Page 1

Installation Instructions

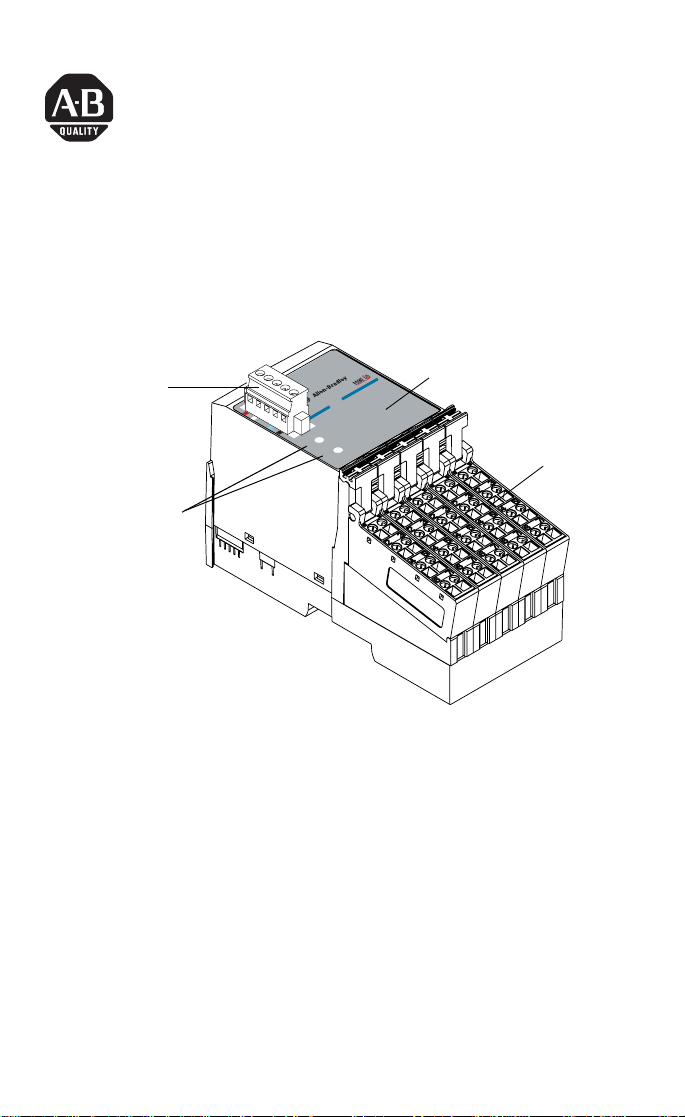

POINTBlock ac 16 Input Module

(Cat. No. 1734D-IA16 and -IA16S)

I/O Status

DeviceNet

Connector

DeviceNet Node

Setting Switches

(1s and 10s)

Module

Status

Network

Status

0-9

12

8

Inputs

9

4

5

0

6

1

7

2

3

10-63

Indicators

13

14

15

10

11

Remote

Termination

Blocks

This 1734D input module is a DIN-rail mounted device with an

integrated DeviceNet communication interface, 16 ac inputs,

removable terminations, and a PointBus expansion port. The

expansion port allows you to add up to 12 additional POINT I/O

modules.

The module includes a non-isolated DeviceNet communication

interface. The 24V dc from the DeviceNet connection powers a

non-isolated dc/dc converter that generates +5V dc which powers the

POINTBlock electronics and connects to the PointBus port to power

the expansion I/O electronics.

The 1734D-IA16 uses cage-clamp terminations, and the 1734D-IA16S

uses spring-clamp terminations.

POINTBlock and POINT I/O are trademarks

of Rockwell Automation1 Publication 1734D-IN001A-EN-P - May 2001

Page 2

2 POINTBlock ac 16 Input Module

ATTENTION

!

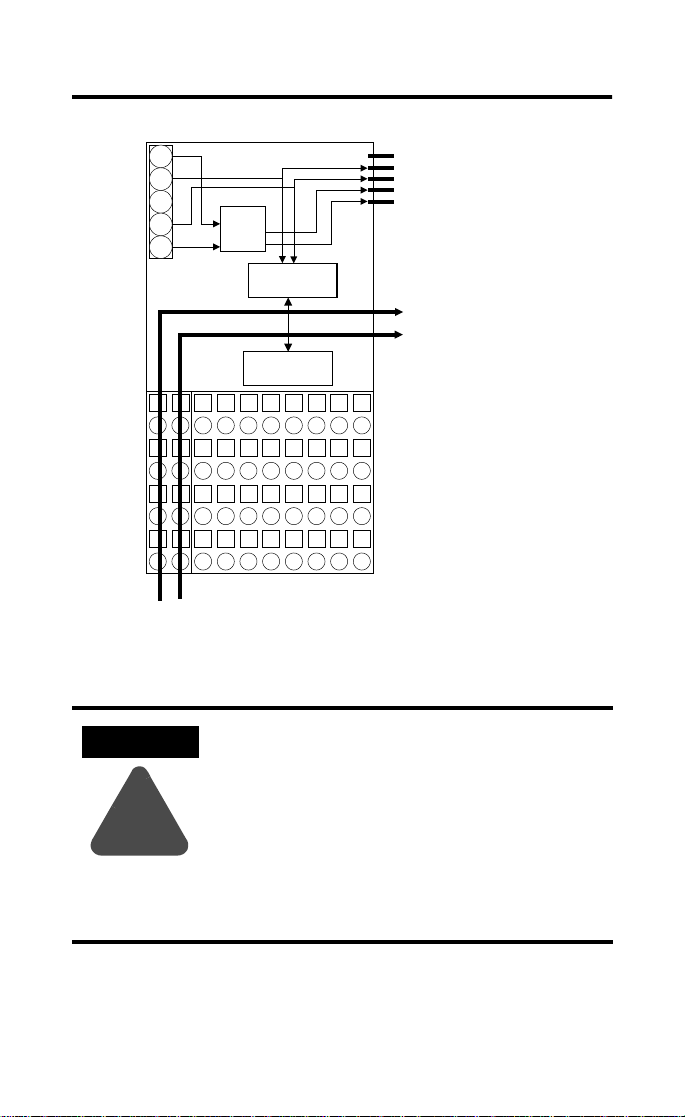

Simplified Schematic of POINTBlock

24

DeviceNet

Connector

CH

SH

CL

RT

24V

to 5V

Microprocessor

I/O Circuits

En

CH

PointBus Expansion Port

CL

5V

(allows expansion of up to

GND

12 POINT I/O modules)

Field Bus

Connector

Power

Connections

120V ac

Publication 1734D-IN001A-EN-P - May 2001

I/O Connections

41971

Whatever field power you supply is connected

to the internal field-power bus. For example, if

120V ac is applied to the power connections,

there will be 120V ac applied to the modules

through the internal field-power bus.

POINT I/O modules to the right of this module

will have this internal power bus voltage

applied, unless you use a 1734-FPD to interrupt

and change the field power-bus voltage.

Page 3

POINTBlock ac 16 Input Module 3

ATTENTION

!

ATTENTION

!

POINTBlock is designed to be grounded through

the DIN rail to chassis ground. To assure proper

grounding of POINTBlock and POINT I/O

adapters and terminal bases to chassis ground, the

recommended DIN rail material is zinc-plated,

yellow-chromated steel. Mount POINTBlock,

POINT I/O adapters and terminal bases only to

zinc-plated, yellow-chromated steel.

Installing the POINTBlock 16 Input Module

To install the 16 Input module on the DIN rail, proceed as follows:

1. Position the block module vertically above the DIN rail.

2. Press down firmly to install the module on the DIN rail. (The

locking mechanism will lock the module to the DIN rail.)

Do not discard the end cap. Use this end cap to

cover the exposed interconnections on the last

mounting base/block module on the DIN rail.

Failure to do so could result in equipment

damage or injury from electric shock.

If installing a replacement POINTBlock module to an existing system:

1. To remove the block module from the DIN rail, pull up on the

RTB removal handles to remove the terminal blocks.

2. Use a small bladed screwdriver to rotate the orange DIN rail

locking screw to a vertical position. This releases the locking

mechanism.

3. Lift straight up to remove.

4. Position the replacement block module vertically above the

DIN rail.

Publication 1734D-IN001A-EN-P - May 2001

Page 4

4 POINTBlock ac 16 Input Module

5. Slide the block module down allowing the interlocking side

pieces to engage the adjacent module/adapter.

6. Press firmly to seat the block module on the DIN rail. The

module locking mechanism will snap into place.

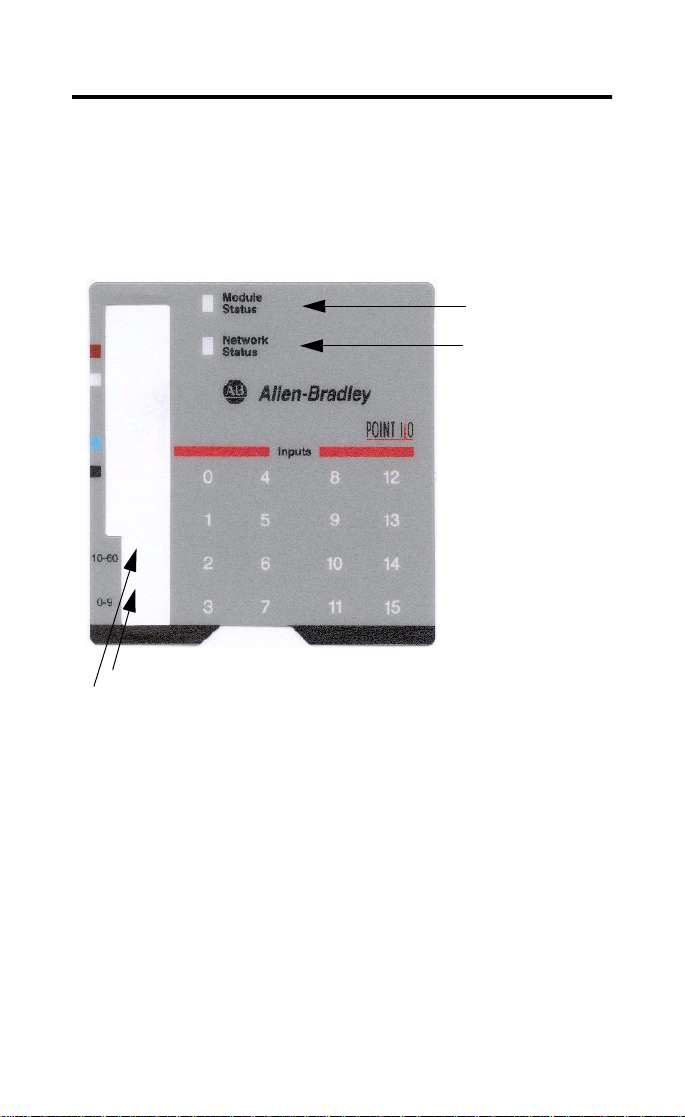

Setting the Node Address

Module Status

Network Status

I/O status

R

1’s Node Address Rotary Switch

10’s Node Address Rotary Switch

To set the node address, set the combination of 1’s and 10’s to

correspond to the required address. (For example, for 61, set the 10’s

switch to 6 and the 1’s switch to 1.)

Publication 1734D-IN001A-EN-P - May 2001

Page 5

Wiring the 16 ac Input Module

Field Power Inputs

POINTBlock ac 16 Input Module 5

1

3

L2

L1

01

4

5

23

6

7

45

L2

L2

67

L1

L1

120V ac

Power

V ac

NCNC0

L2 in

L1in

01

23

2

45

L2

67

L1

01

NC

23

NC

45

L2 in

67

L1in

RTB 0 RTB 1 RTB 2 RTB 3 RTB 4

This supply will be connected to the internal power bus.

NC = No Connection Chas Gnd = Chassis Ground

L2/N = AC Return/Neutral L1 = AC Power

Input Wiring

RTB 1

01

In 0 In 1

2

In 2

Prox

4

6

In 3

L2

L1 L1

L2

01

8

23

10

45

L2

67

L1

3

5

7

01

9

23

11

45

L2

67

L1

12

13

14

15

L2

L2

L1

L1

42064IB

Prox

L1 = 120V ac

Repeat for RTB 2, 3 and 4

41967ac

L2 = Return

Note: When connecting more than 1 wire in a termination point,

make sure that both wires are the same gauge and type.

Publication 1734D-IN001A-EN-P - May 2001

Page 6

6 POINTBlock ac 16 Input Module

Channel Input Terminal Return Voltage

Remote Termination Block 0

Field Power Block No connections to terminals 0, 1, 2, 3 and 4

Vin (L1) 6 and/or 7

Return (L2/N) 4 and/or 5

Remote Termination Block 1

00 6

11 7

22 6

33 7

Remote Termination Block 2

40 6

51 7

62 6

73 7

Remote Termination Block 3

80 6

91 7

10 2 6

11 3 7

Remote Termination Block 4

12 0 6

13 1 7

14 2 6

15 3 7

120V ac is supplied through the internal power bus.

Note: When connecting more than 1 wire in a termination point,

make sure that both wires are the same gauge and type.

Publication 1734D-IN001A-EN-P - May 2001

Page 7

DeviceNet Connector Wiring

POINTBlock ac 16 Input Module 7

+V

CAN - High

Shield

CAN - Low

-V

42132

DeviceNet

connection

Red

White

Bare

Blue

Black

Communicating with Your Module

I/O messages are sent to (consumed) and received from (produced)

the POINTBlock I/O modules. These messages are mapped into the

processor’s memory. This POINTBlock I/O input module produces 2

bytes of input data (scanner Rx). It does not consume I/O data

(scanner Tx).

Default Data for the 1734D-IA16

15 14 13 12 11 10 9876543210

Produces

Consumes

Where: I0 = channel 0, I1 = channel 1; 0 = off, 1 = on

I15 I14 I13 I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1 I0

(Rx)

(Tx)

No consumed data

Publication 1734D-IN001A-EN-P - May 2001

Page 8

8 POINTBlock ac 16 Input Module

CUS

e

Safety Approvals

C-UL and UL Hazardous Location Approval

C-UL and UL cer tifies products for ge neral use as well as for use in

hazardous locations. Actual C-UL and UL certification is indicated

by the product label as shown below, and not by statements in an y

user documentat ion.

Example of the C -UL

and UL certificat ion

product label:

CL I, DIV 2

GP A,B,C,D

TEMP

Approbation d’utilisation dans des

environnements dangereux par la C-UL and UL

La C-UL and UL certi fie des produits pour une utili sation générale aussi

bien que pour une utilisation en environ nements dangereux. La

certification C -UL and UL en vigueur est indiquée pa r l'étiquette produit

et non par des indications dans la docum entation utilisateur.

Exemple d'étiq uette de

certification d'un

produit par la C-UL and

UL :

LISTED

To comply with C-UL and UL ce rtification for use in hazardous locations,

the following infor mation becomes a part of the produ ct literature for

this C-UL and UL-certified industrial constrol product.

• This equipmen t is suitable for use in Class I, Division 2, Groups

A, B, C, D, or no n-hazardous location s only.

• The produc ts having the appropria te C-UL and UL markin gs

(that is, Class I, Di vision 2, Groups A, B, C, D) ar e certified for

use in other equi pment where the suitab ility of combination

(that is, application or use) is deter mined by the C-UL and UL or

the local inspectio n office having jurisdiction

• Peripheral equipment must be sui table for the location in

which it is used .

Important: Due to the mod ular nature of a prog rammable control

system, the product with the highest temperature rating

determines th e overall temperature co de rating of a

programmable control sy stem in a Class I, Division 2,

location. The temperature code rating is marked on the

product label as shown.

Temperature code ratin g: Code de températ ure :

CL I, DIV 2

GP A,B,C,D

TEMP

CUS

LISTED

The following warnings apply to products having C-UL and UL certification

for use in ha zardous location s.

WARNING: Explosion Hazard

• Substitution of components may impair suitab ility for Class I,

Division 2.

• Do not repl ace components unl ess power has been sw itched

off or the area is known to be non-hazardous.

• Do not discon nect equipment unless power has been switched

off or the area is known to be non-hazardous.

• Do not disc onnect connectors u nless power has been sw itched

off or the area is known to be non-hazardous. Secure any

user-supplied co nnectors that mate to external circuits on this

equipment by u sing screws, sliding latches, threaded

connectors, or other means such that any connection can

withstand a 15 N ewton (3.4 lb.) separating f orce applied for a

minimum of o ne minute.

• Batteries must only be changed in an area known to be

non-hazardous.

C-UL and UL lo go is a registered trad emark of the Underw riters

Laboratories.

Look for temperature code rating her

EPour satisfaire à la certification C-UL and UL en environnements

dangereux, les inf ormations suivantes font pa rtie intégrante de la

documentation d es produits de command e industrielle certifiés.

• Cet éq uipement ne convient qu’à une utilisation dans

des environnem ents de Classe I, Divisi on 2,

Groupes A, B, C , D ou non dangereux.

• Les produits portant le marquage C-UL and UL approprié

(c'est-à-dire Classe I, Divisio n 2, Groupes A, B, C, D) sont certifiés

pour une utilisatio n avec d'autres équipeme nts, les combinaisons

d’applications et d’ut ilisation étant déterminées par la C-UL and

UL ou le bureau local d'inspection.

• L'équi pement périphérique doit convenir à l'emp lacement

d'utilisation.

Important: De par la nature modulaire des systèmes de commande

programmables, le produit ayant le code de température le plus

élevé détermine le code de température global du système

dans un environnement de Classe I, Division 2. Le code de

température est indiqué sur l'étiquette produit.

CUS

LISTED

Les avertissem ents suivants s'appli quent aux produits ayant la certification

C-UL and UL p our une utilisation dans des environnements da ngereux.

AVERTISSEMENT : Risque d’explosion

• La s ubstitution de compos ants peut rendre ce m atériel inadapté à

une utilisation en environnement de

Classe I, Division 2.

• Coup er le courant ou s'assur er que l’environnemen t est classé non

dangereux avant de remplacer des composants.

• Coup er le courant ou s’assur er que l’environnement est classé non

dangereux ava nt de débrancher l'équipe ment.

• Coup er le courant ou s'assur er que l’environnemen t est classé non

dangereux av ant de débrancher le s connecteurs. Fixer to us les

connecteurs fournis par l'utilisateur pour se brancher aux ci rcuits

externes de cet appareil à l 'aide de vis, loquets coulissants,

connecteurs filetés ou autres, de sorte que les con nexions résistent

à une force d e séparation de 15 Newtons (1,5 kg - 3,4 lb.) appliquée

pendant au moins une minute.

• S'assu rer que l'environne ment est classé non da ngereux avant de

changer les piles.

Le sigle C-UL and UL est une marque déposée de la Underwriters

Laboratori es.

CL I, DIV 2

CUS

GP A,B,C,D

TEMP

LISTED

CL I, DIV 2

GP A,B,C,D

TEMP

Le code de tempér ature est indiqué ici.

Publication 1734D-IN001A-EN-P - May 2001

Page 9

POINTBlock ac 16 Input Module 9

Specifications

Specifications - 1734D-IA16, -IA16S

Input Specifications - IEC1+ 120V ac Compliant

Number of Channels 16 input channels

ON-State Voltage 65V ac minimum, 132V ac maximum

ON-State Current 5.0mA min

OFF-State Voltage 43V ac max

OFF-State Current 2.5mA max

Nominal Input Impedance 17.0kΩ

Input Filter Time

OFF to ON

ON to OFF

External AC Power Supply

Voltage

External AC Power Supply

Voltage Range

General Specifications

Pointbus Output Current 1A max @ 5V dc output

DeviceNet Current 95mA maximum for POINTBlock

Number of POINT I/O

Expansion Modules

Isolation Voltage 2104V dc for 1s between user power and DeviceNet

Indicators 1 red/ green module status indicator

Power Dissipation 2.0W maximum @ 24V dc

Power Consumption 8.2W maximum @ 24V dc

Field Power Bus

Supply Voltage

Voltage Range

Supply Current

Dimensions Inches

(Millimeters)

20.0ms hardware + (0 - 65ms selectable)

20.0ms hardware + (0 - 65ms selectable)

120V ac, 60Hz nominal

85-132V ac, 47-63Hz

350mA for maximum with expansion of

12 POINT I/O modules

12 maximum added at expansion port

1 red/green network status indicator

16 yellow I/O status indicators

120V ac nominal

65-132V ac

10A max

3.00H x 2.36W x 5.25L

(76.2 Hx 60.0W x 133.4L)

Publication 1734D-IN001A-EN-P - May 2001

Page 10

10 POINTBlock ac 16 Input Module

Environmental Conditions

Operational Temperature

Storage Temperature

Relative Humidity

Shock Operating

Non-operating

Vibration

Conductors Wire Size

-20 to +55

-40 to 85

5 to 95% noncondensing

30g peak acceleration, 11(±1)ms pulse width

50g peak acceleration, 11(±1)ms pulse width

Tested 5g @ 10-500Hz per IEC 68-2-6

14 AWG (2.5mm

o

C (-4 to +131oF)

o

C (-40 to 185oF)

2

) - 22 AWG (0.25mm2) solid or stranded

copper rated @ 75°C or greater

3/64 inch (1.2mm) insulation max

Category

Terminal Base Screw

1

2

7 pound-inches (0.6 Nm)

Tor qu e

Field Wiring Terminations

DeviceNet 1 - Black Wire -V

2 - Blue Wire CAN Low

3 - Bare Wire Drain

4 - White Wire CAN High

5 - Red Wire +V

Field Power Supply 0 - No Connection1 - No Connection

2 - No Connection3 - No Connection

4 - AC return 5 - AC return

6 - AC power 7 - AC power

Mass 13.88 oz/393.50 grams

Agency Certification

(when product is marked)

• C-UL Listed

• C-UL Class I, Division 2 Groups A, B, C and D certified

• UL listed

• UL Class I, Division 2 Groups A, B, C and D certified

• CE marked for all applicable directives

• C-Tick marked for all applicable acts

1 Use this conductor category information for planning conductor routing. Refer to publication 1770-4.1,

“Industrial Automation Wiring and Grounding Guidelines.”

Publication 1734D-IN001A-EN-P - May 2001

Page 11

POINTBlock ac 16 Input Module 11

Publication 1734D-IN001A-EN-P - May 2001

Page 12

Publication 1734D-IN001A-EN-P - May 2001 PN 957464-53

© 2001 Rockwell Internati onal Corporation. Printed in USA

Loading...

Loading...