Page 1

_Name_Bookmark2_

_Name_Bookmark2_

PNOZmulti Modbus/TCP

PNOZmulti Modular Safety System

Operating Manual — No. 1002104-EN-01

Page 2

_Name_Bookmark2_

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Page 3

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of documentation 1-1

1.1.1 Retaining the documentation 1-1

1.2 Overview of documentation 1-2

1.3 Definition of symbols 1-3

1.4 System requirements 1-4

Chapter 2 Communication via Modbus/TCP

2.1 Modbus/TCP - Basics 2-1

2.2 Modbus/TCP with PNOZmulti 2-2

Chapter 3 Modbus/TCP - Data areas

3.1 Overview 3-1

3.2 Function codes 3-2

3.3 Data transfer limits 3-3

3.4 Assignment of data areas 3-4

3.4.1 Virtual inputs 3-4

3.4.2 Control Register 3-5

3.4.3 Virtual outputs 3-6

3.4.4 LEDs 3-7

3.4.5 Configuration 3-7

3.4.6 State of the inputs from the base unit and

3-10

expansion modules

3.4.7 State of the outputs from the base unit and

3-11

expansion modules

3.4.8 LED status 3-12

3.4.9 Diagnostic word, element types 3-14

3.4.10 Current state of the virtual inputs 3-22

3.4.11 State of process data 3-23

3.5 Updating the data areas 3-24

3.6 Bit addressing in a Register 3-25

Chapter 4 Application example

4.1 Modbus subscriber 4-1

4.2 Data exchange via Modbus/TCP 4-2

4.3 Device configuration 4-5

4.3.1 Modular safety system PNOZmulti 4-5

4.3.2 PSSu system in the automation system

PSS 4000

4.3.3 Operator terminal PMI 4-9

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-6

1

Page 4

Contents

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 5

1 Introduction

1.1 Validity of documentation

11000IntroductionIntroduction1-1.1Validity of docume ntation1100Validity of documenta tion1-Einf Einleitung

This operating manual explains the function and operation, describes

the installation and provides guidelines on how to connect the product .

1.1.1 Retaining the documentation

Retaining the documentation1-Einf Aufbewahren

This documentation is intended for instruction and should be retained

for future reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

Page 6

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-Einf_Uebersicht_über_die_Doku_6_Inbetriebnahme

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the product's most important features.

3 Safety

This chapter must be read as it contains important information on safety

and intended use.

4 Function Description

This chapter describes the product's mode of operation.

5 Installation

This chapter explains how to install the product.

6 Commissioning

This chapter describes the product's commissioning and wiring.

7 Operation

This chapter describes how to operate the product and gives tips in the

case of a fault.

8 Technical Details

This chapter contains the product's technical details and order reference.

1-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 7

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the product or devices could

be damaged and also provides information on preventive measures that can be taken.

INFORMATION

This gives advice on applications and provides information on

special features, as well as highlighting areas within the text that

are of particular importance.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

Page 8

1 Introduction

1.4 System requirements

1.4System requirements1400System requirements1-Systemvoraussetzungen Modbus

` PNOZmulti Configurator: From Version 7.1.0

` Base unit PNOZ m0p ETH: From Version 1.0

` Base unit PNOZ m1p ETH: From Version 2.1

` Base unit PNOZ m2p ETH: From Version 1.0

` Base unit PNOZ m3p ETH: From Version 1.0

` Expansion module PNOZ mmc1p ETH from Version 1.0

Please contact Pilz if you have an older version.

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 9

2 Communication via Modbus/TCP

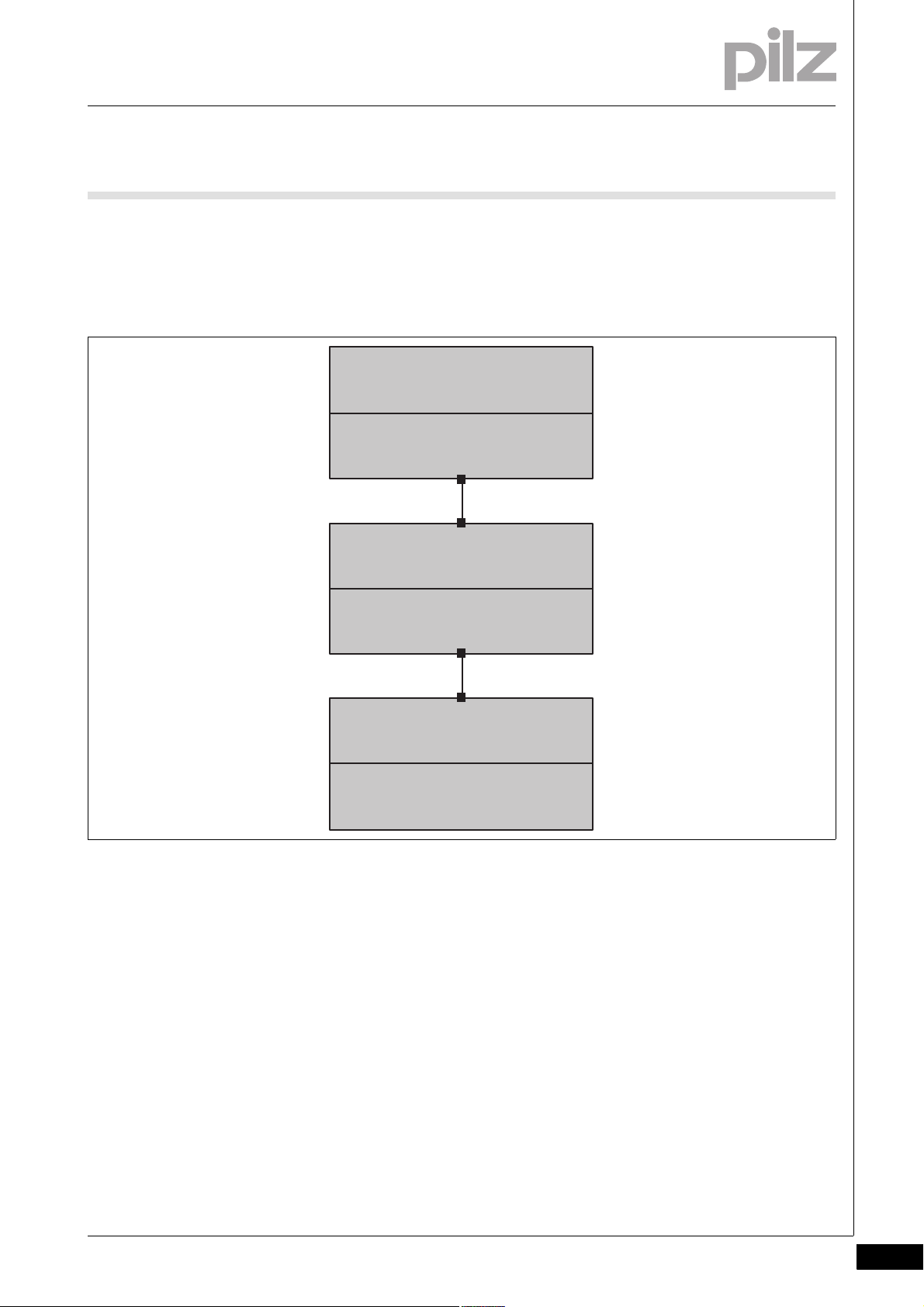

2.1 Modbus/TCP - Basics

22000Communication via Modbus/TCPCommunication via Modbus/TCP2-2.1 Modbus/TCP - Basics2100 Modbus/TCP - Basics2-ModbusTCP_Modbus/TCP Allg-1

Modbus is an open fieldbus standard published by the User Group

MODBUS-IDA (see www.Modbus-IDA.org).

Application Layer

Protocol

Modbus/TCP

TCP

(RFC 793)

IP

(RFC 791)

Industrial Ethernet

Physical Layer

Ethernet

Modbus/TCP is a protocol based on Industrial Ethernet (TCP/IP over

Ethernet). It is a protocol with Client/Server communication. Data is

transferred via a request/response mechanism using function codes

(FC).

Modbus/TCP is connection-oriented, i.e. before usable data is transferred via Modbus/TCP, a connection must first be established between

two Modbus/TCP interfaces. The initiator of the connection is called the

Client. The communications partner with which the Client establishes

the connection is called the Server. Whether a connection on a device

assumes the role of Client or Server is defined when a connection is configured. As a result, the Server/Client role only applies for the used connection.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

Page 10

2 Communication via Modbus/TCP

2.2 Modbus/TCP with PNOZmulti

2.2Modbus/TCP with PNOZmulti2200Modbus/TCP with PNOZmulti2-ModbusTCP_Modbus/TCP Allg-2-PNOZmulti

All base units from the modular safety system PNOZmulti that have an

Ethernet interface (PNOZ m1p ETH from V2.1) support Modbus/TCP.

The same applies for the base units PNOZmulti Mini in conjunction with

a communication module with Ethernet interface.

A PNOZmulti base unit can manage a max. of 8 Modbus/TCP connections. The PNOZmulti is always the Server in a connection. The Clients

in the connections may be various devices, e.g. PC (PNOZmulti Configurator), control system, display unit. They can access the modular safety

system PNOZmulti simultaneously.

The virtual I/Os plus all the information that is polled during fieldbus

communication are contained in data areas. The data is accessed directly. It's no longer necessary to switch via table/segment.

2-2

The configurations required for Modbus/TCP are fully pre-configured in

the PNOZmulti operating system. All that's necessary in the PNOZmulti

Configurator is to activate the virtual inputs and outputs (see PNOZmulti

Configurator's online help, under "Display and edit module selection").

On a modular control system PNOZmulti, port number "502" is fixed as

the default for data exchange via a Modbus/TCP connection. It is not

displayed in the PNOZmulti Configurator and cannot be modified.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 11

3 Modbus/TCP - Data areas

3.1 Overview

33000Modbus/TCP - Data areasModbus/TCP - Data areas3-3.1Overview3100Overview3-ModbusTCP_Modbus/TCP-Datenbereiche-PNOZmulti

A modular safety system PNOZmulti supports the following Modbus/

TCP data areas:

Data area Modbus syntax Example

Coils (Bit)

0x00000 … 0x65535

[read/write]

Discrete Inputs (Bit)

1x00000 … 1x65535

[read only]

Input Register (Word/16 Bits)

3x00000 … 3x65535

[read only]

Holding Register (Word/16 Bits)

4x00000 … 4x65535

[read/write]

0x[xxxxx] 0x00031

(virtual input i31)

1x[xxxxx] 1x08193

(virtual output o1)

3x[xxxxx] 3x00002

(virtual inputs 32 ... 47)

4x[xxxxx] 4x00805

(project name, 1st character)

INFORMATION

Addressing for PNOZmulti systems starts at “0”. On devices

from other manufacturers, addressing can start at “1”.

Please refer to the operating manual provided by the relevant

manufacturer.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

Page 12

3 Modbus/TCP - Data areas

3.2 Function codes

3.2Function codes3200Function codes3-ModbusTCP_Function Codes-PNOZmulti

The following function codes (FC) are available for communication with

the modular safety system PNOZmulti via Modbus/TCP:

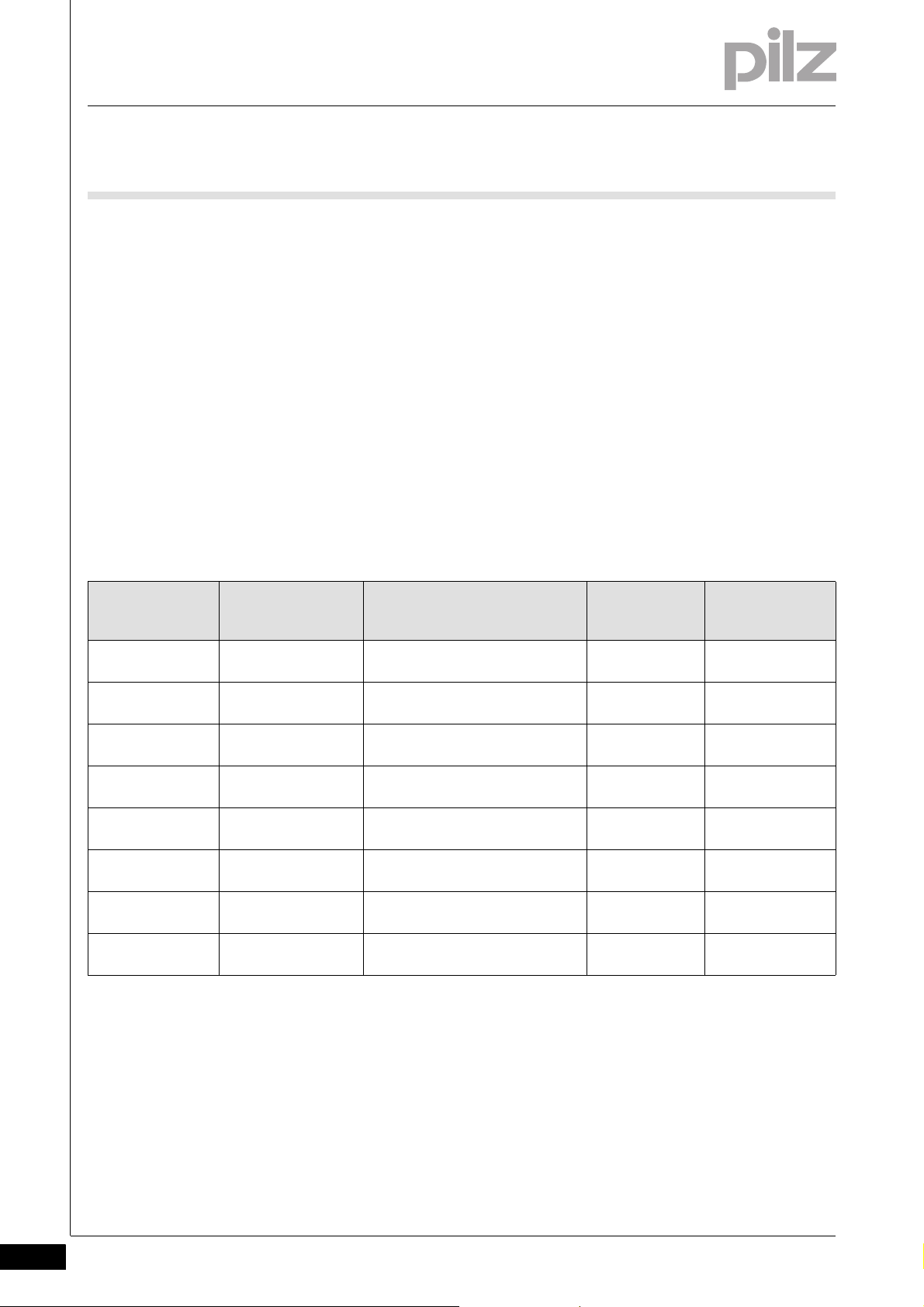

Function code Function

FC 01 Read Coils The Client in a connection reads bit data from the Server in the con-

nection,

data length ≥ 1 Bit, content: input/output data

(data received from 0x)

FC 02 Read Discrete Input The Client in a connection reads bit data from the Server in the con-

nection,

data length ≥ 1 Bit, content: input/output data

(data received from 1x)

FC 03 Read Holding Register The Client in a connection reads word data from the Server in the

connection,

data length ≥ 1 Word, content: diagnostic word

(data received from 4x)

FC 04 Read Input Register The Client in the connection reads word data from the Server in the

connection,

data length ≥ 1 Word, content: diagnostic word

(data received from 3x)

FC 05 Write Single Coil The Client in the connection writes to one bit datum in the Server in

the connection,

data length = 1 Bit, content: input data

(send data to 0x)

FC 06 Write Single Register The Client in the connection writes to one word datum in the Server

in the connection,

data length = 1 Word, content: input data

(send data to 4x)

FC 15 Write Multiple Coils The Client in the connection writes to multiple bit data in the Server

in the connection,

data length ≥ 1 Bit, content: input data

(send data to 0x)

FC 16 Write Multiple Registers The Client in a connection writes to multiple word data in the Server

in the connection,

data length = 1 Word, content: input data

(send data to 4x)

FC 23 Read/Write Multiple Reg-

isters

The Client in a connection reads and writes multiple word data within

a telegram

(receive data from 3x and send data to 4x)

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 13

3 Modbus/TCP - Data areas

3.3 Data transfer limits

3.3Data transfer limits3300Data transfer limits3-ModbusTCP_Grenzen Datenübertragung-PNOZmulti

The following table contains information on the maximum data length

per telegram that is supported:

Data transfer Max. data length per telegram

Read data

(Bit)

Read data

(Bit)

Read data

(Word)

Write data

(Word)

Read and write

data (Word)

FC 01 (Read Coils) 1 … 2000

FC 02 (Read Discrete Inputs)

FC 05 (Write Single Coil) 1 Bit

FC 15 (Write Multiple Coils) 1 … 1968

FC 03 (Read Holding Registers) 1 … 125

FC 04 (Read Input Register)

FC 06 (Write Single Register) 1 Word

FC 16 (Write Multiple Registers) 1 … 123 Words

FC 23 (Read/Write Multiple Registers) Read 1 … 125 Words

Write 1 … 121 Words

INFORMATION

There may be some restrictions in data length, depending on the

device that is used. Please refer to the information stated in the

operating manual of the device you are using.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-3

Page 14

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

3.4Assignment of data areas3400Assignment of data areas3-ModbusTCP_Coil and Register Map-Einleitung-PNOZmulti

Data can be accessed via various Modbus/TCP data areas.

The tables below show the relationship between Modbus/TCP data areas and the content of the data areas.

3.4.1 Virtual inputs

Virtual inputs3-ModbusTCP_Datenbereiche-Virtuelle Eingänge-PNOZmulti

The table below describes the Modbus/TCP data areas that contain the

current state of the virtual inputs on the PNOZmulti. These are the virtual

inputs that can be set by the user.

Relevant areas for the data are defined in each Modbus/TCP data area

(Coils (0x), Discrete Inputs (1x), Input Register (3x), Holding Register

(4x)). Read/write access will depend on the Modbus/TCP data area.

Register

(3x, 4x)

0 15... 0 State of the inputs

1 31... 6 State of the inputs

2 47...32 State of the inputs

3 63...48 State of the inputs

4 79... 64 State of the inputs

5 95...80 State of the inputs

6 111...96 State of the inputs

7 127...112 State of the inputs

Coil/

Discrete Input

(0x, 1x)

Content High Byte Low Byte

0...15

16...31

32...47

48...63

64...79

80...95

96...111

112...127

i15…i8 i7…i0

i31…i24 i23…i16

i47…i40 i39…i32

i63…i56 i55…i48

i79…i72 i71…i64

i95…i88 i87…i80

i111…i104 i103…i96

i127…i120 i119…i112

3-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

3.4.2 Control Register

Control Register3-ModbusTCP_Datenbereiche-Control Register-PNOZmulti

A watchdog can be activated in Control Register 255.

If no input bits are set by a Modbus/TCP subscriber within the preset

time, the PNOZmulti will set the input bits to "0".

The table below describes the Modbus/TCP data areas for the watchdog.

A relevant area for the watchdog is defined in each Modbus/TCP data

area (Coils (0x), Discrete Inputs (1x), Input Register (3x), Holding Register

(4x)). Read/write access will depend on the Modbus/TCP data area.

Register

(3x, 4x)

255 4095...4080 Control Register See table below

High Byte WD-Trig-

ger

Low Byte Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Coil/

Discrete Input

(0x, 1x)

Error Message

Content High Byte Low Byte

Reserved Reserved Reserved W-Timer

Bit 2

W-Timer

Bit 1

W-Timer

Bit 0

Bit 15 "Watchdog Trigger": The watchdog can be triggered by setting Bit

15 constantly to "1", or by a Client writing in the input area of the 128

inputs. The state of the bit when reading is undefined. A 1 or a 0 can be

read.

Bit 14 "Error Message": If this bit is set, an error stack entry is generated

when the watchdog is triggered.

Bit 10 … 8 "WD Timer": If the set time for the watchdog is set, then Bit

15 must be set, or become set, at the same time.

Watchdog Timer Bit 2 Watchdog Timer Bit 1 Watchdog Timer Bit 0 Watchdog time

000Timer deactivated

001100 ms

010200 ms

011500 ms

1001 s

1013 s

1105 s

11110 s

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-5

Page 16

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

INFORMATION

To check whether the watchdog has been triggered, set a virtual

input permanently to "1".

If this input is "0", then the watchdog has been triggered.

3.4.3 Virtual outputs

Virtual outputs3-ModbusTCP_Datenbereiche-Virtuelle Ausgänge-PNOZmulti

The table below describes the Modbus/TCP data areas that contain the

state of the virtual outputs on the PNOZmulti.

Relevant areas for the data are defined in the Modbus/TCP data areas

Discrete Inputs (1x) and Input Register (3x). Read access is available to

these data areas.

Register

(3x)

512 8207...8192 State of the outputs

513 8223...8208 State of the outputs

514 8239...8224 State of the outputs

515 8255...8240 State of the outputs

516 8271...8256 State of the outputs

517 8287...8272 State of the outputs

518 8303...8288 State of the outputs

519 8319...8304 State of the outputs

Discrete Input

(1x)

Content High Byte Low Byte

0...15

16...31

32...47

48...63

64...79

80...95

96...111

112...127

o15…o8 o7…o0

o31…o24 o23…o16

o47…o40 o39…o32

o63…o56 o55…o48

o79…o72 o71…o64

o95…o88 o87…o80

o111…o104 o103…o96

o127…o120 o119…o112

3-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

3.4.4 LEDs

LEDs3-ModbusTCP_Datenbereiche-LEDs-PNOZmulti

The table below describes the Modbus/TCP data areas that contain the

LED status.

Relevant areas for the data are defined in the Modbus/TCP data areas

Discrete Inputs (1x) and Input Register (3x). Read access is available to

these data areas.

Register

(3x)

520 8335...8320 8 Bit LED status;

521…783 Reserved

Discrete Input

(1x)

Content High Byte Low Byte

8 Bit reserved

Bit 0 = 1: LED OFAULT illuminates or flashes

Bit 1 = 1: LED IFAULT illuminates or flashes

Bit 2 = 1: LED FAULT illuminates or flashes

Bit 3 = 1: LED DIAG illuminates or flashes

Bit 4 = 1: LED RUN illuminates

Bit 5: Reserved

Bit 6: Reserved

Bit 7: Reserved

3.4.5 Configuration

Configuration3-ModbusTCP_Datenbereiche-Konfiguration-PNOZmulti

The table below describes the Modbus/TCP data areas that contain the

device data from the base unit and the project data. The data was defined in the PNOZmulti Configurator.

Reserved PNOZmulti LEDs

Relevant areas for the data are defined in the Modbus/TCP data areas

Discrete Inputs (1x) and Input Register (3x). Read access is available to

these data areas.

Register

(3x)

784 12559... 12544 Product number HH Byte HL Byte

785 12575... 12560 Product number LH Byte LL Byte

786 12591... 12576 Device version HH Byte HL Byte

787 12607... 12592 Device version LH Byte LL Byte

788 12623... 12608 Serial number HH Byte HL Byte

789 12639... 12624 Serial number LH Byte LL Byte

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Discrete Input

(1x)

Content High Byte Low Byte

3-7

Page 18

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

790 12655... 12640 Reserved

791 12671... 12656 Project check sum H Byte L Byte

792 12687... 12672 Chip card check sum H Byte L Byte

793 12703... 12688 Project date Day Month

794 12719... 12704 Project date Year (H Byte) Year (L Byte)

795 12735... 12720 Operating hours HL Byte LH Byte

796 12751... 12736 Operating hours / Type of base

797 12767... 12752 Reserved

798 12783... 12768 Configuration, fieldbus modules /

799 12799... 12784 Configuration, expansion module,

800 12815... 12800 Configuration, expansion module,

801 12831... 12816 Configuration, expansion module,

802 12847... 12832 Configuration, expansion module,

803 12863... 12848 Reserved

804 12879... 12864 Reserved

805 12895... 12880 Project name 1stcharacter (H

806 12911... 12896 Project name 2nd character (H

807 12927... 12912 Project name 3rd character (H

808 12943... 12928 Project name 4th character (H

809 12959... 12944 Project name 5th character (H

810 12975... 12960 Project name 6th character (H

811 12991... 12976 Project name 7th character (H

812 13007... 12992 Project name 8th character (H

813 13023... 13008 Project name 9th character (H

814 13039... 13024 Project name 10th character

815 13055... 13040 Project name 11th character

Discrete Input

(1x)

Content High Byte Low Byte

LL Byte Type

unit

Slot 1 Fieldbus

RS232 / expansion module, right

Slot 3 Slot 2

right

Slot 5 Slot 4

right

Slot 7 Slot 6

right

Reserved Slot 8

right

1st character (L

Byte)

Byte)

Byte)

Byte)

Byte)

Byte)

Byte)

Byte)

Byte)

(H Byte)

(H Byte)

Byte)

2nd character (L

Byte)

3rd character (L

Byte)

4th character (L

Byte)

5th character (L

Byte)

6th character (L

Byte)

7th character (L

Byte)

8th character (L

Byte)

9th character (L

Byte)

10th character (L

Byte)

11th character (L

Byte)

3-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

816 13071... 13056 Project name 12th character

817 13087... 13072 Project name 13th character

818 13103... 13088 Project name 14th character

819 13119... 13104 Project name 15th character

820 13135... 13120 Project name 16th character

821 13151... 13136 Project name 0xFF 0xFF

822 13167... 13152 Reserved

823 13183... 13168 Reserved

824 13199... 13184 Reserved

825 13215... 13200 Reserved

826 13231... 13216 Project date Day Month

827 13247... 13232 Project date Year (H Byte) Year (L Byte)

828 13263... 13248 Project date Hour Minute

829 13279... 13264 Project date Time zone Reserved

830 13295... 13280 Reserved

831 13311... 13296 Reserved

832 13327... 13312 Reserved

833 13343... 13328 Fieldbus type Fieldbus type

834 13359... 13344 Fieldbus module software version Version Reserved

835 13375... 13360 Reserved

836 13391... 13376 Reserved

837 13407... 13392 Reserved

838 13423... 13408 Reserved

839 13439... 13424 Reserved

840 13455... 13440 Configuration, expansion module,

841 13471... 13456 Configuration, expansion module,

842 13487... 13472 Configuration, expansion module,

843 13503... 13488 Reserved

844 13519... 13504 Reserved

845 13535... 13520 Reserved

846 13551... 13536 Reserved

Discrete Input

(1x)

Content High Byte Low Byte

12th character (L

(H Byte)

(H Byte)

(H Byte)

(H Byte)

(H Byte)

(H Byte)

Slot 2 Slot 1

left

Slot 4 Slot 3

left

Slot 6 Slot 5

left

Byte)

13th character (L

Byte)

14th character (L

Byte)

15th character (L

Byte)

16th character (L

Byte)

Fieldbus type

(L Byte)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-9

Page 20

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

3.4.6 State of the inputs from the base unit and expansion modules

State of the inputs from the base unit and expansion modules3-ModbusTCP_Datenbereiche-Status Eingänge Basisgerät u Module-PNOZmulti

The table below describes the Modbus/TCP data areas that contain the

state of the inputs from the base unit and expansion modules.

Relevant areas for the data are defined in the Modbus/TCP data areas

Discrete Inputs (1x) and Input Register (3x). Read access is available to

these data areas.

Register

(3x)

847 13567... 13552 Base unit i0 - i15 i15 ….i8 i7 ….i0

848 13583... 13568 Base unit i16 - 23 Reserved i23...i16

849 13599... 13584 Reserved /

850 13615... 13600 Expansion module, right Right 3 (i7...i0) Right 2 (i7...i0)

851 13631... 13616 Expansion module, right Right 5 (i7...i0) Right 4 (i7...i0)

852 13647... 13632 Expansion module, right Right 7 (i7...i0) Right 6 (i7...i0)

853 13663... 13648 Expansion module, right / re-

854 13679... 13664 Expansion module, left Left 1 (i15…i8) Left 1 (i7…i0)

855 13695... 13680 Expansion module, left Left 1 (i31…i24) Left 1 (i23…i16)

856 13711... 13696 Expansion module, left Left 2 (i15…i8) Left 2 (i7…i0)

857 13727... 13712 Expansion module, left Left 2 (i31…i24) Left 2 (i23…i16)

858 13743... 13728 Expansion module, left Left 3 (i15…i8) Left 3 (i7…i0)

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

Right 1 (i7...i0) Reserved

expansion module, right

Reserved Right 8 (i7...i0)

served

3-10

859 13759... 13744 Expansion module, left Left 3 (i31…i24) Left 3 (i23…i16)

860 13775... 13760 Reserved

861 13791... 13776 Expansion module, left Left 4 (i15…i8) Left 4 (i7…i0)

862 13807... 13792 Expansion module, left Left 4 (i31…i24) Left 4 (i23…i16)

863 13823... 13808 Expansion module, left Left 5 (i15…i8) Left 5 (i7…i0)

864 13839... 13824 Expansion module, left Left 5 (i31…i24) Left 5 (i23…i16)

865 13855... 13840 Expansion module Left 6 (i15…i8) Left 6 (i7…i0)

866 13871... 13856 Expansion module, left Left 6 (i31…i24) Left 6 (i23…i16)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

867 13887... 13872 Reserved

868 13903... 13888 0 0 0

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

Register 854 to 866"Expansion module, left"

Please note: for analogue input modules, the content for "High Byte"

and "Low Byte" is transposed.

3.4.7 State of the outputs from the base unit and expansion modules

State of the outputs from the base unit and expansion modules3-ModbusTCP_Datenbereiche-Status Ausgänge Basisgerät u Module-PNOZmulti

The table below describes the Modbus/TCP data areas that contain the

state of the outputs from the base unit and expansion modules.

Relevant areas for the data are defined in the Modbus/TCP data areas

Discrete Inputs (1x) and Input Register (3x). Read access is available to

these data areas.

Register

(3x)

869 13919... 13904 0 / Base unit o0 - 03 4 Bit re-

870 13935... 13920 Base unit o4 - o5 / expansion

871 13951... 13936 Expansion module Right 3 o7…o0 Right 2 o7…o0

872 13967... 13952 Expansion module, right Right 5 o7…o0 Right 4 o7…o0

873 13983... 13968 Expansion module, right Right 7 o7…o0 Right 6 o7…o0

874 13999... 13984 Expansion module, right

875 14015... 14000 0 0 0

876 14031... 14016 0 0 0

877 14047... 14032 0 / Expansion module, right Right 1 o15…o8 0

878 14063... 14048 Expansion module, right Right 3 o15…o8 Right 2 o15…o8

879 14079... 14064 Expansion module, right Right 5 o15…o8 Right 4 o15…o8

880 14095... 14080 Expansion module, right Right 7 o15…o8 Right 6 o15…o8

881 14111... 14096 Expansion module, right / res Reserved Right 8 o15…o8

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

0

served..o3…o0

Right 1 o7…o0 6 Bit reserved

module, right

Reserved Right 8 o7…o0

/ res

o5,o4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-11

Page 22

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

882 14127... 14112 Expansion module, left Left 1 (o15…o8) Left 1 (o7…o0)

883 14143... 14128 Expansion module, left Left 1 (o31…o24) Left 1 (o23…o16)

884 14159... 14144 Expansion module, left Left 2 (o15…o8) Left 2 (o7…o0)

885 14175... 14160 Expansion module, left Left 2 (o31…o24) Left 2 (o23…o16)

886 14191... 14176 Expansion module, left Left 3 (o15…o8) Left 3 (o7…o0)

887 14207... 14192 Expansion module, left Left 3 (o31…o24) Left 3 (o23…o16)

888 14223... 14208 0

889 14239... 14224 Expansion module, left Left 4 (o15…o8) Left 4 (o7…o0)

890 14255... 14240 Expansion module, left Left 4 (o31…o24) Left 4 (o23…o16)

891 14271... 14256 Expansion module, left Left 5 (o15…o8) Left 5 (o7…o0)

892 14287... 14272 Expansion module, left Left 5 (o31…o24) Left 5 (o23…o16)

893 14303... 14288 Expansion module, left Left 6 (o15…o8) Left 6 (o7…o0)

894 14319... 14304 Expansion module, left Left 6 (o31…o24) Left 6 (o23…o16)

895 14335... 14320 0

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

3.4.8 LED status

LED status3-ModbusTCP_Datenbereiche-Status-LEDs

The table below describes the Modbus/TCP data areas that contain the

LED status.

Relevant areas for the data are defined in the Modbus/TCP data areas

Discrete Inputs (1x) and Input Register (3x). Read access is available to

these data areas.

Register

(3x)

896 14351... 14336 LEDs RUN / DIAG Diag Run

897 14367... 14352 LEDs FAULT/IFAULT I Fault Fault

898 14383... 14368 LEDs OFAULT / Expansion mod-

899 14399... 14384 LEDs expansion module, right Right 3 Right 2

900 14415... 14400 LEDs Right 5 Right 4

901 14431... 14416 LEDs Right 7 Right 6

902 14447... 14432 LEDs / res Reserved Right 8

903 14463... 14448 LED base unit i0 - i15 LED i15…i8 LED i7…i0

904 14479... 14464 LED base unit i16-i19 / 0 0 LED i19…i16

905 14495... 14480 0 / LEDs expansion module, right LED right 1 0

906 14511... 14496 LEDs expansion module, right LED right 3 LED right 2

Discrete Input

(1x)

Content High Byte Low Byte

Right 1 O Fault

ule, right

3-12

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

907 14527... 14512 LEDs expansion module, right LED right 5 LED right 4

908 14543... 14528 LEDs expansion module, right LED right 7 LED right 6

909 14559... 14544 LED right 8 / res Reserved LED right 8

910 14575... 14560 LEDs fieldbus status LED 2 LED 1

911 14591... 14576 LEDs fieldbus status LED 4 LED 3

912 14607... 14592 0

913 14623... 14608 0

914 14639... 14624 0

915 14655... 14640 0

916 14671... 14656 0

917 14687... 14672 LEDs speed monitor 1 Axis 2 Axis 1

918 14703... 14688 LEDs speed monitor 2 Axis 2 Axis 1

919 14719... 14704 LEDs speed monitor 3 Axis 2 Axis 1

920 14735... 14720 LEDs speed monitor 4 Axis 2 Axis 1

921 14751... 14736 0

922 14767... 14752 0

923 14783... 14768 0

924 14799... 14784 LEDs expansion module, left Left 2 Left 1

925 14815... 14800 LEDs expansion module, left Left 4 Left 3

926 14831... 14816 LEDs expansion module, left Left 6 Left 5

927 14847... 14832 0

928 14863... 14848 0

929 14879... 14864 0

930 14895... 14880 0

Discrete Input

(1x)

Content High Byte Low Byte

Register 896 "LEDs" and Register 924 to 926 “LEDs expansion module, left"

0x00 = LED off

0xFF = LED on

0x30 = LED flashes

Register 910 to 911 "LEDs fieldbus"

Position of LED1 ... LED4:

PNOZ mc...

LED4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

LED1LED3

LED2

3-13

Page 24

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

0x00 = LED off

0xFF = LED green

0x30 = LED red

The LED functions are described in the relevant operating manual.

Register 917 to 920 "LEDs speed monitor 1 ... 4"

State of the LEDs on the speed monitors

PNOZ ms1p, PNOZ ms2p:

I10, I11, I20, I21, X12, X22

PNOZ ms3p:

X12, X22

PNOZ ms4p:

X12

Bit 76543210

Axis 1 0 0 I11 I11 I10 I10 0 X12

Axis 2 0 0 I21 I21 I20 I20 0 X22

LEDs for proximity switch: I10, I11, I20, I21:

If the LED is lit, the corresponding Bit will contain “1”. The proximity

switch is energised.

LEDs for incremental encoder: X12, X22:

If the LED is lit, the corresponding Bit will contain “1”; The incremental

encoder is connected correctly.

The LED functions are described in the operating manuals for the speed

monitors.

3.4.9 Diagnostic word, element types

Diagnostic word, element types3-ModbusTCP_Datenbereiche-Diagnosewort-Elementtypen

The table below describes the Modbus/TCP data areas that contain information on the elements in the PNOZmulti Configurator and the diagnostic word.

Relevant areas for the data are defined in the Modbus/TCP data areas

Discrete Inputs (1x) and Input Register (3x). Read access is available to

these data areas.

3-14

Register

(3x)

931 14911... 14896 Number of elements that can

932 14927... 14912 Reserved

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

store a state

0Number

Page 25

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

933 14943... 14928 Reserved

934 14959... 14944 Reserved

935 14975... 14960 Reserved

936 14991... 14976 Reserved

937 15007... 14992 Reserved

938 15023... 15008 Element enable 1-16 16…9 8…1

939 15039... 15024 Element enable 17-32 32…25 24…16

940 15055... 15040 Element enable 33-48 48…41 40…33

941 15071... 15056 Element enable 49-64 64…57 56…49

942 15087... 15072 Element enable 65-80 80…73 72…65

943 15103... 15088 Element enable 81-96 96…89 88…81

944 15119... 15104 Element enable 96-100 / reserved Reserved 100…96

945 15135... 15120 Reserved

946 15151... 15136 Reserved

947 15167... 15152 Reserved

948 15183... 15168 Reserved

949 15199... 15184 Reserved

950 15215... 15200 Reserved

951 15231... 15216 Reserved

952 15247... 15232 Diagnostic word 1 Bit 15… 8 Bit 7… 0

953 15263... 15248 Diagnostic word 2 Bit 15… 8 Bit 7… 0

954 15279... 15264 Diagnostic word 3 Bit 15… 8 Bit 7… 0

955 15295... 15280 Diagnostic word 4 Bit 15… 8 Bit 7… 0

956 15311... 15296 Diagnostic word 5 Bit 15… 8 Bit 7… 0

957 15327... 15312 Diagnostic word 6 Bit 15… 8 Bit 7… 0

958 15343... 15328 Diagnostic word 7 Bit 15… 8 Bit 7… 0

959 15359... 15344 Diagnostic word 8 Bit 15… 8 Bit 7… 0

960 15375... 15360 Diagnostic word 9 Bit 15… 8 Bit 7… 0

961 15391... 15376 Diagnostic word 10 Bit 15… 8 Bit 7… 0

962 15407... 15392 Diagnostic word 11 Bit 15… 8 Bit 7… 0

963 15423... 15408 Diagnostic word 12 Bit 15… 8 Bit 7… 0

964 15439... 15424 Diagnostic word 13 Bit 15… 8 Bit 7… 0

965 15455... 15440 Diagnostic word 14 Bit 15… 8 Bit 7… 0

966 15471... 15456 Diagnostic word 15 Bit 15… 8 Bit 7… 0

967 15487... 15472 Diagnostic word 16 Bit 15… 8 Bit 7… 0

968 15503... 15488 Diagnostic word 17 Bit 15… 8 Bit 7… 0

969 15519... 15504 Diagnostic word 18 Bit 15… 8 Bit 7… 0

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-15

Page 26

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

970 15535... 15520 Diagnostic word 19 Bit 15… 8 Bit 7… 0

971 15551... 15536 Diagnostic word 20 Bit 15… 8 Bit 7… 0

972 15567... 15552 Diagnostic word 21 Bit 15… 8 Bit 7… 0

973 15583... 15568 Diagnostic word 22 Bit 15… 8 Bit 7… 0

974 15599... 15584 Diagnostic word 23 Bit 15… 8 Bit 7… 0

975 15615... 15600 Diagnostic word 24 Bit 15… 8 Bit 7… 0

976 15631... 15616 Diagnostic word 25 Bit 15… 8 Bit 7… 0

977 15647... 15632 Diagnostic word 26 Bit 15… 8 Bit 7… 0

978 15663... 15648 Diagnostic word 27 Bit 15… 8 Bit 7… 0

979 15679... 15664 Diagnostic word 28 Bit 15… 8 Bit 7… 0

980 15695... 15680 Diagnostic word 29 Bit 15… 8 Bit 7… 0

981 15711... 15696 Diagnostic word 30 Bit 15… 8 Bit 7… 0

982 15727... 15712 Diagnostic word 31 Bit 15… 8 Bit 7… 0

983 15743... 15728 Diagnostic word 32 Bit 15… 8 Bit 7… 0

984 15759... 15744 Diagnostic word 33 Bit 15… 8 Bit 7… 0

985 15775... 15760 Diagnostic word 34 Bit 15… 8 Bit 7… 0

986 15791... 15776 Diagnostic word 35 Bit 15… 8 Bit 7… 0

987 15807... 15792 Diagnostic word 36 Bit 15… 8 Bit 7… 0

988 15823... 15808 Diagnostic word 37 Bit 15… 8 Bit 7… 0

989 15839... 15824 Diagnostic word 38 Bit 15… 8 Bit 7… 0

990 15855... 15840 Diagnostic word 39 Bit 15… 8 Bit 7… 0

991 15871... 15856 Diagnostic word 40 Bit 15… 8 Bit 7… 0

992 15887... 15872 Diagnostic word 41 Bit 15… 8 Bit 7… 0

993 15903... 15888 Diagnostic word 42 Bit 15… 8 Bit 7… 0

994 15919... 15904 Diagnostic word 43 Bit 15… 8 Bit 7… 0

995 15935... 15920 Diagnostic word 44 Bit 15… 8 Bit 7… 0

996 15951... 15936 Diagnostic word 45 Bit 15… 8 Bit 7… 0

997 15967... 15952 Diagnostic word 46 Bit 15… 8 Bit 7… 0

998 15983... 15968 Diagnostic word 47 Bit 15… 8 Bit 7… 0

999 15999... 15984 Diagnostic word 48 Bit 15… 8 Bit 7… 0

1000 16015... 16000 Diagnostic word 49 Bit 15… 8 Bit 7… 0

1001 16031... 16016 Diagnostic word 50 Bit 15… 8 Bit 7… 0

1002 16047... 16032 Diagnostic word 51 Bit 15… 8 Bit 7… 0

1003 16063... 16048 Diagnostic word 52 Bit 15… 8 Bit 7… 0

1004 16079... 16064 Diagnostic word 53 Bit 15… 8 Bit 7… 0

1005 16095... 16080 Diagnostic word 54 Bit 15… 8 Bit 7… 0

1006 16111... 16096 Diagnostic word 55 Bit 15… 8 Bit 7… 0

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

3-16

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

1007 16127... 16112 Diagnostic word 56 Bit 15… 8 Bit 7… 0

1008 16143... 16128 Diagnostic word 57 Bit 15… 8 Bit 7… 0

1009 16159... 16144 Diagnostic word 58 Bit 15… 8 Bit 7… 0

1010 16175... 16160 Diagnostic word 59 Bit 15… 8 Bit 7… 0

1011 16191... 16176 Diagnostic word 60 Bit 15… 8 Bit 7… 0

1012 16207... 16192 Diagnostic word 61 Bit 15… 8 Bit 7… 0

1013 16223... 16208 Diagnostic word 62 Bit 15… 8 Bit 7… 0

1014 16239... 16224 Diagnostic word 63 Bit 15… 8 Bit 7… 0

1015 16255... 16240 Diagnostic word 64 Bit 15… 8 Bit 7… 0

1016 16271... 16256 Diagnostic word 65 Bit 15… 8 Bit 7… 0

1017 16287... 16272 Diagnostic word 66 Bit 15… 8 Bit 7… 0

1018 16303... 16288 Diagnostic word 67 Bit 15… 8 Bit 7… 0

1019 16319... 16304 Diagnostic word 68 Bit 15… 8 Bit 7… 0

1020 16335... 16320 Diagnostic word 69 Bit 15… 8 Bit 7… 0

1021 16351... 16336 Diagnostic word 70 Bit 15… 8 Bit 7… 0

1022 16367... 16352 Diagnostic word 71 Bit 15… 8 Bit 7… 0

1023 16383... 16368 Diagnostic word 72 Bit 15… 8 Bit 7… 0

1024 16399... 16384 Diagnostic word 73 Bit 15… 8 Bit 7… 0

1025 16415... 16400 Diagnostic word 74 Bit 15… 8 Bit 7… 0

1026 16431... 16416 Diagnostic word 75 Bit 15… 8 Bit 7… 0

1027 16447... 16432 Diagnostic word 76 Bit 15… 8 Bit 7… 0

1028 16463... 16448 Diagnostic word 77 Bit 15… 8 Bit 7… 0

1029 16479... 16464 Diagnostic word 78 Bit 15… 8 Bit 7… 0

1030 16495... 16480 Diagnostic word 79 Bit 15… 8 Bit 7… 0

1031 16511... 16496 Diagnostic word 80 Bit 15… 8 Bit 7… 0

1032 16527... 16512 Diagnostic word 81 Bit 15… 8 Bit 7… 0

1033 16543... 16528 Diagnostic word 82 Bit 15… 8 Bit 7… 0

1034 16559... 16544 Diagnostic word 83 Bit 15… 8 Bit 7… 0

1035 16575... 16560 Diagnostic word 84 Bit 15… 8 Bit 7… 0

1036 16591... 16576 Diagnostic word 85 Bit 15… 8 Bit 7… 0

1037 16607... 16592 Diagnostic word 86 Bit 15… 8 Bit 7… 0

1038 16623... 16608 Diagnostic word 87 Bit 15… 8 Bit 7… 0

1039 16639... 16624 Diagnostic word 88 Bit 15… 8 Bit 7… 0

1040 16655... 16640 Diagnostic word 89 Bit 15… 8 Bit 7… 0

1041 16671... 16656 Diagnostic word 90 Bit 15… 8 Bit 7… 0

1042 16687... 16672 Diagnostic word 91 Bit 15… 8 Bit 7… 0

1043 16703... 16688 Diagnostic word 92 Bit 15… 8 Bit 7… 0

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-17

Page 28

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

1044 16719... 16704 Diagnostic word 93 Bit 15… 8 Bit 7… 0

1045 16735... 16720 Diagnostic word 94 Bit 15… 8 Bit 7… 0

1046 16751... 16736 Diagnostic word 95 Bit 15… 8 Bit 7… 0

1047 16767... 16752 Diagnostic word 96 Bit 15… 8 Bit 7… 0

1048 16783... 16768 Diagnostic word 97 Bit 15… 8 Bit 7… 0

1049 16799... 16784 Diagnostic word 98 Bit 15… 8 Bit 7… 0

1050 16815... 16800 Diagnostic word 99 Bit 15… 8 Bit 7… 0

1051 16831... 16816 Diagnostic word 100 Bit 15… 8 Bit 7… 0

1052 16847... 16832 Reserved

1053 16863... 16848 Reserved

1054 16879... 16864 Reserved

1055 16895... 16880 Reserved

1056 16911... 16896 Reserved

1057 16927... 16912 Reserved

1058 16943... 16928 Reserved

1059 16959... 16944 Reserved

1060 16975... 16960 Reserved

1061 16991... 16976 Reserved

1062 17007... 16992 Reserved

1063 17023... 17008 Reserved

1064 17039... 17024 Reserved

1065 17055... 17040 Reserved

1066 17071... 17056 Reserved

1067 17087... 17072 Reserved

1068 17103... 17088 Reserved

1069 17119... 17104 Reserved

1070 17135... 17120 Reserved

1071 17151... 17136 Element type Element ID = 2 Element ID = 1

1072 17167... 17152 Element type Element ID = 4 Element ID = 3

1073 17183... 17168 Element type Element ID = 6 Element ID = 5

1074 17199... 17184 Element type Element ID = 8 Element ID = 7

1075 17215... 17200 Element type Element ID = 10 Element ID = 9

1076 17231... 17216 Element type Element ID = 12 Element ID = 11

1077 17247... 17232 Element type 0 Element ID = 13

1078 17263... 17248 Element type Element ID = 15 Element ID = 14

1079 17279... 17264 Element type Element ID = 17 Element ID = 16

1080 17295... 17280 Element type Element ID = 19 Element ID = 18

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

3-18

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

1081 17311... 17296 Element type Element ID = 21 Element ID = 20

1082 17327... 17312 Element type Element ID = 23 Element ID = 22

1083 17343... 17328 Element type Element ID = 25 Element ID = 24

1084 17359... 17344 Element type 0 Element ID = 26

1085 17375... 17360 Element type Element ID = 15 Element ID = 27

1086 17391... 17376 Element type Element ID = 17 Element ID = 29

1087 17407... 17392 Element type Element ID = 19 Element ID = 31

1088 17423... 17408 Element type Element ID = 21 Element ID = 33

1089 17439... 17424 Element type Element ID = 23 Element ID = 35

1090 17455... 17440 Element type Element ID = 25 Element ID = 37

1091 17471... 17456 Element type 0 Element ID = 39

1092 17487... 17472 Element type Element ID = 41 Element ID = 40

1093 17503... 17488 Element type Element ID = 43 Element ID = 42

1094 17519... 17504 Element type Element ID = 45 Element ID = 44

1095 17535... 17520 Element type Element ID = 47 Element ID = 46

1096 17551... 17536 Element type Element ID = 49 Element ID = 48

1097 17567... 17552 Element type Element ID = 51 Element ID = 50

1098 17583... 17568 Element type 0 Element ID = 52

1099 17599... 17584 Element type Element ID = 54 Element ID = 53

1100 17615... 17600 Element type Element ID = 56 Element ID = 55

1101 17631... 17616 Element type Element ID = 58 Element ID = 57

1102 17647... 17632 Element type Element ID = 60 Element ID = 59

1103 17663... 17648 Element type Element ID = 62 Element ID = 61

1104 17679... 17664 Element type Element ID = 64 Element ID = 63

1105 17695... 17680 Element type 0 Element ID = 65

1106 17711... 17696 Element type Element ID = 67 Element ID = 66

1107 17727... 17712 Element type Element ID = 69 Element ID = 68

1108 17743... 17728 Element type Element ID = 71 Element ID = 70

1109 17759... 17744 Element type Element ID = 73 Element ID = 72

1110 17775... 17760 Element type Element ID = 75 Element ID = 74

1111 17791... 17776 Element type Element ID = 77 Element ID = 76

1112 17807... 17792 Element type 0 Element ID = 78

1113 17823... 17808 Element type Element ID = 80 Element ID = 79

1114 17839... 17824 Element type Element ID = 82 Element ID = 81

1115 17855... 17840 Element type Element ID = 84 Element ID = 83

1116 17871... 17856 Element type Element ID = 86 Element ID = 85

1117 17887... 17872 Element type Element ID = 88 Element ID = 87

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-19

Page 30

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Register

(3x)

1118 17903... 17888 Element type Element ID = 90 Element ID = 89

1119 17919... 17904 Element type 0 Element ID = 91

1120 17935... 17920 Element type Element ID = 93 Element ID = 92

1121 17951... 17936 Element type Element ID = 95 Element ID = 94

1122 17967... 17952 Element type Element ID = 97 Element ID = 96

1123 17983... 17968 Element type Element ID = 99 Element ID = 98

1124 17999... 17984 Element type Reserved Element ID = 100

1125 18015... 18000 Element type Reserved Reserved

1126 18031... 18016 Element type Reserved Reserved

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

Register 938 to 944 "Element enable 1 ... 100"

Each element is assigned an ID in the PNOZmulti Configurator. If the element's output = 0 (no enable), the corresponding bit is set.

Byte 0 87654321

Byte 1 161514131211109

Byte 2 2423222120191817

...

Byte 10 88 87 86 85 84 83 82 81

Byte 11 96 95 94 93 92 91 90 89

Byte 12 ----100999897

3-20

Register 1071 to 1126 "Element type"

The available element types are listed below.

Element type

(Byte)

01 Switch type 1: N/C contact

02 Switch type 1: N/C contact, monitored reset

03 Switch type 1: N/C contact, manual reset

04 Switch type 1: N/C contact, start-up test

05 Switch type 1: N/C contact, start-up test, monitored reset

06 Switch type 1: N/C contact, start-up test, manual reset

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Element

Function elements

Page 31

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

Element type

(Byte)

07 Switch type 2: N/C contact, N/O contact

08 Switch type 2: N/C contact, N/O contact, monitored reset

09 Switch type 2: N/C contact, N/O contact, manual reset

0A Switch type 2: N/C contact, N/O contact, start-up test

0B Switch type 2: N/C contact, N/O contact, start-up test, monitored reset

0C Switch type 2: N/C contact, N/O contact, start-up test, manual reset

0D Switch type 3: N/C contact, N/C contact

0E Switch type 3: N/C contact, N/C contact, monitored reset

0F Switch type 3: N/C contact, N/C contact, manual reset

10 Switch type 3: N/C contact, N/C contact, start-up test

11 Switch type 3: N/C contact, N/C contact, start-up test, monitored reset

12 Switch type 3: N/C contact, N/C contact, start-up test, manual reset

13 Switch type 4: N/C contact, N/C contact, N/O contact

14 Switch type 4: N/C contact, N/C contact, N/O contact, monitored reset

15 Switch type 4: N/C contact, N/C contact, N/O contact, manual reset

16 Switch type 4: N/C contact, N/C contact, N/O contact, start-up test

17 Switch type 4: N/C contact, N/C contact, N/O contact, start-up test, monitored reset

18 Switch type 4: N/C contact, N/C contact, N/O contact, start-up test, manual reset

19 Switch type 5: N/C contact, N/C contact, N/C contact

1A Switch type 5: N/C contact, N/C contact, N/C contact, monitored reset

1B Switch type 5: N/C contact, N/C contact, N/C contact, manual reset

1C Switch type 6: Two-hand, N/C contact, N/O contact

1D Switch type 7: Two-hand, N/O contact

1E Operating mode selector switch 1 from 2

1F Operating mode selector switch 1 from 3

20 Operating mode selector switch 1 from 4

21 Operating mode selector switch 1 from 5

22 Safety mat, with automatic reset

23 Safety mat, with start-up test

24 Safety mat, with reset button

25 Cascading input

26 Switch type 5, N/C contact, N/C contact, N/C contact, start-up test

Element

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-21

Page 32

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

3.4.10 Current state of the virtual inputs

Current state of the virtual inputs3-ModbusTCP_Datenbereiche-aktuelle Zustände der virtuellen Eingänge

The table below describes the Modbus/TCP data areas that contain the

current state of the virtual inputs. These are the virtual inputs that can be

set by various subscribers (e.g. fieldbus).

Relevant areas for the data are defined in the Modbus/TCP data areas

Discrete Inputs (1x) and Input Register (3x). Read access is available to

these data areas.

Register

(3x)

1127 18047... 18032 Inputs, feedback status

1128 18063... 18048 Inputs, feedback status

1129 18079... 18064 Inputs, feedback status

1130 18095... 18080 Inputs, feedback status

1131 18111... 18096 Inputs, feedback status

1132 18127... 18112 Inputs, feedback status

1133 18143... 18128 Inputs, feedback status

1134 18159... 18144 Inputs, feedback status

1135 18175... 18160 Reserved

1136 18191... 18176 Reserved

1137 18207... 18192 Reserved

1138 18223... 18208 Reserved

1139 18239... 18224 Reserved

1140- 2047 Reserved

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

0...15

16...31

32...47

48...63

64...79

80...95

96...111

112...127

i15…i8 i7…i0

i31…i24 i23…i16

i47…i40 i39…i32

i63…i56 i55…i48

i79…i72 i71…i64

i95…i88 i87…i80

i111…i104 i103…i96

i127…i120 i119…i112

3-22

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 33

3 Modbus/TCP - Data areas

3.4 Assignment of data areas

3.4.11 State of process data

State of process data3-ModbusTCP_Datenbereiche-Zustand der Prozessdaten

The table below describes the Modbus/TCP data areas that contain the

status info register. The general state of the data is reproduced in the

status info register.

Relevant areas for the data are defined in the Modbus/TCP data areas

Discrete Inputs (1x) and Input Register (3x). Read access is available to

these data areas.

Register

(3x)

2048 32783... 32768 Status information See below

High Byte Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Low Byte Reserved Reserved WD Time-

Coil/

Discrete Input

(1x)

Content High Byte Low Byte

Reserved Reserved Reserved Reserved Global Er-

out

ror Bit

Bit 5 "WD Timeout": The set watchdog for the input bits has been triggered and the inputs set to "0".

Bit 0 "Error Bit": The content of the data areas is not current or the set

watchdog for the input bits has been triggered.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-23

Page 34

3 Modbus/TCP - Data areas

3.5 Updating the data areas

3.5Updating the data areas3500Updating the data areas3-ModbusTCP_Aktualisierung der Datenbereiche-PNOZmulti

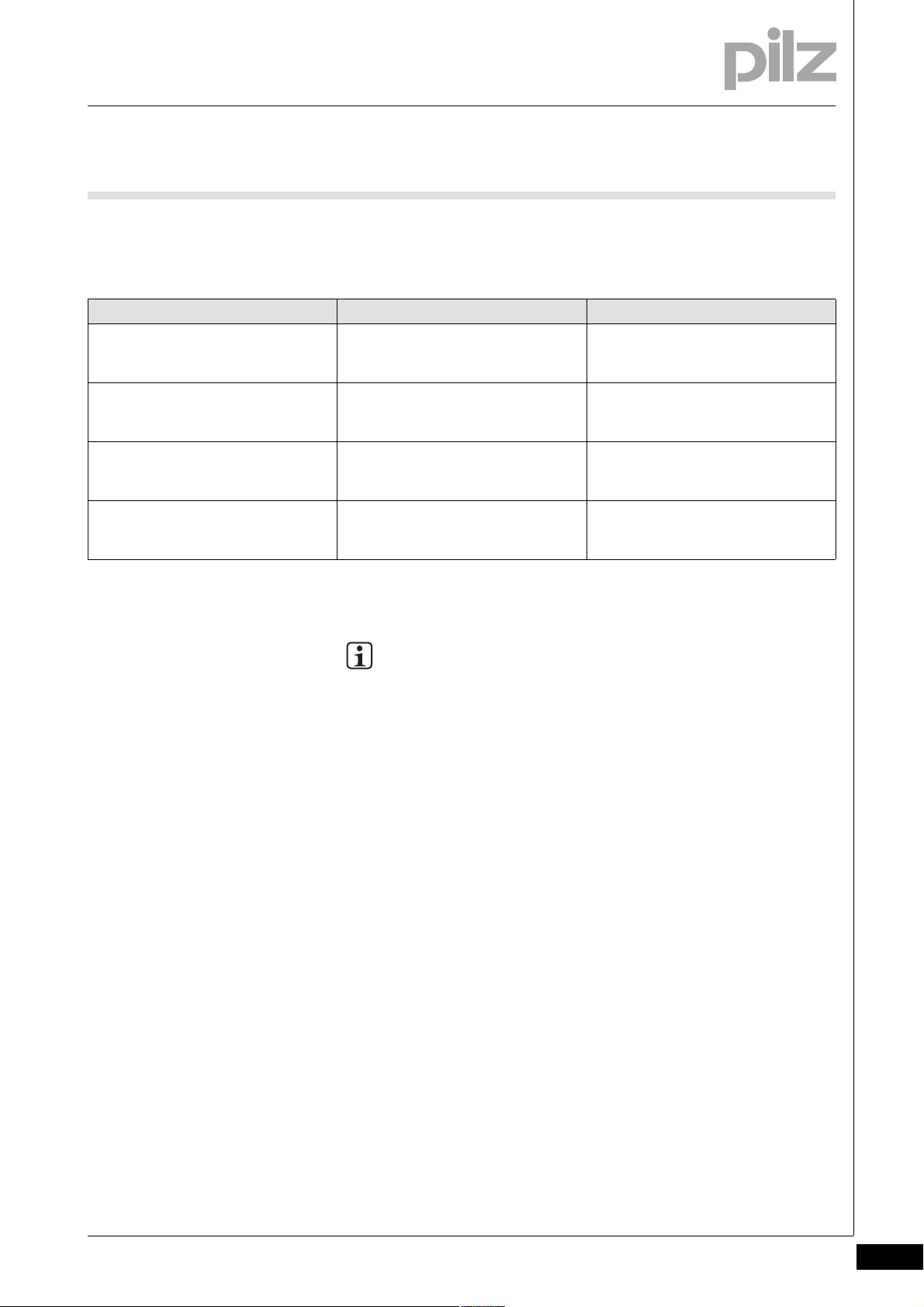

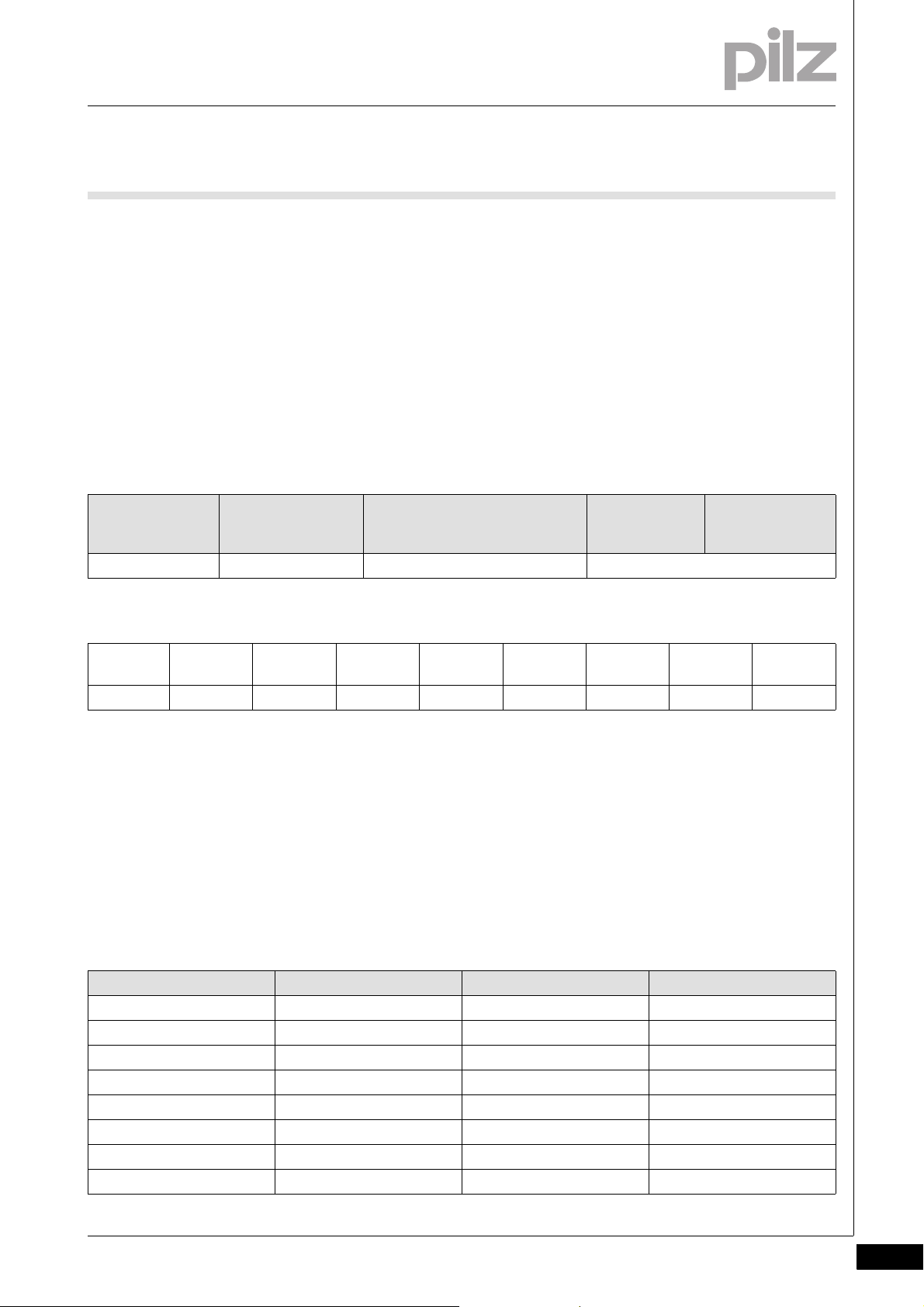

Data is updated with varying priority.

The table below shows the typical update cycles for the various data.

Content Typ. update cycle

Virtual inputs/outputs 20 ms

Configuration Once during initialisation

State of the inputs/outputs from the base unit and expansion modules 320 ms

LED status 1000 ms

Number of elements that can store a state Once during initialisation

Element enable 320 ms

Diagnostic words 1000 ms

Element types Once during initialisation

Current state of the virtual inputs 1000 ms

INFORMATION

The update time may increase if there are additional TCP/IP connections (e.g. PNOZmulti Configurator, PMI, control system) on

the PG port (Port 9000).

3-24

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 35

3 Modbus/TCP - Data areas

3.6 Bit addressing in a Register

3.6Bit addressing in a Register3600Bit addressing in a Register3-ModbusTCP_Bit-Adressierun g in einem Register -PNOZmulti

Addressing the virtual inputs (coils) on the PNOZmulti

1514131211109876543210

Register 0 Bit 15Bit 14Bit 13Bit 12Bit 11Bit 10Bit 9Bit 8Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit

Register 1 Bit 31Bit 30Bit 29Bit 28Bit 27Bit 26Bit 25Bit 24Bit 23Bit 22Bit 21Bit 20Bit 19Bit 18Bit 17Bit

Register 2 Bit 47Bit 46Bit 45Bit 44Bit 43Bit 42Bit 41Bit 40Bit 39Bit 38Bit 37Bit 36Bit 35Bit 34Bit 33Bit

Register 3 Bit 63Bit 62Bit 61Bit 60Bit 59Bit 58Bit 57Bit 56Bit 55Bit 54Bit 53Bit 52Bit 51Bit 50Bit 49Bit

Register 4 Bit 79Bit 78Bit 77Bit 76Bit 75Bit 74Bit 73Bit 72Bit 71Bit 70Bit 69Bit 68Bit 67Bit 66Bit 65Bit

Register 5 Bit 95Bit 94Bit 93Bit 92Bit 91Bit 90Bit 89Bit 88Bit 87Bit 86Bit 85Bit 84Bit 83Bit 82Bit 81Bit

Register 6 Bit

Register 7 Bit

111

127

Bit

110

Bit

126

Bit

109

Bit

125

Bit

108

Bit

124

Bit

107

Bit

123

Bit

106

Bit

122

Bit

105

Bit

121

Bit

104

Bit

120

Bit

103

Bit

119

Bit

102

Bit

118

Bit

101

Bit

117

Bit

Bit 99Bit 98Bit 97Bit

100

Bit

Bit

Bit

116

115

114

Bit

113

0

16

32

48

64

80

96

Bit

112

Addressing the virtual outputs (discrete inputs) on the PNOZmulti

1514131211109876543210

Register 512 Bit 15Bit 14Bit 13Bit 12Bit 11Bit 10Bit 9Bit 8Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit

0

Register 513 Bit 31Bit

Register 514 Bit 47Bit 46Bit 45Bit 44Bit 43Bit 42Bit 41Bit 40Bit 39Bit 38Bit 37Bit 36Bit 35Bit 34Bit 33Bit

Register 515 Bit 63Bit 62Bit 61Bit 60Bit 59Bit 58Bit 57Bit 56Bit 55Bit 54Bit 53Bit 52Bit 51Bit 50Bit 49Bit

Register 516 Bit 79Bit 78Bit 77Bit

Register 517 Bit 95Bit 94Bit 93Bit 92Bit 91Bit 90Bit 89Bit 88Bit 87Bit 86Bit 85Bit 84Bit 83Bit 82Bit 81Bit

Register 518 Bit

111

Register 519 Bit

127

Bit 29Bit 28Bit 27Bit 26Bit 25Bit 24Bit 23Bit 22Bit 21Bit 20Bit 19Bit 18Bit 17Bit

30

Bit 75Bit 74Bit 73Bit 72Bit 71Bit 70Bit 69Bit 68Bit 67Bit 66Bit 65Bit

76

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit 99Bit 98Bit 97Bit

110

109

108

107

106

105

104

103

102

101

100

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

126

125

124

123

122

121

120

119

118

117

116

115

114

Bit

113

16

32

48

64

80

96

Bit

112

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-25

Page 36

3 Modbus/TCP - Data areas

3-26

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 37

4 Application example

4.1 Modbus subscriber

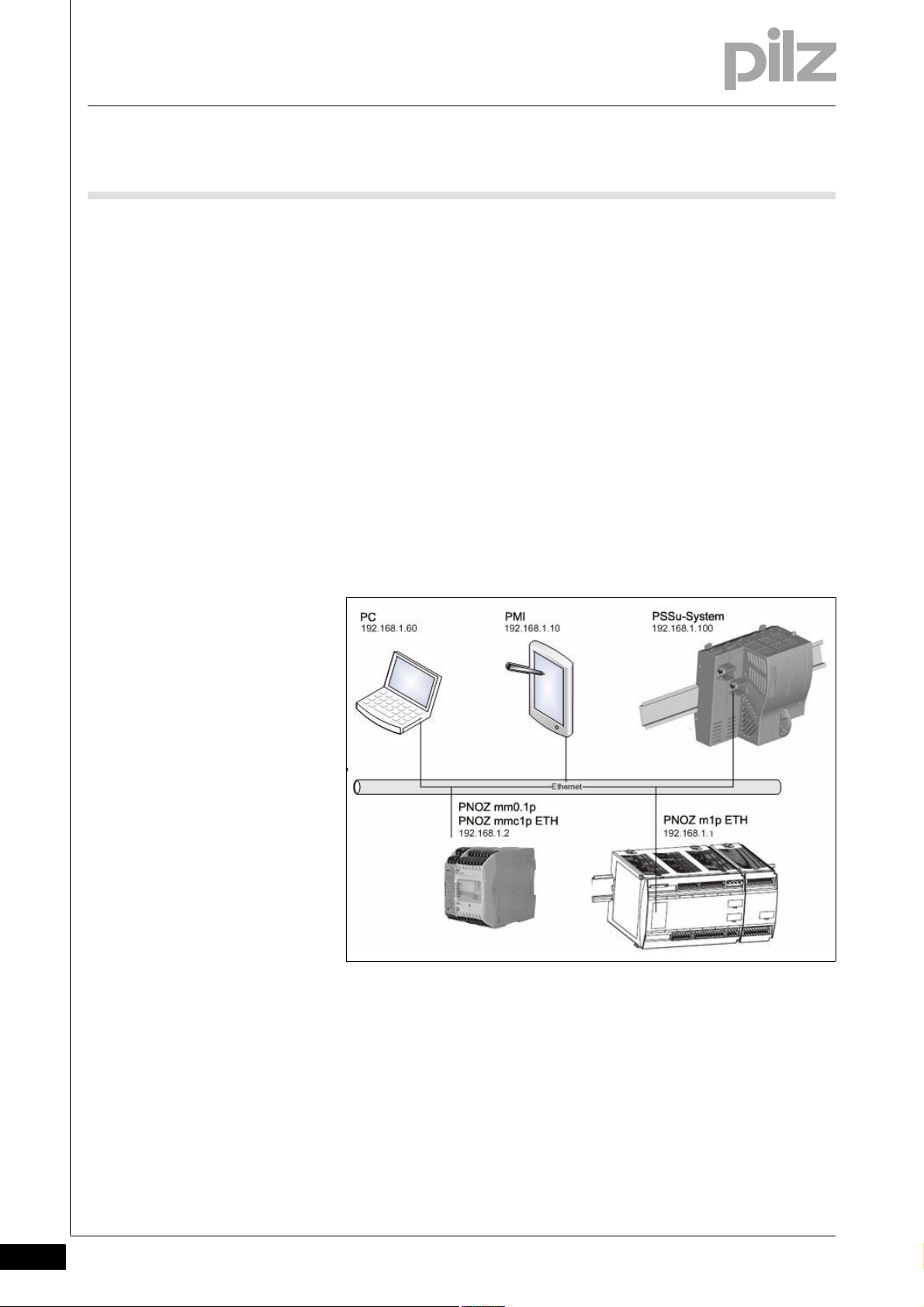

44000Application exampleApplication example4-4.1Modbus subscriber4100Modbus subscriber4-ModbusTCP_Bsp_Teilnehmer

In this example, the following subscribers communicate via Modbus/

TCP or Ethernet:

` Devices with server role:

– PNOZmulti base unit PNOZ m1p ETH

– PNOZmulti Mini base unit PNOZ mm0.1p with the expansion mod-

ule PNOZ mmc1p ETH

` Devices with client role:

– PSSu system in the automation system PSS 4000

– Operator terminal PMI

` PC as programming device for PNOZmulti, PSSu system and PMI

The PSSu system and the operator terminal PMI access both modular

safety systems PNOZmulti (server roles) simultaneously.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-1

Page 38

4 Application example

4.2 Data exchange via Modbus/TCP

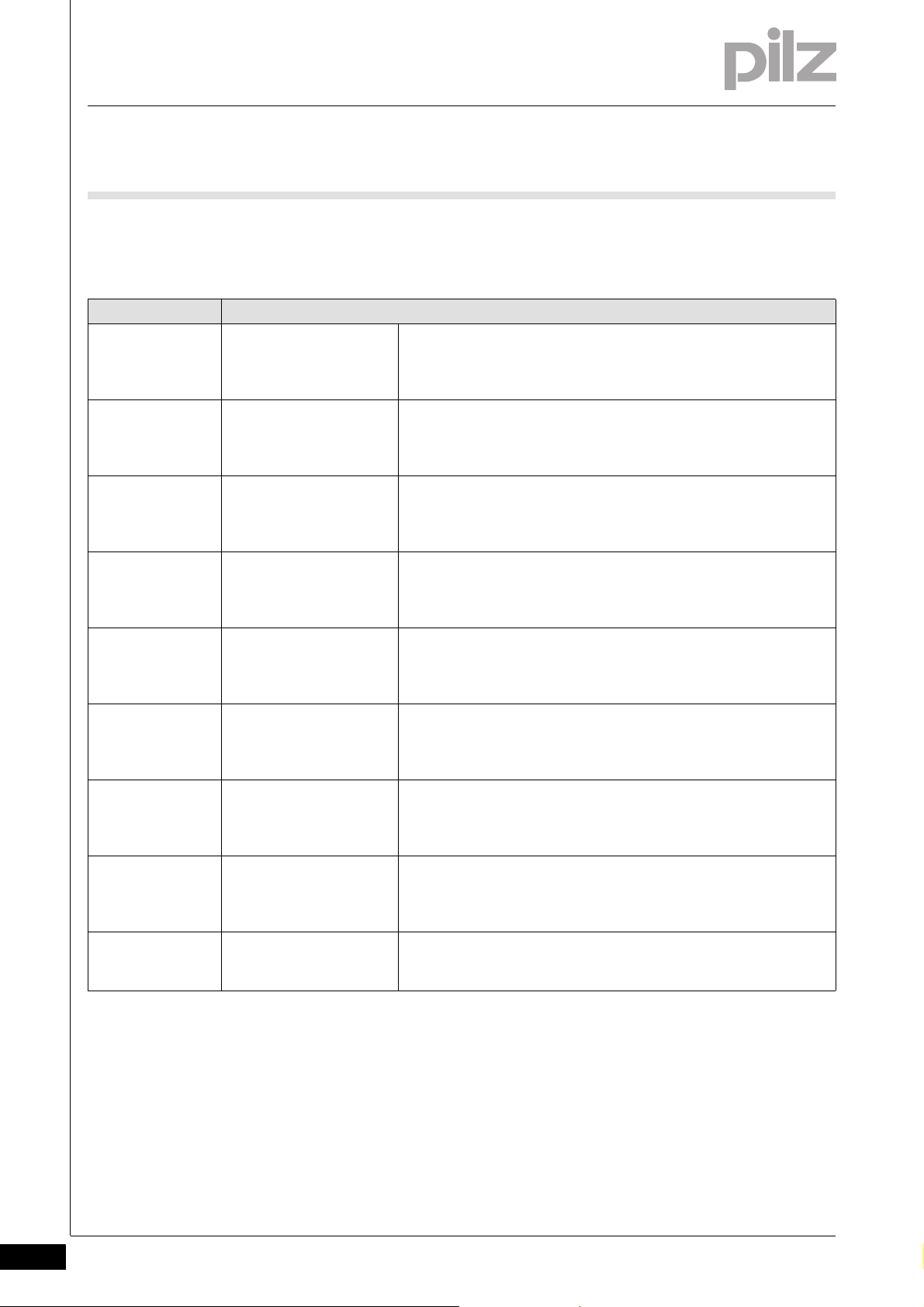

4.2Data exchange via Modbus/TCP4200Data exchange via Modbus/TCP4-ModbusTCP_Bsp_Kommunikation Client - Server

An example of data exchange is shown below. The modular safety system PNOZmulti is always the server in a connection and the PSSu system from the automation system PSS 4000 is always the client in a

connection.

It is always the connection's client that initiates data transfer. The direction of the data flow (send/receive) and access to Modbus/TCP data areas (coils, discrete inputs, input registers, holding register) is defined by

the function code.

When sending, the connection's client sends data to a data area belonging to the connection's server. This is also known as "Writing data".

When receiving, the connection's client requests and receives data located in a data area belonging to the connection's server. This is also

known as "Reading data".

4-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 39

4 Application example

4.2 Data exchange via Modbus/TCP

PSS 4000

192.168.1.100

IP Connections

PNOZmulti m1p ETH

192.168.1.1

ModbusTCPClient_0

Remote-IP-Address:

192.168.1.1

ReadCoils0x

ModbusTCPClient_1

Remote-IP-Address:

192.168.1.1

WriteMultipleCoils0x

ModbusTCPClient_2

Remote-IP-Address:

192.168.1.2

ReadCoils0x

ModbusTCPClient_3

Remote-IP-Address:

192.168.1.2

Server

Coil &

Register

Map

0x

1x

3x

4x

PNOZmulti m1p ETH

192.168.1.2

Server

Coil &

Register

Map

0x

1x

3x

4x

WriteMultipleCoils0x

In this program, inputs on the PNOZmulti are copied to virtual outputs.

The PSSu system reads the data from the PNOZmulti, processes it and

then writes it back to the virtual inputs on the PNOZmulti. There the state

of the virtual inputs is written to signal outputs.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-3

Page 40

4 Application example

4.2 Data exchange via Modbus/TCP

POU PI- Variables I/O Mapping

IP-Connections

Client

WriteCoils

Read

discrete

inputs

Modbus/TCP

Modbus/TCP

Server

Virtual Inputs

I 00

I 01

.

.

.

.

.

.

.

I 126

I 127

Virtual Outputs

O 00

O 01

.

.

.

.

.

.

.

O 126

O 127

PNOZmulti Project

Digital Inputs

Digital

Outputs

4-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 41

4 Application example

4.3 Device configuration

4.3Device configuration4300Device configuration4-

4.3.1 Modular safety system PNOZmulti

Modular safety system PNOZ multi 4-ModbusTCP_Bsp_Konfiguration-PNOZmulti

Insert the required modules in the PNOZmulti Configurator, in the "Hardware Configuration" window.

Base unit PNOZm1p ETH:

1. Insert base unit PNOZ m1p ETH

2. Insert inputs/outputs that are downloaded via the integrated interface

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-5

Page 42

4 Application example

4.3 Device configuration

Base unit PNOZ mm0.1p

1. Base unit PNOZ mm0.1p

2. Configure communication module PNOZ mmc1p ETH

3. Insert inputs/outputs that are downloaded via the integrated interface

4-6

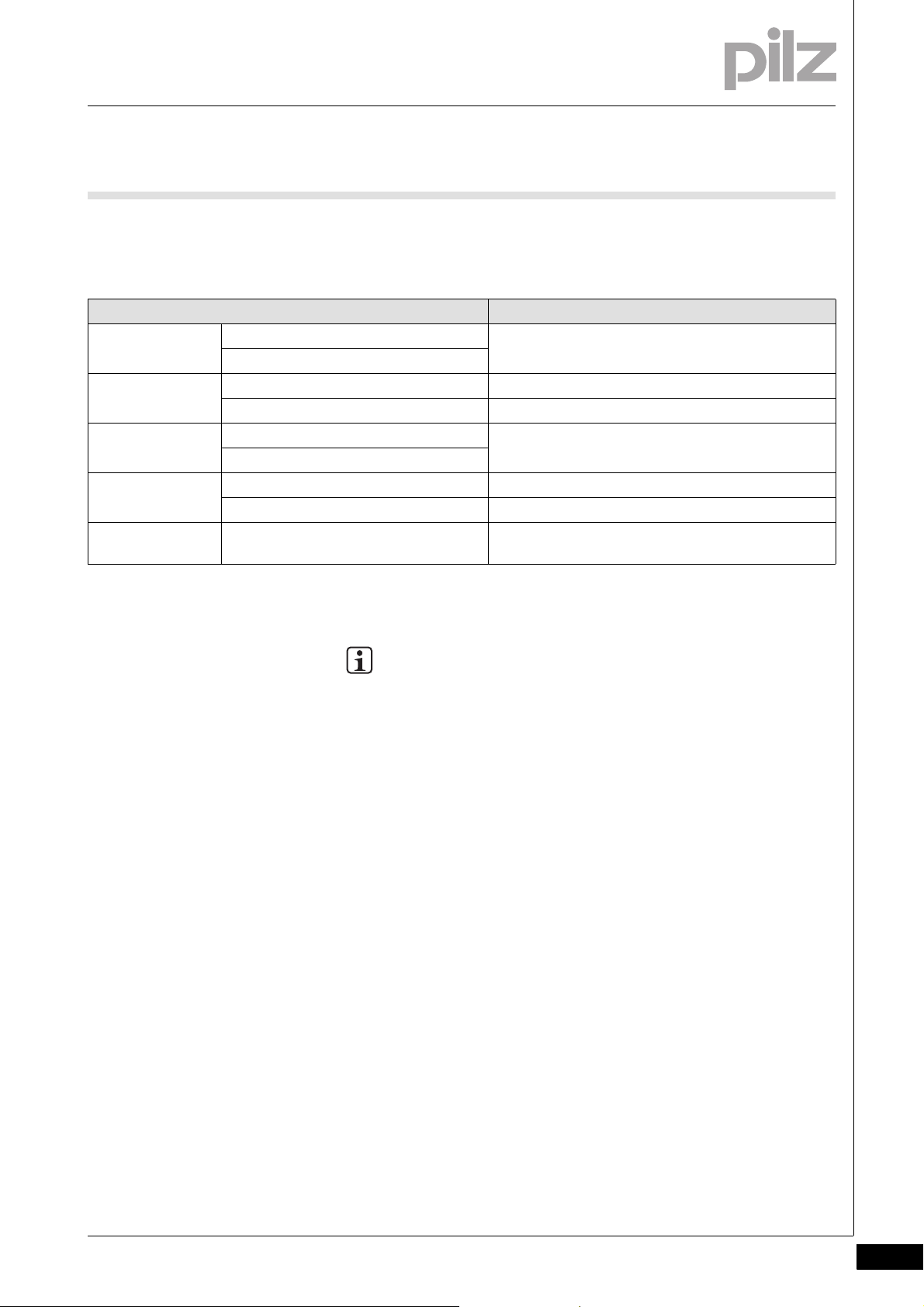

4.3.2 PSSu system in the automation system PSS 4000

PSSu system in the automation system PSS 40004-ModbusTCP_Bsp_Konfiguration-PSS 4000

The configuration is made in PAS4000.

Create IP connection

Create the IP connection in the IP Connections Editor

1. Enter remote IP address

> Enter the IP addresses of the PNOZmulti Ethernet connections.

2. Enter remote port number

> Enter the port number "502".

The number may not be modified.

3. Select function code

> From the list, select "WriteMultipleCols0x"

4. Define the start address and the length of the data block

> Enter the start address and the data length in the "Send" field

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 43

4 Application example

4.3 Device configuration

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-7

Page 44

4 Application example

4.3 Device configuration

Perform I/O mapping

The PI variables are mapped to the data in the Modbus/TCP connection.

Map the PI variables in the I/O Mapping Editor as follows:

1. Set filter

> Select the option "PI variables < - > IP connections"

2. Map PI variables

4-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 45

4 Application example

4.3 Device configuration

4.3.3 Operator terminal PMI

Operator terminal PMI4-ModbusTCP_Bsp_Konfiguration-PMI

The configuration is made in the PMImicro Configurator

Select Modbus/TCP driver, create IP connection

Select the Modbus/TCP driver in the Configuration window and set the

IP connection:

1. Enter remote IP address

> Enter the IP addresses of the PNOZmulti.

2. Enter remote port number

> Enter the port number "502".

The number may not be modified.

A variable is defined in the variable list for each display or operator element.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-9

Page 46

4 Application example

4.3 Device configuration

The offset refers to the data block provided by the PNOZmulti.

4-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 47

© Pilz GmbH & Co. KG, 2010

1002104-EN-01, 2010-09 Printed in Germany

... www

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our homepage

for further details or contact our

headquarters.

www.pilz.com

Technical support

+49 711 3409-444

support@pilz.com

are registered and protected trademarks

®

, the spirit of safety

®

, SafetyNET p

®

, SafetyEYE

®

, SafetyBUS p

®

, PVIS

®

, PSS

®

, PSEN

®

, Primo

®

, PNOZ

®

, PMI

®

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

, PMCprotego

®

, PIT

®

, Pilz

®

InduraNET p

of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary from the details stated in this document, depending on the status at the time of publication and the scope

of the equipment. We accept no responsibility for the validity, accuracy and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Loading...

Loading...