Page 1

ControlLogix

Ethernet

Communication

Interface Module

1756-ENET/B

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Page 3

Throughout this manual we use these notes to make you aware of

safety considerations:

WARNING

Identifies information about practices or

circumstances that have the potential to create an

explosion hazard.

!

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage or economic loss.

!

Warning and Attention statements help you to:

identify a hazard

•

avoid a hazard

•

recognize the consequences

•

IMPORTANT

Allen-Bradley and ControlLogix are trademarks of Rockwell Automation.

Ethernet is a trademark of Digital Equipment Corporation, Intel, and Xerox Corporation.

RSLinx and RSLogix 5000 are trademarks of Rockwell Software.

Windows 95/98 and Windows NT are trademarks of Microsoft Corporation.

Identifies information that is critical for successful

application and understanding of the product.

Page 4

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

EN 50081-2 EMC — Generic Emission Standard, Part 2 —

•

Industrial Environment

EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

•

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests. For specific information required by EN 61131-2, see the

appropriate sections in this publication, as well as the Allen-Bradley

publication Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1.

Open style devices must be provided with environmental and safety

protection by proper mounting in enclosures designed for specific

application conditions. See NEMA Standards publication 250 and IEC

publication 529, as applicable, for explanations of the degrees of

protection provided by different types of enclosure.

Page 5

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors and 260 authorized

systems integrators located throughout the United States alone, as well

as Rockwell Automation representatives in every major country in the

world.

Local Product Support

Contact your local Rockwell Automation representative for:

sales and order support

•

product technical training

•

warranty support

•

support service agreements

•

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

call your local Rockwell Automation representative, or call Rockwell

directly at: 1 440 646-6800.

For presales support, call 1 440 646-3NET.

You can also obtain technical assistance online from the following

Rockwell Automation WEB sites:

www.ab.com/mem/technotes/kbhome.html

•

www.ab.com/networks/eds

•

(electronic data sheets)

(knowledge base)

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us of it on the

enclosed Publication Problem Report.

Page 6

Page 7

About This User Manual

Preface

What this Preface Contains

Who Should Use This Manual

This preface describes how to use this manual. The following table

describes what this preface contains and where to find specific

information.

For information about See page

Who Should Use This Manual P-1

Common Techniques Used in This Manual P-2

How To Use This Manual P-2

About the Example Applications P-3

System Components P-4

Where to Find More Information P-5

Terminology P-6

This manual is intended for control engineers and technicians who are

installing, programming, and maintaining a control system that

communicates on an Ethernet network through a 1756-ENET/B

module.

We assume you have a good understanding of Ethernet and the

(TCP/IP) protocol. This user manual contains a brief description of

Ethernet and TCP/IP in Chapter 3. For detailed information on TCP/IP

protocol and networking in general, see the following publications:

Comer, Douglas E. Internetworking with TCP-IP, Volume 1:

•

Protocols and Architecture, 2nd ed. Englewood Cliffs, N.J.:

Prentice-Hall, 1995. ISBN 0-13-216987-8.

Tanenbaum, Andrew S. Computer Networks, 2nd ed.

•

Englewood Cliffs, N.J.: Prentice-Hall, 1989. ISBN 0-13-162959-X.

1 Publication 1756-UM051B-EN-P - November 2000

Page 8

P-2 About This User Manual

Common Techniques Used in This Manual

The following conventions are used throughout this manual:

Bulleted lists provide information, not procedural steps.

•

Numbered lists provide sequential steps.

•

Information in bold contained within text identifies menu

•

windows, or screen options, screen names and areas of the

screen, such as dialog boxes, status bars, radio buttons and

parameters.

TIP

This is a definition

box. When a word is

bold within the text

of a paragraph, a

definition box will

appear in the left

margin to further

define the text.

This symbol identifies helpful tips.

A definition box defines terms that may be

unfamiliar to you.

How To Use This Manual

Screen captures are pictures of the software’s

actual screens. The names of screen buttons and

fields are often in bold in the text of a

procedure. Pictures of keys represent the actual

keys you press.

This manual provides an overview of the 1756-ENET/B module, as

well as general information about Ethernet. It describes how to install

and configure the module, and provides three example applications

showing how to use the module to communicate over Ethernet.

The example applications are intended as building blocks to help you

get your own network up and running. We recommend that you set

up and run the example applications and use them as a guide for

setting up your own system.

Publication 1756-UM051B-EN-P - November 2000

Page 9

About This User Manual P-3

About the Example Applications

The example applications presented in this manual are as follows:

Rack Optimized I/O (chapter 5)

•

Using Analog I/O with Direct Connection (chapter 6)

•

Produced and Consumed tags (chapter 7)

•

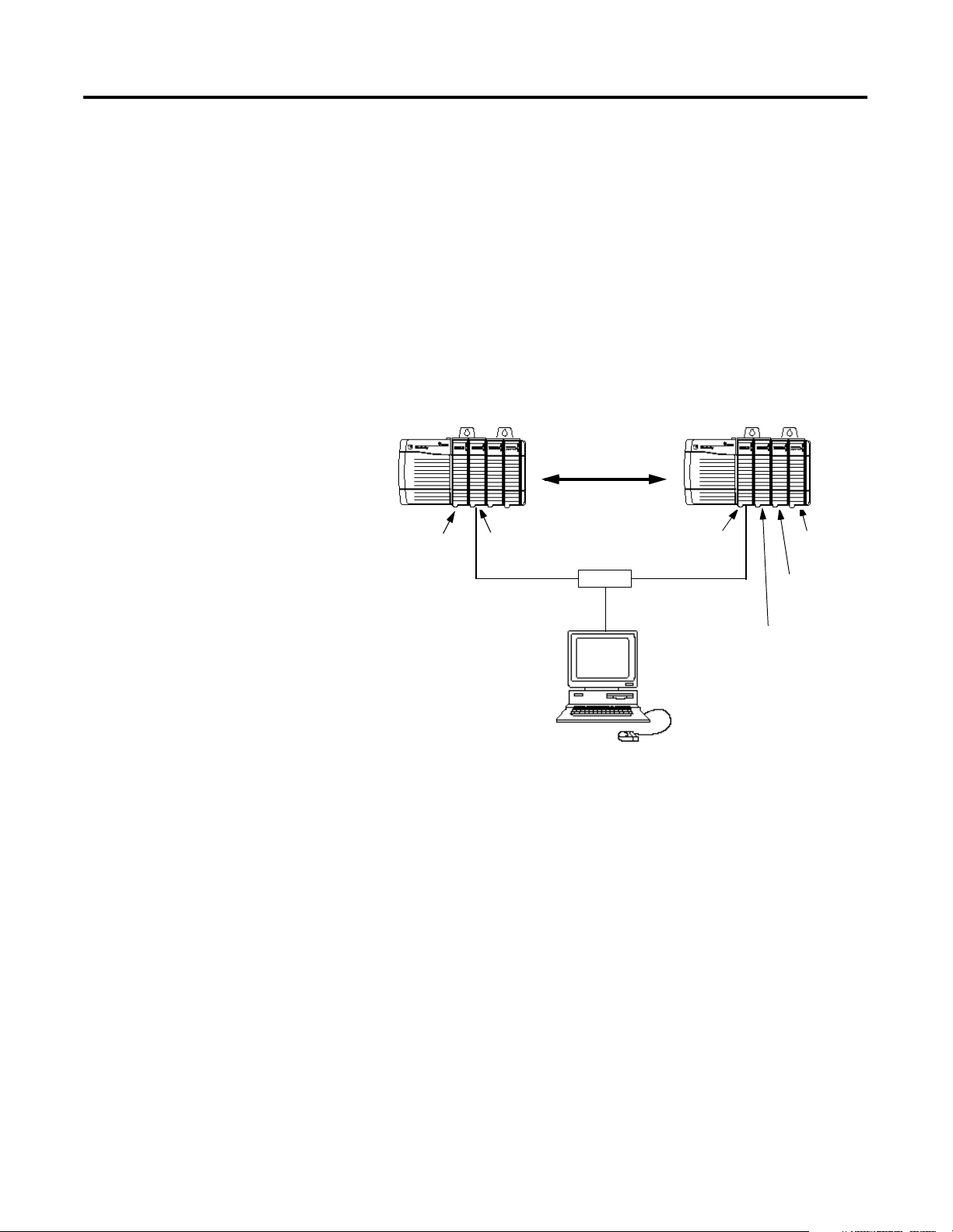

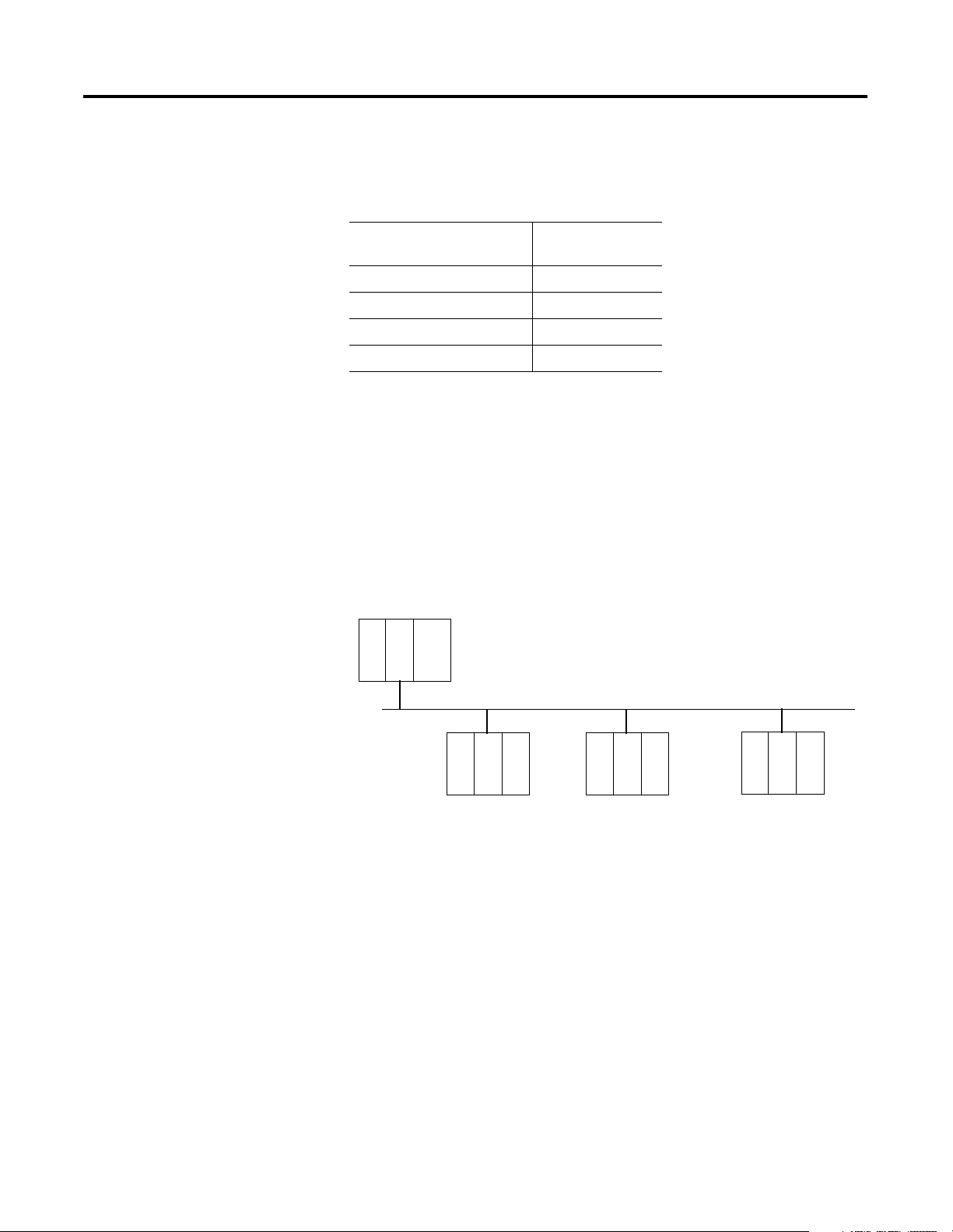

Here’s an example of the type of system you’ll be creating for I/O

applications:

Slot 0 1 Slot 0 1 2 3

Local

Chassis

Logix5550

Controller

1756-ENET/B

130.130.130.2

130.130.130.1

Data

Switch

1756-ENET/B

130.130.130.3

Programming

Ter mi na l

Remote

Chassis

1756-OF8

Analog Output

1756-OB16I

Digital Output

1756-IB16I

Digital Input

Publication 1756-UM051B-EN-P - November 2000

Page 10

P-4 About This User Manual

System Components

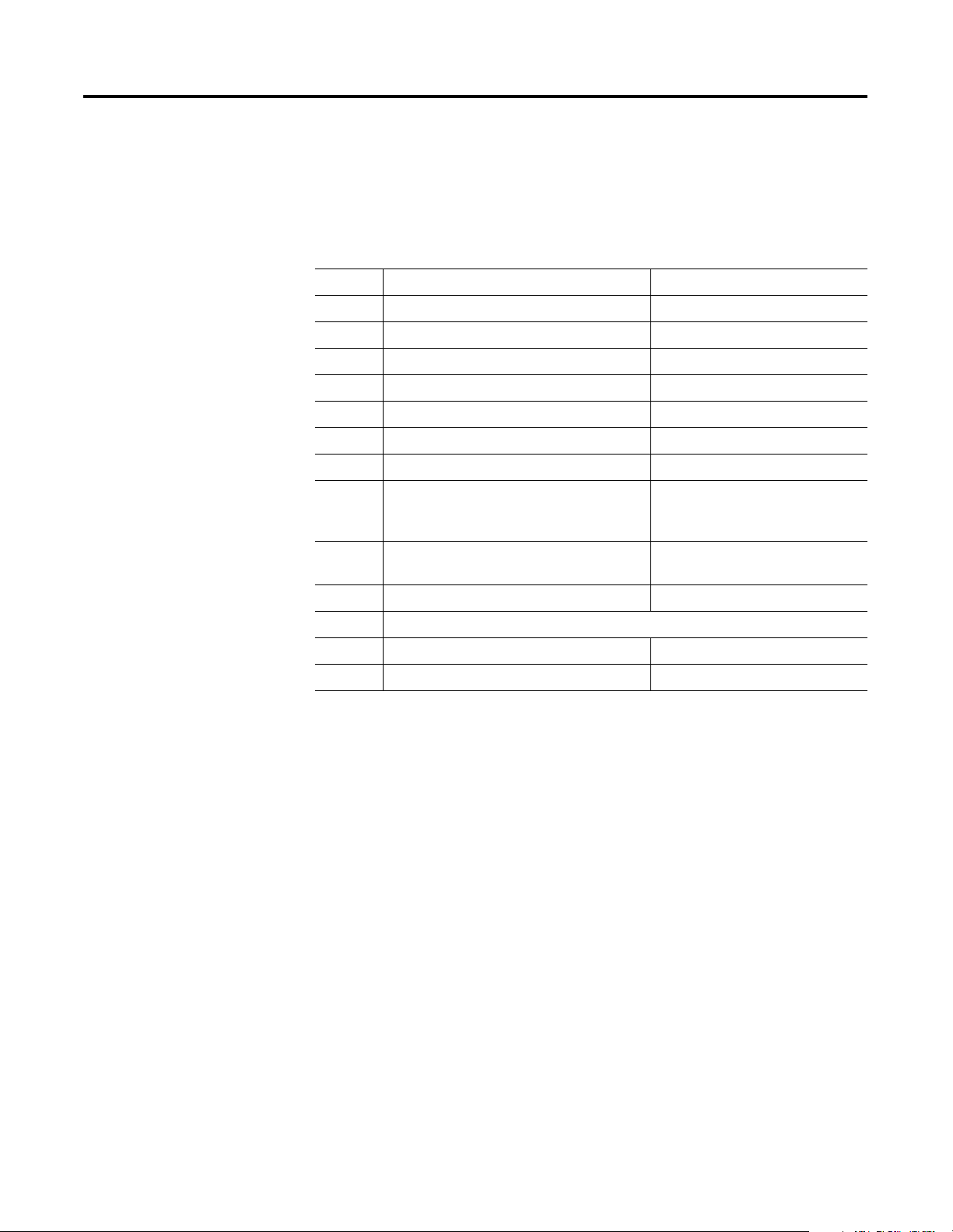

We used the following components for the example applications:

Quantity Product Name Catalog Number

Hardware

2 ControlLogix chassis 1756-A4, (or -A7, -A13, -A13, -A17)

2 ControlLogix power supply 1756-PA72, (or -PB72)

2 Ethernet Communications Interface Module 1756-ENET/B

2 Logix5550 controller 1756-L1

1 Analog Output Module 1756-OF8

1 Digital Input Module 1756-IB16I

1 Digital Output Module 1756-0B16I

1 Personal computer that supports RSLogix

5000 software

1 Ethernet switch Refer to manufacturer’s

Associated media and connectors as needed

Software

1 RSLinx 9355-WAB, -WABOEM, -WABC

1 RSLogix 5000 programming software 9324-RLD300ENE

Any appropriate model running

Windows NT 4.0, Service Pack 5 or

higher

specifications

Publication 1756-UM051B-EN-P - November 2000

Page 11

About This User Manual P-5

Where to Find More Information

For information about See this publication Publication number

Using Ethernet for Industrial Control Ethernet/IP Performance and Application Guide ENET-AP001A-EN-P

Ethernet Media Ethernet/IP Cable Planning and Installation Guide ENET-IN001A-EN-P

1756-ENET/B module ControlLogix Ethernet Communication Module Installation

ControlLogix Chassis ControlLogix Chassis Installation instructions 1756-5.69 (Series A)

ControlLogix power supplies ControlLogix Power Supplies Installation Instructions 1756-5.67 (PA72/PB72)

Logix5550 programmable controllers Logix5550 Controller User Manual 1756-6.5.12

ControlLogix Analog I/O modules ControlLogix Analog I/O Users Manual 1756-6.5.9

ControlLogix Digital I/O modules ControlLogix Digital I/O Users Manual 1756-6.5.8

RSLogix 5000 programming software Getting Results with RSLogix5000 9399-RLD300GR

RSLinx Lite software RSLinx Lite User’s Guide 9399-WAB32LUG

Refer to the following Rockwell publications as needed for additional help

when setting up and using your network.

1756-IN015B-EN-P

Instructions

1756-5.80 (Series B)

1756-5.78 (PA75/PB75)

TIP

Many of the above publications are available online

from the Automation Bookstore:

TIP

http://www.theautomationbookstore.com

.

For more information about Rockwell Software

products, visit the Rockwell Software internet site:

http://www.software.rockwell.com

.

Publication 1756-UM051B-EN-P - November 2000

Page 12

P-6 About This User Manual

Terminology

This term Means

bandwidth The transmission capacity of the network, expressed in bits per

second. Traditional Ethernet has a 10Mbit bandwidth. Fast

Ethernet is 100Mbit.

BootP BootP (Bootstrap Protocol) is a low-level protocol that provides

configurations to other nodes on a TCP/IP network. BootP

configuration files let you automatically assign IP addresses to

an Ethernet module (you can also obtain subnet masks and

gateway addresses from BootP).

The Ethernet module factory default is BootP enabled. Upon

powerup, the module sends a message containing its hardware

address to the BootP server on the network. The server is a

computer with BootP server software installed. The server

compares that hardware address to those in its lookup table in

the configuration file and sends a message back to the module

with the appropriate IP address.

bridge An internetwork node between two similar communication

subnets where protocol translation is minimal.

CIP Control and Information Protocol, the Ethernet/IP application

layer. CIP uses the “producer/consumer” networking model. In

this model one producer broadcasts (multicasts) the data once to

all the consumers. All consumers see the data simultaneously,

and may choose whether to consume (receive) the data or not.

Delivery time is consistent, no matter how many consumers

there are.

consumer A destination device in the CIP networking model. See CIP.

CSMA/CD Carrier Sense Multiple Access/Collision Detection. The access

method used in Ethernet. When a device wants to gain access to

the network, it checks to see if the network is quiet (senses the

carrier). If it is not, it waits a random amount of time before

retrying. If the network is quiet and two devices access the line

at exactly the same time, their signals collide. When the

collision is detected, they both back off and each waits a

random amount of time before retrying.

determinism The ability to predict when information will be delivered.

Important in time critical applications.

DHCP The Dynamic Host Configuration Protocol (DHCP) is an Internet

protocol, similar to BootP, for automating the configuration of

computers that use TCP/IP. DHCP can be used to automatically

assign IP addresses, to deliver TCP/IP stack configuration

parameters such as the subnet mask and default router, and to

provide other configuration information such as the addresses

for printer, time and news servers.

DNS The Domain Name System (DNS) is a hierarchical, distributed

method of organizing the name space of the Internet. The DNS

administratively groups hosts into a hierarchy of authority that

allows addressing and other information to be widely distributed

and maintained. A big advantage to the DNS is that using it

eliminates dependence on a centrally-maintained file that maps

host names to addresses.

Ethernet

A physical layer standard using Carrier Sense Multiple Access with

Collision Detection (CSMA/CD) methods.

Publication 1756-UM051B-EN-P - November 2000

Page 13

About This User Manual P-7

This term Means

Ethernet network A local area network designed for the high-speed exchange of

information between computers and related devices.

Ethernet/IP

Ethernet Industrial Protocol. Ethernet/IP

applies a common

application layer (CIP) over Ethernet by encapsulating

messages in TCP/UDP/IP.

explicit messaging

Non-time critical messaging used for device configuration

and data collection, such as downloading programs or

peer-to-peer messaging between two PLCs.

fast Ethernet Ethernet operating at 100Mbps/second.

full duplex A mode of communication that allows a device to send and

receive information at the same time, effectively doubling the

bandwidth.

fully qualified

domain name

gateway A module or set of modules that allows communications

A Fully Qualified Domain Name (FQDN) is a domain name that

includes all higher level domains relevant to the entity named. If

you think of the DNS as a tree-structure with each node having

its own label, a Fully Qualified Domain Name for a specific node

would be its label followed by the labels of all the other nodes

between it and the root of the tree. For example, for a host, a

FQDN would include the string that identifies the particular host,

plus all domains of which the host is a part up to and including

the top-level domain (the root domain is always null). For

example, PARIS.NISC.SRI.COM is a Fully Qualified Domain

Name for the host at 192.33.33.109.

between nodes on dissimilar networks.

host name The Host Name is the unique name for a computer within its

domain. It’s always the first element of a full name, and, with its

domain and top-level domain suffix, creates the unique name of

that computer on the Internet. For example, let’s say the foobar

website is www.foobar.com. The Host Name is “www”, which

is not unique on the web, but is unique within the foobar

domain.

The Host Name can also refer to the Fully Qualified Domain

Name, or in this example, www.foobar.com. Both naming

methods seem to be used interchangeably in various documents.

For the purposes of this document, the Host Name will refer to

the FQDN, or as in this example, www.foobar.com.

hub A central connecting device that joins devices together in a star

configuration. Hubs are generally not suitable for use in I/O

control systems, since they are time critical applications that

cannot tolerate lost packets.

implicit messaging Real time messaging of I/O data.

IP

Internet Protocol that

provides the routing mechanism for

messages. All messages contain not only the address of

the destination station, but the address of a destination

network, which allows messages to be sent to multiple

networks within an organization or around the world.

Publication 1756-UM051B-EN-P - November 2000

Page 14

P-8 About This User Manual

This term Means

IP address 32-bit identification number for each node on an Internet

Protocol network. These addresses are represented as four sets

of 8-bit numbers (numbers from 0 to 255), with periods between

them. Each node on the network must have a unique IP address.

latency The time between initiating a request for data and the beginning

of the actual data transfer.

module address A six-bit number used to uniquely identify any module on the

local and extended ControlLogix backplane.

multicast In the CIP producer/consumer model one producer multicasts

(broadcasts) the data once to all the consumers.

producer The source of information in the CIP networking model. See CIP.

rack A physical and logical collection of application modules sharing

a common power supply and backplane for module to module

communication.

star configuration A network configuration in which the devices are connected to a

central hub or switch.

subnet mask An extension of the IP address that allows a site to use a single

net ID for multiple networks.

switch A network device that cross connects devices or network

segments. A switch provides each sender/receiver the full

network bandwidth (2x in full duplex mode), reduces collisions,

and increases determinism.

TCP Transport Control Protocol. More reliable but slower transport

protocol than UDP. Used for explicit (not time critical) messaging

in Ethernet/IP.

TCP/IP Transmission Control Protocol/Internet Protocol (TCP/IP). A

transport-layer protocol (TCP) and a network-layer protocol (IP)

commonly used for communication within networks and across

internetworks.

transaction An exchange of request and data and response and data

UDP

User Datagram Protocol. Transport protocol that provides a

.

very simple, but fast capability to send datagrams

between two devices. Used for I/O (implicit) messaging in

Ethernet/IP.

Publication 1756-UM051B-EN-P - November 2000

Page 15

About the 1756-ENET/B Module

Installing the Ethernet Module

Table of Contents

Chapter 1

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Module Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hardware/Software Compatibility . . . . . . . . . . . . . . . . . . . . . . 1-2

What the Module Does. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Support of Rack Optimized and Direct Connections. . . . . . . . . 1-2

Mixing Rack Optimized and Direct Connections. . . . . . . . . 1-3

Use of the Control and Information Protocol (CIP) . . . . . . . . . 1-4

Understanding the Producer/Consumer Model. . . . . . . . . . . . . 1-4

Specifying the Requested Packet Interval (RPI) . . . . . . . . . . . . 1-5

What’s Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Identifying Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Insertion and Removal Under Power. . . . . . . . . . . . . . . . . . . . 2-2

Installing the Ethernet Module . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Preparing the Chassis for Module Installation. . . . . . . . . . . 2-2

Determining Module Slot Location. . . . . . . . . . . . . . . . . . . 2-3

Inserting the Module in the Chassis . . . . . . . . . . . . . . . . . . 2-4

Removing or Replacing the Module (when applicable). . . . 2-5

Wiring the Ethernet Connector . . . . . . . . . . . . . . . . . . . . . 2-6

Connecting the Module to the Ethernet Network . . . . . . . . 2-6

Applying Chassis Power . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Checking Power Supply and Module Status . . . . . . . . . . . . 2-8

What’s Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Chapter 3

Before You Configure Your

Module

i Publication 1756-UM051B-EN-P - November 2000

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Ethernet Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Transmission Control Protocol/Internet Protocol (TCP/IP) . 3-1

User Datagram Protocol (UDP) . . . . . . . . . . . . . . . . . . . . . 3-2

Ethernet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Simple Network Management Protocol (SNMP) . . . . . . . . . 3-2

Configuring the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Gateways . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Subnet Masks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

For More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

What’s Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Page 16

Table of Contents ii

Configuring the Ethernet Module

Rack Optimized I/O

Chapter 4

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Using the Rockwell BootP Utility . . . . . . . . . . . . . . . . . . . . . . 4-1

Using RSLinx Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Using a BootP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Using DHCP Software to Configure Your Module . . . . . . . . . . 4-7

What’s Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Chapter 5

About the Example Application . . . . . . . . . . . . . . . . . . . . . . . 5-1

Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Create the Example Application . . . . . . . . . . . . . . . . . . . . . . . 5-3

Add the Local Ethernet Module to the I/O Configuration . . 5-4

Add the Remote Ethernet Module to the I/O Configuration. 5-6

Add the Remote I/O Modules to the I/O Configuration . . . 5-8

Add the Remote Digital Input Module . . . . . . . . . . . . . 5-8

Add the Remote Digital Output Module . . . . . . . . . . . 5-10

Edit the Controller Tags . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Create the Ladder Program . . . . . . . . . . . . . . . . . . . . . . . 5-14

Download the Program to the Controller . . . . . . . . . . . . . 5-15

Test the Example Application . . . . . . . . . . . . . . . . . . . . . . . . 5-16

What’s Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Analog I/O with Direct Connection

Produced and Consumed Tags

Chapter 6

About the Example Application . . . . . . . . . . . . . . . . . . . . . . . 6-1

Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Create the Example Application . . . . . . . . . . . . . . . . . . . . . . . 6-3

Add the Remote Analog I/O Module

to the I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Edit the Controller Tags . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Modify the Ladder Program. . . . . . . . . . . . . . . . . . . . . . . 6-10

Download the Program. . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Test the Example Application . . . . . . . . . . . . . . . . . . . . . . . . 6-12

What’s Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Chapter 7

About the Example Application . . . . . . . . . . . . . . . . . . . . . . . 7-1

Set Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Create the Producer Application . . . . . . . . . . . . . . . . . . . . . . . 7-3

Create the Producer Tags . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Create the Producer Ladder Program . . . . . . . . . . . . . . . . . 7-6

Download the Producer Application . . . . . . . . . . . . . . . . . 7-7

Create the Consumer Application . . . . . . . . . . . . . . . . . . . . . . 7-8

Create the Consumer Controller. . . . . . . . . . . . . . . . . . . . . 7-8

Add the Producer to the Consumer’s I/O Configuration . . . 7-9

Add the Local ENET/B Module

to the I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . 7-9

Publication 1756-UM051B-EN-P - November 2000

Page 17

LED Status Indicators

1756-ENET/B Module Web Pages

Table of Contents iii

Chapter 7 (continued)

Add the Remote ENET/B Module

to the I/O Configuration . . . . . . . . . . . . . . . . . . . . . . 7-11

Add the Remote (Producer) Controller

to the I/O Configuration . . . . . . . . . . . . . . . . . . . . . . 7-13

Create the Consumer Tags. . . . . . . . . . . . . . . . . . . . . . . . 7-15

Download the Configuration to the Consumer . . . . . . . . . 7-18

Test the Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

What’s Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Appendix A

Interpreting the Status Indicators. . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B

Web Page Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

TCP/IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

ENET/IP Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

ENET/IP (CIP) STATISTICS . . . . . . . . . . . . . . . . . . . . . B-4

Chassis Who. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Configuring the RSLinx Ethernet

Communication Driver

1756-ENET/B Support of

ControlLogix Gateway

Communication

Example Network Configurations

Electronic Keying

Index

Appendix C

What This Appendix Contains. . . . . . . . . . . . . . . . . . . . . . . . . C-1

Installing the RSLinx Software . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Configuring the AB_ETH Driver . . . . . . . . . . . . . . . . . . . . . . . C-2

Appendix D

Using the 1756-ENET/B Module in a ControlLogix Gateway. . D-1

Appendix E

What This Appendix Contains. . . . . . . . . . . . . . . . . . . . . . . . . E-1

Small System Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Expanded System with FLEX I/O . . . . . . . . . . . . . . . . . . . . . . E-3

Larger Control Networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

Appendix F

Specifying Electronic Keying. . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Publication 1756-UM051B-EN-P - November 2000

Page 18

Table of Contents iv

Publication 1756-UM051B-EN-P - November 2000

Page 19

About the 1756-ENET/B Module

Chapter

1

What This Chapter Contains

Module Features

This chapter provides an overview of the ControlLogix 1756-ENET/B

module, its primary features, what it does, and how to use it. You will

need to understand the concepts discussed in this chapter in order to

configure your Ethernet module and use it in a control system. The

following table lists where to find specific information in this chapter.

.

For information about See page

Module Features 1-1

What the Module Does 1-2

Hardware/Software Compatibility 1-2

Support of Rack Optimized and Direct Connections 1-2

Mixing Rack Optimized and Direct Connections 1-3

Use of the Control and Information Protocol (CIP) 1-4

Understanding the Producer/Consumer Model 1-4

Specifying the Requested Packet Interval (RPI) 1-5

The 1756-ENET/B module’s features include:

use Ethernet/IP messages encapsulated within standard

•

TCP/UDP/IP protocol

common application layer with ControlNet and DeviceNet

•

interfacing via AUI and 10 Base-T media

•

removal or insertion under power

•

• number of modules per chassis limited only by chassis size

• communication to and from other ControlLogix modules in the

same chassis

• communication supported by RSLinx software

• configurable via RSLinx or standard BootP tools

• no network scheduling required

• no routing tables required

1 Publication 1756-UM051B-EN-P - November 2000

Page 20

1-2 About the 1756-ENET/B Module

Hardware/Software Compatibility

What the Module Does

The 1756-ENET/B module is compatible with the following firmware

versions and software releases. Contact Rockwell Automation if you

need software or firmware upgrades to use this equipment.:

Product Firmware Version/

Software Release

1756-ENET/B module 2.01 or higher

Logix 5550 Controller 6.10 or higher

RSLogix 5000 software 7.0 or higher

RSLinx software 2.2 or higher

The 1756-ENET/B module performs two primary tasks:

1. Control of real time I/O data (also known as “implicit messaging”)

in conjunction with a Logix 5550 controller. The Ethernet module

may serve as an adaptor, interfacing the I/O modules to the

network, or as a scanner, sending and receiving data between the

controller and the network.

Support of Rack Optimized and Direct Connections

Scanner

L

E

5

N

5

E

5

T

0

EtherNet Network

I/O

Adaptor

E

N

I/O

E

T

I/O

Adaptor

E

N

I/O

E

T

I/O

Adaptor

E

N

I/O

E

T

2. Support of messaging data for configuration and programming

information, operator interfaces, etc. (also known as “explicit

messaging.”).

The 1756-ENET/B module supports both Rack Optimized and Direct

Connections. A direct connection is a real-time data transfer link

between the controller and the device that occupies the slot that the

configuration data references. A rack optimized connection is a

grouping of data from more than one I/O module into a single block

of data sent over a single connection.

Publication 1756-UM051B-EN-P - November 2000

Page 21

About the 1756-ENET/B Module 1-3

Rack optimized connections reduce the total number of connections

needed to transfer data when using many I/O modules in a system.

The following example illustrates the benefit of rack optimized

connections.

Assume you have set up a system that contains 10 discrete I/O

modules in a remote ControlLogix chassis. If you use direct

connections to transfer data to each of the these I/O modules, you

need 10 connections to transfer all of the data, one to each of the ten

I/O modules. If you use a rack-optimized connection to transfer the

data, you only need a single connection – the connection to the

Ethernet module.

IMPORTANT

Although rack optimized connections offer an

efficient way to use resources, there are a few

limitations on their use:

You can only use rack optimized connections to

•

send data to and from discrete digital I/O

modules. Analog I/O requires direct connections.

Rack optimized connections can contain I/O data

•

and status information only. Additional module

information, such as diagnostics, is not available

through a rack-optimized connection.

All data is sent at the same time at the RPI rate of

•

the Ethernet module, regardless of a COS on a

particular module.

See the Ethernet Performance and Application Guide, publication

number ENET-AP001A-EN-P, for more information on connections.

Mixing Rack Optimized and Direct Connections

You can mix communication formats for different I/O modules in the

same chassis. I/O modules set up to use Rack Optimization will

communicate at the rate of the RPI (requested packet interval)

configured for the 1756-ENET/B module. I/O modules configured for

direct communication will communicate at their set RPI and ignore the

Ethernet module’s RPI.

Publication 1756-UM051B-EN-P - November 2000

Page 22

1-4 About the 1756-ENET/B Module

Use of the Control and Information Protocol (CIP)

Understanding the Producer/Consumer Model

The Ethernet module uses the Control and Information Protocol (CIP).

CIP is the application layer protocol specified for Ethernet/IP, the

Ethernet Industrial Protocol, as well as for ControlNet and DeviceNet.

It is a message-based protocol that implements a relative path to send

a message from the “producing” device in a system to the

“consuming” devices. The producing device contains the path

information that steers the message along the proper route to reach its

consumers. Since the producing device holds this information, other

devices along the path simply pass this information; they do not need

to store it. This has two significant benefits:

You do not need to configure routing tables in the bridging

•

module, which greatly simplifies maintenance and module

replacement.

You maintain full control over the route taken by each message,

•

which enables you to select alternative paths for the same end

device.

CIP uses the “producer/consumer” networking model, replacing the

old source/destination (master/slave) model. The producer/consumer

model reduces network traffic and increases speed of transmission. In

traditional I/O systems, controllers poll input modules to obtain their

input status. In the CIP system digital input modules are not polled by

a controller. Instead, they produce (“multicast”) their data either upon

a change of state (COS) or periodically. The frequency of update

depends upon the options chosen during configuration and where on

the network the input module resides. The input module, therefore, is

a producer of input data and the controller is a consumer of the data.

The controller can also produce data for other controllers to consume.

The produced and consumed data is accessible by multiple controllers

over the ControlLogix backplane and over the Ethernet network. This

data exchange conforms to the producer/consumer model.

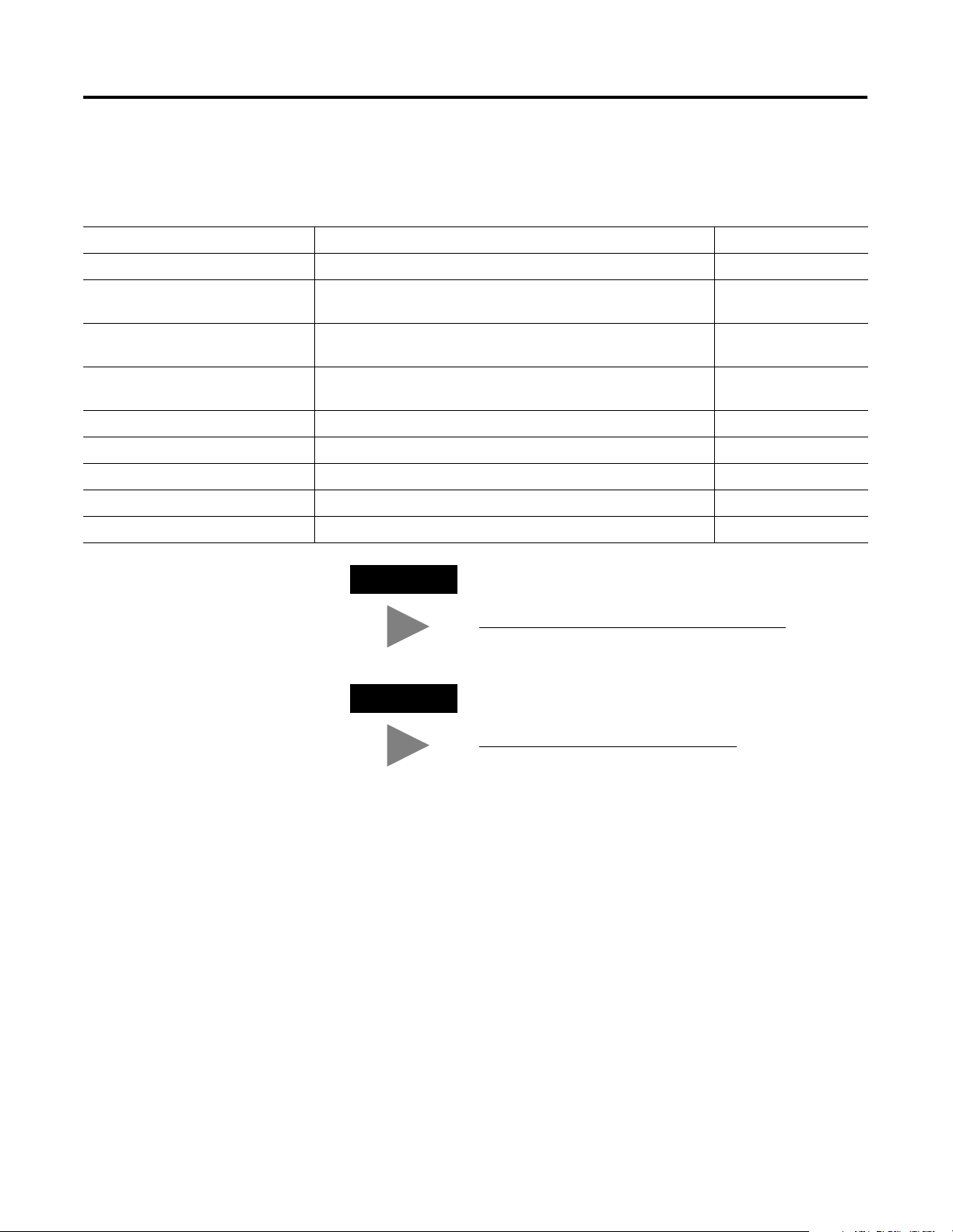

You configure the producer and consumer by creating controller

scoped tags using RSLogix 5000 software (see chapter 7).

Tag Type Description Specify Using RSLogix5000 Software

Produced

Consumed

(1)

Publication 1756-UM051B-EN-P - November 2000

(1)

(1)

Produced and consumed tags must be controller-scoped tags of DINT or REAL data type, or in an array or structure.

Tags that the controller produced for other

nodes to consume.

Tags whose values are produced by another

controller.

Enabled for producing

Number of consumers allowed

Name of controller that owns the tag the local controller wants

to consume

Tag name or instance that the local controller wants to consume

Data type of the tag to consume

Update interval of how often the local controller consumes the tag

data

Page 23

About the 1756-ENET/B Module 1-5

Specifying the Requested Packet Interval (RPI)

What’s Next?

The RPI is the update rate specified for a particular piece of data on

the network. The RPI can be specified for an entire rack (using a rack

optimized connection) or for a particular module (using direct

connection). When you add a module to the I/O configuration of a

controller, you must enter the RPI as a parameter. ‘This value specifies

how often to produce the data for that module. For example, if you

specify an RPI of 50ms, it means that every 50ms the I/O module

should send its data to the controller or that the controller should send

its data to the I/O module.

RPIs are only used for modules that produce data. For example a local

1756-ENET/B module (i.e., an ENET/B module in the same chassis as

the controller) does not require an RPI because it is not a

data-producing member of the system; it is used only as a bridge to

remote racks.

The following chapter describes how to install the Ethernet module

and connect it to the network.

Publication 1756-UM051B-EN-P - November 2000

Page 24

1-6 About the 1756-ENET/B Module

Publication 1756-UM051B-EN-P - November 2000

Page 25

Installing the Ethernet Module

Chapter

2

What This Chapter Contains

Identifying Module Features

This chapter describes how to install the module in the ControlLogix

chassis and connect it to the network. The following table describes

what this chapter contains and where to find specific information.

For information about See page

Insertion and Removal Under Power 2-2

Installing the Ethernet Module 2-2

Preparing the Chassis for Module Installation 2-2

Determining Module Slot Location 2-3

Inserting the Module in the Chassis 2-4

Removing or Replacing the Module (when applicable) 2-5

Wiring the Ethernet Connector 2-6

Connecting the Module to the Ethernet Network 2-6

Applying Chassis Power 2-7

Checking Power Supply and Module Status 2-8

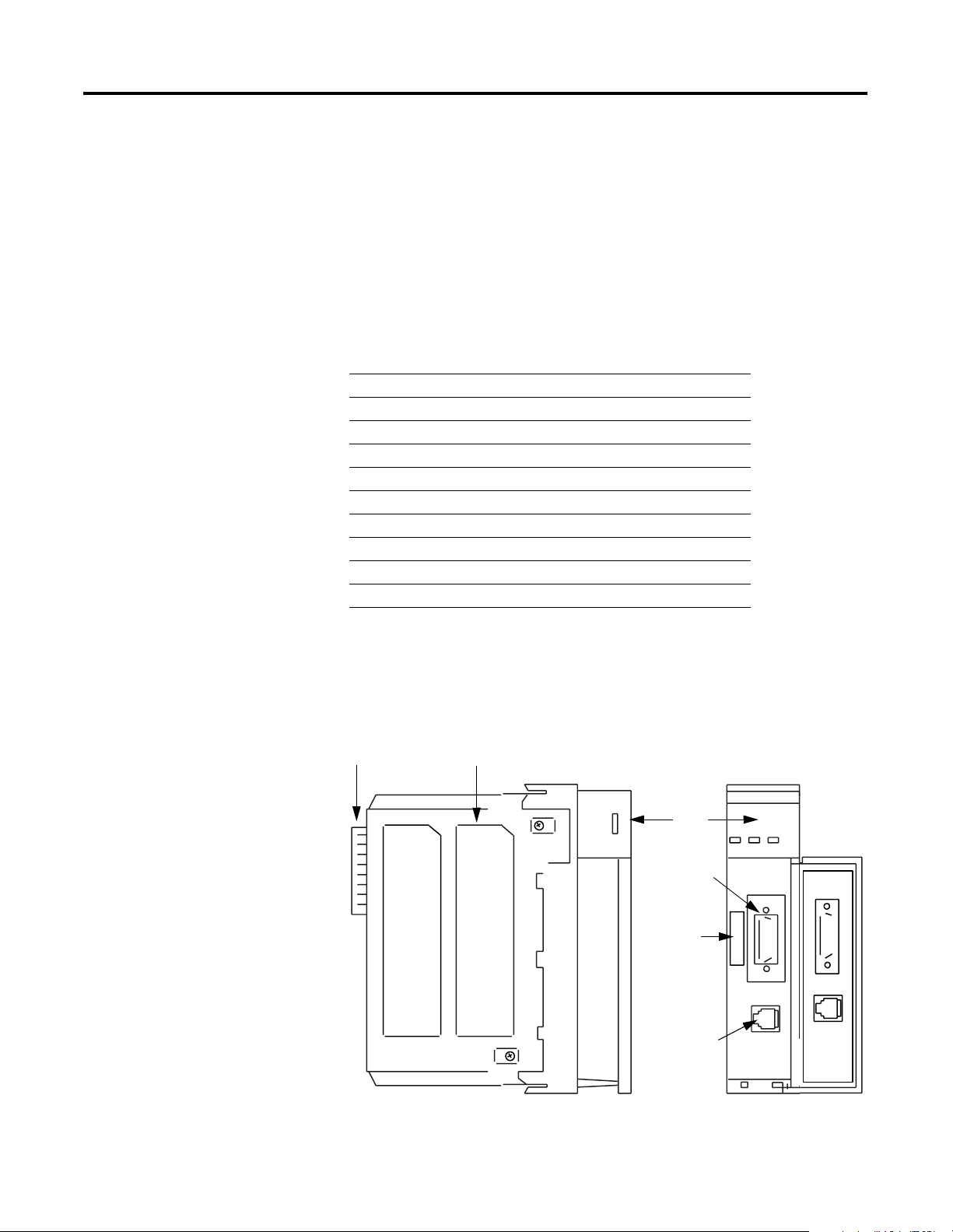

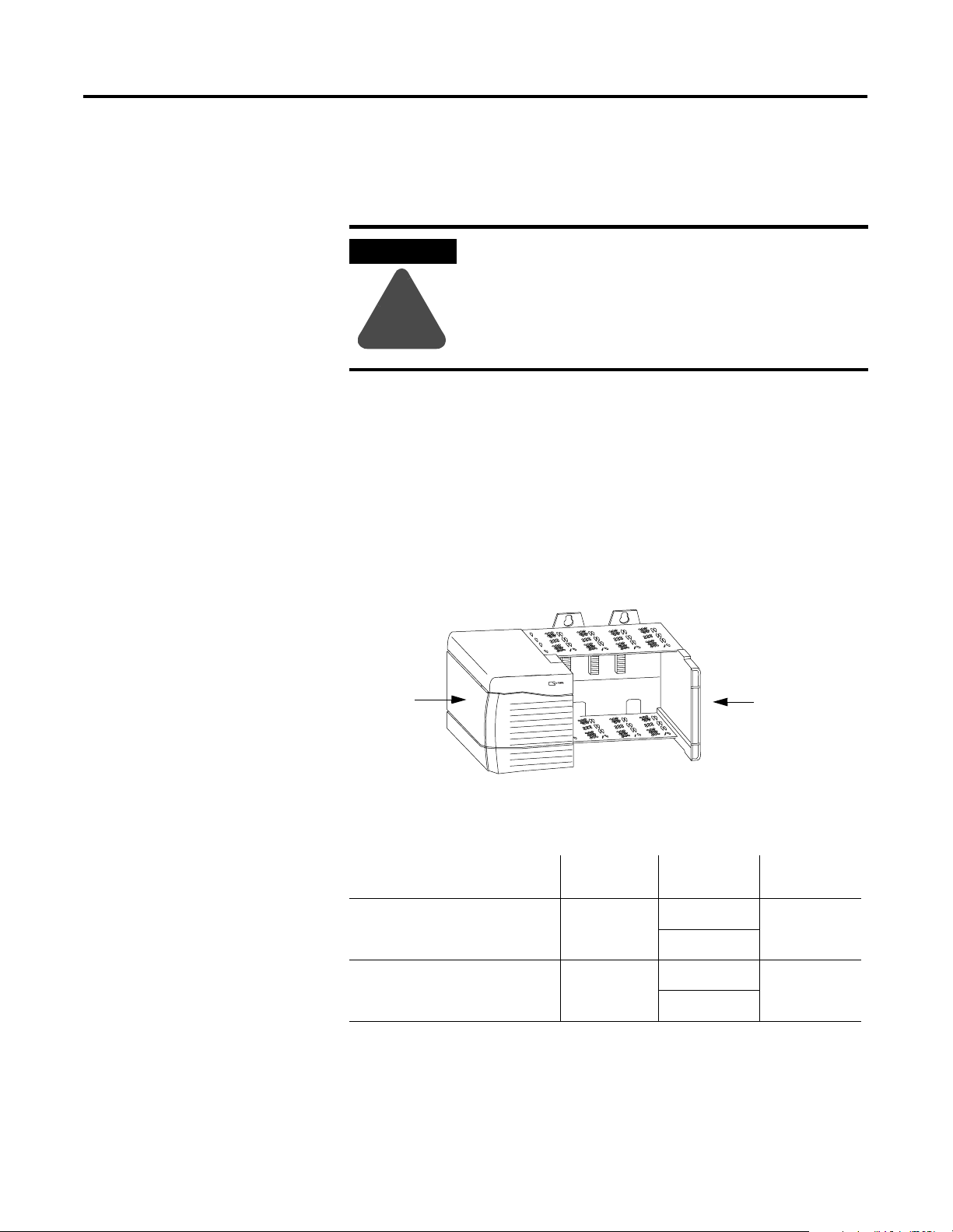

Use the following illustration to identify the external features of the

1756-ENET/B module.

Backplane

Connector

1 Publication 1756-UM051B-EN-P - November 2000

Product

Label

Side View

Front

Panel

AUI Ethernet

Connector

MAC ID

Label

10BT Ethernet

Connector

<

www

>

Front View

ETHERNET

OKTXDRXD

AUI

10 BASET

1756-ENET

Page 26

2-2 Installing the Ethernet Module

Insertion and Removal Under Power

Installing the Ethernet Module

The Ethernet module is designed to be installed or removed while

chassis power is applied. However, please observe the following

precautions.

WARNING

!

Use the following procedure to install the Ethernet module.

When you insert or remove the module while

backplane power is on, or you connect or disconnect

the communications connectors, an electrical arc can

occur. This could cause an explosion in hazardous

location installations. Be sure that power is removed

or the area is nonhazardous before proceeding.

Preparing the Chassis for Module Installation

Before you install the Ethernet module, you must install and connect a

ControlLogix chassis and power supply.

20805-M

(1)

(1)

(2)

(2)

1756-A4

Chassis

Power Suppl y

Installation

1756-5.67

1756-5.78

Power

Supply

For information on installing these products, refer to the publications

listed in the following table.

Chassis

Ty pe

Series A: 1756-A4, -A7, -A10, -A13 1756-5.69

Series B: 1756-A4, -A7, -A10, -A13 1756-5.80

(1)

Compatible with Series A chassis

(2)

Compatible with Series B chassis

Chassis

Installation

Power

Supply

1756-PA72/B

1756-PB72/B

1756-PA75/A

1756-PB75/A

Publication 1756-UM051B-EN-P - November 2000

Page 27

Installing the Ethernet Module 2-3

Determining Module Slot Location

You can install the module in any slot in the ControlLogix chassis. You

can also install multiple ENET/B modules in the same chassis. The

figure below shows chassis slot numbering in a 4-slot chassis. In a

ControlLogix chassis slot 0 is the first slot and is always the leftmost

slot in the rack (the first slot to the right of the power supply).

Power Supply

Slot 0

Slot 1

Slot 2

Slot 3

Chassis

Publication 1756-UM051B-EN-P - November 2000

Page 28

2-4 Installing the Ethernet Module

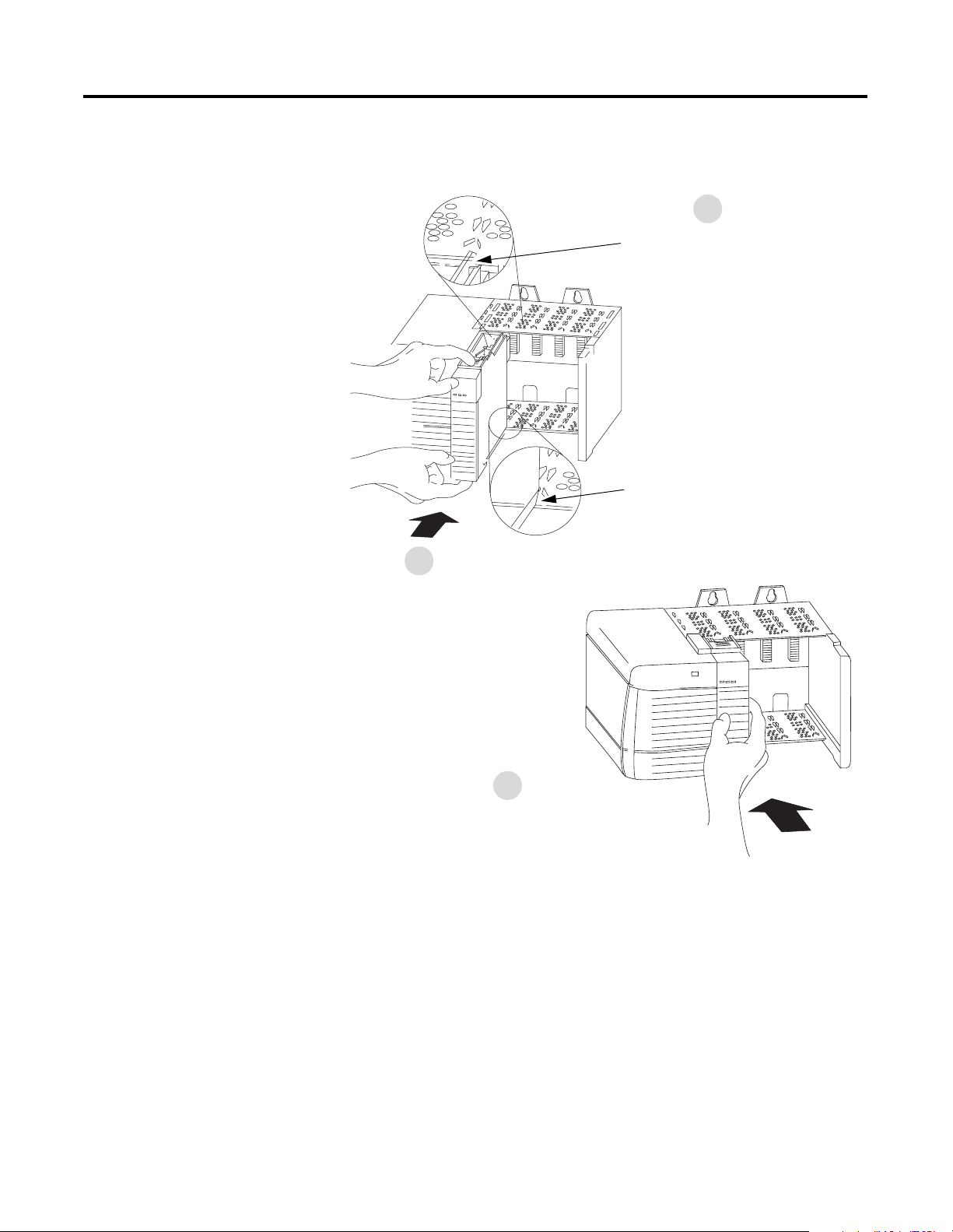

Inserting the Module in the Chassis

1

Align the circuit board with top and

bottom guides in the chassis.

Circuit Board

2

Slide the module into the chassis.

Make sure the module backplane

connector properly connects to the

chassis backplane.

3

The module is properly installed

when it is flush with the power

supply or other installed modules.

Publication 1756-UM051B-EN-P - November 2000

Page 29

Installing the Ethernet Module 2-5

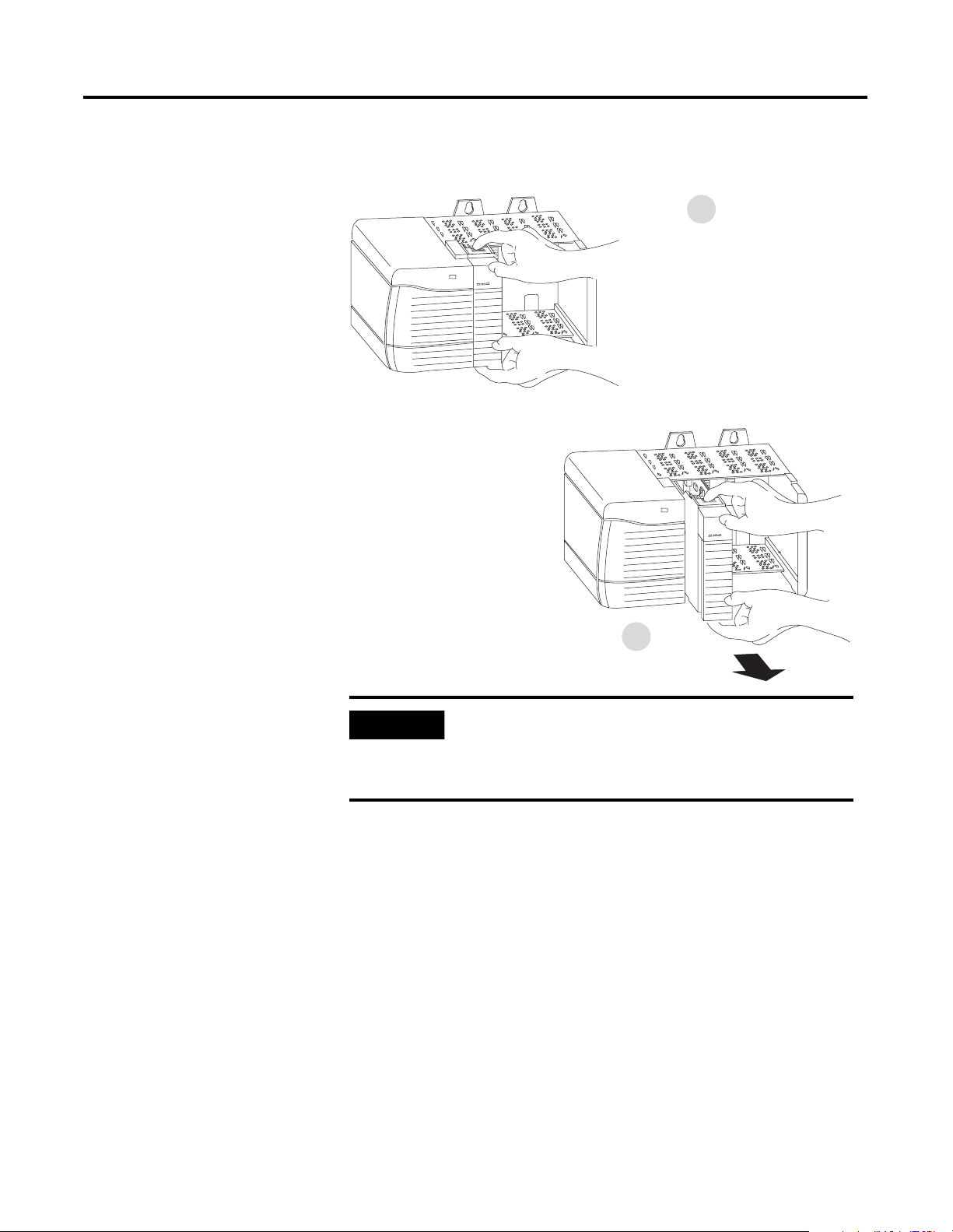

IMPORTANT

Removing or Replacing the Module (when applicable)

1

Push on upper and lower module

tabs to disengage them.

2

Slide module out of chassis.

If you are replacing an existing module with an

identical one, and you want to resume identical

system operation, you must install the new module

in the same slot.

Publication 1756-UM051B-EN-P - November 2000

Page 30

2-6 Installing the Ethernet Module

N

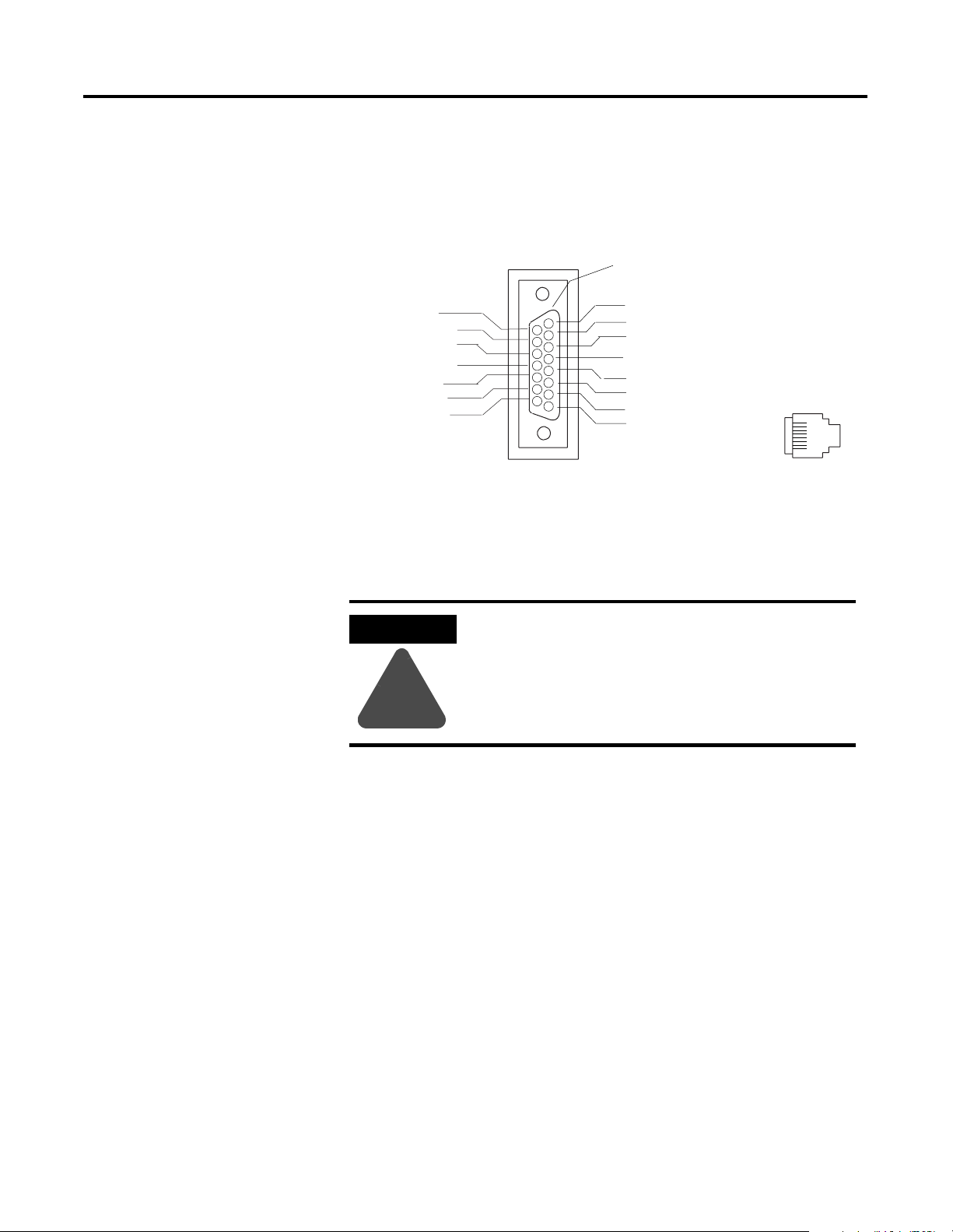

Wiring the Ethernet Connector

ote: If your application requires the module

door to be closed, use one of the custom AUI

connector cables, available in two lengths:

• 2 meters (cat. no. 1756- TC02)

• 15 meters (cat. no. 1756- TC15)

Use either an AUI or an RJ45 connector to connect to the Ethernet

network. Wire the appropriate connector as shown below:

Protective Ground

1 ------ TD+

2 ------ TD3 ------ RD+

4 ------ NC

5 ------ NC

6 ------ RD7 ------ NC

8 ------ NC

8

1

RJ 45

9-Ctrl IN Ckt B

10-Data OUT Ckt B

11-Data OUT Ckt B

12-Data OUT Ckt B

13-Voltage Plus

14-Voltage Shield

15-Ctrl OUT Ckt B

1-Ctrl IN Ckt Shield

2-Ctrl IN Ckt A

3-Data OUT Ckt A

4-Data IN Ckt Shield

5-Data In Ckt A

6-Voltage Comm

7-Ctrl OUT Ckt A

8-Ctrl OUT Ckt Shield

AUI

Connecting the Module to the Ethernet Network

ATTENTION

!

If you connect or disconnect the Ethernet cable

with power applied to the module or any device

on the network, an electrical arc can occur. This

could cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceding.

Publication 1756-UM051B-EN-P - November 2000

Page 31

Installing the Ethernet Module 2-7

Attach either the AUI or RJ45 connector to the matching Ethernet port.

POWER

OR

IMPORTANT

Connecting the module to the network via an

Ethernet switch instead of a hub reduces the number

of collisions and lost packets and increases the

bandwidth. See the Ethernet/IP Performance and

Application Guide, publication ENET-AP001A-EN-P,

for more information.

Applying Chassis Power

POWER

ON

POWER

OFF

ON

POWER

OFF

20921-M

Publication 1756-UM051B-EN-P - November 2000

Page 32

2-8 Installing the Ethernet Module

Checking Power Supply and Module Status

Check the LED indicators to determine if the power supply and the

Ethernet module are operating properly.

<www> ETHERNET

What’s Next?

POWER

RXD TXD

Power Supply indicator

is GREEN.

OKTXDRXD

OK indicator is RED,

then FLASHING RED

(or is GREEN if module

is configured).

If the Power Supply and module OK indicators are not in the states

described above refer to Appendix A for help in troubleshooting your

module.

The following chapter describes some Ethernet basics you should

know before configuring your module.

Publication 1756-UM051B-EN-P - November 2000

Page 33

Before You Configure Your Module

Chapter

3

What This Chapter Contains

Ethernet Protocols

This chapter describes some of the basics you should know about

Ethernet before you configure your Ethernet module. The following

table describes where to find specific information in this chapter.

For information about See page

Ethernet Protocols 3-1

Transmission Control Protocol/Internet Protocol (TCP/IP) 3-1

User Datagram Protocol (UDP) 3-2

Simple Network Management Protocol (SNMP) 3-2

Configuration Requirements 3-3

IP Address 3-3

Gateways 3-4

Subnet Mask 3-5

For More Information 3-6

On the most basic level, Ethernet is a wire or cable that connects

computers and peripheral devices so that they can communicate. The

actual wire used for the network is referred to as the network

“medium.” Beyond the physical medium, all Ethernet networks

support protocols that provide sophisticated data transfer and network

management functionality.

Transmission Control Protocol/Internet Protocol (TCP/IP)

Transmission Control Protocol/Internet Protocol (TCP/IP) is a

transport-layer protocol (TCP) and a network-layer protocol (IP)

commonly used in business environments for communication within

networks and across internetworks. The 1756-ENET/B module uses

TCP/IP for “explicit” messaging, that is, messages in which time is not

a critical factor, such as uploading or downloading programs.

1 Publication 1756-UM051B-EN-P - November 2000

Page 34

3-2 Before You Configure Your Module

User Datagram Protocol (UDP)

UDP is a much simpler transport protocol. It is connectionless and

provides a very simple capability to send datagrams between two

devices. UDP is used by applications that implement their own

handshaking between devices and only want a minimal transport

service. UDP is smaller, simpler, and faster than TCP and can operate

in unicast, multicast, or broadcast mode. The 1756-ENET/B module

employs UDP for real time I/O messaging.

Ethernet/IP

Ethernet/IP applies a common application layer over Ethernet by

encapsulating messages in TCP/UDP/IP. This common application

layer is the control and information protocol (CIP, see chapter 1),

which provides interoperability and interchangeability of industrial

automation and control devices on Ethernet. Ethernet/IP supports

both real-time I/O (“implicit” messaging) and explicit messaging.

Refer to the Ethernet/IP Performance and Application Guide,

publication number ENET-AP001A-EN-P, for more information on the

Ethernet/IP protocol.

Simple Network Management Protocol (SNMP)

Simple Network Management Protocol (SNMP) is a standard for

network management within TCP/IP environments. This lets client

applications monitor and manage network information on host

computers and gateways.

SNMP uses a distributed architecture consisting of management

systems and agents. Data is passed from SNMP agents, which are

hardware and/or software processes reporting activity in each

network device (switch, router, bridge, etc.) to the workstation

console used to oversee the network. The agents return information

contained in a MIB (Management Information Base), which is a data

structure that defines what is obtainable from the device and what can

be controlled (turned off, on, etc.).

The ENET/B module is an agent, and its primary function is to process

the operations requested by the management system. The Ethernet

module supports the SNMP protocol at the MIB II level.

Publication 1756-UM051B-EN-P - November 2000

Page 35

Before You Configure Your Module 3-3

EXAMPLE

Configuration Requirements

Class A

Class B

Before you can use your Ethernet module, you must configure its IP

address, gateway address, and subnet mask. The module ships with

the Rockwell BootP utility, which you can use to perform the

configuration. You can also use RSLinx software, generic BootP

software, or, within some limitations, a DHCP server. These methods

are described in chapter 4.

IP Address

The IP address identifies each node on the IP network (or system of

connected networks). Each TCP/IP node on a network (including the

Ethernet module) must have a unique IP address.

The IP address is 32 bits long and has a net ID part and a host ID part.

Each network is a Class A, Class B, or Class C network. The class of a

network determines how an IP address is formatted.

1

0

0

0

1

net ID

1

net ID

0

8

8

16

host ID

16

24

24

31

31

host ID

Class C

0

1

1

0

1

8

net ID

16

24

host ID

31

Each node on the same physical network must have an IP address of

the same class and must have the same net ID. Each node on the

same network must have a different host ID thus giving it a unique IP

address.

IP addresses are written as four decimal integers (0-255) separated by

periods where each integer gives the value of one byte of the IP

address.

For example, the 32-bit IP address:

10000010 00000000 00000000 00000001 is written as 130.0.0.1.

You can distinguish the class of an IP address from the first integer in

its dotted-decimal IP address as follows:

Range of first integer Class Range of first integer Class

0 -127 A 192 - 223 C

128 -191 B 224 - 255 other

Publication 1756-UM051B-EN-P - November 2000

Page 36

3-4 Before You Configure Your Module

TIP

Contact your network administrator or the Network

Information Center for a unique fixed IP address to

assign to your module.

Tip

For more information on Internet addressing, see Comer, Douglas E;

Internetworking with TCP-IP, Volume 1: Protocols and Architecture;

Englewood Cliffs, N.J.: Prentice-Hall, 1990.

Gateways

A gateway connects individual physical networks into a system of

networks. When a node needs to communicate with a node on

another network, a gateway transfers the data between the two

networks. The following figure shows gateway G connecting Network

1 with Network 2.

A

128.1.0.1

B

128.2.0.1 128.2.0.2

C

Network 1

Network 2

128.1.0.2

G

128.2.0.3

When host B with IP address 128.2.0.1 communicates with host C, it

knows from C’s IP address that C is on the same network. In an

Ethernet environment, B can then resolve C’s IP address to a MAC

address and communicate with C directly.

When host B communicates with host A, it knows from A’s IP address

that A is on another network (the net IDs are different). In order to

send data to A, B must have the IP address of the gateway connecting

the two networks. In this example, the gateway’s IP address on

Network 2 is 128.2.0.3.

The gateway has two IP addresses (128.1.0.2 and 128.2.0.3). The first

must be used by hosts on Network 1 and the second must be used by

hosts on Network 2. To be usable, a host’s gateway must be addressed

using a net ID matching its own.

Publication 1756-UM051B-EN-P - November 2000

Page 37

Before You Configure Your Module 3-5

EXAMPLE

Subnet Mask

Subnet addressing is an extension of the IP address scheme that

allows a site to use a single net ID for multiple physical networks.

Routing outside of the site continues by dividing the IP address into a

net ID and a host ID via the class. Inside a site, the subnet mask is

used to redivide the IP address into a custom net ID portion and host

ID portion.

Take Network 2 (a Class B network) in the previous example and add

another physical network. Selecting the following subnet mask would

add two additional net ID bits allowing for four physical networks:

11111111 11111111 11000000 00000000 = 255.255.192.0

Two bits of the Class B host ID have been used to extend the net ID.

Each unique combination of bits in the part of the host ID where

subnet mask bits are 1 specifies a different physical network.

The new configuration is:

A

128.1.0.1

Network 1

B

128.2.64.1 128.2.64.2

D

128.2.128.1 128.2.128.2

C

Network 2.1

E

Network 2.2

128.1.0.2

G

128.2.64.3

G2

128.2.128.3

A second network with Hosts D and E has been added. Gateway G2

connects Network 2.1 with Network 2.2. Hosts D and E will use

Gateway G2 to communicate with hosts not on Network 2.2. Hosts B

and C will use Gateway G to communicate with hosts not on Network

2.1. When B is communicating with D, G (the configured Gateway for

B) will route the data from B to D through G2.

Publication 1756-UM051B-EN-P - November 2000

Page 38

3-6 Before You Configure Your Module

For More Information

What’s Next?

For more information about Ethernet, refer to the following

publications:

Internetworking with TCP/IP

•

Vol. 1, 2nd ed.

by Douglas E. Comer

The Ethernet Management Guide –

•

Keeping The Link

An Introduction to TCP/IP ISBN 3-540-96651-X

•

Computer Networks

•

by Andrew S. Tanenbaum

The following chapter describes how to configure your Ethernet

module.

ISBN 0-13-216987-8

ISBN 0-07-046320-4

ISBN 0-13-162959-X

Publication 1756-UM051B-EN-P - November 2000

Page 39

Configuring the Ethernet Module

Chapter

4

What This Chapter Contains

Before you can use your Ethernet module in a network you must

configure it by providing an IP address, Gateway address, and Subnet

mask. There are several way you can do this:

1. Using the Rockwell BootP utility that ships with RSLogix 5000

software

2. Using RSLinx

3. Using a standard BootP server

4. Having your network administrator configure the module via the

network server

This chapter describes these procedures for configuring the

1756-ENET/B Ethernet module. The following table describes where

to find specific information.

For information about See page

Using the Rockwell BootP Utility 4-1

Using RSLinx Software 4-2

Using a BootP Server 4-5

Using DHCP Software to Configure Your Module 4-7

Using the Rockwell BootP Utility

1 Publication 1756-UM051B-EN-P - November 2000

BootP (Bootstrap Protocol) is a low-level protocol that provides

configurations to the nodes on a TCP/IP network. The Rockwell

BootP utility is a stand alone program that incorporates the

functionality of standard BootP software with a user friendly graphical

interface. It is located in the Utils directory on the RSLogix 5000

installation CD. Refer to the Readme file that accompanies the utility

and to the utility’s Help menu for directions on how to use this

software. The Ethernet module must have BootP enabled (factory

default) to use the utility.

Page 40

4-2 Configuring the Ethernet Module

Using RSLinx Software

You can use RSLinx software, version 2.2 or higher, to configure the

Ethernet module via a ControlNet or Data Highway Plus network, or

via the serial port on a Logix 5550 processor, if you insert the Ethernet

module into a ControlLogix chassis containing:

a 1756-CNB module connected to your workstation via

•

ControlNet, or

a 1756-DHRIO module connected to your workstation via DH+,

•

or

a Logix 5550 processor connected to your workstation via its

•

serial port.

You must have an appropriate communication driver configured in

RSLinx. After configuring the Ethernet module, you can move it to the

chassis where you want to use it.

To configure the Ethernet module using RSLinx, perform the following

steps:

1. Insert the ENET/B module in the ControlLogix chassis with the

communications module you will be using.

2. Start RSLinx. The RSWho window will open.

3. Select the appropriate driver (e.g., AB_KT-1 for Data Highway Plus,

AB_KTC-1 for ControlNet, or AB_DF1-1 for the Logix 5550’s serial

port).

Publication 1756-UM051B-EN-P - November 2000

Page 41

Configuring the Ethernet Module 4-3

The following example uses the Data Highway Plus driver. You can

perform the same steps using one of the other drivers.

4. Expand the driver tree through the backplane of the chassis

containing the 1756-ENET/B module.

5. Right click on the module. The following pop-up menu will

appear.

6. Select Module Configuration.

Publication 1756-UM051B-EN-P - November 2000

Page 42

4-4 Configuring the Ethernet Module

The 1756-ENET Configuration window will open.

7. Select the Port Configuration tab.

8. Uncheck the Obtain IP Address from BootP Server box.

9. Enter the desired IP Address, Subnet Mask, and Gateway

Address. The values we used for one of the ENET/B modules in

the example applications are shown above.

Publication 1756-UM051B-EN-P - November 2000

10.Click on OK.

You can now move the module to another chassis and access it over

Ethernet using this configuration.

Page 43

Configuring the Ethernet Module 4-5

EXAMPLE

Using a BootP Server

The Ethernet module factory default is BootP enabled. The following

is an example BootP tab file that can be used with a BootP server:

# Example /etc./bootptab: database for bootp server (/etc./bootpd).

#

# Format:

# nodename:tag=value:tag=value: . . . .:tag=value

#

# first field – – nodename (hostname) of terminal followed by colon

# (should be full domain name)

#

# Blank lines and lines beginning with ’#’ are ignored.

# Make sure you include a colon and a backslash to continue a line.

# Don’t put any spaces in the tag–value string.

# The ht tag MUST precede the ha tag.

#

# The options below are specified as tag=value and delimited by colons

# These are the options used by the 1756-ENET/B module:

#

# gw – – gateway IP address

# ha – – hardware address (link level address) (hex)

# ht – – hardware type (either) (must precede the ha tag)

# ip – – IP address

# sm – – network subnet mask

# tc – – template for common defaults (should be the first option listed)

#

# vm – – vendor magic cookie selector (MUST be rfc1048 for

1756-ENET/B)

#

#-––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

# default values for 1756-ENET/B

icp.defaults:\

ht=ether:\

vm=rfc1048:\

sm=255.255.254.0:\

gw=130.151.132.1

#-––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

zappa0:\

tc=icp.defaults:\

ha=0000bc03404f:\

ip=130.151.132.121

zappa1:\

tc=icp.defaults:\

ha=0000bc034073:\

ip=130.151.132.122

zappa2:\

Publication 1756-UM051B-EN-P - November 2000

Page 44

4-6 Configuring the Ethernet Module

31153-M

AUI

10 BASET

1756-ENET

RXD TXD OK

ETHERNET

tc=icp.defaults:\

ha=0000bc034022:\

ip=130.151.132.123

To use a BootP server to configure the ENET/B module perform the

following steps:

1. Access and open the BootP tab file using a text editor.

2. Enter the IP address of your module.

If you need more information on setting IP addresses, refer to

pages 3-3 to 3-4.

3. Use the text editor to enter the Ethernet hardware address

(MAC ID) of your module. You must enter all digits, including

zeroes.

Hardware

Address

IMPORTANT

When using the BootP protocol, you must enter the

Ethernet hardware address of your module. Rockwell

assigns each Ethernet module a unique 48-bit

hardware address at the factory. The address is

printed on a label on the front of your Ethernet

module as shown in the figure on the left. It consists

of six hexadecimal digits separated by dots. This

address is fixed by the hardware, and cannot be

changed.

If you change or replace this Ethernet module, you must enter the

new Ethernet hardware address of the module when you configure

the new module.

4. Enter the Gateway Address.

If you need more information on assigning gateway addresses,

refer to pages 3-4 to 3-4.

5. Enter the Subnet Mask

If you need more information on selecting subnet masks, refer to

pages 3-5 to 3-5.

Publication 1756-UM051B-EN-P - November 2000

6. After you have entered all the configuration data, save the file in a

directory where the BootP server can access it.

Page 45

Configuring the Ethernet Module 4-7

Using DHCP Software to Configure Your Module

DHCP (Dynamic Host Configuration Protocol) software automatically

assigns IP addresses to client stations logging onto a TCP/IP network.

DHCP is based on BootP and maintains some backward compatibility.

The main difference is that BootP was designed for manual

configuration, while DHCP allows for dynamic allocation of network

addresses and configurations to newly attached devices.

Be cautious about using DHCP software to configure your module. A

BootP client, such as the 1756-ENET/B module, can boot from a

DHCP server only if the DHCP server is specifically written to also

handle BootP queries. This is specific to the DHCP software package

you use. Check with your system administrator to see if your DHCP

package supports BootP commands and manual IP allocation.

ATTENTION

!

The 1756-ENET/B module must be assigned a fixed

network address. The IP address of this module must

not be dynamically provided.

Failure to observe this precaution may result in

unintended machine motion or loss of process

control.

What’s Next?

The following chapter describes an example application in which you

configure remote digital I/O using a rack optimized connection.

Publication 1756-UM051B-EN-P - November 2000

Page 46

4-8 Configuring the Ethernet Module

Publication 1756-UM051B-EN-P - November 2000

Page 47

Rack Optimized I/O

Chapter

5

About the Example Application

This example uses rack optimized connections to read data from a

remote digital input module and send data to a remote digital output

module.

What you will do See page

Set Up the Hardware 5-2

Create the Example Application 5-3

Add the Local Ethernet Module to the I/O Configuration 5-4

Add the Remote Ethernet Module to the I/O Configuration 5-6

Add the Remote I/O Modules to the I/O Configuration 5-8

Add the Remote Digital Input Module 5-8

Add the Remote Digital Output Module 5-10

Edit the Controller Tags 5-12

Create the Ladder Program 5-14

Download the Program to the Controller 5-15

Test the Example Application 5-16

1 Publication 1756-UM051B-EN-P - November 2000

Page 48

5-2 Rack Optimized I/O

Set Up the Hardware

For this example, the one ControlLogix chassis contains a Logix 5550

controller in slot 0 and a 1756-ENET/B module in slot 1. A second

chassis contains a 1756-ENET/B module in slot 0 and the I/O modules

in slots 1 and 2.

Slot 0 1 Slot 0 1 2

Local

Chassis

Logix5550

Controller

1756-ENET/B

130.130.130.2

130.130.130.1

Data

1756-ENET/B

130.130.130.3

Switch

Programming

Ter mi na l

Remote

Chassis

1756-OB16I

Digital Output

1756-IB16I

Digital Input

To work along with this example set up your system as shown above.

Note that in the example application, the Logix5550 controller,

•

I/O modules, and the 1756-ENET/B modules are in the slots

shown above.

Verify the IP addresses for your PC and 1756-ENET/B modules

•

(see chapter 4).

Verify that all wiring and cabling is properly connected.

•

Make sure you have your communication driver (e.g.,

•

AB_ETH-1) configured in RSLinx as described in Appendix C.

Publication 1756-UM051B-EN-P - November 2000

Page 49

Rack Optimized I/O 5-3

Create the Example Application

Perform the following steps to create the example application:

1. Start RSLogix5000. The RSLogix 5000 Main Window will open.

2. From the File menu, select New.

The New Controller pop-up window will open.

3. Enter an appropriate name for the Controller, e.g.,

“Ethernet_IO_Controller.”

4. Select the correct Chassis Type and Slot number of the Logix5550

controller, and the folder where you want to save the RSLogix 5000

file (Create In). The Description is optional.

5. Click on OK.

Publication 1756-UM051B-EN-P - November 2000

Page 50

5-4 Rack Optimized I/O

You now add the remote digital I/O modules to the controller’s I/O

configuration. To do this you first add the local 1756-ENET/B module

to the I/O configuration. Next you add the 1756-ENET/B in the remote

chassis with the digital I/O modules as a “child” of the local

1756-ENET/B module. Then you add the I/O modules as “children” of

the remote 1756-ENET/B module.

Add the Local Ethernet Module to the I/O Configuration

1. Select the IO Configuration folder in the project window and

click the right mouse button.

Publication 1756-UM051B-EN-P - November 2000

The following pop-up window will open.

2. Click on New Module.

Page 51

Rack Optimized I/O 5-5

The Select Module Type window will open.

3. Select the 1756-ENET/B module and click on OK.

The Module Properties window will open.

4. Enter or select the following parameters: Name, IP Address, Slot,

and Electronic Keying. We used the following values:

Name Local_ENET

IP Address 130.130.130.2

Slot 1

Electronic Keying

(1)

See Appendix F for important information about Electronic

Keying.

(1)

Compatible Module

5. Click on Finish to accept the configuration.

Publication 1756-UM051B-EN-P - November 2000

Page 52

5-6 Rack Optimized I/O

Add the Remote Ethernet Module to the I/O Configuration

Next, you must add the remote 1756-ENET/B module as a “child” of

the local 1756-ENET/B module.

1. In the Project window, right click on the local 1756-ENET/B

module under the I/O Configuration folder and select New

Module from the pop-up window.

The Select Module Type window will open.

2. Select the 1756-ENET/B module from the list and click on OK.

Publication 1756-UM051B-EN-P - November 2000

Page 53

Rack Optimized I/O 5-7

The Module Properties window will open.

3. Enter or select the following parameters (the values we used are

listed in the table):

Name Remote_ENET

IP Address 130.130.130.3

Chassis Size 4

Slot 0

Comm Format Rack Optimization

Electronic Keying

(1)

See Appendix F for important information about Electronic Keying.

(1)

Compatible Module

4. Click on Next.

The following page will open:

5. Make sure the Requested Packet Interval (RPI) is 5ms or greater

for this example.

Publication 1756-UM051B-EN-P - November 2000

Page 54

5-8 Rack Optimized I/O

6. Click on the Finish button to accept the configuration. The remote

1756-ENET/B module will appear indented under the local

1756-ENET/B in the I/O Configuration folder.

Add the Remote I/O Modules to the I/O Configuration

You must now add the remote I/O modules to the I/O Configuration

List under the remote 1756-ENET/B module.

In this example, you will add a a 1756-IB16I digital input module and

a 1756-OB16I digital output module with standard configurations. Use

these steps as a guide when you are configuring different I/O

modules for your actual system.

TIP

This example application uses the I/O module

default configurations. For information on altering

the default configurations see the ControlLogix

Digital I/O Module User Manual, publication

1756-6.5.8.

Add the Remote Digital Input Module

1. Right click on the remote 1756-ENET/B module under the I/O

Configuration folder and select New Module.

Publication 1756-UM051B-EN-P - November 2000

Page 55

Rack Optimized I/O 5-9

2. The Select Module Type window will open.

3. Select the 1756-IB16I digital input module from the list and click

on OK.

The Module Properties window will open.

4. Enter the following parameters (the values we used are listed in the

table):

Name Remote_Digital_Input

Slot 1

Comm Format Rack Optimization

Electronic Keying

(1)

See Appendix F for important information about Electronic Keying.

(1)

Compatible Module

Publication 1756-UM051B-EN-P - November 2000

Page 56

5-10 Rack Optimized I/O

TIP

If you want to alter the default parameters, click on

the Next button. Refer to the ControlLogix Digital

I/O User Manual, publication 1756-6.5.8, for details.

5. Click on the Finish button to save the configuration.

The digital input module will appear in the I/O configuration

indented under the remote 1756-ENET/B module.

Add the Remote Digital Output Module

Publication 1756-UM051B-EN-P - November 2000

6. Right click on the remote 1756-ENET/B module and again select

New Module.

Page 57

Rack Optimized I/O 5-11

The Select Module Type window will open.

7. Select the 1756-OB16I digital output module from the list.

The Module Properties window will open.

8. Enter the following parameters (the values we used are listed in the

table):

Name Remote_Digital_Output

Slot 2

Comm Format Rack Optimization

Electronic Keying

(1)

See Appendix F for important information about Electronic Keying.

(1)

Compatible Module

Publication 1756-UM051B-EN-P - November 2000

Page 58

5-12 Rack Optimized I/O

TIP

If you want to alter the default parameters, click on

the Next button. Refer to the ControlLogix Digital

I/O User Manual, publication 1756-6.5.8, for details.

9. Click on the Finish button to accept the configuration.

The I/O Configuration in the Project window should look similar to

the one shown below.

Edit the Controller Tags

When you add modules to the I/O configuration the system creates

tags for those modules to use in the application program. For our

example application we need to add another Controller Tag.

Tags created

by the system

Enter the new tag here

Publication 1756-UM051B-EN-P - November 2000

1. Double-click on the Controller Tags folder in the project window.

The Controller Tags window will open. You will see the tags

created for the 1756-ENET/B and digital I/O modules.

Page 59

Rack Optimized I/O 5-13

2. Select the Edit Tags tab at the bottom of the Controller Tags

window.

3. Create the following tag:

Tag Type

Parts_Count Counter

4. Close the Controller Tags window.

Publication 1756-UM051B-EN-P - November 2000

Page 60

5-14 Rack Optimized I/O

Create the Ladder Program

1. Double-click on Main Routine under the Main Program folder,

and enter the following ladder program, using the tags previously

created.

Publication 1756-UM051B-EN-P - November 2000

2. Save the program.

Page 61

Rack Optimized I/O 5-15

Download the Program to the Controller

1. Click on the Communications menu and select Who Active.

The Who Active window will open (Your window will show the

drivers and devices you have installed).

2. Select your Ethernet driver (e.g., AB_ETH-1) and expand the tree

through the backplane of the local ControlLogix chassis.

3. Highlight the Logix 5550 controller and click on the Download

button.

You will see a message similar to the following:

4. Click on the Download button.

5. Minimize RSLogix5000.

Publication 1756-UM051B-EN-P - November 2000

Page 62

5-16 Rack Optimized I/O

Test the Example Application

You will test the example application by using a momentary switch to

simulate a parts sensor.

1. Wire the 1756-IB16I digital input module as shown in the following

figure:

1756-IB16I

2

GND-0

4

GND-1

IN-0

IN-1

1

Count

3

Reset

24V

+

–

2. Restore the RSLogix5000 software and place the controller in Run

mode.

3. Repeatedly press and release the momentary switch at IN-0 (Count)

on the 1756-IB16I digital input module. Each time you press the

switch you should see the Parts_Count accumulated value

increment on the screen and the LED display of the OB16I output

module increment in binary.

Accumulated Value

will increment and

be moved to Output

module. LED display will

increment in

binary count

Publication 1756-UM051B-EN-P - November 2000

4. Press and release the momentary switch at IN-1 (Reset) on the

1756-IB16 digital input module. You should see the accumulated

value of the Parts_Count reset to zero and all of the LEDs on the

1756-OB16I output module turn off.

Page 63

Rack Optimized I/O 5-17

What’s Next?

TIP

This completes the Rack Optimized I/O example.

The following chapter describes an example application in which you

add an analog output module to the I/O configuration using a direct

connection.

Refer to the ControlLogix Digital I/O Modules User

Manual, publication 1756-6.5.8, for assistance in

wiring and debugging the I/O modules.

Publication 1756-UM051B-EN-P - November 2000

Page 64

5-18 Rack Optimized I/O

Publication 1756-UM051B-EN-P - November 2000

Page 65

Analog I/O with Direct Connection

Chapter

6

About the Example Application