filtering on a module-wide basis Other digital input modules offer input filtering on a per group basis. The Sequence of Events

1 Publication 1756-UM528A-EN-P - April 2004

The Sequence of Events module does not support Rack-Optimized Connections from the

owner-controller.

The module does support Enable CST Capture, a feature used to timestamp input transitions, that

is analogous to COS. For more information on Enable CST Capture, see page 2-6.

connections between the module and its owner-controller are direct connections.

module offers two input filter settings–one for OFF to ON transitions and one for ON to OFF

transitions–and is set on a module-wide basis.

Page 18

2-2 How Does the Sequence of Events Module Operate in a ControlLogix System?

Similar Functionality to

With respect to general module operation in a ControlLogix system,

the Sequence of Events module operates similarly to other

Standard ControlLogix DC

Input Modules

ControlLogix digital input modules in many ways. This chapter

focuses on how the Sequence of Events module’s behavior differs

from that of other ControlLogix digital input modules.

However, you should be aware of aspects in which the Sequence of

Events module is similar to standard ControlLogix digital input

modules. For more information on these similarities, see Table 2.3.

Table 2.3 Ways that a Sequence of Events Module Behave Like Other ControlLogix Digital Input Modules

Concept: Description:

Ownership Every Sequence of Events module in the ControlLogix system must be owned by a Logix5000 controller. This

owner-controller:

• stores configuration data for every module that it owns.

• can be local or remote in regard to the Sequence of Events module’s position.

• sends the Sequence of Events module configuration data to define the module’s behavior and begin

operation with the control system.

This module does not support multiple owner-controllers.

Using RSNetWorx and

RSLogix 5000

The I/O configuration portion of RSLogix5000, v13 or greater, generates the configuration data for each

Sequence of Events module in the control system, whether the module is located in a local or remote chassis.

A remote chassis, also known as networked, contains the Sequence of Events module but not the module’s

owner-controller. Remote chassis can be connected to the controller via a scheduled ControlNet or an

EtherNet/IP network.

Configuration data is transferred to the controller during the program download and subsequently transferred

to the appropriate Sequence of Events modules.

Sequence of Events modules in the local chassis, and modules in a remote chassis that is connected via the

EtherNet/IP network, are ready to run as soon as the configuration data has been downloaded. However, you

must run RSNetWorx for ControlNet to enable Sequence of Events modules in a scheduled ControlNet

chassis.

Running RSNetWorx transfers configuration data to Sequence of Events modules on scheduled ControlNet

and establishes a Network Update Time (NUT) for ControlNet that is compliant with the desired

communications options specified for each module during configuration.

Anytime a controller references a Sequence of Events module in a scheduled ControlNet chassis, you must

run RSNetWorx to configure ControlNet. Follow these general guidelines when configuring Sequence of

Events modules:

1. Configure all Sequence of Events modules for a given controller using RSLogix 5000 and download

that information to the controller.

2. If the module configuration data references a module in a remote chassis connected by scheduled

ControlNet, run RSNetWorx.

3. After running RSNetWorx, perform an online save of the RSLogix 5000 project so the configuration

information that RSNetWorx sends to the controller is saved.

IMPORTANT: You must run RSNetWorx whenever a new module is added to a scheduled ControlNet

chassis. When a module is permanently removed from a remote chassis, we recommend that RSNetWorx be

run to optimize the allocation of network bandwidth.

Publication 1756-UM528A-EN-P - April 2004

Page 19

How Does the Sequence of Events Module Operate in a ControlLogix System? 2-3

Table 2.3 Ways that a Sequence of Events Module Behave Like Other ControlLogix Digital Input Modules

Concept: Description:

Making Connections ControlLogix controllers can make direct or rack connections to digital I/O modules. The controller can only make

a direct connection to the Sequence of Events module. The controller cannot make rack connections to the

Sequence of Events module. Additionally, the controller cannot make listen-only connections to the

Sequence of Events module.

A direct connection is a real-time data transfer link between the controller and the device that occupies the slot

that the configuration data references. When module configuration data is downloaded to an owner-controller,

the controller attempts to establish a direct connection to each of the modules referenced by the data.

If a controller has configuration data referencing a slot in the control system, the controller periodically checks for

the presence of a device there. When a device’s presence is detected there, the controller automatically sends the

configuration data.

If the data is appropriate to the module found in the slot, a connection is made and operation begins. If the

configuration data is not appropriate, the data is rejected and an error message appears in the software. In this

case, the configuration data can be inappropriate for any of a number of reasons. For example, a module’s

configuration data may be appropriate except for a mismatch in electronic keying.

The controller maintains and monitors its connection with a module. Any break in the connection, such as module

faults or removal of the module from the chassis while under power, causes the controller to set fault status bits

in the data area associated with the module. RSLogix 5000 monitors connection status to annunciate the

modules’ failures.

Transmitting Data In the ControlLogix system, a controller does not poll the Sequence of Events module to obtain input status. When

you configure a Sequence of Events module to capture a CST value for a specific transition, the module produces

data whenever that input transitions and also at a user-configured rate. The type of input data transmitted and

transmission frequency depends on module configuration and where in the control system that input module

physically resides.

Triggering Event

Tasks

This is called the Producer/Consumer model. The Sequence of Events module produces the input data and the

controller consumes the data.

All Sequence of Events module inputs are updated asynchronous to the controller’s task execution. In other

words, an input may be updated in the controller at any time during the controller’s execution of the tasks it is

configured to run. The input device determines when the input is sent, based on its configuration.

You can configure Sequence of Events modules to trigger an event task. The event task offers ControlLogix

controller users a task that executes a section of logic immediately when an event (i.e., receipt of new, unseen,

data) occurs.

Your Sequence of Events module can trigger event tasks. When using a Sequence of Events module to trigger an

event task, remember these considerations:

• Only one input module can trigger a specific event task.

• The input module triggers the event task based on the Enable CST Capture configuration for the module.

The Enable CST Capture configuration defines which points prompt the module to produce data if they turn

ON or OFF. This production of data triggers the event task.

• Typically, Enable CST Capture for only one point on the module. If you Enable CST Capture for multiple

points, a task overlap of the event task may occur.

For more information on using Event tasks, see the Logix5000 Controllers Common Procedures Programming

Manual, publication 1756-PM001.

Publication 1756-UM528A-EN-P - April 2004

Page 20

2-4 How Does the Sequence of Events Module Operate in a ControlLogix System?

Propagating a Signal From Field Device to Backplane

As shown in Figure 2.1, the Sequence of Events module receives a

signal at the RTB and processes it internally before sending a signal to

the ControlLogix backplane via the Requested Packet Interval (RPI) or

at na Enable CST Capture occurrence.

However, when you operate the Sequence of Events module, you

must account for signal propagation delays that exist during internal

processing. Some of these delays are inherent to the module and

others can be controlled via the user-defined module configuration.

During processing, the following delays exist:

• hardware delay - varies according to module type (i.e., catalog

number) and input transition type (i.e., OFF to ON/ON to OFF)

IMPORTANT

The hardware delay is relatively consistent across

inputs on a module and across modules in a chassis.

Therefore, assuming the inputs and modules are

used in similar environmental conditions and with

similar voltages applied, the hardware delay is a

minor consideration affecting timestamping accuracy.

• input filter delay - user-configurable number from 0 to 50ms

• firmware scan time - up to 25µs, depending on when the input

transitions relative to the sample time

• ASIC delay - 25µs

Typically, the Sequence of Events module can deliver a signal to the

ControlLogix backplane within 275µs in FIFO mode and 725µs in CST

Per Point mode after it was received at the removable terminal block

(RTB); these 275µs or 725µs numbers represent a scenario where the

hardware delay is at maximum levels but no input filter is used.

TIP

For fastest propagation of a signal from a field device

to the controller, use the module in FIFO mode in a

local chassis.

Publication 1756-UM528A-EN-P - April 2004

Page 21

Figure 2.1

How Does the Sequence of Events Module Operate in a ControlLogix System? 2-5

Digital

CST captured here

signal

processor

Signal applied

at the RTB

For OFF to ON:

For ON to OFF:

1756-IB16ISOE

• 10µs - nominal

• 20µs - maximum

• 25µs - nominal

• 50µs - maximum

EXAMPLE

Hardware

delay

For OFF to ON:

For ON to OFF:

Filter

delay

User configurable

0 - 50ms

1756-IH16ISOE

• 10µs - nominal

• 20µs - maximum

• 50µs - nominal

• 75µs - maximum

Scan

time

Up to 25µs

ASIC

delay

Typi ca ll y

175µs - FIFO

mode or

625µs - CST

Per Point

mode

Many factors (e.g. voltage, operating temperature, if

the module is turning ON or OFF) affect the signal

propagation delay on a module. But a nominal delay

time can be estimated.

For example, if you are turning ON a

1756-IB16ISOE module at 24V dc in 25°C

conditions, the signal propagation delay is

affected by:

Signal

sent to

backplane

42701

• hardware delay to energize the module

(nominally 10µS on this module)

• user-configurable input filter time (0 to 50ms)

• firmware scan time (up to 25µs)

• ASIC delay (175µs - FIFO mode/625µs - CST Per

Point mode)

In the typical case scenario (i.e., filter time of 0ms),

the module has a signal propagation delay of

approximately 210µs (FIFO) to 660µs (CST Per

Point).

Publication 1756-UM528A-EN-P - April 2004

Page 22

2-6 How Does the Sequence of Events Module Operate in a ControlLogix System?

Sequence of Events Module in a Local Chassis

When a Sequence of Events module resides in the local chassis (i.e.,

the same chassis as the owner-controller), the following two

configuration parameters affect how and when an input module

multicasts data:

Requested Packet Interval (RPI)

This interval specifies the rate at which a module multicasts its data to

the controller. The time ranges from 250µs to 750ms and is sent to the

module with all other configuration parameters. When the specified

time frame elapses, the module multicasts data. This is also called a

cyclic update.

Because each operational mode (CST Per Point or FIFO) generates a

unique set of controller tags, the operational mode determines exactly

what data is sent to the controller at the RPI. For more information on

which tags are generated in each operational mode and, therefore,

what data is sent to the controller at each RPI, see Appendix D, Using

Module Tags.

• Requested Packet Interval (RPI)

• Enable CST Capture

Enable CST Capture

Enable CST Capture instructs the Sequence of Events module to

capture the CST whenever specific input points transition. You can

use this feature to instruct the module to capture the CST when the

inputs transition from:

• OFF to ON only

• ON to OFF only

or

• both OFF to ON and ON to OFF

Publication 1756-UM528A-EN-P - April 2004

Page 23

How Does the Sequence of Events Module Operate in a ControlLogix System? 2-7

When Enable CST Capture is enabled for specific points and

transitions occur for those points, the Sequence of Events

module not only captures the CST at the transition occurrence

but also sends input data to the controller.

Because the RPI and Enable CST Capture functions are asynchronous

to the program scan, it is possible for an input to change state during

program scan execution. The point must be “buffered” to prevent this.

Copy the input data from your input tags to another structure and use

the data from there.

TIP

IMPORTANT

To minimize traffic and conserve bandwidth, we

recommend you use a larger RPI value if the

Enable CST Capture option is used and the module

is located in the same chassis as its owner.

All points on the Sequence of Events module have

Enable Capture CST enabled by default for both

ON to OFF and OFF to ON.

Additionally, you must specify an RPI regardless of

whether you use Enable Capture CST on any input

points. The default RPI at module creation in an

RSLogix 5000 project is 10ms.

Publication 1756-UM528A-EN-P - April 2004

Page 24

2-8 How Does the Sequence of Events Module Operate in a ControlLogix System?

Sequence of Events Module

If your Sequence of Events module physically resides in a chassis

other than where the owner-controller is (e.g. a remote chassis

in a Remote Chassis

connected via ControlNet), the role of the RPI and the module’s

Enable CST Capture behavior changes slightly with respect to getting

data to the owner-controller.

The RPI and Enable CST Capture behavior still define when the

module multicasts data within its own chassis (as described in the

previous section), but only the value of the RPI determines when the

owner-controller receives it over the network.

Remote Input Module Connected Via ControlNet

When a Sequence of Events module resides in a remote chassis

connected by a scheduled ControlNet network, the RPI:

• instructs the module to multicast data in its own chassis at a

specific interval.

• reserves a “spot” in the stream of data flowing across the

ControlNet network.

The timing of this “reserved” spot may or may not coincide with the

exact value of the RPI, but the control system guarantees that the

owner-controller receives data at least as often as the specified RPI.

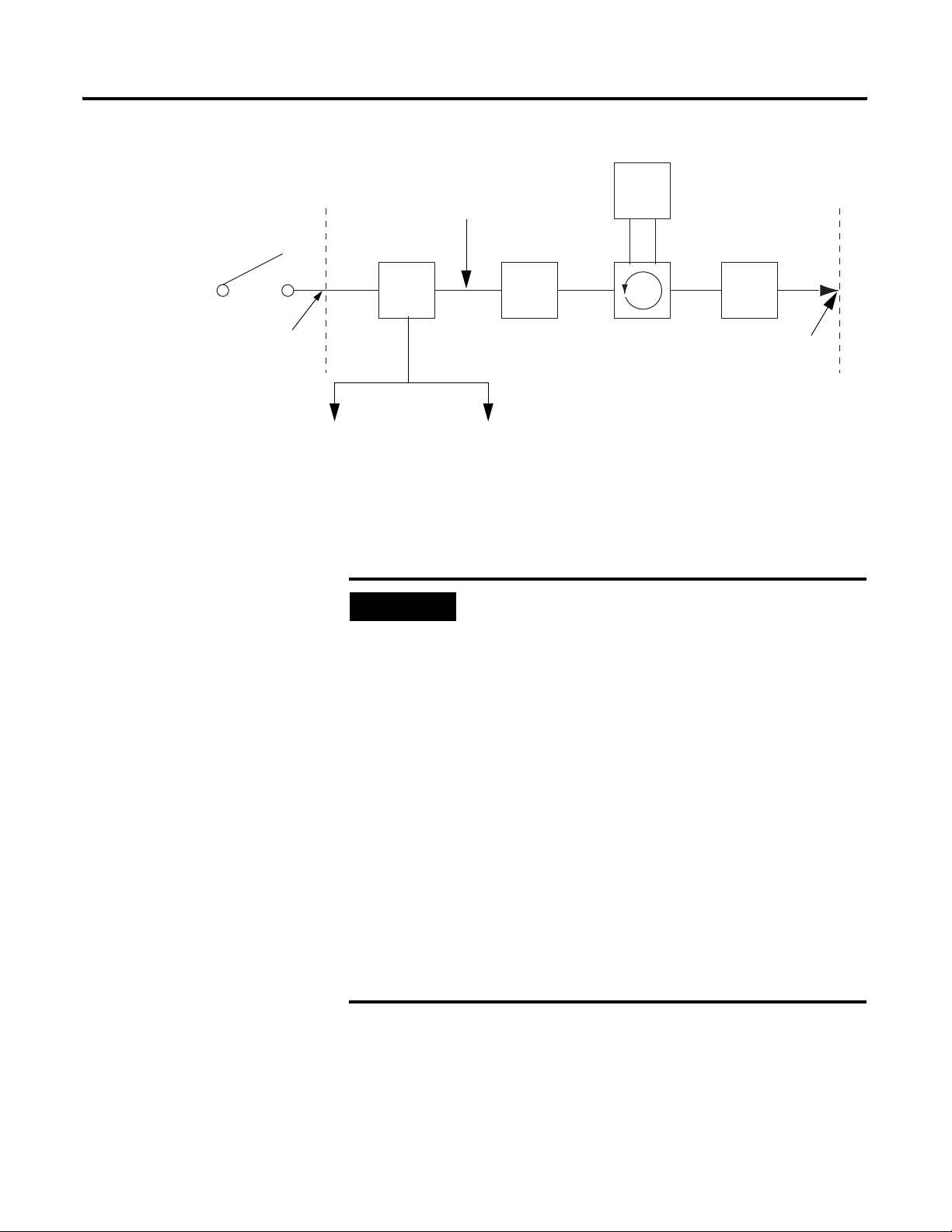

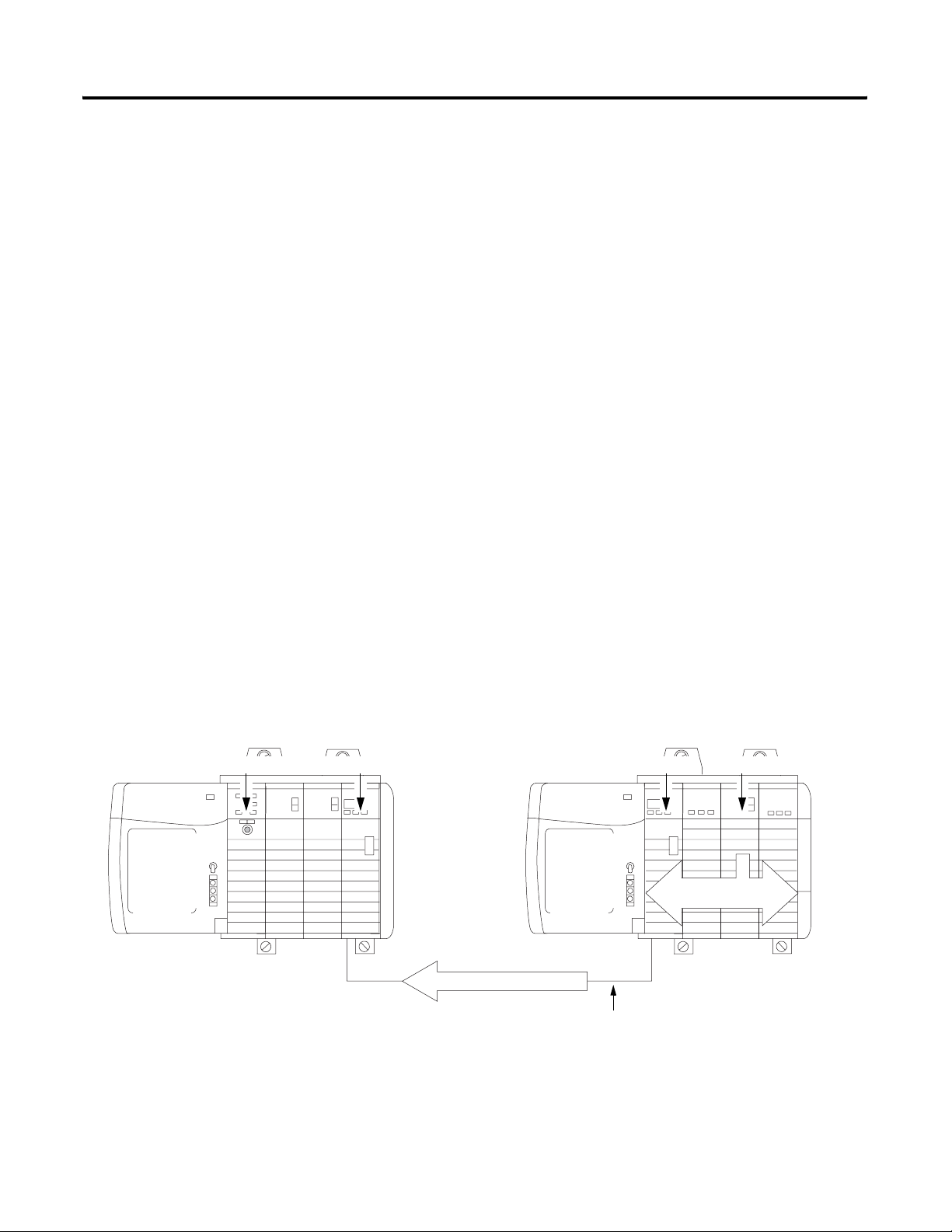

Figure 2.2 Sequence of Events Module in Remote Chassis with Data Coming At

Least as Often as RPI

Owner-controller ControlNet Bridge module Sequence of Events moduleControlNet Bridge module

Input data multicast in

module’s chassis at RPI

Input data at least as often as RPI

ControlNet

40947

Publication 1756-UM528A-EN-P - April 2004

Page 25

How Does the Sequence of Events Module Operate in a ControlLogix System? 2-9

The “reserved” spot on the network and the module’s RPI are

asynchronous to each other. This means there are Best and Worst Case

scenarios as to when the owner-controller will receive updated

channel data from the module in a remote chassis.

Best Case RPI Multicast Scenario

In the Best Case scenario, the module performs an RPI multicast with

updated channel data just before the “reserved” network slot is made

available. In this case, the owner-controller receives the data almost

immediately.

Worst Case RPI Multicast Scenario

In the Worst Case scenario, the module performs an RPI multicast just

after the “reserved” network slot has passed. In this case, the

owner-controller does not receive data until the next available

network slot.

IMPORTANT

Enabling the Enable CST Capture feature on an

input module in a remote chassis allows the

module to multicast data at both the RPI rate and

when the input changes state. This helps to

reduce the Worst Case time.

Table 2.4 summarizes the Best Case and Worst Case scenarios, from

the time an input changes state to the time the owner-controller will

receive the data:

Table 2.4 Best and Worst Case Scenarios For Remote Input Data Transfer

Best case scenario Worst case scenario

Enable CST Capture

disabled

Enable CST Capture

enabled

Backplane/Network

transfer times (<1mS)

Backplane/Network

transfer times (<1mS)

Twice the RPI

RPI

Publication 1756-UM528A-EN-P - April 2004

Page 26

2-10 How Does the Sequence of Events Module Operate in a ControlLogix System?

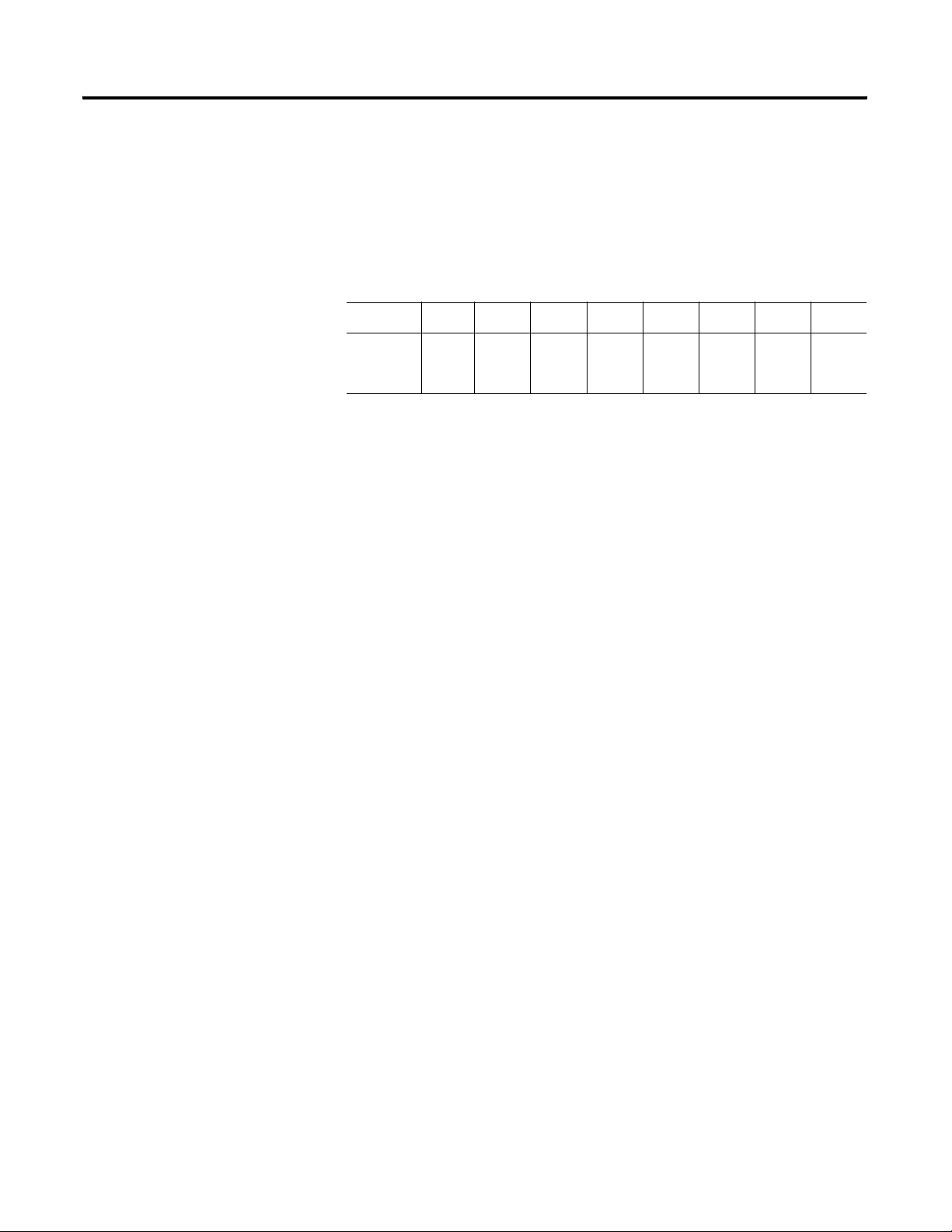

When selecting values for the remotely located module’s RPI,

system throughput is optimized when its RPI value is a power of 2

times the current NUT running on ControlNet.

For example, Table 2.5 shows recommended RPI values for a system

using a NUT of 5mS:

Table 2.5 Recommended RPI Values for System Using NUT of 5mS

NUT=5mS

Optimal

RPI Values

(mS)

0

x2

5mS 10mS 20mS 40mS 80mS 160mS 320mS 640mS

x2

1

x2

2

x2

3

x2

4

x2

5

x2

6

x2

7

Remote Input Modules Connected Via EtherNet/IP

When the Sequence of Events module is connected to the

owner-controller via an EtherNet/IP network, data is transferred to

the owner-controller in the following way:

• At the RPI or on an Enable CST Capture event, the module

multicasts data within its own chassis.

• The 1756-ENBT module in the remote chassis immediately

sends the module’s data over the network to the

owner-controller as long as it has not sent data within a time

frame that is 1/4 the value of the digital input module’s RPI.

For example, if a Sequence of Events module uses an RPI =

100ms, the 1756-ENBT module only sends module data

immediately on receiving it if another data packet was not

sent within the last 25ms.

Chapter Summary and What’s Next

Publication 1756-UM528A-EN-P - April 2004

In this chapter you read about how the Sequence of Events module

operates in a ControlLogix system.

Chapter 3 explains the Installing the Sequence of Events Module.

Page 27

Chapter

3

Installing the Sequence of Events Module

What This Chapter Contains

Installing the Sequence of

Events Module

This chapter describes how to install the Sequence of Events

module.

Table 3.1

For information on: See page:

Installing the Sequence of Events Module 3-1

Keying the Removable Terminal Block 3-3

Connecting Wiring 3-4

Assembling The Removable Terminal Block and the Housing 3-7

Choosing the Extended-Depth Housing 3-8

Installing the Removable Terminal Block 3-10

Removing the Removable Terminal Block 3-12

Removing the Module from the Chassis 3-13

You can install or remove the module while chassis power is

applied.

ATTENTION

The module is designed to support Removal and

Insertion Under Power (RIUP). However, when

you remove or insert an RTB with field-side power

applied, unintended machine motion or loss of

process control can occur. Exercise extreme

caution when using this feature.

1 Publication 1756-UM528A-EN-P - April 2004

Page 28

3-2 Installing the Sequence of Events Module

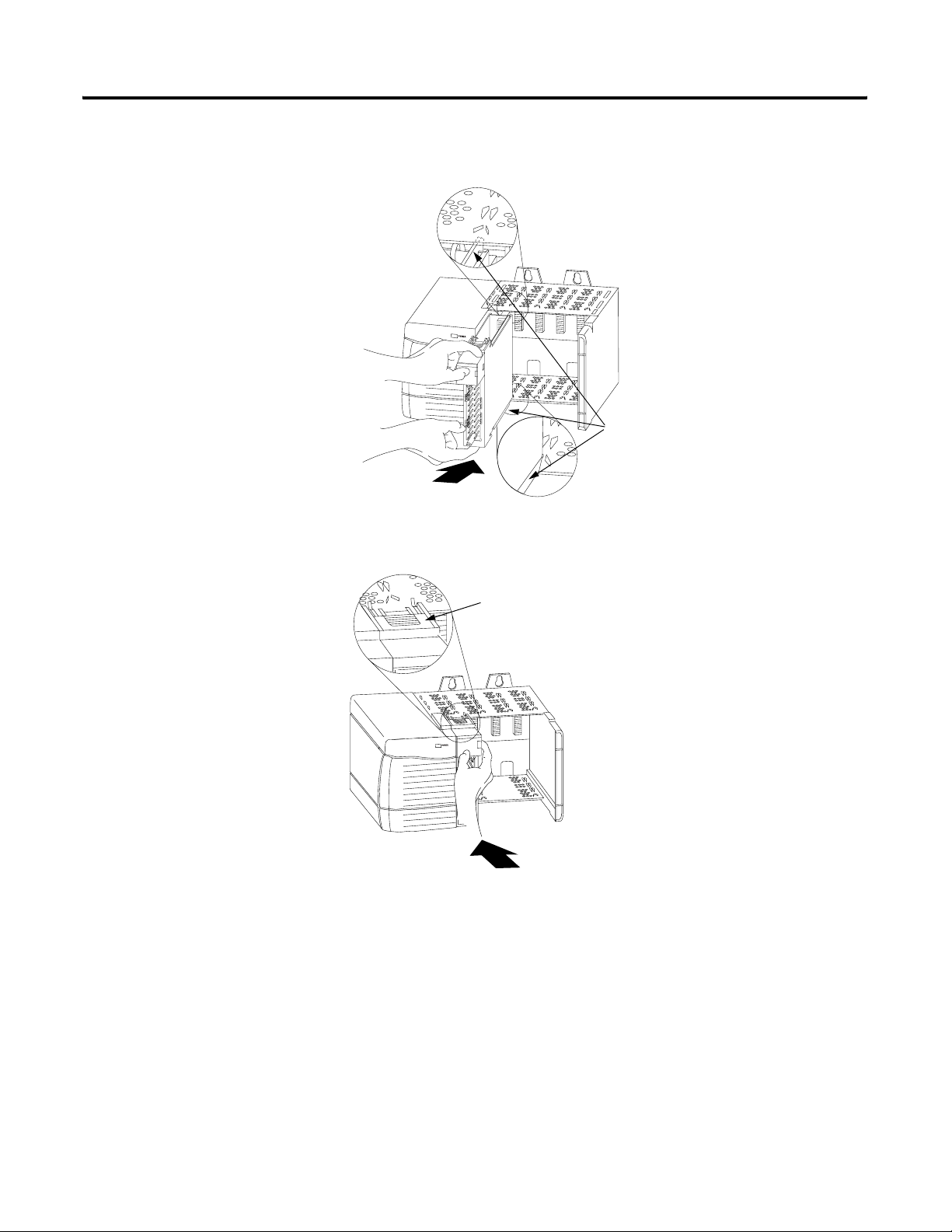

1. Align circuit board with top and bottom chassis guides.

Figure 3.1

Printed Circuit Board

20861-M

2. Slide module into chassis until module tabs ‘click’.

Figure 3.2

Locking Tab

20862-M

Publication 1756-UM528A-EN-P - April 2004

Page 29

Installing the Sequence of Events Module 3-3

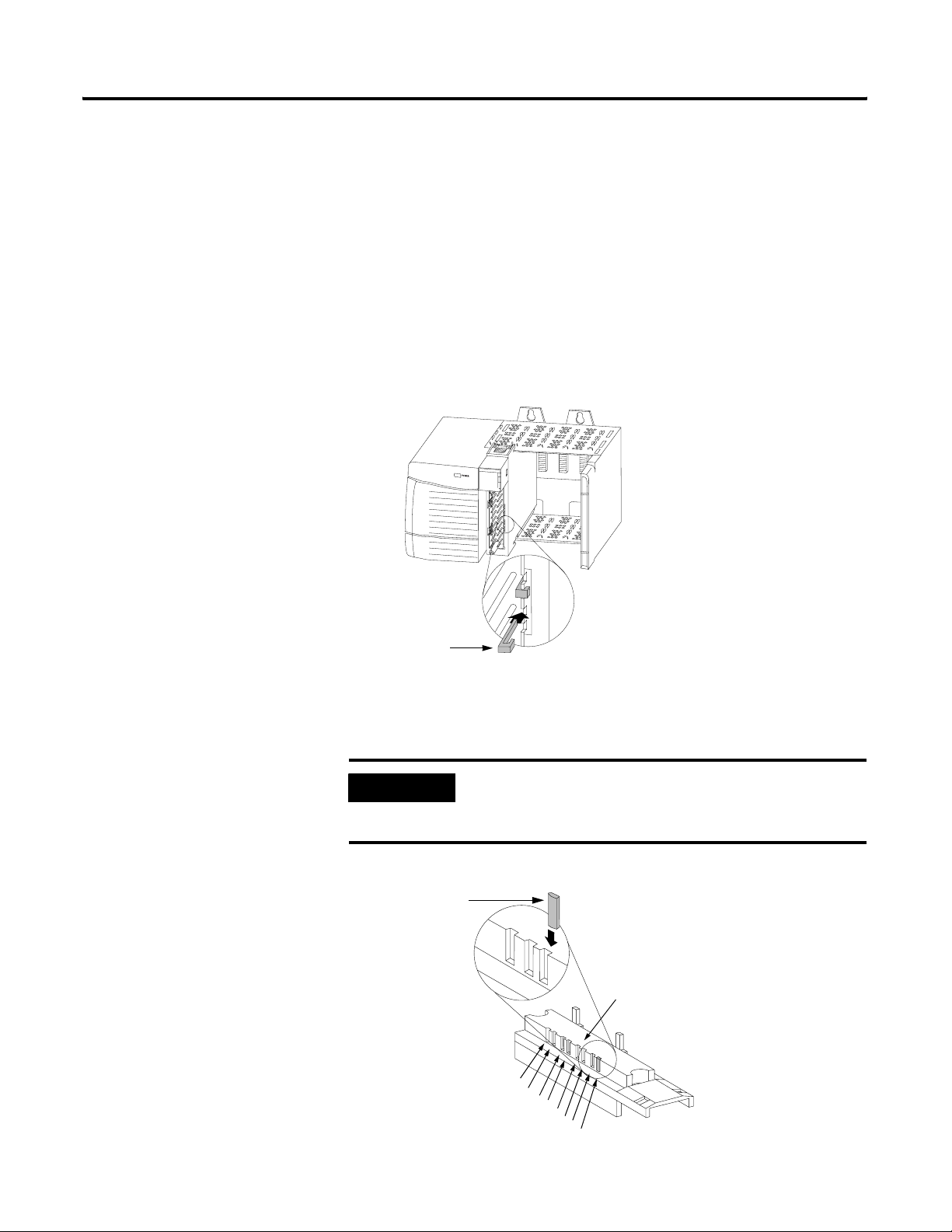

Keying the Removable Terminal Block

Key the RTB to prevent inadvertently connecting the incorrect RTB

to your module. When the RTB mounts onto the module, keying

positions match up. For example, if you place a U-shaped keying

band in position #4 on the module, you cannot place a

wedge-shaped tab in #4 on the RTB or your RTB does not mount

on the module. We recommend that you use a unique keying

pattern for each slot in the chassis.

1. Insert the U-shaped band with the longer side near the

terminals. Push the band onto the module until it snaps in

place.

Figure 3.3 .

U-shaped

Keying Band

20850-M

2. Key the RTB in positions that correspond to unkeyed module

positions. Insert the wedge-shaped tab on the RTB with the

rounded edge first. Push the tab onto the RTB until it stops.

IMPORTANT

When keying your RTB and module, you must

begin with a wedge-shaped tab in position #6 or

#7.

Figure 3.4

Wedge–shaped

Keying Tab

Module side of RTB

0

1

2

3

4

5

6

7

Publication 1756-UM528A-EN-P - April 2004

20851–M

Page 30

3-4 Installing the Sequence of Events Module

Connecting Wiring

You can use an RTB or a Bulletin 1492 prewired Interface Module

(IFM) to connect wiring to your module. You must connect wires

to the RTB. An IFM has been prewired before you received it. If

you are using an IFM to connect wiring to the module, skip this

section and go to page 3-7.

Wiring the RTB

You can use either of the following RTBs with your Sequence of

Events module.

• Cage Clamp RTB - Catalog number 1756-TBCH

• Spring Clamp RTB - Catalog number 1756-TBS6H

Wire the RTB with a 1/8 inch (3.2mm) maximum flat-bladed

screwdriver before installing it onto the module.

WARNING

When you connect or disconnect the Removable

Terminal Block (RTB) while field side power is on,

an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or that the area is nonhazardous

before proceeding.

Cage Clamp RTB

1. Strip 3/8 inch (9.5mm) maximum length of wire.

2. Insert the wire into the open terminal.

3. Turn the screw clockwise to close the terminal on the wire.

Figure 3.5

Strain relief area

20859-M

Publication 1756-UM528A-EN-P - April 2004

Page 31

Installing the Sequence of Events Module 3-5

Spring Clamp RTB

1. Strip 7/16 inch (11mm) maximum length of wire.

2. Insert the screwdriver into the inner hole of the RTB.

3. Insert the wire into the open terminal and remove the

screwdriver.

Figure 3.6

Strain relief area

20860-M

Recommendations for Wiring Your RTB

Consider the following guidelines when wiring your RTB:

• Begin wiring the RTB at the bottom terminals and move up.

• Use a tie to secure the wires in the strain relief area of the

RTB.

• The jumper bar part number is 97739201. Contact your local

Rockwell Automation sales representative to order additional

jumper bars, if necessary.

• Order and use an extended-depth housing (Catalog

number 1756-TBE) for applications that require heavy gauge

wiring. For more information, see page 3-8.

Publication 1756-UM528A-EN-P - April 2004

Page 32

3-6 Installing the Sequence of Events Module

Wiring the Sequence of Events Module

Isolated wiring

DC-0 (-)

DC-1 (-)

Source input wiring

DC-5 (-)

DC-6 (-)

Non-isolated wiring

Jumper bar

(Cut to length)

Use Figure 3.7 to wire your Sequence of Events module.

WARNING

If you connect or disconnect wiring while the

field-side power is on, an electrical arc can occur.

This could cause an explosion in hazardous

location installations. Be sure that power is

removed or the area is nonhazardous before

proceeding.

Figure 3.7

Sink input wiring

GND-0

GND-1

GND-2

GND-3

GND-4

GND-5

GND-6

GND-7

GND-8

GND-9

GND-10

GND-11

GND-12

GND-13

GND-14

12

34

56

78

910

1112

1314

1516

1718

1920

2122

2324

2526

2728

2930

IN-0

IN-1

IN-2

IN-3

IN-4

IN-5

IN-6

IN-7

IN-8

IN-9

IN-10

IN-11

IN-12

IN-13

IN-14

DC-0 (+)

DC-1 (+)

Source input wiring

DC-5 (+)

DC-6 (+)

Sink input wiring

DC (-)

Daisy chain to other RTBs

NOTES:

1. All terminals with the same name are connected together on the module. For example, DC (-) can be connected to either terminal marked

GND-15.

2. When you use the second GND-15 terminal to daisy chain to other RTBs, always connect the daisy chain to the terminal directly connected

to the supply wire, as shown in the example above.

3. If separate power sources are used, do not exceed the specified isolation voltage.

4. Do not connect more than 2 wires to any single terminal.

5. The jumper bar part number is 97739201. Contact your local Rockwell Automation sales representative to order jumper bars, if necessary.

Publication 1756-UM528A-EN-P - April 2004

GND-15

GND-15

Not used

3132

3334

3536

IN-15

Not used

Not used

DC (+)

40167-M

Page 33

Installing the Sequence of Events Module 3-7

Assembling The Removable

Removable housing covers the wired RTB to protect wiring

connections when the RTB is seated on the module.

Terminal Block and

the Housing

Figure 3.8

1. Align the grooves at the bottom of each side of the housing

with the side edges of the RTB.

Housing

Groove

Side edge of RTB

Groove

Strain relief area

Side edge of RTB

RTB

1756-TBCH RTB shown for reference

2. Slide the RTB into the housing until it snaps into place.

IMPORTANT

If additional wire routing space is required for your

application, use extended-depth housing

1756-TBE.

20858-M

Publication 1756-UM528A-EN-P - April 2004

Page 34

3-8 Installing the Sequence of Events Module

Choosing the Extended-Depth Housing

There are two housing options you must consider when wiring

your Sequence of Events module–standard-depth or extended-depth.

When you order an RTB for your module, you receive a

standard-depth housing with the RTB. If your application uses

heavy gauge wiring, you can order an extended-depth housing.

This housing does not come with an RTB.

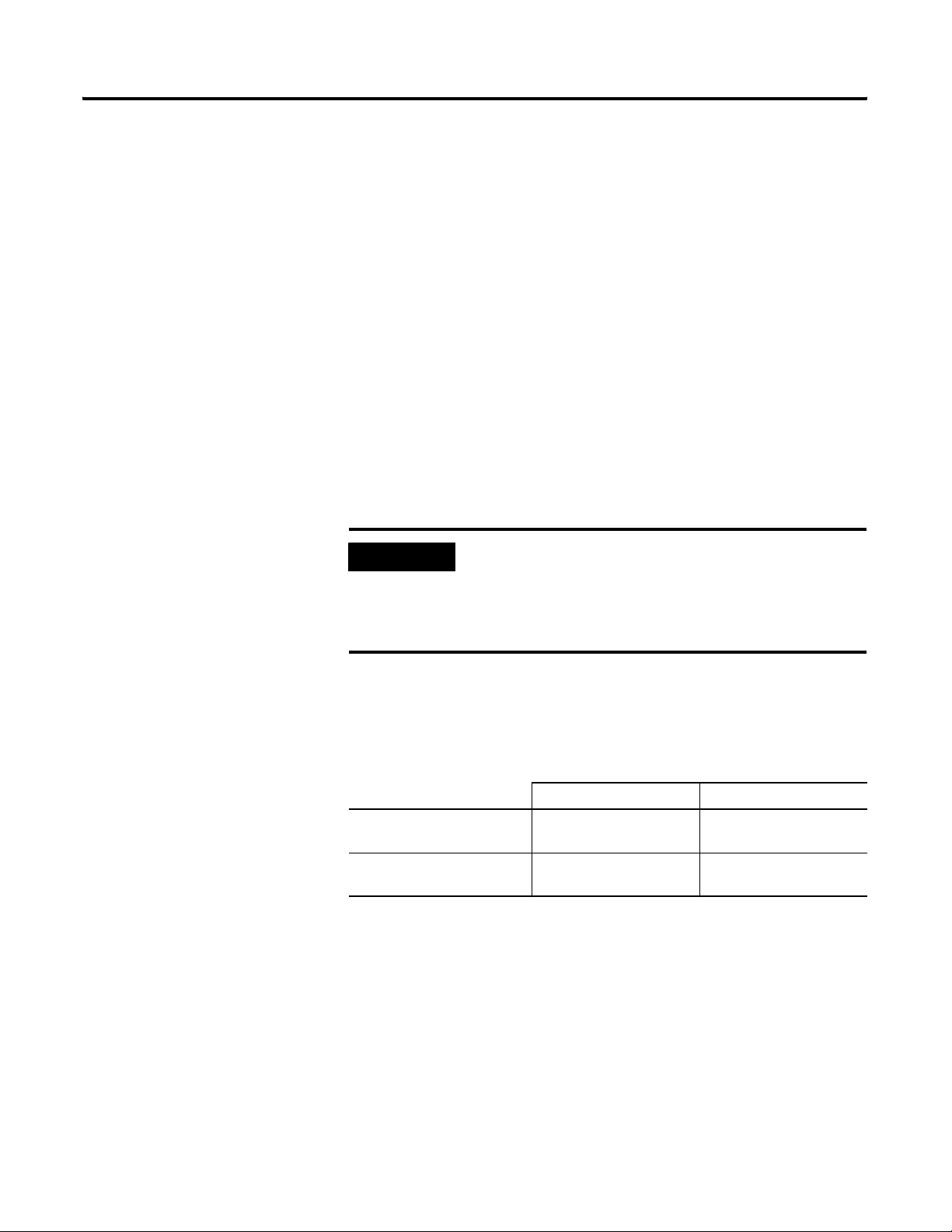

You can use one of the housings listed in Table 3.2.

Table 3.2

Use this

housing:

1756-TBCH Cage clamp 336 sq. mm

1756-TBS6H Spring clamp (36-position)

1756-TBE Any RTB that uses heavy

with this RTB: This combination allows up

to this capacity of wires:

628 sq. mm

gauge wiring

Figure 3.9 shows the difference, in terms of capacity, between the

housing options.

Maximum Area = 336mm

36 - 18AWG wires

23 - 14AWG wires

IMPORTANT

The housings shown are used with a spring clamp

RTB, but the capacity for each remains the same

regardless of RTB type.

Figure 3.9

Standard-Depth Housing Extended-Depth Housing

2

30484-M

Maximum Area = 628mm

40 - 14AWG wires

2

Publication 1756-UM528A-EN-P - April 2004

Page 35

Installing the Sequence of Events Module 3-9

Recommendations for Using the Extended-Depth Housing

Consider the following recommendations when deciding to use an

extended-depth housing on your Sequence of Events module. It is

recommended you use the 1756-TBE when:

• using >36 18AWG wires

• using >23 14AWG wires

Cabinet Size Considerations With the Extended-Depth Housing

When you use an extended-depth housing (1756-TBE), the module

depth is increased. The diagram below shows the difference, in

terms of depth, between a Sequence of Events module using a

standard-depth housing and one using an extended-depth housing.

Figure 3.10

12.7mm

(0.5in)

Standard-Depth Housing

Extended-Depth Housing

3.18mm (0.125in)

144.73mm

(5.698in)

131.75mm

(5.187in)

Rear Surface of

ControlLogix Chassis

41682

IMPORTANT

The depth from front of the module to the back of

the chassis is as follows:

– standard-depth housing = 147.91mm (5.823in)

– extended-depth housing = 157.43mm (6.198in)

Publication 1756-UM528A-EN-P - April 2004

Page 36

3-10 Installing the Sequence of Events Module

Installing the Removable Terminal Block

Install the RTB onto the module to connect wiring.

ATTENTION

Shock hazard exists. If the RTB is installed onto

the module while the field-side power is applied,

the RTB will be electrically live. Do not touch the

RTB’s terminals. Failure to observe this caution

may cause personal injury.

The RTB is designed to support Removal and

Insertion Under Power (RIUP). However, when

you remove or insert an RTB with field-side power

applied, unintended machine motion or loss of

process control can occur. Exercise extreme

caution when using this feature. It is

recommended that field-side power be removed

before installing the RTB onto the module.

Before installing the RTB, make certain:

• field-side wiring of the RTB has been completed.

• the RTB housing is snapped into place on the RTB.

• the RTB housing door is closed.

• the locking tab at the top of the module is unlocked.

1. Align the top, bottom and left side guides of the RTB with the

guides on the module.

Top guide

Left side guides

Bottom guide

20853-M

Publication 1756-UM528A-EN-P - April 2004

Page 37

Installing the Sequence of Events Module 3-11

2. Press quickly and evenly to seat the RTB on the module until

the latches snap into place.

Locking tab

20854-M

3. Slide the locking tab down to lock the RTB onto the module.

Publication 1756-UM528A-EN-P - April 2004

Page 38

3-12 Installing the Sequence of Events Module

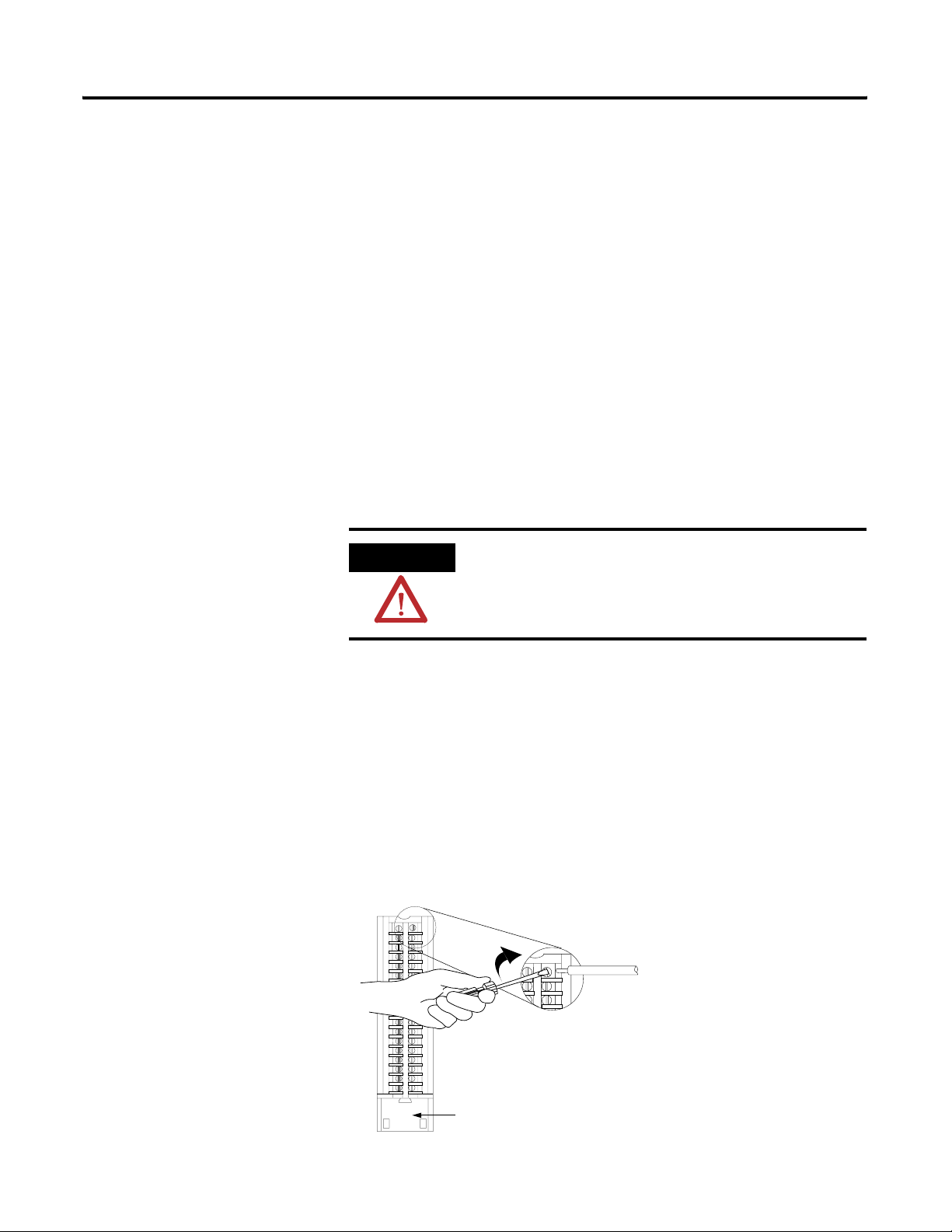

Removing the Removable Terminal Block

If you need to remove the module from the chassis, you must first

remove the RTB from the module.

ATTENTION

Shock hazard exists. If the RTB is removed from

the module while the field-side power is applied,

the module will be electrically live. Do not touch

the RTB’s terminals. Failure to observe this caution

may cause personal injury.

The RTB is designed to support Removal and

Insertion Under Power (RIUP). However, when

you remove or insert an RTB with field-side power

applied, unintended machine motion or loss of

process control can occur. Exercise extreme

caution when using this feature. It is recommended

that field-side power be removed before removing

the module.

1. Unlock the locking tab at the top of the module.

2. Open the RTB door using the bottom tab.

3. Hold the spot marked PULL HERE and pull the RTB off the

module.

IMPORTANT

Do not wrap your fingers around the entire door.

A shock hazard exists.

Publication 1756-UM528A-EN-P - April 2004

20855-M

Page 39

Installing the Sequence of Events Module 3-13

Removing the Module from the Chassis

1. Push in the top and bottom locking tabs.

Locking tabs

20856-M

2. Pull module out of the chassis.

20857-M

Publication 1756-UM528A-EN-P - April 2004

Page 40

3-14 Installing the Sequence of Events Module

Chapter Summary and What’s Next

In this chapter, you read about:

• installing the module.

• keying the RTB and IFM.

• connecting wiring.

• assembling the RTB and the housing.

• installing the RTB or IFM onto the module.

• removing the RTB from the module.

• removing the module from the chassis.

Chapter 4 explains Configuring the Sequence of Events Module.

Publication 1756-UM528A-EN-P - April 2004

Page 41

Chapter

4

Configuring the Sequence of Events Module

What This Chapter Contains

Configuring Your I/O Module

This chapter describes how to configure your Sequence of Events

module.

Table 4.1

For information on: See page:

Configuring Your I/O Module 4-1

Overview of the Configuration Process 4-2

Adding a New Module to Your RSLogix 5000 Project 4-3

Using the Default Configuration 4-6

Altering the Default Configuration 4-6

Downloading Configuration 4-7

Editing Configuration 4-7

Configuring Modules in a Remote Chassis 4-9

You must configure your module upon installation. The module

will not work until it has been configured with at least the default

configuration.

IMPORTANT

This chapter focuses on configuring I/O modules in

a local chassis. To configure I/O modules in a

remote chassis, you must follow all the detailed

procedures with two additional steps. To see the

additional steps, see page 4-9.

RSLogix 5000 Configuration Software

You must use RSLogix 5000, version 13 to set configuration for

your Sequence of Events module. You have the option of accepting

default configuration for your module or writing point level

configuration specific to your application.

Both options are explained in detail, including views of software

screens, in this chapter.

1 Publication 1756-UM528A-EN-P - April 2004

Page 42

4-2 Configuring the Sequence of Events Module

Overview of the Configuration Process

Click on the Next Button to

Set Specific Configuration

When you use the RSLogix 5000 software to configure a Sequence

of Events module, you must perform the following steps:

1. Add the new module to your RSLogix 5000 project.

2. Accept the default configuration or change it to specific

configuration for the module.

3. Edit configuration for a module when changes are needed.

Figure 4.1 shows an overview of the configuration process.

Figure 4.1

Select a:

• New module

• Major Revision

Configure the:

• Name

• Slot number

• Comm. format

• Minor revision

• Keying choice

Click on the Finish Button to

Use Default Configuration

Make custom

configuration

choices here

NEXT FINISH

Series of

Application

Specific

Screens

Configuration complete

Download

configuration to

owner-controller

Reconfigure module as needed via

series of screens or controller tags

41058

Publication 1756-UM528A-EN-P - April 2004

Page 43

Configuring the Sequence of Events Module 4-3

Adding a New Module to Your RSLogix 5000 Project

If you are not offline, use this

pull-down menu to go offline

After you have started RSLogix 5000 and created a controller, you

must add a new module to your project. The wizard allows you to

create a new module and write configuration. You can use default

configuration or write specific configuration for your application.

IMPORTANT

You must be offline when you create a new module.

1. If necessary, go offline.

A. Right-click on I/O

Configuration.

B. Select New Module

2. Add the Sequence of Events module to your

RSLogix 5000 project.

Publication 1756-UM528A-EN-P - April 2004

Page 44

4-4 Configuring the Sequence of Events Module

A. Select the

Sequence of

Events module.

B. Click OK.

3. When the Select Module Type screen appears, select the

Sequence of Events module.

4. Configure the module. The first screen of the configuration

wizard is shown below.

A. Name the module.

B. Select the module’s slot number.

C. Choose a Communications Format. For

more information, see page 4-5.

D. Make sure the Minor Revision number

matches your module’s minor revision.

E. Choose an Electronic Keying method. For

more information, see page 5-13.

F. If you are altering the default

configuration, click Next. Go to page 4-6.

G. If you are using default configuration,

click Finish. Go to page 4-6.

Publication 1756-UM528A-EN-P - April 2004

Page 45

Configuring the Sequence of Events Module 4-5

Communications Format

The communications format determines what operational mode

your Sequence of Events module uses and, consequently, what tags

RSLogix 5000 generates when configuration is complete. Once a

module is created, you cannot change the communications format

unless you delete and recreate the module.

Table 4.2 lists the communications formats used with input modules:

Table 4.2

If you want the Sequence of Events

module to operate in this mode

CST Per Point mode CST Per Point

FIFO mode CST FIFO Mode

choose this communication format:

For more information on the Sequence of Events module’s

operational modes, see page 5-3.

Electronic Keying

Electronic keying allows the ControlLogix system to control what

modules belong in the various slots of a configured system.

During module configuration, you must choose one of the

following keying options for your Sequence of Events module:

• Exact Match

• Compatible Module

• Disable Keying

For more information on electronic keying, see page 5-13.

Publication 1756-UM528A-EN-P - April 2004

Page 46

4-6 Configuring the Sequence of Events Module

Using the Default Configuration

Altering the Default Configuration

On this screen, you can:

A. Change the RPI. For more information

on the RPI, see page 2-6.

B. Inhibit the module. For more

information on inhibiting the module,

see page 5-15.

If you use the default configuration and click on Finish, you are done.

If you click Next in step 4 on page 4-4, you can write specific

configuration for your module in RSLogix 5000.

Some of the screens that appear during this initial module

configuration process are blank and are not shown here. However,

those screens can be important during online monitoring. To see

these screens in use, see Chapter 8, Troubleshooting the Sequence of

Events Module.

Write specific configuration for your Sequence of Events module

on the following screens.

C. Make sure a Major Fault occurs on

the module’s owner-controller if there

is a connection failure between the

module and the controller.

D. Click Next until you see the

screen below.

On this screen, you can:

A. Enable CST Capture for each input

point. For more information on CST

Capture, see page 5-5.

B. Configure Chatter Detection for each

input point. For more information on

Chatter Detection, see page 5-8.

C. Set the Input Filter Times. For more

information on Input Filters, see

page 5-10.

D. Click on the box to enable CST

Latching. For more information on CST

Latching, see page 5-7.

E. Click Finish.

Publication 1756-UM528A-EN-P - April 2004

Page 47

Configuring the Sequence of Events Module 4-7

Downloading Configuration

A. Click here to see the

pull-down menu.

B. Click download.

After you write configuration for your Sequence of Events module,

the module does not use this configuration until you download it to

the owner-controller. The download transfers the entire program to

the controller, overwriting any existing program.

Download module configuration as shown below.

Depending on your application, a variety of RSLogix 5000 screens

may appear to choose a path to your ControlLogix controller and to

verify the download. Navigate those screens as best fits

your application.

Editing Configuration

This completes the download process.

After you have set configuration for a module, you can review and

change your choices. You can change configuration data and

download it to the controller while online. This is called dynamic

reconfiguration.

Your freedom to change some configurable features, though,

depends on whether the controller is in Remote Run Mode or

Program Mode.

IMPORTANT

Although you can change configuration while

online, you must go offline to add or delete

modules from the project.

Publication 1756-UM528A-EN-P - April 2004

Page 48

4-8 Configuring the Sequence of Events Module

A. Right-click on the module.

B. Select Properties

The editing process begins on the main page of RSLogix 5000.

A. Click the tab where you need to

reconfigure the module.

In this example, CST Capture

was disabled for several input

points.

B. When the module is

reconfigured, click OK.

The General tab of the configuration wizard appears. Click on the

tab of the page that you want to view or reconfigure and make any

appropriate changes.

Make any necessary changes as shown in the example below.

Publication 1756-UM528A-EN-P - April 2004

Page 49

Configuring the Sequence of Events Module 4-9

Configuring Modules in a Remote Chassis

ControlLogix ControlNet Interface modules (1756-CNB or

1756-CNBR) or the EtherNet/IP Bridge module (1756-ENBT) are

required to communicate with Sequence of Events modules in a

remote chassis.

You must configure the communications module in the local

chassis and the remote chassis before adding remote Sequence of

Events modules to your project.

1. Add a communications module to the local chassis.

A. Right-click on I/O Configuration.

B. Select New Module

2. Choose a communications module (1756-CNB, 1756-CNBR or

1756-ENBT) for the local chassis.

3. Configure the communications module in the local chassis.

For more information on the ControlLogix ControlNet

Interface modules, see the Using ControlNet Communication

Modules in Logix5000 Control Systems user manual,

publication CNET-UM001.

For more information on the ControlLogix EtherNet/IP Bridge

module, see the Using EtherNet/IP Communication Modules

in Logix5000 Control Systems user manual, publication

ENET-UM001.

Publication 1756-UM528A-EN-P - April 2004

Page 50

4-10 Configuring the Sequence of Events Module

A. Right-click on the local

communication module.

B. Select New Module

4. Add a communications module to the remote chassis.

A. Right-click on the remote

communication module.

B. Select New Module

5. Select a communications module for the remote chassis.

6. Configure the communications module in the remote chassis.

7. Add a Sequence of Events module to the remote chassis.

Publication 1756-UM528A-EN-P - April 2004

8. Configure the new Sequence of Events module as described

earlier in this chapter.

Page 51

Configuring the Sequence of Events Module 4-11

Chapter Summary and What’s Next

In this chapter, you read about configuring your Sequence of Events

module.

Chapter 5 describes Using the Sequence of Events Module Features.

Publication 1756-UM528A-EN-P - April 2004

Page 52

4-12 Configuring the Sequence of Events Module

Notes:

Publication 1756-UM528A-EN-P - April 2004

Page 53

Using the Sequence of Events

Module Features

Chapter

5

What This Chapter Contains

This chapter describes the features available on the Sequence of

Events module.

Table 5.1

For information on: See page:

Determining Module Compatibility 5-2

Two Operational Modes 5-3

Enable CST Capture 5-5

Latch CST 5-7

Chatter Detection 5-8

Software Configurable Input Filters 5-10

Electronic Keying 5-13

Module Inhibiting 5-15

Removal and Insertion Under Power (RIUP) 5-16

Module Fault Reporting 5-16