Page 1

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2010

ADD-ON NAVIGATION SYSTEM

ORDER NO.

CRT4545

AVIC-U220/XZUC

AVIC-U220

HIDE-AWY NAVIGATION SYSTEM

AVIC-F220

AVIC-F220

AVIC-F220

AVIC-F220

/XZEU5

/XZUW5

/XZAU

/XZCS

/XZUC

For details, refer to "Important Check Points for Good Servicing".

K-ZZZ. APR. 2010 Printed in Japan

Page 2

1234

1234

C

D

F

A

B

E

SAFETY INFORMATION

CAUTION

WARNING

Where in a manufacturer’s service documentation, for example in circuit diagrams or lists

of components, a symbol is used to indicate that a specific component shall be replaced only

by the component specified in that documentation for safety reasons, the following symbol shall

be used:

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

This product may contain a chemical known to the State of California to cause cancer, or birth defects or

other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

2

AVIC-U220/XZUC

Page 3

5678

56

7

8

C

D

F

A

B

E

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

AVIC-U220/XZUC

3

Page 4

1234

1234

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SERVICE PRECAUTIONS............................................................................................................................... 5

1.1 SERVICE PRECAUTIONS ........................................................................................................................ 5

1.2 NOTES ON SOLDERING.......................................................................................................................... 5

2. SPECIFICATIONS............................................................................................................................................ 6

2.1 SPECIFICATIONS ..................................................................................................................................... 6

2.2 DISC/CONTENT FORMAT ........................................................................................................................ 7

2.3 PANEL FACILITIES.................................................................................................................................... 7

2.4 CONNECTION DIAGRAM ......................................................................................................................... 8

3. BASIC ITEMS FOR SERVICE........................................................................................................................ 10

3.1 CHECK POINTS AFTER SERVICING..................................................................................................... 10

4. BLOCK DIAGRAM.......................................................................................................................................... 12

4.1 BLOCK DIAGRAM................................................................................................................................... 12

5. DIAGNOSIS.................................................................................................................................................... 14

5.1 DIAGNOSIS FLOWCHART ..................................................................................................................... 14

5.2 CONNECTOR FUNCTION DESCRIPTION............................................................................................. 17

6. SERVICE MODE............................................................................................................................................ 19

6.1 TEST MODE............................................................................................................................................ 19

7. DISASSEMBLY .............................................................................................................................................. 25

8. EACH SETTING AND ADJUSTMENT ........................................................................................................... 27

9. EXPLODED VIEWS AND PARTS LIST.......................................................................................................... 28

9.1 PACKING ................................................................................................................................................. 28

9.2 EXTERIOR............................................................................................................................................... 32

4

AVIC-U220/XZUC

Page 5

5678

56

7

8

C

D

F

A

B

E

1. You should conform to the regulations governing the product (safety, radio and noise, and other regulations),

and should keep the safety during servicing by following the safety instructions described in this manual.

2. Be careful in handling ICs. Some ICs such as MOS type are so fragile that they can be damaged by electrostatic

induction.

3. Before disassembling the unit, be sure to turn off the power. Unplugging and plugging the connectors during

power-on mode may damage the ICs inside the unit.

4. This model must be required to connect AVH series 2010 year or later for operation check.

For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

1. SERVICE PRECAUTIONS

1.1 SERVICE PRECAUTIONS

1.2 NOTES ON SOLDERING

AVIC-U220/XZUC

5

Page 6

1234

1234

C

D

F

A

B

E

2. SPECIFICATIONS

General

Rated power source............... 14 .4 V DC

(allowable voltage range:

10.8 V to 15.1 V DC)

Grounding system................... Negative type

Maximum current consumption

..................................................... 1.0 A

Dimensions (W × H × D):

............................................... 85 mm × 28 m m × 147 m m

(3-3/8 in. × 1-1/8 in. ×

5-3/4 in.)

Detachable device........ 7 0 mm ×1 7 mm ×99 mm

(2-3/4 in. × 5/8 in. ×

3-7/8 in.)

Weight .......................................... 195 g (0.43 lbs)

NAND flash memory ............. 2 GB

Navigation

GPS receiver:

System ................................ L1 , C/Acode GPS

SPS (Standard Positioning

Service)

Reception system.......... 20-channel multi-channel

reception system

Reception frequency.... 1 575.42 MHz

Sensitivity .......................... – 1 40 dBm (typ)

Position update frequency

........................................... Approx. once per second

GPS antenna:

Antenna ............................. Micro strip flat antenna/

right-handed helical polari-

zation

Antenna cable................. 3. 55 m ( 11 ft. 10 in.)

Dimensions (W × H × D)

........................................... 33 m m × 14.7 m m × 3 6 mm

(1-1/4 in. × 4/7 in. ×

1-3/8 in.)

Weight ................................ 96 g (0.21 lbs)

USB

USB standard spec................ U SB 2.0 H igh Speed

Max current supply................. 500 m A

File system.................................. FAT16, FAT32

USB class.................................... Mass storage class

SD

Compatible physical format

..................................................... Version 2.00

Max memory capacity........... 1 6 G B

File system.................................. FAT16, FAT32

Note

Specifications and design are subject to possible

modifications without notice due to improvements.

Backup current .......................... 0. 2 mA or l ess

AVIC-U220

General

Rated power source............... 14.4 V DC

(allowable voltage range:

10.8 V to 15.1 V DC)

Earthing system ....................... Negative type

Maximum current consumption

..................................................... 1.0 A

Dimensions (W × H × D):

............................................... 85 mm × 28 m m × 147 mm

Detachable device........ 70 mm ×17 mm ×99 mm

Weight .......................................... 19 6 g(EU5 ,AU)

NAND flash memory ............. 2 GB (AU, UW5, CS)

4 GB (EU5)

Navigation

GPS receiver:

System ................................ L1, C/Acode GPS

SPS (Standard Positioning

Service)

Reception system.......... 20-channel multi-channel

reception system

Reception frequency.... 1 575.42 MHz

Sensitivity .......................... –1 40 dBm (typ)

Position update frequency

........................................... Approx. once per second

GPS aerial:

Aerial ................................... Micro strip flat aerial/right-

handed helical polarisation

Aerial cable ...................... 3.55 m

Dimensions (W × H × D)

........................................... 33 m m × 14.7 m m × 36 mm

Weight ................................ 96 g

USB

USB standard spec................ USB 2.0 Hi gh Speed

Max current supply................. 500 mA

File system.................................. FAT 16, FAT 32

USB class.................................... Mas s s tor age class

SD

Compatible physical format

..................................................... Version 2.00

Max memory capacity........... 16 GB

File system.................................. FAT16, FAT32

RDS-TMC tuner(EU5, AU)

Earthing system ....................... N egative type

Maximum current consumption

..................................................... 60 mA

Dimensions (W × H × D) ... 68 mm × 49 mm × 19 mm

Weight .......................................... 18 0 g

Note

Specifications and design are subject to possible

modifications without notice due to improvements.

Backup current .......................... 0.2 mA or l ess

AVIC-F220

.......................................... 1 95 g(UW 5, C S)

2.1 SPECIFICATIONS

6

AVIC-U220/XZUC

Page 7

5678

56

7

8

C

D

F

A

B

E

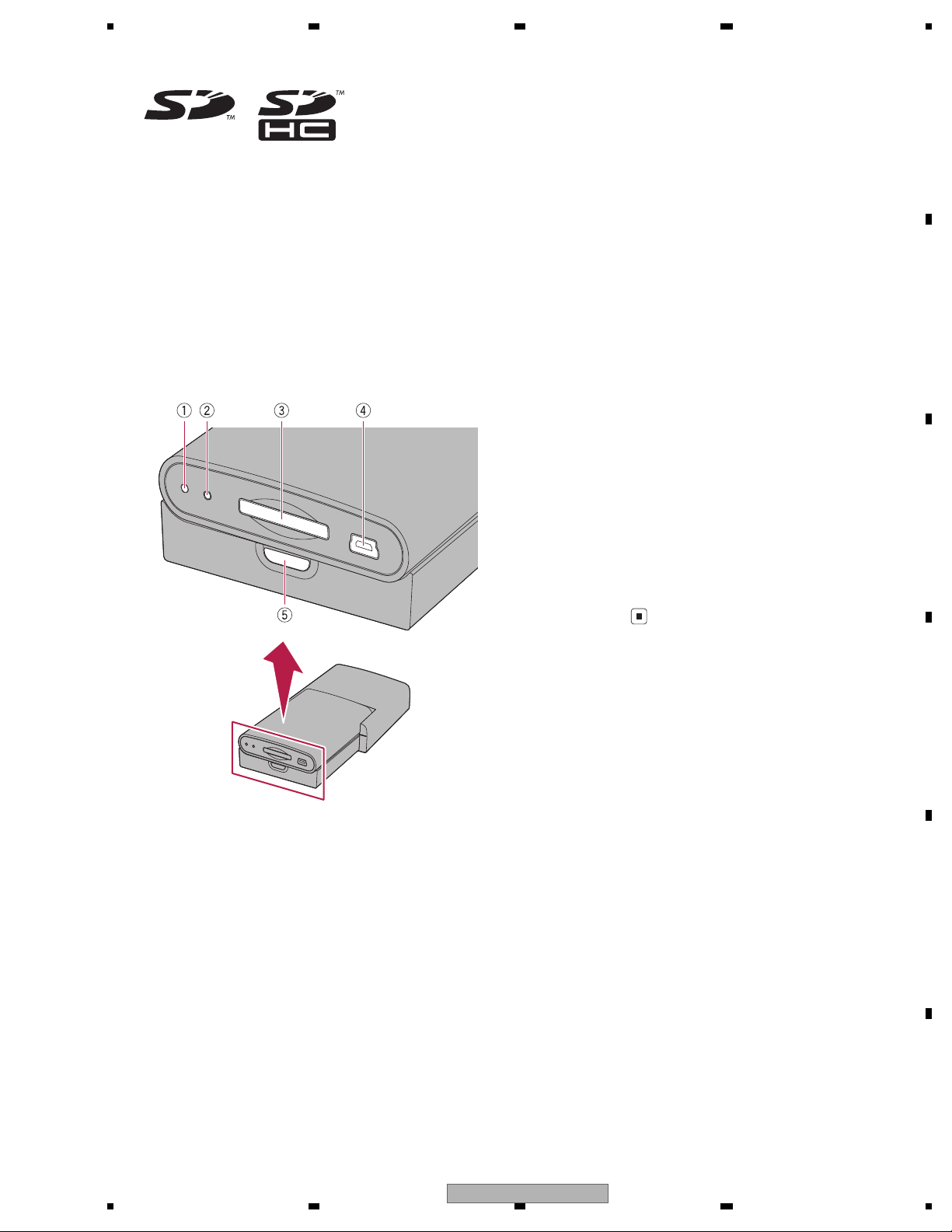

1 Power indicator

2 RESET button

3 SD card slot

4 USB port (Mini-B)

Use to connect with your PC.

5 Detach button

Press to remove the detachable device from

the base unit.

2.2 DISC/CONTENT FORMAT

2.3 PANEL FACILITIES

AVIC-U220/XZUC

7

Page 8

1234

1234

C

D

F

A

B

E

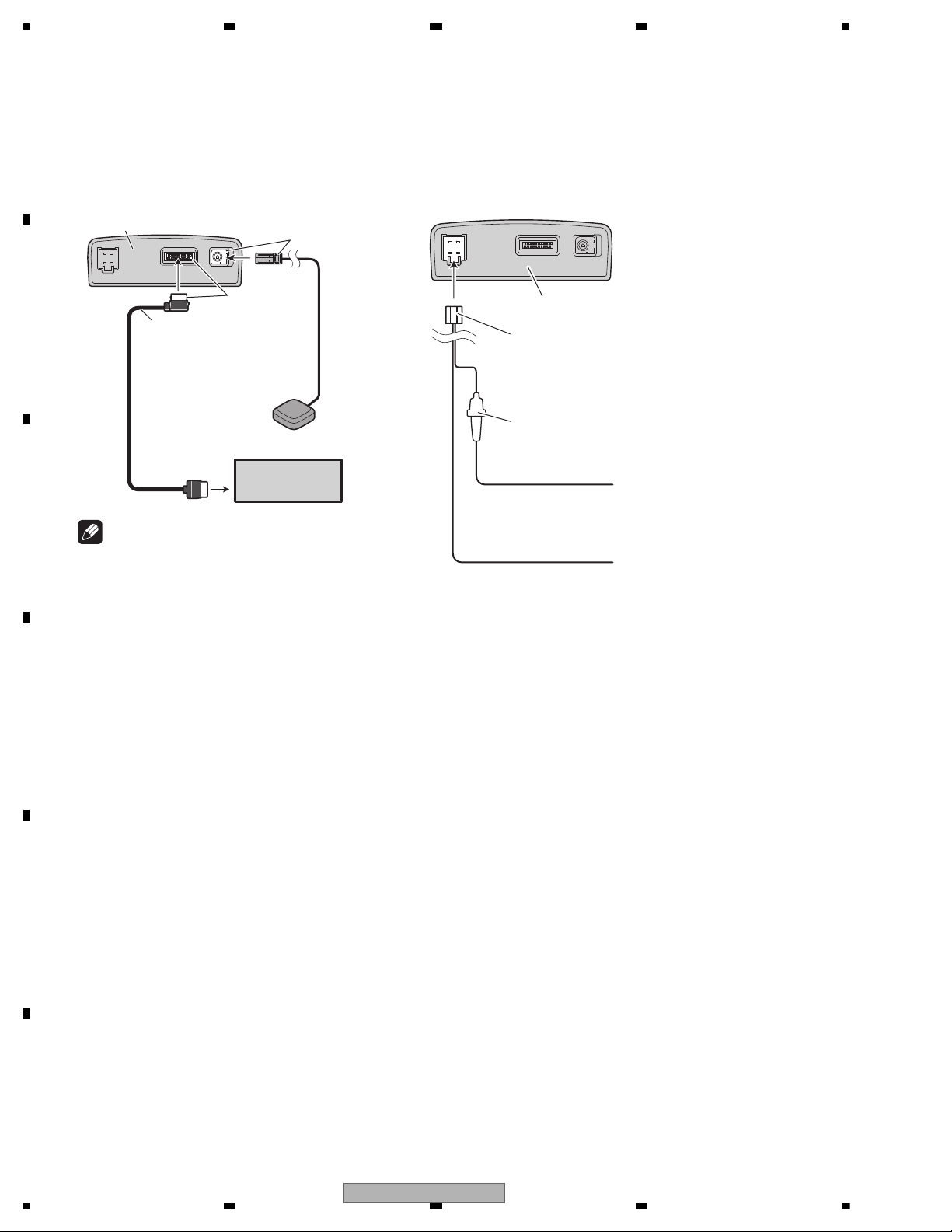

2.4 CONNECTION DIAGRAM

Connecting the system

26-pin cable

(supplied)

3.55 m

(11 ft. 8 in.)

2 m (6 ft. 7 in.)

GPS antenna

Green

Yellow

Base unit

AV receiver

Note

The terminal form of the 26-pin cable may differ

depending on the terminal type of the AV receiver.

For details of connection, refer to the installation

manual supplied with the AV receiver.

Connecting the power cord

Yellow

To terminal always supplied

with power regardless of

ignition switch position.

Black (ground)

To vehicle (metal) body.

Power cord

Base unit

Fuse holder

- UC, EW5, CS

8

AVIC-U220/XZUC

Page 9

5678

56

7

8

C

D

F

A

B

E

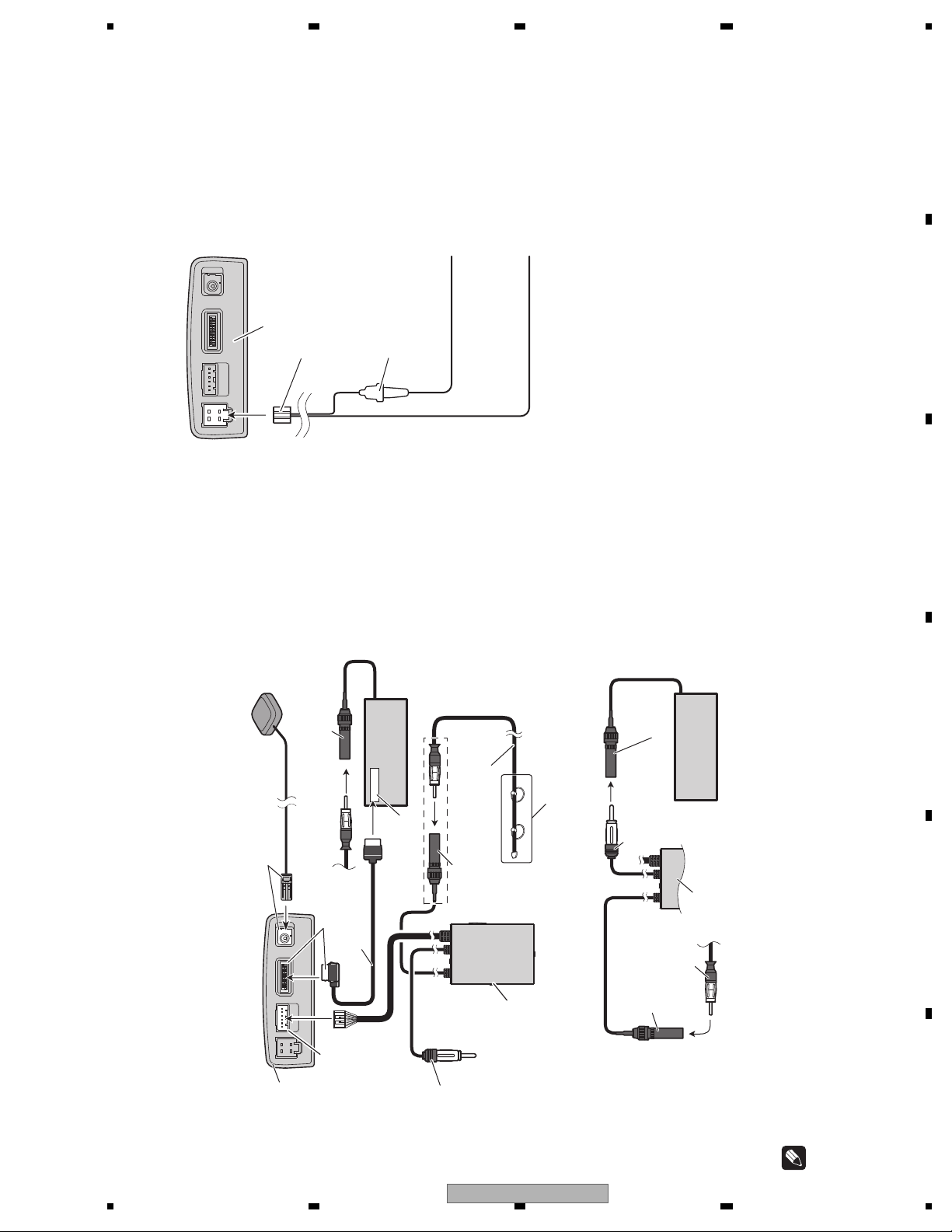

Connecting the system

We recommend connecting the supplied external aerial. Connect the aerial plug of your vehicle to the AV receiver di-

rectly (Fig. 1).

If you do not use the supplied external aerial in order to split radio signal between this product and the built-in tuner of

the AV receiver (Fig. 2), the radio sensitivity of the AV receiver may decrease.

26-pin cable (supplied)

3.55 m

2 m

GPS aerial

Green

Yellow

Base unit

RDS-TMC tuner

(supplied)

Not used.

Expansion port

30 cm

1 m

30 cm

AV receiver

RGB input

Aerial jack of AV receiver

External aerial (supplied)

Aerial jack

Vehicle aerial

For more details about the wiring.

(Fig. 1)

RDS-TMC tuner

AV receiver

A

erial jack of AV receiver

Vehicle aerial

Aerial jack

Aerial plug

(Fig. 2)

Note

The terminal form of the 26-pin cable may differ

depending on the terminal type of the AV receiver.

For details of connection, refer to the installation

manual supplied with the AV receiver.

Connecting the power cord

Yellow

To terminal always supplied

with power regardless of

ignition switch position.

Black (earth)

To vehicle (metal) body.

Power cord

Base unit

Fuse holder

- EU5, AU

AVIC-U220/XZUC

9

Page 10

1234

1234

C

D

F

A

B

E

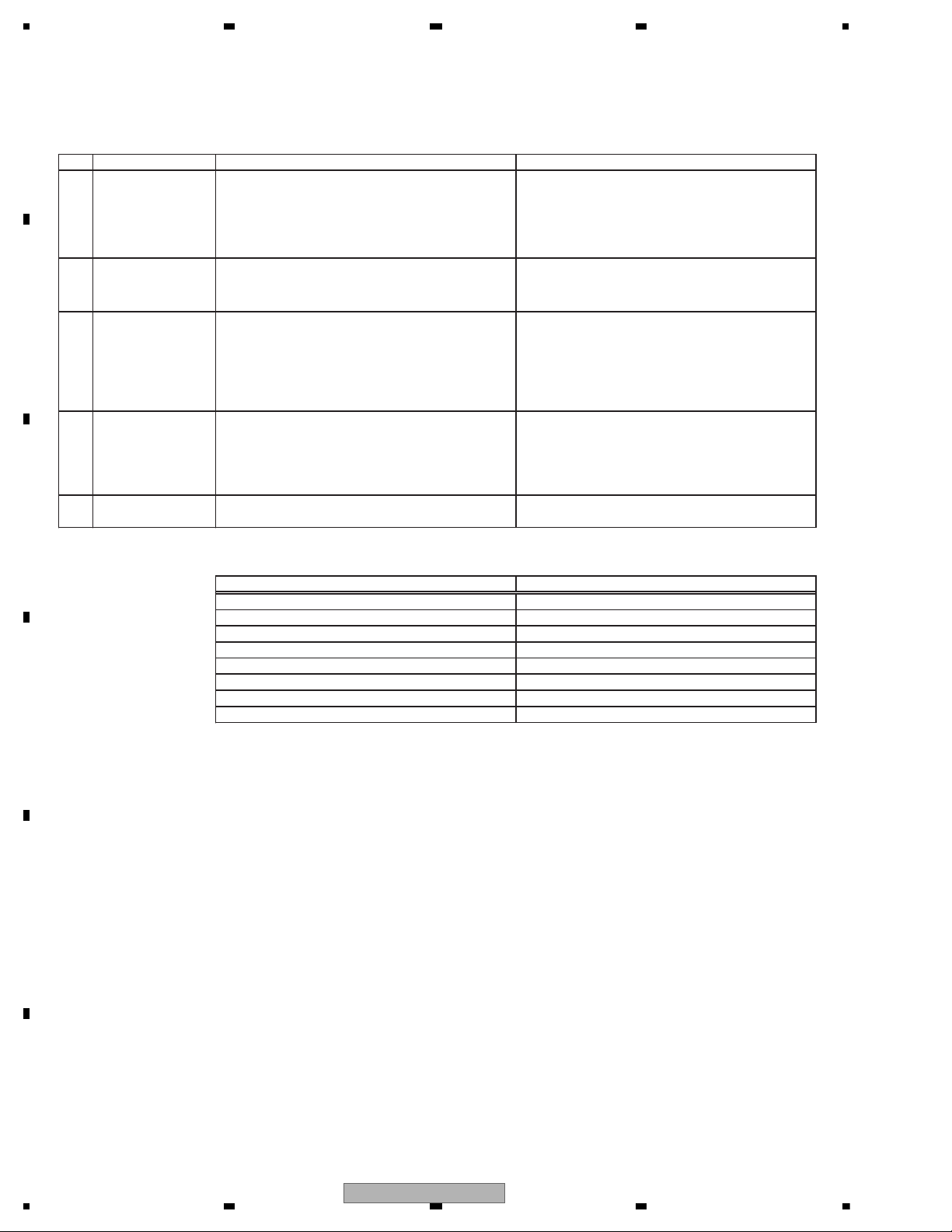

3. BASIC ITEMS FOR SERVICE

To keep the product quality after servicing, please confirm following check points.

No. Procedures Item to be confirmed

1

Confirm whether the customer complain has

been solved.

If the customer complain occurs with the

specific media, use it for the operation check.

The customer complain must not be reappeared.

Display, video, audio and operations must be

normal.

2 GPS positioning Connect GPS antenna to the product, and

check whether the current location is correct.

Current location must be correct.

Display and operations must be normal.

3 Map display

Touch-panel

operation

Remote-control

operation

Check functions of map scale change and map

scroll.

Display and operations must be normal.

4 Delete data added during the operating check.

Check whether no media (CD etc.) is inside the

product.

Make sure to delete data added during the

operating check.

The media used for the operating check must

be ejected.

5 Appearance check No scratches or dirt on its appearance after

receiving it for service.

See the table below for the items to be checked regarding video and audio:

Item to be checked regarding video Item to be checked regarding audio

Block-noise Distortion

Horizontal noise Noise

Dot noise Volume too low

Disturbed image (video jumpiness) Volume too high

Too dark Volume fluctuating

Too bright Sound interrupted

Mottled color

3.1 CHECK POINTS AFTER SERVICING

10

AVIC-U220/XZUC

Page 11

5678

56

7

8

C

D

F

A

B

E

AVIC-U220/XZUC

11

Page 12

1234

1234

C

D

F

A

B

E

4. BLOCK DIAGRAM

guide on signal

TV on Signal(AVH detects navi connection.)

CSYNC C

3.3Vp-p 0.

(w

M

I2C

Guide Signal

NAND FLASH

2GB/4GB

SOC

Samsung 2450

400MHz

SDRAM

64MB+64MB

SD Card Slot

CPLD

Battery

Charger IC

System

Power_IN

Mini-B USB

Connector

Reset Button

SDRAM Address Bus

SDRAM Data Bus

32-bit Bus

SD Contrpl

/Data Bus

Misc. Logic

Client USB2.0

XTAL

32.768KHz

XTAL

12MHz

XTAL

12MHz

RGB Digital 6-bit

Video

Decoder

V/H SYNC DCLK

Audio Codec

RGB Analog

Level Shift

u-COM TX/RX

TMC TX/RX

GPS TX/RX

NAVI UNIT

I2S

SD CN

mini USB CN

Deta

NAND Flash Bus

8bit Data BUS

4.1 BLOCK DIAGRAM

12

AVIC-U220/XZUC

Page 13

5678

56

7

8

C

D

F

A

B

E

CSYNC

0.3Vp-p

(with AVH)

Main 5V

Level Shift

u-COM TX/RX

TMC TX/RX

GPS TX/RX

CN

DC/DC

Converter

CN

CN

To TMC Unit

To AVH Unit

Power in(BUP)

CRADLE UNIT

BUP

GPS Module

other pwr

RTC pwr

Reg

ASENB

CN

GPS CN

Detach CN

AVIC-U220/XZUC

13

Page 14

1234

1234

C

D

F

A

B

E

5. DIAGNOSIS

Flow chart for Start / Navi Trouble Shooting

Note) Please refer to “Measure point” page, when you check the signal.

This model

connect to AVH.

AVH can change to

Navi source

Trouble in Navi unit

Does LED of

this model

light?

Is Battery connected

to Navi board?

Trouble in Cradle unit

After replacing the

Cradle unit to new one,

can AVH change the

source to Navi ?

Trouble in RGB cable

Is BUP in cradle unit

OK?

Trouble in power cable

or fuse

Is ASENB_OUT

in cradle unit

OK?

Trouble in detach

connector

Trouble in Cradle unit

Trouble in Battery

connector

After replacing the

Navi unit to new one,

can AVH change the

source to Navi ?

Flow Chart for BEEP, GUIDE Trouble Shooting

Is Sounds outputted

from front Speaker?

BEEP, GUIDE

After replacing the

Cradle unit to new one,

is sounds outputted

from the SP?

Trouble in Cradle unit

Trouble in Navi unit

Trouble in AVH unit

No

No

No

No

No

No

No

No

No

No

No

Yes

YesYes

Yes

Yes

Yes Yes

YesNo Yes

Yes

LED(green) lighting condition

Main_5V is active

*BUP is hi and ASENB_IN (from AVH) is hi.

*Lighting mode is above one kind. (always lighting)

Is there

"Guide_audio_cradle"?

Is there

"Guide_audio_navi"?

Trouble in Navi unit

Trouble in detach

connector

After replacing the

RGB cable to new one,

is sounds outputted

from the SP?

5.1 DIAGNOSIS FLOWCHART

14

AVIC-U220/XZUC

Page 15

5678

56

7

8

C

D

F

A

B

E

Flow Chart for TMC Trouble Shooting (EU5/AU) Flow Chart for GPS Trouble Shooting

Can the product receive

TMC information?

No

No

No

Yes

No

Yes

Yes

No

No

No

Yes

No

No

Yes

Yes

Is electric wave in a

TMC TUNER JASO

connector?

Can the product receive

GPS?

Trouble in GPS anntena

Trouble in Cradle unit

Trouble in Navi unit

Trouble in TMC anntena

or TMC cable

Trouble in Cradle unit

Trouble in Navi unit

Trouble in TMC UNIT

Trouble in Cradle unit

Is TMC_BUP in

cradle unit OK?

Trouble in RGB cable

Is GPS_RF_IN OK?

When you change

TMC unit into new it.

Can the product receive

TMC information?

When you change

Cradle unit into new it.

Can the product receive

TMC information?

When you change

Navi unit into new it.

Can the product receive

TMC information?

When you change

Navi unit into new it.

Can the product receive

GPS?

When you change

Cradle unit into new it.

Can the product receive

GPS?

AVIC-U220/XZUC

15

Page 16

1234

1234

C

D

F

A

B

E

Measure point

GPS_RF_IN

TMC_BUP

BUP

1

32

2

31

2

1

3

4

4

3

31

32

Navi unit

Cradle unit

GND

Main_5V

Guide_audio_

cradle

25

ASENB_OUT

Cradle unit

Cradle unit

Navi unit

21

ASENB_IN

*It pass the navi unit from

"ASENB_OUT"

Guide_audio_

navi

16

AVIC-U220/XZUC

Page 17

5678

56

7

8

C

D

F

A

B

E

NAVI UNIT

CRADLE UNIT

SD Card slot connectorUSB connector

Power connector

TMC connector AVH connector

GPS connector

1 : NC

2 : BUP

3 : GND

4 : NC

42

31

1 : TMC BUP

2 : TMC ON

3 : TMC SNS

4 : PND TO TMC

5 : TMC TO PND

6 : GND

123456

1 : VIDEO R

2 : VIDEO G

3 : VIDEO B

4 : COMP SYNC

5 : AV GND

6 : NC

7 : NC

8 : NC

9 : ASENB

10 : NC

11 : NC

12 : NC

13 : AUDIO OUT+

14 : AUDIO OUT15 : NC

16 : NC

17 : NC

18 : NC

19 : DSEN_PND#

20 : TVON AVH

21 : GION#

22 : NC

23 : NC

24 : STON

25 : NTOS

26 : GND

252321191715131197531

2624222018161412108642

5.2 CONNECTOR FUNCTION DESCRIPTION

AVIC-U220/XZUC

17

Page 18

1234

1234

C

D

F

A

B

E

Navi unit Cradle unit

NAVI UNIT CRADLE UNIT

Interface connector B to B connector B to B connector Interface connector

USB connector Detach connector Detach connector Power connector AVH connector

No. Terminal name No. Terminal name No. Terminal name No. Terminal name No. Terminal name

1 VCC_USB_BUS 1 MAIN_5V 1 VCC_IN_5V 1 NA 1 VIDEO_R

2 TX_USBN- 2 MAIN_5V 2 VCC_IN_5V 2 BUP 2 VIDEO_G

3 RX_USBP+ 3 GUIDE_AUDIO_N 3 GUIDE_AUDIO_N 3 GND 3 VIDEO_B

4 USBID_CPLD 4 GUIDE_AUDIO 4 GUIDE_AUDIO 4 KMODE 4 COMP_SYNC

5 GND 5 TMC_TXD_MAIN_M 5 PNDTOTMC 5 AV_GND

6 A_GND 6 A_GND TMC connector 6 CVBS_OUT

Battery connector 7 TMC_RXD_MAIN_M 7 TMCTOPND No. Terminal name 7 AV_GND

No. Terminal name 8 DSEN_TMC_M# 8 DSEN_TMC_M# 1 TMCBUP 8 NA

1 NA 9 TMC_ON_M 9 TMC_ON_M 2 TMCON 9 ASENB

2 VBAT 10 GPS_RST_M# 10 GPS_RST_M# 3 TMCSNS# 10 AUDIO_L

3 VBAT 11 GPS_BS1_M 11 GPS_GS1_M 4 PNDTOTMC 11 AUDIO_R

4 CHG_V2P8 12 U_TXD_MAIN_M 12 U_TXD_MAIN_M 5 TMCTOPND 12 AGND

5 GND 13 GPS_EN_M 13 GPS_EN_M 6 GND 13 AUDIO_OUTPUT

14 U_RXD_MAIN_M 14 U_RXD_MAIN_M 14 AUDIO_OUTPUT_N

SD card slot connector 15 GPS_WAKE_M# 15 RF_WAKE_M# GPS connector 15 NA

No. Terminal name 16 TVON_M 16 TVON_M No. Terminal name 16 NA

1 SD0_DATA3 17 GND 17 GND 1 GND_GPS 17 NA

2 SD0_CMD 18 GION_M# 18 GION_M# 2 RFIN 18 NA

3 GND 19 DEN_PND_M# 19 DSEN_PND_M# 3 GND_GPS 19 DSEN_PND#

4 VCC_SD 20 GND 20 GND 20 TVON_AVH

5 SD0_CLK 21 ASENB_IN 21 ASENB_IN_M 21 GION#

6 GND 22 GPS_TXD_MAIN_M 22 GPS_TXD_MAIN_M 22 NA

7 SD0_DATA0 23 ACC_IN_M# 23 ACCON# 23 NA

8 SD0_DATA1 24 GPS_RXD_MAIN_M 24 GPS_RXD_MAIN_M 24 STON

9 SD0_DATA2 25 ASENB_OUT 25 ASENB_OUT 25 NTOS

10 COM 26 KMODE_MAIN_M 26 KMODE_CPU_M 26 GND

11 SD0_WP 27 AV_GND 27 AV_GND

12 SD0_DETECT 28 AV_GND 28 AV_GND

29 COMP_SYNC 29 COMP_SYNC

30 VIDEO_B 30 VIDEO_B

31 VIDEO_R 31 VIDEO_R

32 VIDEO_G 32 VIDEO_G

SD Card slot connector

Battery connector

USB connector

Detach connector

1

32

1

9

10

12

32

1

1

5

1

5

Power connector

1

6

1

26

1

3

43

21

Detach connector

TMC connectorAVH connector

GPS connector

18

AVIC-U220/XZUC

Page 19

5678

56

7

8

C

D

F

A

B

E

How to Use Test Mode

Startup procedures

1. Store the Test Mode folder on GGS1092 to the SD card root.

2. Download a ID file from the Service Site and copy it to the “Test Mode” folder on the SD card.

3. Insert the SD card in which the program is stored to the Navi unit and attach the Navi unit to the Cradle unit.

4. Turn ON the BUP and ACC of the main unit/AVH.

5. Press the Reset button on the Navi unit.

6. Press the Mode button on the AVH and go to the Navi source.

7. Test Mode will start up automatically.

* The touch panel may become inactive due to the state transition. Perform ACC_OFF/ON in that case.

Jig No : GGS1092

Test Mode menu

No. Test item Description of test

1 SD Test Not for service

2 System Load Not for service

3 Battery Displays the battery status, remaining quantity.

4 GPS Check Displays GPS reception status.

5 Flash ROM Read/Write/Compare test on Flash ROM

6 TMC TMC tuner error rate measurement

7 Voice Test Guide voice output test

8 Graphics Displays various test graphics.

9 Version Info Displays the version information of various SW.

10 USB Test Not for service

11 Port Test Displays Interface connection status.

6. SERVICE MODE

6.1 TEST MODE

AVIC-U220/XZUC

19

Page 20

1234

1234

C

D

F

A

B

E

Operation details

Battery

Displays the battery status.

GPS Check

GPS reception test is executed by “CN Value” command.

Battery Life Percent

ADC Value

Battery Flag

AC Line Status

AC Line Status

“Use Battery”: Indicates that it is operating only on battery.

“Use AC”: Indicates that it is operating on externally supplied power (power from

the main unit or PC).

Battery Flag

“CHARGING”: Indicates that the battery is being charged.

“HIGH”:It doesn't charge it. (Charge end or the power supply doesn't feed power.)

Battery Voltage Displays the voltage value for the battery.

ADC Value This is the AD conversion value of battery voltage.

Battery Life Percent This is the remaining battery quantity indicated as percent.

Battery Voltage

When it is unable to receive GPS

0 or N is indicated in red in the # and USE columns.

The values of DOP (precision) are not displayed.

20

AVIC-U220/XZUC

Page 21

5678

56

7

8

C

D

F

A

B

E

Flash ROM

Executes an operation test on Flash ROM

Folder Name Selects the partition to be tested.

Write files Writes the test file in an open area.

Read/verify files Reads the file written by Write files to compare it and check if it is correct.

Delete files Deletes the file written by Write files.

Format disk Formats the selected partition. (All files will be deleted. Caution is required.)

TMC

Measures the error rate for the external TMC tuner.

The reception frequency can be set up by operating “<” or “>.”

AVIC-U220/XZUC

21

Page 22

1234

1234

C

D

F

A

B

E

Voice Test

It is necessary to turn off the MUTE by Port Test menu before performing Voice Test.

Port Test

Click Port Test2

Click MUTE_ON (Turn off the MUTE)

Voice Test

Select a voice file.

Set DAC_Volume to "-4.5 dB", and then double-click the "Set" button.

Set MONO_out_Volume to "0 dB", and then double-click the "Set" button.

Double-click the Play (Loop) button.

22

AVIC-U220/XZUC

Page 23

5678

56

7

8

C

D

F

A

B

E

Graphics

Graphic test is executed by selecting the type of graphic with “Test” tab.

(Ex.) When center-marker is selected,

Version info

Click "Get Ver".

The versions of Bootloader (UBOOT), BSP and OS are displayed.

Click "APL".

The version of APL is displayed.

Click "MAP Ver".

The version of MAP is displayed.

AVIC-U220/XZUC

23

Page 24

1234

1234

C

D

F

A

B

E

Port Test

Executes the connection check with AVH.

For indications, please see the table below;

Parking brake signal

Port Test

“Hi” indication if Parking terminal of AVH is set to Low.

ILM Signal

“Hi” indication if ILM terminal of AVH is set to Hi.

Main Unit Get Connect

Main Unit Power Connect “Hi” indication if Main power supply of Cradle Unit is set to Hi

ACC status

Port Test 2

“Hi” indication if ACC terminal of AVH is set to Hi.

TMC status

“Hi” indication if TMC Unit is connected.

(Supported only for EU and AU model)

“Hi” indication if K-Mode terminal of this model is set to Low.

(Supported only for UC model)

K-Mode signal

24

AVIC-U220/XZUC

Page 25

5678

56

7

8

C

D

F

A

B

E

2

While the photograph shown is slightly different from this model in shape, the disassembly procedure is the same.

-

Removing the NAVI PCB (Fig.1, 2)

Fig.1

Remove the twelve hooks

in order of the number of the mark ( )

and then remove the Cover. (Fig.1)

* Case opener Jig (GGF1626) is available.

Remove the four screws. (Fig.1)

Fig.2

Fig.3

Fig.4

1

Remove the two screws

and then remove the NAVI PCB. (Fig.2)

- Removing the Cradle PCB (Fig.3, 4)

Remove the four screws. (Fig.3)

1

2

Remove the screw

and then remove the Cradle PCB. (Fig.4)

Cover

2

2

2

2

2

1

1

4

3

4

4

3

1

1

1

1

2

2

NAVI PCB

Remove the eleven hooks

in order of the number of the mark ( )

and then remove the Cover. (Fig.3)

Cover

Cradle PCB

1

1

2

3 4

2

3 4

5

5

5

2

1

1

1

1

7. DISASSEMBLY

AVIC-U220/XZUC

25

Page 26

1234

1234

C

D

F

A

B

E

The sponge (345172300100) must align line.

- How to assemble Rear Cover

26

AVIC-U220/XZUC

Page 27

5678

56

7

8

C

D

F

A

B

E

8. EACH SETTING AND ADJUSTMENT

There is not information to be shown in this chapter.

AVIC-U220/XZUC

27

Page 28

1234

1234

C

D

F

A

B

E

9. EXPLODED VIEWS AND PARTS LIST

N

OTES : Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

9.1 PACKING

Screw adjacent to mark on the product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions,apply as you think it appropriate.)

""

28

AVIC-U220/XZUC

Page 29

5678

56

7

8

C

D

F

A

B

E

(1) PACKING SECTION PARTS LIST

Mark

Mark No. Description Part No.

1 TF-CABLE ASSY POWER 422176700001

2 •••••

3 TF-CABLE ASSY RGB 422176700002

4 GPS Antenna Assy CXE3204

5 RDS-TMC Tuner See Contrast table (2)

6 TF-ANTENNA See Contrast table (2)

7 Cord Assy CDP1261

8

9 SCREW FOR INSTALLATION 452176700200

10 Lock Tie 344176700001

11 GIFT BOX See Contrast table (2)

12 INNER SOCK 227176700001

13 TF-DOCUMENT KIT See Contrast table (2)

14 IM CD-ROM See Contrast table (2)

VELCRO STRAP FOR INS

452176700100

No. Description Part No.

15-1 Quick Start Guide See Contrast table (2)

15-2 Quick Start Guide See Contrast table (2)

15-3 Quick Start Guide See Contrast table (2)

15-4 Quick Start Guide See Contrast table (2)

15-5 Quick Start Guide See Contrast table (2)

15-6 Quick Start Guide See Contrast table (2)

15-7 Important Information See Contrast table (2)

15-8 Installation Manual See Contrast table (2)

* 15-9 Warranty Card See Contrast table (2)

* 15-10 Registration Card See Contrast table (2)

15-11 Caution Card 561817670003

16 GND Sheet CZN8510

(2) CONTRAST TABLE

AVIC-U220/XZUC, AVIC-F220/XZEU5, AVIC-F220/XZUW5, AVIC-F220/XZAU and AVIC-F220/XZCS are constructed the same except for the following:

Mark No. Description

5 RDS-TMC Tuner Not used CXE2176 Not used CXE2176 Not used

6 TF-ANTENNA Not used 313002000624 Not used 313002000624 Not used

11 GIFT BOX 221176740001 221176740002 221176740004 221176740003 221176740005

13 TF-DOCUMENT KIT ••••• ••••• ••••• ••••• •••••

14 IM CD-ROM 565117670051 565117670052 565117670054 565117670053 565117670055

AVIC -U220

/XZUC

AVIC -F220

/XZEU5

AVIC -F220

/XZUW5

AVIC -F220

/XZAU

AVIC -F220

/XZCS

15-1 Quick Start Guide 561517670001 561517670003 561517670016 561517670020 561517670017

15-2 Quick Start Guide 561517670002 561517670004 561517670021 Not used Not used

15-3 Quick Start Guide Not used 561517670005 Not used Not used Not used

15-4 Quick Start Guide Not used 561517670018 Not used Not used Not used

15-5 Quick Start Guide Not used 561517670019 Not used Not used Not used

15-6 Quick Start Guide Not used 561517670022 Not used Not used Not used

15-7 Important Information 561517670006 561517670007 561517670009 561517670008 561517670010

15-8 Installation Manual 561517670011 561517670012 561517670014 561517670013 561517670015

* 15-9 Warranty Card 561817670001 561817670002 561817670002 Not used Not used

* 15-10 Registration Card 561817670004 Not used Not used Not used Not used

AVIC-U220/XZUC

29

Page 30

1234

1234

C

D

F

A

B

E

Owner's Manual,Installation Manual

Part No. Language

561517670001 English

561517670002 French

561517670006 English, French

561517670011 English, French

561517670003 English

561517670004 Spanish(Espanol)

561517670005 German

561517670018 French

561517670019 Italian

561517670022 Dutch

561517670007 English, Spanish(Espanol), German, French, Italian, Dutch

561517670012 English, Spanish(Espanol), German, French, Italian, Dutch

561517670016 English

561517670021 Russian

561517670009 English, Russian

561517670014 English, Russian

561517670020 English

561517670008 English

561517670013 English

561517670017 Portuguese(B)

561517670010 Portuguese(B)

561517670015 Portuguese(B)

CONTENTS OF CD-ROM (Operation Manual)

Part No. Language CD-ROM Part No

* CRB3368 English 565117670051

* CRB3369 French 565117670051

* CRB3370 English 565117670052

* CRB3371 Spanish(Espanol) 565117670052

* CRB3372 German 565117670052

* CRB3373 French 565117670052

* CRB3374 Italian 565117670052

* CRB3375 Dutch 565117670052

* CRB3377 English 565117670054

* CRB3378 Russian 565117670054

* CRB3376 English 565117670053

* CRB3379 Portuguese(B) 565117670055

All operation manuals are supplied in PDF files by the CD-ROM.

Regarding the availability of paper manual, contact Pioneer Service representative in your region.

30

AVIC-U220/XZUC

Page 31

5678

56

7

8

C

D

F

A

B

E

AVIC-U220/XZUC

31

Page 32

1234

1234

C

D

F

A

B

E

9.2 EXTERIOR

DETACHABLE DEVICE

BASE UNIT

32

AVIC-U220/XZUC

Page 33

5678

56

7

8

C

D

F

A

B

E

(1) EXTERIOR SECTION PARTS LIST

Mark

Mark No. Description Part No.

1 •••••

2 TF-FRONT COVER ASSY See Contrast table (2)

3 TF-NAVI BD ASSY See Contrast table (2)

4 TF-BATTERY PACK 338937010176

5 TF-ADHESIVE 346172300200

6 TF-MYLAR 346161000900

7 TF-SPONGE 345172300100

8 TF-SCREW M1.6L3 371101610324

9 TF-REAR COVER 344176700400

10 TF-SCREW M1.6L4 371101610412

11 WINDOWS CE LABEL 242160500101

12 •••••

13 •••••

14 TF-CAP FRONT COVER CRADLE 344176700600

15 TF-SPRING CAP CRADLE 344176700800

No. Description Part No.

16 TF-SPRING-SPRING CAP COVER 341176700100

17 TF-RAIL FRONT COVER CRADLE 344176700700

18 TF-HOOK BUTTON CRADLE 344176700900

19 TF-SPRING-HOOK BUTTON 341176700200

20 TF-CRADLE BD ASSY See Contrast table (2)

21 Connector(GPS) CKS5702

22 Connector(RGB) CKS4497

23 Connector(TMC) See Contrast table (2)

24 Fuse(3.15 A) CEK1259

>

25 TF-SCREW M1.6L3 371101610324

26 TF-REAR COVER CRADLE See Contrast table (2)

27 TF-SCREW M1.6L4 371101610412

28 •••••

29 Connector 331510032004

30 Connector 331510032003

(2) CONTRAST TABLE

AVIC-U220/XZUC, AVIC-F220/XZEU5, AVIC-F220/XZUW5, AVIC-F220/XZAU and AVIC-F220/XZCS are constructed the same except for the following:

Mark No. Description

2 TF-FRONT COVER

ASSY

3 TF-NAVI BD ASSY 441176700022 441176700023 441176700025 441176700024 441176700026

20 TF-CRADLE BD

ASSY

23 Connector(TMC) Not used CKS6115 Not used CKS6115 Not used

26 TF-REAR COVER

CRADLE

AVIC -U220

/XZUC

340176700200 340176700100 340176700100 340176700100 340176700100

411176700009 411176700011 411176700009 411176700011 411176700009

344176701200 344176701000 344176701200 344176701000 344176701200

AVIC -F220

/XZEU5

AVIC -F220

/XZUW5

AVIC -F220

/XZAU

AVIC -F220

/XZCS

AVIC-U220/XZUC

33

Loading...

Loading...