Rockwell Automation Allen-Bradley ControlLogix B Series, 1756HP-TIME User Manual

User Manual

ControlLogix Time Syncronization Module - Series B

Catalog Number 1756HP-TIME

Allen-Bradley Motors

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

t

o be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

aired.

imp

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

or application of this equipment.

use

The examples and diagrams in this manual are included solely f

or illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

tware described in this manual.

sof

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

nc., is prohibited.

I

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, ControlFLASH, ControlLogix, Logix5000, R SLogix, Studio 5000 Automation Engineering & Design Environment, Studio 5000, Studio 5000 Logix Designer, Rockwell S oftware, and Rockwell Automation

are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Table of Contents

Preface

Installation

Setup

Operation

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1756HP-TIME Module Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Chapter 1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GPS Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2

BOOTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ControlFLASH Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

The Logix Designer Application Configuration. . . . . . . . . . . . . . . . . . . . . 10

View the Satellite Status in the Logix Designer Application . . . . . . . . . . 12

Satellite Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Satellite Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1756HP-TIME Module AOP Configuration Parameters. . . . . . . . . . . . 13

Chapter 3

Logix5000 Controller Input Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Logix5000 Controller Output Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Time Synchronization

Specifications

Chapter 4

1588 Precision Time Protocol (CIP Sync). . . . . . . . . . . . . . . . . . . . . . . . . . 23

1756HP-TIME Module as a PTP Master. . . . . . . . . . . . . . . . . . . . . . . 23

Configure the Ethernet Module/Controller PTP/CIP

Sync Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTP as a Time Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Network Time Protocol (NTP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1756HP-TIME Module as an NTP Server. . . . . . . . . . . . . . . . . . . . . .

1756HP-TIME Module as an NTP Client . . . . . . . . . . . . . . . . . . . . . 28

IRIG-B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1756HP-TIME Module as an IRIG-B Master

1756HP-TIME Module as an IRIG-B Slave . . . . . . . . . . . . . . . . . . . . 30

CST and UTC Time Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . 29

24

26

26

29

30

Appendix A

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPS Antenna Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31

33

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 3

Table of Contents

Appendix B

1756HP-TIME Module Status

CST/UTC Conversion Message Blocks

Operating Modes

GPS Antenna Cable Extensions

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36

Appendix C

CST to UTC and Gregorian Time Conversion . . . . . . . . . . . . . . . . . . . . . 37

UTC to Gregorian Time Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Satellite Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Appendix D

GPS Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

IRIG-B Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

PTP Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

NTP Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Appendix E

Cable Extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Determine the Length of the Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Determine the Attenuation Rate of the Cable . . . . . . . . . . . . . . . . . . . 43

Example – Determining Cable Requirements . . . . . . . . . . . . . . . . . . . 44

Cable Extension Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Lightning Protection Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Glossary

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Top ic Page

Studio 5000 Environment 5

1756HP-TIME Module Overview 5

Additional Resources 6

Preface

Studio 5000 Environment

The Studio 5000 Automation Engineering & Design Environment™ combines

engineering and design elements into a common environment. The first element

is the Studio 5000 Logix Designer™ application. The Logix Designer application

is the rebranding of RSLogix™ 5000 software and will continue to be the product

to program Logix5000™ controllers for discrete, process, batch, motion, safety,

and drive-based solutions.

The Studio 5000® environment is the foundation for the future of Rockwell

A

utomation® engineering design tools and capabilities. The Studio 5000

environment is the one place for design engineers to develop all of the elements of

their control system.

1756HP-TIME Module Overview

Allen-Bradley Motors

This user manual describes the functionality, installation, configuration, and

operation of the 1756HP-TIME module, series B, firmware revision 3.001.

The 1756HP-TIME module provides accurate time synchronization on different

terfaces by using Global Positioning System (GPS) technology. The

in

1756HP-TIME module can obtain time from various sources, and provide time

synchronization on other devices by acting as a gateway between different time

synchronization methods and standards.

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 5

Preface

Time synchronization is accomplished by using these methods, standards, and

protocols:

• The

ControlLogix® backplane for Coordinated System Time (CST) and

Coordinated Universal Time (UTC) conversion.

• Inter-range Instrumentation Group, code B (IRIG-B) standards.

• Precision Time Protocol (PTP) on Ethernet and the ControlLogix

backplane.

• Network Time Protocol (NTP) on Ethernet.

The 1756HP-TIME module provides GPS position in the form of latitude,

gitude, and altitude (LLA).

lon

The 1756HP-TIME module provides course and route information in the form

round speed (knots) with heading in the form of degrees from true north.

of g

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Integrated Architecture and CIP Sync Configuration

Application Technique, publication IA-AT003

ControlLogix System User Manual, publication 1756-UM001 Describes the necessary tasks to install, configure,

EtherNet/IP Network Configuration User Manual,

publication

ControlFLASH® Firmware Upgrade Software User Manua l,

publication 1756-UM105

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website,

ENET-UM001

http://www.ab.com Provides declarations of conformity, certificates, and

This document explains CIP sync technology and how

you can synchronize clocks within the Rockwell

Automation Integrated Architecture.

program, and operate a ControlLogix system.

Provides Bootstrap Protocol/ Dynamic Host

Configuration Protocol (BOOTP/DHCP) information for

setting the IP address of the module.

Describes the necessary tasks to install, and use the

ControlFLASH software to update the module firmware.

Provides general guidelines for installing a Rockwell

Automation industrial system.

other certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

R

ockwell Automation sales representative.

6 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

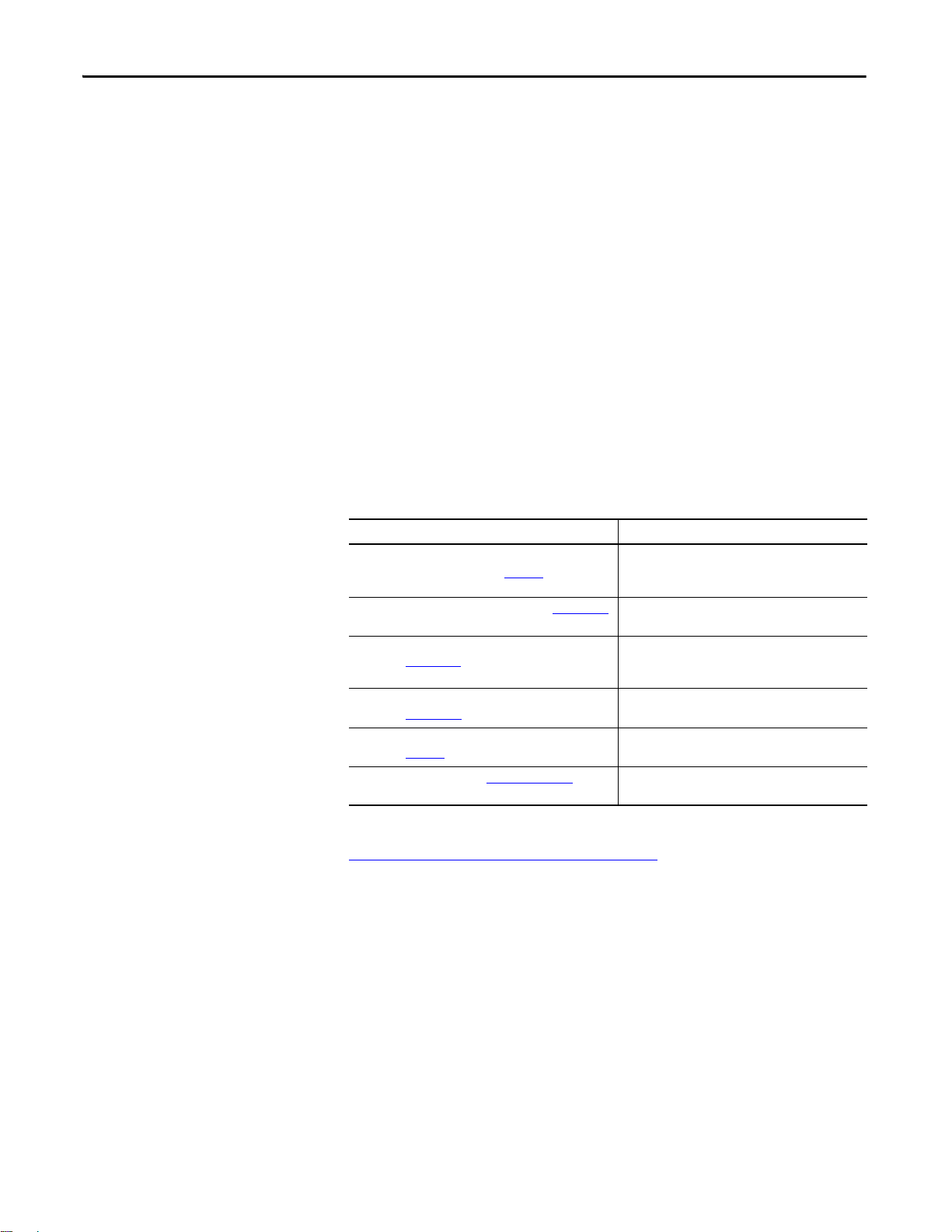

Installation

Status Indicators and Messages

Ethernet Connection 1

Ethernet Connection 2

GPS Subminiture Version A (SMA) Connector

IRIG-B Coaxial Connector

Top ic Page

Hardware 7

GPS Antenna 8

Software 8

Chapter 1

Hardware

The 1756HP-TIME module operates within the ControlLogix platform. All

power required for the operation of the module is supplied by the ControlLogix

backplane.

Figure 1 - 1756HP-TIME Module, Front View

Table 1 - 1756HP-TIME Module Hardware Descriptions

Hardware Description

Status indicators and messages Provides status and operational information for the 1756HP-TIME module.

Ethernet connector 1 and

Ethernet connector 2

(uses Rockwell Automation®

dual-port switch technology)

GPS SMA connector Connect the GPS b ullet antenna to this connector. See GPS Antenna on page 8.

IRIG-B coaxial connec tor Connect the IRIG-B network cable to this connector. The 1756HP-TIME module

See 1756HP-TIME Module Status on page 35.

PTP and NTP time synchronization uses the Ethernet connections.

Note: This connection is not a bridge to the backplane and cannot be used to

view m

odules on the backplane.

can be configured as a master clock or a slave clock on the IRIG-B network.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 7

Chapter 1 Installation

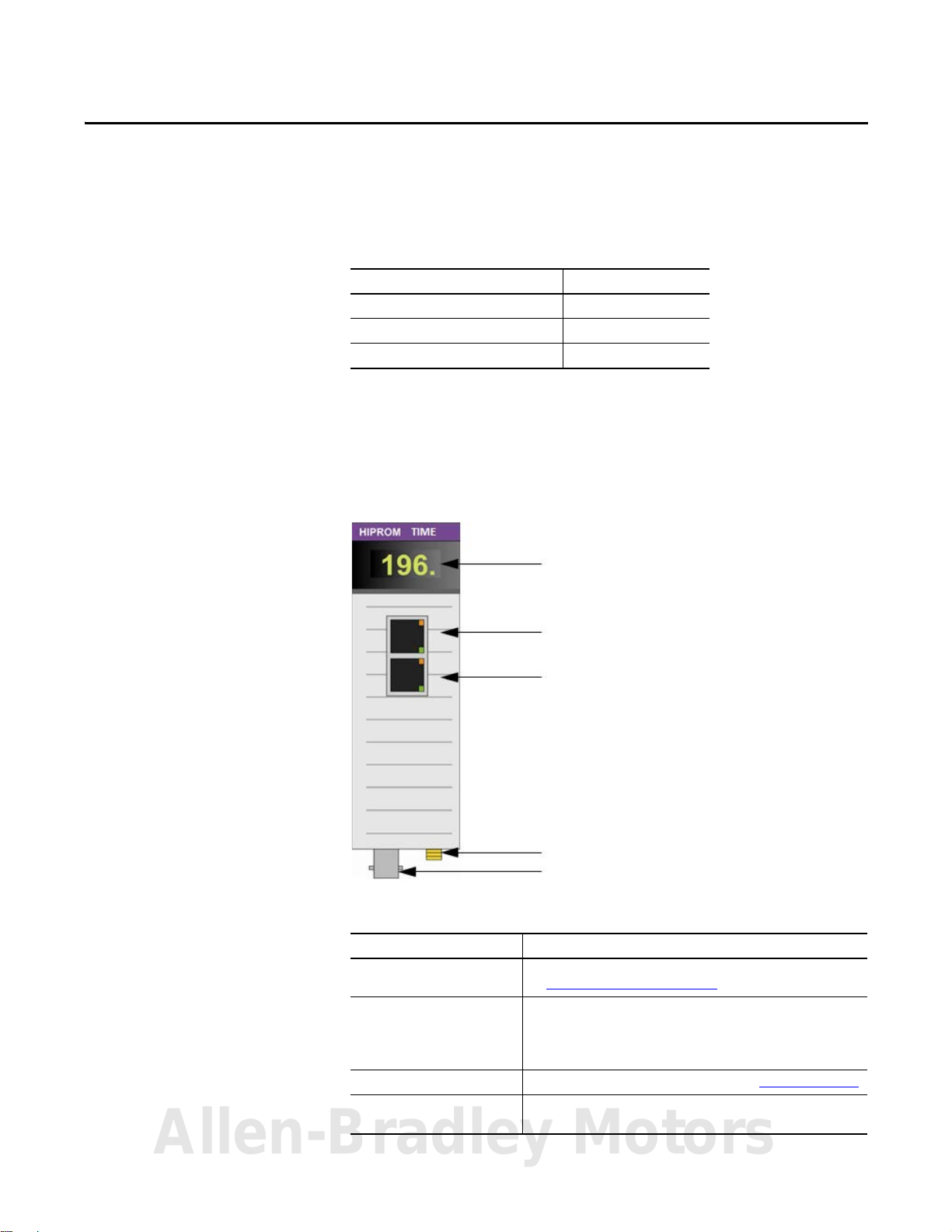

GPS Antenna

Install the GPS antenna with a clear view of the sky (do not install the antenna

where objects can obstruct the view of the antenna to the sky). If an antenna is

installed with a limited view of the sky, the GPS receiver can have a low satellite

lock count, or be unable to obtain a lock. A limited view of the sky can cause

inaccurate time synchronization.

Figure 2 - GPS Antenna Installation with Clear View of the Sky

Figure 3 - GPS Antenna Installation with Obstructed View of the Sky

Software

Use this software to configure and operate the 1756HP-TIME module:

• The Studio 5000 Logix Designer application

• The Add-on Profile (AOP) for the 1756HP-TIME module, available for

download at this link:

http://www.hiprom.com/Pages/Products/1756_CLX/1756HP-TIME/

web/1756HP-TIME.htm

8 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Setup

Top ic Page

BOOTP 9

Fac tory Defaul ts 9

ControlFLASH Software 10

The Logix Designer Application Configuration 10

View the Satellite Status in the Logix Designer Application 12

1756HP-TIME Module AOP Configuration Parameters 13

Chapter 2

BOOTP

Factory Defaults

Use BOOTP to set the initial IP address for the 1756HP-TIME module. The

module comes from the factory with BOOTP enabled.

The BOOTP/DHCP server is a standalone server that you can use to set an IP

s.

addres

Access the BOOTP/DHCP server from one of these locations:

rograms > Rockwell Software > BOOTP-DHCP Server

• P

• Tools directory on the Studio 5000 environment installation CD

If you have not installed the BOOTP/DHCP server, you can download and

ll it from

insta

To set the IP address of the module with a BOOTP/DHCP server, follow the

ps found in EtherNet/IP Network Configuration User Manual, publication

ste

ENET-UM001.

If the module fails or becomes inoperable, the module reboots with

factory-loaded boot software. The display informs you of the error and suggests a

method to fix the error. If there is a firmware error, use the ControlFLASH

software to restore the module to a working condition.

http://www.ab.com/linked/networks/ethernet/bootp.html.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 9

Chapter 2 Setup

IMPORTANT

IMPORTANT

ControlFLASH Software

The Logix Designer Application Configuration

Use the ControlFLASH software to upgrade the software to a newer version.

For more information on the ControlFLASH software and how to use it, see

C

ontrolFLASH Firmware Upgrade Software User Manual, publication

UM105.

The latest firmware can be found at this link:

Products/1756_CLX/1756HP-TIME/web/1756HP-TIME.htm.

Before you can program the 1756HP-TIME module, the AOP for the module

must be installed. You also need admin rights for the module to view and

configure the AOP.

The installer for the AOP can be found at this link:

http://www.hiprom.com/Pages/Products/1756_CLX/1756HP-TIME/web/

1756HP-TIME.htm.

Each 1756HP-TIME module is programmed to work with a single Logix5000

controller.

http://www.hiprom.com/Pages/

1756-

There is no direct communication between the 1756HP-TIME module Ethernet

ports and a Logix5000 controller. If the 1756HP-TIME module resides in a

remote Logix rack, it needs to communicate through an EN2T(R) module in the

same rack.

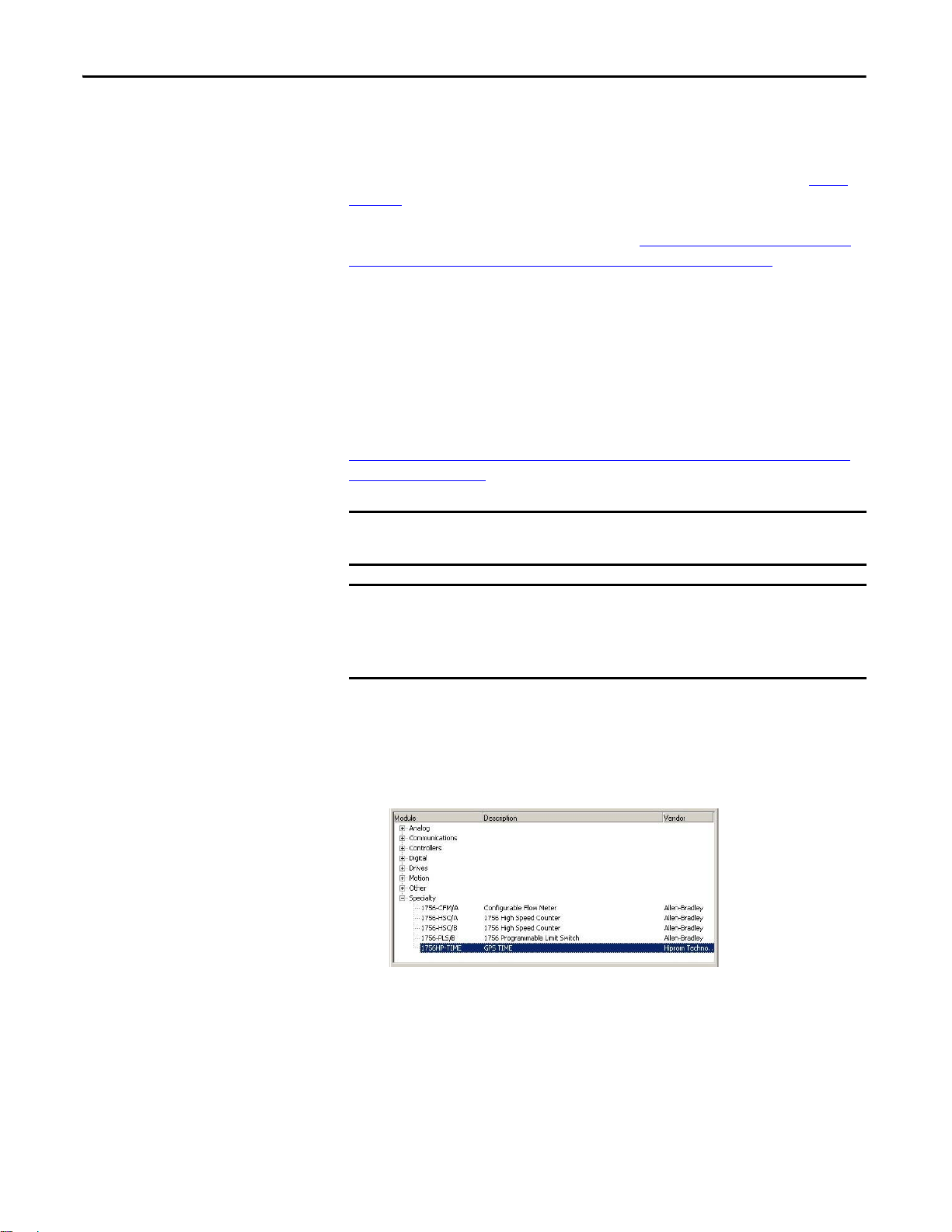

Follow these steps to configure the 1756HP-TIME module in the Logix

Designer application.

1. Doub

le-click the 1756HP-TIME module in the I/O tree in the Logix

Designer application.

The New Module dialog box appears.

10 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

2. Enter a name for the module.

3. Enter a brief description for the module.

4. Enter the IP address for the module.

Setup Chapter 2

5. Click the Configuration tab.

6. From the Source Settings pull-down menu, choose the time source that

you want to use.

See Chapter 4

7. Select the Time Output format.

8. Enter the Advanced CIP Sync Settings.

9. Enter the Description Settings.

10. Click OK.

for more information on the source types.

The time properties of the 1756HP-TIME module are now configured.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 11

Chapter 2 Setup

View the Satellite Status in the Logix Designer Application

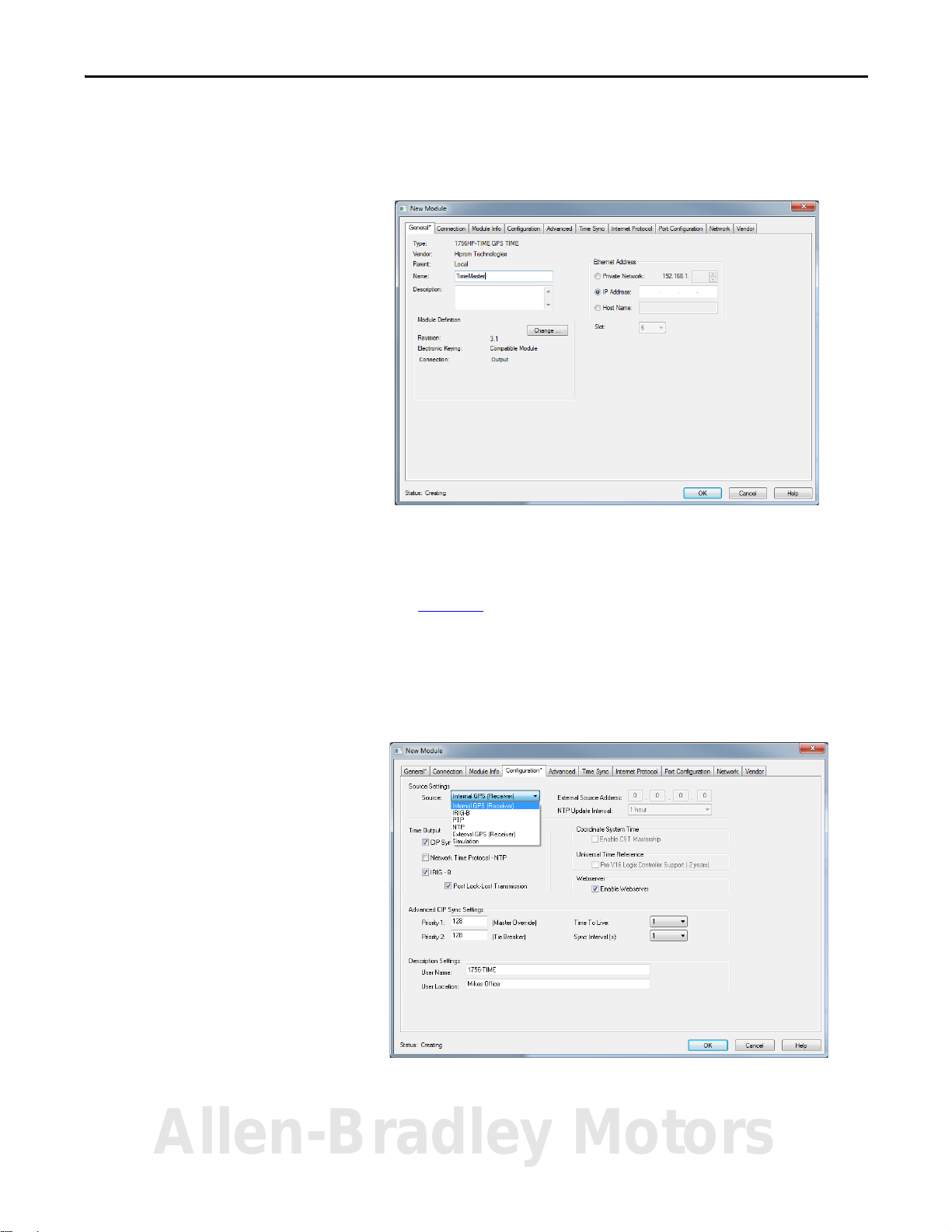

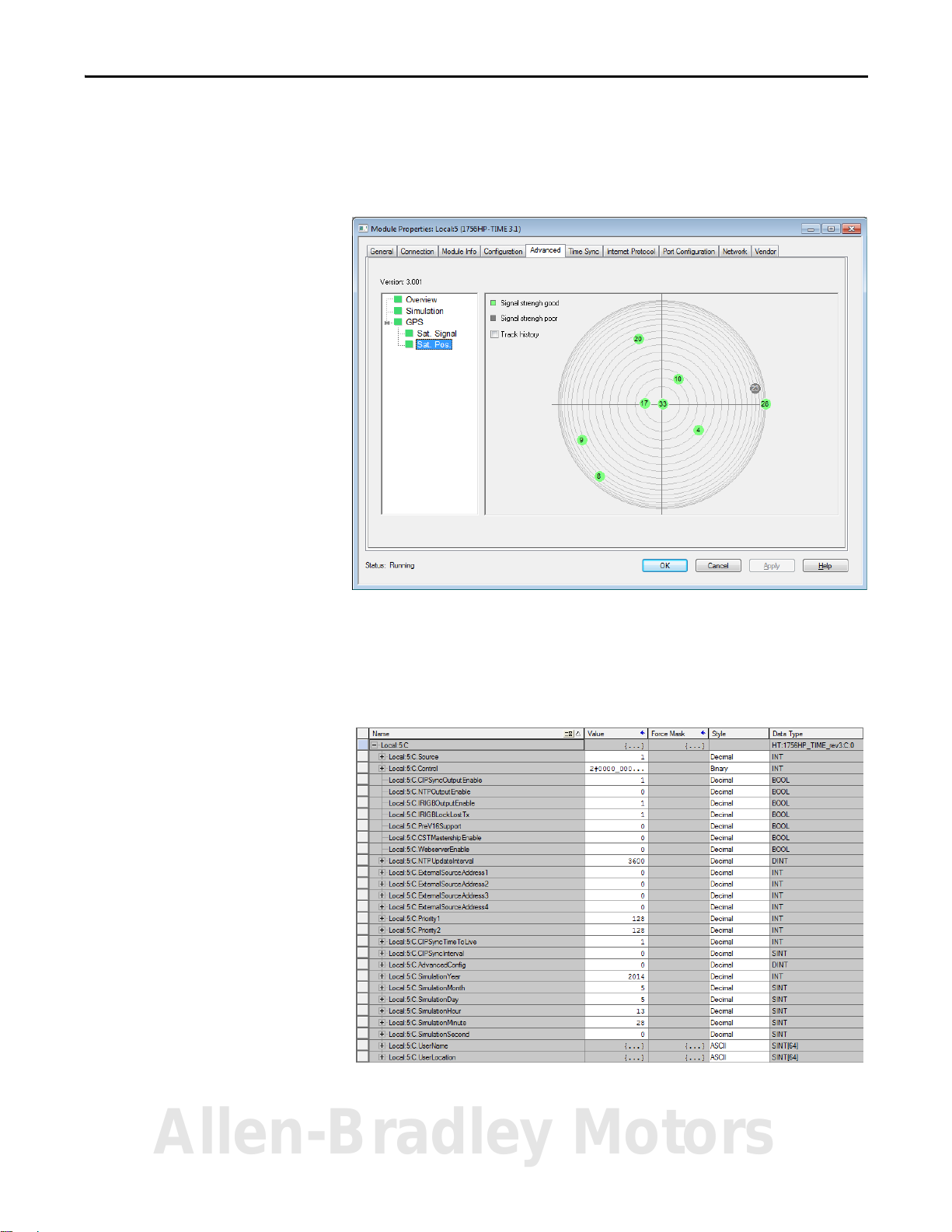

Click the Advanced tab to view the source of the time (Time Input), and see if

the time source is valid and available (green) or invalid (red). You can also view

the output type (Time Output), the UTC time of the 1756HP-TIME module,

and the GPS coordinates of the satellite (when a connection is locked).

Figure 4 - 1756HP-TIME Module Properties Dialogue Box, Advanced Tab

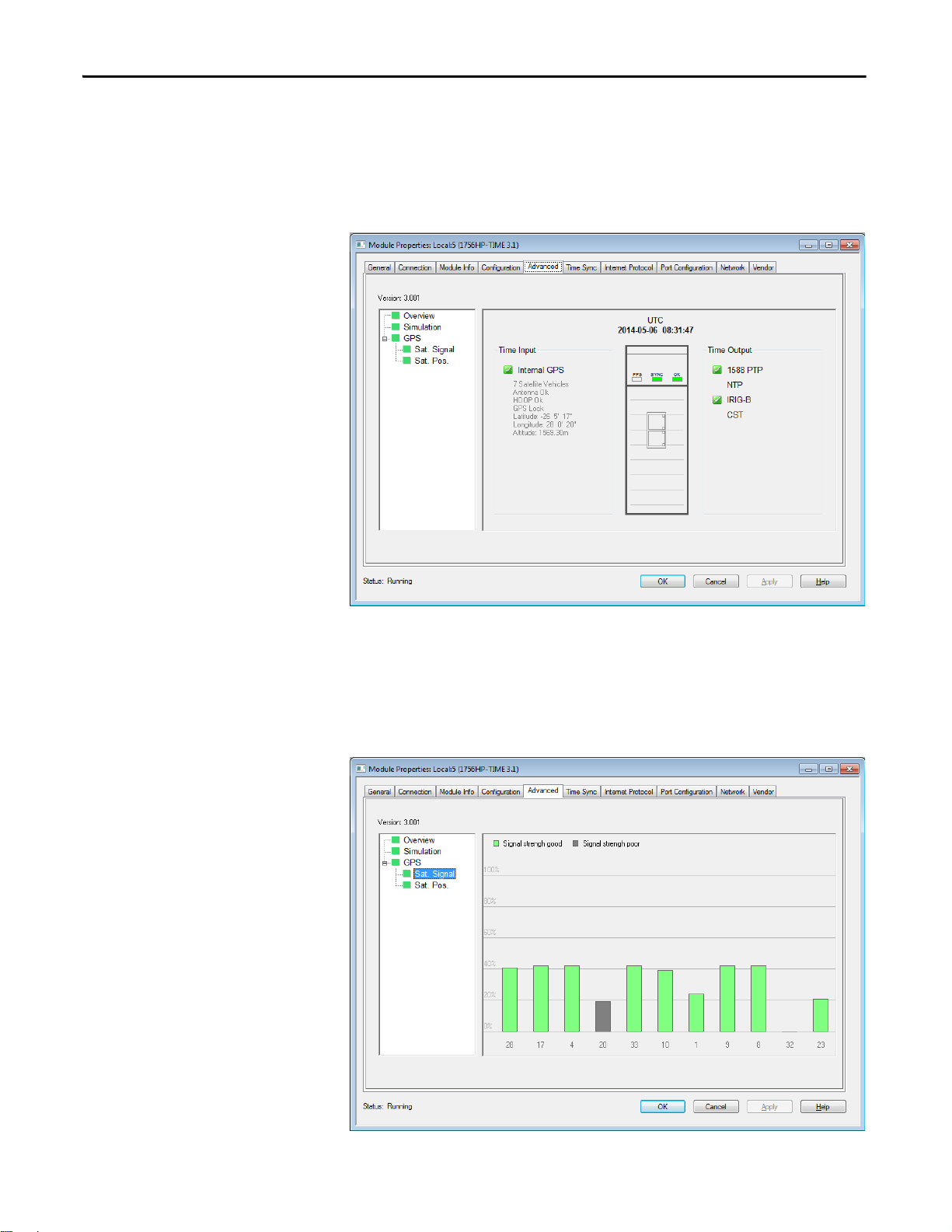

Satellite Signal

Click Sat. Signal to view the signal strength of the satellites.

Figure 5 - 1756HP-TIME Module Properties Dialogue Box, Sat. Signal Node

12 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Satellite Position

Click Sat. Pos. to view the position of the satellites in the sky.

Figure 6 - 1756HP-TIME Module Properties Dialogue Box, Sat. Pos. Node

Setup Chapter 2

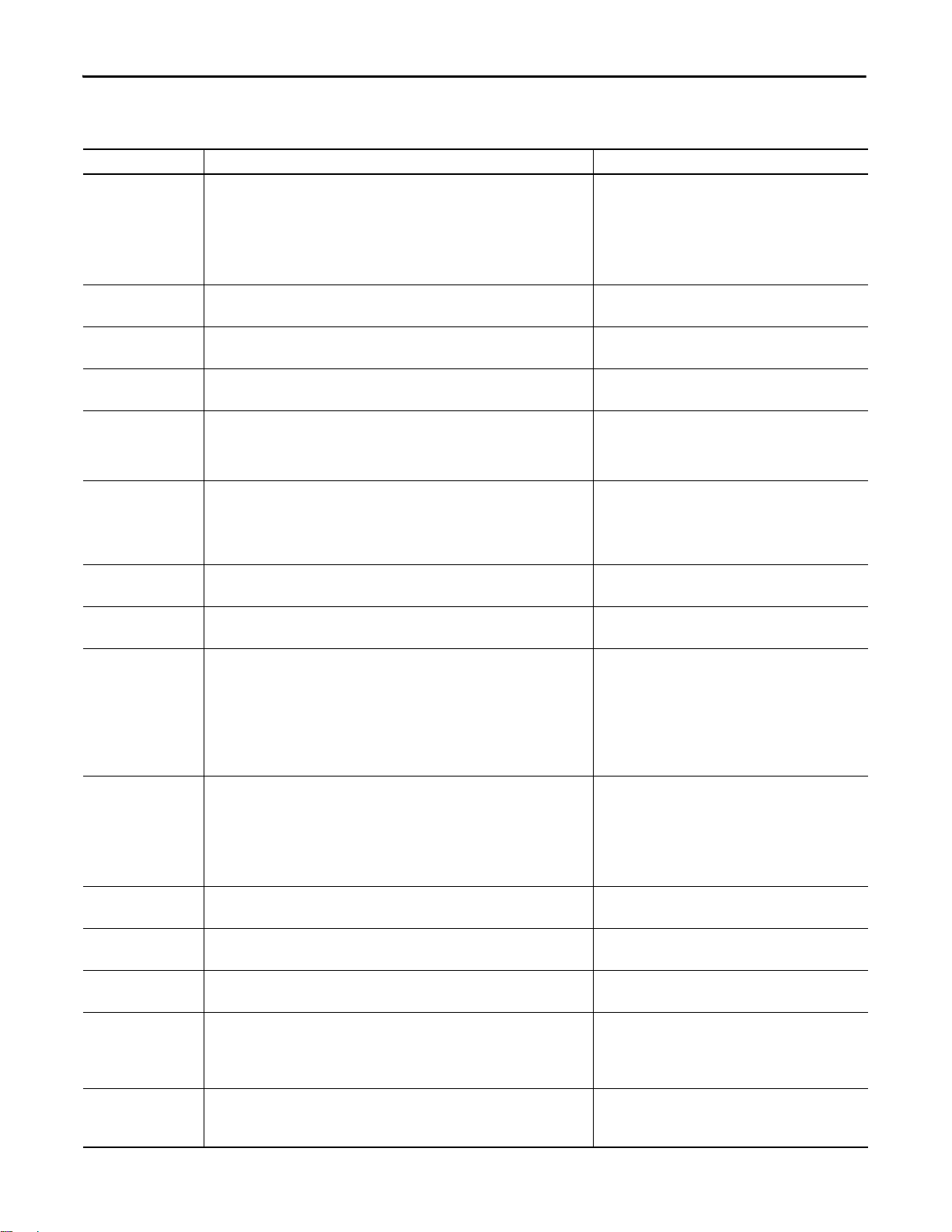

1756HP-TIME Module AOP Configuration Parameters

This section describes the AOP configuration parameters for the 1756HP-TIME

module. This section is for information purposes. The AOP is used to configure

all the relevant module parameters.

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 13

Chapter 2 Setup

Table 2 - AOP Configuration Parameters

Parameter Description Value

Source Indicates the time source that is used for the module. 1 = GPS

2 = IRIG-B

3 = PTP

4 = NTP

5 = External GPS (future)

6 = Simulation

CIPSyncOutputEnable When this bit is set, the module enables 1588 PTP (CIP sync) output. 0 = 1588 PTP (CIP sync) output is disabled

1 = 1588 PTP (CIP sync) output is enabled

NTPOutputEnable When this bit is set, the module enables NTP on Ethernet. 0 = NTP v3 RF(1305) output is disabled

1 = NTP v3 RF(1305) output is enabled

IRIGBOutputEnable When this bit is set, the module enables IRIG-B on the coaxial interface. 0 = IRIG-B-122 output is disabled

1 = IRIG-B-122 output is enabled

IRIGBLockLostTX When this bit is set, the module keeps sending an IRIG-B signal aft

PreV16Support If you are using RSLogix 5000 software, version 16.00.00 and later, or the Studio 5000

CSTMastershipEnable Indicates if the module is the CST master clock on the local rack (if no other CST master

WebserverEnable Allows you to access the web server from a web browser pointed to the IP address of the

NTPUpdateInterval The time (in seconds) when the module requests an update of the time from the NTP

ExternalSo urceAddress The external source address is used for one of two sources depending on how the

Priority1 This is the override for the Best Master Clock Algorithm (BMCA). The default is 128.

Priority2 This is used to break a tie between two modules with the same priority 1 value. The default is 128.

CIPSyncTimeToLive Limits the lifespan of data in a network. It

CIPSyncInterval The time interval when the module sends out a PTP sync packet. Allowed values:

AdvancedConfig These are various bits used to set c

time source.

If this bit is clear, the module stops sending a valid IRIG-B signal when it has lost lock

with the time source, as long as it has had lock at least once previously.

environment, version 21.00.00 and later, the UTC time base is different than earlier

versions of RSLogix 5000 software.

The setting syncs the time between Logix5000 controllers that use any version of

RSLogix 5000 software or the Studio 5000 environment.

clocks are currently active).

module.

server.

guration is set:

confi

• If the time source is set to NTP, this is the IP address of the source that is used.

• If the source is set to External GPS, this is the IP address of the GPS receiver.

indefinitely.

prevents the IP packet from circulating

ertain options in the module. Bit:

er it has lost lo ck to th e

0 = Module stops sending IRIG-B when lock is lost

1 = Module continues sending IRIG-B, even when a lock is

lost

0 = For all versions of RSLogix 5000 software or the Studio

5000 environment

1 = For RSLogix 5000 software, version 16.00.00 and earlier.

0 = Module does not attempt to be the CST master clock

1 = Module does attempt to be the CST master clock

0 = Module does not allow access to the web server

1 = Module allows access to the web server

Example:

5 = 5 seconds

30 = 30 seconds

300 = 5 minutes

3600 = 1 hour

86400 = 1 day

604800 = 1 week

In this example, the module uses external IP address:

192.168.1.100

Byte 0 = 192

Byte 1 = 168

Byte 2 = 1

Byte 3 = 100

Values lower than 128 indicate preference on the network.

Values lower than 128 indicate preference on the network.

Example:

1 = the packet circulates once

1/2 = 500 ms

1 = 1 second

2 = 2 seconds

0 =Simulation Mode

1…31 = Reserved

14 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Table 2 - AOP Configuration Parameters (Continued)

Parameter Description Value

SimulationYear When the module is in simulation mode, use this to set the initial year to be used by the

SimulationMonth When the module is in simulation mode, use this to set the initial month to be used by

SimulationDay When the module is in simulation mode, use this to set the initial day to be used by the

SimulationHour When the module is in simulation mode, use this to set the initial hour to be used by the

SimulationMinute When the module is in simulation mode, use this to set the initial minute to be used by

SimulationSecond When the module is in simulation mode, use this to set the initial second to be used by

UserName Use this parameter to identify the time module, visible in CIP sync synchronization. Example:

UserLocation Use this parameter to provide extra information to identify the location of the module. Example:

module.

the module.

.

module

module.

the module.

the module

.

Example:

29 April 2014

Year = 2014

Example:

29 April 2014

Month = 4

Example:

29 April 2014

Day = 29

Example:

11:14:23 AM

Hour =11

Example:

11:14:23 AM

Minute =14

Example:

11:14:23 AM

Second =23

1756HP-TIME

Basement

Setup Chapter 2

Allen-Bradley Motors

Rockwell Automation Publication 1756-UM542A-EN-P - September 2014 15

Chapter 2 Setup

Notes:

16 Rockwell Automation Publication 1756-UM542A-EN-P - September 2014

Loading...

Loading...