Page 1

DRILL PUMP PBMP 30 A1

DRILL PUMP

Operating instructions

POMPĂ PENTRU MAŞINA

DE GĂURIT

Instrucţiuni de utilizare

BOHRMASCHINENPUMPE

Bedienungsanleitung

IAN 75640

PUMPA ZA BUŠILICU

Upute za upotrebu

ПОМПА ЗА БОРМАШИНА

Ръководство за експлоатация

Page 2

Before reading, unfold the page containing the illustrations and familiarise

yourself with all functions of the device.

Prije nego što pročitate tekst, otvorite stranicu sa slikama i upoznajte se na

osnovu toga sa svim funkcijama uređaja.

Înainte de a citi instrucţiunile, priviţi imaginile şi familiarizaţi-vă cu toate funcţiile

aparatului.

Преди да прочетете отворете страницата с фигурите и след това се

запознайте с всички функции на уреда.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen

Sie sich anschließend mit allen Funktionen des Gerätes vertraut.

GB / CY Operating instructions Page 1

HR Upute za upotrebu Stranica 11

RO Instrucţiuni de utilizare Pagina 21

BG Ръководство за експлоатация Cтраница 31

DE / AT / CH Bedienungsanleitung Seite 41

Page 3

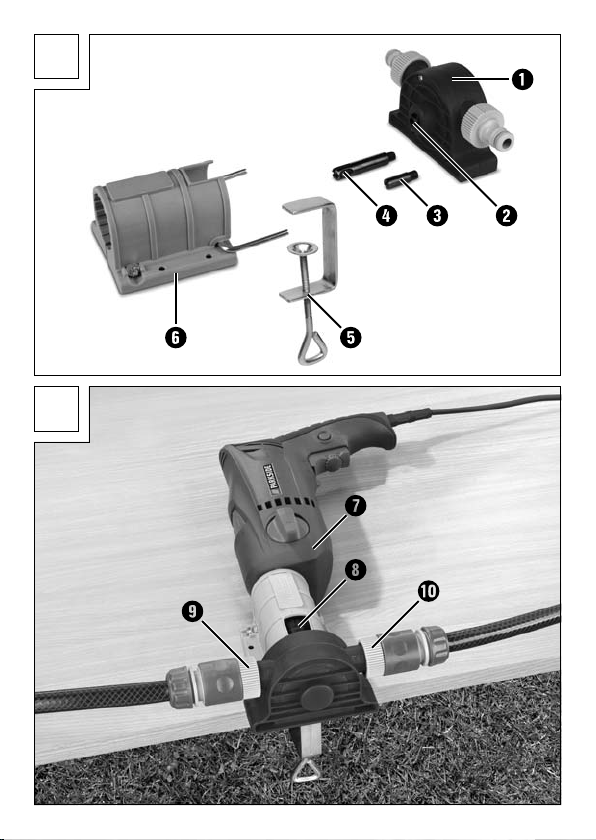

A

B

Page 4

CONTENT PAGE

Introduction 2

Safety instructions 2

Intended Usage 3

Technical Data 3

Items supplied 4

Overview of the appliance 4

Assembly material required 4

Assembly and connection 5

Disassembly of the drive shaft 7

Utilisation 8

Cleaning and care 8

Disposal 9

Declaration of conformity 9

Importer 9

Warranty and Service 10

- 1 -

Page 5

Introduction

Congratulations!

With your purchase you have decided in favour of a quality product. Familiarise

yourself with the product before taking it into use. To do this, read the following

operating instructions attentively. Use the product only as described and only

for the specified areas of application. Retain these instructions for future reference. In addition, pass these documents on, together with the product, to any

future owner.

Safety instructions

To avoid the risk of accidents and damage to the

appliance:

• Operate the pump ONLY when it is secured by the supplied mounting

against jolting, twisting and canting.

• Check the pump for a faultfree condition before ever taking it into use.

The pump may not be used if it shows signs of damage.

The drive shaft of the pump does not allow itself to be turned by hand.

This does not indicate that the pump is defective.

• Use only hoses certified as being able to withstand a pressure of at least

3 bars (44 psi).

• Check the plug-in connectors on the hoses for firm seating.

• Take steps to ensure that the fluid being pumped cannot come into contact

with the electric drill during pumping. Should it nonetheless occur, immediately remove the power plug.

• Avoid the intake of coarse dirt, otherwise the pump could be damaged.

If needs be, use a filter on the suction hose.

- 2 -

Page 6

• This appliance is not intended for use by children or other individuals whose

physical, sensorial or intellectual abilities prevent safe usage of the appliance should they not receive support or supervision in the correct operation of the appliance. Children should be supervised to ensure that they do

not play with the appliance.

Intended Usage

This pump is intended for ...

– standard commercial right/left rotating electric drills with a 43 mm Euro-

spindle and a gear-wheel rim chuck/quick-release chuck or drill chuck

with SDS fitting, up to rotation speed of 3400 rpm,

– the pumping of cold or up to 40°C warm fluids, such as non-potable or

dirty water from fish tanks or ponds.

This pump is

– the pumping of flammable, explosive, poisonous or caustic liquids or

foodstuffs.

– for industrial or commercial applications.

NNOOTT

intended for ...

Technical Data

Capacity: max. 2,4 m3/h

Hose connection: 3/4” (19 mm)

Pressure: max. 3 bar

Delivery height: max. 30 m

Suction height: max. 3 m

Temperature of the fluid being pumped: max. 40°C

Dry run time: max. 12 seconds

Rotation speed: max. 3400 rpm

- 3 -

Page 7

Items supplied

- Pump

- Short drive shaft

- Long drive shaft

- Clamp fixing

- Mounting

- Open-ended spanner

- Storage box for the drive shafts and open-ended spanner

- This operating manual

Overview of the appliance

Figure A:

Pump

q

Drive shaft of the pump

w

Short drive shaft (suitable for gear-wheel/quick-release chuck)

e

Long drive shaft (suitable for a drill chuck with SDS fitting)

r

Clamp fastening

t

Mounting

y

Figure B:

Electric drill (not supplied)

u

Recess for chuck key

i

Connection for suction hose

o

Connection for pressure hose

a

Assembly material required

- Philips-type screwdriver

- Flat-headed screwdriver

- Open-ended spanner (supplied)

- 4 -

Page 8

Assembly and connection

Assemble the mounting

as shown in figure B.

Alternatively, the mounting

with screws (assembly material not supplied).

with the clamp fastening tonto a work surface,

y

can also be secured to a work surface

y

When using a gear-wheel chuck and the short drive

shaft e...

Screw the short drive shaft

Insert the electric drill

Now push the pump

projects into the chuck and the pins of the mounting yare located in the

reception holes on the pump

q

Now tighten the chuck with the chuck key through the recess

that the pump

can no longer release itself from the mounting y.

q

Tighten the cross-headed screw on the mounting

cannot jolt around.

u

Attach the suction hose to the connection

connection

pump

. Pay heed to the direction of flow detailed on the

a

.

q

onto the drive shaft wof the pump q.

e

with the chuck into the mounting y.

u

onto the mounting yso that the drive shaft

.

q

i

firmly, so that the drill

y

and the pressure hose to the

o

so firmly

When using a quick-release chuck and the short drive

shaft e...

Secure the short drive shaft

Insert the electric drill

chuck, into the mounting

u

Securely tighten the cross-head screw on the mounting

is being firmly held.

into the chuck.

e

, with the pre-assembled drive shaft ein the

.

y

so that the drill

y

e

u

- 5 -

Page 9

Now push the pump

projects into the thread of the drive shaft w, and the pins of the mounting

are located in the reception holes on the pump q.

y

Let the drill

and then guide the pump

shaft

e

start to run in a clockwise rotation and at low revolutions

u

is thereby secured to the pump q.

Attach the suction hose to the connection

connection

pump

. Pay heed to the direction of flow detailed on the

a

.

q

onto the mounting yso that the drive shaft

q

straight onto the drive shaft e. The drive

q

and the pressure hose to the

o

e

When using a chuck with SDS fitting and the long drive

shaft r...

Attach the long drive shaft

Insert the electric drill

chuck, into the mounting

Tighten the cross-headed screw on the mounting

cannot jolt around.

Now push the pump

projects into the thread of the drive shaft wand the pins of the mounting

are located in the reception holes on the pump q.

y

q

Allow the electric drill

ons and guide the pump

drive shaft

will be fixated onto the pump q.

r

Attach the suction hose to the connection

connection

pump

. Pay heed to the direction of flow detailed on the

a

.

q

into the chuck.

r

, with the pre-assembled drive shaft rin the

u

.

y

firmly, so that the drill

y

onto the mounting yso that the drive shaft

to run with a clockwise rotation and low revoluti-

u

straight on to the drive shaft r. With this the

q

and the pressure hose to the

o

r

u

- 6 -

Page 10

Disassembly of the drive shaft

Disassembly of the short drive shaft

Wheel rim chuck

e

Open the chuck with the chuck key through the recess

the pump

Unscrew the short drive shaft

the open-ended spanner from the pump

Quick-release chuck

Using the open-ended spanner through the recess

drive shaft

Allow the electric drill

volutions. The drive shaft

Remove the pump

Remove the drive shaft

Disassembly of the long drive shaft

Chuck with SDS fitting

from the mounting y.

q

of the pump q.

w

to run with an anti-clockwise rotation and low re-

u

e

from the mounting y.

q

e

by using a cross-headed screwdriver and

e

.

q

i

is thereby released from the pump q.

from the chuck.

r

Using the open-ended spanner through the recess,

drive shaft

Allow the electric drill

revolutions. With this the drive shaft

Remove the pump

Remove the drive shaft

of the pump q.

w

q

to run with an anti-clockwise rotation and low

u

will be released from the pump q.

r

from the mounting y.

from the chuck.

r

and then remove

i

, counter screw the

counter screw the

i

- 7 -

Page 11

Utilisation

Attention!

The pump is self priming. If the pump qdoes not start to suck up within 12

seconds, turn the drill

son, do not allow the pump

the discharge side is closed.

Place the open end of the suction hose into the liquid that is to be pumped.

The suction hose may not be longer than 3 m. Ensure that the suction hose

does not pull in air.

off immediately to avoid seizure. For this same rea-

u

to commence suction if the pressure hose on

q

If the pump

and then lift it so that the liquid runs before the pump.

Allow the drill

so that you can react quickly in the event of danger. Absolutely ensure

that the electric drill

Should the rotation speed of the electric drill

use this to regulate the discharge flow.

does not commence suction, fill the hose with some water

q

, now the pump q, to start-up – but not without supervision,

u

is rotating to the right, as with normal drilling.

u

be adjustable, you can

u

Turn the drill off immediately after the container is empty.

Cleaning and care

Clean the pump qwith a dry or lightly moistened cloth only. To avoid damage

to the plastic surfaces, do not use solvents or abrasive cleaning agents.

The pump is maintenance free.

- 8 -

Page 12

Disposal

Do not dispose of the appliance in your normal domestic waste.

Dispose of the appliance through an approved disposal centre or at your

community waste facility. Observe the currently applicable regulations. In

case of doubt, please contact your waste disposal centre.

Dispose of all packaging materials in an environmentally friendly

manner.

Declaration of conformity

We, Kompernaß Handelsgesellschaft GmbH, Burgstraße 21, D-44867 Bochum

declare under our sole responsibility that this product complies with all requirements of the Machinery Directive: 2006/42/EC.

Type/Appliance Designation: Powerfix Profi Plus Drill Pump PBMP 30 A1

Serial number: IAN 75640

Year of manufacture: 05/2012

Bochum, dated 10.05.2012

Semi Uguzlu, Quality Manager

Importer

KOMPERNASS GMBH

BURGSTRASSE 21

44867 BOCHUM, GERMANY

www.kompernass.com

- 9 -

Page 13

Warranty and Service

The warranty for this appliance is for 3 years from the date of purchase. The

appliance has been manufactured with care and meticulously examined before delivery. Please retain your receipt as proof of purchase. In the event of

a warranty claim, please make contact by telephone with our Service Department. Only in this way can a post-free despatch for your goods be assured.

The warranty covers only claims for material and manufacturing defects, but

not for transport damage, for wearing parts or for damage to fragile components, e.g. buttons or batteries. This product is for private use only and is not

intended for commercial use. The warranty is void in the case of abusive and

improper handling, use of force and internal tampering not carried out by our

authorized service branch. Your statutory rights are not restricted in any way

by this warranty.

The warranty period will not be extended by repairs made under warranty.

This applies also to replaced and repaired parts. Any damage and defects

extant on purchase must be reported immediately after unpacking the appliance, at the latest, two days after the purchase date. Repairs made after the

expiration of the warranty period are subject to payment.

Service Great Britain

Tel.: 0871 5000 720 (£ 0.10/Min.)

E-Mail: kompernass@lidl.co.uk

IAN 75640

Service Ireland

Tel.: 1890 930 034 (0,08 EUR/Min., (peak)) (0,06 EUR/Min., (off peak))

E-Mail: kompernass@lidl.ie

IAN 75640

CY

Service Cyprus

Tel.: 8009 4409

E-Mail: kompernass@lidl.com.cy

IAN 75640

- 10 -

Page 14

SADRŽAJ STRANA

Uvod 12

Sigurnosne upute 12

Upotreba u skladu sa namjenom 13

Tehnički podaci 13

Obim isporuke 14

Pregled uređaja 14

Potreban materijal za montažu 14

Montaža i priključak 15

Demontaža pogonskog nastavka 17

Uporaba 18

Čišćenje i održavanje 18

Zbrinjavanje 19

Izjava konformiteta 19

Uvoznik 19

Jamstvo i servis 20

- 11 -

Page 15

Uvod

Srdačno čestitamo!

Vašom kupnjom ste se odlučili za visokovrijedan proizvod. Prije prvog puštanja

u pogon se upoznajte sa proizvodom. U tu svrhu pažljivo pročitajte slijedeće

upute za rukovanje. Proizvod koristite isključivo na opisani način i u navedenim

područjima primjene. Ove upute dobro sačuvajte. Svu dokumentaciju u slučaju

predaje proizvoda trećim osobama priložite i takođe predajte.

Sigurnosne upute

Da biste izbjegli opasnost od nezgode i oštećenje

uređaja:

• Sa pumpom radite samo onda, kada je ona pomoću priloženog držača

osigurana od udaranja, uvrtanja ili zaglavljivanja.

• Prije svake uporabe prekontrolirajte besprijekorno stanje pumpe.

Pumpa ne smije biti korištena, ako postoje vidljiva oštećenja.

Pogonska osovina pumpe ne može biti okrenuta ručno.

To ne ukazuje na defekt pumpe.

• Koristite isključivo crijeva, koja su otporna na tlak od 3 bara ili više.

• Kontrolirajte čvrstoću položaja bajonet-spojeve na crijevima.

• Pobrinite se za to, da tekućine ne mogu dospjeti do bušilice, sa kojom

pogonite pumpu. Ukoliko se to dogodi, odmah izvucite mrežni utikač.

• Izbjegavajte usisavanje grubih nečistoća, jer u protivnom može doći do

oštećenja pumpe. Po potrebi koristite filtar na usisnom crijevu.

• Ovaj uređaj nije prikladan za djecu ili druge osobe, čije fizičke, senzorične

ili mentalne sposobnosti bez pomoći ili nadzora ne dopuštaju sigurnu

uporabu. Djeca trebaju biti pod nadzorom, kako bi bilo osigurano da se

ne mogu igrati uređajem.

- 12 -

Page 16

Upotreba u skladu sa namjenom

Ova pumpa je predviđena za ...

– uobičajene ručne bušilice sa desnim/lijevim smjerom okretanja sa Euro-za-

tezačem dimenzije 43 mm i zupčastim/brzoprihvatnim prstenom ili zatezačem sa SDS-prihvatom, te sa brojem okretaja do 3400 o/min,

– za pumpanje hladnih tekućina ili tekućina temperature do 40 °C, kao

na primjer uporabne ili otpadne vode iz akvarija ili jezeraca.

Ova pumpa

– za pumpanje zapaljivih, eksplozivnih, otrovnih ili agresivnih tekućina,

niti za pumpanje namirnica.

– za industrijske ili gospodarske namjene.

nniijjee

predviđena ...

Tehnički podaci

Transportna količina: maks. 2,4 m3/h

Priključak crijeva: 3/4” (19 mm)

Pogonski tlak:

Transportna visina: maks. 30 m

Usisna visina : maks. 3 m

Temperatura transportne

tekućine: maks. 40°C

Vrijeme suhog pogona: maks. 12 sekundi

Broj okretaja: maks. 3400 U/min

- 13 -

Page 17

Obim isporuke

- Pumpa

- Pogonski nastavak kratki

- Pogonski nastavak dugi

- Steznik za učvršćenje

- Držač

- Viličasti ključ

- Kutija za čuvanje pogonskih nastavaka i viličastih ključeva

- Ove upute za uporabu

Pregled uređaja

Slika A:

Pumpa

q

Pogonska osovina pumpe

w

Pogonski nastavak kratki (prikladno za zatezače sa zupčastim prstenom/

e

brzoprihvatne zatezače)

Pogonski nastavak dugi (prikladan za SDS-prihvat)

r

Stezni učvršćivač

t

Držač

y

Slika B:

Bušilica (nije sadržana u obimu isporuke)

u

Utor za smještanje ključa zatezača

i

Priključak usisnog crijeva

o

Priključak tlačnog crijeva

a

Potreban materijal za montažu

- Križni odvijač

- Običan odvijač

- Viličasti ključ (sadržan u obimu isporuke)

- 14 -

Page 18

Montaža i priključak

Montirajte držač

prikazan na slici B.

Alternativno držač

(materijal za montažu nije sadržan u obimu isporuke).

sa steznim učvršćenjem tna radnoj ploči, na način

y

može biti sa vijcima montiran na radnoj ploči

y

U slučaju uporabe zatezača sa zupčastim prstenom i

kratkog pogonskog nastavka e...

Zavrtanjem pričvrstite kratki pogonski nastavak

pumpe q.

Postavite bušilicu

Sada gurnite pumpu

zahvata steznik bušilice, a klinovi držača ystoje u prihvatnim otvorima

na pumpi

q

sa steznikom u držač y.

u

tako na držač y, da pogonski nastavak

q

.

Okrenite steznik bušilice sa ključem kroz utor

više ne može iz držača yosloboditi.

Zavrnite križni vijak na držaču

, tako da bušilica une može udarati.

y

Priključite usisno crijevo na priključnom mjestu

priključnom mjestu

naveden na pumpi

. Pritom obratite pažnju na protočni smjer

a

.

q

na pogonskoj osovini

e

tako čvrsto, da se pumpa

i

i tlačno crijevo na

o

e

U slučaju uporabe brzoprihvatnog zatezača i kratkog

pogonskog nastavka e...

Učvrstite kratki pogonski nastavak

Umetnite bušilicu

zatezaču, u držač

, sa predmontiranim pogonskim nastavkom eu

u

.

y

Zavrnite križni vijak na držaču

pokreta bušilice

u

.

u zatezaču.

e

čvrsto, da ne može doći do udarnih

y

w

q

- 15 -

Page 19

Gurnite pumpu

voj pogonske osovine

otvorima pumpe

Pokrenite bušilicu

i pođite pumpom

će time biti pričvršćeni na pumpi q.

e

Spojite priključno crijevo preko priključka

kom

. Pritom obratite pažnju na protočni smjer naveden na

a

pumpi

q

.

tako na držač y, da pogonski nastavak estrši u na-

q

, a klinovi držača ybudu umetnuti u prihvatnim

w

.

q

sa desnim okretnim smjerom i niskim brojem okretaja

u

ravno na pogonski nastavak e. Pogonski nastavak

q

, a tlačno crijevo sa priključ-

o

Ukoliko koristite zatezač sa SDS-prihvatom i dugi

pogonski nastavak r...

Učvrstite dugi pogonski nastavak

Umetnite bušilicu

u stezniku u držač y.

, zajedno sa predmonitranim pogonskim nastavkom

u

Zavrnite križni vijak na držaču

Sada gurnite pumpu

vata navoj pogonske osovine

vorima pumpe

q

Pustite da bušilica

ravno na pogonski nastavak r. Pogonski nastavak rće na taj način

q

biti pričvršćen na pumpi

tako na držač y, da pogonski nastavak rzah-

q

.

sa okretajima u desnu stranu krene i stavite pumpu

u

.

q

Priključite usisno crijevo na priključnom mjestu

priključnom mjestu

naveden na pumpi

. Pritom obratite pažnju na protočni smjer

a

.

q

u stezniku bušilice.

r

, tako da bušilica une može udarati.

y

, a klinovi držača ystoje u prihvatnim ot-

w

i tlačno crijevo na

o

r

- 16 -

Page 20

Demontaža pogonskog nastavka

Demontaža kratkog pogonskog nastavka

Zatezač sa zupčastim prstenom

Otvorite steznik sa ključem preko utora

Odvrnite kratki pogonski nastavak

ključa sa pumpe

Brzoprihvatni zatezač

q

.

Pomoču viličastog ključa kroz utor

pumpe q.

Pustite bušilicu

taja pokrene. Pogonski nastavak

Izvadite pumpu

Izvadite pogonski nastavak

, da se okretanjem u lijevu stranu sa niskim brojem okre-

u

iz držača y.

q

iz zatezača.

e

i izvadite pumpu qiz držača y.

i

uz pomoć običnog odvijača i viličastog

e

kontrirajte pogonsku osovinu

i

će time biti odvojen od pumpe q.

e

Demontaža dugog pogonskog nastavka

Zatezač sa SDS-prihvatom

Pomoću viličastog ključa kroz utor

pumpe q.

Pustite bušilicu

pokrene. Pogonski nastavak

Izvadite pumpu

Izvadite pogonski nastavak

da se okretanjem u lijevu stranu sa niskim brojem okretaja

u

r

iz držača y.

q

r

kontrirajte pogonsku osovinu

i

će tako biti odvojen od pumpe q.

iz steznika.

e

w

r

w

- 17 -

Page 21

Uporaba

Oprez!

Pumpa samostalno vrši usisavanje. Ako pumpa qu roku od 12 sekundi ne

izvrši prisisavanje, bušilicu

vanje u radu. Iz tog razloga ne pustite pumpu

dok je tlačno crijevo na izlaznoj strani zatvoreno.

Umetnite otvoreni kraj usisnog crijeva u tekućinu, koja treba biti usisana.

Usisno crijevo ne smije biti duže od 3 m. Obratite pažnju na to, da usisno

crijevo ne povuče zrak.

odmah isključite, kako biste izbjegli zaglavlji-

u

u transportni pogon, sve

q

Ukoliko pumpa

nadignite ga, kako bi tekućina curila pred pumpu.

Pustite da bušilica

slučaju opasnosti možete brzo reagirati. Obavezno obratite pažnju na to,

da se bušilica

okretaja bušilice

transportiranu količinu.

ne usisa, napunite usisno crijevo sa malo tekućine i

q

pogoni pumpu q– ali ne bez nadzora, tako da u

u

okreće u desnu stranu, dakle kao kod bušenja. Ukoliko broj

u

može biti podešavan, na taj način možete regulirati

u

Nakon završetka usisavanja neizostavno isključite bušilicu.

Čišćenje i održavanje

Očistite pumpu qsamo uz pomoć suhe ili blago navlažene krpe.

Ne koristite ribajuća sredstva, kako ne biste oštetili plastične površine.

Pumpa je samoodržavajuća.

- 18 -

Page 22

Zbrinjavanje

Uređaj nikako ne bacajte u obično kućno smeće. Uređaj otklonite preko ovlaštenog poduzeća za otklanjanje otpada ili preko vašeg komunalnog poduzeća za otklanjanje otpada. Obratite pažnju na aktualno važeće propise.

U slučaju dvojbe se povežite sa svojim poduzećem za uklanjanje otpada.

Sve materijale ambalaže zbrinite na način neškodljiv za okoliš.

Izjava konformiteta

Mi, Kompernaß Handelsgesellschaft GmbH, Burgstraße 21, D-44867 Bochum

izjavljujemo sa samostalnom odgovornošću, da proizvod odgovara svim

zahtjevima smjernice za strojeve: 2006/42/EC.

Tip/Naziv uređaja: Powerfix Profi Plus Pumpa za bušilicu PBMP 30 A1

Serijski broj: IAN 75640

Godina proizvodnje: 05/2012

Bochum, dana 10.05.2012

Semi Uguzlu, Menadžer kakvoće

Izjava o sukladnosti za ovaj proizvod dostupna je na internet stranici www.lidl.hr.

Uvoznik

Lidl Hrvatska d.o.o. k.d.,

p.p. 61

10020 Novi Zagreb

- 19 -

Page 23

Proizvođač:

KOMPERNASS GMBH

BURGSTRASSE 21

D-44867 BOCHUM, Njemačka

www.kompernass.com

Jamstvo i servis

Na ovaj uređaj vrijedi jamstvo u trajanju od 3 godine od datuma kupovine.

Uređaj je pažljivo proizveden i prije isporuke brižljivo kontroliran. Molimo

sačuvajte blagajnički račun kao dokaz o kupnji. Molimo da se u slučaju ostvarivanja prava na jamstvo telefonski povežete sa Vašom servisnom ispostavom. Samo na taj način vaša roba može biti besplatno uručena.

Jamstvo vrijedi samo za greške materijala i izrade, a ne za transportne štete,

potrošne dijelove ili oštećenja lomljivih dijelova, na primjer prekidača ili baterija.

Proizvod je namijenjen isključivo za privatnu, a ne za gospodarstvenu uporabu.

U slučaju nestručnog rukovanja, rukovanja protivnog namjeni uređaja, primjene

sile i zahvata, koji nisu izvršeni od strane našeg ovlaštenog servisnog predstavništva, važenje jamstva prestaje. Vaša zakonska prava ovim jamstvom

ostaju netaknuta.

Jamstveni rok se ne produžava uslijed ostvarivanja prava na jamstvo. To vrijedi

i za zamijenjene i popravljene dijelove. Eventualno već prilikom kupovine

prisutna oštećenja i nedostaci moraju biti javljena neposredno nakon raspakiranja, ali najkasnije dva dana nakon datuma kupovine. Popravke vršene

nakon isteka jamstvenog roka podliježu obavezi plaćanja.

Servis Hrvatska

Tel.: 0800 777 999

E-Mail: kompernass@lidl.hr

IAN 75640

- 20 -

Page 24

CUPRINS PAGINA

Introducere 22

Indicaţii de siguranţă 22

Utilizarea conform destinaţiei 23

Date tehnice 23

Furnitura 24

Prezentarea aparatului 24

Materialul necesar pentru montaj 24

Montajul şi racordarea 25

Demontarea tijei de antrenare 27

Utilizarea 28

Curăţarea şi mentenanţa 28

Eliminarea aparatelor uzate 29

Declaraţia de conformitate 29

Importator 29

Garanţia şi service-ul 30

- 21 -

R

Page 25

Introducere

Felicitări!

Prin această achiziţie v-aţi decis pentru un produs de calitate excepţională.

Înainte de punerea în funcţiune a produsului, familiarizaţi-vă cu acesta. În

acest scop citiţi cu atenţie instrucţiunile de utilizare de mai jos. Utilizaţi acest

produs numai în modul descris ţi doar pentru domeniile de utilizare specificate.

Păstraţi bine aceste instrucţiuni. Dacă înmânaţi produsul altor persoane, predaţi, de asemenea, ţi documentele aferente.

Indicaţii de siguranţă

Pentru a evita pericolul de accidente şi defectarea

aparatului:

• utilizaţi pompa numai dacă este asigurată cu suportul de fixare alăturat

împotriva mişcării necontrolate, a răsucirii sau înclinării;

• înainte de fiecare utilizare, verificaţi starea ireproşabilă de funcţionare

a pompei. Este interzisă utilizarea pompei, dacă s-au observat defecţiuni.

Arborele de antrenare al pompei nu poate fi rotit manual.

Acest lucru nu înseamnă că pompa este defectă.

• Utilizaţi numai furtunuri care rămân etanşe la o presiune de minim 3 bari;

• verificaţi ajustajul racordurilor de la furtunuri;

• asiguraţi-vă că la bormaşină nu ajung lichidele transportate cu pompa.

Dacă se întâmplă acest lucru, scoateţi imediat ştecărul din priză;

• Evitaţi să aspiraţi resturi de dimensiuni mari, deoarece pompa se poate

defecta. Eventual montaţi un filtru pe furtunul de aspirare.

• acest aparat nu poate fi utilizat de către copiii sau alte persoane ale căror

capacităţi motrice, senzoriale şi mentale împiedică utilizarea în siguranţă

a aparatului fără sprijinul sau supravegherea unei alte persoane.

Supravegheaţi copiii pentru a vă asigura că nu se joacă cu aparatul.

R

- 22 -

Page 26

Utilizarea conform destinaţiei

Această pompă poate fi utilizată ...

– bormaşini uzuale, cu rotire spre dreapta / stânga, gât euro de 43 mm şi

mandrină cu coroană dinţată / cu strângere rapidă sau mandrină de găurit cu locaş de prindere SDS, cu turaţie de până la 3400 rot./min;

– pentru pomparea lichidelor reci sau cu o temperatură de până la 40° C,

de exemplu, apă uzată sau apă murdară din acvarii sau iazuri.

Această pompă

– pompării lichidelor inflamabile, explozive, nocive sau corozive ori

alimentelor;

– a fi utilizată în scopuri industriale sau profesionale.

nnuu

este destinată...

Date tehnice

Cantitatea pompată: max. 2,4 m3/h

Racord furtun: 3/4” (19 mm)

Presiune: max. 3 bari

Înălţimea de pompare: max. 30 m

Înălţimea de sucţiune: max. 3 m

Temperatura lichidului pompat: max. 40° C

Timpul de funcţionare în gol: max. 12 secunde

Turaţia: max. 3400 rot./min

- 23 -

R

Page 27

Furnitura

- Pompă

- Tijă de antrenare scurtă

- Tijă de antrenare lungă

- Cleme de fixare

- Suport

- Cheie fixă

- Cutie de depozitare pentru tijele de antrenare şi cheia fixă

- Instrucţiuni de utilizare

Prezentarea aparatului

Figura A:

Pompă

q

Arbore de antrenare al pompei

w

Tijă de antrenare scurtă (adecvat pentru mandrine cu coroană dinţată /

e

cu strângere rapidă)

Tijă de antrenare lungă (adecvată pentru locaşul cu prindere SDS)

r

Cleme de fixare

t

Suport

y

Figura B:

Bormaşină (nu este inclusă în furnitură)

u

Decupaj pentru cheia de mandrină

i

Racord furtun de aspirare

o

Racord furtun pneumatic

a

Materialul necesar pentru montaj

- Şurubelniţă în cruce

- Şurubelniţă pentru şuruburi cu cap crestat

- Cheie fixă (livrată în furnitură)

R

- 24 -

Page 28

Montajul şi racordarea

Montaţi suportul

aşa cum este indicat în imagine B.

Alternativ, suportul

şuruburilor (materialul pentru montaj nu este cuprins în furnitură).

cu ajutorul clemelor de fixare tpe o placă de lucru,

y

poate fi montat pe placa de lucru şi cu ajutorul

y

La utilizarea unei mandrine cu coroană dinţată şi a tijei

de antrenare scurte e...

înşurubaţi tija de antrenare scurtă

pompei

introduceţi bormaşina

împingeţi pompa

prin mandrina de găurire, iar ştifturile din suport

prindere de pe pompă

q

;

cu mantrina de găurire în suport y;

u

pe suport yastfel încât tija de antrenare esă iasă

q

;

q

rotiţi strâns mandrina de găurire cu ajutorul cheii prin decupaj

încât pompa

să nu se mai poată desprinde din suport y;

q

strângeţi şurubul cu fantă pe suport

se poată deplasa;

conectaţi furtunul de absorbţie la racordul

racordul

. Atenţie la direcţia de curgere indicată pe pompă q.

a

în arborele de antrenare wal

e

să intre în găurile de

y

astfel încât bormaşina usă nu

y

şi furtunul peneumatic la

o

i

astfel

La utilizarea unei mandrine cu prindere rapidă şi a tijei de

antrenare scurte e...

Fixaţi tija de antrenare scurtă

Poziţionaţi bormaşina

pe suport

y

.

u

Strângeţi şurubul cu fantă pe suport

poată deplasa.

în mandrină.

e

, cu tija de antrenare premontată eîn mandrină,

, astfel încât bormaşina usă nu se

y

- 25 -

R

Page 29

Împingeţi pompa

prin filetul arborelui de antrenare

găurile de prindere de pe pompă

Porniţi bormaşina

pompa

este fixată de pompă q.

drept pe tija de antrenare e. Prin aceasta, tija de antrenare

q

conectaţi furtunul de absorbţie la racordul

racordul

. Respectaţi direcţia de curgere indicată pe pompă q.

a

pe suport yastfel încât tija de antrenare esă iasă

q

, iar ştifturile suportului ysă intre în

w

.

q

cu rotire spre dreapta şi la turaţie redusă şi ghidaţi

u

şi furtunul pneumatic la

o

Dacă utilizaţi o mandrină cu locaş de prindere SDS şi tija

lungă de antrenarer...

fixaţi tija de antrenare lungă

introduceţi bormaşina

premontată în mandrina de găurire;

u

strângeţi şurubul cu fantă pe suport

poată deplasa;

împingeţi pompa

prin filetul arborelui de antrenare

găurile de prindere de pe pompă

porniţi bormaşina

pompa

este fixată la pompă q.

drept pe tija de antrenare r. În acest mod tija de antrenare

q

pe suport yastfel încât tija de antrenare rsă iasă

q

cu rotire spre dreapta şi la turaţie redusă şi ghidaţi

u

conectaţi furtunul de absorbţie la racordul

racordul

. Respectaţi direcţia de curgere indicată pe pompă q.

a

în mandrina de găurit;

r

în suport yîmpreună cu tija de antrenare

astfel încât bormaşina usă nu se

y

, iar ştifturile suportului ysă intre în

w

;

q

şi furtunul pneumatic la

o

e

r

r

R

- 26 -

Page 30

Demontarea tijei de antrenare

Demontarea tijei de antrenare scurte

Mandrină cu coroană dinţată

e

Deschideţi mandrina de găurire cu ajutorul cheii pentru mandrine prin

decupaj

Deşurubaţi tija de antrenare scurtă

pentru şuruburi cu fantă şi al cheii fixe.

Mandrină cu prindere rapidă

Prin decupaj

pompei

Porniţi bormaşina

Prin aceasta, tija de antrenare

Scoateţi pompa

Scoateţi tija de antrenare

Demontarea tijei de antrenare lungi

Mandrină cu locaş de prindere SDS

Cu ajutorul cheii fixe contraţi prin decupaj

al pompei q.

Porniţi maşina

antrenare

Scoateţi pompa

Scoateţi tija de antrenare

şi scoateţi pompa qdin suport y.

i

de la pompă qcu ajutorul şurubelniţei

e

, contraţi cu cheia fixă arborele de antrenare wal

i

.

q

cu rotire pe stânga şi la turaţie redusă.

u

este desprinsă de pompă q.

e

din suport y.

q

din mandrină.

e

r

arborele de antrenare

i

cu rotire pe stânga la turaţie redusă. În acest mod tija de

u

este desprinsă de la pompă q.

r

din suport y.

q

din mandrina de găurire.

r

w

- 27 -

R

Page 31

Utilizarea

Atenţie!

Pompa începe automat absorbţia. Dacă pompa qnu începe să absoarbă în

interval de 12 secunde, bormaşina

rea. De aceea, nu porniţi pompa

partea de ieşire este închis.

Introduceţi capătul deschis al furtunului de absorbţie în lichidul de transpor-

tat. Furtunul de absorbţie nu trebuie să aibă o lungime mai mare de 3 m.

Asiguraţi că furtunul de absorbţie nu trage aer.

se opreşte imediat, pentru a evita gripa-

u

atât timp cât furtunul pneumatic de pe

q

Dacă pompa

ridicaţi-l pentru ca lichidul să curgă în faţa pompei.

Bormaşina

pentru a putea interveni prompt în caz de pericol. Este foarte important ca

bormaşina

bormaşinii

portată.

nu absoarbe, umpleţi furtunul de absorbţie cu lichid şi

q

poate acum porni pompa q– totuşi sub supraveghere

u

să se rotească spre dreapta, deci ca la găurire. Dacă turaţia

u

este reglabilă, se poate regulariza cantitatea de lichid trans-

u

După mersul în gol opriţi imediat bormaşina

Curăţarea şi mentenanţa

Curăţaţi pompa qnumai cu ajutorul unui material uscat sau uşor umezit. Nu

utilizaţi dizolvanţi sau substanţe corozive, pentru a nu deteriora suprafeţele

sintetice.

Pompa nu necesită mentenanţă.

R

- 28 -

Page 32

Eliminarea aparatelor uzate

Nu aruncaţi aparatul sub nicio formă în gunoiul menajer obişnuit.

Eliminaţi aparatul prin intermediul unei firmei specializate şi autorizate sau

prin intermediul serviciului local de eliminare a deşeurilor.

Respectaţi reglementările actuale în vigoare. Pentru informaţii suplimentare

luaţi legătura cu centrul de colectare a deşeurilor din zona dumneavoastră.

Eliminaţi toate materialele de ambalare într-un mod ecologic.

Declaraţia de conformitate

Noi, Kompernaß Handelsgesellschaft GmbH, Burgstraße 21, D-44867 Bochum

declarăm pe propria răspundere că produsul corespunde tuturor cerinţelor

Directivei maţini: 2006/42/EC.

Tip/denumire aparat: Powerfix Profi Plus Pompă pentru maşina de găurit

PBMP 30 A1

Număr de serie: IAN 75640

Anul de fabricaţie: 05/2012

Bochum, la 10.05.2012

Semi Uguzlu, Manager de calitate

Importator

KOMPERNASS GMBH

BURGSTRASSE 21

44867 BOCHUM, GERMANY

www.kompernass.com

- 29 -

R

Page 33

Garanţia şi service-ul

Pentru acest aparat, se acordă o garanţie de 3 ani începând cu data cumpărării.

Aparatul a fost produs cu grijă şi verificat cu scrupulozitate înaintea livrării.

Păstraţi bonul de casă pentru a dovedi cumpărarea. Dacă aveţi solicitări privind garanţia, contactaţi telefonic centrul dumneavoastră de service. Numai astfel poate fi asigurată o expediere gratuită a produsului dumneavoastră.

Garanţia acoperă numai defectele de material sau de fabricaţie, nu şi deteriorările rezultate în urma transportului, piesele de uzură sau deteriorările

apărute la componentele fragile, de ex. comutatoare sau acumulatoare. Aparatul este destinat numai pentru uz privat şi nu pentru o utilizare profesională.

În cazul manevrării abuzive sau necorespunzătoare, uzului de forţă şi intervenţiilor care nu au fost realizate de către filiala noastră autorizată de service,

garanţia îşi pierde valabilitatea. Drepturile dumneavoastră legale nu sunt limitate prin această garanţie.

Perioada de garanţie nu este prelungită după realizarea reparaţiilor realizate

în perioada garanţie. Acest lucru este valabil şi pentru piesele înlocuite şi reparate. Deteriorările şi deficienţele prezente deja la cumpărare trebuie semnalate imediat după dezambalare sau cel târziu în două zile de la data

cumpărării. Reparaţiile necesare după expirarea perioadei de garanţie se

efectuează contra cost.

R

Service România

Tel.: 0800896637

E-Mail: kompernass@lidl.ro

IAN 75640

R

- 30 -

Page 34

Cъдържание Cтраница

Увод 32

Указания за безопасност 32

Употреба по предназначение 33

Технически данни 33

Окомплектовка на доставката 34

Преглед на уреда 34

Необходим материал за монтаж 34

Монтаж и свързване 35

Демонтаж на шийката на задвижващия

механизъм 37

Употреба 38

Почистване и поддържане 38

Рециклиране 39

Декларация за съответствие 39

Вносител 39

Гаранция и сервиз 40

- 31 -

Page 35

Увод

Поздравяваме ви!

С вашата покупка сте избрали висококачествен продукт. Преди първото

пускане в експлоатация се запознайте с продукта. За тази цел прочетете

внимателно следващото ръководство за потребителя. Използвайте продукта,

само както е описано и за посочените области на приложение. Пазете

добре това ръководство. Предавайте продукта на трети лица заедно с

цялата документация.

Указания за безопасност

За да предотвратите опасността от злополука и

повреда на уреда

• Пускайте помпата само, когато е обезопасена с приложения държач

срещу увиване, усукване или поръбване.

• Контролирайте преди всяка употреба безупречното състояние на

помпата. Помпата не трябва да се използва, ако тя има видими повреди.

Задвижващият вал не може да се завърти на ръка.

Това не означава, че помпата е дефектна.

• Използвайте само маркучи, които са устойчиви на налягане до

най-малко 3 bar.

• Контролирайте здравата сглобка на щепселните съединения на

маркучите.

• Погрижете се в бормашината, с която задвижвате помпата, да

не попадат никакви течности. Ако това се случи въпреки това,

изключете веднага щепсела.

• Избягвайте засмукване на едри замърсявания, защото в противен

случай помпата може да се повреди. При необходимост използвайте

филтър за засмукващия маркуч.

:

- 32 -

Page 36

• Този уред не е годен за деца или други лица, чийто психически,

органолептични и умствени способности предотвратяват безопасното

използване без съдействие или надзор. Децата трябва да останат под

наблюдение, за да се гарантира, че не играят с машината.

Употреба по предназначение

Тази помпа е предвидена за ...

– стандартни ръчни бормашини с ляво/дясно въртене с 43 мм-ова

еврошийка и патронник със зъбен венец/бързозатягащ патронник

или патронник за свредла със SDS захват, честота на въртене до

3400 об./мин.,

– за изпомпване на студени или затоплени до 40°C течности, като

напр. използвана или замърсена вода от аквариуми или домашни

езерца.

Тази помпа

– за изпомпване на горими, експлозивни или разяждащи течности

или хранителни продукти.

– за промишлени или стопански цели.

ннее

е предвидена ...

Технически данни

Дебит: макс. 2,4 m3/h

Връзка за маркуча: 3/4” (19 mm)

Напорна мощност: макс. 3 bar

Напорна височина: макс. 30 m

Височина на засмукване: макс. 3 m

Температура на

транспортната течност: макс. 40°C

Време на сух режим: макс. 12 секунди

Честота на въртене: макс. 3400 U/min

- 33 -

Page 37

Окомплектовка на доставката

- Помпа

- Къса задвижваща шийка

- Дълга задвижваща шийка

- Затегателно устройство

- Държач

- Гаечен ключ

- Кутия за съхранение на задвижващите шийки и гаечния ключ

- Ръководство за експлоатация

Преглед на уреда

Фигура A:

помпа

q

задвижващ вал на помпата

w

къса шийка на задвижващия механизъм (подходяща за патронник със

e

зъбен венец/бързозатягащ патронник за свредла)

дълга шийка на задвижващия механизъм (подходяща за SDS държач)

r

клемно закрепване

t

държач

y

Фигура B:

Бормашина (не е включена в окомплектовката на доставката)

u

Отвор за ключа за патронника за свредла

i

Съединител за засмукващия маркуч

o

Съединител за напорния маркуч

a

Необходим материал за монтаж

- отвертка с кръстообразен шлиц

- отвертка с шлицова глава

- гаечен ключ (съдържащ се в обема на доставката)

- 34 -

Page 38

Монтаж и свързване

Монтирайте държача

плот, така както е показано на изображението (B).

Алтернативно държачът

плот и с помощта на болтове (монтажният материал не се съдържа

в обема на доставката).

с клемното закрепване tвърху работен

y

може да се монтира върху работния

y

При използване на патронник със зъбен венец за свредла

и късата задвижваща шийка e...

завинтете късата шийка

поставете бормашината

пъхнете сега помпата

се покаже от патронника, а щифтовете да се пъхнат от държача

отворите на помпата

Затегнете патронника през процепа

помпата

да не може да се отдели от държача y.

q

Затегнете здраво болта с кръстатия шлиц към държача

може бормашината

Свържете засмукващия маркуч към връзката

към връзката

на помпата

. При това съблюдавайте посоката на течение

a

.

q

върху задвижващия вал wна помпата q.

e

с патронника в държача y.

u

така върху държача y, че шийката eда

q

.

q

с ключа до такава степен, че

i

y

да се увива.

u

и напорния маркуч

o

y

, за да не

в

При използване на бързозатягащ патронник за свредла и

късата задвижваща шийка e...

Закрепете късата задвижваща шийка

Пъхнете бормашината

шийка

в патронника за свредла, в държача y.

e

, с предварително монтираната задвижваща

u

Затегнете здраво винта с кръстообразен шлиц на държача

не може да се завърта бормашината

в патронника за свредла.

e

.

u

y

, за да

- 35 -

Page 39

Поставете помпата

шийка

държача

да влезе в резбата на задвижващия вал w, а щифтовете на

e

да се пъхнат в приемните отвори на помпата q.

y

Пуснете бормашина

вкарайте помпата

задвижващата шийка

Свържете засмукващия маркуч към връзката

към връзката

на помпата

a

q

върху държача yтака, че задвижващата

q

да работи с дясно въртене и ниски обороти и

u

право в задвижващата шийка e. По този начин

q

се затяга към помпата q.

e

и напорния маркуч

o

. При това съблюдавайте посоката на течение

.

При използване на патронник за свредла със SDS захват

и дългата задвижваща шийка r...

Затегнете дългата шийка

Пъхнете бормашината

шийка

в държача y.

r

Затегнете здраво болта с кръстатия шлиц към държача

не може бормашината

Поставете помпата

покаже от резбата на задвижващия вал

да са пъхнати в отворите на помпата q.

q

Пуснете бормашина

въртене и пъхнете помпата

По този начин шийката

Свържете засмукващия маркуч към връзката

към връзката

на помпата

. При това съблюдавайте посоката на течение

a

.

q

в патронника.

r

с предварително монтираната в патронника

u

, за да

y

да се увива.

u

така върху държача y, че шийката rда се

и щифтовете на държача

w

с дясно завъртане на ниска честота на

u

направо върху шийката r.

q

се закрепва към помпата q.

r

и напорния маркуч

o

y

- 36 -

Page 40

Демонтаж на шийката на задвижващия

механизъм

Демонтиране на къса шийка

Патронник със зъбен венец за свредла

e

Отворете патронника със съответния ключ през процепа

помпата

Отвинтете късата шийка

с шлицова глава и гаечен ключ.

Бързозатягащ патронник за свредла

С гаечния ключ през отвора

на помпата q.

Пуснете бормашината

По този начин задвижващата шийка

Извадете помпата

Извадете задвижващата шийка

Демонтиране на дълга шийка

Патронник за свредла със SDS захват

Контрирайте през процепа

с помощта на гаечния ключ. .

Пуснете бормашината

По този начин задвижващият вал

Извадете помпата

Извадете шийката

от държача y.

q

от помпата qс помощта на отвертка

e

дръжте контра на задвижващия вал

i

да работи с ляво въртене и ниски обороти.

u

се освобождава от помпата q.

e

от държача y.

q

от патронника за свредла.

e

r

задвижващия вал wна помпата

i

с ляво движение и ниска честота на въртене.

u

се развинтва от помпата q.

r

от държача y.

q

от патронника.

r

и извадете

i

w

q

- 37 -

Page 41

Употреба

Внимание!

Помпата е самозасмукваща. Ако помпата qне засмуква в течение

на 12 секунди, изключете веднага бормашината

задиране. По тази причина не оставяйте помпата

докато напорният маркуч е затворен от изходната страна.

Поставете отворения край на засмукващия маркуч в течността, която

трябва да бъде засмуквана. Засмукващият маркуч не трябва да е подълъг от 3 м. Внимавайте засмукващият маркуч да не тегли въздух.

, за да избегнете

u

да изпомпва,

q

Ако помпата

малко течност и го повдигнете, за да стигне течността пред помпата.

Оставете бормашината

се под надзор, за да може да се реагира бързо при наличието на

опасност. Обърнете непременно внимание на това бормашината

да се върти надясно, тоест както при пробиване. Ако честотата на

въртене на бормашината

регулирате и дебита.

не засмуква, напълнете засмукващия маркуч с

q

да задвижи помпата q– но разбира

u

може да се регулира , Вие можете да

u

След изсмукването изключете веднага бормашината.

Почистване и поддържане

Почиствайте помпата qсамо със суха или леко навлажнена кърпа.

Не използвайте разтворители или агресивни почистващи препарати,

за да не повредите пластмасовите повърхности.

Помпата не се нуждае от техническо обслужване.

- 38 -

u

Page 42

Рециклиране

Не изхвърляйте в никакъв случай уреда с битовите отпадъци. Рециклирайте

уред при оторизирано предприятие за рециклиране или в пункта за

вторични суровини на общината. Съблюдавайте валидните актуални

разпоредби. В случай на съмнение се обърнете към депото за рециклиране.

Рециклирайте опаковъчния материал без да замърсявате

околната среда.

Декларация за съответствие

Ние, фирма Kompernaß Handelsgesellschaft GmbH, ул. Бургщрасе 21,

44867 гр. Бохум, Германия, декларираме на собствена отговорност, че

продуктът отговаря на всички изисквания на Директивата за машини.

2006/42/ЕC.

Тип/Обозначение на уреда: ПОМПА ЗА БОРМАШИНА Powerfix Profi Plus

PBMP 30 A1

Сериен номер: IAN 75640

Година на производство: 05/2012

гр. Бохум, 10.05.2012

Semi Uguzlu, Мениджър по качеството

Вносител

KOMPERNASS GMBH

BURGSTRASSE 21

44867 BOCHUM, GERMANY

www.kompernass.com

- 39 -

Page 43

Гаранция и сервиз

За този уред Вие получавате гаранция от 3 години от датата на закупуване.

Уредът е произведен старателно и е контролиран преди да бъде доставен.

Запазете касовата бележка, за да удостоверите датата на закупуване. В

случай на гаранция се свържете по телефона с Вашия сервиз. Само по

този начин може да се гарантира безплатното изпращане на Вашата стока.

Гаранционната претенция важи само за материални или фабрични

дефекти, но не и за транспо-ртни щети, износени части или при повреда

на лесно чупливи части, напр. прекъсвачи, акумулаторни батерии.

Продуктът е предназначен само за лична, но не и за стопанска употреба.

При злонамерена и неправилна употреба, при употреба на сила или

дейности, които не са извършени от нашия оторизиран сервизен филиал,

гаранцията се заличава. Законните Ви права не се ограничават с тази

гаранция.

Гаранционният срок не се удължава от гаранцията. Това важи за заменени

и ремонтирани части. Евентуалните налични още при закупуването щети

и дефекти трябва да се съобщават още при разопаковането, но най-късно

два дена след датата на закупуване. След като изтече гаранционният срок,

ремонтите трябва да бъдат заплатени.

Сервизно обслужване България

Тел.:00800 111 4920

Е-мейл: kompernass@lidl.bg

IAN 75640

- 40 -

Page 44

INHALTSVERZEICHNIS SEITE

Einführung 42

Sicherheitshinweise 42

Bestimmungsgemäßer Gebrauch 43

Technische Daten 43

Lieferumfang 44

Geräteübersicht 44

Benötigtes Montagematerial 44

Montage und Anschluss 45

Demontage des Antriebsschafts 47

Verwenden 48

Reinigen und Warten 48

Entsorgen 49

Konformitätserklärung 49

Importeur 49

Garantie und Service 50

- 41 -

Page 45

Einführung

Herzlichen Glückwunsch!

Mit Ihrem Kauf haben Sie sich für ein hochwertiges Produkt entschieden.

Machen Sie sich vor der ersten Inbetriebnahme mit dem Produkt vertraut.

Lesen Sie hierzu aufmerksam die nachfolgende Bedienungsanleitung. Benutzen

Sie das Produkt nur wie beschrieben und für die angegebenen Einsatzbereiche.

Bewahren Sie diese Anleitung gut auf. Händigen Sie alle Unterlagen bei

Weitergabe des Produkts an Dritte ebenfalls mit aus.

Sicherheitshinweise

Um Unfallgefahr und Geräteschäden zu vermeiden:

• Betreiben Sie die Pumpe nur, wenn sie mit der beiliegenden Halterung

gegen Herumschlagen, Verdrehen oder Verkanten gesichert ist.

• Kontrollieren Sie die Pumpe auf einwandfreien Zustand vor jedem

Gebrauch. Die Pumpe darf nicht verwendet werden, wenn Schäden

erkennbar sind.

Die Antriebswelle der Pumpe läßt sich nicht mit der Hand drehen.

Dies deutet nicht auf einen Defekt der Pumpe hin.

• Verwenden Sie nur Schläuche, die bis mindestens 3 bar druckfest sind.

• Kontrollieren Sie die Steckverbinder an den Schläuchen auf festen Sitz.

• Sorgen Sie dafür, dass keine Flüssigkeiten an die Bohrmaschine gelangen

können, mit der Sie die Pumpe antreiben. Falls doch, ziehen Sie sofort den

Netzstecker.

• Vermeiden Sie das Ansaugen von groben Schmutz, da sonst die Pumpe

beschädigt werden kann. Verwenden Sie ggf. einen Filter am Ansaugschlauch.

- 42 -

Page 46

• Dieses Gerät ist nicht für Kinder oder andere Personen geeignet, deren

physische, sensorische oder geistige Fähigkeiten ohne Unterstützung oder

Aufsicht eine sichere Nutzung des Gerätes verhindern. Kinder sollten

beaufsichtigt werden, um sicherzustellen, dass sie nicht mit dem Gerät spielen.

Bestimmungsgemäßer Gebrauch

Diese Pumpe ist vorgesehen für ...

– handelsübliche Rechts/Links drehende Handbohrmaschinen mit 43 mm

Eurohals und Zahnkranzfutter/Schnellspannfutter oder Bohrfutter mit SDSAufnahme, bis zu einer Drehzahl von 3400 U/min,

– zum Pumpen von kalten oder bis zu 40°C warmen Flüssigkeiten,

wie z.B. Brauch- oder Schmutzwasser aus Aquarien oder Teichen.

Diese Pumpe ist

– zum Pumpen von brennbaren, explosiven, giftigen oder ätzenden

Flüssigkeiten oder Lebensmitteln.

– für industrielle oder gewerbliche Zwecke.

nniicchhtt

vorgesehen ...

Technische Daten

Fördermenge: max. 2,4 m3/h

Schlauchanschluss: 3/4” (19 mm)

Druckleistung: max. 3 bar

Förderhöhe: max. 30 m

Ansaughöhe: max. 3 m

Temperatur der

Förderflüssigkeit: max. 40°C

Trockenlaufzeit: max. 12 Sekunden

Drehzahl: max. 3400 U/min

- 43 -

Page 47

Lieferumfang

- Pumpe

- Antriebsschaft kurz

- Antriebsschaft lang

- Klemmbefestigung

- Halterung

- Maulschlüssel

- Aufbewahrungsbox für die Antriebsschäfte und Maulschlüssel

- Diese Bedienungsanleitung

Geräteübersicht

Abbildung A:

Pumpe

q

Antriebswelle der Pumpe

w

Antriebsschaft kurz (geeignet für Zahnkranz-/Schnellspannbohrfutter)

e

Antriebsschaft lang (geeignet für SDS-Aufnahme)

r

Klemmbefestigung

t

Halterung

y

Abbildung B:

Bohrmaschine (nicht im Lieferumfang enthalten)

u

Aussparung für Bohrfutterschlüssel

i

Anschluss Ansaugschlauch

o

Anschluss Druckschlauch

a

Benötigtes Montagematerial

- Kreuzschlitzschraubendreher

- Schlitzschraubendreher

- Maulschlüssel (im Lieferumfang enthalten)

- 44 -

Page 48

Montage und Anschluss

Montieren Sie die Halterung

Arbeitsplatte, wie in Abbildung B gezeigt.

Alternativ kann die Halterung

Arbeitsplatte montiert werden (Montagematerial nicht im Lieferumfang

enthalten).

mit der Klemmbefestigung tauf einer

y

auch mittels Schrauben auf einer

y

Bei Verwendung eines Zahnkranzbohrfutters und des

kurzen Antriebsschafts e...

Schrauben Sie den kurzen Antriebsschaft

Pumpe

Stecken Sie die Bohrmaschine

Schieben Sie nun die Pumpe

Antriebsschaft

in den Aufnahmelöchern an der Pumpe qstecken.

q

.

mit dem Bohrfutter in die Halterung y.

u

so auf die Halterung y, dass der

q

in das Bohrfutter ragt, und die Stifte von der Halterung

e

auf die Antriebswelle wder

e

Drehen Sie das Bohrfutter mit dem Bohrfutterschlüssel durch die

Aussparung

Halterung

Drehen Sie die Kreuzschlitzschraube an der Halterung

damit die Bohrmaschine

Schließen Sie den Ansaugschlauch an den Anschluss

Druckschlauch an den Anschluss

angegebene Flussrichtung auf der Pumpe

Bei Verwendung eines Schnellspannbohrfutters und des

kurzen Antriebsschafts e...

Befestigen Sie den kurzen Antriebsschaft

Stecken Sie die Bohrmaschine

im Bohrfutter, in die Halterung y.

Drehen Sie die Kreuzschlitzschraube an der Halterung

damit die Bohrmaschine

so fest, dass die Pumpe qsich nicht mehr aus der

i

lösen kann.

y

nicht herumschlagen kann.

u

an. Beachten Sie dabei die

a

.

q

im Bohrfutter.

e

, mit dem vormontierten Antriebsschaft

u

nicht herumschlagen kann.

u

- 45 -

y

und den

o

y

fest,

fest,

y

e

Page 49

Schieben Sie die Pumpe

schaft

Halterung

in das Gewinde der Antriebswelle wragt, und die Stifte der

e

in den Aufnahmelöchern der Pumpe qstecken.

y

Lassen Sie die Bohrmaschine

anlaufen und führen Sie die Pumpe

Der Antriebsschaft

e

Schließen Sie den Ansaugschlauch an den Anschluss

Druckschlauch an den Anschluss

angegebene Flussrichtung auf der Pumpe

so auf die Halterung y, dass der Antriebs-

q

im Rechtslauf und mit niedriger Drehzahl

u

gerade auf den Antriebsschaft e.

q

wird dadurch an der Pumpe qbefestigt.

und den

o

an. Beachten Sie dabei die

a

.

q

Bei Verwendung eines Bohrfutters mit SDS-Aufnahme

und des langen Antriebsschafts r...

Befestigen Sie den langen Antriebsschaft

Stecken Sie die Bohrmaschine

im Bohrfutter, in die Halterung y.

, mit dem vormontierten Antriebsschaft

u

Drehen Sie die Kreuzschlitzschraube an der Halterung

damit die Bohrmaschine

Schieben Sie die Pumpe

schaft

Halterung

in das Gewinde der Antriebswelle wragt, und die Stifte der

r

in den Aufnahmelöchern der Pumpe qstecken.

y

Lassen Sie die Bohrmaschine

anlaufen und führen Sie die Pumpe

Der Antriebsschaft

r

nicht herumschlagen kann.

u

so auf die Halterung y, dass der Antriebs-

q

im Rechtslauf und mit niedriger Drehzahl

u

q

wird dadurch an der Pumpe qbefestigt.

Schließen Sie den Ansaugschlauch an den Anschluss

Druckschlauch an den Anschluss

angegebene Flussrichtung auf der Pumpe

a

im Bohrfutter.

r

fest,

y

gerade auf den Antriebsschaft r.

und den

o

an. Beachten Sie dabei die

.

q

r

- 46 -

Page 50

Demontage des Antriebsschafts

Kurzen Antriebsschaft edemontieren

Zahnkranzbohrfutter

Öffnen Sie das Bohrfutter mit dem Bohrfutterschlüssel durch die

Aussparung

Schrauben Sie den kurzen Antriebsschaft

bendrehers und dem Maulschlüssel von der Pumpe

Schnellspannbohrfutter

Kontern Sie mit dem Maulsschlüssel durch die Aussparung

Antriebswelle

Lassen Sie die Bohrmaschine

anlaufen. Der Antriebsschaft

Entnehmen Sie die Pumpe

Entnehmen Sie den Antriebsschaft

Langen Antriebsschaft rdemontieren

Bohrfutter mit SDS-Aufnahme

Kontern Sie mit dem Maulsschlüssel durch die Aussparung

Antriebswelle

Lassen Sie die Bohrmaschine

anlaufen. Der Antriebsschaft

Entnehmen Sie die Pumpe

Entnehmen Sie den Antriebsschaft

und entnehmen Sie die Pumpe qaus der Halterung y.

i

mithilfe eines Schlitzschrau-

e

.

q

i

der Pumpe q.

w

im Linkslauf und mit niedriger Drehzahl

u

wird dadurch von der Pumpe qgelöst.

e

aus der Halterung y.

q

aus dem Bohrfutter.

e

i

der Pumpe q.

w

im Linkslauf und mit niedriger Drehzahl

u

wird dadurch von der Pumpe qgelöst.

r

aus der Halterung y.

q

aus dem Bohrfutter.

r

die

die

- 47 -

Page 51

Verwenden

Achtung!

Die Pumpe ist selbstansaugend. Wenn die Pumpe qnicht innerhalb von

12 Sekunden ansaugt, schalten Sie die Bohrmaschine

Festlaufen zu vermeiden. Lassen Sie aus diesem Grund auch die Pumpe

nicht fördern, solange der Druckschlauch auf der Auslaufseite verschlossen ist.

Legen Sie das offene Ende vom Ansaugschlauch in die Flüssigkeit, die

angesaugt werden soll. Der Ansaugschlauch darf nicht länger als 3 m

sein. Achten Sie darauf, dass der Ansaugschlauch keine Luft zieht.

sofort ab, um ein

u

q

Sollte die Pumpe

mit etwas Flüssigkeit und heben Sie ihn an, damit die Flüssigkeit vor die

Pumpe läuft.

Lassen Sie die Bohrmaschine

nicht unbeaufsichtigt, um bei Gefahr schnell reagieren zu können. Achten

Sie unbedingt auch darauf, dass die Bohrmaschine

also wie beim Bohren. Falls die Drehzahl der Bohrmaschine

können Sie darüber die Fördermenge regulieren.

nicht ansaugen, befüllen Sie den Ansaugschlauch

q

nun die Pumpe qantreiben – jedoch

u

nach rechts dreht,

u

regelbar ist,

u

Schalten Sie nach dem Leersaugen sofort die Bohrmaschine aus.

Reinigen und Warten

Reinigen Sie die Pumpe qnur mit einem trockenen oder leicht

angefeuchteten Tuch. Verwenden Sie keine Lösungs- oder Scheuermittel,

um die Kunststoffflächen nicht zu beschädigen.

Die Pumpe ist wartungsfrei.

- 48 -

Page 52

Entsorgen

Werfen Sie das Gerät keinesfalls in den normalen Hausmüll.

Entsorgen Sie das Gerät über einen zugelassenen Entsorgungsbetrieb oder

über Ihre kommunale Entsorgungseinrichtung.

Beachten Sie die aktuell geltenden Vorschriften. Setzen Sie sich im

Zweifelsfall mit Ihrer Entsorgungseinrichtung in Verbindung.

Führen Sie alle Verpackungsmaterialien einer umweltgerechten

Entsorgung zu.

Konformitätserklärung

Wir, Kompernaß Handelsgesellschaft GmbH, Burgstraße 21, D-44867 Bochum,

erklären in alleiniger Verantwortung, dass das Produkt allen Anforderungen

der Maschinenrichtlinie 2006/42/EC entspricht.

Typ/Gerätebezeichnung: Powerfix Profi Plus Bohrmaschinenpumpe PBMP 30 A1

Seriennummer: IAN 75640

Herstellungsjahr: 05/2012

Bochum, den 10.05.2012

Semi Uguzlu, Qualitätsmanager

Importeur

KOMPERNASS GMBH

BURGSTRASSE 21

D-44867 BOCHUM

www.kompernass.com

- 49 -

Page 53

Garantie und Service

Sie erhalten auf dieses Gerät 3 Jahre Garantie ab Kaufdatum. Das Gerät

wurde sorgfältig produziert und vor Anlieferung gewissenhaft geprüft.

Bitte bewahren Sie den Kassenbon als Nachweis für den Kauf auf. Bitte setzen Sie sich im Garantiefall mit Ihrer Servicestelle telefonisch in Verbindung.

Nur so kann eine kostenlose Einsendung Ihrer Ware gewährleistet werden.

Die Garantieleistung gilt nur für Material- oder Fabrikationsfehler, nicht aber

für Transportschäden, Verschleißteile oder für Beschädigungen an zerbrechlichen Teilen, z. B. Schalter oder Akkus. Das Produkt ist lediglich für den privaten und nicht für den gewerblichen Gebrauch bestimmt.

Bei missbräuchlicher und unsachgemäßer Behandlung, Gewaltanwendung

und bei Eingriffen, die nicht von unserer autorisierten Service-Niederlassung

vorgenommen wurden, erlischt die Garantie. Ihre gesetzlichen Rechte werden durch diese Garantie nicht eingeschränkt.

Die Garantiezeit wird durch die Gewährleistung nicht verlängert. Dies gilt

auch für ersetzte und reparierte Teile. Eventuell schon beim Kauf vorhandene

Schäden und Mängel müssen sofort nach dem Auspacken gemeldet werden,

spätestens aber zwei Tage nach Kaufdatum. Nach Ablauf der Garantiezeit

anfallende Reparaturen sind kostenpflichtig.

Service Deutschland

Tel.: 01805 772 033 (0,14 EUR/Min. aus dem dt. Festnetz,

Mobilfunk max. 0,42 EUR/Min.)

E-Mail: kompernass@lidl.de

IAN 75640

Service Österreich

Tel.: 0820 201 222 (0,15 EUR/Min.)

E-Mail: kompernass@lidl.at

IAN 75640

Service Schweiz

Tel.: 0842 665566 (0,08 CHF/Min., Mobilfunk max. 0,40 CHF/Min.)

E-Mail: kompernass@lidl.ch

IAN 75640

- 50 -

Page 54

KOMPERNASS GMBH

Burgstraße 21

D-44867 Bochum

www.kompernass.com

Last Information Update · Stanje informacija · Versiunea informaţiilor

Актуалност на информацията · Stand der Informationen:

05 / 2012 · Ident.-No.: PBMP30A1052012-1

IAN 75640

7

Loading...

Loading...