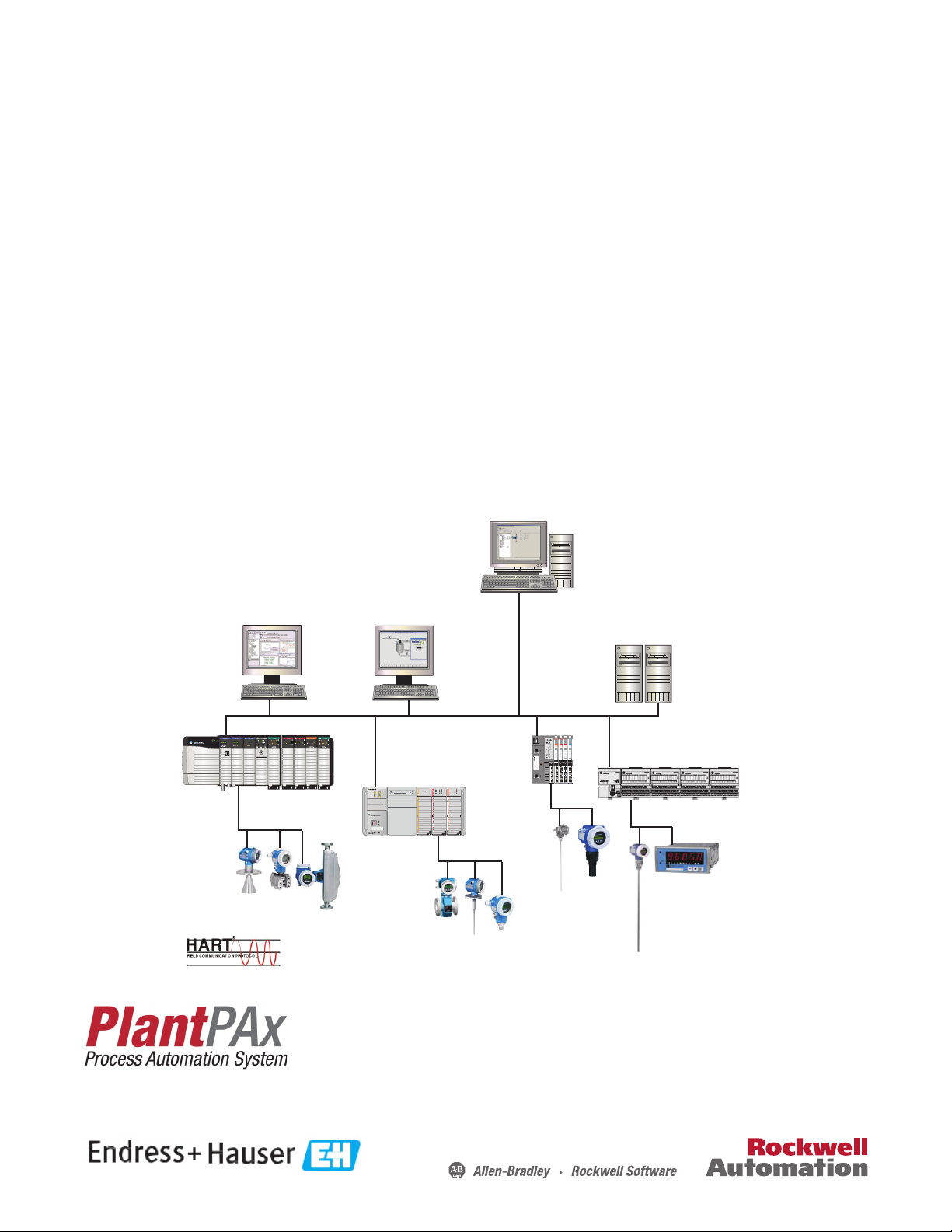

Page 1

Integration Document

Endress+Hauser Instruments via HART to the PlantPAx

Process Automation System

Systems with Analog I/O Modules: 1756-IF8H, 1756-IF8IH, 1756-IF16H, 1794-IF8IH, 1769sc-IF4IH, 1734sc-IE2CH, 1734sc-IE4CH

Endress+Hauser Devices: Promag 53 Electromagnetic, Flowmeter, Proline T-mass 65 Thermal Flowmeter, Promass 83 Coriolis

Mass Flowmeter, Prowirl 73 Flowmeter, Prosonic M Ultrasonic Level, Levelflex M Guided Radar Level, Micropilot M Radar Level,

Deltabar S Differential Pressure, Prosonic S Transmitter, Cerabar S Pressure Transmitter, iTEMP TMT162 Temperature Transmitter,

iTEMP TMT182 Temperature Transmitter, Liquiline M CM42 Transmitter

Module

Module

Module

Module

Status

Status

Status

Status

Network

Network

Network

Network

Status

Status

Status

Status

NODE:

NODE:

NODE:

NODE:

24VDC

220 VAC

Relay

120 VAC

Sink

Input

Output

Input

Input

0

0

0

0

4

0

0

0

0

4

1

1

1

1

5

1

1

1

1

1

5

2

2

2

2

6

2

2

2

6

3

3

3

3

7

3

3

3

7

1734

1734

1734

1734

OW4

IB8

IA4

IM4

L33ERM

RUN

NS

LINK 1

FORCE

I/O

LINK 2

SD

OK

RUN

REM

PROG

XX:XX:XX:XX:XX:XX

1 (Front)

2 (Rear)

AC/DC OUT

RELAY115 VAC

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, CompactLogix, ControlLogix, FactoryTalk, RSLogix , and and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Preface

Installation

Configure the HART Device in RSLogix

5000 Programming Software

Preferred Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Application Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

HART Handheld Device (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 10

System Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hardware Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Software Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Performance Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

Connect a 2-Wire Field Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connect a 4-Wire Field Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 2

Configure a HART Input Module in a ControlLogix System . . . . . . . . 21

Configure a HART Input Module in a Compact I/O System . . . . . . . . 27

Configure a HART Input Module in a FLEX I/O System . . . . . . . . . . . 29

Configure a HART Input Module in a POINT I/O System . . . . . . . . . 31

Configure A HART Input Module via CIP Messages . . . . . . . . . . . . . . . 34

Configure the HART Device in

FactoryTalk AssetCenter Software

Configure the HART Device in E+H

Fieldcare Software

Chapter 3

Configure a HART Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Configure the DTM Network Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Configure a HART Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Configure a FLEX I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Chapter 4

Configure a HART Input Module and Device. . . . . . . . . . . . . . . . . . . . . . 53

Access Instrument Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Additional Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 3

Page 4

Table of Contents

Chapter 5

Visualization

Promag 53 Electromagnetic

Flowmeter

Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Download the Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Import Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Add an Add-On Instruction to a Routine. . . . . . . . . . . . . . . . . . . . . . . 63

Configure I_AB56IF8H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Configure I_AB56IFxH_Chan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Configure P_AIn56H. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Link an Add-On Instruction to Graphics in FactoryTalk View SE

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Add Library Components to an HMI Application. . . . . . . . . . . . . . . 71

Global Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Add Global Objects to a Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Configure Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Faceplates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Appendix A

Measured Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Signals from Instrument to Control System . . . . . . . . . . . . . . . . . . . . . 84

Connect a Promag 53 Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Configure a Promag 53 Flowmeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Pulsating Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Batching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Proline T-mass 65 Thermal

Flowmeter

Promass 83 Coriolis Mass Flowmeter

Prowirl 73 Flowmeter

Appendix B

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Signals from Instrument to Control System . . . . . . . . . . . . . . . . . . . . . 90

Connect a Proline T-mass 65 Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Configure a Proline T-mass 65 Flowmeter. . . . . . . . . . . . . . . . . . . . . . . . . . 92

Appendix C

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Signals from Instrument to Control System . . . . . . . . . . . . . . . . . . . . . 94

Connect a Promass 83 Flowmeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Configure a Promass 83 Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Appendix D

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Signals from Instrument to Control System . . . . . . . . . . . . . . . . . . . . . 99

Connect a Prowirl 73 Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Configure a Prowirl 73 Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

4 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 5

Appendix E

Table of Contents

Prosonic M Ultrasonic Level

Levelflex M Guided Radar Level

Micropilot M Radar Level

Cerabar S Pressure Transmitter

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Signals from Instrument to Control System. . . . . . . . . . . . . . . . . . . . 104

Connect a Prosonic M Ultrasonic Level. . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Configure a Prosonic M Ultrasonic Level . . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix F

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Signals from Instrument to Control System. . . . . . . . . . . . . . . . . . . . 111

Connect a Levelflex M Guided Level-Radar . . . . . . . . . . . . . . . . . . . . . . . 111

Configure a Levelflex M Guided Level-Radar . . . . . . . . . . . . . . . . . . . . . . 113

Appendix G

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Signals from Instrument to Control System. . . . . . . . . . . . . . . . . . . . 116

Connect a Micropilot M Level-Radar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Configure a Micropilot M Level-Radar . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Appendix H

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Signals from Instrument to Control System. . . . . . . . . . . . . . . . . . . . 121

Connect a Cerabar S Pressure Transmitter . . . . . . . . . . . . . . . . . . . . . . . . 122

Configure a Cerabar S Pressure Transmitter. . . . . . . . . . . . . . . . . . . . . . . 123

Pressure Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Level Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Deltabar S Differential Pressure

Prosonic S Transmitter

Appendix I

Metal Measuring Cell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Measured Variable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Signals from Instrument to Control System. . . . . . . . . . . . . . . . . . . . 128

Connect a Deltabar S Differential Pressure . . . . . . . . . . . . . . . . . . . . . . . . 129

Configure a Deltabar S Differential Pressure. . . . . . . . . . . . . . . . . . . . . . . 130

Flow Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Level Measuring Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Pressure Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Appendix J

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Signals from Instrument to Control System. . . . . . . . . . . . . . . . . . . . 135

Connect a Prosonic S Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Sensor Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Configure a Prosonic S Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 5

Page 6

Table of Contents

Appendix K

iTEMP TMT162 Temperature

Transmitter

iTEMP TMT182 Temperature

Transmitter

Liquiline M CM42 Transmitter

Index

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Signals from Instrument to Control System . . . . . . . . . . . . . . . . . . . . 140

Connect an iTEMP TMT162 Temperature Transmitter . . . . . . . . . . . 141

Configure an iTEMP TMT162 Temperature Transmitter. . . . . . . . . . 142

Appendix L

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Signals from Instrument to Control System . . . . . . . . . . . . . . . . . . . . 144

Connect an iTEMP TMT182 Temperature Transmitter . . . . . . . . . . . 144

Configure an iTEMP TMT182 Temperature Transmitter. . . . . . . . . . 145

Appendix M

Measuring System Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Measured Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Signals from Instrument to Control System . . . . . . . . . . . . . . . . . . . . 149

Connect a Liquiline M CM42 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . 150

Housing Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Stainless Steel Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Supply and Signal Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Sensor Connection: pH / ORP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Sensor Connection: Conductivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Sensor Connection: pH / ORP / ISFET / Oxygen (digital sensors) . .

155

Configure a Liquiline M CM42 Transmitter . . . . . . . . . . . . . . . . . . . . . . 156

Menu Structure, Top Hierarchy Level . . . . . . . . . . . . . . . . . . . . . . . . . 156

Quick Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

6 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 7

Preface

Preferred Integration

Rockwell Automation and Endress+Hauser have strengthened their strategic

alliance to provide complete process automation solutions that use best-in-class

instrumentation, software, and control systems.

There are hundreds of different components in a typical plant: controllers,

remote I/O, electrical drives, safety equipment, and sensors. Each must be

integrated, configured and optimized during start-up and operation. Recognizing

the challenges this creates, Rockwell Automation and Endress+Hauser are

focused on providing you with scalable, off-the-shelf solutions.

To supply robust system solutions, Rockwell Automation pre-tests many thirdparty manufactured HART, FOUNDATION Fieldbus, and Profibus field

devices in the system test laboratory for compatibility with the Integrated

Architecture based plant automation system. Each field device is connected to

the Rockwell Automation Integrated Architecture based system and is subjected

to interoperability testing procedures similar to operating procedures in your

plant. The results of each field test are recorded in a test report for integration

planning purposes.

For Endress+Hauser field devices, an additional step provides an “Integration

Document” and “Interoperability Statement” for each tested instrument. The

Integration Document provides information on installation, configuration,

startup, and operation of the integrated system. The Interoperability Statement is

assurance that the Endress+Hauser field device meets Integrated Architecture

system interoperability performance measures, as jointly established by Rockwell

Automation and Endress+Hauser and verified through completion of common

test procedures performed by either company. Both the Integration Document

and Interoperability Statement ensure a no risk solution highlighted by ease of

integration and optimum performance.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 7

Page 8

Preface

The overall mission of the alliance is to provide you with proven solutions that

combine field instrumentation with fieldbus networks, such as HART,

FOUNDATION Fieldbus, and Profibus networks, with asset management

capabilities and Rockwell Automation’s system capabilities to provide a total

engineered solution.

Through preferred integration and support of increasing requirements for plantwide control, the alliance offers the following benefits:

• Reduced integration costs throughout engineering, commissioning, and

start-up

• Optimized plant availability and output

• Ensured product quality and consistency

• Optimized traceability to meet regulatory demands

• Predictive maintenance through intelligent instruments

For new construction, process improvements at an existing plant, or operating

cost reductions, the alliance delivers the following:

• Integration reduces risk, reduces integration costs, and protects investment

with assured interoperability. Both companies believe open systems and

standardized interfaces bring maximum benefits.

• Advanced diagnostics with plant-wide support offers better visibility of

plant health and easier access to instrument diagnostics, which leads to

faster troubleshooting and improves decision-making.

• Collaborative lifecycle management to design, engineer, and startup

systems faster. This collaboration increases productivity, manages

information about instrumentation assets, optimizes plant assets, and

results in a complete lifecycle management solution.

Application Overview

This document provides a step-by-step approach to integrating Endress+Hauser

devices into a Rockwell Automation Integrated Architecture for Process Control

system.

This Section Describes

Application overview Details about the field instrument and control system.

System details Specifications on the required hardware and software components.

Installation How to:

Configuration How to:

Visualization How to implement and configure a graphical display of device information.

8 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

• Connect the measurement instrument to the HART I/O module.

• Connect a HART handheld device.

• Configure the HART I/O module.

• Configure the measurement instrument and manage parameters.

Page 9

Preface

Integrated Asset Management

Process Automation

System Server (PASS)

Operator

Work stati on (OW S)

Engineering

Work stati on (E WS)

POINT I/O

System

CompactLogix

System

ControlLog ix

System

FLEX I/O System

The tested HART devices are the following:

• Promass 83 flowmeter

• Promag 53 flowmeter

• Proline t-mass 65 flowmeter

• Prosonic S transmitter

• Prowirl 73 flowmeter

• Levelflex M guided level-radar

• Micropilot M level-radar

• Prosonic M ultrasonic level

• Liquiline M CM42 transmitter

• Cerabar S pressure transmitter

• Deltabar S differential pressure

• iTEMP TMT162 temperature transmitter

• iTEMP TMT182 temperature transmitter

The ControlLogix platform provides a full range of input and output modules to

span a wide variety of applications. The ControlLogix architecture uses

producer/consumer technology, allowing input information and output status to

be shared by all ControlLogix controllers in the system.

L33ERM

RUN

NS

LINK 1

FORCE

I/O

LINK 2

SD

OK

RUN

REM

PROG

XX:XX:XX:XX:XX:XX

1 (Front)

2 (Rear)

AC/DC OUT

RELAY115 VAC

Module

Module

Module

Module

Status

Status

Status

Status

Network

Network

Network

Network

Status

Status

Status

Status

NODE:

NODE:

NODE:

NODE:

24VDC

220 VAC

Relay

120 VAC

Sink

Input

Output

Input

Input

0

0

0

0

4

0

0

0

0

4

1

1

1

1

5

1

1

1

1

1

5

2

2

2

2

6

2

2

2

6

3

3

3

3

7

3

3

3

7

1734

1734

1734

1734

OW4

IB8

IA4

IM4

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 9

Page 10

Preface

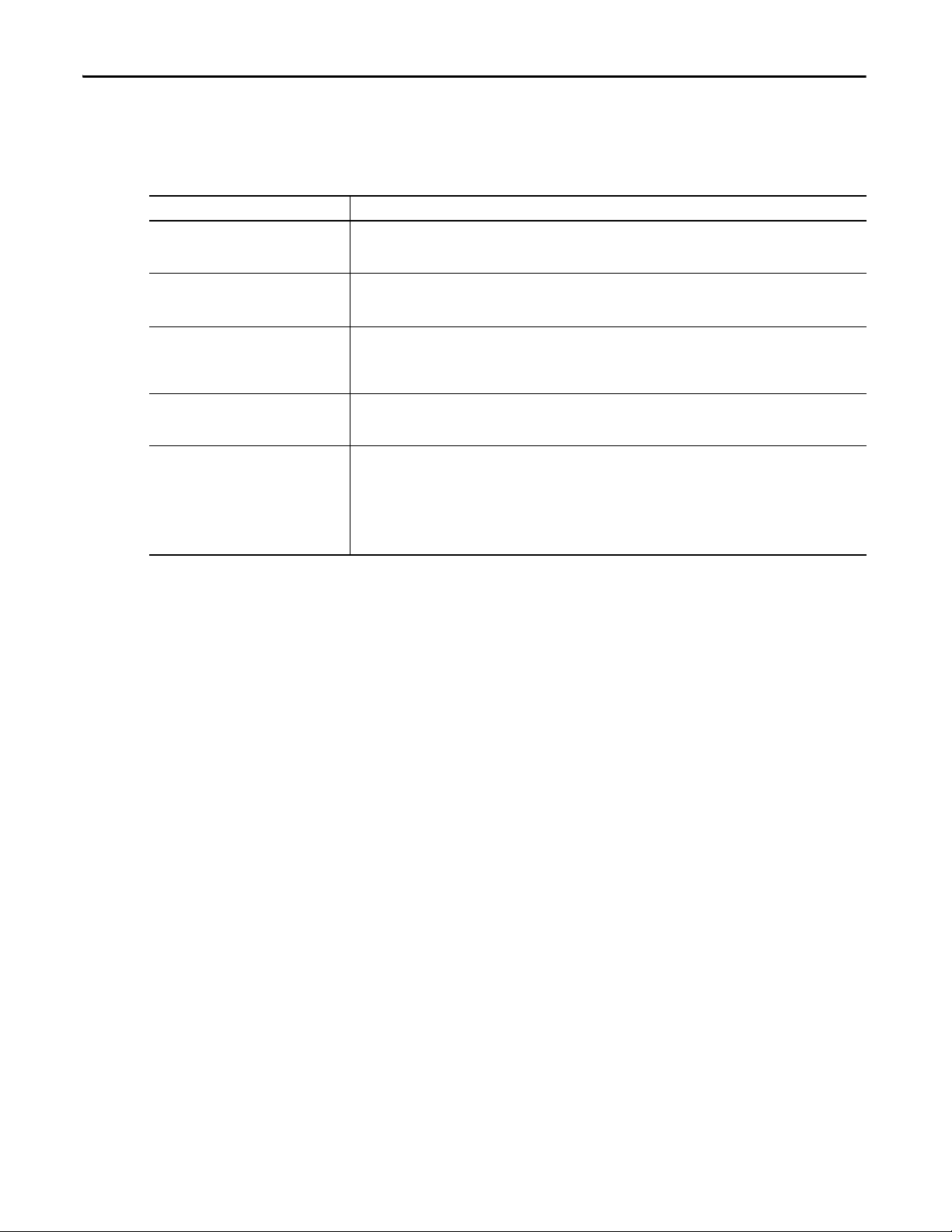

Control System

The control system includes these components:

Component Description

Controller The ControlLogix controller is a modular, high performance controller, that uses RSLogix 5000 programming software

to configure, program, and monitor a system. The ControlLogix controller is certified by TUV for SIL 1 and SIL 2

applications.

HART I/O module The HART analog I/O module converts to or from 4...20 mA analog signals and the digital values used in the controller.

The I/O module automatically collects dynamic process data from the HART field instrument. The I/O module also

bridges HART messages from CIP clients to HART field instruments.

Programming software RSLogix 5000 programming software is the design and configuration tool for HART I/O that includes status and

diagnostic information. The software has predefined data struc tures for status and configuration. A common tag

database in the controller allows HMI development to directly reference I/O and controller tags without the need to

manage another database in your HMI software.

Operating software FactoryTalk View Site Edition software is an HMI software program for monitoring, controlling, and acquiring data from

manufacturing operations throughout an enterprise. A generic display provides a graphical representation via

faceplates of the field instrument connected to the HART input module.

Asset management software FactoryTalk AssetCentre software and FieldCare software are options asset management options for configuring and

managing the intelligent field devices in your plant.

• Support Ethernet, HART, and Profibus networks.

• Support Endress+Hauser field instruments.

• Integrate third-party devices, such as actuators, I/O systems, and sensors that support the FDT standard.

• Ensure full functionality for all devices with DTMs.

• Offer generic profile operation for any third-party fieldbus device that does not have a vendor DTM.

HART Handheld Device (Optional)

The Field Xpert handheld device is an industrial PDA with integrated 3.5" touch

screen based on Windows Mobile. The PDA meets the needs and requirements

of the process industry with protection from static electricity, water and dust with

shockproof housing. It is available in different versions for operation both inside

and outside of explosion hazardous areas.

10 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 11

Preface

System Details

These components and specifications are recommended for preferred

integration.

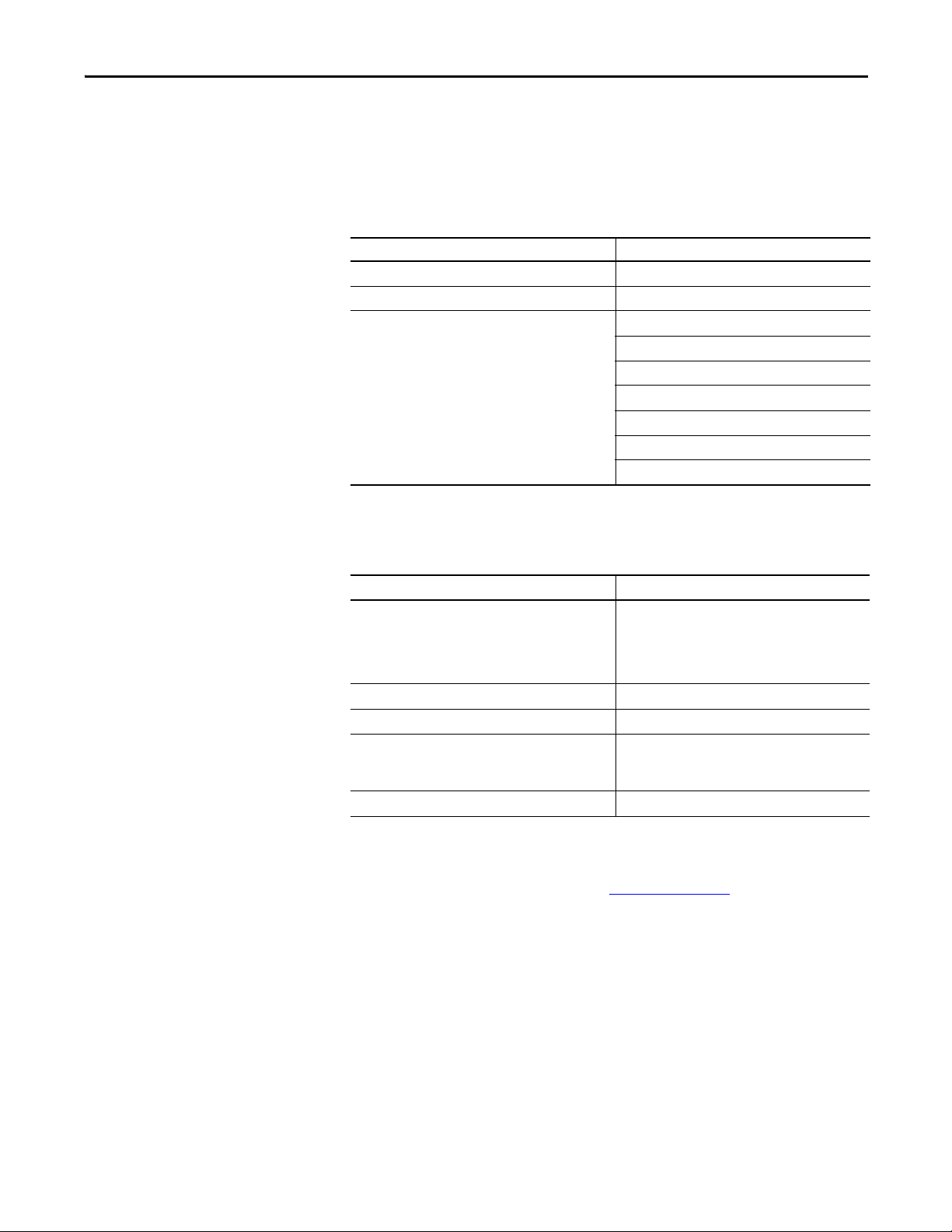

Hardware Components

Component Catalog Number

HART device See appropriate appendix

ControlLogix controller 1756-L7 controllers

HART input module (select any one) 1756-IF8H

1756-IF8IH

1756-IF16H

1794-IF8H

1769sc-IF4IH

1734sc-IE2CH

1734sc-IE4CH

Software Components

Component Catalog Number

RSLogix 5000 Enterprise Series programming software,

Professional edition

Includes:

• RSLinx Classic software

• RSLinx Enterprise software

FactoryTalk View Site Edition (SE) software 9701-VWSXXXXXENE

FactoryTalk AssetCentre softare 9515-ASTCAPXXXXX

FieldCare Standard Asset Management software (optional)

9324-RLD700NXENE

SFE551

Includes:

• DTM library

RSLinx Communication DTM software (optional) 1756-Backplane

For specifications of the engineering workstation (EWS) and operator

workstation (OWS), see the Integrated Architecture for Process Control System

Recommendations Manual, publication PROCES-RM001

.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 11

Page 12

Preface

Performance Considerations

Keep in mind these considerations when integrating HART instruments:

• The HART communication protocol has a relatively slow baud rate at

1200/2400 bits per second.

• The 1756-IF8H HART module executes one HART command per

instrument at a time. Analog (4-20ma) data are delivered from all channels

simultaneously.

• The time of execution for Universal Command 3 is estimated from

200...600 ms, but varies based on the complexity and response time of the

instrument.

• Upload and download time of instrument parameters to and from

FieldCare software can take several minutes depending on the instrument.

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Control System Components

ControlLogix Controllers User Manual, publication 1756-UM001

ControlLogix Analog HART I/O Modules User Manual, publication 1756-UM533 How to install, configure, operate, and maintain a 1756-IF8H input module.

Accessing HART Device Parameters using CIP Messages, Knowledgebase document

required. Please contact your sales representative.)

Operator Components

Add-On Instructions and Faceplates for Visualizing HART Instrument Data in FactoryTalk

View SE, Knowledgebase document (Login required. Please contact your sales

representative.)

FactoryTalk View Site Edition User's Guide Volume 1, publication VIEWSE-UM004

FactoryTalk View Site Edition User's Guide Volume 2, publication VIEWSE-UM005

Faceplates, Add-On Instructions, project files, etc. (Login required. Please contact your

sales representative.)

www.products.endress.com/fieldcare

www.products.endress.com/dtm-download Information about field instrument DTMs.

Process Control Information

Integrated Architecture for Process Control System Recommendations Manual,

publication PROCES-RM001

http://www.rockwellautomation.com/process

http://literature.rockwellautomation.com

http://www.endress.com

How to install, configure, operate, and maintain a ControlLogix controller.

(Login

How to use MSG instructions in controller logic to access instrument parameters.

How to implement the HART Add-On-Instruction in controller logic to work with the

FactoryTalk View faceplates for HART instruments.

How to design, develop, and deploy FactoryTalk View SE applications.

Download AOIs, Faceplates and Global Object graphics, and project files.

Information about FieldCare Asset Management software.

Process system recommendations that organize Rockwell Automation products

functionally as system elements, which can then be applied in proven, scalable

configurations for continuous and batch control.

Information about Rockwell Automation process control and Integration Documents.

Available Rockwell Automation publications, including Integration Documents.

Information about Endress+Hauser field instruments.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

12 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

. To order paper copies of

Page 13

Installation

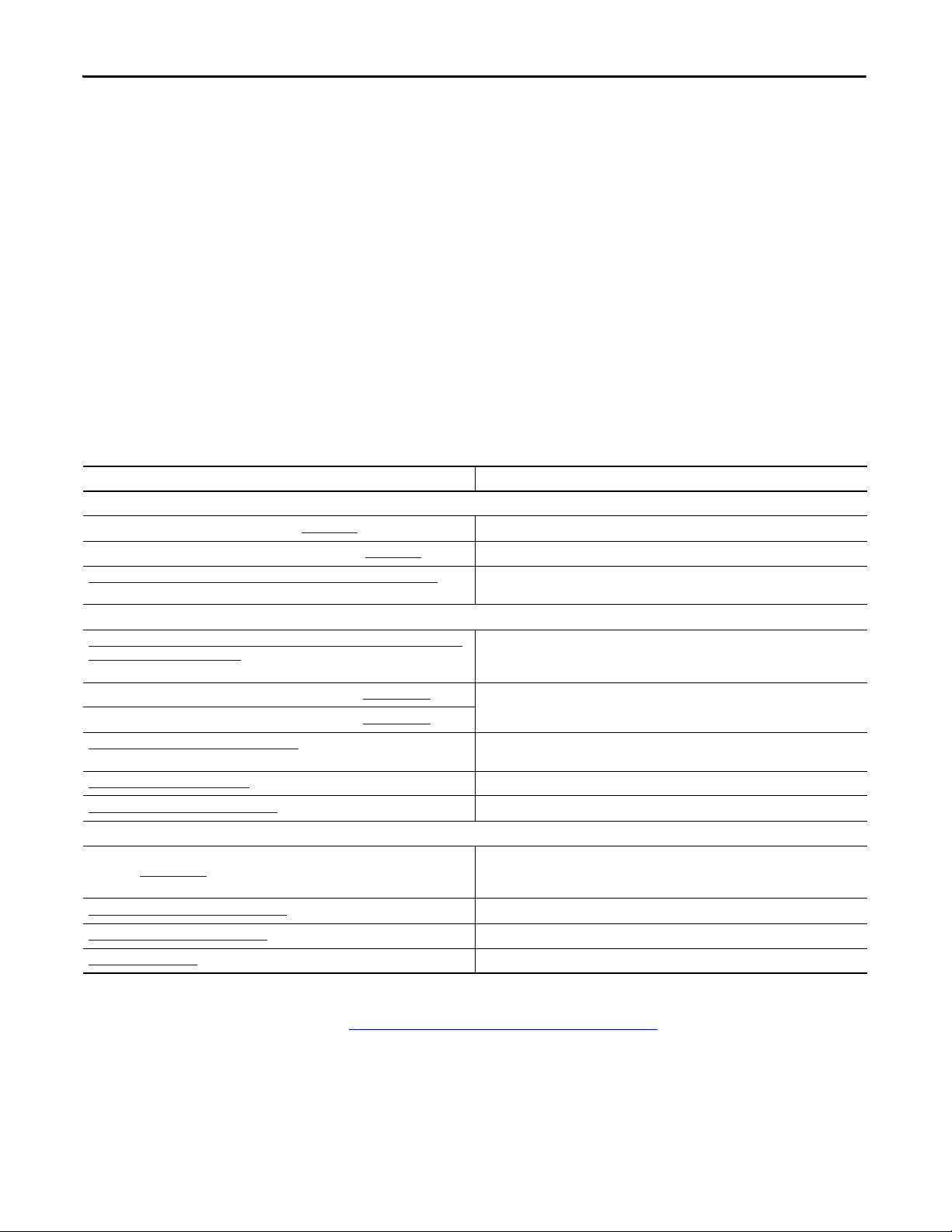

Top ic Pag e

Connect a 2-Wire Field Instrument 13

Connect a 4-Wire Field Instrument 17

Chapter 1

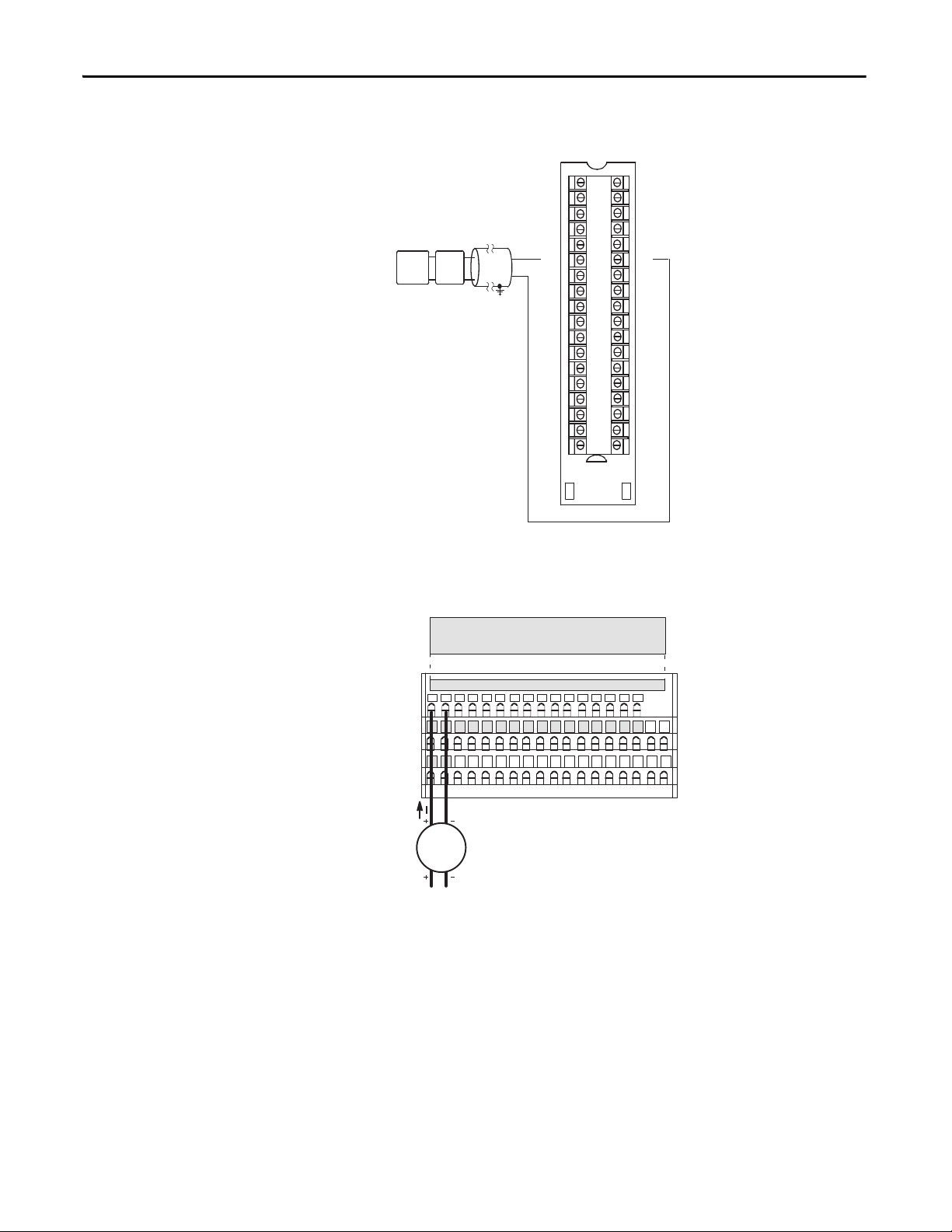

Connect a 2-Wire Field Instrument

HART communication is active only with current inputs. Connect a 2-wire field

instrument to any channel of the HART input module in a 2-wire configuration

for current input.

HART devices that support 2-wire connections include the following.

Device See appendix

Prowirl 73 flowmeter Appendix D on page 97

Levelflex M guided level-radar Appendix F on page 10 9

Micropilot M level-radar Appendix G on page 115

Prosonic M ultrasonic level Appendix E on page 103

Liquiline M CM42 transmitter Appendix M on page 147

Cerabar S pressure transmitter App endix H on page 119

Deltabar S differential pressure Appendix I on page 125

iTEMP TMT162 temperature transmitter Appendix K on page 139

iTEMP TMT182 temperature transmitter Appendix L on page 143

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 13

Page 14

Chapter 1 Installation

+

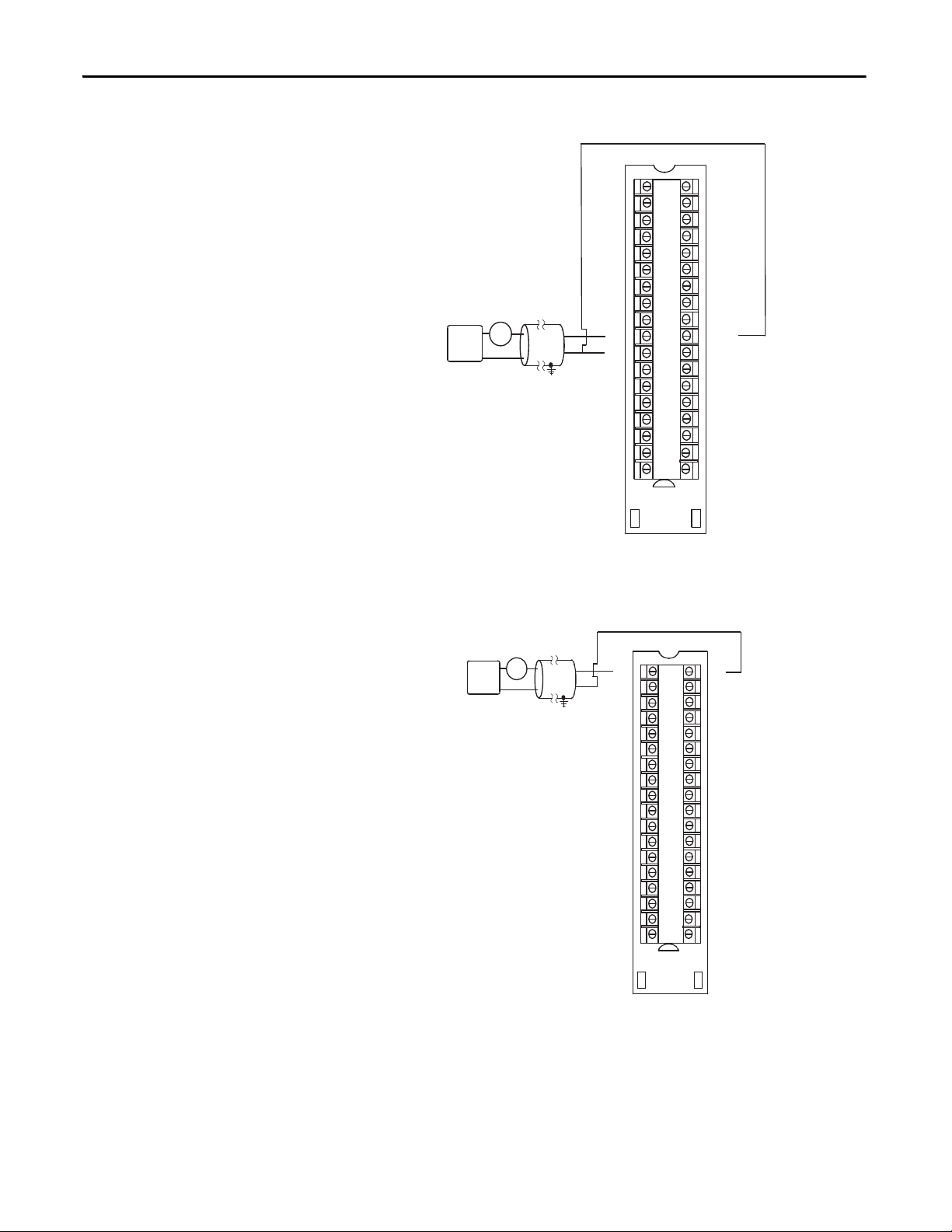

-

+ -

2 Wire HART Device

IN0+

IN1+

IN2+

IN3+

RTN

IN4+

IN5+

IN6+

IN7+

IN8+

IN9+

IN10+

IN11+

RTN

IN12+

IN13+

IN14+

IN15+

IN0IN1IN2IN3RTN

IN4IN5IN6IN7IN8IN9IN10IN11RTN

IN12IN13IN14IN15-

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

24V DC

Power

Supply

2 Wire

XMTR

Figure 1 - 2-Wire Connection to 1756-IF8H Input Module

2 Wire Current I nput

IN0+

IN0-

IN1+

IN1-

RTN

IN2+

IN2-

IN3+

IN3-

IN4+

IN4-

IN5+

IN5-

RTN

IN6+

IN6-

IN7+

IN7-

24 VDC

Power

Supply

2 Wire

HART

Device

+ -

+

-

1

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

I RTN-0

3

NC

5

I RTN-1

7

NC

9

RTN

11

I RTN-2

13

NC

15

I RTN-3

17

NC

19

I RTN-4

21

NC

23

I RTN-5

25

NC

27

RTN

29

I RTN-6

31

NC

33

I RTN-7

35

NC

Figure 2 - 2-Wire Connection to 1756-IF16H Input Module

14 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 15

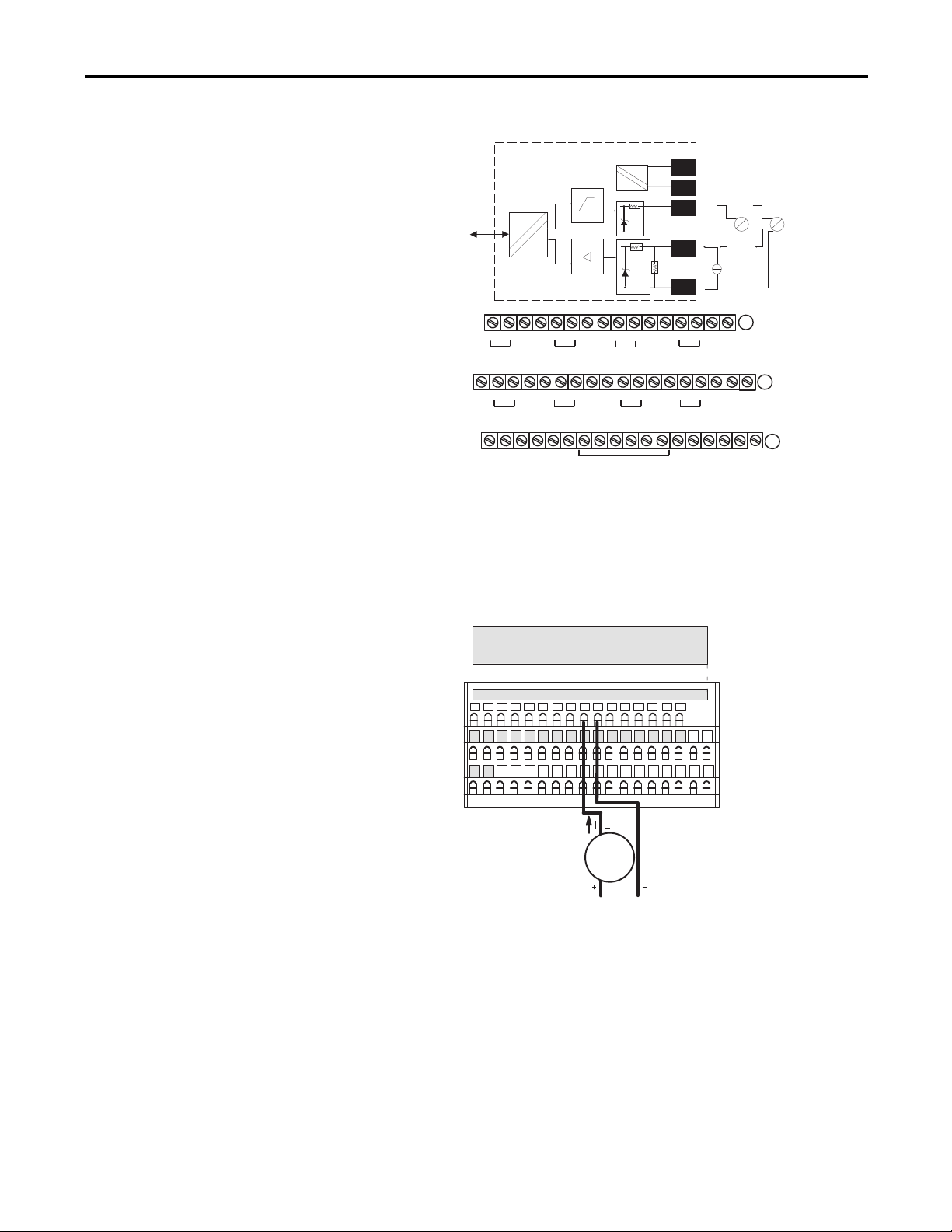

Figure 3 - 2-Wire Connection to 1794-IE8H Input Module

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

33322212029181 24 2526 2728 2930 313217

059484748373635334

51

16

39 40 41 42 43 44 45 46

Row A

Row B

Row C

Row B

Row C

Row A

1794-TB3S shown

Label placed at top of wiring area

Current

input

Flexbus

Bus

uC

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

_

+

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

16

_

Chassis

+

Ground

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

+V -V (COM)

24C dc

Supply In

+V = +24V dc = Terminals C-34 and C-50

-V = COM = C-35 and C-51

Chassis Ground = Terminals B-16, B-33, C-38, C-40…45, and C-47

NC = No connection

For daisy-chaining: Supply in - C-34 (+) and C-35 (-)

_

+

_

+

Ch5

Supply out - C-50 (+) and C-51 (-)

_

+

Ch2

+

Chassis Grounds for Shields

Installation Chapter 1

+V

-V

22 Ω

+

Sig

-

_

+

3hC1hC0hC

_

+

7hC6hC4hC

(1794-TB3G shown)

91 Ω

17V

_

4 to 20mA

Xmit

I

P

Chassis

Ground

+V -V (COM)

CNCN

24C dc

Supply Out

4 to 20mA

Xmit

I

P

40072

A

B

C

Figure 4 - 2-Wire Connection to 1794-IF8IH Input Module

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 15

Page 16

Chapter 1 Installation

Figure 5 - 2-Wire Connection to 1769sc-IF4IH Input Module

Ch0+

2 Wire Current Input

24V DC

Power

Supply

2 Wire

XMTR

+ -

+

-

N/C

N/C

Ch1+

Ch1-iRtn

Ch1-

N/C

Ch3+

Ch3-iRtn

Ch3-

Ch0-iRtn

Ch0-

N/C

Ch2+

Ch2-iRtn

Ch2-

N/C

N/C

Figure 6 - 2-Wire Connection to 1734sc-IE2CH Input Module

0

IN 0

2

+ 24

4

COM

6

FGN

1

IN 1

3

+ 24

5

COM

7

FGN

Figure 7 - 2-Wire Connection to 1734sc-IE4CH Input Module

0

IN 0

2

IN 2

4

COM

6

FGN

IN 1

IN 3

+ 24

FGN

1

2 Wire

Device

3

5

7

2 Wire

Device

16 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 17

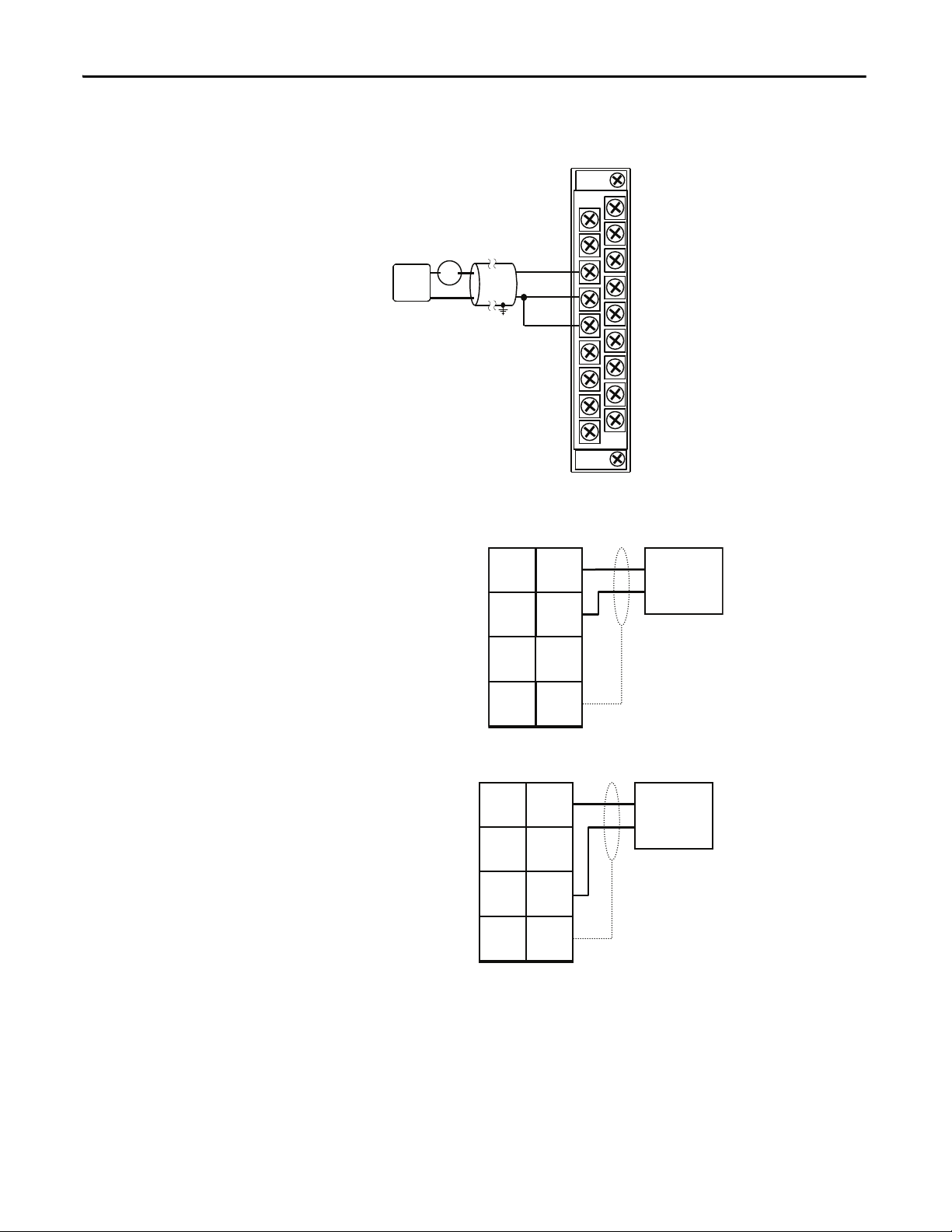

Installation Chapter 1

RTN

IN4+

IN4IN5+

IN5RTN

IN6+

IN6IN7+

IN7-

IN0+

IN0IN1+

IN1-

IN2+

IN2IN3+

IN3-

I RTN- 0

NC

I RTN- 1

NC

I RTN- 2

NC

I RTN- 3

NC

RTN

I RTN- 4

NC

I RTN- 5

NC

RTN

I RTN- 6

NC

I RTN- 7

NC

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

+

-

+

+

--

4-wire Current Input

4-wire

MTR

24V DC

Power

Supply

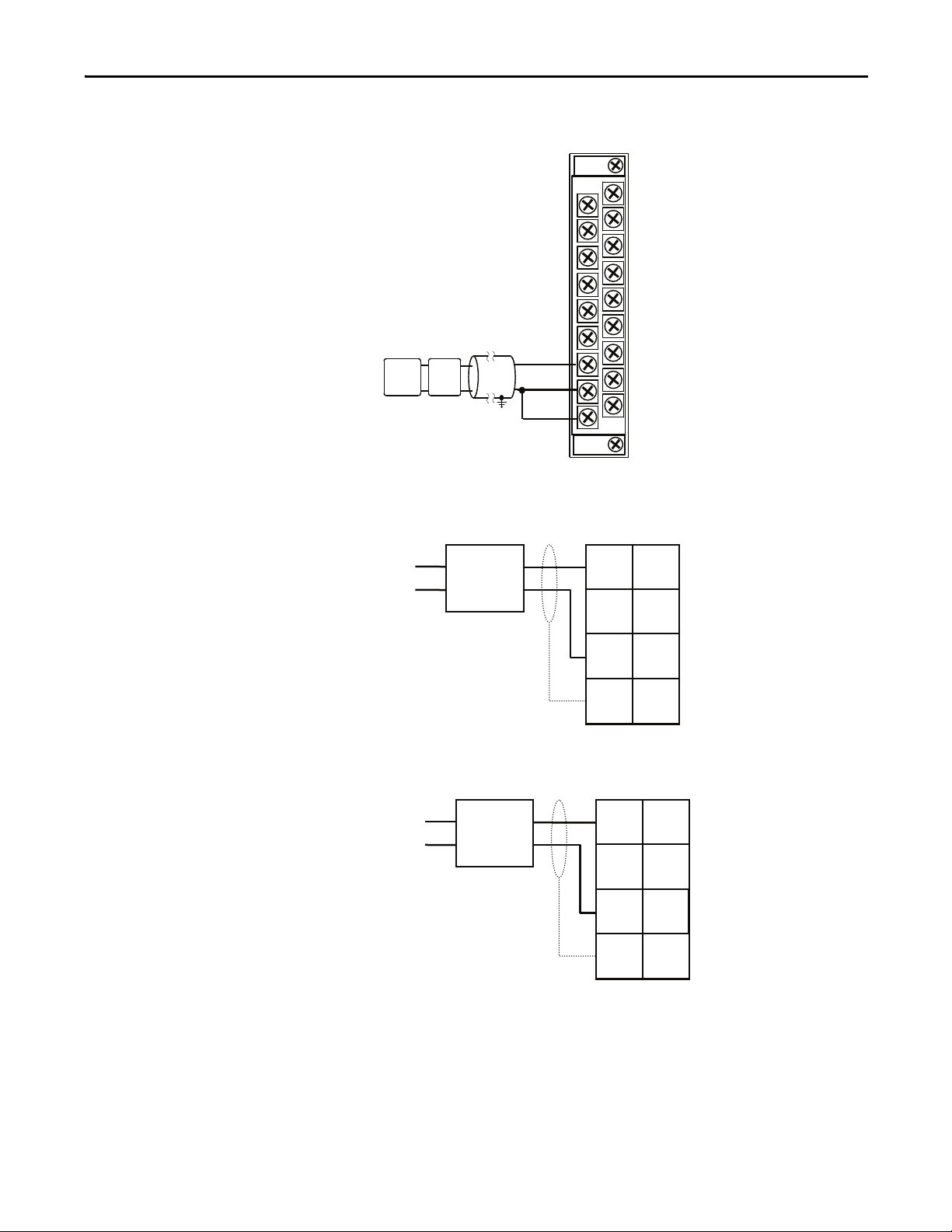

Connect a 4-Wire Field Instrument

HART communication is active only with current inputs. Connect a 4-wire field

instrument to any channel of the HART input module in a 4-wire configuration

for current input.

HART devices that support 4-wire connections include the following.

Device See appendix

Promass 83 flowmeter Appendix A on page 83

Promag 53 flowmeter Appendix C on page 93

Proline t-mass 65 flowmeter Appendix B on page 89

Prosonic S transmitter Appendix J on page 133

Figure 8 - 4-Wire Connection to 1756-IF8H Input Module

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 17

Page 18

Chapter 1 Installation

+

-

+

--

4 Wire HART Device

IN0+

IN1+

IN2+

IN3+

RTN

IN4+

IN5+

IN6+

IN7+

IN8+

IN9+

IN10+

IN11+

RTN

IN12+

IN13+

IN14+

IN15+

IN0IN1IN2IN3RTN

IN4IN5IN6IN7IN8IN9IN10IN11RTN

IN12IN13IN14IN15-

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

24V DC

Power

Supply

4 Wire

XMTR

+

Figure 9 - 4-Wire Connection to 1756-IF16H Input Module

Figure 10 - 4-Wire Connection to 1794-IF8IH Input Module

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16

39 40 41 42 43 44 45 46

Label placed at top of wiring area

Current

input

Row A

33322212029181 24 2526 2728 2930 313217

Row B

51

059484748373635334

Row C

Row A

Row B

Row C

1794-TB3S shown

18 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 19

Figure 11 - 4-Wire Connection to 1769sc-IF4IH Input Module

0

IN 0

2

+ 24

4

COM

6

FGN

1

IN 1

3

+ 24

5

COM

7

FGN

4 Wire

Device

AC/DC Pwr

A

Ch0+

+

24V DC

+

-

4 Wire

XMTR

--

Power

Supply

4 Wire Current Input

N/C

N/C

Ch1+

Ch1-iRtn

Ch1-

N/C

+

Ch3+

Ch3-iRtn

Ch3-

Ch0-iRtn

Ch0-

N/C

Ch2+

Ch2-iRtn

Ch2-

N/C

N/C

Installation Chapter 1

Figure 12 - 4-Wire Connection to 1734sc-IE2CH Input Module

Figure 13 - 4-Wire Connection to 1734sc-IE4CH Input Module

0

IN 0

2

IN 2

4

COM

6

FGN

FGN

C/DC Pwr

4 Wire

Device

1

IN 1

3

IN 3

5

+ 24

7

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 19

Page 20

Chapter 1 Installation

Notes:

20 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 21

Chapter 2

Configure the HART Device in RSLogix 5000 Programming Software

Top ic Pag e

Configure a HART Input Module in a ControlLogix System 21

Configure a HART Input Module in a Compact I/O System 27

Configure a HART Input Module in a FLEX I/O System 29

Configure a HART Input Module in a POINT I/O System 31

The examples in this chapter use RSLogix 5000 programming software,

version 20.

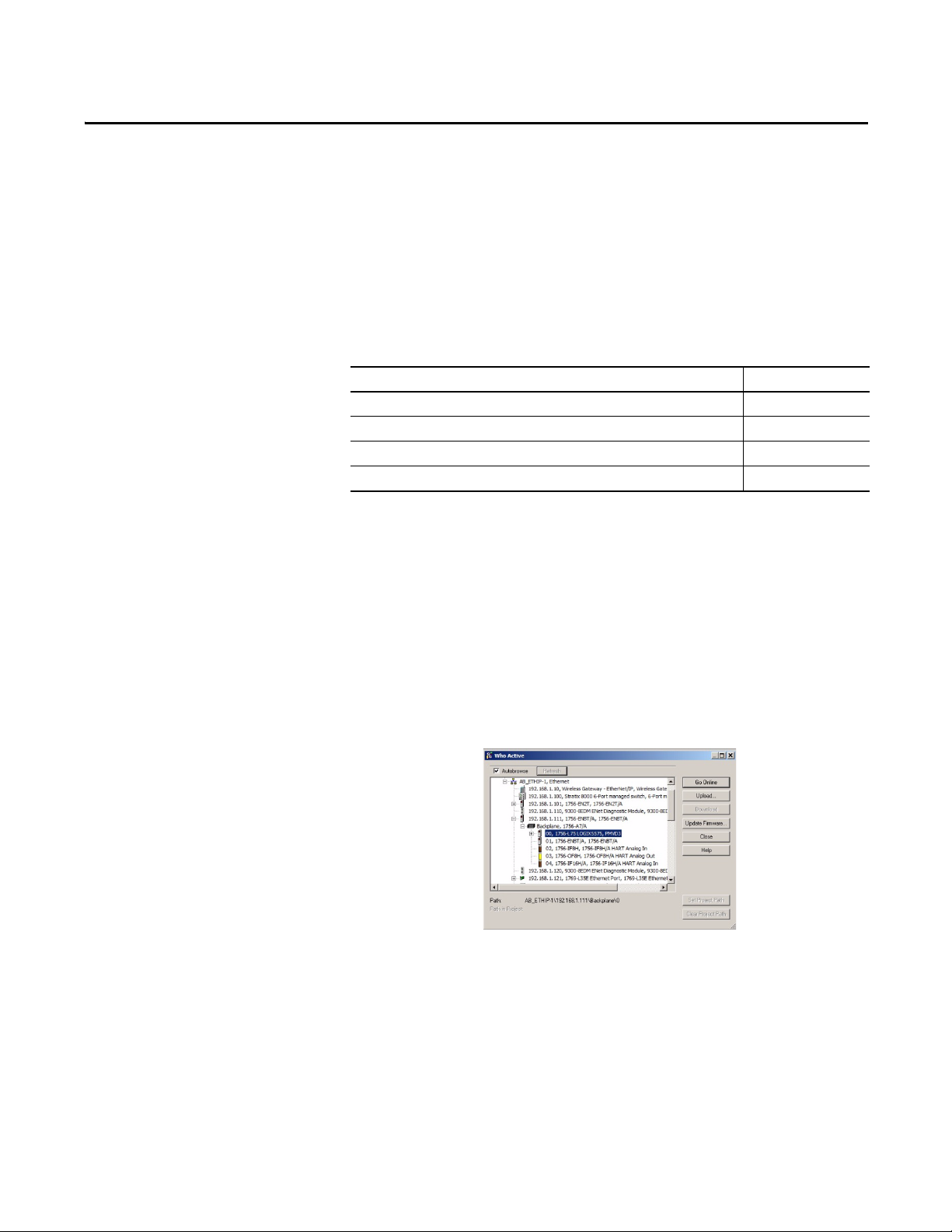

Configure a HART Input Module in a ControlLogix System

In RSLogix 5000 software, you must have a project open with a ControlLogix

controller already configured. Make sure the project path is set to the correct

controller.

Use RSWHO Active in RSLogix 5000 software to verify that the controller,

HART input module, and devices are active.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 21

Page 22

Chapter 2 Configure the HART Device in RSLogix 5000 Programming Software

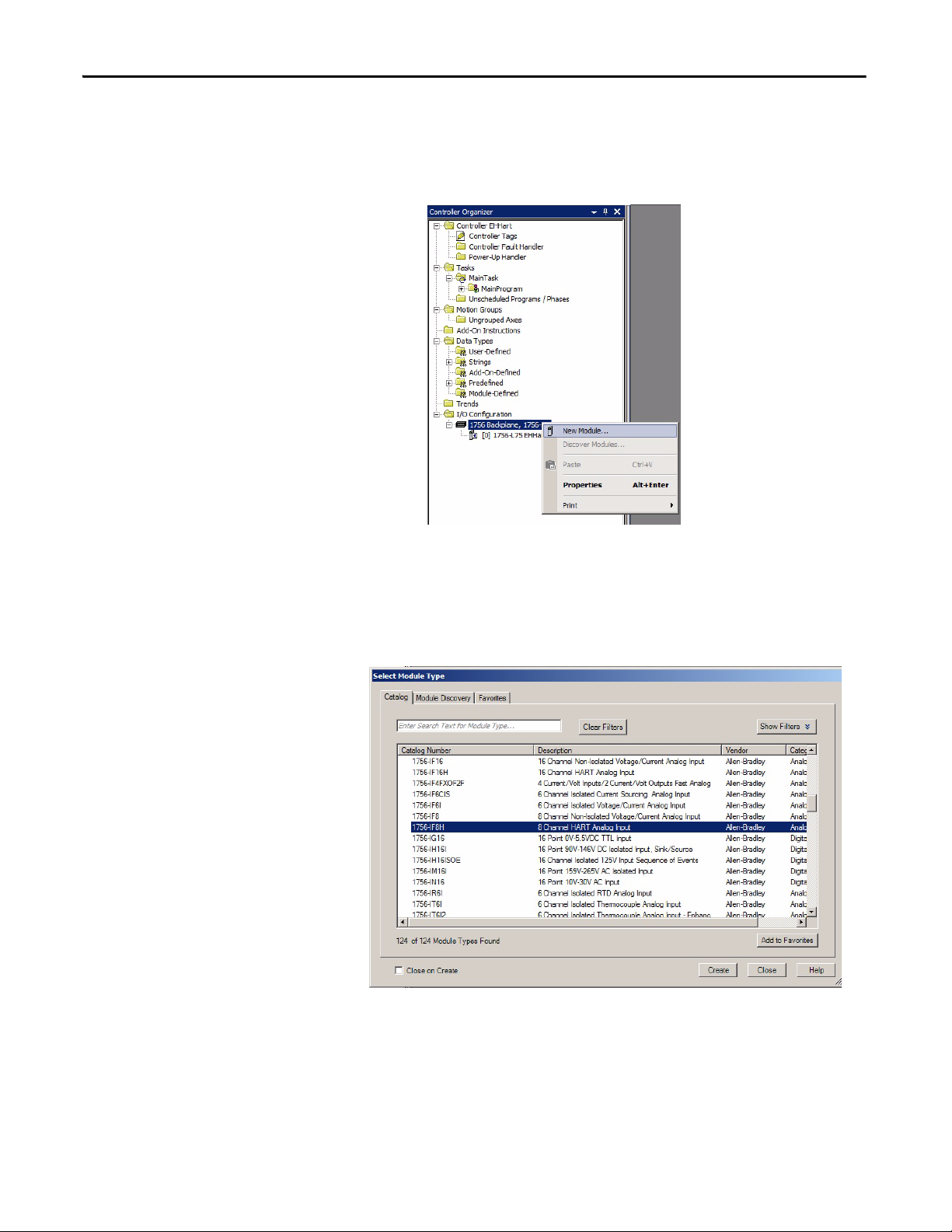

To configure the I/O module, follow these steps within the configuration tree.

1. From the configuration tree, right click the 1756 backplane and choose

New Module.

If the controller communicates with the I/O module over a network, the

network interfaces must be added to the configuration tree before adding

the I/O module.

2. From the list, select the 1756-IF8H input module.

22 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 23

Configure the HART Device in RSLogix 5000 Programming Software Chapter 2

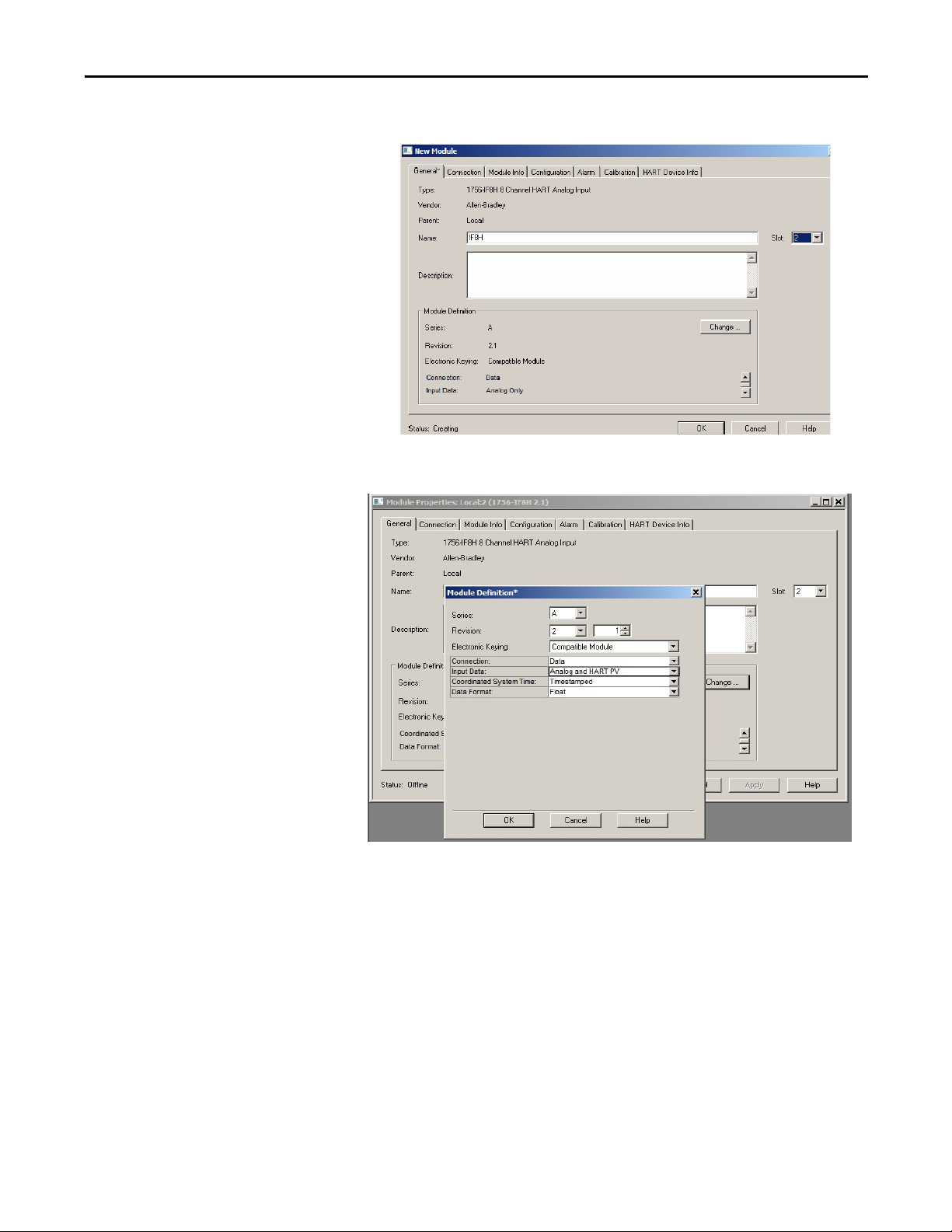

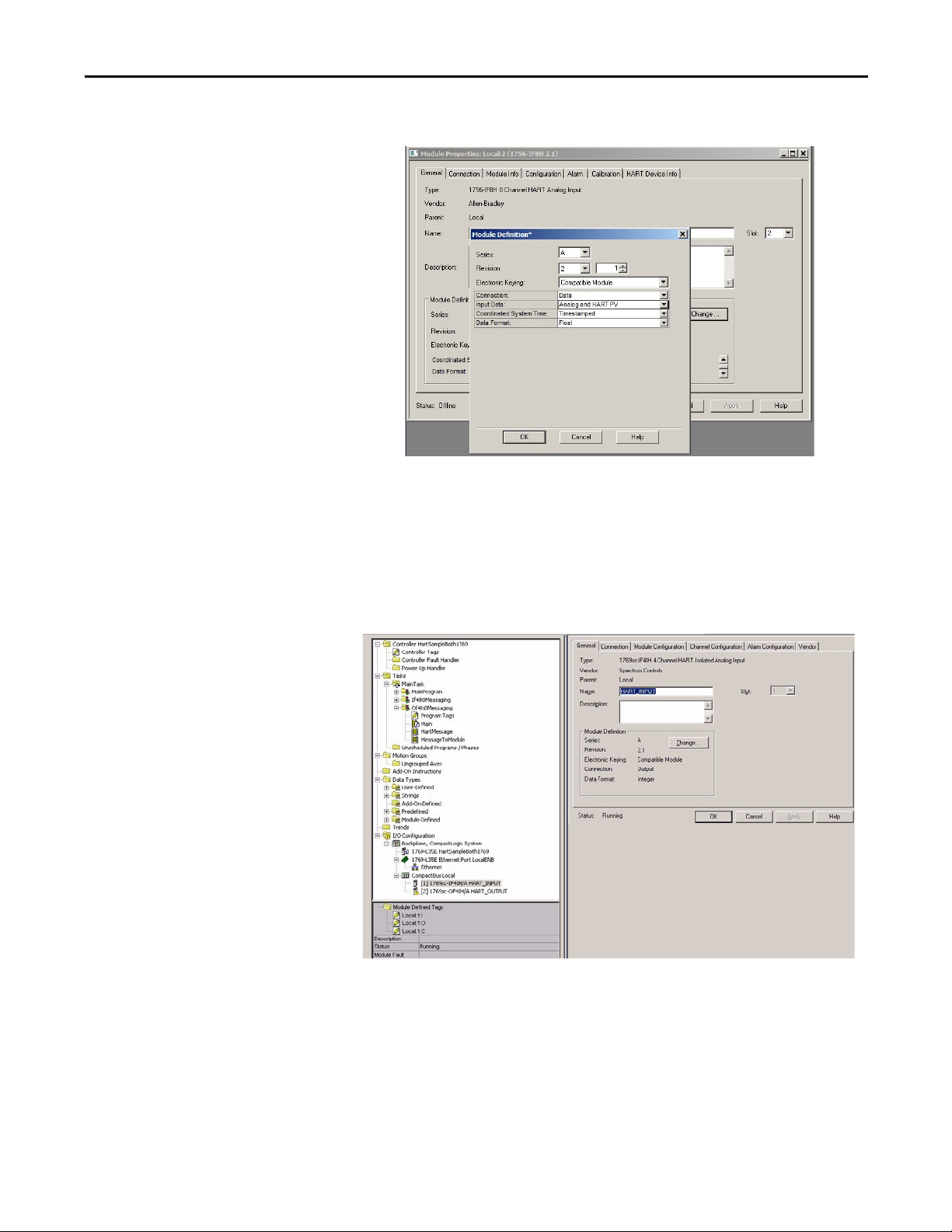

3. On the General tab, enter the configuration information for the module.

4. Click Change.

5. For Input Data, choose Analog and HART PV.

6. On the Configuration tab, enable HART for each channel connected to a

device.

Each channel must be enabled to pass HART data to the controller.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 23

Page 24

Chapter 2 Configure the HART Device in RSLogix 5000 Programming Software

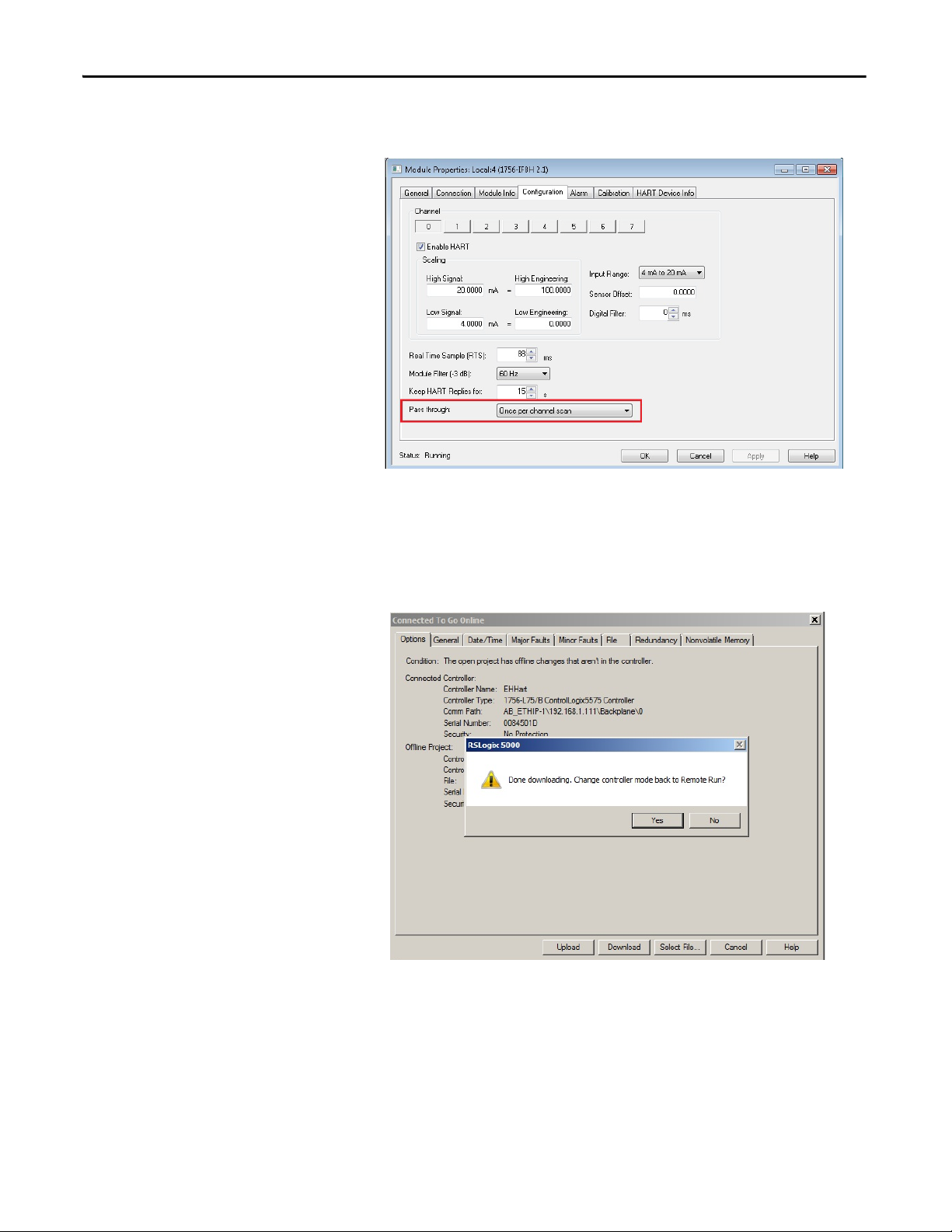

7. On the Configuration tab, for Passthrough, choose Once per channel

scanned.

This passthrough selection is the fastest and best for asset management

software.

8. When complete, click OK.

9. Click Download to go online.

24 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 25

Configure the HART Device in RSLogix 5000 Programming Software Chapter 2

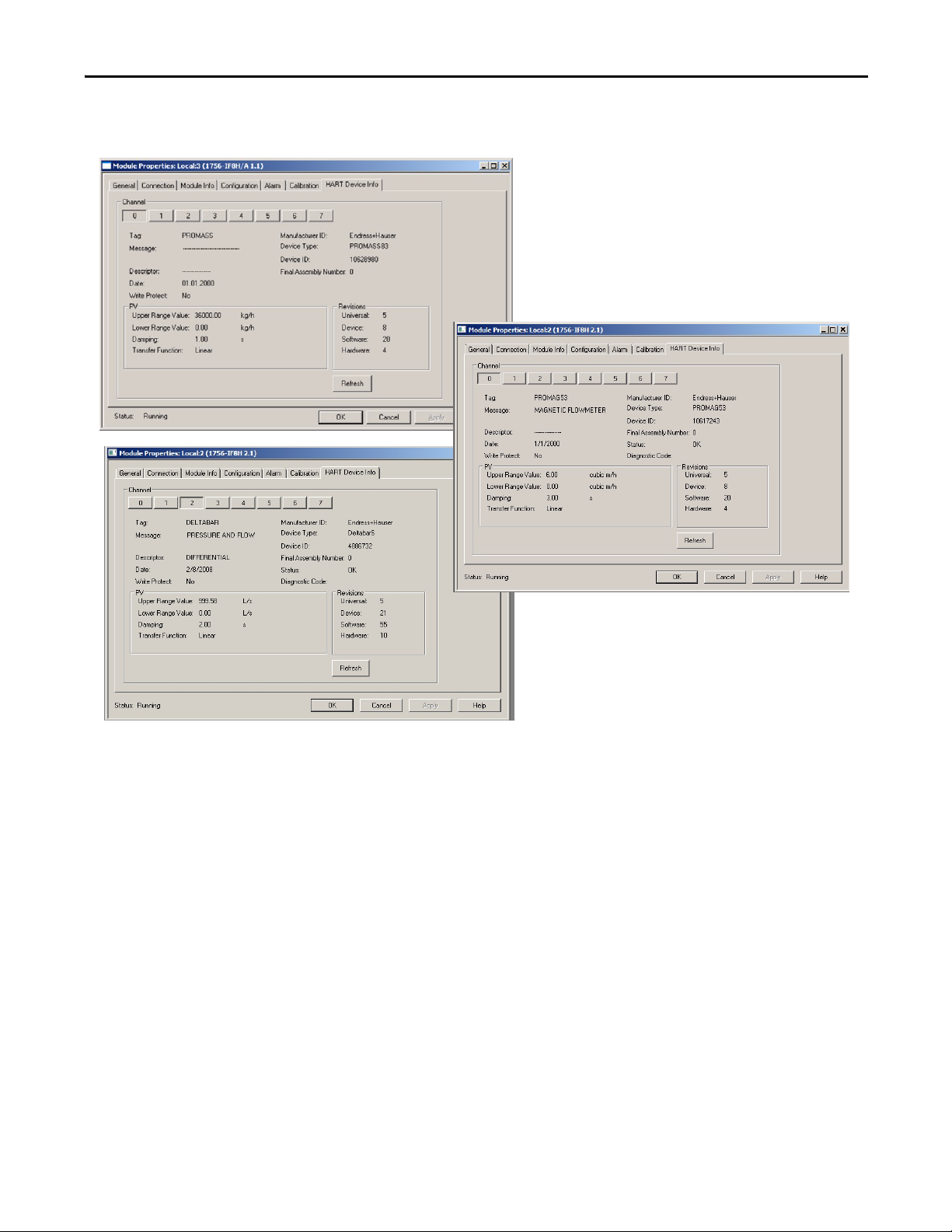

10. From the HART Device Info tab in the HART module properties, verify

that the instrument is connected.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 25

Page 26

Chapter 2 Configure the HART Device in RSLogix 5000 Programming Software

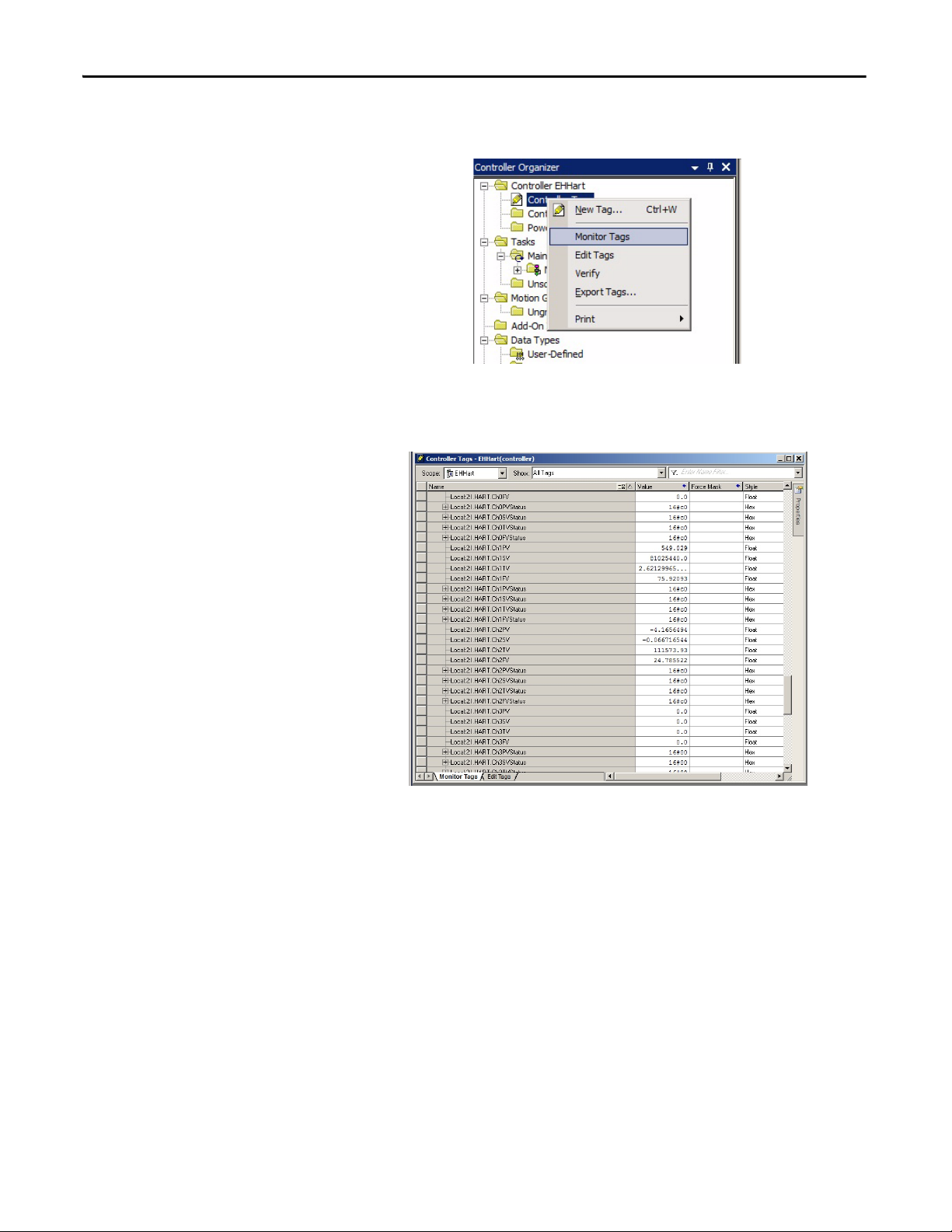

11. Check Controller Tags to verify that the HART instrument is connected

and passing data.

A connected instrument displays values in the PV, SV, TV, and FV fields.

This tag example shows that the HART input module is in slot 6.

26 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 27

Configure the HART Device in RSLogix 5000 Programming Software Chapter 2

If HART data is not present, make sure the HART function is enabled.

Configure a HART Input Module in a Compact I/O System

Use RSWHO Active in RSLogix 5000 software to verify that the controller,

HART input module, and devices are active.

This example has a 1769-L35E CompactLogix controller and the Spectrum

1769sc-IF4IH module and uses the Spectrum sample ACD file.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 27

Page 28

Chapter 2 Configure the HART Device in RSLogix 5000 Programming Software

The Spectrum 1769sc-IF4IH is configured as shown.

Make sure that Enable Channel and Enable HART Communication are both

checked.

The Spectrum 1769sc-IF4IH has these controller tags.

28 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 29

Configure the HART Device in RSLogix 5000 Programming Software Chapter 2

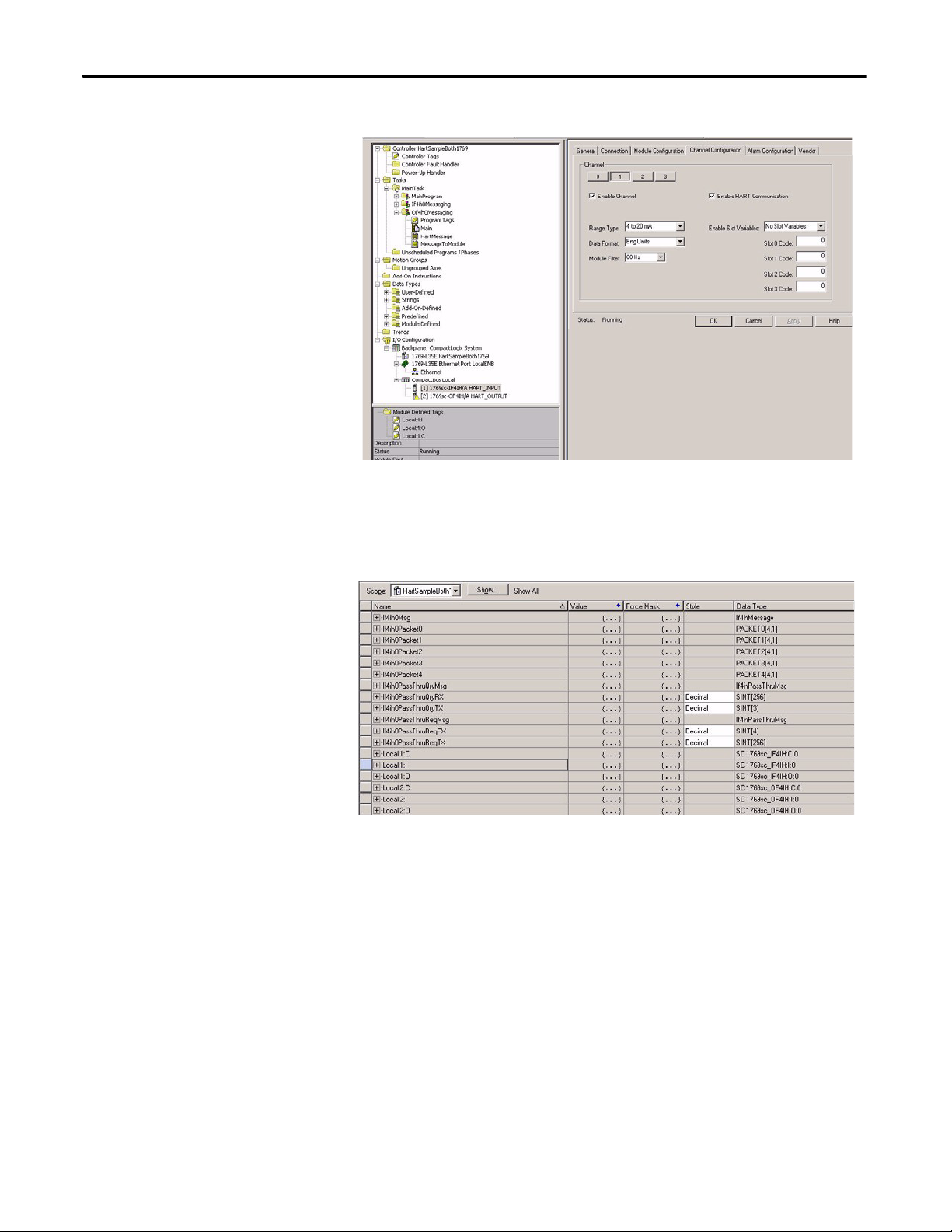

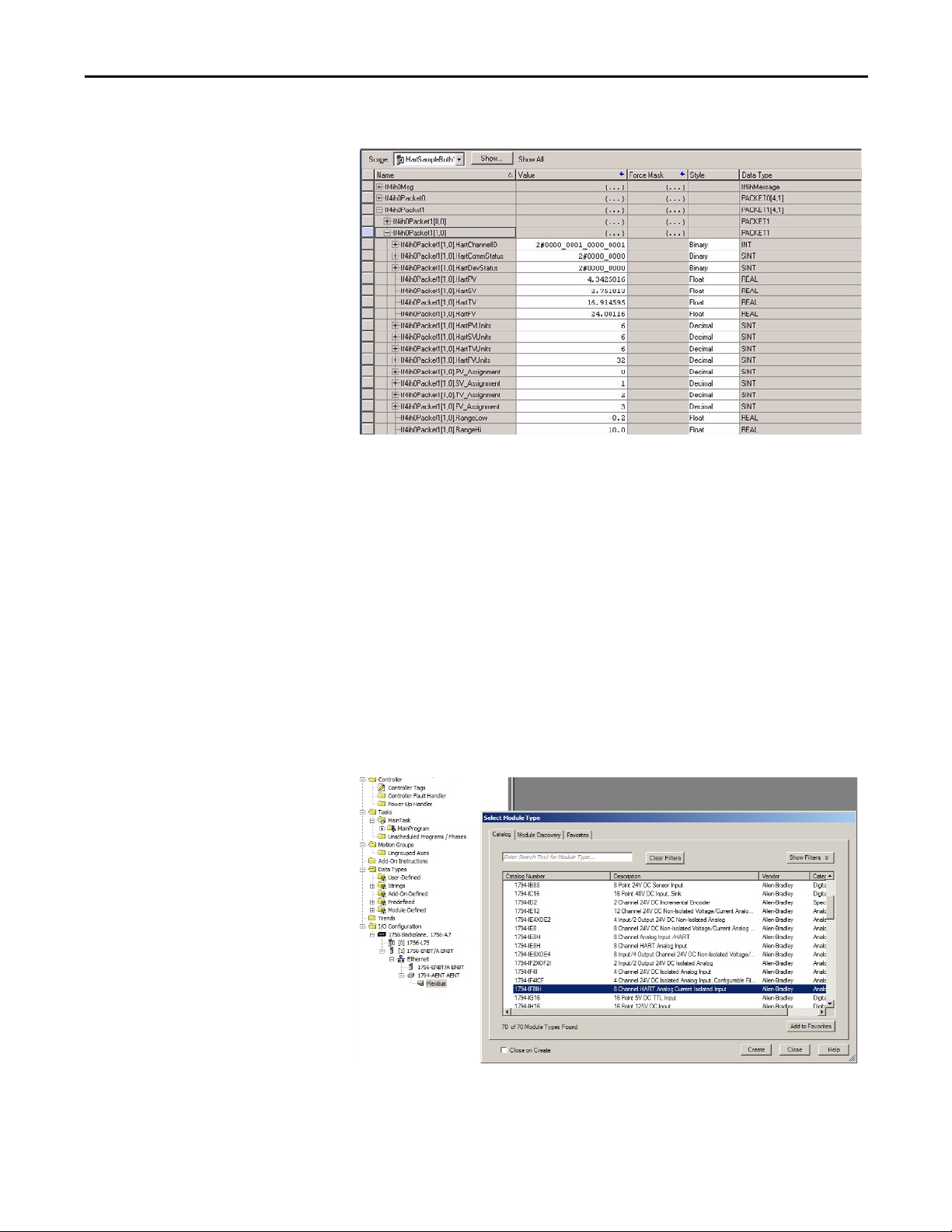

This example shows the PV values from the device mapped to the data structure.

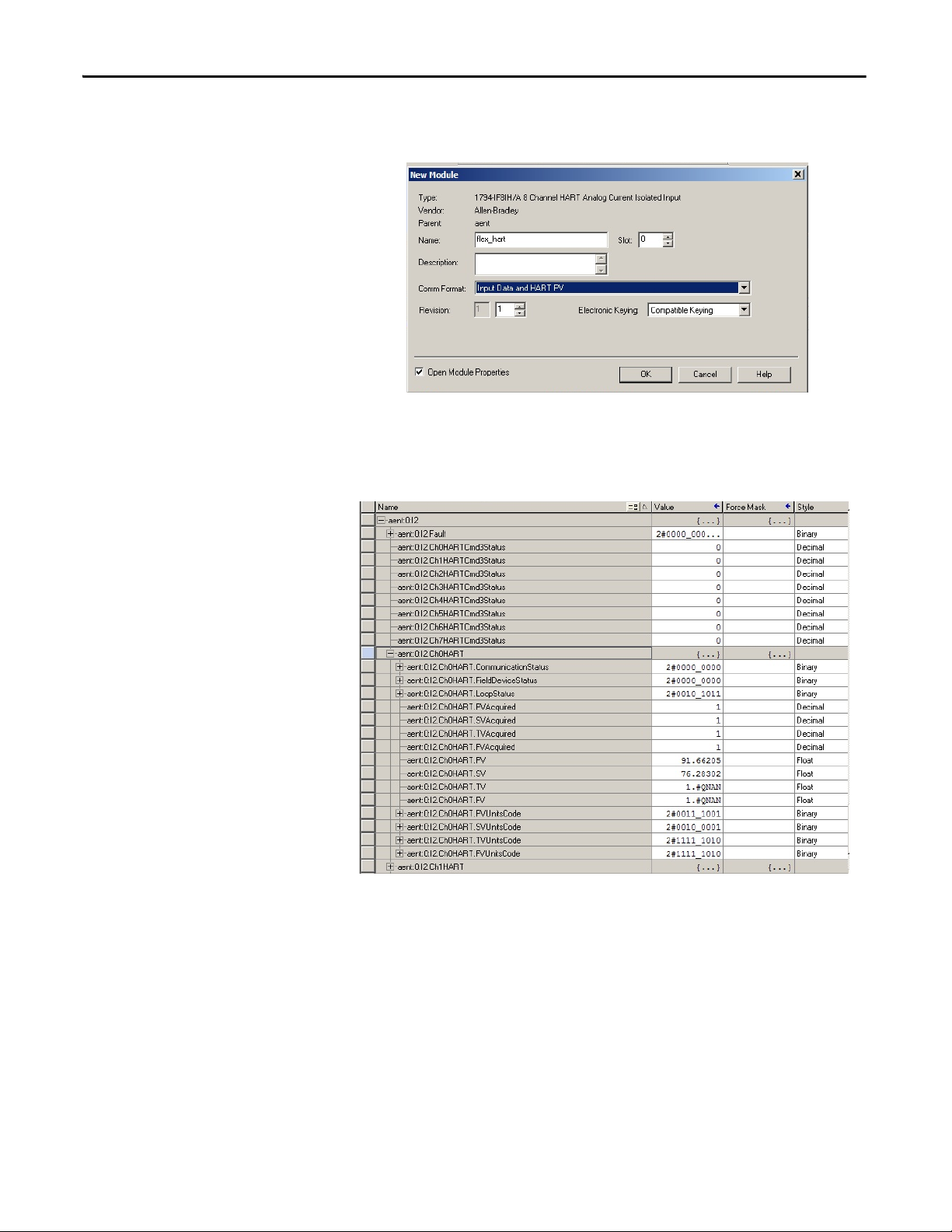

Configure a HART Input Module in a FLEX I/O System

In RSLogix 5000 software, you must have a project open with a controller already

configured. Make sure the project path is set to the correct controller.

Use RSWHO Active in RSLogix 5000 software to verify that the controller,

HART input module, and devices are active.

To configure the I/O module, follow these steps within the configuration tree.

This example assumes you have a 1756-ENBT interface and a 1794-AENT

adapter.

1. From the configuration tree, right click the 1794-AENT adapter and

choose New Module.

2. From the list, select the HART input module and click Create.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 29

Page 30

Chapter 2 Configure the HART Device in RSLogix 5000 Programming Software

3. Enter the configuration information for the module and choose the

HART communication format.

4. Click OK.

5. Go online and check the controller tags to make sure the device is

connected.

30 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 31

Configure the HART Device in RSLogix 5000 Programming Software Chapter 2

Configure a HART Input Module in a POINT I/O System

In RSLogix 5000 software, you must have a project open with a controller already

configured. Make sure the project path is set to the correct controller.

Use RSWHO Active in RSLogix 5000 software to verify that the controller,

HART input module, and devices are active.

To configure the I/O module, follow these steps within the configuration tree.

This example assumes you have a 1756-ENBT interface and a 1734-AENT

adapter.

1. From the configuration tree, right click on the 1734-AENT module and

choose New Module.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 31

Page 32

Chapter 2 Configure the HART Device in RSLogix 5000 Programming Software

2. From the list, select the HART input module and click Create.

3. Enter the configuration information for the module and click Change.

4. Enter additional configuration information and click OK.

5. From the Channel Configuration tab, choose the channel.

32 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 33

Configure the HART Device in RSLogix 5000 Programming Software Chapter 2

6. Enable the HART function for each channel required.

7. Click OK.

8. Go Online and check the controller tags to verify operation.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 33

Page 34

Chapter 2 Configure the HART Device in RSLogix 5000 Programming Software

Notes:

34 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 35

Chapter 3

IMPORTANT

Configure the HART Device in FactoryTalk AssetCentre Software

Top ic Pag e

Update the DTM Catalog 35

Configure the DTM Network Path 36

Configure a HART Device 44

Configure a FLEX I/O Module 50

FactoryTalk AssetCentre Software is a FDT-based, plant asset management

software tool that you use to configure intelligent field instruments for

Endress+Hauser.

Update the DTM Catalog

Before beginning this process, make sure the DTMs and EDSs have been

downloaded from the vendor websites, imported, and installed.

1. Launch AssetCentre software and open a project.

2. Choose Tools > DTM catalog to update the available DTMs.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 35

Page 36

Chapter 3 Configure the HART Device in FactoryTalk AssetCentre Software

3. Look through the catalog of installed DTMs and look for a green

checkmark on the appropriate DTM.

A yellow triangle indicates that the DTM is found but needs to be

scanned.

Configure the DTM Network Path

4. If necessary, click Scan Now and then verify that the DTMs you installed

exist in the catalog.

5. Close the DTM catalog.

The network path will vary based on your system. In this example the host

personal computer communicates through a 175 backplane.

1. Choose Tasks > DTM Networks.

36 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 37

Configure the HART Device in FactoryTalk AssetCentre Software Chapter 3

2. Click on the name of the Host PC network on the tree to the left and then

click Add DTM.

3. Click on the 1756 Chassis DTM.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 37

Page 38

Chapter 3 Configure the HART Device in FactoryTalk AssetCentre Software

The tree should look like the following screen.

4. Select the chassis and click Add DTM

The following screen should appear.

5. Browse to the backplane containing the appropriate controller. and click

OK.

38 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 39

Configure the HART Device in FactoryTalk AssetCentre Software Chapter 3

6. Click Select path to autobrowse.

For some I/O it may be necessary to click Open to configure the path.

7. Click Next.

8. Select DTM Networks and view the tree.

9. Select the chassis and click Add DTM.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 39

Page 40

Chapter 3 Configure the HART Device in FactoryTalk AssetCentre Software

10. Select the I/O module.

11. Click OK.

12. Enter the slot number and other configuration data.

40 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 41

Configure the HART Device in FactoryTalk AssetCentre Software Chapter 3

13. Click Next.

14. Select the module and click Add DTM.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 41

Page 42

Chapter 3 Configure the HART Device in FactoryTalk AssetCentre Software

15. Select the correct channel and click OK.

Repeat for additional channels with devices.

16. Click Scan network to locate devices.

17. Click OK.

42 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 43

Configure the HART Device in FactoryTalk AssetCentre Software Chapter 3

18. Click DTM Info.

19. Make sure the correct DTMS are available and green.

Scan for any required DTMS that appear in yellow.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 43

Page 44

Chapter 3 Configure the HART Device in FactoryTalk AssetCentre Software

Configure a HART Device

1. Right click on the device an select Online.

2. Click Open.

Device information should appear.

3. Click Next.

4. Click Design.

44 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 45

Configure the HART Device in FactoryTalk AssetCentre Software Chapter 3

5. Choose Process Area > New.

6. In the Process Area tree, select Instrument.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 45

Page 46

Chapter 3 Configure the HART Device in FactoryTalk AssetCentre Software

7. Enter the name of the device and click OK.

8. Right click on the name of the device you just created and select

Properties.

46 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 47

Configure the HART Device in FactoryTalk AssetCentre Software Chapter 3

9. Select DTM Addressing Info and click on the ellipsis.

10. Select the device and click OK.

The device information appears.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 47

Page 48

Chapter 3 Configure the HART Device in FactoryTalk AssetCentre Software

11. Click OK.

12. Right click on the device name and select DTM View.

48 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 49

Configure the HART Device in FactoryTalk AssetCentre Software Chapter 3

13. When the device information appears, go online.

14. Select any views desired and save the project.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 49

Page 50

Chapter 3 Configure the HART Device in FactoryTalk AssetCentre Software

Configure a FLEX I/O Module

1. From the DTM Networks tree, select the FLEX rail.

2. Click Add DTM.

3. Select the FLEX I/O module and click OK.

The tree should look similar to this.

50 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 51

Configure the HART Device in FactoryTalk AssetCentre Software Chapter 3

4. Select the FLEX rail.

5. Use AutoBrowse to select the path.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 51

Page 52

Chapter 3 Configure the HART Device in FactoryTalk AssetCentre Software

Notes:

52 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 53

Chapter 4

IMPORTANT

Configure the HART Device in E+H Fieldcare Software

Top ic Pag e

Configure a HART Input Module and Device 53

Access Instrument Data 56

Additional Functions 58

FieldCare is the Endress+Hauser FDT-based, plant-asset management tool for

configuring intelligent field instruments.

Configure a HART Input Module and Device

1. Start FieldCare and open a new project.

To optimize FieldCare performance, it is recommended that you

verify that the correct DTMs are loaded in the catalog.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 53

Page 54

Chapter 4 Configure the HART Device in E+H Fieldcare Software

2. Choose DTM Catalog > Update.

3. Select desired DTMs and click Move.

If you do not find the desired DTMs, or if the left pane of the dialog box is

empty, click Update. FieldCare software searches for DTMs installed on

your computer.

If necessary, to remove DTMs, select the desired DTMs in the right pane

and click Move.

4. Click OK.

54 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 55

Configure the HART Device in E+H Fieldcare Software Chapter 4

5. From the Device Operation/Add Device menu, select the RSLinx 1756

Backplane and click OK.

6. To configure the RSLinx backplane, double-click on the RSLinx

backplane in the left pane.

7. Click Select Path and drill down to the ControlLogix backplane.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 55

Page 56

Chapter 4 Configure the HART Device in E+H Fieldcare Software

8. From the Device Operation/Add Device menu, select the 1756-IF8H/A

module and click OK.

Access Instrument Data

9. To configure the 1756-IF8H module, double-click on the module

backplane in the left pane.

10. Enter the slot number and click the Create Network icon.

11. When prompted, click OK.

The Com DTM now scans the entire HART network behind the multiplexer

and searches for the right DTM.

If the right DTM is installed, the instrument comes up in the Explorer view on

the left side.

If only one DTM is added to the network, the software automatically goes

online. Otherwise a warning occurs that must be confirmed. To switch this

behavior off, in the Fieldcare-context-menu Extras/Options, select After

Scanning within page Scanning.

You can use FieldCare software to access instrument data.

The following examples show a Promass field instrument. The screens vary

depending on the field instrument.

1. In an open FieldCare project, right-click on the instrument in the left pane

and choose Connect.

2. Double-click on the instrument in the left pane.

56 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 57

Configure the HART Device in E+H Fieldcare Software Chapter 4

3. In the Online pane, choose Device Data.

4. To view measured values, right-click on the instrument in the left pane and

choose Observe.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 57

Page 58

Chapter 4 Configure the HART Device in E+H Fieldcare Software

Additional Functions

You can use FieldCare software to perform these additional functions:

• Toggle between connected and disconnected modes

• Read from device

• Wri te to de vic e

• Device-specific functions

58 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 59

Chapter 5

Visualization

Top ic Pag e

Add-On Instructions 59

Global Object 75

Face pla tes 81

To use the predesigned faceplates to monitor the instrument, HART must be

enabled for the HART input module. FactoryTalk View SE faceplates provide for

visualization of instruments connected to a HART input module. The HART

input module provides the necessary data to the faceplates.

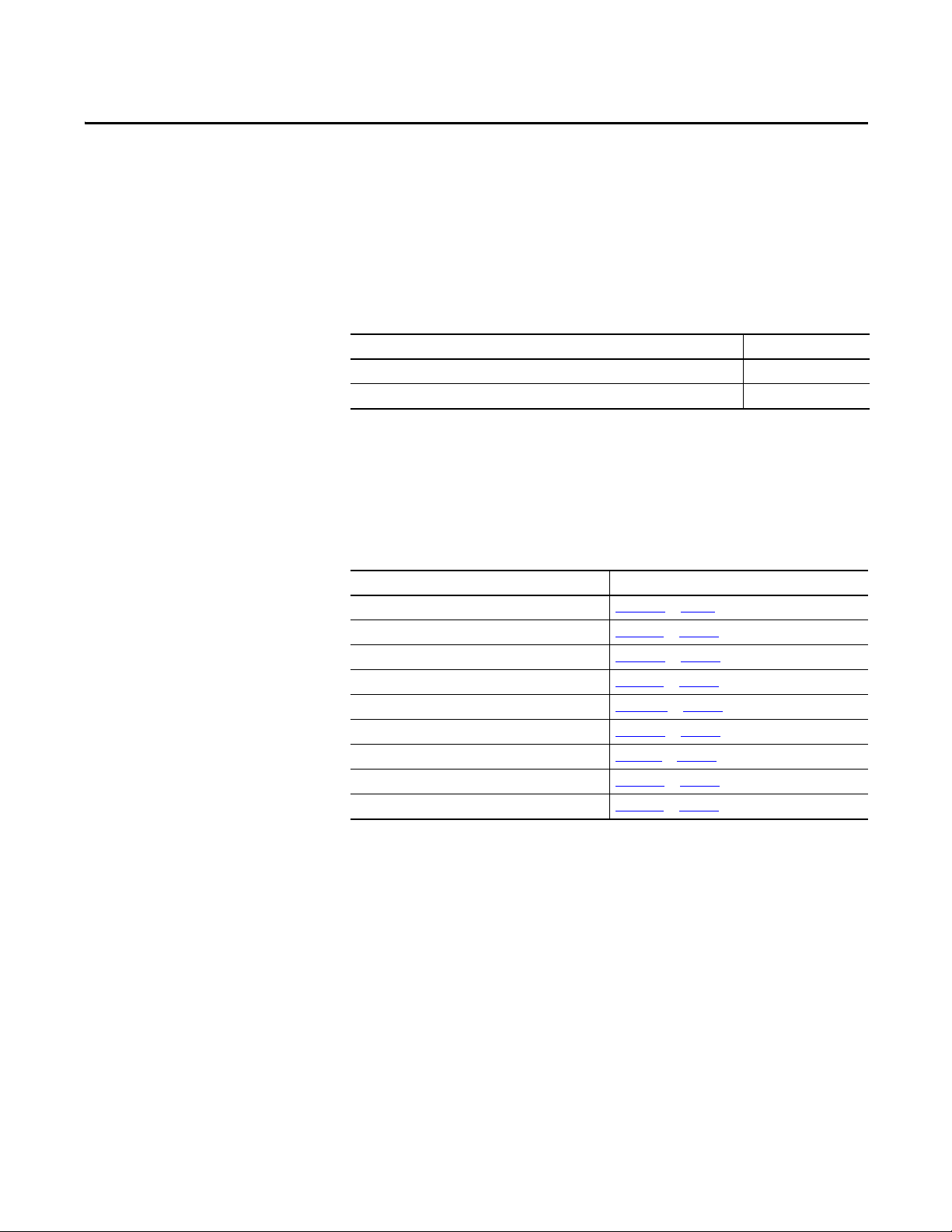

Add-On Instructions

Add-on instructions provide the basis for an object-oriented programming

methodology, where code is encapsulated into pre-validated modules that can be

reused without modification. This lets you create standardized libraries that can

both reduce project development time and provide consistency to reduce

equipment startup and support costs. When using the PlantPAx device

faceplates, you need to use the Add-on Instructions provided in the PlantPAx

Process Object Library. For more information about Add-On Instructions, see

Logix5000 Controllers Add-On Instructions Programming Manual, publication

1756-PM010

The HART IO provides the primary analog process variable, primary HART

process variable, secondary HART process variable, tertiary process variable and

the fourth process variable along with status when HART is enabled.

There are pre-designed Add-On Instructions that exchange data between the

faceplates and the controller. The name of the specific instance of the Add-On

.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 59

Page 60

Chapter 5 Visualization

IMPORTANT

Instruction becomes the link from the actual instrument to the faceplate on the

graphic.

Add-On Instruction Description

I_AB56IF8H Structured input data for each HART 8 channel input module.

The I_AB56IF8H Add-On Instruction collects and organizes data from module parameters and from a module query

that provides extra HART data via a CIP message from the controller to the I/O module.

I_AB56IF16H Structured input data for each HART 16 channel input module.

The I_AB56IF16H Add-On Instruction collects and organizes data from module parameters and from a module query

that provides extra HART data via a CIP message from the controller to the I/O module.

I_AB56FxHChan Structured data for each instrument.

The I_AB56IFxH_Chan Add-On Instruction takes specific data from each channel and point and arranges it for the

P_AIn56H Add-On Instruction. The I_AB56IFxH_Chan Add-On Instruction deciphers and prioritizes the HART

Command 48 diagnostic message and sends the highest priority message (numerically) to the P_AIn56H Add-On

Instruction.

P_AIn56H Send the analog and process variable values from each instrument to one or more faceplates.

The P_AIn56H Add-On Instruction uses embedded P_MODE and P_ALARM Add-On Instructions.

The P_AIn56H Add-On Instruction not only organizes data in a similar fashion as other PlantPAx operator interfaces but

it organizes the data so operators can expect interaction to remain the same throughout the HMI.

The P_AIn_HART Add-On Instruction uses embedded P_MODE and P_ALARM

Add-On Instructions. These embedded Add-On Instructions must already be in

the project before importing the P_AIn_HART Add-On Instruction.

Download the Add-On Instructions

For the latest compatible software information and to download the PlantPAx

Library, see the Product Compatibility and Download Center at

http://www.rockwellautomation.com/rockwellautomation/support

(Log-in required).

.

60 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 61

Visualization Chapter 5

Import Add-On Instructions

To use the Add-On Instructions, you import them into a controller project.

Follow these steps for each Add-On Instruction.

1. In the Controller Organizer window, right click on Add-On Instructions

and choose Import Add-On Instruction.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 61

Page 62

Chapter 5 Visualization

2. Select the Add-On Instruction to import from the File Explorer window

and click Import.

3. Click OK in the Import Configuration Window.

62 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 63

Visualization Chapter 5

4. Once the import is complete, the Add-On Instructions and any additiona

data types are visible in the Controller Organizer.

Add an Add-On Instruction to a Routine

Follow these steps to add an Add-On Instruction to a routine.

1. Open the routine by double clicking the routine name in the Controller

Organizer.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 63

Page 64

Chapter 5 Visualization

2. Right click in field of the sheet and select Add Element.

3. Browse to the Add-On Instruction folder, select the Add-On Instruction,

and click OK.

Repeat this process for each required Add-On Instruction. Each analog input

module needs one I_AB56IF8H(for 8 channel) or I_AB56IF16H(for 16

channel), one I_AB56IFxH_Chan per HART device, and one P_AIn56H per

device.

64 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 65

Visualization Chapter 5

When all the Add-On Instructions are in the routine, connect them as shown

below. Each I_AB56IFxH_Chan connects to one of P_AIn56H.

Configure I_AB56IF8H

Make the following modifications to each I_AB56IF8H Add-On Instruction.

• You must create the backing tag and all of the reference input tags. Follow a

system or naming convention for your application to keep multiple

instances of this Add-On Instruction organized.

• Configure the Ref_Inp tag to point to the location of the Analog HART

Interface module in the chassis.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 65

Page 66

Chapter 5 Visualization

• Configure the Ref_ChanDevInfoMSG tag so the path points to the

Analog HART Interface module in the chassis.

66 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 67

Visualization Chapter 5

• Configure the Ref_ModDiagMSG tag so the path points to the Analog

HART Interface module in the chassis.

Configure I_AB56IFxH_Chan

Make the following modifications to the I_AB56IFxH_Chan Add-On

Instruction.

• You must create the backing tag. Follow a system or naming convention for

your application to indicate the channel of the analog input module that it

is referencing.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 67

Page 68

Chapter 5 Visualization

• Configure Ref_ChanData and Ref_ChanDiag to point to the appropriate

array channel position from the tags created in conjunction with

I_AB56IF8H.

Configure P_AIn56H

Make the following modifications to the P_AIN56H Add-On Instruction.

• You must create the backing tag. Follow a system or naming convention for

your application to indicate the channel of the analog input module that it

is referencing.

• Configure Ref_DevInfo to point to the appropriate array channel position

from the tags created in conjunction withI_AB56IF8H.

68 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 69

Visualization Chapter 5

• Configure the Ref_FaultTable and Ref_EUTable tags. These tables

provide the fault codes and engineering units for the device. You can create

your own table with device-specific codes and descriptions, or there are

generic tables available in the sample projects contained within the

PlantPAx Process Object Library.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 69

Page 70

Chapter 5 Visualization

Link an Add-On Instruction to Graphics in FactoryTalk View SE Software

This graphic displays how the P_AIn56H works within an HMI.

• Pre-designed AOIs provide a two-way exchange of data between the

faceplates and the ControlLogix controller.

• FactoryTalk View SE faceplates provide visualization of instruments

connected to the network interface

• By clicking the pushbutton with a value on a screen the faceplate is linked

to the P_AIn56H AOI via a tag name and the faceplate values get

populated with the AOIs data.

70 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 71

Visualization Chapter 5

Add Library Components to an HMI Application

Follow these steps (in this exact order) to add library components.

1. Import the images.

Import all the .BMP and .PNG files. The .BMP and .PNG files must be

imported separately.

a. Right click on Images and choose Add Component Into Application.

b. Select all of the .PNG image files from the Process Objects Library and

click Open.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 71

Page 72

Chapter 5 Visualization

You will need to change the path to the image folder and the file type to

.PNG.

2. Import the global objects.

Import the .GGFX files.

a. Right click on Global Objects and choose Add Component Into

Application.

72 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 73

b. Select all of the .ggfx files and click Open.

Visualization Chapter 5

3. Import the displays.

a. Right click on Displays and select Add Component Into Application.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 73

Page 74

Chapter 5 Visualization

b. Select the Faceplate and Quick file associated with the P_AIn56H and

click Open.

Import the Macro.

4.

a. Right click on Macro and select Add Component Into Application.

b. Select the NavToObject.mcr file and click Open.

74 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 75

Visualization Chapter 5

Fac toryTa lk Vie w SE Display

Add-On Instructions in a

function block routine.

Click on global object.

Global object

IMPORTANT

Global Object

A global object links the tag name to the faceplate, provides a touch area for the

faceplate to be launched from, and displays the process variables and alarms.

A unique global object and faceplates are available for each field instrument

due to the display of instrument-specific diagnostic information.

Add Global Objects to a Display

Follow these steps too add global objects.

1. Open the (RA-BAS) P_AIn Graphics Library by expanding the Global

Objects and double-clicking on the library.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 75

Page 76

Chapter 5 Visualization

2. Click on the object that best suites your display to highlight it, right click,

and select Copy.

3. Go to the display and paste the global object into the display.

76 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 77

Visualization Chapter 5

Configure Tags

Follow these steps to configure tags for a global object.

1. Right click on the global object and select Global Object Parameter

Va l u e s .

You need to configure the first, second, and fifth parameters.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 77

Page 78

Chapter 5 Visualization

2. Click the Tag browse button for the first parameter Object

Ta g .

3. Click the Refresh All Folders button.

78 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 79

Visualization Chapter 5

4. Expand the shortcut for the project controller and then click Online.

5. Expand and scroll down the Online menu so you can select the tag for the

P_AIn56H AOI instance you created and click OK.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 79

Page 80

Chapter 5 Visualization

You might have to expand the program if the tag is program scoped.

6. Select the same tag for the second parameter as had been selected for the

first.

Return to the Global Object Parameter Values window, edit the value field

for the second parameter, and leave just the path to the tag.

7. Click on the value field for the fifth parameter and enter the value 2.

This value causes a smaller, ‘Quick’ faceplate to appear, which can be

expanded to the full faceplate.

80 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 81

These parameter values should appear.

8. Click OK.

Visualization Chapter 5

Faceplates

9. Click the Save button at the top, left corner of the screen.

The FactoryTalk View SE generic display provides a graphical representation of

the instrument based on the information contained within each Add-On

Instruction. Navigation buttons at the top of the faceplate change the

information displayed. Status displays show information using a bar graph,

numeric values, and a trend display. Other displays show specific alarms and

warning indication.

Here are some examples of predesigned faceplates.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 81

Page 82

Chapter 5 Visualization

IMPORTANT

A unique global object and faceplates are available for each field instrument

due to the display of instrument-specific diagnostic information.

The faceplates provide the following information:

• Tag name from instrument

• Description from instrument

• Engineering units from instrument

• Typical analog process values (PV)

• Analog fault status (channel fault, broken wire, module fault)

• HART PV (first, second, third)

• HART PV fault status (first, second, third, fourth)

• HART PV range (minimum and maximum)

• HART command 48 diagnostic information

Configure the faceplates to provide the following:

• Mode (such as operator or program)

• High-high, high, low, and low-low alarms

• Over-range and under-range alarms

• Alarm delay

• Alarm hysteresis

82 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 83

Promag 53 Electromagnetic Flowmeter

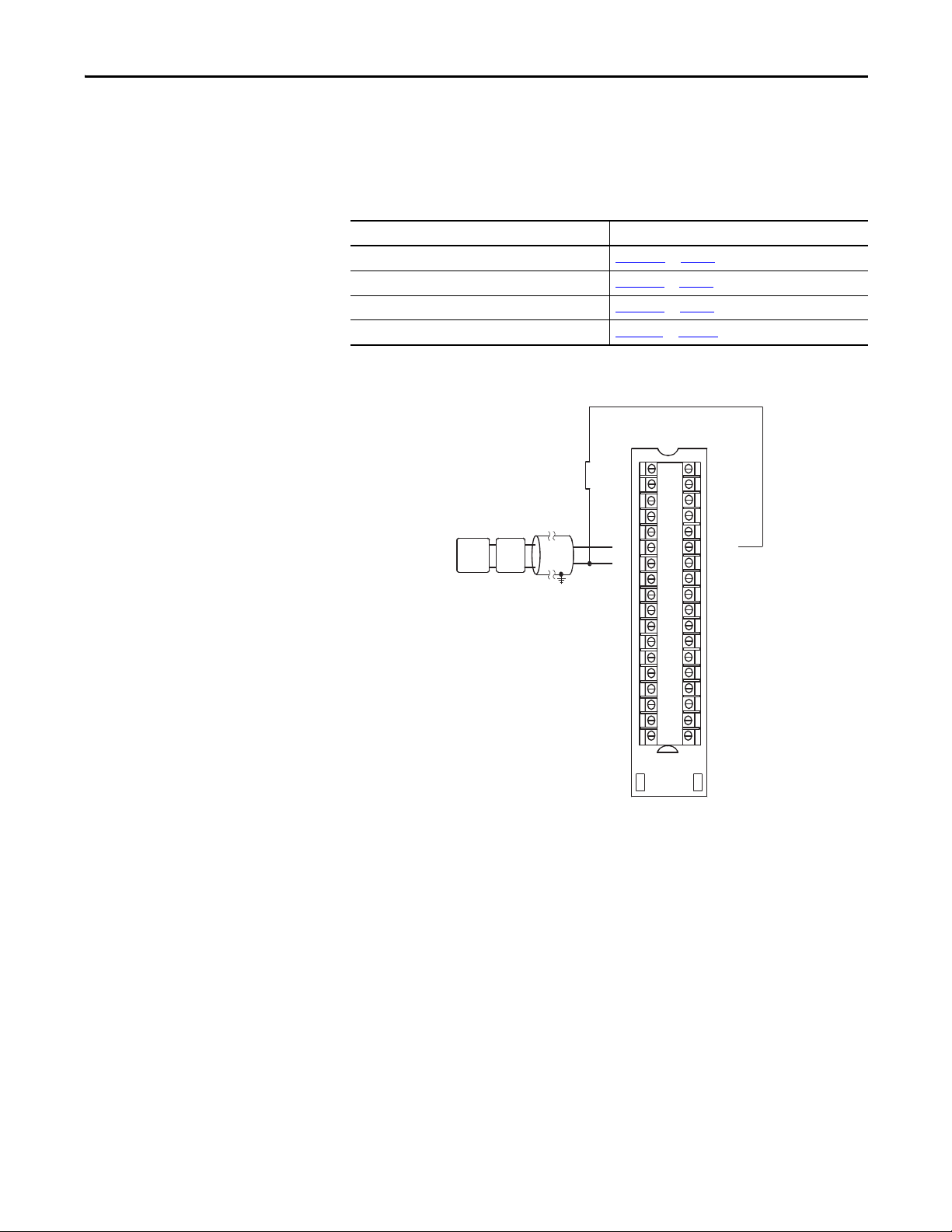

Top ic Pag e

Connect a Promag 53 Flowmeter 84

Configure a Promag 53 Flowmeter 86

Component Catalog Number Details

Promag 53 electromagnetic flowmeter 53P15-EL081AA0BAAA Firmware revision 2.01

Appendix A

Promag measuring instruments are electromagnetic flowmeters for bidirectional

measurement of liquids. They provide cost-effective flow measurement with a

high degree of accuracy for a wide range of process conditions.

The tried-and-tested Promag sensor offers the following:

• No pressure loss

• No sensitivity to vibrations

• Simple installation and commissioning

Faraday's law of induction states that a voltage is induced in a conductor moving

in a magnetic field. In electromagnetic measuring, the flowing medium

corresponds to the moving conductor. The induced voltage is proportional to the

flow velocity and is detected by two measuring electrodes and transmitted to the

amplifier. Flow volume is computed on the basis of the pipe's diameter. The

constant magnetic field is generated by a switched direct current of alternating

polarity.

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 83

Page 84

Appendix A Promag 53 Electromagnetic Flowmeter

Item Description

Ue Induced voltage, Ue = B· L· v

B Magnetic induction (magnetic field)

LElectrode gap

VFlow velocity

Q Volume flow,

A Pipe cross-section

I Current strength

Q = A· v

Signal Details

Current Output Active/passive selectable, galvanically isolated

Pulse/Frequency Output Active/passive selectable, galvanically isolated (Ex i version: only passive)

Connect a Promag 53 Flowmeter

Measured Variable

Flow rate (proportional to induced voltage)

Signals from Instrument to Control System

• Active: 0/4...20 mA, RL < 700 Ω (HART: RL ≥ 250 Ω)

• Passive: 4...20 mA, operating voltage VS 18...30V DC, Ri <

• Active: 24 V DC, 25 mA (max. 250 mA during 20 ms), RL > 100 Ω

• Passive: open collector, 30V DC, 250 mA

• Frequency output: full scale frequency 2...10000 Hz (fmax = 12500 Hz), EEx-ia: 2...5000 Hz; on/off ratio 1:1;

pulse width max. 10 s

• Pulse output: pulse value and pulse polarity adjustable, pulse width configurable (0.05...2000 ms)

Use a 4-wire connection to the HART input module.

1. Remove the cover of the connection compartment (f ) from the

transmitter housing.

150 Ω

2. Feed the power supply cable (a) and signal cables (b) through the

appropriate cable entries.

84 Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014

Page 85

Promag 53 Electromagnetic Flowmeter Appendix A

b

b

c

d

a

a

2

1

–27

–25

–23

–21

+26

+24

+22

+20

L1 (L+)

N (L-)

g

f

e

3. Connect the HART communications cable to the HART connector in

the order white (+), black (-) on pins 26, 27 of the connector.

4. For AC powered instruments, connect the AC cable to the power

connector in the order ground (as shown), black (pin1), white (pin2).

5. Screw the cover of the connection compartment (f ) firmly onto the

transmitter housing.

Item Description

a Cable for power supply: 85...260 V AC, 20...55 V AC, 16...62 V DC

• Terminal No. 1: L1 for AC, L+ for DC

• Terminal No. 2: N for AC, L- for DC

b Signal cable: Terminal Nos. 20-27

c Ground terminal for protective conductor

d Ground terminal for signal cable shield

e Service adapter for connec ting service interface FXA 193 (FieldCheck, FieldCare)

f Cover of the connection compartment

gSecuring clamp

Rockwell Automation Publication PROCES-UM002A-EN-P - July 2014 85

Page 86

Appendix A Promag 53 Electromagnetic Flowmeter

➀

➂

➁

➃

➄

➅

Esc

E

+

-

XXX.XXX.XX

F

O

F

Commission

Language

Defaults

Quick Setup

HOME-POSITION

QS

Volume

Mass

Quit

Configure another unit?

NOYES

Unit

Unit

Volume Flow

Totalizer

Unit

Density

Value

Density

Unit

Unit

Mass flow

Totalizer

Selection

System units

1002

2000

0402

3001

0420

0700

0400

3001

B

Frequency Pulse

Current Output Freq.-/ Pulse Output

Quit

Assign

Current

Current

Span

Value

0_4 mA

Value

20 mA

Measuring

Mode

Time

Constant

Failsafe

Mode

Failsafe

Mode

Failsafe

Mode

4000

4001

4002

4003

4004

4005

4006

Operation

Mode

4200

Selection

Output type

Assign

Frequency

End

Value Freq.

Value

F low

Value

F high

Measuring

Mode

Output

Signal

Time

Constant

4201

4203

4204

4205

4206

4207

4208

4209

Pulse

Value

Pulse

Width

Measuring

Mode

Output

Signal

4221

4222

4223

4225

4226

4227

Assign

Pulse

Configure another Output?

Autom. Configuration of Display?

NO

NO

YES

Pulsating Flow

Carrying out the

Quick Setup

Pulsating Flow

Carrying out the

Quick Setup

Batching

Automatic parameterization

of the display

Inquiry: another

Quick Setup?

NOYES

Batching