Page 1

PNOZ mmc11p

Configurable Control System PNOZmulti

Operating Manual-1002697-EN-01

Page 2

Preface

This document is the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes. Suggestions and comments for improving this documentation will be

gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of Pilz GmbH

& Co. KG in some countries.

SD means Secure Digital

Page 3

Content

Section 1 Introduction 4

1.1 Validity of documentation 4

1.2 Retaining the documentation 4

1.3 Overview of documentation 4

1.4 Definition of symbols 5

Section 2 Overview 6

2.1 Scope of supply 6

2.2 Unit features 6

2.3 Front view 7

Section 3 Safety 8

3.1 Intended use 8

3.2 System requirements 8

3.3 Safety regulations 8

3.3.1 Use of qualified personnel 8

3.3.2 Warranty and liability 9

3.3.3 Disposal 9

3.3.4 For your safety 9

Section 4 Function description 10

4.1 Operation 10

4.2 Input and output data 10

4.3 Assigning the inputs/outputs in the PNOZmulti Configurator to the Ether-

11

CAT inputs/outputs

4.4 Block diagram 11

Section 5 Installation 12

5.1 General installation guidelines 12

5.2 Connect the base unit and expansion modules 12

5.3 Dimensions 12

Section 6 Commissioning 13

6.1 General wiring guidelines 13

6.2 Connecting the supply voltage 13

6.3 Interface assignment 14

6.4 Download modified project to the PNOZmulti safety system 14

6.5 Preparing for operation 14

6.6 Connection example 15

Section 7 Operation 16

7.1 Display elements for device diagnostics 16

Section 8 Technical details 18

Section 9 Order reference 20

Operating Manual PNOZ mmc11p

1002697-EN-01

3

Page 4

Introduction

1

1.1

1.2

1.3

Introduction

Validity of documentation

This documentation is valid for the product PNOZ mmc11p. It is valid until new documentation is published.

This operating manual explains the function and operation, describes the installation and

provides guidelines on how to connect the product.

Retaining the documentation

This documentation is intended for instruction and should be retained for future reference.

Overview of documentation

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific

order of this manual.

2 Overview

This chapter provides information on the product's most important features.

3 Safety

This chapter must be read as it contains important information on safety and intended use.

4 Function Description

This chapter describes the product's mode of operation.

5 Installation

This chapter explains how to install the product.

6 Commissioning

This chapter describes the product's commissioning and wiring.

7 Operation

This chapter describes how to operate the product and gives tips in the case of a fault.

8 Technical Details

This chapter contains the technical details.

9 Supplementary Data

This chapter contains additional technical details such as diagrams and tables.

10 Order Reference

This chapter contains the product's order references and accessories.

Operating Manual PNOZ mmc11p

1002697-EN-01

4

Page 5

Introduction

1.4

Definition of symbols

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that poses

an immediate threat of serious injury and death and indicates preventive

measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that could

lead to serious injury and death and indicates preventive measures that can

be taken.

ATTENTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

CAUTION!

This describes a situation in which the product or devices could be damaged and also provides information on preventive measures that can be

taken. It also highlights areas within the text that are of particular importance.

Information

This gives advice on applications and provides information on special

features.

Operating Manual PNOZ mmc11p

1002697-EN-01

5

Page 6

Overview

2

2.1

2.2

Overview

Scope of supply

} Expansion module PNOZ mmc11p

} Jumper 779 260

Unit features

Using the product PNOZ mmc11p:

Expansion module for connection to a base unit from the configurable control system

PNOZmulti Mini .

The product has the following features:

} Can be configured in the PNOZmulti Configurator

} Network protocols: EtherCAT

} Supports CANopen over EtherCAT (DS301 V4.02 compliant)

} Status indicators for communication with EtherCAT and for errors

} 24 virtual outputs on the control system PNOZmulti can be defined in the PNOZmulti

Configurator for communication with the fieldbus EtherCAT. The number of inputs and

outputs can be extended to 128. Please note that when the extended inputs and

outputs 24 - 127 are used they have different properties (see document entitled "Communication Interfaces").

} Max. 1 PNOZ mmc11p can be connected to the base unit

} Plug-in connection terminals:

either spring-loaded terminal or screw terminal available as an accessory (see order

reference)

} Please refer to the document "PNOZmulti System Expansion" for details of the base

units PNOZmulti Mini that can be connected.

Operating Manual PNOZ mmc11p

1002697-EN-01

6

Page 7

Overview

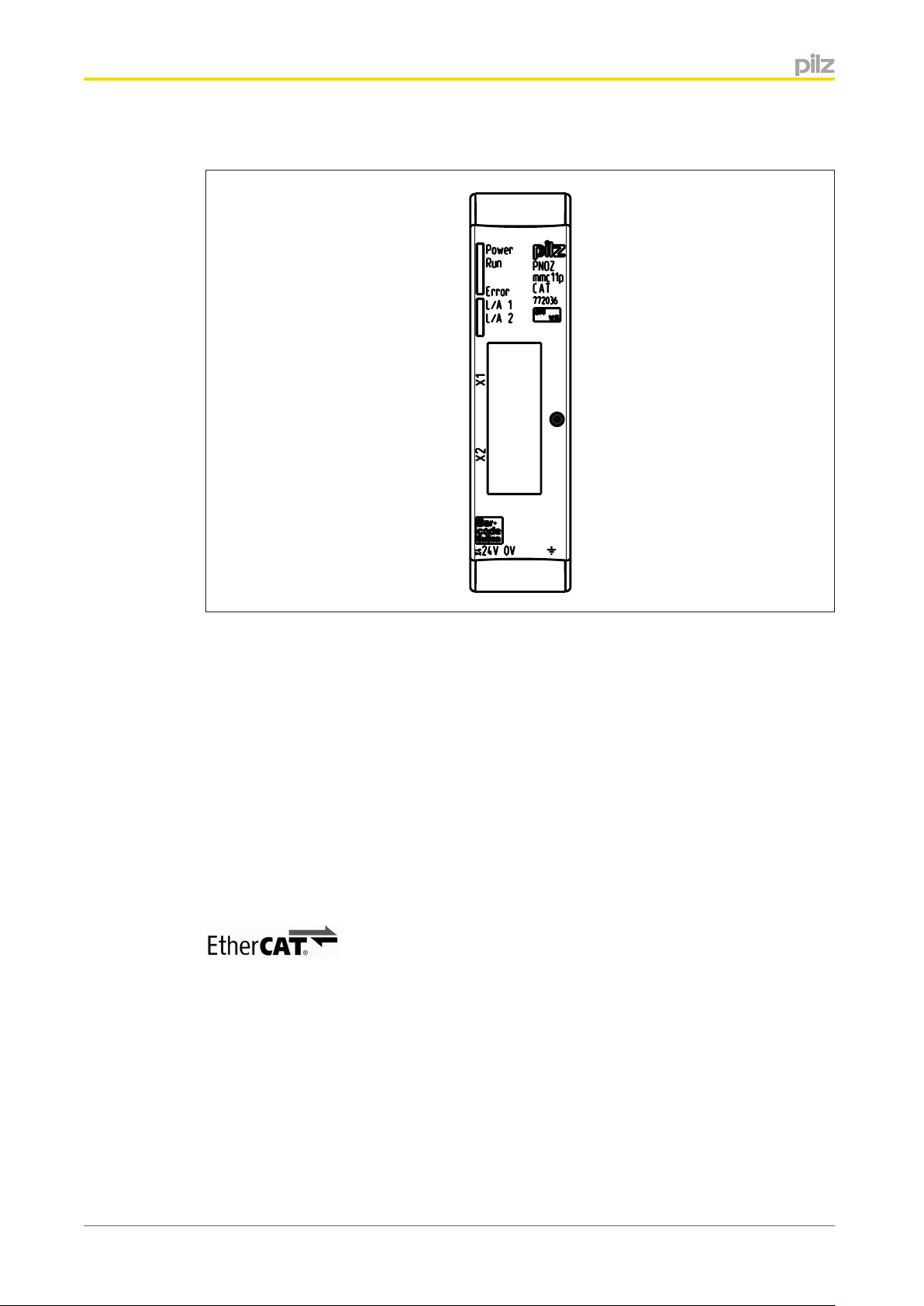

2.3

Front view

Legend:

} X1: EtherCAT IN

} X2: EtherCAT OUT

} X4: 0 V, 24 V:

Supply connections

} LEDs:

– Power

– Run

– Error

– L/A 1

– L/A 2

is registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany

Operating Manual PNOZ mmc11p

1002697-EN-01

7

Page 8

Safety

3

3.1

Safety

Intended use

The expansion module PNOZ mmc11p is used for communication between the configurable control system PNOZmulti with EtherCAT.

EtherCAT is designed for fast data exchange at field level. The expansion module PNOZ

mmc11p is a passive EtherCAT subscriber (Slave). The basic communication functions

with EtherCAT conform to the system description published by the EtherCAT User Group.

The central controller (master) reads input information from the slaves and writes output

information to the slaves as part of each cycle.

The expansion module may only be connected to a base unit from the configurable control

system PNOZmulti (please refer to the document "PNOZmulti System Expansion" for

details of the base units that can be connected)

The configurable control system PNOZmulti is used for the safety-related interruption of

safety circuits and is designed for use in:

} E-STOP equipment

} Safety circuits in accordance with VDE 0113 Part 1 and EN 60204-1

The expansion module may not be used for safety-related functions.

Intended use includes making the electrical installation EMC-compliant. The product is

designed for use in an industrial environment. It is not suitable for use in a domestic environment, as this can lead to interference.

3.2

3.3

3.3.1

The following is deemed improper use in particular:

} Any component, technical or electrical modification to the product

} Use of the product outside the areas described in this manual

} Use of the product outside the technical details (see chapter entitled “Technical De-

tails”)

System requirements

Please refer to the "Product Modifications" document in the "Version overview" section for

details of which versions of the base unit and PNOZmulti Configurator can be used for this

product.

Safety regulations

Use of qualified personnel

The products may only be assembled, installed, programmed, commissioned, operated,

maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current

professional activity, has the specialist knowledge required to test, assess and operate the

work equipment, devices, systems, plant and machinery in accordance with the general

standards and guidelines for safety technology.

Operating Manual PNOZ mmc11p

1002697-EN-01

8

Page 9

Safety

It is the company’s responsibility only to employ personnel who:

} Are familiar with the basic regulations concerning health and safety / accident preven-

tion

} Have read and understood the safety guidelines given in this description

} Have a good knowledge of the generic and specialist standards applicable to the

specific application.

3.3.2

3.3.3

3.3.4

Warranty and liability

All claims to warranty and liability will be rendered invalid if

} The product was used contrary to the purpose for which it is intended

} Damage can be attributed to not having followed the guidelines in the manual

} Operating personnel are not suitably qualified

} Any type of modification has been made (e.g. exchanging components on the PCB

boards, soldering work etc.).

Disposal

} In safety-related applications, please comply with the mission time tM in the safety-re-

lated characteristic data.

} When decommissioning, please comply with local regulations regarding the disposal of

electronic devices (e.g. Electrical and Electronic Equipment Act).

For your safety

The unit meets all necessary conditions for safe operation. However, you should always

ensure that the following safety requirements are met:

} This operating manual only describes the basic functions of the unit. Information on the

advanced functions can be found in the online help for the PNOZmulti Configurator and

in the PNOZmulti technical catalogue. Only use these functions after you have read and

understood the documentation. All necessary documentation can be found on the

PNOZmulti Configurator CD.

} Do not open the housing or make any unauthorised modifications.

} Please make sure you shut down the supply voltage when performing maintenance

work (e.g. exchanging contactors).

Operating Manual PNOZ mmc11p

1002697-EN-01

9

Page 10

Function description

4

4.1

4.2

Function description

Operation

The virtual inputs and outputs that are to be transferred via EtherCAT are selected and

configured in the PNOZmulti Configurator. The base unit and the expansion module PNOZ

mmc11p are connected via a jumper. After the supply voltage is switched on or the PNOZmulti control system is reset, the expansion module PNOZ mmc11p is configured and

started automatically.

The connection to EtherCAT is made via the two RJ45 sockets.

LEDs indicate the status of the expansion module on EtherCAT.

The configuration is described in detail in the PNOZmulti Configurator's online help.

Input and output data

The data is structured as follows:

} Input range

The inputs are defined in the master and transferred to the PNOZmulti. Each input has

a number, e.g. input bit 4 of byte 1 has the number i12.

} Output range

The outputs are defined in the PNOZmulti Configurator. Each output that is used is

given a number there, e.g. o0, o5... The status of output o0 is stored in bit 0 of byte 0;

the status of output o5 is stored in bit 5 of byte 0 etc.

} Output range only: Byte 3

Bits 0 … 4: Status of LEDs on the PNOZmulti

– Bit 0: OFAULT

– Bit 1: IFAULT

– Bit 2: FAULT

– Bit 3: DIAG

– Bit 4: RUN

Bit 5: Data is being exchanged.

Detailed information on data exchange (tables, segments) is available in the document

"Communication Interfaces" in the section entitled "Fieldbus modules".

Operating Manual PNOZ mmc11p

1002697-EN-01

10

Page 11

Function description

4.3

Assigning the inputs/outputs in the PNOZmulti Configurator to the EtherCAT inputs/outputs

Virtual inputs on PNOZmulti Configurator I0 ... I7 I8 ... I15 I16 ... I23

Input data EtherCAT Byte 0: Bits 0 … 7 Byte 1: Bits 0 … 7 Byte 2: Bits 0 … 7

Virtual outputs on PNOZmulti Configurator O0 ... O7 O8 ... O15 O16 ... O23

Output data EtherCAT Byte 0: Bits 0 … 7 Byte 1: Bits 0 … 7 Byte 2: Bits 0 … 7

The number of virtual inputs and outputs can be extended to 128 (see document "Communication Interfaces" in the section entitled "Fieldbus modules")

4.4

Block diagram

Operating Manual PNOZ mmc11p

1002697-EN-01

11

Page 12

Installation

5

5.1

Installation

General installation guidelines

} The unit should be installed in a control cabinet with a protection type of at least IP54.

} Fit the safety system to a horizontal mounting rail. The venting slots must face upwards

and downwards. Other mounting positions could destroy the safety system.

} Use the notch on the rear of the unit to attach it to a mounting rail.

} In environments exposed to heavy vibration, the unit should be secured using a fixing

element (e.g. retaining bracket or end angle).

} Push the unit upwards or downwards before lifting it from the mounting rail.

} To comply with EMC requirements, the mounting rail must have a low impedance

connection to the control cabinet housing.

} The ambient temperature of the PNOZmulti units in the control cabinet must not exceed

the figure stated in the technical details, otherwise air conditioning will be required.

ATTENTION!

Damage due to electrostatic discharge!

Electrostatic discharge can damage components. Ensure against discharge

before touching the product, e.g. by touching an earthed, conductive surface

or by wearing an earthed armband.

5.2

5.3

Connect the base unit and expansion modules

Connect the base unit and the expansion module as described in the operating instructions

for the base units.

} Connect the black/yellow terminator to the expansion module.

} Install the expansion module in the position in which it is configured in the PNOZmulti

Configurator.

Dimensions

Operating Manual PNOZ mmc11p

1002697-EN-01

12

Page 13

Commissioning

6

6.1

Commissioning

General wiring guidelines

The wiring is defined in the circuit diagram of the PNOZmulti Configurator.

It is possible to define which inputs and outputs on the safety system will communicate with

EtherCAT.

Note:

} Information given in the "Technical details" must be followed.

} Use copper wire that can withstand 75 °C.

Please note the following when connecting to EtherCAT:

} The following minimum requirements of the connection cable and connector must be

met:

– Only use standard industrial Ethernet cable and connectors.

– Only use double-shielded twisted pair cable and shielded RJ45 connectors (indus-

trial connectors).

– 100BaseTX cable in accordance with the Ethernet standard (min. Category 5)

} Measures to protect against interference:

Ensure the requirements for the industrial use of EtherCAT are met, as stated in the

Installation Manual published by the User Group.

6.2

ATTENTION!

Only connect and disconnect the expansion module when the supply

voltage is switched off.

Connecting the supply voltage

Connect the supply voltage to the fieldbus module:

} Terminal 24 V: + 24 V DC

} Terminal 0 V: 0 V

Operating Manual PNOZ mmc11p

1002697-EN-01

13

Page 14

Commissioning

6.3

6.4

Interface assignment

RJ45 socket

8-pin PIN Standard

1 TD+ (Transmit+)

2 TD- (Transmit-)

3 RD+ (Receive+)

n.c.: Not connected

4 n.c.

5 n.c.

6 RD- (Receive-)

7 n.c.

8 n.c.

Download modified project to the PNOZmulti safety system

As soon as an additional expansion module has been connected to the system, the project

must be amended using the PNOZmulti Configurator. Proceed as described in the operating instructions for the base unit.

6.5

CAUTION!

For the commissioning and after every program change, you must check

whether the safety devices are functioning correctly.

Preparing for operation

} Install Device Description File

Install the Device Description File in your configuration software. You can only then use

the PNOZ mmc11p.

} Connect the supply voltage to the base unit:

Terminals 24 V and A1 (+): + 24 VDC

Terminals 0 V and A2 (-) : 0 V

Operating Manual PNOZ mmc11p

1002697-EN-01

14

Page 15

Commissioning

6.6

Connection example

Operating Manual PNOZ mmc11p

1002697-EN-01

15

Page 16

Operation

1

2

1

7

7.1

Operation

When the supply voltage is switched on, the PNOZmulti safety system copies the configuration from the chip card.

The LEDs "POWER","DIAG", "FAULT", "IFAULT" and "OFAULT" light up on the base unit.

The expansion module PNOZ mmc11p is configured and started automatically. The LEDs

"L/A 1" and "L/A 2", "Run " and "Error" indicate the status of the PNOZ mmc11p on EtherCAT.

Display elements for device diagnostics

LED LED status Meaning

L/A 1

L/A 2

Green Bus connection available at X1

Green Data traffic present at X1

Bus connection is not available at X1

Green Bus connection available at X2

Green Data traffic present at X2

Run

Error

Bus connection not available at X2

Green The device is in "OPERATIONAL" status

Green The device is in "SAFE-OPERATIONAL" status

Green The device is in "PRE-OPERATIONAL" status

The device is in "INIT" status

Red Application Watchdog Timeout

Red Sync Manager Watchdog Timeout.

Red The Slave device application has changed the Ether-

CAT status independently: The "Change" parameter in

the AL status register is set to 01 (change/error).

Red Configuration error

EtherCAT communication is in operation

Operating Manual PNOZ mmc11p

1002697-EN-01

16

Page 17

Operation

1

2

Key:

LED off

LED flashes once

LED flashes twice

LED flashes once

LED flashes

LED on

Operating Manual PNOZ mmc11p

1002697-EN-01

17

Page 18

Technical details

8

General 772036

Approvals CCC, CE, GOST

Electrical data 772036

Supply voltage

for Module supply

Voltage 24 V

Type DC

Voltage tolerance -20 %/+25 %

Output of external power supply (DC) 1,5 W

Status indicator LED

Fieldbus interface 772036

Fieldbus interface EtherCAT

Unit type Slave

Protocol CANopen over EtherCAT

Transmission rates 100 MBit/s

Connection RJ45

Galvanic isolation Yes

Times 772036

Supply interruption before de-energisation 20 ms

Environmental data 772036

Ambient temperature

In accordance with the standard EN 60068-2-14

Temperature range 0 - 60 °C

Forced convection in control cabinet off 55 °C

Storage temperature

In accordance with the standard EN 60068-2-1/-2

Temperature range -25 - 70 °C

Climatic suitability

In accordance with the standard EN 60068-2-30, EN 60068-2-78

Humidity 93 % r. h. at 40 °C

Condensation Not permitted

EMC EN 61131-2

Vibration

In accordance with the standard EN 60068-2-6

Frequency 10,0 - 150,0 Hz

Max. acceleration 1g

Airgap creepage

In accordance with the standard EN 61131-2

Overvoltage category II

Rated insulation voltage 30 V

Shock stress

In accordance with the standard EN 60068-2-27

Acceleration 15g

Duration 11 ms

Max. operating height above sea level 2000 m

Technical details

Operating Manual PNOZ mmc11p

1002697-EN-01

18

Page 19

Technical details

Potential isolation 772036

Potential isolation between Fieldbus and module voltage

Type of potential isolation Functional insulation

Rated surge voltage 500 V

Mechanical data 772036

Mounting position Horizontal on top hat rail

Protection type

In accordance with the standard EN 60529

Mounting (e.g. cabinet) IP54

Housing IP20

Terminals IP20

DIN rail

Top hat rail 35 x 7,5 EN 50022

Recess width 27 mm

Material

Bottom PC

Front PC

Top PC

Cross section of external conductors with screw

terminals

1 core flexible 0,25 - 2,50 mm², 24 - 12 AWG

2 core with the same cross section, flexible with

0,20 - 2,50 mm², 24 - 16 AWG

crimp connectors, no plastic sleeve

2 core with the same cross section, flexible without

0,20 - 1,50 mm², 24 - 16 AWG

crimp connectors or with TWIN crimp connectors

Torque setting with screw terminals 0,50 Nm

Connection type Spring-loaded terminal, screw terminal

Cross section of external conductors with spring-load-

0,20 - 2,50 mm², 24 - 12 AWG

ed terminals: flexible with/without crimp connector

Spring-loaded terminals: Terminal points per connec-

2

tion

Stripping length 9 mm

Dimensions

Height 100,0 mm

Width 22,5 mm

Depth 115,0 mm

Weight 95 g

The standards current on 2012-10 apply.

Operating Manual PNOZ mmc11p

1002697-EN-01

19

Page 20

Order reference

9

Order reference

Product type Features Order no.

PNOZ mmc11p Fieldbus module, EtherCAT 772 036

Order reference: Terminator, jumper

Product type Features Order no.

PNOZ mm0.xp connector

left

Order reference: Accessories

Product type Features Order no.

Spring terminals

PNOZ mmcxp 1 pc.

Spring terminals

PNOZ mmcxp 10 pcs.

Order reference

Jumper yellow/black to connect the modules, 1 piece 779 260

Spring-loaded terminals, 1 piece 783 542

Spring-loaded terminals, 10 pieces 783 543

Screw terminals

PNOZ mmcxp 1 pc.

Screw terminals

PNOZ mmcxp 10 pcs.

Screw terminals, 1 piece 793 542

Screw terminals, 10 pieces 793 543

Operating Manual PNOZ mmc11p

1002697-EN-01

20

Page 21

© Pilz GmbH & Co. KG, 2011

Front cover

Sachnummer Printed in Germany

1002697-EN-01, 2013-02 Printed in Germany

© Pilz GmbH & Co. KG, 2011

...

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our homepage

for further details or contact our

headquarters.

Technical support

+49 711 3409-444

support@pilz.com

are registered and protected trademarks

®

, the spirit of safety

®

, SafetyNET p

®

, SafetyEYE

®

, SafetyBUS p

®

, PVIS

®

, PSS

®

, PSEN

®

, Primo

®

, PNOZ

®

, PMI

®

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

Internet: www.pilz.com

, PMCprotego

®

, PIT

®

, Pilz

®

of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary from the details stated in this document, depending on the status at the time of publication and the scope

InduraNET p

of the equipment. We accept no responsibility for the validity, accuracy and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Loading...

Loading...