Page 1

Page 2

Contact Rockwell

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/

Copyright Notice

Trademark Notices

Other Trademarks

Warran ty

© 2011 Rockwell Automation Technologies, Inc. All rights reserved. Printed in USA.

This document and any accompanying Rockwell Software products are copyrighted by Rockwell Automation

Technologies, Inc. Any reproduction and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement for details.

Allen-Bradley, ControlLogix, eProcedure, FactoryTalk, Rockwell Automation, Rockwell Software, RSLinx, RSView,

and the Rockwell Software logo, are registered trademarks of Rockwell Automation, Inc.

The following logos and products are trademarks of Rockwell Automation, Inc.:

RSBizWare, the RSBizWare logo, RSBizWare Batch, FactoryTalk Batch, RSBizWare BatchCampaign, RSBizWare

BatchHistorian, FactoryTalk Historian Classic for Batch, RSBizWare Historian, FactoryTalk Historian Classic,

RSBizWare MaterialTrack, FactoryTalk Batch Material Manager, and RSLoop Optimizer.

Any Rockwell software or hardware not mentioned here are also trademarks, registered or otherwise, of Rockwell

Automation Technologies, Inc.

ActiveX, Microsoft, Microsoft Access, SQL Server, Visual Basic, Visual C++, Visual SourceSafe, Windows, Windows

ME, Windows NT, Windows 2000, Windows Server 2003, Windows XP, and Vista are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or other countries.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the

United States and/or other countries.

Oracle is a registered trademark of Oracle Corporation.

All other trademarks are the property of their respective holders and are hereby acknowledged.

This product is warranted in accordance with the product license. The product’s performance may be affected by system

configuration, the application being performed, operator control, maintenance, and other related factors. Rockwell

Automation is not responsible for these intervening factors. The instructions in this document do not cover all the

details or variations in the equipment, procedure, or process described, nor do they provide directions for meeting every

possible contingency during installation, operation, or maintenance. This product’s implementation may vary among

users.

This document is current as of the time of release of the product; however, the accompanying software may have

changed since the release. Rockwell Automation, Inc. reserves the right to change any information contained in this

document or the software at anytime without prior notice. It is your responsibility to obtain the most current information

available from Rockwell when installing or using this product.

Page 3

Contents

1 • Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Distributed FactoryTalk Historian Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FactoryTalk and ControlLogix Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FactoryTalk Services Platform and FactoryTalk Product Suite . . . . . . . . . . . . . . . 6

ControlLogix System Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hardware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Where to Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Additional Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FactoryTalk Licensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Knowledgebase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Worldwide Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TechConnect Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Consulting Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Training Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2 • Getting Started. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

IE Internet Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

IE 7 Hot Fix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

IE 8 Compatibility Mode Internet Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

FactoryTalk Historian SE Patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Client Tools Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Hardware Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Client Computer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ControlLogix Chassis Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setting up Your ControlLogix Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing FactoryTalk Historian ME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

FactoryTalk Historian ME Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Installing FactoryTalk Historian ME Client Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installing FactoryTalk Services Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installing FactoryTalk Historian Management. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installing FactoryTalk Historian ME Rule Editor . . . . . . . . . . . . . . . . . . . . . . . . 28

Installing FactoryTalk Historian ME RSLogix 5000 AOP . . . . . . . . . . . . . . . . . 28

iii

Page 4

FACTORYTALK HISTORIAN ME USER GUIDE

Installing FactoryTalk View SE Patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

FactoryTalk Historian ME EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Logging In to FactoryTalk Historian ME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Logging Out of FactoryTalk Historian ME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3 • Viewing Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

System Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Point Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Module Identity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Security Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Client Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

System Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

System Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Network Manager Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Snapshot and Archive Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Archive File Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4 • Viewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Viewing Current Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Defining Search Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Exporting Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Viewing Archive Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Selecting Archive Data Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Exporting Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Viewing Trends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Displaying the Trend Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Changing the Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Filtering Search Results Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Sorting Columns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Refreshing a View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Auto Refreshing a View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Start and End Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5 • Managing Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

iv

Page 5

CONTENTS

Using the Add Points Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Discovering Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Creating Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Reviewing Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Using the Tag Browser to Create Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Folders Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Contents Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Selected Tags Pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Creating Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Manually Creating and Editing Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Defining Point Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Configuring Scan Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Configuring Trigger Input and Output Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Input Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Output Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Point Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Trigger Point Configuration Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Working with Scan Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Creating a Scan Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Editing a Scan Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Removing a Scan Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

6 • Collecting Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Collecting Data Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Viewing Data Collection Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Starting and Stopping Data Collection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Storing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Archive Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Archive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Event Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Log Threshold Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Archive Disk Threshold Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Archive Usage Threshold Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Exception Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Compression Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7 • Transferring Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Transferring Data Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Connecting to a FactoryTalk Historian SE or PI Server . . . . . . . . . . . . . . . . . . 111

Uploading Historical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

v

Page 6

FACTORYTALK HISTORIAN ME USER GUIDE

Connecting to a New FactoryTalk Historian SE or PI Server . . . . . . . . . . . . . . 112

Failing to Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Processing Tag Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Monitoring Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Shutting Down the Data Transfer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Configuring Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Prerequisite Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Establishing a FactoryTalk Historian SE or PI Server Connection . . . . . . . . . . 114

Setting Data Transfer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Maximum Events per Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Enable Auto Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Viewing Data Transfer Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Archive File Time Span for ME-to-SE or PI Server Data Transfer. . . . . . . . . . 119

Selecting Points to Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Adding Points to Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Manually Transferring Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Removing Points from Data Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8 • Administering the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Setting User Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Factory Talk Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Native Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Managing Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Creating Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Modifying Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Removing Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Managing Groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Managing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Clock Drifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Current Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Battery Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Time Synchronization Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Verifying Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Setting the Time Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Working with System Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Configuring the Module Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Configuring Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Uploading Files to the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Check the Format of an Uploaded File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Viewing an Uploaded File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Deleting an Uploaded File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

vi

Page 7

CONTENTS

Backing Up and Restoring Module Configuration Files . . . . . . . . . . . . . . . . . . . . . . 140

Displaying Backup Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Downloading Files to a Client Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Uploading a Backup File to the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Restoring the Module from a Backup File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Restoring the Module Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Using the System Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Sorting the System Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Defining a System Log View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Repairing Archives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Restoring Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Retaining Backup Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Resetting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Resetting the Security Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Resetting the Web Diagnostics Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Shutting Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Restarting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Rebooting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

9 • Managing Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Security Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

FactoryTalk Security Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Configuring Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Protocol Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Security Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Using FactoryTalk Directory Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Selecting Certificate Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Managing Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Changing User Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Resetting Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Resetting Default Admin Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Understanding User Privileges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Managing Security Trusts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Default Trusts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Client Application Trusts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Creating a Trust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Editing a Trust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Deleting a Trust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Creating a Trust Connection with FactoryTalk Historian SE or PI Server . . . . 173

10• Using Web Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

vii

Page 8

FACTORYTALK HISTORIAN ME USER GUIDE

Web Diagnostics Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Hardware Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

CPU, RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

NAND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Controller Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

ControlBus Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Display LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Time Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Firmware Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Historian Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

CIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Data Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Web Configuration Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Web Diagnostics Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Startup Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Admin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Hosts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Restart Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Core Dump Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

PI Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Download Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Change Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

viii

A • FactoryTalk Historian ME Rule Editor . . . . . . . . . . . . . . . . . . . 211

Rule Editor Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

File Management Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Current Rule File Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Rule Table Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Defining Rule Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Defining Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Creating Tag Attribute Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

B • Data Transfer Sample Scenario . . . . . . . . . . . . . . . . . . . . . . . . 227

Configuring Data Transfer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Page 9

CONTENTS

Initiating Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Using FactoryTalk Historian DataLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Defining the Server Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Using Excel as an Add-In: Example Scenario . . . . . . . . . . . . . . . . . . . . . . . . . . 231

C • FactoryTalk Directory Integration . . . . . . . . . . . . . . . . . . . . . . . 239

Integration Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Registering the Module in FactoryTalk Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Creating the Server Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Creating a FactoryTalk Historian ME Connection. . . . . . . . . . . . . . . . . . . . . . . 241

Creating a New User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Using FactoryTalk Historian DataLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Using DataLink as an Add-In: Sample Scenario . . . . . . . . . . . . . . . . . . . . . . . . 247

Inserting Trends with the Trend Add-In Wizard . . . . . . . . . . . . . . . . . . . . . . . . 251

D • RSLogix 5000 Add-on Profile . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Using AOP: Sample Scenario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Setting Up an Ethernet Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Configuring the Module in RSLogix 5000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Starting and Stopping Data Collection: Ladder Logic Control Example . . . . . . 266

Using the AOP Module Properties Configuration Tab . . . . . . . . . . . . . . . . . . . . . . . 268

E • Hardware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

F • Design Considerations and Limitations. . . . . . . . . . . . . . . . . . 273

Point Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Point Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Add Points Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Point Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Data Collection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Scan Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

High Speed Trend Pace Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Data Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Backup and Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

System Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

ix

Page 10

FACTORYTALK HISTORIAN ME USER GUIDE

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

ControlLogix Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Logix Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

CompactFlash Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Web Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

FactoryTalk Product Suite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

FactoryTalk Historian SE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

G• Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

General Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Providing Issue Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Rebooting the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Working in Safe Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Hardware Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Web Client Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Data Collection Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Data Storage Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Data Transfer Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Data Export Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Auto Recovery Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Time Management Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Client Computer Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Point Server Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Related FactoryTalk Product Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

FactoryTalk Historian DataLink. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

FactoryTalk Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

x

Page 11

1

FactoryTalk Historian

ME Web Interface

Overview

The FactoryTalk® Historian Machine Edition (ME) Module is a fully embedded

historian in a ControlLogix

ControlLogix chassis to utilize backplane communications and collect data from

multiple controllers. It collects data at very high speeds, runs calculations and

statistics on the data inside its storage archive, utilizing exception and compression

filtering to significantly reduce the data archive space. System and data information

are viewed through the FactoryTalk Historian ME web interface and all standard

FactoryTalk Historian web clients.

®

module that can be inserted into a Rockwell

1

Page 12

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

To provide an overview of your FactoryTalk Historian ME, this chapter provides the

following sections:

“Features”

“Benefits”

“Distributed FactoryTalk Historian Architecture”

“FactoryTalk and ControlLogix Integration”

“Hardware Specifications”

“Where to Start”

“Additional Information”

“FactoryTalk Licensing”

“Technical Support”

“Consulting Services”

“Training Programs”

Features

Key advantages of FactoryTalk Historian ME include:

Easy, automated installation and configuration and a rich, interactive browser

experience.

As an embedded historian in a ControlLogix chassis connected to the backplane,

FactoryTalk Historian ME is easily installed and configured. It communicates at

very high speeds with the controllers in its backplane, reducing implementation

time from hours, days, or months to minutes. It quickly auto-detects ControlLogix

controllers and configures all relevant tags to be historized. The web interface

provides easy configuration, administration, and reporting.

High speed Data Collection rates that are ten times (or more) faster than

traditional historian collection rates.

FactoryTalk Historian ME is not limited by network bandwidth. It leverages

backplane communication to increase the speed of Data Collection and, with

down to a 10 millisecond scan rate, the unit provides more granular data than is

possible on a traditional, network-connected plant historian.

2

Page 13

Reliable and robust hardened, embedded appliance with a low total cost of

ownership. Only a client computer is needed to install and configure your

FactoryTalk Historian ME.

FactoryTalk Historian ME records data safely and accurately with solid-state data

capture. It has no moving parts and requires no operating system or computer

maintenance. It is not subject to downtime due to network outage or the need to

perform maintenance on any subsequent firmware updates. It can be pre-qualified

from an OEM in a Factory Acceptance Test (FAT), thereby significantly reducing

overall validation efforts for end users.

Scalable Data Collection from machine through enterprise

FactoryTalk Historian ME is modular. It is rack-ready to stand alone or can easily

be rolled up and configured into a plant-wide historian for full resolution Data

Collection and transfer. It can capture data from up to four controllers in the local

backplane.

Benefits

FactoryTalk Historian ME provides these benefits:

1 • OVERVIEW

Reduces time-to-market by monitoring and analyzing operational and product

quality in accord with specifications and operations and product constraints.

Helps reduce time to execute grade or product changes by:

Assisting with product waste reduction, recycling, and blending.

Increasing effective equipment capacity and positively impacting materials

cost management.

Improving product development as it collects and evaluates data related to

new operation actions, materials, equipment, equipment capabilities, and

procedures.

Identifying operational or production bottlenecks and improving operating

efficiency to avoid unnecessary capital spending.

Increases compliance as it:

Facilitates, validates, and documents performance within regulatory or

permitted boundaries.

Increases management effectivity.

3

Page 14

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

Reduces validation by including OEM delivery and testing.

Enhances performance by:

Monitoring or calculatings effective equipment usage and performance.

Detecting degradation of performance and initiating alerts or requests for

operations and maintenance actions.

Providing real-time, time-stamped operational and production data.

Maximizes delivery, quality, and continuous process improvement by:

Documenting actual versus model production and identifying deviations.

Analyzing for new process and operational boundaries when throughput,

material, or equipment changes occur.

Distributed FactoryTalk Historian Architecture

Data or process historians are software applications that log data from process

equipment, manufacturing devices, and other main data sources that are important

and relevant for the overall manufacturing process and for product quality. The

FactoryTalk Historian collects time series data, which is very different from

traditional relational data and event data. The FactoryTalk Historian collects data

points at given intervals whether or not the data points are changing. This allows

customers to see how these data points are trending, and allows them to look at

correlations of data points.

Because the FactoryTalk Historian continuously collects data, it allows customers to

review past data and view what occurred at a specific past point(s) in time. This

means that if a specific event such as a downtime event, a bad batch, or an alarm

occurs, an operator can look at any process variable in the FactoryTalk Historian for

the same time frame as the event, and search for correlations that might explain the

event. This allows the user to improve production and operational processes,

eliminating the anomaly in the future.

The FactoryTalk Historian distributed architecture is multi-tiered. It redefines

available options for manufacturers who want to maximize their ability to collect and

analyze process data. It introduces a scalable, modular, synchronized methodology

for collecting, maintaining, and analyzing process data at each level of manufacturing

operations - machine or line, plant and enterprise (multi-plant). Specifically,

FactoryTalk Historian ME:

4

Page 15

1 • OVERVIEW

Enterprise

Edition

(future)

Machine

Edition

Site Edition

Provides an engine of unmatched performance and scalability, tightly integrated

with the FactoryTalk Services Platform to provide data accuracy and availability

across the Rockwell Automation

Introduces a historian appliance that offers scalable connectivity to Rockwell

®

Integrated Architecture.

Automation controllers.

Offers Rockwell customers a feature-rich set of commercially proven, industry-

focused applications that are widely regarded as the de-facto standard for plant

and enterprise historian capabilities.

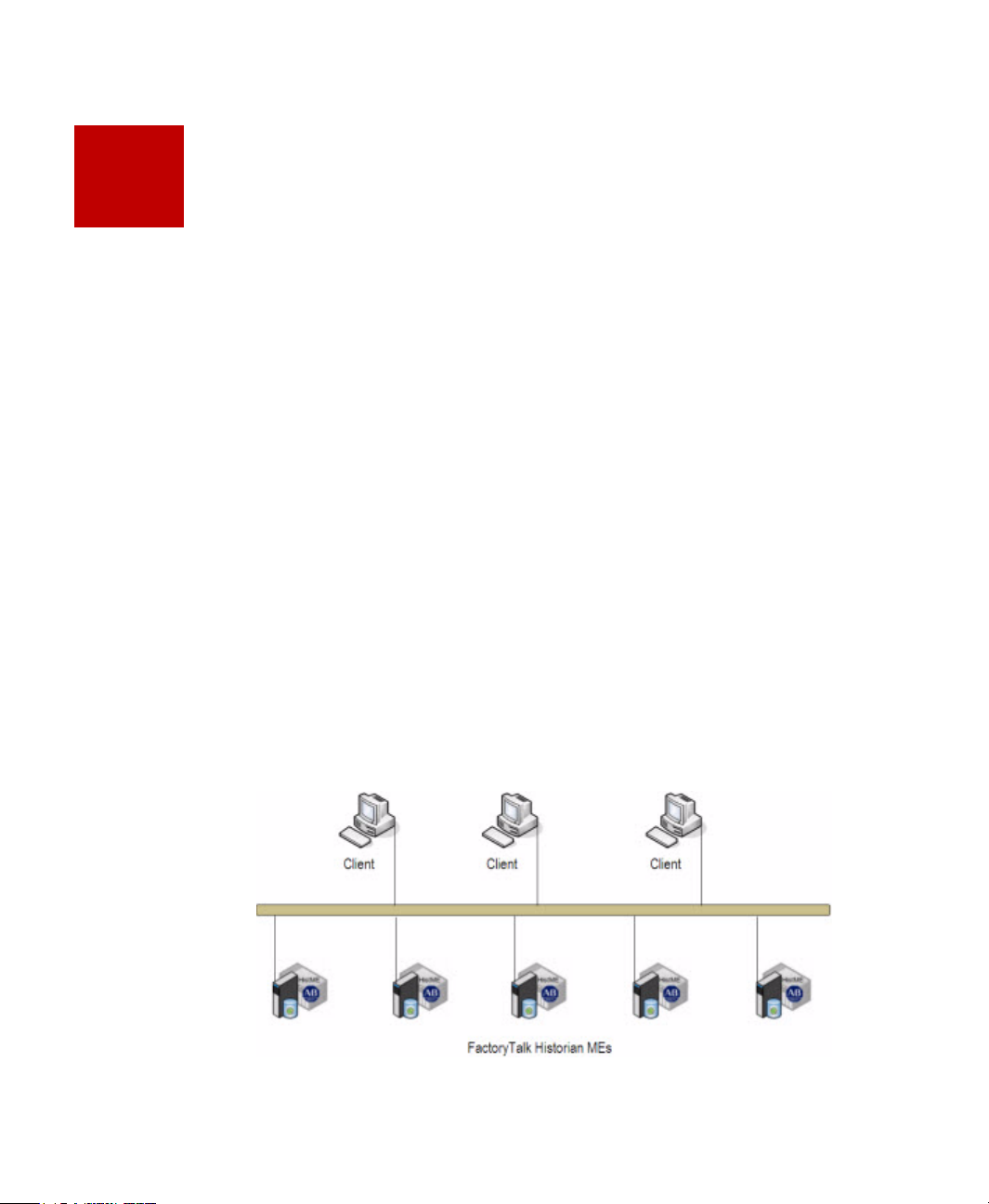

The following diagram depicts the three levels of the FactoryTalk Historian

distributed architecture.

5

Page 16

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

FactoryTalk and ControlLogix Integration

FactoryTalk Historian ME works with the FactoryTalk product suite and Rockwell

ControlLogix devices. The ControlLogix hardware and software provide easy and

secure access to resources (data, status, and configuration) within the ControlLogix

devices.

FactoryTalk Services Platform and FactoryTalk Product Suite

You must install the FactoryTalk Services Platform V2.10.02, Coordinated Product

Release 9 (CPR 9) Service Release 2 (SR2) first, on any computer where you plan to

run FactoryTalk Historian ME. Currently, FactoryTalk Historian ME supports these

services:

FactoryTalk Directory

FactoryTalk Security

FactoryTalk Administration Console

FactoryTalk Web Services

If you are using FactoryTalk Services Platform CPR 9 SR1 (or earlier), you must

upgrade to SR2 by installing the FactoryTalk Services Platform CPR 9 SR2 provided

on the FactoryTalk Historian ME Client Tools CD that was shipped with your

module. If you are upgrading a client computer to FactoryTalk Services Platform

version 2.10.02 CPR 9 SR 2, you may also need to upgrade the computer hosting the

6

Page 17

1 • OVERVIEW

FactoryTalk Network Directory Server to FactoryTalk Services Platform version

2.10.02.

For additional information on upgrading a previous version of the FactoryTalk Network

Directory Server, see the Rockwell Automation Knowledgebase at

http://www.rockwellautomation.com/resources/support.html.

The FactoryTalk Services PlatformV2.10.02 CPR 9 SR2 includes services and

applications listed in the following table.

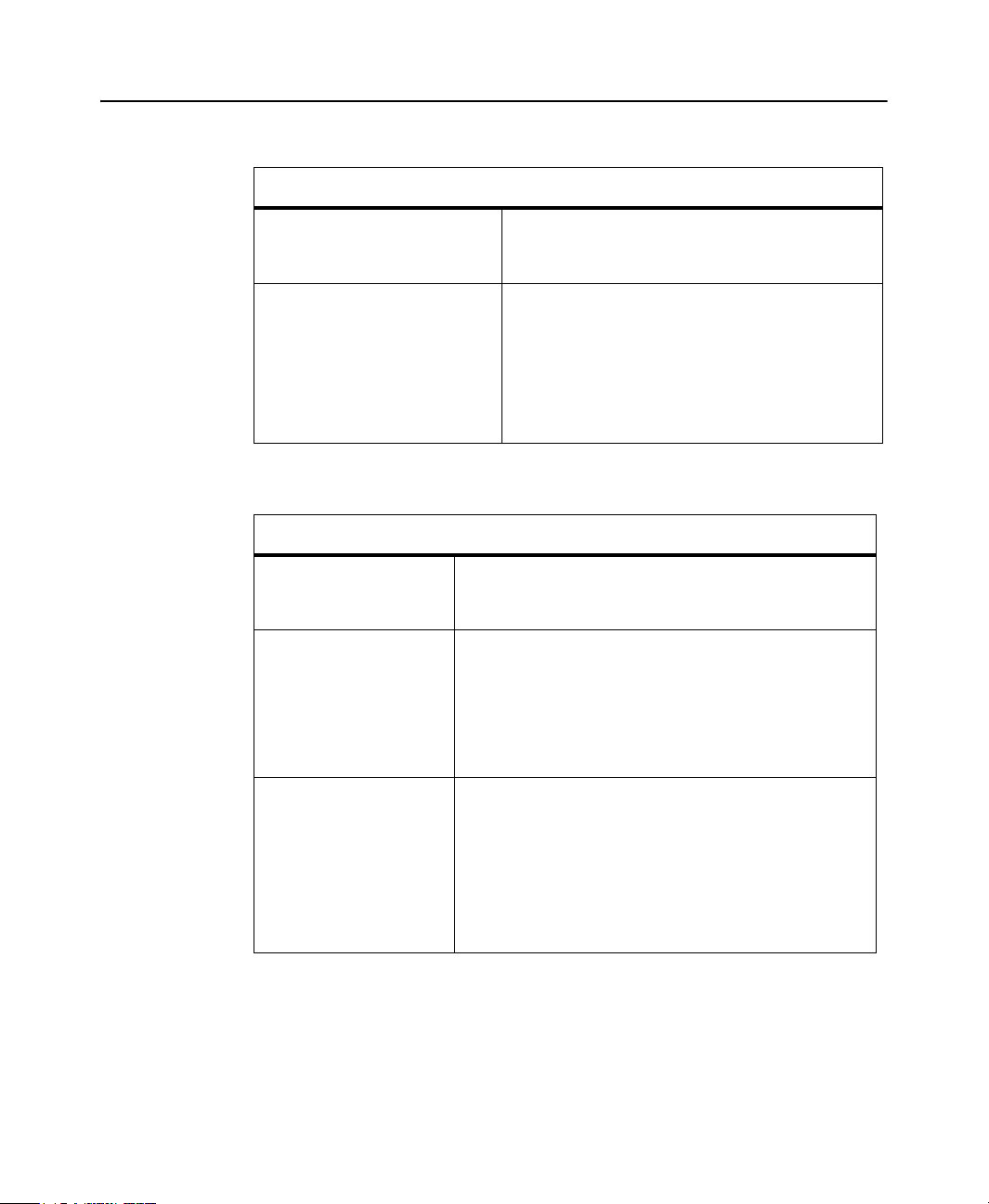

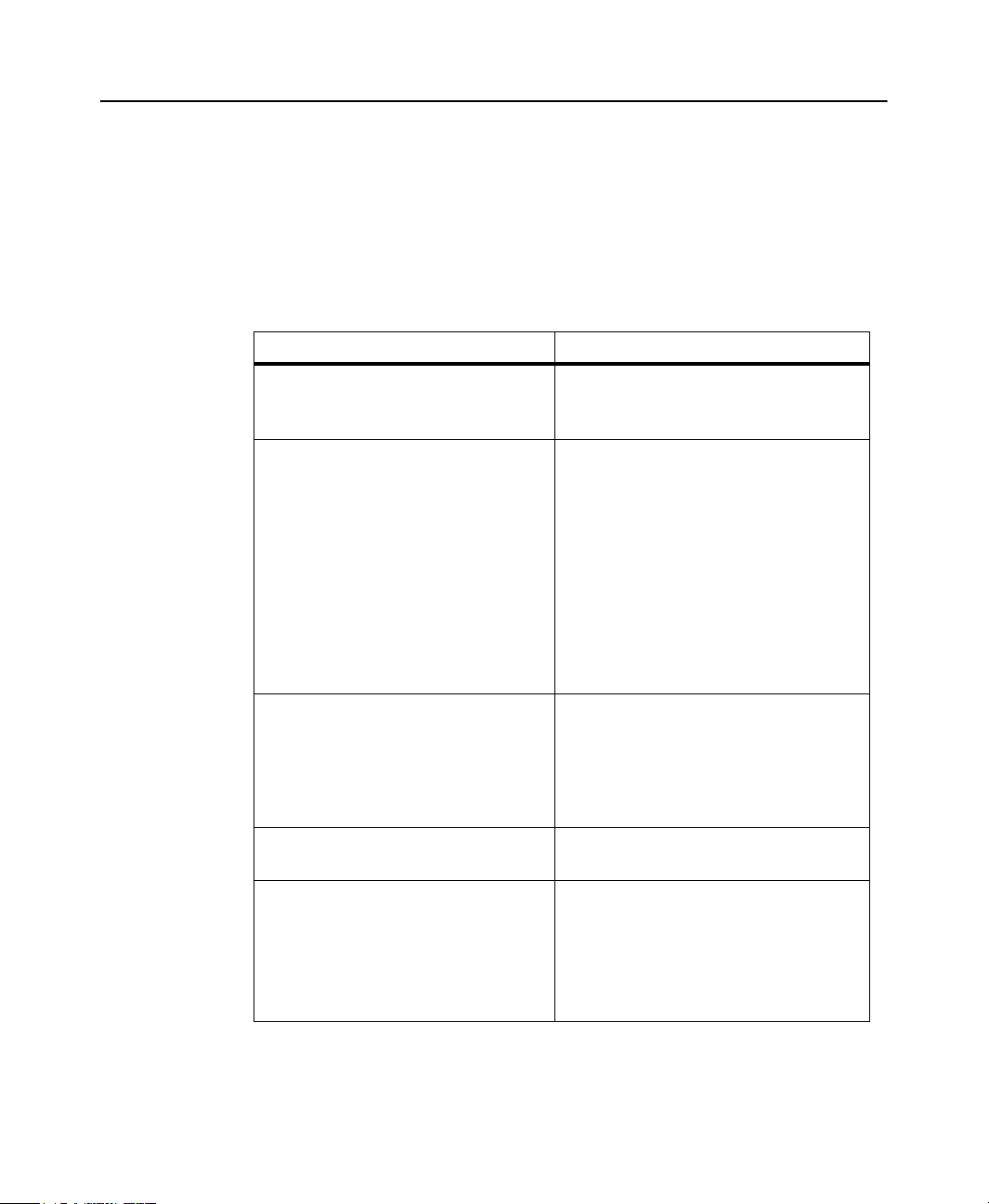

FactoryTalk Services Platform V2.10.02 CPR 9 SP2

FactoryTalk Administration

Console

V2.10.02.24

FactoryTalk Alarms and Events

V2.20.00

FactoryTalk Diagnostics

V2.10.02.24

FactoryTalk Directory

FactoryTalk Security

V2.10.02.24

Provides a way to configure connections to other

FactoryTalk applications such as FactoryTalk

Security. It also allows FactoryTalk Historian ME

and FactoryTalk Historian SE to use FactoryTalk

View SE for data monitoring and trending.

Allows multiple FactoryTalk products to produce a

common, consistent view of alarms and events that

occur in a FactoryTalk system.

Allows FactoryTalk-enabled products to define,

route, and store information about errors or changes

that occur in a FactoryTalk system.

Centralizes access to resources and components for

all FactoryTalk products participating in a control

system.

FactoryTalk Historian ME supports Network

Directory, not Local Directory. Network Directory

manages applications that can consist of multiple

clients and servers on separate computers connected

over a network, such as FactoryTalk Historian ME’s

network applications. You must set up all

participating computers to point at the same Network

Directory computer.

FactoryTalk Security centralizes user authentication

and authorization for FactoryTalk-enabled system.

These security services are fully integrated into the

FactoryTalk Directory.

7

Page 18

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

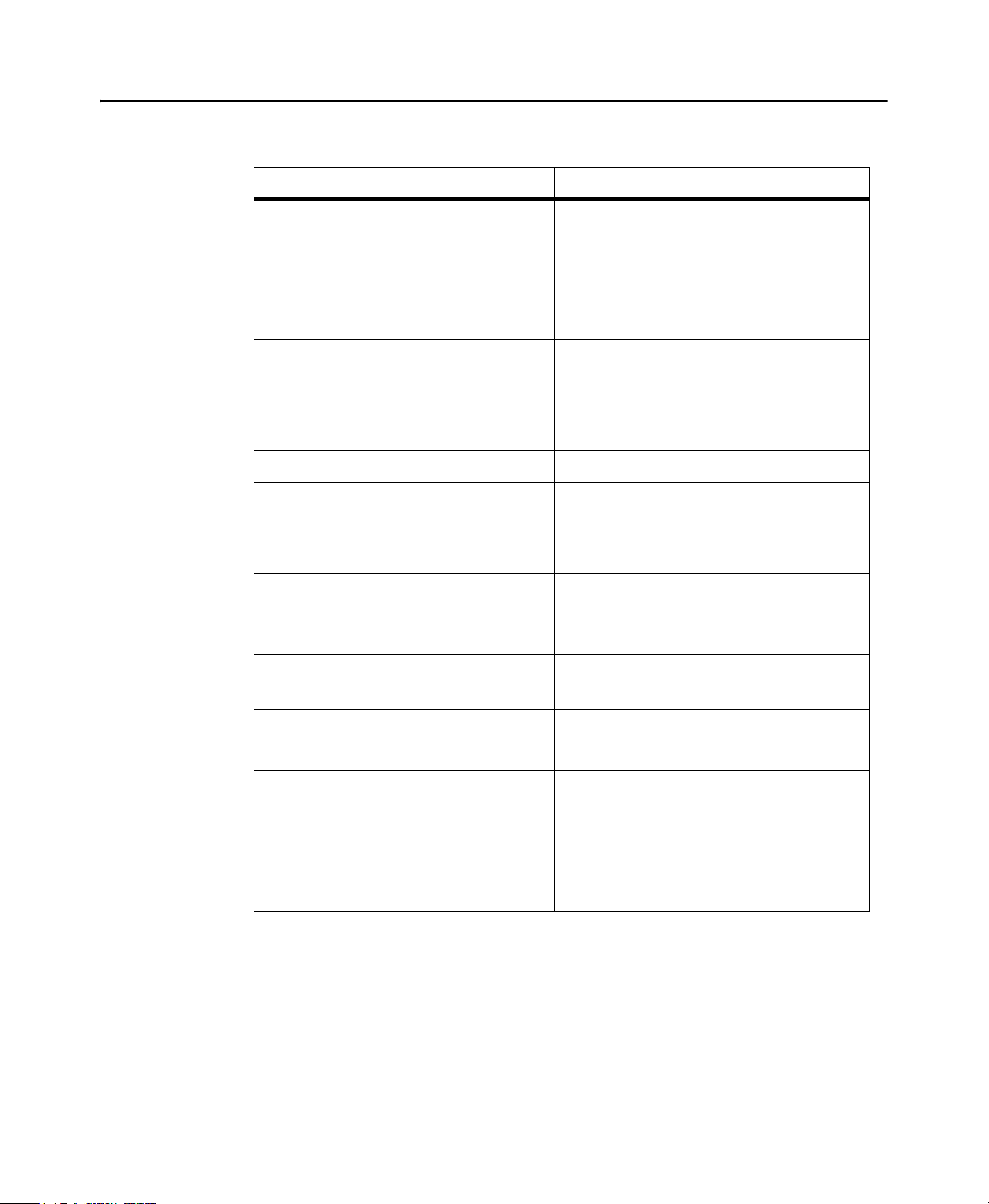

FactoryTalk Services Platform V2.10.02 CPR 9 SP2

FactoryTalk Live Data

V2.10.02.24

FactoryTalk Web Services

V2.10.02

Allows FactoryTalk services-enabled products to

discover, connect, and share real-time data in a

secure, scalable manner.

Provides the ability for thin clients to connect to

Web-based Rockwell Automation software products

through a Web browser. Before installing

FactoryTalk Web Services, install Microsoft Internet

Information Services (IIS). The steps for installing

IIS may be slightly different depending on your

operating system.

The FactoryTalk product suite includes the products listed in the following table.

FactoryTalk Product Suite

FactoryTalk Activation

FactoryTalk Historian SE

V2.1

Software-based product activation. To access the Rockwell

Software Activation website, go to http://

www.licensing.rockwellsoftware.com

Provides Data Transfer service for data logged by

FactoryTalk Historian ME for long-term storage and

analysis.

Before using FactoryTalk Historian SE, you must install

the FactoryTalk Historian SE patch for FactoryTalk

Historian SE Server.

FactoryTalk View SE

V5.0 and above

8

Provides a Trending Object for you to trend FactoryTalk

Historian ME data or FactoryTalk Historian SE data

acquired using FactoryTalk Historian ME.

FactoryTalk Historian ME can be integrated with

FactoryTalk View SE Trending.

See “Installing FactoryTalk View SE Patch” for required

patch information.

Page 19

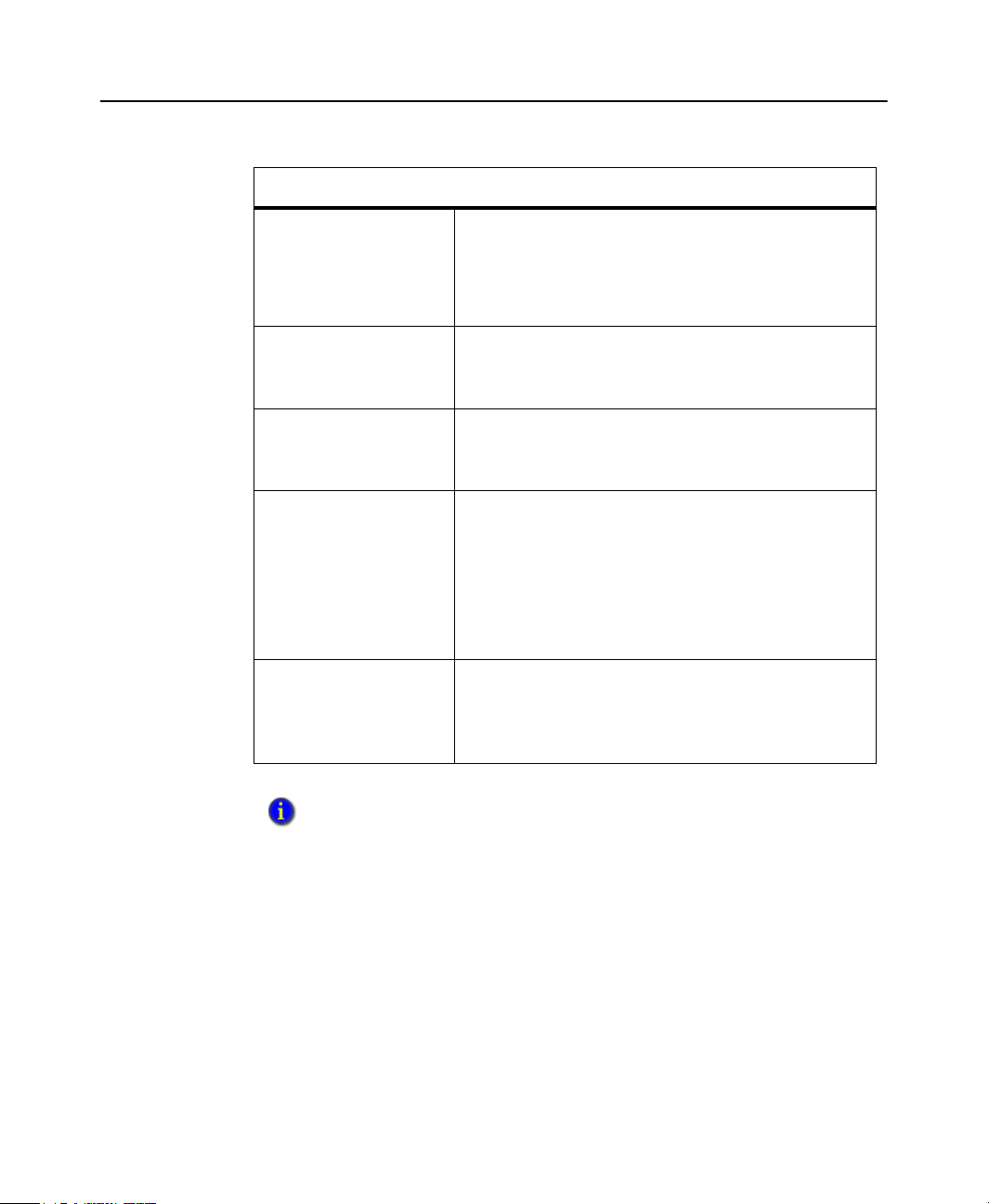

FactoryTalk Product Suite

1 • OVERVIEW

FactoryTalk VantagePoint

FactoryTalk

and

VantagePoint EMI

V3.1 and above

FactoryTalk Historian

DataLink

V3.1 and above

FactoryTalk Historian

ProcessBook

V3.0 and above

FactoryTalk Historian

Batch View

V3.1 and above

FactoryTalk Historian SQC

Add-in

V3.0 and above

Allows you to view process data from FactoryTalk

Historian ME in VantagePoint Excel® reports, dashboards,

and portals. Integrates the FactoryTalk Historian ME data

into the VantagePoint model, allowing you to correlate the

data with various other data sources.

Provides a Microsoft® Excel add-in component that allows

you to develop Excel reports based on the data in

FactoryTalk Historian ME.

Provides an ad-hoc data analysis capability in FactoryTalk

Historian ME that allows you to visualize the data in trends

and other graphical components.

Adds advanced batch trending and batch comparison

capabilities to FactoryTalk Historian ProcessBook and

FactoryTalk Historian DataLink, providing the ability to

visualize the batches and events collected in the

FactoryTalk Historian batch database.

This is a FactoryTalk Historian ProcessBook and a

FactoryTalk Historian DataLink add-in component.

Allows users to visualize historic data in Statistical Quality

Chart (SQC) ProcessBook displays.

This is a FactoryTalk Historian ProcessBook add-in

component.

For help with the FactoryTalk product suite, select Programs > Rockwell Software >

FactoryTalk Tools, and then click FactoryTalk Help from the Windows

®

Start menu.

9

Page 20

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

ControlLogix System Communications

A ControlLogix system consists of anything from your FactoryTalk Historian ME

and a stand-alone controller in a single chassis to more complex configurations that

include Ethernet/IP communication modules. The ControlLogix system in a chassis

uses connections to establish communication links between devices such as a

Logix5000 controller-to-local communication modules such as an EN2T or ENBT

module. RSLogix™ 5000 programming software and RSLinx Classic™ software are

used to facilitate communication and connections in the ControlLogix system.

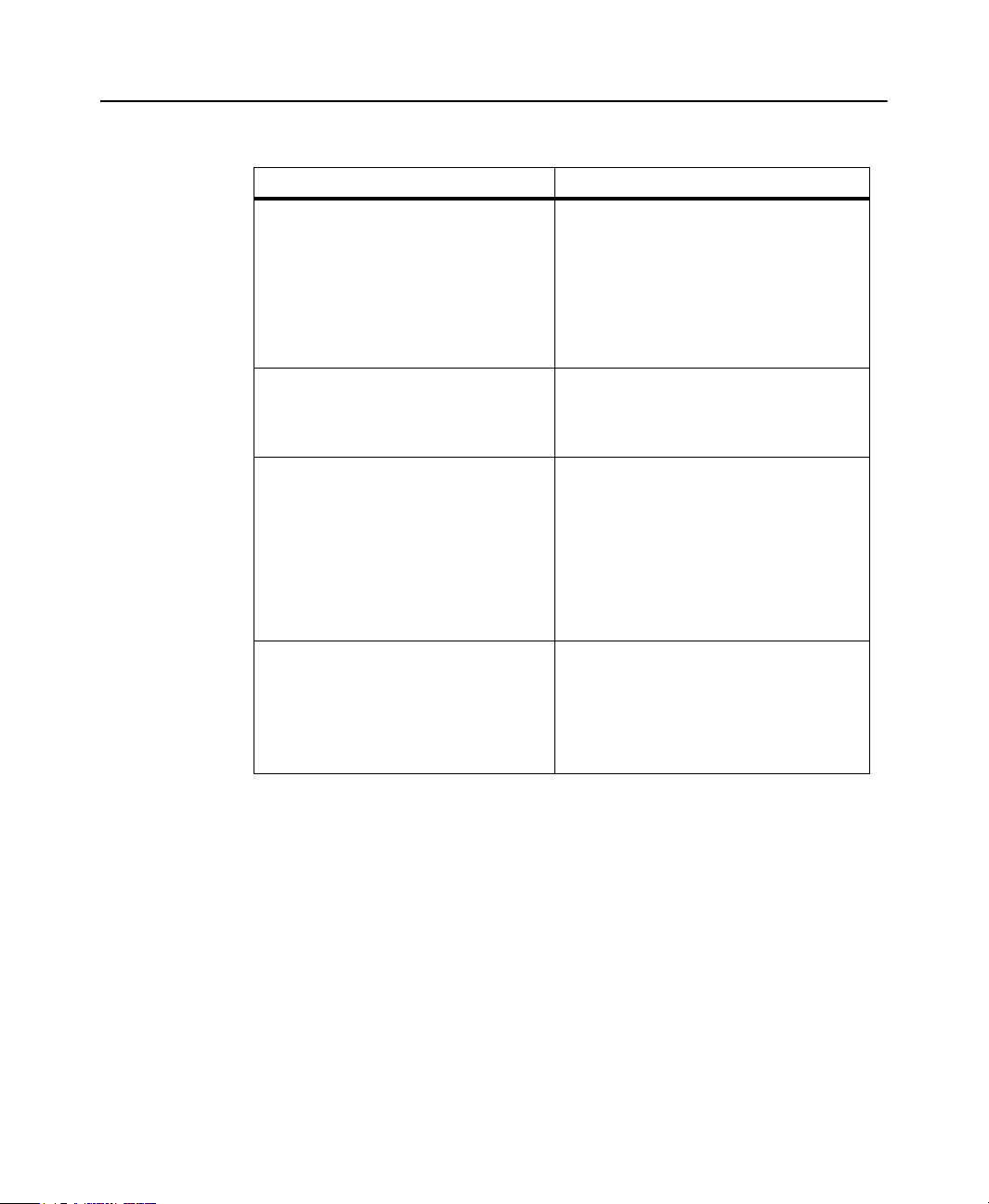

ControlLogix System Communication Applications

RSLogix 5000 Without AOP:

V13 - V18

With AOP:

V16 - V18

RSLinx Classic V2.55 A communications software that provides

Hardware Specifications

Refer to the “Hardware Specifications” appendix for a summary of hardware

specifications.

A programming software for Logix5000

controllers.

The FactoryTalk Historian ME Add On

Profile (AOP) is a RSLogix 5000 module

profile that allows FactoryTalk Historian

ME users to perform operations such as

tag monitoring, module shutdown, and

module restart without using the

FactoryTalk Historian ME web interface.

Refer to the “RSLogix 5000 Add-on

Profile” appendix for information about

using AOP.

an easy way to upload and download

Ladder logic files from Logix5000

controllers.

RSLogix 5000 uses RSLinx Classic to

browse your controller.

10

Page 21

Where to Start

This User’s Guide should be used as a companion to the online help in the

FactoryTalk Historian ME web interface. It is not necessary to read it from front to

back in sequential order. The following table provides a quick reference for tasks you

may want to perform.

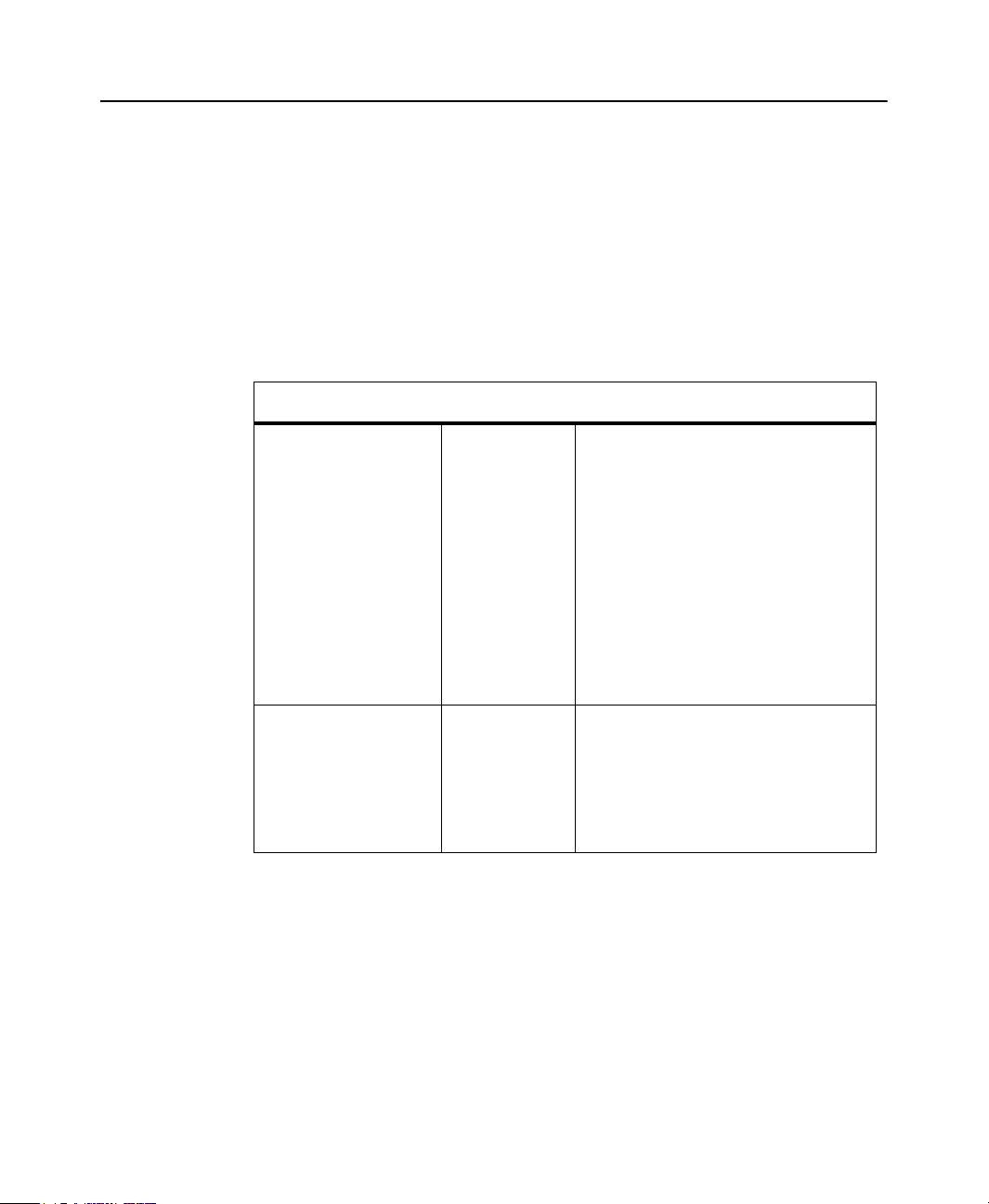

If You Want To Go to This Chapter

1 • OVERVIEW

Read about factors that may influence

the design of your FactoryTalk Historian ME environment.

Configure the module for the first time.

Configure time management.

Set up security.

Set up users.

Use the system log.

Backup or restore module configura-

tion files.

Upload configuration or other files.

Fix archives.

Manage administrative or user pass-

words.

Set up trust connections.

Create, edit or delete a trust connec-

tion.

Configure security with FactoryTalk

Directory and FactoryTalk Security.

View, create, or edit points.

Define point attributes.

Configure scan classes.

Work with exception filtering or com-

pression.

“Design Considerations and Limitations”

“Administering the Module”

“Managing Security”

“FactoryTalk Directory Integration”

“Managing Points”

11

Page 22

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

If You Want To Go to This Chapter

Stop or start Data Collection.

View the status of Data Collection.

Configure disk or log thresholds.

Work with Compression or Exception

“Collecting Data”

Filtering

Configure Data Transfer.

Stop or start Data Transfer.

Transfer data to a FactoryTalk Histo-

“Transferring Data”

rian SE.

View a model Data Transfer scenario. “Data Transfer Sample Scenario”

View current or archive data.

Create trends in the web interface.

Export data to a spreadsheet.

View performance information about

your module.

View statistics about your module data.

Get diagnostic information about your

“Viewing Data”

“Viewing Module Information”

“Using Web Diagnostics”

“Using Web Diagnostics”

module.

Find guidance to resolve simple issues. “Troubleshooting”

“Using Web Diagnostics”

12

Read introductory information about

your module.

Find related technical publications.

Get training information.

Contact Technical Support.

“Overview”

Page 23

If You Want To Go to This Chapter

1 • OVERVIEW

Learn about software, hardware, or

system requirements.

Work with the Client Tools CD.

Use your module for the first time.

Log In to your module.

Log Out of your module.

Use the Rule Editor.

Create rule files.

Create tag attribute files.

Use the Add-on Profile (AOP).

Start or stop your module without

using the web interface controls.

Restore module default settings with-

out using the web interface controls.

Reset module security without using

the web interface controls.

View a module hardware summary.

Check proper operating temperatures

for your module.

View environmental certifications for

your module.

“Getting Started”

“FactoryTalk Historian ME Rule Editor”

“RSLogix 5000 Add-on Profile”

“Hardware Specifications”

Additional Information

Click Browse FactoryTalk Historian ME User Documents on the FactoryTalk

Historian Client Tools CD that is shipped with

FactoryTalk Historian ME user documentation. In addition to this User’s Guide,

which explains how to configure your

features, the

FactoryTalk Historian ME Quick Start Guide (1756-QS106A-EN-P) - describes

how to quickly install and configure FactoryTalk Historian ME so that users can

start collecting and viewing data without having to configure all features.

FactoryTalk Historian ME documentation set includes the following:

FactoryTalk Historian ME to access

FactoryTalk Historian ME and use its various

13

Page 24

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

The quick start guide is also provided as a printed manual.

FactoryTalk Historian ME Installation Instructions (1756-IN106A-EN-P) -

explains how to install

testing and certification information.

The installation information is provided as a printed manual.

FactoryTalk Historian ME Online Help - describes FactoryTalk Historian ME

web interface in detail. Access the help files by clicking the About... links in the

left-side navigation bar of the individual web interface pages and by clicking the

main Help link located in the upper right-hand corner of the web interface.

FactoryTalk Historian ME Release Notes - contains the latest information about

your FactoryTalk Historian ME including new features and a list of known issues.

FactoryTalk Licensing

FactoryTalk Historian ME limits the clients that can access it to the following

Rockwell Automation clients:

FactoryTalk VantagePoint and FactoryTalk VantagePoint EMI

FactoryTalk Historian ME. It also includes environmental

14

FactoryTalk Historian DataLink

FactoryTalk Historian ProcessBook

FactoryTalk View SE Trending

FactoryTalk Administration Console

PI System Management Tools (SMT)

PI SMT Tag Configurator

In addition, you must purchase a point license for FactoryTalk Historian ME-toFactoryTalk Historian SE Data Transfer. Data Transfer works with the Data Storage

and Data Collection services to transfer historical data to a FactoryTalk Historian SE

server. The point license determines the number of points that can be transferred to

FactoryTalk Historian SE. For each FactoryTalk Historian ME, the licensed limit is

2500 points.

Page 25

Technical Support

Please visit Rockwell Automation Customer Support Center at http://

support.rockwellautomation.com/ for access to user forums, sample code, software

and firmware updates, product manuals, and other downloads.

Knowledgebase

The Customer Support Center offers an extensive online knowledgebase that includes

frequently asked questions (FAQs) and the latest patches. Please visit http://

www.rockwellautomation.com/resources/support.html and select the

Knowledgebase link located under Tools & Resources to:

View technical and application notes.

Obtain software patches and firmware updates.

Subscribe to product and service e-mail notifications.

Ask questions.

Worldwide Support

If you are not located in North America and want to contact Rockwell Automation

Support use the Worldwide Locator at http://www.rockwellautomation.com/

locations/ for worldwide contact information.

1 • OVERVIEW

TechConnect Support

With TechConnect Support, your site has unlimited, real-time access to Rockwell

Automation's global network of Customer Support Centers and technical resources.

TechConnect service levels are provided at http://www.rockwellautomation.com/

services/onlinephone/techconnect/

When you call you should be at your computer and be prepared to give the following

information:

Product version number.

Type of hardware you are using.

15

Page 26

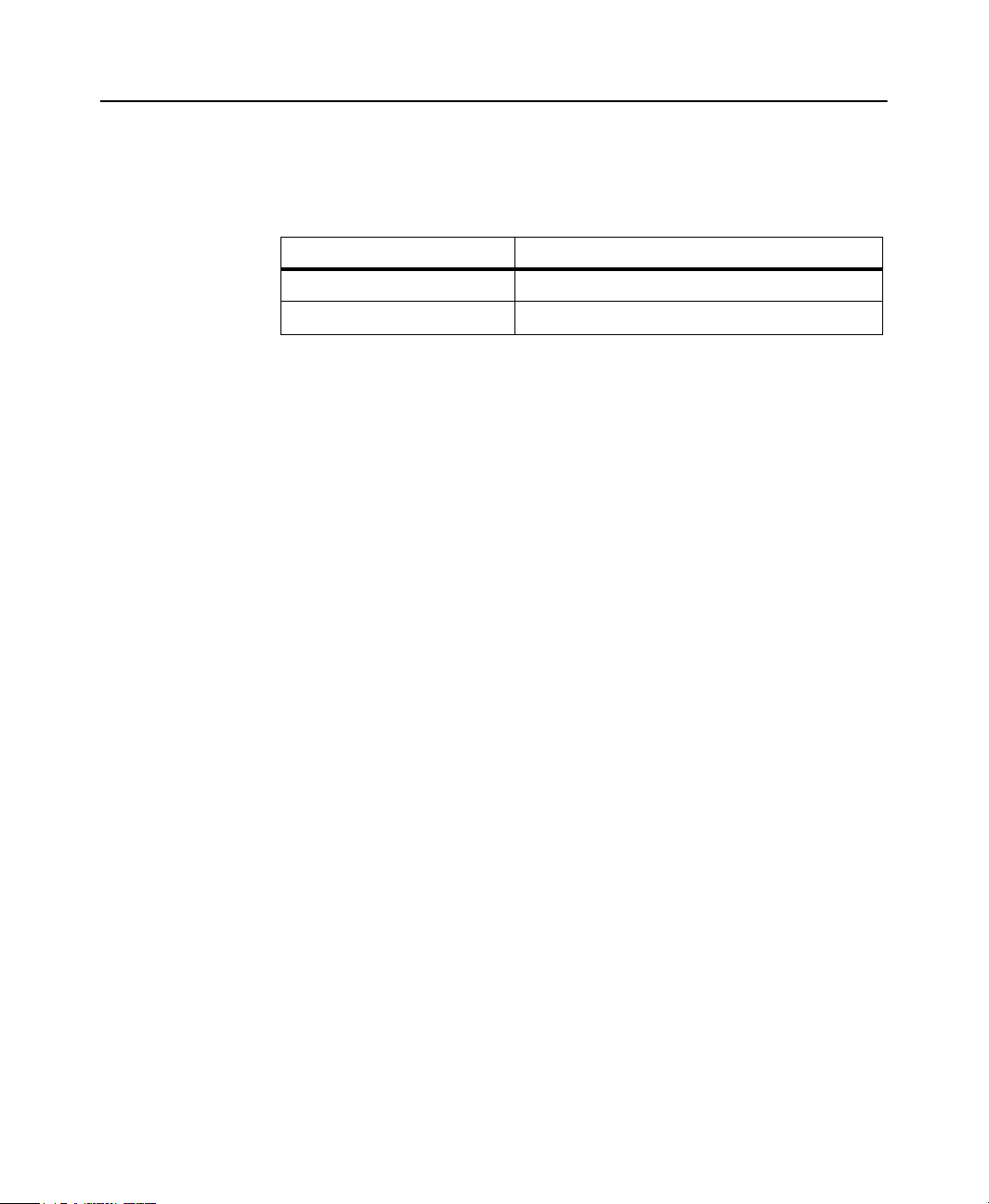

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

FactoryTalk Historian ME has two product numbers. The 1G or 2G in the part

number indicates how much data storage is associated with the module.

Product Catalog Number Description

1756-HIST1G FactoryTalk Historian ME 1GB module

1756-HIST2G FactoryTalk Historian ME 2GB module

Exact wording of any messages that appeared on your screen.

Descriptions of:

What happened and what you were doing when the problem occurred.

How you tried to solve the problem.

Consulting Services

Rockwell Automation provides expert consulting and turnkey implementations for

making optimal use of Rockwell Software products. Please contact your local

distributor for more information.

16

Training Programs

Rockwell Automation offers a wide range of training programs that include elearning, regularly scheduled and custom-tailored classes, self-paced training, and

certificate programs.

If you would like more information about training, visit the Rockwell Automation

Training site at http://www.rockwellautomation.com/services/training/ or call

1.440.646.3434.

Page 27

2

Getting Started

Before installing FactoryTalk Historian Machine Edition (ME), determine your

platform requirements and configuration environment. The information in this

chapter offers some guidelines as you begin planning.

“System Requirements”

“Software Requirements”

“Hardware Specifications”

“Setting up Your ControlLogix Environment”

“Installing FactoryTalk Historian ME”

“FactoryTalk Historian ME Web Interface”

“Installing FactoryTalk Historian ME Client Tools”

“Logging In to FactoryTalk Historian ME”

“Logging Out of FactoryTalk Historian ME”

System Requirements

The hardware and software required with FactoryTalk Historian ME depends on the

demands an application places on the system. A simple stand-alone architecture is

shown below.

17

Page 28

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

The greater the demand, the more powerful a system must be to support this demand.

For large or complex applications, use computers with faster CPUs and more RAM.

In addition to this, there should always be sufficient disk space to provide virtual

memory that is at least twice the size of the physical RAM.

Software Requirements

Software requirements include:

Windows Vista® SP1, Windows XP SP2 or SP3, or Windows Server® 2003 SP2

Windows Vista is only supported for the FactoryTalk Historian ME web interface and

FactoryTalk VantagePoint. It is not supported for FactoryTalk Historian DataLink or

FactoryTalk ProcessBook.

Microsoft Excel 2003 for FactoryTalk Historian DataLink

Microsoft Internet Explorer® (IE) 6, 7, or 8 (in Compatibility Mode)

IE 6 P

ATCHES

For IE 6, the requirements may include installation of the patch KB974455 (10/12/

09) http://support.microsoft.com/kb/974455.

Windows XP SP2

If the \windows\system32\mshtml.dll file has a version that is less than or equal to

6.0.2900.2180 or a date that is before or equal to 08/03/2004, apply patch

KB974455. After the patch has been applied, the \windows\system32\mshtml.dll

file will have a version of 6.0.2900.3627 and a date of 09/24/2009.

Windows XP SP3

If the \windows\system32\mshtml.dll file has a version that is less than

6.0.2900.5512 or a date that is before 04/14/2008, apply the patch KB974455.

After the patch has been applied, the \windows\system32\mshtml.dll file will

have a version of 6.0.2900.5880 and a date 09/24/2009.

Windows Server 2003 SP2

The minimum supported version is 6.0.3790.3959. If the IE 6.0 version is less

than the minimum supported version, apply the patch KB974455 SP2.

18

Page 29

2 • GETTING STARTED

IE Internet Options

The location of your Internet options settings vary according to which operating

system you are using. However, in general, you should:

Disable any popup blockers to view online help.

Select the Local Intranet icon (generally located under Security settings), and

click [Sites] to use the default setting, Automatically detect internet network.

Use the default Security level for this zone. In general, the settings should remain

at the default level and should not be changed. Use the medium-low default

setting.

Enable the following settings:

Binary and script behaviors

Run ActiveX® controls and plug-ins

Script ActiveX controls marked safe for scripting

Initialize and script ActiveX controls not marked as safe for scripting

IE 7 Hot Fix

If you are using IE 7.0 and want to export to Excel, you must install Microsoft’s IE 7

hot fix 929863 (http://support.microsoft.com/kb/929863.) This fix addresses an Excel

file export issue on the Current Data and System Log pages the FactoryTalk Historian

ME web interface. Installing the hot fix adds these registry values:

[HKEY_CLASSES_ROOT\.doc] “PerceivedType”=”document

[HKEY_CLASSES_ROOT\.dot] “PerceivedType”=”document

[HKEY_CLASSES_ROOT\.xls] “PerceivedType”=”document

[HKEY_CLASSES_ROOT\.xlt] “PerceivedType”=”document

[HKEY_CLASSES_ROOT\.ppt] “PerceivedType”=”document

[HKEY_CLASSES_ROOT\.pot] “PerceivedType”=”document

You must manually add the [HKEY_CLASSES_ROOT\.csv]

“PerceivedType”=”document” registry value for the .csv document type.

19

Page 30

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

IE 8 Compatibility Mode Internet Option

If you are using Internet Explorer 8 in compatibility mode, you must enable the

security setting for Include local directory path when uploading files to a server.

FactoryTalk Historian SE Patch

FactoryTalk Historian ME can be integrated with FactoryTalk Historian SE 2.1 after

you have installed the FactoryTalk Historian SE patch. The FactoryTalk Historian SE

patch must be installed on the FactoryTalk Historian SE that will be used with

FactoryTalk Historian ME. You can download the FactoryTalk Historian SE patch

from the Rockwell Knowledgebase at http://support.rockwellautomation.com. Click

the Search Answers tab and search for Answer ID 63530.

Once the patch is installed, the FactoryTalk Activation licenses that support the

FactoryTalk Historian ME-to-FactoryTalk Historian SE (FTMS) point source can be

configured for the FactoryTalk Historian SE server within the FactoryTalk

Administration Console. The FactoryTalk Historian SE patch enables the FTMS

point source support. A license is a prerequisite for FactoryTalk Historian ME-toFactoryTalk Historian SE Data Transfer.

In addition, the patch will allow FactoryTalk Historian ME to work with FactoryTalk

Historian SE collecting, storing, analyzing, and visualizing data using reporting tools

such as time-series trends, bar charts, pie charts, pareto, and tabular trends.

20

Client Tools Software

The FactoryTalk Historian ME Client Tools CD shipped with your module includes:

FactoryTalk Services Platform

V2.10.02 CPR 9 SR2 is supported.

FactoryTalk Historian Management

If you install the FactoryTalk Historian Management (Admin Console) on a

remote client computer that has no previously installed Admin Console, you must

make a Windows Registry entry to be able to use a Universal Naming Convention

(UNC) path as the current directory. Manually add the key

[HKEY_CURRENT_USER\Software\Microsoft\Command

Processor\DisableUNCCheck REG_DWORD] and set the value to 0x1 (Hex).

FactoryTalk Historian ME Rule Editor

FactoryTalk Historian ME RSLogix 5000 Module Profile

Page 31

This installs the Add-On Profile (AOP) for your module.

Getting Started Videos

These videos provide instruction in how to install, configure and use the various

FactoryTalk Historian ME components. You must have Adobe Flash Player

installed on your system in order to view these videos.

RSLogix 5000 Clock Update Tool

This tool is located in the \Redist folder on the Client Tools CD.

RSLinx Classic

This tool is located in the \Redist folder on the Client Tools CD.

FactoryTalk Historian ME User Documentation and Release Notes

Hardware Requirements

This section lists client computer and 1756 ControlLogix chassis requirements.

Client Computer Requirements

Client computer requirements include:

2 • GETTING STARTED

Recommended

Intel Celeron

3GHz or higher

1GB of RAM or more

or

Minimum

Intel Pentium III

600MHz

512MB RAM

Mouse or compatible pointing device

21

Page 32

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

ControlLogix Chassis Requirements

The ControlLogix chassis is part of a modular system that you can create with

FactoryTalk Historian ME, an Ethernet/IP communication module(s), and controller

module(s). Chassis are available with 4, 7, 10, 13, and 17 slots. You can place the

FactoryTalk Historian ME module into any slot. Slot 0 is the first slot and is always

the left-most slot in the rack (the first slot to the right of the power supply.)

The FactoryTalk Historian ME module communicates with the control processor(s)

in controller module(s) through the ControlLogix backplane (also known as the

ControlBus). The backplane is an electrical interface, or bus, to which modules

connect when inserted into the rack. The backplane provides a high-speed

communication path between modules and distributes power to each of the modules

within the chassis. Controller modules on the backplane can send data to and receive

data from the module.

Chassis requirements include:

1756 ControlLogix Chassis (1756-AXX) and proper chassis power supply for

your environment

RSLogix 5000 software and RSLinx Classic communications software

An Ethernet/IP communication bridge module (1756-ENBT, 1756-EN2T, 1756-

EN2TR, or 1756-EWEB, depending on your environment)

22

ControlLogix 55xx (1756-Lxx) controllers, version 13 or higher

A 1GB or 2GB FactoryTalk Historian ME module

FactoryTalk Historian ME does not support multiple modules collecting data from a

single controller.

U

PGRADING AND REINSTALLING THE FIRMWARE

To upgrade the FactoryTalk Historian ME firmware (or reinstall it in case it becomes

corrupted), you must use the ControlFlash Firmware upgrade kit.

Any kind of firmware upgrade or reinstall will clear out all logs. A firmware upgrade will

preserve archived data and application configuration information, but a reinstall will clear

out all application configuration information and archived data. If you want to save your

settings, download and back up your configuration and logs.

Before you upgrade ensure that:

Data Collection and Data Transfer are stopped.

Page 33

2 • GETTING STARTED

Firmware

version

All clients (including web clients) are logged out and disconnected.

Log files are packaged and downloaded from the Download Logs page of the

Web Diagnostics interface.

See “Download Logs” for more information about web diagnostics.

You collect the following information for the upgrade process:

The catalog number of FactoryTalk Historian ME (1756-HIST1G or 1756-

HIST2G, depending on the size of the CompactFlash drive.)

The network configuration information.

The network path to FactoryTalk Historian ME.

The firmware version number. Click the About link on the on FactoryTalk

Historian ME’s home page to access the version number.

Instructions on how to perform the upgrade, located in the ControlFLASH

Firmware Upgrade Kit Quick Start Guide, Publication Number 1756-

QS105C-EN-E.

23

Page 34

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

Setting up Your ControlLogix Environment

Perform the following steps to set up your ControlLogix environment before

installing FactoryTalk Historian ME:

1. Set up the ControlLogix chassis.

2. Insert the ControlLogix controller(s) into the chassis.

3. Power on the system.

4. Configure the ControlLogix device(s).

See your ControlLogix Chassis and ControlLogix Controller documentation for more

detailed information.

Installing FactoryTalk Historian ME

To install FactoryTalk Historian ME, unpack it and insert it into the chassis.

See your FactoryTalk Historian ME Installation Instructions for more hardware

information.

24

FactoryTalk Historian ME Web Interface

FactoryTalk Historian ME receives data from the ControlLogix Data Collection

interface and stores it locally in the module. The module’s data and system

information can be viewed and managed through the FactoryTalk Historian ME web

interface. The web interface supports multiple layers of firmware applications that are

designed to collect data and provide system and module status and statistics.

FactoryTalk Historian ME web interface can be accessed through a web browser after

the installation of the module.

See “Logging In to FactoryTalk Historian ME” for login instructions.

Page 35

2 • GETTING STARTED

Installing FactoryTalk Historian ME Client Tools

After you have selected the platform that best suits your needs and have installed

FactoryTalk Historian ME into the chassis, you will then determine the configuration

environment for the FactoryTalk Historian ME client tools. The client tools can be found on

the CD that was shipped with FactoryTalk Historian ME.

If you plan to use FactoryTalk Historian ME Client Tools, such as the FactoryTalk Historian ME

Rule Editor, FactoryTalk Directory, and/or FactoryTalk Security, then these tools must be installed

before you continue. If you do not plan to use FactoryTalk Historian Client Tools, then skip to

“Logging In to FactoryTalk Historian ME”.

Insert the CD into your computer’s CD drive. If autoplay is turned on, the FactoryTalk

Historian ME installation screen will automatically launch and display the FactoryTalk

Historian ME installation options. If the screen does not automatically launch, click Start >

Run and type D:\setup, where D is the letter of your CD drive.

To access the FactoryTalk Historian ME Client Tools, click Install ME Client Tools from the

main menu. This takes you to the Installation menu. The FactoryTalk Historian ME Client

Tools installation screen allows you to perform the following tasks:

“Installing FactoryTalk Services Platform”

“Installing FactoryTalk Historian Management”

“Installing FactoryTalk Historian ME Rule Editor”

“Installing FactoryTalk Historian ME RSLogix 5000 AOP”

A patch for FactoryTalk View SE and electronic data sheet (EDS) files are also available on

the Client Tools CD. However you should always check the Rockwell Technical Support

Knowledgebase to ensure that you have the latest patches.

See the “Installing FactoryTalk View SE Patch” and “FactoryTalk Historian ME EDS Files”

sections for information.

25

Page 36

FACTORYTALK HISTORIAN ME MODULE USER’S GUIDE

In addition to the tools and patches, the FactoryTalk Historian ME release notes and

user documentation are available on the CD.

26

Installing FactoryTalk Services Platform

This option installs FactoryTalk Services Platform CPR 9 SR2. The FactoryTalk

Services Platform is an underlying architecture and set of common services that

Rockwell Automation products build upon. It must be installed on the computer that

hosts the FactoryTalk Directory server. It is also required if you plan to use

FactoryTalk Security. However, it is optional if you plan to use the FactoryTalk

Historian ME Native security mode.

Refer to the FactoryTalk Services Platform online help for detailed information about the

FactoryTalk Services Platform.

The following components and services are installed as part of the platform:

FactoryTalk Directory organizes project information from multiple FactoryTalk

products across multiple computers on a network. It allows products to share a

Page 37

2 • GETTING STARTED

common address book, which finds and provides access to plant-floor resources,

such as data tags and graphic displays. Only Network Directory is supported.

FactoryTalk Security can be used to secure your FactoryTalk network after

installing FactoryTalk Services Platform.